Maintenance Log January 2011

January 31, 2011, Monday.

Went to

Nutria Marina to pick up Fedencio. He was going

to paint the letters on the bow so we would have the name back on the

bow of Dream Away. Fedencio made an evaluation, then he and I went into

town to purchase paint and brushes. We came back from town with a quart

of single part polyurethane paint and two brushes. I put the dinghy in

the water, and Fedencio worked on how the lettering was to be done. He

did the job, and it was not quite what we wanted, but the name is now

back on the bow. Fedencio charged us about $2.50 to do the job!

Fedencio Getting Ready To Paint On Letters

Moved more items from storage to

Dream Away. Except for the old name boards from the bow and a couple of

pieces of wood from the old cap rail, everything from the storage area

in the shop is now on Dream Away.

Moved the repaired man overboard

pole to Dream Away and installed the pole, light and the horseshoe ring

on Dream Away. Installed Jerry Jugs and new covers Looks good! Also

went and did some shopping and picked up laundry for us and for friend

Paul.

Jerry Jugs And New Covers Partially Installed

January 30, 2011, sunday.

Day

off, flea market, social engagements

January 29, 2011, Saturday.

Unpacked

storage area in shop and started to move stuff to Dream Away. This

included all of the Jerry Jugs for diesel and water, also moved two

suitcases of clothes to the rancho to be separated out and gone

through, the rescue Ring and the man overboard retrieval system, and

various boxes of stuff!

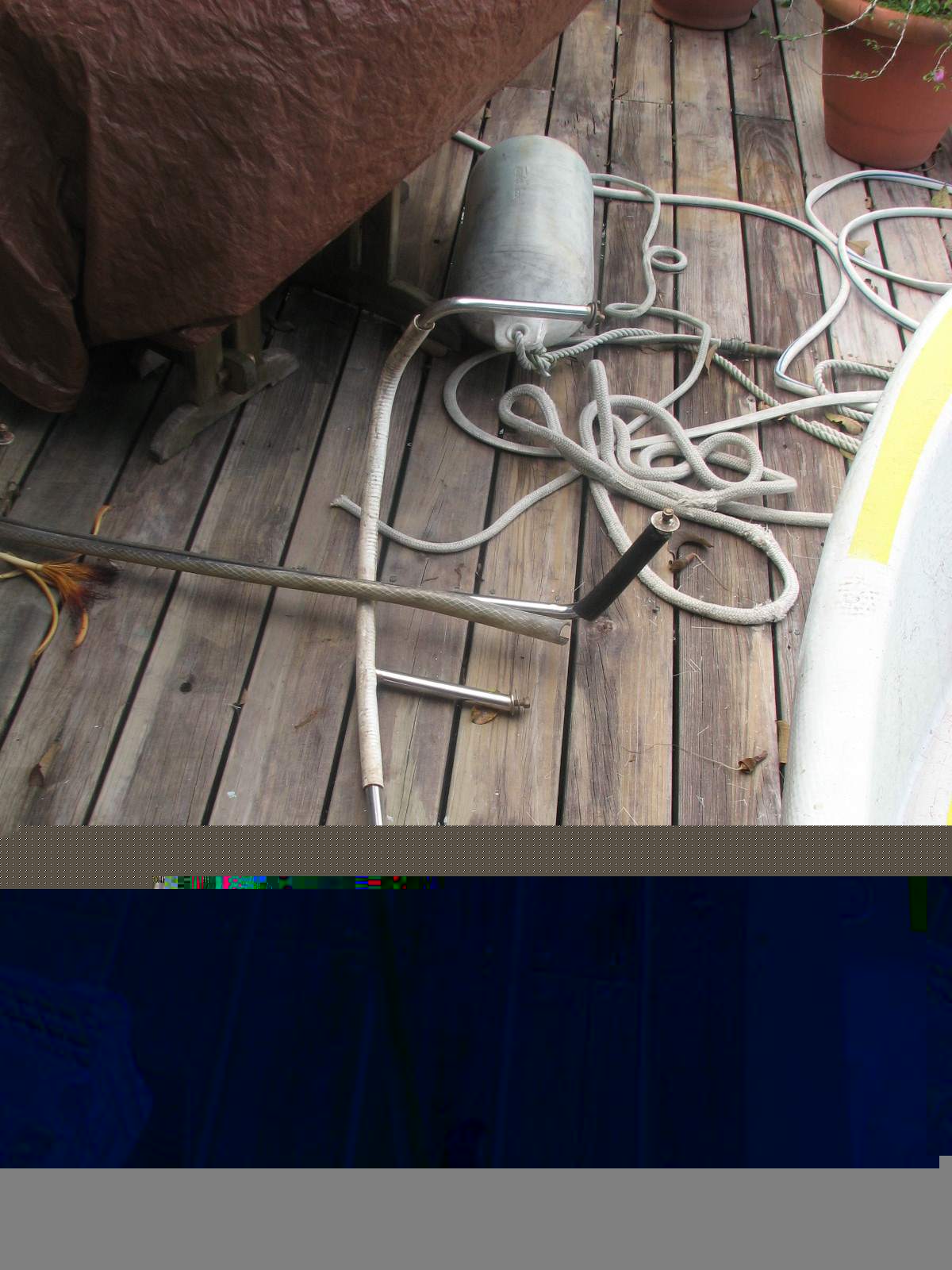

When I moved the man overboard

pole, I realized the fiberglass pole had started to delaminate. This

needed repair. I mixed a pot oof resin, and mixed some of the yellow

gelcoat with it. I added the catalyst, and applied the mixture to the

fiberglass man overboard pole. The resin kicked off and the repair

worked great. The pole is good for another few years until the UV takes

it toll.

Went to Backpackers for a Cajun

food. Had a great meal, wonderful entertainment, and a very good time.

Checked Dream Away Fuel Tanks.

Port tank contains 48 gallons, and the starboard tank contains 60

gallons of diesel.

January 28, 2011, Friday.

Yesterday

I got the physical pumps moved and installed. I did run the hose from

the valve to the water maker system, but it had not been attached.

Today I wanted to get the hose installed. I started by removing

everything off of the first shelf of the store room. This was necessary

to get the hose installed to the input of the water maker system. I

also wanted to thoroughly check the water maker system and the

refrigeration system. Once the shelf was cleared, I removed the

shelf, and I was able to gain complete access to the water maker system

and the refrigeration system

I removed the hose that was

attached to the input of the water maker system, and installed the hose

that I ran yesterday. I also put in a third filter housing for the

pre-filters to the high pressure pump on the water maker system. I used

to have three pre-filters, but when I changed the system over from 1/2"

hoses to 3/4" hoses, I could not find a 3/4" filter housing in Honduras

or Guatemala. When I was in the states last year, I brought back with

me a new 3/4" filter housing.

I installed this 3/4" filter housing in the

system. So now the pre-filters are back to design. First pre-filter is

30 micron, second pre-filter is 5 micron, and the third pre-filter is

for petroleum products.

I then checked the oil in the

high pressure pump, and checked the drive belts for wear. I also

checked and tightened all the hose connections in the system. Now it

was time to actually check water flow. When I turned on the pump, the

water flow was not good. I then switched the system to run on the main

cabin air conditioner. The water flow was not good either. the new March AC-5C-MD pump has a

much larger capacity in gallons per minute than the previous pump, but

I had used the March AC-5C-MD pump as the water

maker lift pump last year, so it seemed. there was a blockage in the

system.

First thing I did was to clean

the strainers for the water line into the March AC-5C-MD pump. While I was in

the area, I also cleaned the strainer for the refrigeration system.

Some trash in the strainers, which I cleaned out, but not enough to

cause a problem. I next went to the main raw water input strainer. This

is feed by a 1 1/2" input water line. When I took the top off of the

strainer, I discovered a plastic bag in the strainer! I removed the

plastic bag, put the strainer back together. I stared up the pump, and

then I had a lot of water going through the cooling line for the main cabin air conditioner. I then switched the water

system to the water maker and started the pump again. Now we had water

going through the system. I got the filter housings bleed, and the

system was working great. Now I was able to make water!

I then checked the refrigeration

system. I checked all of the connections for the refrigerant, checked

the oil in the compressor, and checked the drive belt for abnormal

wear. All looked good. I put the storeroom shelf back together, and the

boxes abck on the shelf. Last item for the day was to cut out a plastic

cover for the March AC-5C-MD pump. The pump is not

waterproof, so I wanted to have a cover for the pump whenever I had to

bleed either the input or output water hose.

Water Maker System Under Storage Room Shelf

Captain Working On Water Maker System

Water flowing Through New Filter Housing

January 27, 2011, Thursday.

A

really wet and rainy day, but I had an inside project scheduled.

One thing that really bothers me

about living on a boat is having enough spares to cover most problems.

One way to keep up with the amount of spares is to make one piece of

equipment work for several different uses. One place this is handy is

with water pumps. I have tried several times to find water one pump for

several uses, but you can not imagine how hard it is to

find one. Just in 12 VDC pumps, I have three different and

separate pumps. For my 115 VAC pumps, I have three different types. So,

spares for six different pumps!!

Today I started out to at least

solve the 115 VAC pump problem. Last year I put in a new lift pump for

the water maker. It is actually a cooling pump for large marine air

conditioners. When I got the new lift pump working with the water

maker, I decided to use this model pump, the March AC-5C-MD, as my air conditioner

cooling pump also. I came up with a plan to use the March AC-5C-MD as my water

maker lift pump, and my main cabin air conditioner cooling pump. This

plan eliminated the original main cabin air conditioner cooling pump, a

March LC-3CP-MD. This pump is now a spare

pump.

Today I rewired and re-plumbed

for the March AC-5C-MD pump. I have a relay

in the electrical system that provides power to the March AC-5C-MD pump. The normally

closed contacts allow the pump to be used as the main cabin air

conditioner cooling pump. With the main cabin air

conditioner powered off, I can turn on the water maker lift pump

from the circuit breaker panel. This opens the contacts on the relay to

the main cabin air conditioner, and switches

electricity to the pump so it can run as the water

maker lift pump.

The second part of getting the

system to work properly was to re-plumb the water to the pump. I ran

the input hose to the March AC-5C-MD pump through a

strainer. The output of the pump then goes to a valve that switches the

water to the main cabin air conditioner

or to the water maker. The actual hose to the water maker is not

connected as yet, but I did check out the system, and all works as

planned

Pump Configuration At Beginning Of The Day

Pump Configuration With Just The March AC-5C-MD Installed

So the situation with the 115 VAC

pumps is this. I am using the March AC-5C-MD as the

main cabin air conditioner pump and the

water maker lift pump. If this pump goes bad, I have a spare pump, and

a rebuild kit for it. I have a second air conditioner for the aft

cabin, and it uses a March LC-2CP-MD as the cooling pump. If

the LC-2CP-MD pump goes bad it will be

replaced with the March LC-3CP-MD. If that pump goes

bad, it will be replaced with another March AC-5C-MD, the one

that is now the spare pump. At some point in time, way in the future,

all the 115 VAC pumps will be the same type and brand.

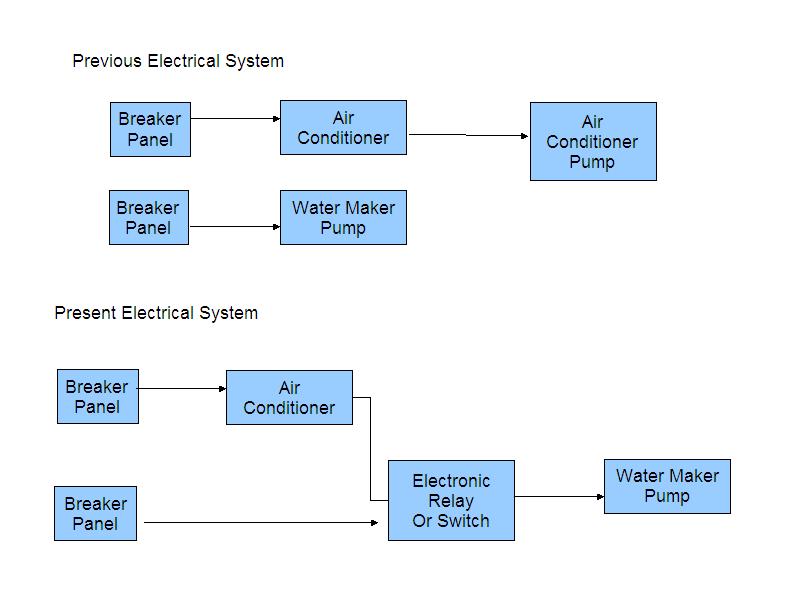

The following three drawings show

the electrical and water connections for the new system. The first

drawing shows connections for the relay that enables the March AC-5C-MD pump to be

turned on with either the main cabin air conditioner,

or the water maker lift pump. The second drawing shows

the electrical system as it was and now. The third drawing shows the

water system as it was and now.

Diaram Of The Connections For The Enabling Relay

Diagram Of The Electrical System (Before And After)

Diagram Of The Electrical System (Before And After)

Diagram Of The Water System (Before And After)

January 26, 2011, Wednesday.

First

on the agenda today was to put tender into the

water. Had help from friend Paul on that, and he also helped me carry

the Yamaha outboard form the shop to the front porch to re-install on

the tender. Also put the newly painted oars onto the tender, the fuel

tank, cushions, and small storage box. I also re-installed the Bimini

top on the tender. I started the outboard and moved the dinghy

from the porch over to the area reserved for tenders and dinghies.

Yamaha Outboard With Newly Painted Cover

Today was the day of bilge pumps.

I checked out the Rule 2000 gallons per hour bilge pump.

Verified operation in automatic and manual mode. I

checked out the Rule 3700 gallons per hour bilge pump.

Verified operation in automatic and manual mode. I then checked

the Edson 30 gallon per minute manual pump.

This pump worked great with the long extension handle I made for it.

The last pump to check out was

the PAR Jabsco electric bilge pump. I

planned to move this pump as in its present location, something could

fall onto it, and prevent it from working. When I check the pump before

moving it , the pump would not work! I started troubleshooting

the problem by cleaning the input strainer, but it was not in bad shape

and was not the problem. I took the pump apart, but could find no

problem. I replaced the pump with my spare, but the same problem. OK, I

concluded the problem was the pickup that was in the bilge. Getting to

it, checking it out and putting it back was no small task. Just that

consumed about two hours, but the pickup was clean, and it was not the

problem. I finall took the strainer off of the input hose and looked at

it. The input to the strainer was clogged with junk from the bilge! I

cleaned it out and the pump worked fine. I then moved the pump to its

new location. All four of the manual and automatic bilge pumps work

along with the visual and audio alarms.

PAR Jabsco Electric Bilge Pump

In Its Original Location (The Shelf AboveIs A New Location)

PAR Jabsco Electric Bilge Pump

In Its New Location

January 25,

2011, Tuesday.

Started

off the day with a shopping trip into town. Stopped at severl stores,

and got several items.

When I returned from the shopping

trip, I mixed up the anti-fouling paint and applied it to the bottom of

the tender. I did one coat of the anti-fouling paint and removed the

masking tape. I cleaned up the tender from any paint spills with

acetone and a rag. The directions on the paint said to wait for 16

hours before splashing the tender, so it will go into the water

tomorrow. I did not get any photos of the tender with the anti-fouling

paint on.

I got the small Mercury outboard

off of the stern of Dream Away, and serviced it. I removed and cleaned

the spark plug and put it back into the engine. I greased and

lubricated all if the parts that appeared to possibly be prone to

corrosion. If needed the Mercury outboard is ready to go.

I re-installed the pad eyes for

the boarding ladder on the starboard side. Finishing this completes the

forward cap rail project. There is now a lot less teak to maintain on

Dream Away, and probably four to five leaks that have been fixed.

January 24, 2011, Monday.

Installed

PVC side bumpers on the tender. This was a time consuming project, but

now we will be able come up beside other boats, and not mark them. We

should also be able bump into docks, and the tender will win!

Captain Installing PVC Bumper/Rub Rail On Tender

Captain Installing PVC Bumper/Rub Rail On Tender

Captain Installing PVC Bumper/Rub Rail On Tender

I masked the waterline on the bottom of

tender to apply the anti-fouling paint.

Captain Applying masking Tape To Bottom Of

Tender

January 23, 2011, Sunday.

A

rainy day on the Rio. Spent the whole day doing work on the computers.

Did updates on the Apple with the Windows XP virtual machine, and also

did all the updates on the Gateway backup navigation computer. I tried

to download the Weather FAX on the XP virtual machine on the Apple, but

had a problem. I have seen the problem before, so will have to find the

solution in the help file. Would it be nice if the software worked as

advertised, out of the box!!

January 22, 2011, Saturday.

Went to the shop and mixed up two 5-ounce pots of gelcoat. I got

everything that I needed ready for the application, including getting

the dingy in the water and tied beside the boat. I was applying gelcoat

on the step at the life rail gate, so needed to be in the dinghy to

apply the gelcoat on the outside of the cap rail. Brought the gelcoat

to Dream Away and applied the two pots of gelcoat to the deck around

the cockpit and the starboard eyebrow.

I then mixed a third pot of

gelcoat and instead of using the Styrene substitute I purchased in the

Rio Dulce, I used some Styrene that I had left over from purchases in

Texas. This pot of gelcoat rolled on just fine, and it kicked off and

hardened really well without an application of standard floor wax. I

have to apply the standard floor wax over the

gelcoat that did not have the real Styrene in it.

I then removed the masking tape

for the areas where the gelcoat was applied. Because the first two pots

of gelcoat did not kick off completely because of the lack of Styrene

in the mix, I had to put standard floor wax over

the gelcoat so it would kick off.

Captain Rolling Non-skid Gelcoat On Starboard Step Through Life Rail

Rolled On Non-skid Gelcoat On The Starboard Side Near The Cockpit Deck

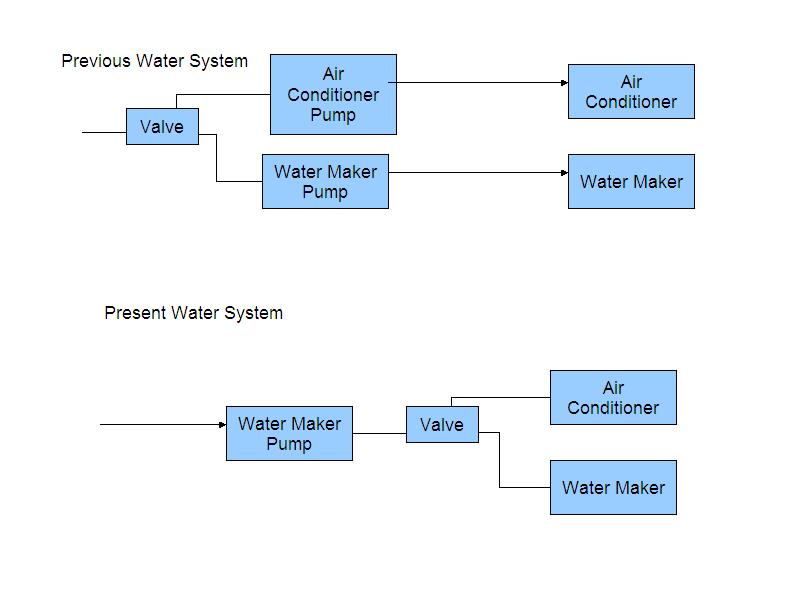

Bow Non-skid Gelcoat With Masking Tape Removed

Last year we had a problem where

sometimes when we rolled up the Genoa with the roller furling system,

it wrapped to tight, and we could not roll the sail completely in.

Today, I added seven extra revolutions of the line on the furling drum.

This should fix that problem.

Could not find any green quarts

of anti-fouling paint, so purchased a quart of blue anti-fouling paint

from a boater on the Rio. This is for the bottom of the tender. I also

purchased a 20 foot piece of 2 1/2" PVC pipe for bumpers on tender.

January 21, 2011, Friday.

Installed

genoa "T" track and the fair leads on the starboard forward cap rail.

Drilling And Tapping Bolt Holes For The Genoa "T" Track On Starboard

Side Forward Cap Rail

Captain Working On The Starboard Cap Rail Genoa "T" Track

Masked off starboard deck just

outside the cockpit, starboard cockpit eyebrow and a portion of the bow

deck area getting ready to apply the non-skid gelcoat.

Starboard Deck And Eyebrow Masked-off In Preparation For Application Of

Non-skid Gelcoat

Captain Applying Masking Tape On Bow Of Dream Away

Bow Of Dream Away Masked-off

January 20, 2011, Thursday.

Early

this morning we turned Dream Away around. I had to finish installing

some of the hardware on the cap rail on the Starboard side, plus we get

better breezes into the boat because of the prevailing wind.

I had to go into town to do some

shopping. While I was gone, Efrain cleaned the starboard side hull,

which is now away from the dock. The whole hull from the waterline to

the shear stripe has been washed and cleaned. It looks really good to

start on this years cruise.

I sanded the deck on the

starboard side deck just outside the cockpit, and the starboard side

eyebrow in preparation for gelcoat and non-skid gelcoat application. I

then painted on white gelcoat to cover most of the blemishes on the

eyebrow and the deck just outside the cockpit.

I went back to the shop and

scraped all opf the Yamaha insignia off of my outboard cover. I then

sanded the cover and painted the cover with white two part paint. I do

this to hide the fact that I have a Yamaha engine. Pretty much outside

the US, Yamaha is the outboard of choice. I have made threats that when

I get back to the US, I am going to purchase Honda Outboard stickers

and put them on my outboard cover. Down here no one steals a Honda

outboard, because they have such a bad reputation.

Last item for the day was to cut

all the 5/16" flat head bolts I am going to use to attach the genoa "T"

track to the starboard forward cap rail. I had 4" and 4 1/2" bolts and

only needed 2 1/2" bolts. I had to cut 15 bolts.

January 19, 2011, Wednesday.

Since

I had the outboard off of the tender and hanging up in the shop, I

decided to give it a servicing. Took the fuel filter apart and cleaned

the filter and housing, and re-installed the fuel filter. Drained the

carburetor, and did not see any water or foreign material in the fuel

that was drained. Removed the spark plugs, cleaned them and reinstalled

them. Pumped grease into the one zerc fitting on the motor, and then

wiped grease on all of the stainless steel parts that are attached or

screwed into the aluminum housing.

I then bent the tender bow rails

back to as close as they were before our anchor dragging incident in

Roatan. I then drilled the necessary holes in the newly applied

fiberglass backing plates on the tender for the tender bow rails. I

installed the tender rails, adjusted their shape

a bit and they went right on.

Rails Laying Beside Tender Before Intsallation

Newly Bent Bow Rails Re-Installed on Tender

Designed and fitted a bumper for

the bow of the tender from 3 1/2 inch PVC pipe.

The old system of a fender just did not protect the bow of the tender.

As you can see from the photo above there is already a chunk out of the

port side bow. This new system should protect the bow. Time will tell.

I also plan to purchase a piece of 2 1/2 inch PVC pipe and use it to

protect the sides of the tender. I also installed a new security wire

to lock the tender up when we leave it at a dock. The new wire is 1/4

inch 7 X19 wire.

Front View Of Newly Installed Tender Bumper

New Tender Forward Bumper Viewed From Starboard Side

Luis helper, from Progresso

Upholstery, finished the installation of the snaps on navigation

station chair. This completes all of the work done on new fabric covers

for the main salon.

I did some repairs on the tender

bimini. I had to drill out some rivets, and then use a tap to put

threads in the holes, and then install 1/4 X 20 X 1/2 pan head bolts to

hold the pieces together. While I had all of the tools out, I also

drilled and tapped a hole on the starboard life rail on Dream Away.

When I was doing all of the work on the cap rail, I noticed a joint in

the life rail that did not have a proper bolt in it. This problem was

fixed!

Efrain cleaned hull on port side

and stern.

January 18, 2011, Tuesday.

While waiting for the dew to dry, Kitty and I installed the plastic

enclosures on the starboard side that Luis had modified to fit better.

Luis had installed the female side of the snaps at the bottom of the

enclosures. Kitty and I installed the male end of the snaps on the side

of the cockpit. We are now ready for rainy or heavy weather on the

starboard and the port side. We then removed the starboard side

enclosures, rolled them up and put then in the forward cabin storage

area. I then removed each of the male snaps on the port and starboard

side of the cockpit, applied a coat of Life

Seal on each snap, and re-installed the snaps.

Starboard Side Of Cockpit With No Snaps Installed

Starboard Side Of Cockpit With Male Snaps Installed

Starboard Cockpit Enclosures Installed

Next I went to the

shop and mixed up a 5 ounce pot of non-skid gelcoat. I applied the

non-skid gelcoat to the front of the tender, and used the remainder of

the pot and applied it to the bow area of Dream Away. Got the

non-skid gelcoat all applied, then went back and removed all of the

masking tape. I then turned over the tender

Non-Skid Gelcoat On front Of Tender

Captain Rolling On Non Skid Gelcoat On Bow Of Dream Away

Bow Of Dream Away Mostly Done

Yesterday I had installed masking

tape dams around the areas on the tender where the hand rails are

installed on the tender. It was very difficult to cut and install

backing plates under where the hand rails come through the side of the

tender, so I decided to apply fiberglass and resin, and basically

install a permanent backing plate. The masking tape dams allowed this

to happen. I cut seven pieces of fiberglass for each backing plate. I

then mixed a pot of resin, added catalyst, and went to work. I got all

of the backing plates made, and the tender turned right side up.

January 17, 2011, Monday.

Removed

Yamaha outboard from tender,

removed tender bimini, and removed all loose items from tender. Friend

Paul and I pulled the tender out of water and up onto the front porch

of the owners house to do some repairs and maintenance. Brought the

hoses from Dream Away over to the porch and washed off the bottom of

tender. After seven months of being in the Rio Dulce, the bottom and

sides were pretty filthy with slime and sludge. It was also obvious I

need to raise the waterline at the back of the tender, as the slime and

sludge was about two inches above the present waterline.

One of the maintenance projects

on the tender was to roll on the non-skid gelcoat. Last year I had

applied some non-skid tape on the front of the tender so we would not

slip while getting into and out of the tender. This tape worked for a

while, but the sun did it's thing, and the tape started coming off of

the front of the tender. I pulled off all of the remaining tape and

cleaned off the remaining adhesive. I then sanded down the area, and

wiped it all down with acetone. I then masked off the areas on the

front of the tender for the gelcoat non-skid. I also masked off the bow

of Dream Away in case I had too much gelcoat mixed up and needed a

place to roll it on. The plan is to completely roll on the yellow

non-skid gelcoat on the deck of Dream Away.

Dream Away Bow Masked Off To Roll On Non-Skid Gelcoat

Tender With Masked Off Area For Non Skid Gelcoat

January 16, 2011, Sunday.

Kitty and I installed the plastic

enclosures on the port side that Luis had modified to fit better. Luis

had installed the female side of the snaps at the bottom of the

enclosures. Kitty and I installed the male end of the snaps on the side

of the cockpit. We are now ready for rainy or heavy weather on the port

side.

Newly Installed Port Side Weather Cockpit Enclosures Looking Aft

Newly Installed Port Side Weather Cockpit

Enclosures Looking Forward

The

last project for the day was sewing the forward awning. I resewed the

the seam down the middle and then sewed on a black piece of webbing on

the the underside of the long awning seam. I used a zig zag stitch on

each side of the webbing and one down the middle. That should hold it

all together until I can afford to replace the awnings.

Underside Of Forward Awning Installed

January 15, 2011, Saturday.

Today

we went to the swap meet at Mario's Marina, then went into

town to do some shopping and have lunch.

I applied the third coat of paint

to the dinghy oar.

Next was coming up with a way to

keep the privacy handset for the Iridium satellite phone plugged into the

base. It has been a problem pretty much since it was installed, but

since Kitty and I usually talk with the speaker on, we do not use the

privacy hand set. I came up with a jury rig that will work until I can

get a more permanent fix made.

Iridium

Phone Privacy Handset Fix

I put compressor box back into

place over the SCUBA compressor.

Captain With Compressor Box In Place, Also

Showing Boarding Ladder Cover, Life Raft Cover, And Mizzen Sail Cover

Skirts

January 14, 2011, Friday.

Day Off

January 13, 2011, Thursday.

Last

night we had high winds and the forward awning split the long seam. It is still a rainy day so

decided to break out my new Sailrite sewing machine that I purchased

from Paul. I started sewing and when I went around a grommet, I got to

close and broke a needle. I have many new needles, but they are a

different length, so I have to adjust the needle stroke. I had so many

interruptions during the day I did not get the adjustment done. Still

have to get the awning sewn!

The yellow non-skid gelcoat I

applied yesterday on the compressor box top and the port side eyebrow

was still a bit sticky, so applied a coat of wax to both.

January 12, 2011, Wednesday.

Finished

up engine room. I replaced all of the oil soak pads under the main

engine and the gen set. I also replaced the zinc in the main engine

heat exchanger, and checked the oil in the main engine transmission.

Ran the gen set for two hours to verify operation and make sure nothing

happed when I changed the oil and fuel filters.

I applied the second coat of

paint on dinghy oar.

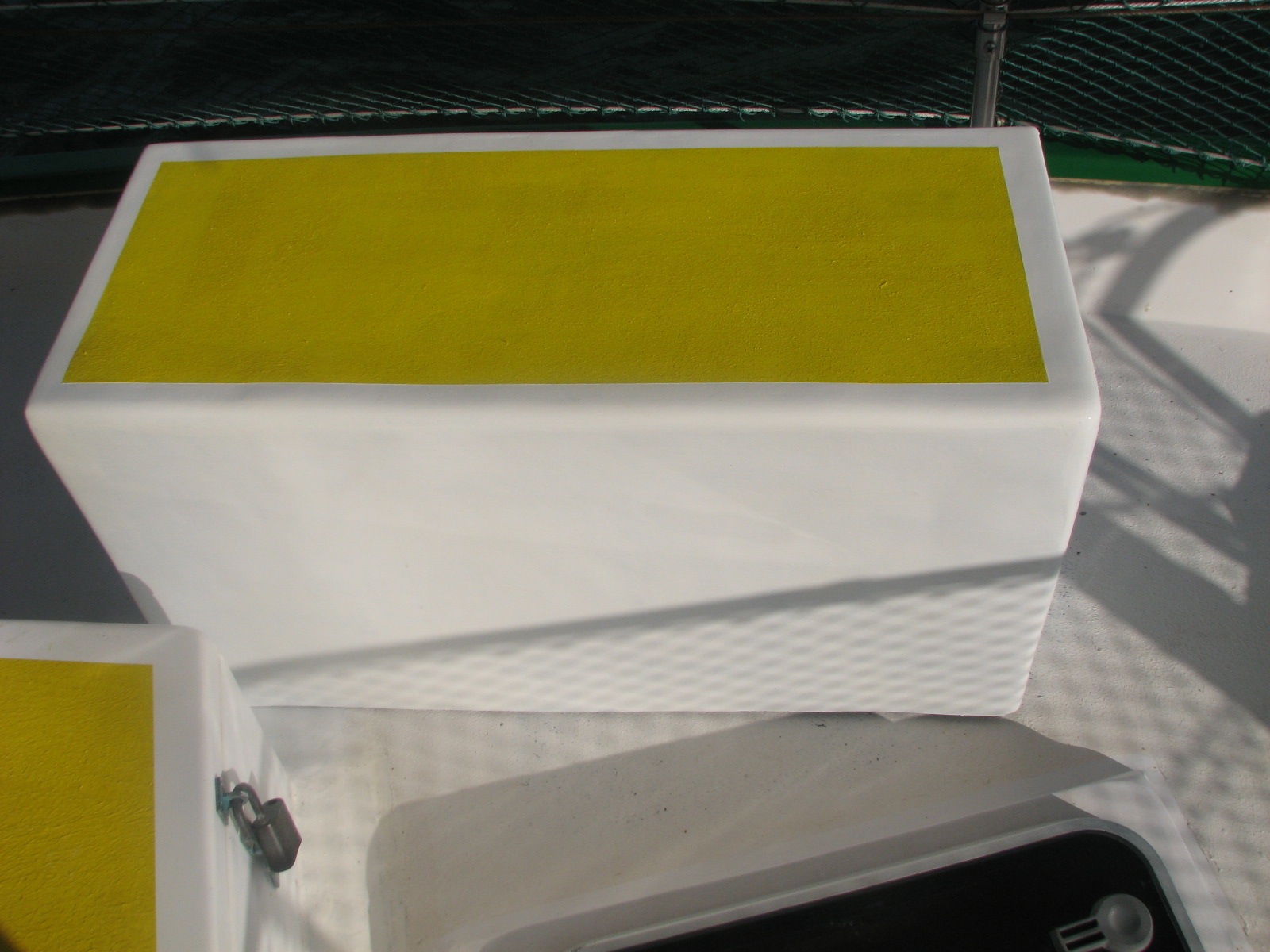

I masked the compressor box and

the port side eyebrow. I mixed up one five ounce pot of yellow gelcoat

and rolled it on the top of the compressor box and the port side

eyebrow. In this pot of gelcoat I added another 1/2 ounce of wax.

Forward Port Side Eyebrow Non-Skid Gelcoat

Port Side Eyebrow Non-Skid Gelcoat

Compressor Box With Yellow Non-Skid On Top

January 11, 2011, Tuesday.

Today

is going to be nasty day. Started out by draining all of the yuk out of

the diesel standpipe. Next was to change out the Racor filters for the main engine and the

gen set. I also drained out the yuk in the bottom

of the Racor filter housings. This was

pretty much the "clean" part of the operation.

While I was doing the fuel

filters, I was filling the main engine and gen set oil filters with

oil. I had decided to change both of the Amsoil

oil filters. One of the filters is the full flow filter, and the second is the

by pass filter. The full flow filter is to be changed

at 300 hours of engine run time, and the bypass filter is to be changed at 600 hours of engine run time. Since the full flow filter was due to

be changed, and I had enough spares to change both filters, I decided

to do both. I was able to successfully change all four of the oil

filters without making a major mess. I cleaned up the area and got

everything looking good. I ran the main engine and the gen set for

about 10 minutes each. I then checked the oil in each engine, and

topped off the oil.

Paul and I removed the Sharp Microwave to get

turntable motor part number. The turntable is not turning reliably, so

I wanted to see if I could find the motor and replace it, and hopefully

it will fix the problem. We were able to get the part number, and I

turned the research of the motor over to my friend Jim who is coming

down to Dream Away the first of February. Jim found the part number and

we ordered the part. Paul and I put the Sharp Microwave

back into it's hole without any problems. It is so much easier with two

people putting the Sharp Microwave back.

Next Paul and I removed the Seaward Princess gas stove from its place

in the galley. It had been several years since we had cleaned the

ourtside of the stove and the area in which it rests, so it was in

need. Kitty worked on cleaning the outside of the stove, and I cleaned

the area in which the stove is placed so it can gimble. I did not take

any photos of the stove and area after it was cleaned, but did take

before photos.

Kitty Cleaning The outside of the Stove.

Area In Galley Where The Seaward Princess Gas Stove Normally

Resides

Last item fo rthe day was to

apply two coats of white gelcoat on top of the compressor box in

preparation of the non-skid gelcoat application.

January 10, 2011, Monday.

Helped

friend Paul get up his mast twice to try and repair his tri-color

light. This time it looks like we finally got the problem fixed on the

second try!

I went up the mizzen mast and

checked all of the rigging connections. Everything look good, no

problems found. I also took the VHF antenna connections apart, checked

them for corrosion, and sprayed corrosion block

into them, and re-connected them. No problems found there either. When

I got down from that project, we checked out all of the navigation

light, and they checked out, with no Problems found.

Kevin was on Dream Away all day

and finished up cleaning and polishing the stainless steel on Dream

Away. The will keep the stainless steel from showing rust stains for a

couple of months of the salt water environment once we leave the Rio.

Kevin Polishing The Stainless Steel

I sanded down the second dinghy

oar, and applied the first coat of yellow paint on the oar.

I applied a couple of coats of

the new polyurethane paint on compressor box. I only wanted to apply

one coat, but I mixed up too much paint. By the time I got the paint,

the catalyst and the reducer mixed up, I had enough for three coats!! I

decided if the paint did not kick off I would apply it until it started

to kick, or I ran out of paint. Fortunately I ran out of paint, and got

three good coats on the compressor box. It looks prett doon, and only

time will tell how well the paint lasts. I still have to apply white

gelcoat on the top of the box so I can roll on the yellow gelcoat

non-skid.

Compressor Box, Masked Off, Waiting For Paint

Compressor Box After Three Coats Of Paint

Compressor Box, Another View With Paint Applied

January 9, 2011, Sunday.

Helped

friend Paul get up his mast twice to try and repair his tri-color

light. Not successful, but should be able to finish the job tomorrow.

Paul

helped me to go up my main mast. I always do a rigging and light check

before going off on any long passage. I knew I had one spreader light

out and needed to repair that. I also had to get the halyards out of

the mast. When we came into Monkey Bay, I knew we would be here several

months, so I pulled down all of the halyards and the topping lift in

the main mast and tied messengers to the ends. This was done to keep

the halyards out of the sun. I also took down the two spinnaker

halyards. Before I could go up the mast I had to pull down the halyards

and the topping lift.

When I went up the main mast to

do my checks, I pulled the two spinnaker halyards up with me and ran

them in their proper blocks. I checked electrical connections and radio

connections at the top of the mast. I also sprayed all of the

connections down with corrosion block. As I came down the mast, I

checked all of the rigging and tangs. All looked really good. I

replaced the bulb in the starboard main spreader light, and came back

to the ground. I fell the main mast is ready for a long passage.

January 8, 2011, Saturday.

I

reinstalled the netting on the forward port side, and got the fair

leads back onto the genoa "T" track. I can finally say the forward port

side cap rail is officially finished. I just have to put some gelcoat

non-skid down on the port side eyebrow, and we can turn Dream Away

around, and I can finish the starboard side.

I applied one coat of thinned

epoxy on the second dinghy oar.

Kevin worked on the stainless

steel and was able to get it all cleaned. He will be back on Monday to

wax the stainless steel.

I put five gallons of diesel fuel

into the starboard fuel tank.

January 7, 2011, Friday.

Finished

installation of the hardware on the port side cap rail. This included

two lifeline stanchion support, one chock and the genoa "T" track. The

genoa "T" track consisted of 15 bolts that had to be drilled and tapped.

While I was working on the cap

rail parts, our friend Kevin was working on cleaning and waxing all of

the stainless steel on Dream Away. He needed soame work, and I needed

to get ahead on projects.

January 6, 2011, Thursday.

Started

the Nyalic

protectorant application on the repaired areas

of the port cap rail. It started to crinkle up again, just like the

last time. I am not a happy camper. I have been six days waiting for

the Easypoxy Kelly Green

paint to dry. The recommended drying for the Easypoxy Kelly Green

paint is 24 hours. Will have to contact the Nyalic folks to see

what they say.

I masked the area for gelcoat

application where I have to install a cleat, chock and the "T" track on

the port side. Since I already had the cleat off it is much easier to

apply the gelcoat. I then applied the gelcoat, two coats, on the port

side cap rail area, the port side of the forward deck box, and the area

behind the anchor windlass. It set up very quickly, so removed the

masking tape.

Gelcoat Application, First Coat, Side Of Cap Rail.

Gelcoat Application, First Coat, Port Side Forward Deck Box

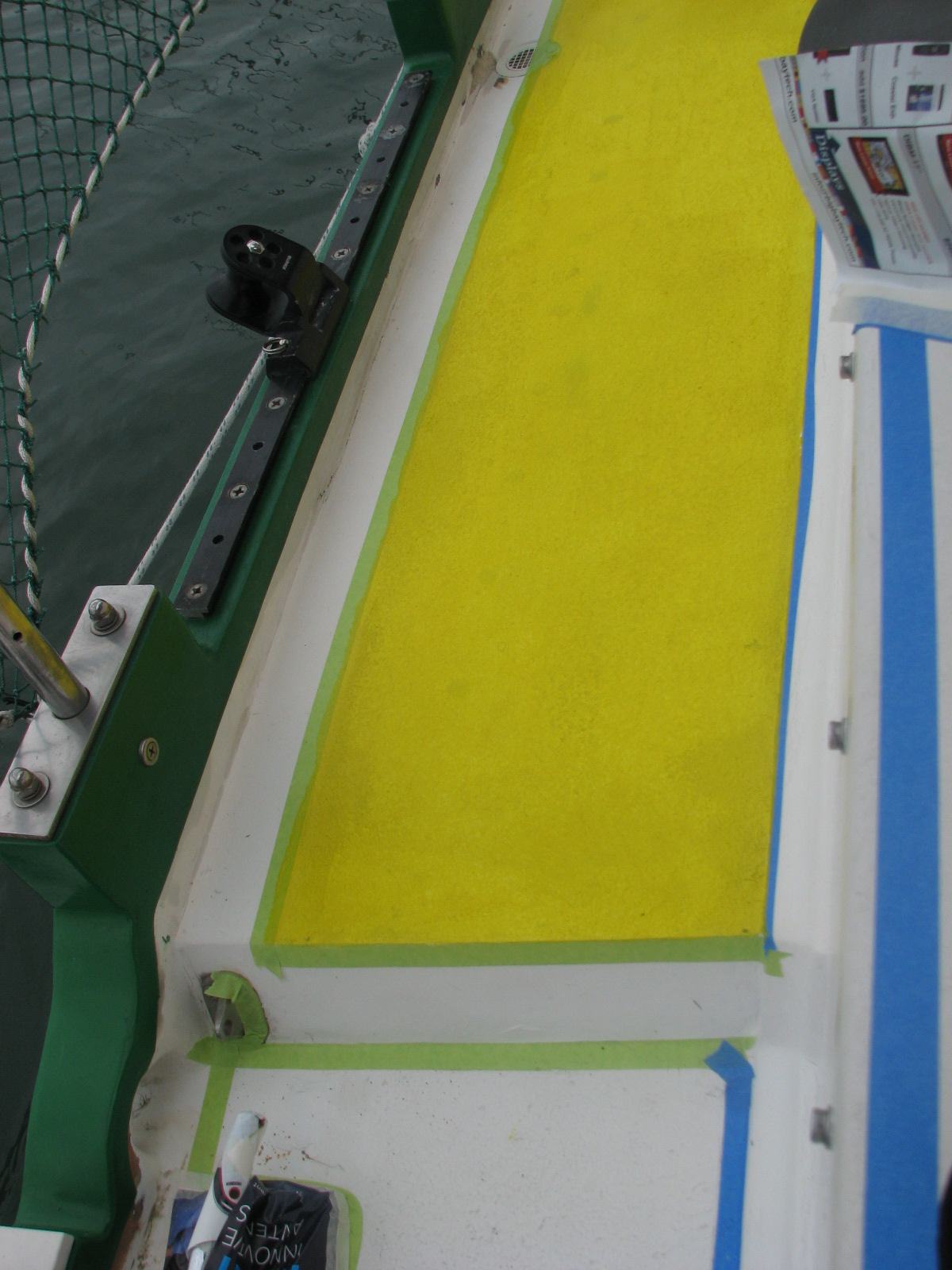

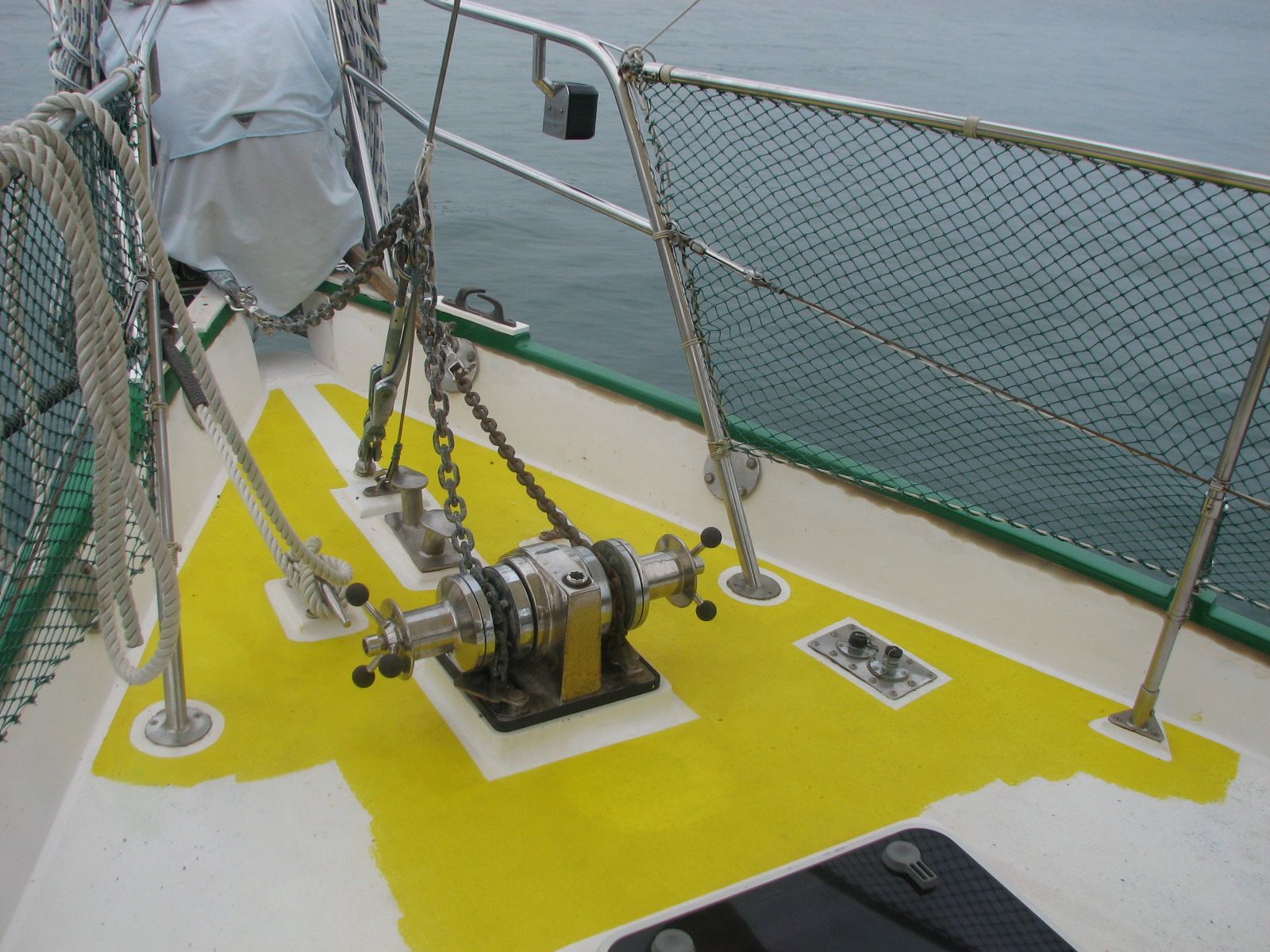

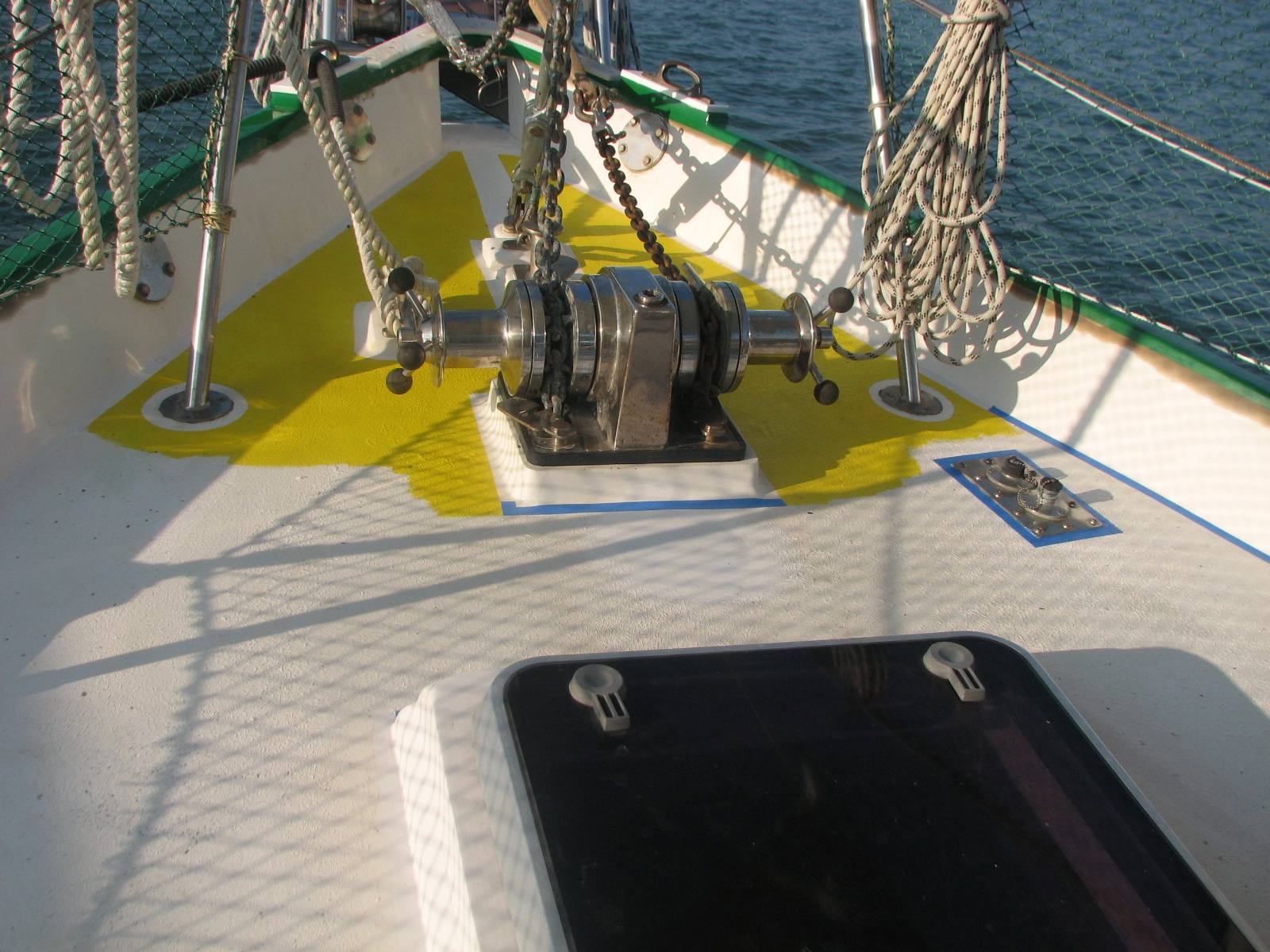

Gelcoat Application, Second Coat, Anchor Windlass Repair Area

Gelcoat Application, First Coat, Port Cap Rail, Near Cleat And Chock

Area

I removed the masking tape from

the shear stripe. I will attempt to repair the crinkled at a later

date.

I removed the paint sanded down

second oar. It is now ready for an epoxy application

January 5, 2011, Wednesday.

Sanded down

the repaired area just behind the anchor windlass, and the repaired

area on the port side of the forward deck box. Areas are now ready for

gelcoat application.

Area Behind Anchor Windlass Sanded And Ready For Gelcoat

Area Beside Forward Deck Box Sanded And Ready For Gelcoat

Started installing the port side

cap rail hardware back onto the port side cap rail. This include three

rope chocks and four lifeline stanchion supports. I also installed the sacrificial pieces for anchor and rode on the very front of

the cap rail. These pieces are used to prevent the anchor chain from

damaging the cap rail when the anchor is lowered or raised. I was now

able to get the anchors and the chain all back where it belonged. I did

not have time to complete the installation of the port side "T" track

for the jib fair leads.

Port Side Chock Installation

Port Side Lifeline Stanchion Support Installation.

sacrificial Strips Back Into Place

Anchors, Rode, And Windlass Cover Back In Place

January 4, 2011, Tuesday.

When we were in The Bay Islands of Honduras last year and had our

anchor dragging problem, and almost lost our dinghy, one of the

stainless steel bows, Bimini fitting, on the dinghy was lost. I had

asked Luis if he could bend one for me and install it on our dinghy. Luis brought back bow for dinghy and installed it. It looked

really good, and it was nice to have the dinghy Bimini back to normal.

Luis also brought back the repaired cockpit enclosures. They fit very

well also. Now when I get the eyebrow finished with the gelcoat

non-skid, I will be able to complete the installation of the cockpit

enclosures.

I finally finished painting the

first oar for the dinghy, and put it back on the dinghy. I brought the

second oar to shop and started sanding and stripping the paint on it.

Dinghy Oar With Last Coat Of Paint Hanging In The Shop

I applied another another coat of

putty on compressor box and the port side of the

forward deck box, and the area I filled with fiberglass just behind the

anchor windlass on Dream Away. I then

sanded down the compressor box again.

Compressor Box, Just After Putty Application

Compressor Box After Sanding

Compressor Box After Sanding

January 3, 2011, Monday.

Went

back to the shop and sanded the compressor cover. Got the cover as

smooth as possible, and then applied more putty.

Went to

Dream Away and sanded down the area that I repaired on

the port side of the forward deck box, and the area I filled with

fiberglass just behind the anchor windlass. I then washed down the

front deck of Dream Away. I also scrubbed off the wax I put on the

yellow gelcoat. It seems like the yellow non-skid gelcoat I applied has

set up very well, and should not have any problems.

We waited for Luis, the canvas

man we have been working with, to come over to the boat. He arrived and

we got a very good price for curtains in the main cabin. We also

arrived at a good price to have him repair the bad weather enclosures

we have for the cockpit. We have had them since we first left in 2004,

but they were barely serviceable. When Luis gets finished, we should be

able to be in the cockpit with the rain or waves splashing on the boat

during a passage, and remain very dry and comfortable.

January 2, 2011, Sunday.

Worked

on the computer doing updates to get some information on Christmas and

other stuff on the web page.

Went back to the shop and sanded

the compressor cover. Got the cover as smooth as possible, and then

applied more putty. hopefully the last application, but since I have

done this before, there will be at least another application.

January 1, 2011, Saturday.

First

this today was to put wax on the yellow gelcoat I rolled on yesterday.

This was done to make sure the gelcoat sets up and hardens.

I then put the second coat

of Easypoxy Kelly Green

paint on the shear stripe. I had just enough paint to cover the

repaired areas of the shear stripe. I will let the paint dry for a

couple of days before applying the Nyalic

protectorant.

I then went back to the shop to

work on the compressor cover. I sanded and cleaned up the cover from

the fiberglass application of yesterday. I mixed up a five ounce pot of

putty and applied it to the compressor cover.