Maintenance Log January 2014

January 31, Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan

and spend time with them brushing their beautiful coats.

Went over to the shop

this morning as the temperature is finally bearable! Cleaned up a

bit, and straightened up the shop to be able to get some work done.

Last week Kitty and I had taken some

measurements for the main mast sail handling platform (SHP). We also

decided pretty much on the exact location of the SHP.

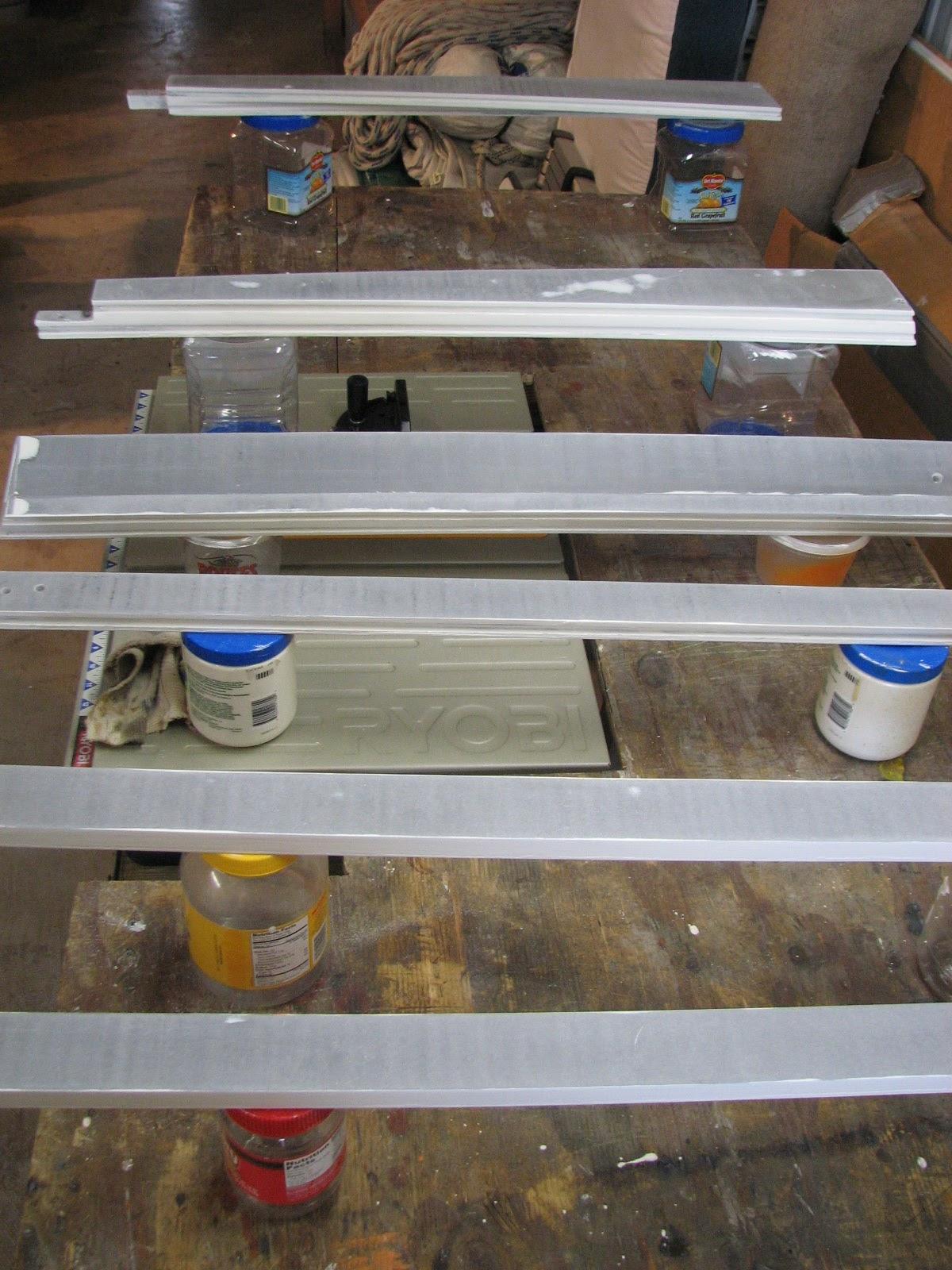

I dug out all of the aluminum pieces I

had purchased months ago for the SHP. I took the measurements from

the Pink Book, and verified I had enough aluminum for the legs of the

SHP and the braces and supports of the SHP.

I then cut out the legs, making sure

they were just a little bit long. When I finished cutting the legs, I

smoothed off the edges, and loaded the legs and all the other

aluminum pieces for the SHP into the

Black Beast.

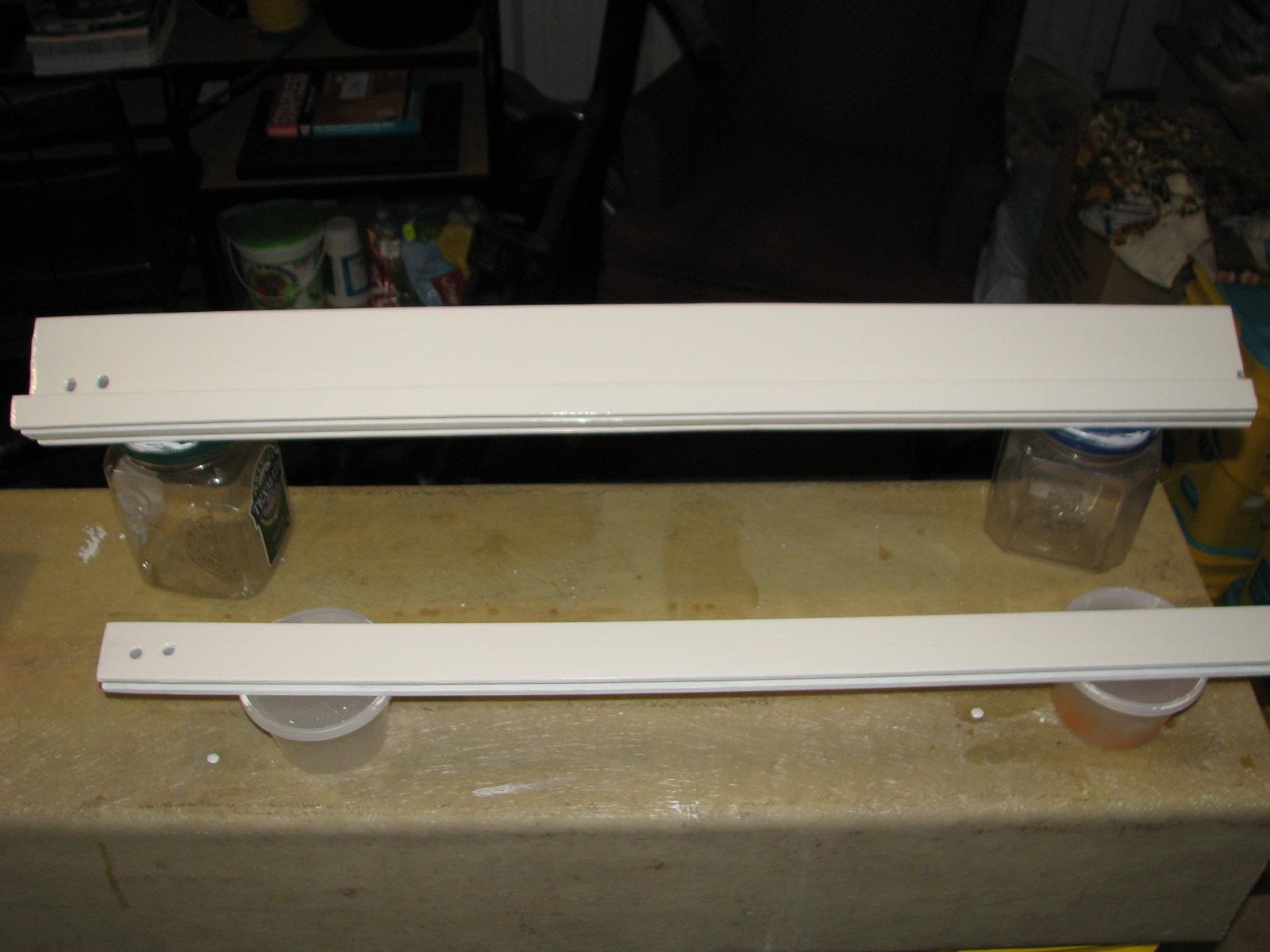

Measured Pieces For SHP

Cutting Aluminum Pieces For SHP

After breakfast, Kitty went into New

Iberia to run some errands. She dropped me off at

LeBlanc Oil to see if they had the 1>X 32 threaded rod. They did not,

so I headed back to DREAM AWAY to get started on applying the last

coat of finishing

putty to the fiberglass

hard dodger base on DREAM AWAY.

While waiting for the finishing

putty to set up, I went down to the galley and set up

the KitchenAid

Stand Mixer, attached the juicer attachment, and

started juicing more oranges. We still had five bags of oranges

remaining to juice.

I juiced oranges for 1 ½ hours, then

back up on deck. I got out two of my sanders, a couple pieces of

sandpaper for hand sanding, and went to work sanding the hard dodger

base. I got the hard dodger base all sanded. It looks very good, but

I know when I apply the gelcoat,

all kinds of imperfections will show up.

I put everything away, and then washed

down the hard dodger base and cockpit with the hose to get all of the

sanding dust washed off the area.

Kitty had come home from her errands. I

went down into the galley and finished up the orange squeezing. When

I finished I had two more gallons of fresh squeezed orange juice. ! ½

gallons went into the freezer, and the remaining ½ gallon went into

the refrigerator. Rum and fresh squeezed orange juice sure tastes

good.

By this time the hard dodger area and

the area in front of the mast was dry. Kitty and I went up to do some

more marking and measuring on the legs for the SHP. We got the

measurements I need to fabricate the legs for the SHP.

Once the legs are fabricated, we can

screw the legs to the deck, and accurately measure the braces needed

to support the fiberglass grating.

January 30 Thursday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the shop

today as it was just too cold in the morning, and I had an

appointment with our mechanic to get the oil changed in the Black

Beast at 0900.

When I returned from the mechanic, I

walked all three Piers to shut off all of the water we had left

trickling during Winter

Storm Leon. All of the ice had melted off of all three

docks, and the temperature kept climbing.

After breakfast, I got to work on the

generator

start problem. I had determined yesterday that I should change the

air filter in the unit. I removed the combination rocker arm

cover/air intake. I removed the old air filter, and put in a new one.

The old filter did not look real bad, but I want to eliminate

problems so I can get the generator to run.

I got the combination rocker arm

cover/air intake back on the engine. Before attempting a start, I

wanted to check the fuel system. I verified we had fuel to the

injection pump using the manual fuel pump. I then had Kitty turn over

the engine, and I verified we had fuel at all three injectors.

We attempted to start the generator

several times, but it would just not start. It seems it might be a

timing problem, but I am not sure how to adjust the timing on this

engine. I think I will put the original injector pump back into the

engine and see if that has any effect.

Top Of Engine Before Rocker Arm/Air

Intake Cover Removal

Top Of Engine After Rocker Arm/Air

Intake Cover Removal

Old Air Filter

New Air Filter

Before the day was finished I drained

the holding tank in the shower trailer.

January 29, Wednesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the shop

today as it was just too cold. Winter Storm Leon was moving on , but

leaving extremely cold conditions. The high temperature for today was

34°. The good news was there was no precipitation today.

I spent most of the day on the

computer, catching up and doing research. Trying to find parts and

what is turning out to be off the wall items.

I did leave DREAM AWAY one time during

the day to check on the shower

trailer, and to walk the docks to make sure the water

was still trickling out of the selected pedestals. All of the ice had

melted off of the docks except where I had the water trickling, so

that was safe.

Ice On DREAM AWAY Deck

Ice On Dock From Water Trickling

The shower

trailer seems OK except I could not get water to run

out of the sink faucet and the shower. I hope that will not be a

problem. We will see tomorrow when the temperature warms up.

Back on DREAM AWAY, I did some more

work on cleaning up the work

bench in the garage. I put away some bolts and screws

that were piling up, and some electrical parts.

I then got out our big KitchenAid

Stand Mixer, attached the juicer attachment and juiced

some more oranges. I fixed a rum and orange juice drink, and filled

up the remaining containers with the juice. I still have four more

bags of oranges to juice, but I will have to find another container.

Oranges Ready To Juice

January 28, Tuesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the shop

today as it was just too cold. We were being hit by Winter Storm

Leon. I pretty much stayed on DREAM AWAY all day, with two

exceptions.

The first time I left DREAM AWAY, was

to check to make sure the water was still dripping out of the faucets

on all of the docks. Let me make note that the temperature was 28°,

and at the same time it was 78° in Marathon, Florida.

I did not want the pipes to freeze.

Pier “A” and Pier “B” were fine, but the water left dripping

at the end of Pier “C” had stopped. Johnal,

from yacht RUTHIE, had noticed the water had stopped at the end of

Pier ”C”. Johnal

got his heat gun out, and I met him at his boat on Pier “C”.

Water was not coming out of his power

and water pedestal, so we hit the water faucets with the heat gun

there. After about five minutes, the water was steadily dripping out

of the two water faucets. We opened both faucets wide open, and moved

down to the next pedestal. No water at this pedestal, so we hit one

of the faucets with the heat gun, until the water started trickling

out. We opened that faucet wide open and moved to the last pedestal

on Pier “C”.

This pedestal was not not dripping at

all, and it was the one I had left open. We hit the faucets with the

heat gun, and after about 10 minutes, there was a drip in one of the

faucets. I had not dressed for a long time outside, so I left Johnal

with the heat gun at the pedestal, and I went back to DREAM AWAY to

get warmer clothes and to put on socks. Do not even think it. I am

out in 28° weather, and I should be on a mooring in Marathon. Who is

the brightest light in the attic?.

On my way back to DREAM AWAY, the two

faucets at Johnal's

boat were running wide open, so we had good water flow at that point

on the dock. I backed off both faucets, and just left them steadily

trickling. I continued on to DREAM AWAY, and put on warmer clothes

and socks, and went back out to the end of Pier “C”.

On the way back out to the end of Pier

“C”, the next to last pedestal was running full blast, so I

backed off the faucet to just a trickle. When I met Johnal

at the last pedestal, he had water coming out at a steady trickle on

one faucet and a drip on the second one. We agreed to leave both

faucets wide open, and I would come back and check them in about two

hours to see if more water was coming out.

When I went back out to the end of Pier

“C” around 1600, the water was flowing full blast out of both

faucets at the last pedestal. I backed both faucets to a pretty fast

trickle, and left it that way for the night. I will check them

tomorrow morning when it gets light and safe to move about the docks.

Water Trickling Out Of Last Pedestal On

Pier “C"

On my way back to DREAM AWAY, I stopped

at Hollis’s boat. He asked me to run both his engines for about 30

minutes to get all of the systems up to temperature, so that none of

the pipes would freeze over night. I got the keys and started both

engines. I ran them for about 45 minutes, and both engines got up to

180°. I turned them off, returned the keys to the secret spot, and

went back to DREAM AWAY for a hot coffee with honey and rum added.

During the day both before and after my

two trips into the freezing temperatures, I did work on the computer

and worked on a couple of projects.

I got the mostly repaired galley faucet

installed back into the galley. I am still researching parts to see

if I have everything I need.

I then worked on putting away a bunch

of items that had been piling up on the

work bench in

the garage. I needed more room to work. I got

a fair amount of “stuff” put away, but I still have more to do.

Next project was to continue work on

the gen set. I am not having much luck getting it to run. It seems to

have something to do with the stop system, as I had the engine

running with the stop solenoid removed from the engine.

I went to the rear of the generator,

and removed the cover to all of the electronics. I removed the start

relay and the shut down relay. I cleaned the contacts on both relays,

and swapped the relays around. I had Kitty operate the start switch

on the control

panel, and the shut down switch, and the relays seemed

to be working properly. I then attempted to start the generator,

but it would not start.

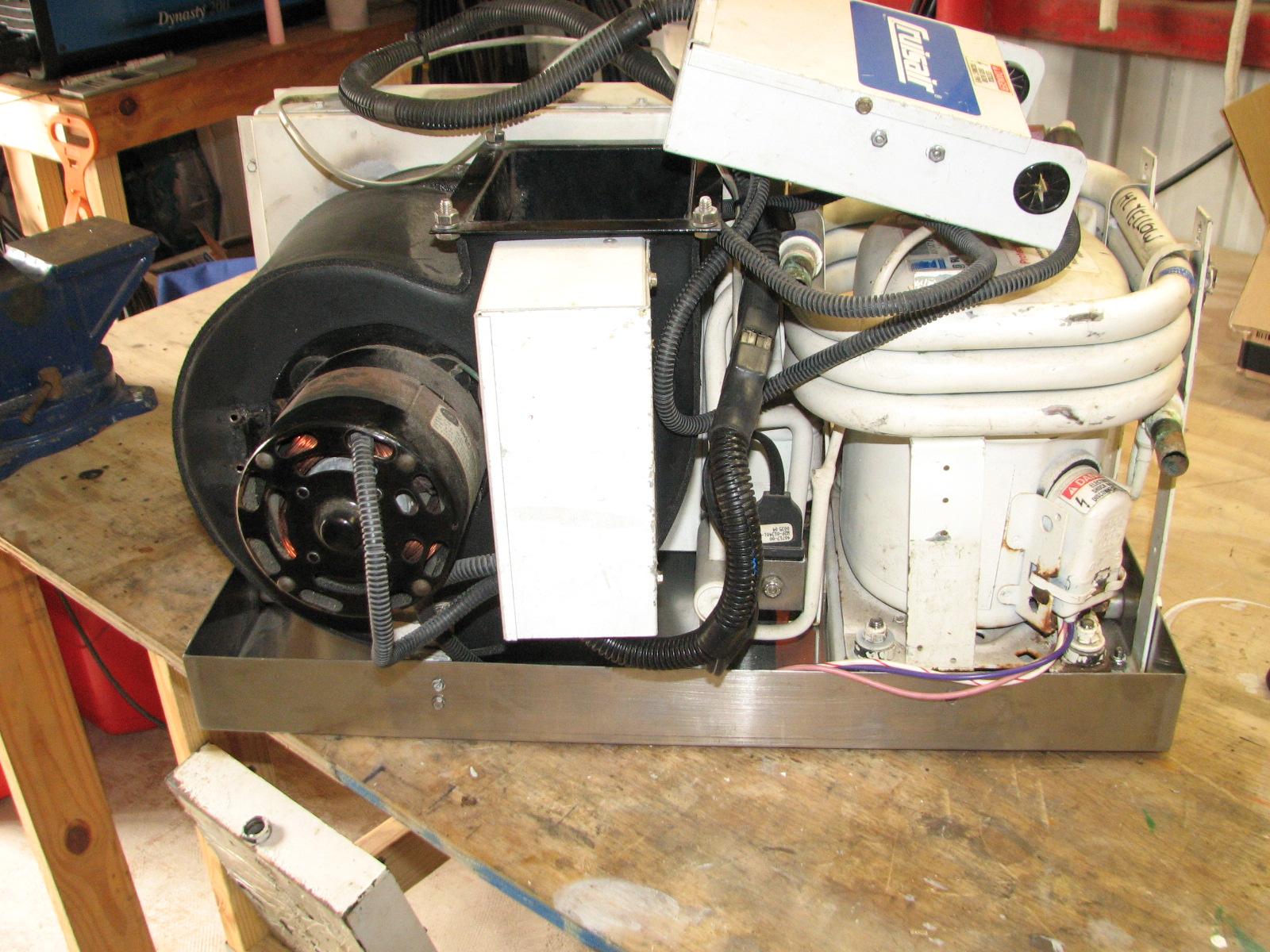

Electronics And Relays At Back Of

Generator

I decided to remove the start solenoid

and see if it was working as designed. When I got the solenoid

removed, I again had Kitty actuate the start and stop switch on the

control

panel. The stop solenoid was working as it should.

We again attempted to start the

generator,

but it would not go. I re-installed the stop solenoid. At this time I

am assuming the fuel system is OK, because the last time I worked on

the generator,

it was running OK. I decided it was time to change the air filter. As

it turns out the air filter should be changed every 250 hours, and I

have about 700 hours on this air filter. I attempted to get the air

filter removed, but could not get it out of the housing.

As it turns out, I have to remove the

rocker arm cover/air filter housing to get to the air filter? All of

my metric tools are in the Black

Beast, and it

was sleeting, so I put off replacing the air filter until tomorrow

when it warms up.

I did some research on solar panels for

DREAM AWAY. As of now it looks like I am going to purchase a 4> watt

system from a company named Renogy.

I was looking at the 400

watt kit they are selling on eBay. I talked to one of

the technicians about how to connect the four 1> watt panels, and

other questions about solar in general.

The way I want to install the panels on

DREAM AWAY, I think I will be cheaper off buying the solar items

individually, because I will have to supply so much myself. We will

see how it works out in the future.

January 27, Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Went to the shop,

and started in on the aluminum plates I am fabricating for the galley

sink faucet. I got the faucet taken apart, as it was very corroded.

It seems there is an O-Ring, but I will have to see if I have a parts

list to see.

Corroded Faucet

After I got the faucet apart, I got it

all cleaned up, and ready for use. I drilled out the aluminum plates

and got them the correct size. It was then I realized the plates were

too thick and would not work.

Faucet With Thick Aluminum Plates

I dug around in my scrap metal pieces

box and came up with a thin piece of aluminum that I could use for

the temporary fix in the galley. I fabricated the two pieces required

to fit the faucet in the galley.

Faucet With Fabricated Aluminum Pieces

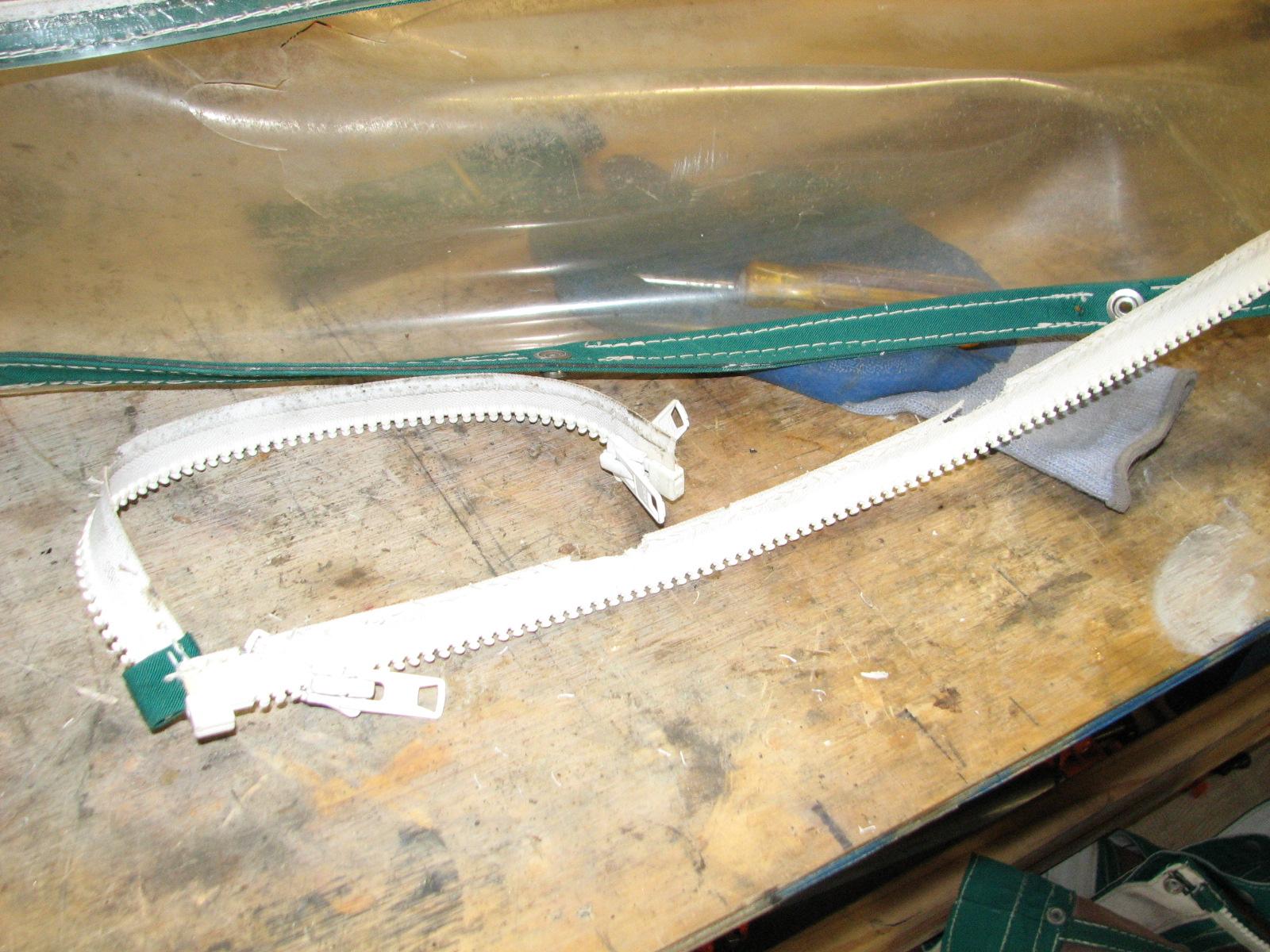

I then started cutting out the zippers

from the old soft dodger. There is not enough material in the old

dodger to save it, but the zippers could be of some use.

Zippers From Old Soft Dodger

Went back to DREAM AWAY from breakfast,

then went over to a friends house, with cruisers

Johnal and Cindy,

to pick some oranges and

satsuma’s

before the hard freeze tomorrow and Wednesday. We loaded our bags of

oranges into the Black

Beast and went back to the marina.

We dropped off Johnal

and Cindy, and we drove to New

Iberia for my doctor’s appointment.

Picking Oranges

When we finished the doctor’s

appointment we ran errands before returning to DREAM AWAY. A couple

of the stops on the way back was to find two 1>X 32 X 4 ½” bolts

for the motor on the refrigeration cooling pump. No luck so far.

Johnal

and Cindy came over to DREAM AWAY, and we squeezed a

lot of oranges to make juice.

January 26, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

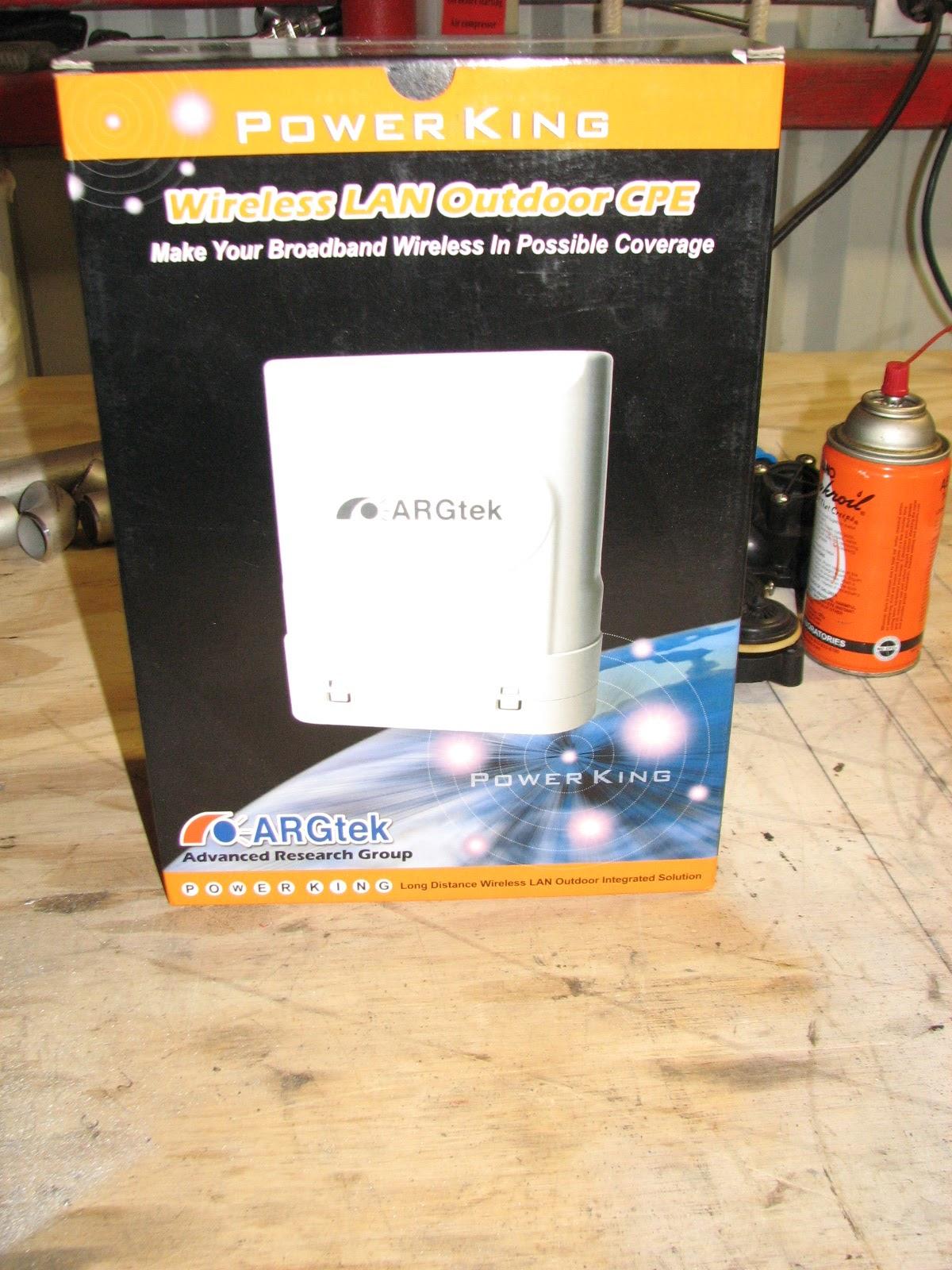

Before going to the shop,

I went over to the electrical panel at the north side of the marina,

and disconnected the unused WiFi router. This router was purchased by

the Port Director, but it did not have a gateway mode, so cannot be

used here at our marina.

I put the router, power and network cables in the Black

Beast, and went over to the shop.

I had the original shipping box for the

unused router at the shop,

so I packed the router and all of the cables into the box. The box is

ready to take to the Port

Office.

On the list now was to try and get a

couple of “left over” projects finished. I had a box of fasteners

and snaps I had removed when I took off the eyebrow to make room for

the hard dodger. I got out the bench grinder with the wire wheel and

cleaned up all of those parts. I will take them back to DREAM AWAY,

and put them away in their storage box.

WiFi Router In Storage Box

I got out two aluminum circles from a

previous project and cleaned them up. I will take them to DREAM AWAY

to see if they can help with a galley faucet problem.

Aluminum Circles To Repair Galley Faucet

Went back over to DREAM AWAY, and had

breakfast. After breakfast I removed the faucet in the galley that is

attached to the fresh water foot pump. I will attempt a temporary

repair on the location of the faucet, because the wood panel it fits

on is rotting away. The wood panel will be completely replaced when

we get to Guatemala.

I verified the size of the bolts I need

to put back together the motor on the refrigeration cooling pump.

They are 10 X 32 X 4 ½”.

Kitty and I measured the distances and

location of the main mast sail handling platform. We have a pretty

good idea now of its location, so I can cut some of the pieces and

see how it will template up.

We also did some talking and measuring

of some changes on the stern. I want to add some storage area, and

also make room for the three outboards motors we will have on board

DREAM AWAY.

Kitty went off to run several errands,

and I stayed on DREAM AWAY and sanded the base for the hard dodger.

After doing the sanding, there are still a couple of places that need

some more putty, but with the weather, I am not sure when I will get

that done.

Hard Dodger Base Before Sanding

Hard Dodger Base After Sanding

January 25, Saturday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the shop first thing as it was way too cold, but it did warm up. As I

was working on the computer projects, the sun was warming up the

boat. As it got warmer, the ice on the mast and all of the standing

rigging started falling on the deck.

Jillian and Jordan

were not impressed, they were very

frightened with all of the noise.

I went out on deck and shook all of the

ice down that I could see. Now that the ice was not crashing on deck,

Jillian

and Jordan started to settle down.

After breakfast I did go over to the

shop.

First project on the list was to get all of our chili pepper lights

back to together and stored away in the Holiday box. They are now

ready for next Christmas in a warmer climate. The last two days has

convinced us that we will not be spending the winter of 2014-2015 in

Louisiana. And to make sure, we have another freeze coming in two

days.

I then got started on the stand offs I

am fabricating for the main cabin grab ropes. When I was in the shop

this past Thursday, I had got all of the parts required cut and

smoothed off, ready for welding.

The first welding project was to weld

the short pieces of threaded rod to the stainless steel rings that

will hold the grab ropes. This was pretty time consuming, as they

were both small parts and had to be clamped down. I got the pieces

welded together, so now I have six rope rings.

Newly Welded Rope Rings On Bench

I then set up to weld the four pieces

of stainless steel pipe to the pieces I had cut off of the stainless

steel rod. I welded the rod pieces to the pipe.

Four Pieces Of Pipe Welded To Stainless

Steel Rod

When all of the welding was finished, I

secured the welder and started to clean up the threaded rod and ring

parts. I used a die to clean out the threads on each piece. On the

inside of the rings, I used a round file and sandpaper to smooth out

the rough surfaces.

Using A Die To Clean Out Threads

When that was complete, I had to drill

and tap the standoffs that now had a solid piece of rod welded to

them. I first used a center punch to get a guide in the top of the

standoff, then drilled a hole in the center.

Top Of Standoff To Be Drilled

I then used a tap to cut the threads in

the newly drilled hole. When I was cutting the threads in one of the

standoffs, the tap broke!

Now I had to cut off the piece I had

just welded onto the standoff, and also cut a new piece off of the

stainless steel round bar. I got that done, then had to set up the

welder again. I got the new piece of round bar welded to the

standoff. I drilled a hole into the round bar on top of the standoff,

and got the treads cut with no problem.

I put away all of the cables and such

for the welder, and got the welder cleaned up. I then polished and

sanded the four standoffs I had just finished.

Four New Standoffs On Bench

Now I have to cut the holes in the

overhead of the main cabin where the standoffs will be installed.

Once the holes are cut I will know how long each standoff will be.

January 24, Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the shop

at all today. It was too cold and too dangerous. The high for today

in Delcambre

was 31°. I left the boat twice today, once to check on a power

failure, and the second time because I had to reboot the WiFi router.

We had freezing rain off and on most of

the day! The good news is I got caught up on my email, scanning, and

made progress on a lot of computer work.

When I was outside walking around the

piers and dock I took some pictures. The floating docks were very

slippery because the freezing rain had frozen on the docks. When I

got to the concrete dock and the parking lot, the rain had not

frozen.

If there was any doubt in my mind where

we will spend next winter, this freeze cleared it up! We had left our

cockpit cushions out in the cockpit so the rain had frozen on them.

Cockpit Cushions WIth Sheet Of Ice On

Top

Icicles Hanging On DREAM AWAY Hatch

Icicles Hanging On Another Boat In The

Marina

One Of The Gardens At The Marina

January 23, Thursday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the shop

this morning. I had a doctor’s appointment in Lafayette,

so just spent a little extra time on the computer. When we returned

from the doctor’s office, we had lunch, and I went over to the

shop.

First item on the list was to put a

third coat of protective paint on the new propane tank. I then put a

piece of automobile edge trim on the bottom to further protect the

propane tank and to prevent rust.

New Propane Tank With Edge Trim

Installed

Next on the list was to clean up and

start getting back together the refrigeration pump. The housing and

connected parts cleaned up very well. As soon as I can get the two

bolts to hold the pump housing together, we will have a spare cooling

pump again.

Refrigeration Cooling Pump Partially

Together

I did some welding for a cruising

friend who is in the marina

for a couple of months. I cut a couple pieces of 1 ¼” stainless

steel pipe for him to use to fabricate an adapter for his life

rails. I will be doing some welding on those pieces when he gets all

of the pieces together.

I had received the 1 ⅜” stainless

steel round bar, so I cut the six pieces I will need to complete the

main cabin grab rails. I also cut some threaded rod to fabricate some

pieces to use on the main cabin grab rails.

By the time I made all of the cuts, and

cleaned up all of the pieces, it was 1730 I knew I would not be

working in the shop tomorrow because of the predicted freezing rain,

so I will be doing my welding probably on Saturday.

Main Cabin Grab Rail Parts On Bench

Stainless Steel Pipe On Bench

Cutting A Piece Off Of The Stainless

Steel Round Bar

January 22, Wednesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the shop

this morning. I drove to V & V auto parts and picked up the new

fuel filter for the Black

Beast, then drove back to the

marina.

I got all of the goodies in place and changed the fuel filter on the

Black

Beast. I bled the fuel system, then started the

engine. The engine ran perfectly, so I cleaned up the area, and

called that project finished.

I went to DREAM AWAY and had breakfast.

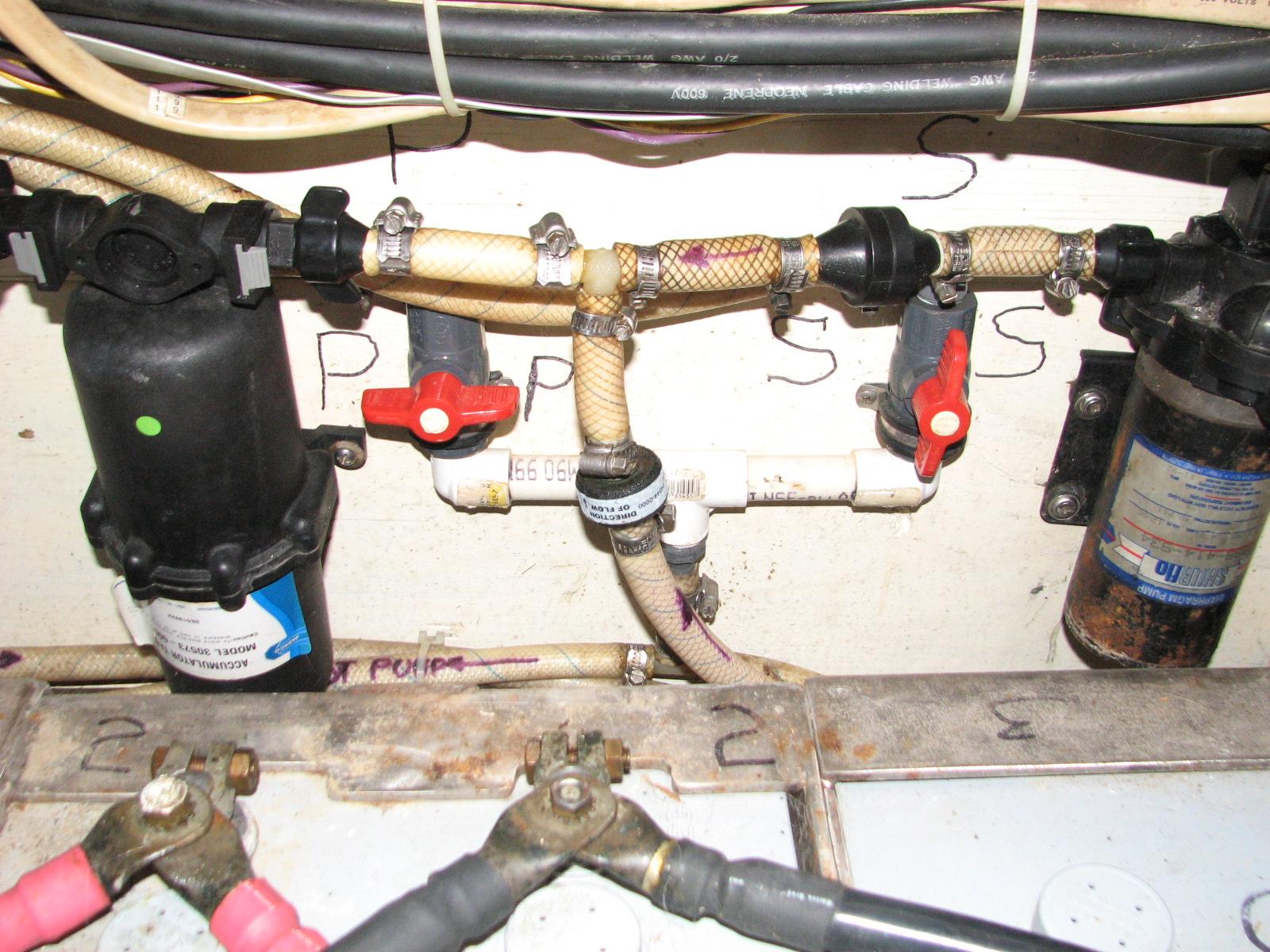

After breakfast, I decided it was time to finally time to replace the

defective check valve in my freshwater system.

I got everything removed from the area,

and shut off the water coming in from the dock. Then it was just a

matter of removing the defective check valve and installing the new

one. When the new one was installed, I verified it worked when I had

the freshwater system activated. I put everything back where it

belonged, and checked off another project completed.

Old Check Valve Installed In Freshwater

System

New Check Valve Installed In Freshwater

System

Kitty and I drove into Lafayette

as I had an appointment with my dermatologist. We did a few errands

on the way home, and got back to DREAM AWAY around 1630

January 21, Tuesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the

shop

this morning. I drove Kitty into

New Iberia for

her colonoscopy. The procedure was a

success, and no problems were encountered.

Had to do some chores around the

marina,

cleanup and garden weeding. The holding tank on the shower

trailer was 3/4’s full, so I drained that into the

sewer system. When I got that all cleaned up and secure, I went over

to the shop.

Did not do very much, but I did put a

second coat of orange spray paint on the new propane tank.

I worked on the motor for the

refrigeration cooling system. Yesterday I took the motor housing

apart, but the two bolts holding the housing together twisted off. I

liberally applied Aero-Kroil

to the broken studs yesterday and let it set.

Today, I smacked the studs with a

hammer, and then using a pair of Vice-Grips, I was able to back out

the broken studs. Now all I have to do is clean up the motor housing,

lubricate the bearings, and find two new bolts, and the pump will be

operational again.

Two Twisted Off Bolts From Cooling

System Pump

I went by V&V auto parts to

exchange the fuel filter I had purchased for the Black

Beast. The filter I had purchased yesterday was the

incorrect filter, so I had to order the proper filter. The new filter

will be in tomorrow morning.

January 20 Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the shop first thing.

Stayed on DREAM AWAY still trying to catch up on email, scanning and

computer work.

Around midday I headed over to the shop

to unload some items. One of the items was my 2 foot long piece of 1

⅜” stainless steel round bar that had arrived for the stand offs

I am fabricating for the main cabin.

While at the

shop,

I was able to get the motor for the spare refrigeration apart. That

was the good news, the bad news is the two bolts twisted off. There

is enough of the broken bolt remaining, I am sure I will be able to

get them removed from the bottom plate of the motor.

I cleaned up the motor as best I could

and the applied a large amount of Aero-Kroil

to the bearing, and to broken bolts in the bottom plate.

Bearing On The Bottom Of The Motor

Bottom Plate Of Motor Showing Broken

Off Bolts

I had purchased a new 30 pound propane

tank last week, to replace my current propane tank that is very rust

on the base. My plan is to paint the bottom third with several coats

of paint, and then put door trim on the base to help prevent rust. My

present tanks have lasted close to 15 years, so the new tank should

last even longer with all of the protection I am adding.

Propane Tank With First Coat Of Paint

I then went back to DREAM AWAY to

install the two new Hella

Turbo fans I had purchased. These were two 12 VDC fans

to replace the 24 VDC fnas I had ordered by mistake.

I installed the first Hella

Turbo fan in the galley, and the second in the aft

cabin on the port side. Now all of the Hella

Turbo fans on DREAM AWAY are operational.

New Fan Installed In The Galley

Fan Removed From Aft Cabin

New Fan Installed In Aft Cabin

January 19, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

After breakfast and some more visiting,

Jimmy and Barbara left to head back home. It was a great visit, and

we initiated the first “Arcadia Rum Distillery Tour”.

We spent the remainder of the day

attempting to catch up on computer related projects, and getting

DREAM AWAY back to normal.

January 18, Saturday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

We were their first “production

tour”, and were hosted by the founders, David and Cole. Their still

is a reflux still, hand

crafted by David and Cole, and named “Lulu”. David

named Lulu after a pot-bellied pig that had been a neighbor’s

family pet when he was young.

David, Cole, And Lulu

The rum they produce,

Sweet Crude white rum,

is made from only sugar cane juice. There is no

molasses in it. The adjustments they make to the juice, and their

fermentation process, are the secrets to their excellent product.

The cane juice they are using is

purchased from a local sugar cane mill, M.A.

Patout & Sons. It is the oldest sugar company in

the United States still owned and operated by the original family.

The mill opened in 1825.

Sweet

Crude rum is not aged. It goes from the still to the

proofing containers, where ionized water is added to bring the proof

down from 170 proof to 80 proof. We tasted the

Sweet Crude, and found

it to be an excellent sipping rum. I

was pleasantly surprised that I enjoyed sipping this white rum.

Cole & David In Front Of Bottled

Sweet

Crude Holding Award.

They are planning on introducing two

aged rums in the future. One will be called Black

Gold Single Harvest, and the other will be called

Black

Gold using the Solera

process.

The Single Harvest product will be a

single batch of three to four barrels of aged rum blended together to

create a special flavor. Once this product is gone it will never be

repeated.

The Solera

process will be repeatable and will be an ongoing

product, and will be their signature aged rum. We are all looking

forward to both products.

We drove back to DREAM AWAY, and had a

bit of a rum tasting before dinner. The first drink was the 13

Pennies Praline Rum from the Donner-Peltier

Distillery and the Swamp Pop Cream

Praline Soda mixed together. The drink tasted just

like eating a pecan praline, it was very sweet, and would make a

great dessert cocktail, or over ice cream.

We then had dinner and watched a movie.

January 17, Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

We arrived at the distillery at about

1530 and met Austin who would be our tour guide, and Tess, who

explained a bit of the distillery’s history. Tess told us the

legend of the Rougaroux.

Like most legends, there are many variations.

Austin and Tess also described the

products distilled by Donner-Peltier

Distillers. As we were waiting for others to join the

tour, we decided to do the tastings before the distillery tour. The

first product offered by Donner-Peltier

distillers was a vodka

under the brand name of Oryza, which is the Latin word for rice. They

distill the vodka from fermented rice. Using the same base alcohol as

the vodka, they also produced a gin

with the same brand name, Oryza.

Austin In The Tasting Room

Tess In The Tasting Room

The vodka

had a nice flavor to it. I am not a gin person, so their gin

did nothing for me. It did taste very good when it was mixed with

tonic.

Next, we tasted all three of their

rums, all under the brand name of Rougaroux.

The first rum is

Sugarshine,

which is their white rum. The second rum is

Full Moon Dark Rum,

which is aged and flavored using oak chips. The third rum is

13

Pennies Praline Rumwhich is aged and flavored with spices and pecans.

The other folks did not show up, so we went on the tour, guided by

Austin. He explained how they use raw sugar and blackstrap molasses,

purchased from Lafourche Sugars which is also located in

Thibodaux,

as the basis of their rums. They use separate fermenting tanks for

the vodka and rums. Their still, “Big Betty”, is very

sophisticated, as it is a pot still and a reflux still combined. It

is also automatically cleaned after a run.

Big Betty The Pot Still

Big Betty The Reflux Still

We got to see Austin add the distilling

yeast to a fermenting tank that had settled out and was ready to

continue the fermenting process.

Austin Adding The Yeast

January 16, Thursday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go to the

shop

today, but spent most of the morning catching up on computer work,

emails, and scanning. Around 1130 we left

Delcambre

and headed west down LA14 to

Lacassine,

LA.

Jim In Front Of Louisiana Spirits

Distillery

Kitty In Front Of Louisiana Spirits

Distillery

The Louisiana

Spirits Distillery is the first stop on our Great

Acadiana Rum Distillery Tour! They showed a very interesting film

before the tour, and the tour itself was very informative. The

spirits they are presently producing are distilled from a raw sugar

and blackstrap molasses combination, both purchased from a local

sugar cane mill, M.A.

Patout & Sons. It is the oldest sugar company in

the United States still owned and operated by the original family.

The company opened in 1825.

The distillery is definitely planning

to be a very large operation. They would allow no pictures to be

taken during the tour, so I do not have any to add to the log.

We went to the tasting room after the

tour and had samples of their Silver

Bayou white rum and the Spiced

Bayou dark rum. Neither rum is aged. The white rum had

a nice, unique flavor that comes from the distilling process. I

purchased a bottle of the Silver

Bayou white rum to have for a future rum tasting at

home.

January 15, Wednesday,

2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go to the shop

today, but spent all morning catching up on computer work and

scanning. We then drove into New

Iberia to run several errands, and I had a doctor

appointment. We returned to Delcambre

around 1700.

January 12 - January 14,

2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

When Kitty got up, we finished our

packing and loaded the Black

Beast to drive from

Delcambre

to New Orleans. We got to our

hotel, The Sleep Inn in Metarie, dropped off our stuff, and then rode the famous

street cars.

We rode the Canal Street

street car

from the cemeteries to

Cafe Du Mode at the

French Market. Kitty had never been to the

Cafe Du Mode for coffee and beignets, so

we experienced that! We finished off the day by riding the famous St. Charles

street car

through the Garden District.

On Monday, we spent the entire day at

the National World

War II Museum complex. What a place, and all very well

done. We did not see it all, and we will go back to finish off the

total experience.

January 11, Saturday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

While on the computer, the bilge alarm

went off. Sure enough, there was a lot of water in the bilge, but the

automatic switch for the pump did not work. I used the manual switch

and pumped down the bilge. When Kitty awakens, this will take some

investigation.

I went over to the shop

and worked on the Black

Beast. I wanted to do a thorough check of the Black

Beast before our trip to

New Orleans. I aired up all

of the tires and put a new application of Rain-x

on the windows. When I opened the hood to check all of the fluids, I

noticed the oil fill cap was missing! The cap had been loose, so I

guess it popped off.

I checked, and topped off all of the

fluids. When I topped off the oil, I nearly finished the gallon

bottle I carry in the Black

Beast, so I will have to get another bottle for the

trip. I also realized I did not have a bottle of coolant in the Black

Beast either. I do carry a gallon bottle of water in

the Black

Beast, but I will also purchase a bottle of coolant

for the trip to

New Orleans.

Before leaving the shop,

I took the pump housing off the spare refrigeration cooling pump.

Sure enough the bearings sounded pretty bad. I attempted to take the

motor housing apart, but the bolts would not budge. I got out my can

of Aero-Kroil

and soaked down the bolts and the bearings in the motor housing, and

the bearings in the pump housing.

I left the shop

and went to V&V

Auto Supply in

Delcambre

where I purchased a new oil filler cap, and a quart of transmission

fluid. I then went to LeBlanc Oil and purchased a gallon of oil and a

gallon of coolant. Now the Black

Beast was ready to roll.

I went back to DREAM AWAY, and Kitty

was up, so I was able to work on the bilge alarm problem. During the

winter months, the bilge collects a lot of water due to condensation.

Kitty reminded me that yesterday I had dumped a lot of water in the

bilge working on the refrigeration cooling pump and the freshwater

system check valve. So that was probably the source of all of the

water in the bilge.

Just in case, I did a check of all of

the connections I worked on yesterday, and sure enough, there was

water leaking around the check valve. I tightened the hose clamps and

stopped the source of the water in the bilge. Now I had to find out

why the small bilge pump was not cycling. You can check out my bilge

pump arrangement on the web page.

Looking at the float

switch for the pump, it did not look as if it was

operating properly. When I manually lifted the float

switch, the pump worked just fine. I determined that

the float

switch was hitting the side of the bilge, so I

adjusted the placement of the bilge

pump, and this moved the float switch away from the

side of the bilge.

It was then I noticed the float

switch was not attached to the bilge

pump as it was supposed to be! Now the fun begins. To

had to get the bilge

pump disconnected from the system that is supposed to

hold it at the bottom of the bilge. With the engine in the engine

room, I cannot reach the bottom of the bilge, which is directly under

the bottom of the main engine.

I disconnected the bilge

pump from my hold-down system, then pulled the bilge

pump up high enough that I could unscrew the hose

clamp holding the hose to the bilge

pump. I then pulled the hose off of the bilge

pump, and got the bilge

pump up on the garage deck where I could work on it.

This was all done at extreme arms length, and I could not keep my

eyes on the operation while performing it.

By the time I had accomplished this

task, it was time to take care of our planned social engagement for

the day. I got cleaned up and dressed, and we met Johnal

and Cindy, off of the sailing yacht RUTHIE, in the

marina

parking lot.

We then drove to the Rank

Wildcat Spirits distillery in Lafayette. When we

arrived Dave and Cole, the founders, were there to greet us and give

us the “tour”. It is a small operation, but their hand-crafted

product “Sweet

Crude” white rum is excellent. We thoroughly enjoyed

the tour, visiting with the founders, and viewing the two awards they

have already received, not to mention the rum tasting.

Lulu, The Reflux Still

Dave & Cole With The Two Awards

Already Won

Dave & Cole In Front of Lulu

When we got back to DREAM AWAY, the

first thing I did was empty the holding tank on the shower

trailer. I had to make sure it was emptied before I

went to

New Orleans for three days.

When I completed that task, I then

cooked up a bunch of food for our kitties. I cooked some chicken,

turkey, and chicken livers. Then I chopped it all up with some cooked

carrots and spinach. I put the mix into containers, and put those in

the freezer to be taken out to feed the kitties on a daily basis.

Last item for the night was to fix the

bilge pump and get it back into the bilge. I needed a small piece of

metal, so I had to go over to the shop

to get it. I also picked up our suitcase. I came back to the boat

where I fabricated a metal fitting I could bolt to the bilge pump,

and to which I could then bolt the float

switch. I put it all back together, and installed the

bilge pump back into the bilge using my attachment system so I was

able to get the pump back at the bottom of the bilge. The bilge pump

went back in much more quickly than it came out.

I tested the pump and the float

switch, and they worked as expected. Now I feel pretty

sure DREAM AWAY will not sink while we are in

New Orleans.

January 10 Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the shop

and worked on cleaning up the workbench and drill press. I had left

it in a mess from the cutting circle project of yesterday. That

project is on hold until the piece of stainless steel rod comes in.

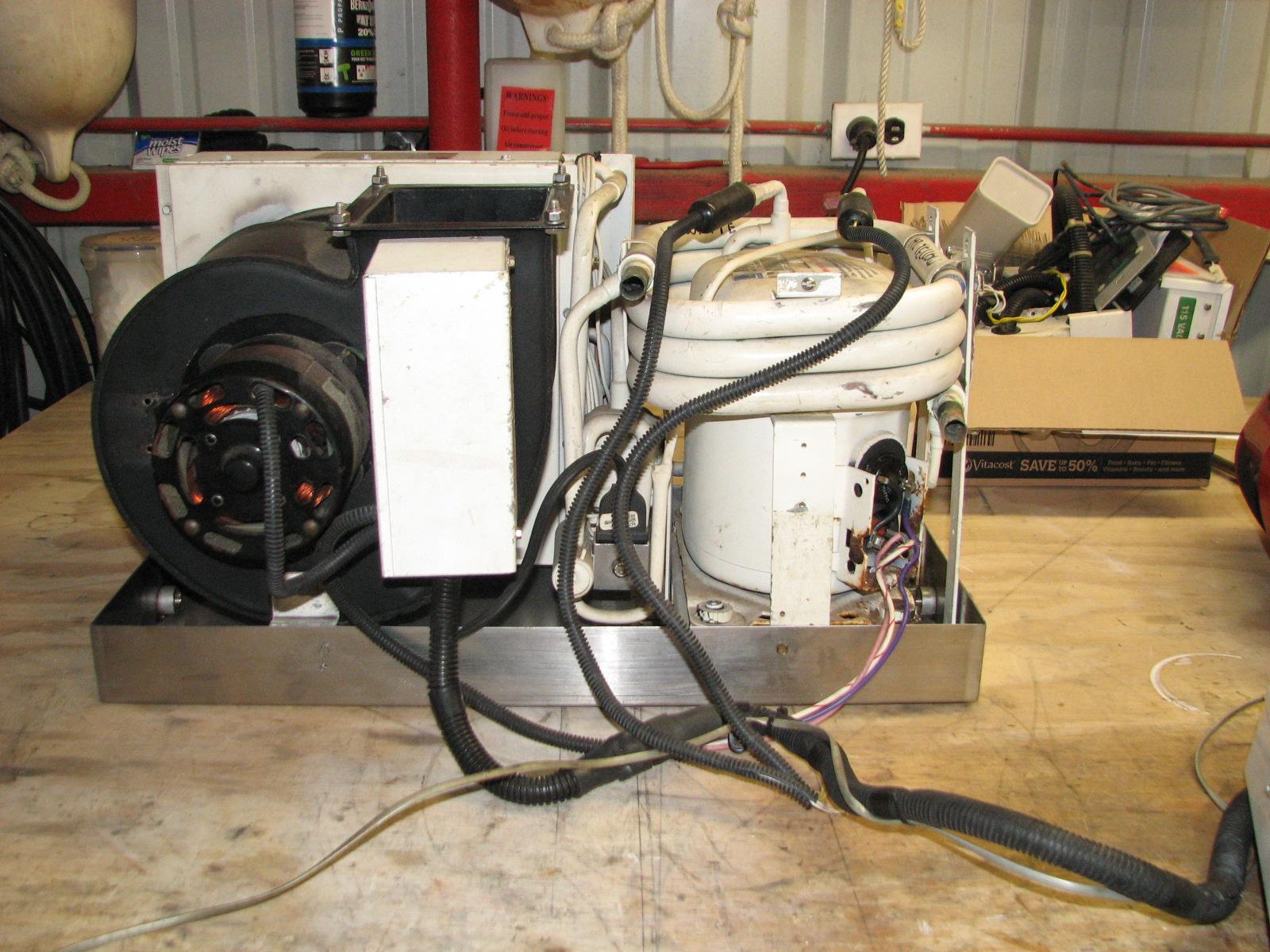

I then got into finishing off the tray

for the spare air conditioner. I had put it all together a couple of

months ago, but never finished. The problem was the length of the

bolt needed to hold the compressor onto the tray. The new spare air

conditioner needed longer bolts. I had looked for sex bolts and

barrel nuts, but could not find the correct sizes.

I had come up with a plan to cut off

the ends of four 5/16” stainless steel bolts, and weld them to the

ends of the existing bolts in the air conditioner tray. Today I was

putting the plan into action.

The first part of the plan is to remove

the air conditioner compressor, condenser, and evaporator from the

tray. This was fairly time consuming as some of the nuts were not

easy to reach. By the time I got the A/C system removed from the

tray, Kitty had called, so I went back to DREAM AWAY for breakfast.

A/C Unit On Tray Before Removal

After breakfast, went back over to the

shop.

The weather was getting nice and warm, so I decided to apply the

second coat of gelcoat

on the hard dodger uprights. I got out the tack

rag and wiped down all of the uprights and anchor

support pieces.

I got out all of the necessary

accoutrements to mix and apply the gelcoat.

I did not make the mixture too hot, so I hope it kicks off in good

time. We will see tomorrow morning.

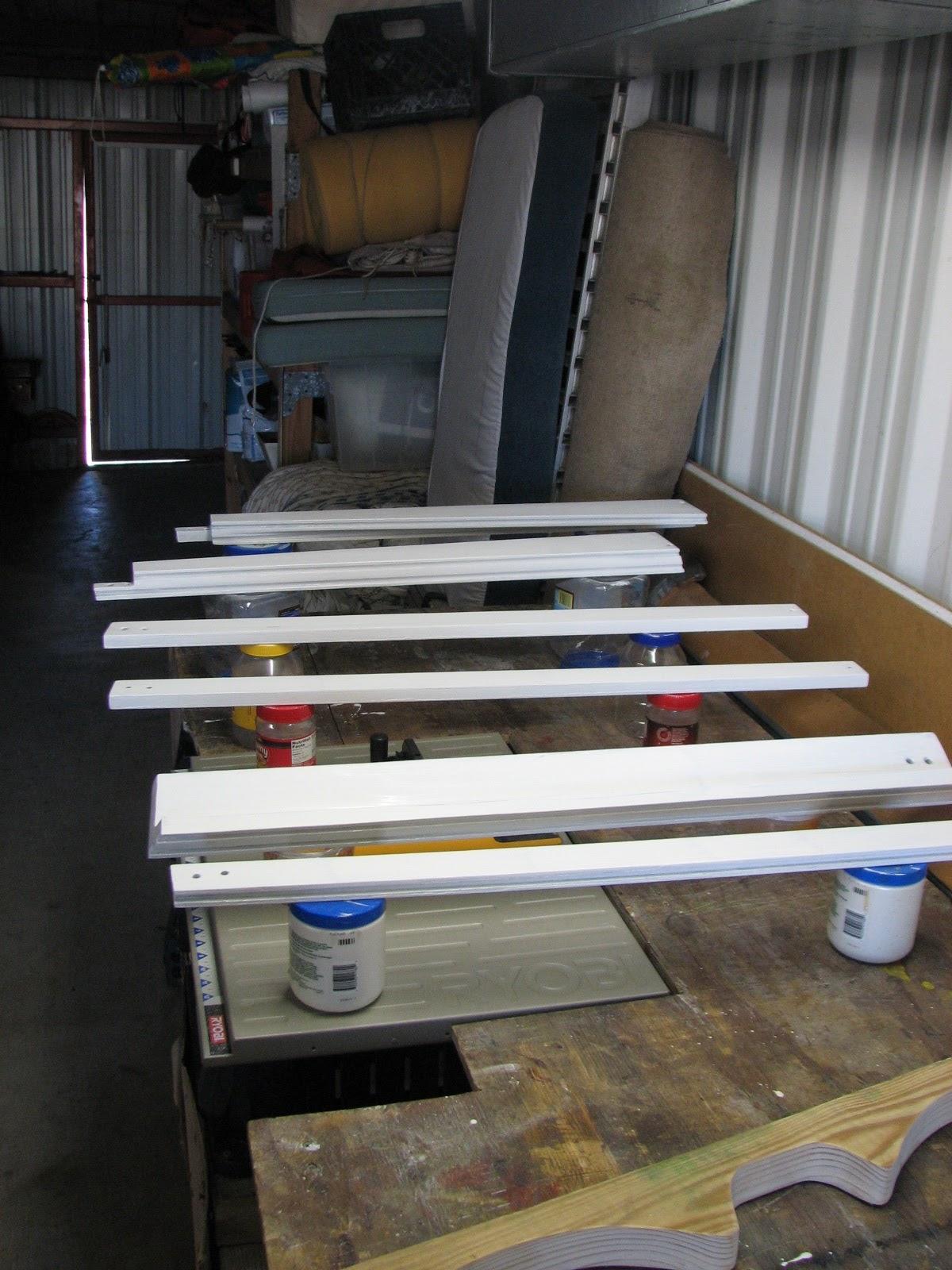

Gelcoat

Applied To The Hard Dodger Uprights

Gelcoat

Applied To The Hard Dodger Uprights

Gelcoat

Applied To The Anchor Support Pieces

After cleanup and putting all of the

accoutrements away, it was back to the A/C tray.

I got the bolt ends cut off, and

smoothed out. I then used a C-clamp

to hold the cut-off end onto the end of the bolt that was welded to

the tray.

Bolts Clamped Together

I then welded the two bolts together.

The weld on such thin metal tended to pull to one side or the other

depending on where I welded last. As soon the weld was finished, I

used pliers to bend the bolts straight. I did this for all four of

the compressor bolts in the tray.

Four Bolt Extensions Welded On

When I got the tray cleaned up, I put

the A/C system back into the tray and got everything bolted down. The

spare A/C system is ready to go to Atlanta to be stored until it is

needed. I may build a pallet on which to put the unit to make

shipping easier.

A/C System Back Into Tray

Close Up Of Nuts Holding Down A/C Compressor

I then left the shop

and walked back to DREAM AWAY. I had purchased a check valve from

Touchard

Marine to replace the one that was failing in my

freshwater system, so I wanted to install it and check it out.

When I got the new valve installed, I

discovered it leaked as badly as the one I was replacing, so I put

the old one back in place. I will have to find a Perko

or ShurFlo

check valve.

As mentioned previously, the cooling

water pump for the refrigeration system was leaking while it was

running. I had cleaned, sanded, and painted the spare pump on

Wednesday, so it was ready to go.

I swapped in the spare pump, and it did

not sound good! It sounded as if the bearings were shot, and in fact,

it quit working in a couple of minutes! I took apart the pump that I

had just removed, and cleaned up all of the its insides. It gets very

nasty due to the stuff that is in the water around here.

I then put the newly cleaned pump back

into the refrigeration cooling system, and it ran with no leaks! I

will have to take my spare pump over to the shop

and determine the problem. That will have to wait until tomorrow.

January 09, Thursday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the shop

immediately after breakfast. Last night, after the Marine

Corps League meeting in Abbeville,

I went to Lowe’s and purchased a new drill bit for the hole saw

arbor.

I chucked up the Milwaukee

hole saw into the drill press and started drilling out

the circles I needed for the main cabin grab rail project. It soon

became obvious that I had worn out the Milwaukee

hole saw. It is a good saw but could not stand up to

the punishment I was giving it.

It was obvious I was going to have to

find another method. I had looked for some stainless steel rod from

suppliers, but none sold drops. The shortest piece of 1 ⅜”

stainless steel rod I could find was 22 feet.

Cutting Circles Using Hole Saw And Drill Press

Two Cut Circles Using Hole Saw

Material Being Used For the Main Cabin

Standoffs/Grab Rope

I had used so much time cutting the

circles with the hole saw it was time to go back to DREAM AWAY.

Before leaving, I sanded down all of the hard dodger uprights in the

shop.

This is in preparation to be able to apply the second coat of gelcoat

on the uprights.

Sanded Uprights Ready For Gelcoat

After lunch we went to the

Shadows On The Teche house.

Kitty and I watched the video

about the house with

Johnal and Cindy, and then they took the tour while Kitty and

I read our books. When the tour was completed, we headed back to

Delcambre,

stopping for groceries on the way.

When we got back to DREAM AWAY, I got

on the internet and found a supplier where I could purchase just two

feet of the 1 ⅜” stainless steel rod. I placed an order for the

piece, and hopefully it will be in sometime next week.

January 08, Wednesday,

2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go to the shop

first thing this morning. The cold weather was still here, and it did

not get above 32° until 0900. After that it warmed up very nicely.

After Kitty got up and we had

breakfast, I went outside to turn the water back on to Pier “A”,

which is our pier. The temperature was now in the 40's so it was no

problem. I connected the marina

water to the shower

trailer so the residents could use the facilities. I

also turned the water on for Pier “B”.

I went back to DREAM AWAY to check on

our water situation. Yesterday, when I filled our water tank, I did

not disconnect the hose and drain the water. Bad move! The filter I

use to filter water before it comes aboard DREAM AWAY was filled with

water, and it froze and the housing broke! With the water on, I was

able to get the ice out of the hose and get it connected back to

DREAM AWAY. I will now have to get a new filter housing.

I disconnected all of the Christmas

lights we had on DREAM AWAY and moved them up to the Black

Beast.

I finally made my way over to the shop.

Kitty dropped me off with my tools, and I got right to work. The

first thing was to get our chili pepper Christmas lights dried out

and ready to put away. The red plastic chili pepper coverings for the

lights get water in them when it rains. So I had to remove the chili

pepper coverings from the lights, let everything dry out, then put

the coverings back on the lights, and put them away for next year.

Working On Chili Pepper Lights

I had brought over a screen from one of

the hatches in the main cabin. It was coming apart and needed repair.

The rubber insert that holds the screen material in the frame was

coming out.

Screen Before Repair

Screen After Repair

The other day when I was working on the

DREAM AWAY fresh water system, I noticed the refrigeration cooling

pump was leaking. The pump housing needs to be cleaned out. I got out

my spare cooling pump to swap it into place. Because of the

additional problems with working on the fresh water system, I was not

able to swap in the cooling pump.

The cooling pump had a very rusty motor

casing, so I decided to clean up the motor and paint it before I

swapped the pump back into the system.

I had the pump in the shop,

and I cleaned off all of the rust, and then wiped down the motor

casing with acetone.

I then applied two coats of clear spray paint to the motor casing

after masking off the pump housing.

Pump Masked Off Ready For Paint Application

Pump After Paint Application

Next I chucked up the new Milwaukee

hole saw into the drill press, and started cutting out

the circles out of the ¼” stainless steel plate. It was wonderful,

the Milwaukee

hole saw does a great job. I had cut out two circles,

when the center drill bit in the hole saw arbor broke! I was not

happy.

Kitty drove up just then so I cleaned

up the area, and went back to DREAM AWAY. We got ready to go to the

Marine

Corps League meeting in

Abbeville.

January 07, Tuesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go to the shop

this morning. I stayed on DREAM AWAY working on the computer. It was

way too cold, 22° in the morning to go outside and work, or go to

the shop where there is no heat.

I spent most of the day on the computer

catching on email, research, scanning, and just general catch up on

business matters.

Later in the afternoon, I went to

LeBlanc Oil to pick up a package and to purchase a new propane tank.

Got the package, but he had sold out of the propane tanks. Hopefully,

will get a new one tomorrow. The package was Kitty’s charging cable

for the new iPhone

5 she received for Christmas from Stacy and Tina.

Went back to DREAM AWAY and worked on

the fresh water pump on the onboard system. Since the water on the

dock is shutdown due to the hard freeze, we are using the water from

the tanks on board DREAM AWAY. No big problem, the system works

great, its just that the freshwater pump keeps cycling.

I assumed the problem was the pressure

switch on the pump. I changed out the pump, for which I have two

spares, but the problem persisted! I cleaned up the pressure switch

on the pump I took out, and put it back into the system, but the

problem persisted.

Next, I inspected the check valve in

the system. In my present configuration, I can connect the dock water

to a fitting on the bow of the boat, and it supplies the fresh water

to the onboard system. This way I do not have to continuously fill

the onboard water tanks. When I use the onboard fresh water system, I

have a check valve in the input dock water line, so the onboard pump

does not pump the water out of the fitting onto the bow of the boat.

As it turned, out this valve is leaking, causing the onboard fresh

water pump to continuously cycle.

By this time it was 1655. When I called

Touchard

Marine, I found they closed at 1700, so there was no

time to get there and purchase a new valve today. The good news is

they have a valve, and they open at 0700 in the morning. So I cleaned

up the area, and put all of the tools away for the night.

January 06, Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go to the shop

this morning. I stayed on DREAM AWAY working on the computer. It was

way too cold, 28° to go outside and work, or go to the shop which

has no heat.

Had to go into New

Iberia to have a procedure done on my toe. On the way

to the doctor, I stopped off at a hardware store and purchased a

Milwaukee

hole saw. Plan on using it to cut the circles I need

out of ¼” stainless steel plate.

Came back to DREAM AWAY, and relaxed.

Drained water from system in shower

trailer because a hard freeze is predicted for

tonight.

Watched national championship football

game on TV.

January 05, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go to the shop

this morning. I stayed on DREAM AWAY working on the computer, again

trying to get caught up on email and doing a lot of research. Some of

the research is for upcoming social events, but also for DREAM AWAY

projects.

After the lunch and the tour, we ran a

couple of errands, and drove around Abbeville

and Erath

a bit, then we headed back to the marina.

We did what is necessary to prepare for

the hard freeze that is coming to the area. I emptied the holding

tank on the shower

trailer, filled up the on-board water tank in the

shower

trailer, and disconnected the hose for city water to

the shower

trailer.

We topped off the water tanks on DREAM

AWAY, and then I shut off the water to the docks in the marina.

Hopefully, that is all that will be necessary.

January 04, Saturday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

I went to the shop

first thing and I brought along one bottle of propane, and all of the

drills, taps, and dies I will be needing for the fabrication process

of the pieces of pipe.

I set up my Oxy-Propane

torch with the cutting tip to see if I could cut away

the excess metal of the plate from the bottom of the pipe. The

Oxy-Propane

torch did cut away some of the stainless steel plate,

but the propane does not get as hot as acetylene so it did not do a

great job. This is not a solution! It left such a ragged edge, I

still had to use the grinder a lot to get a smooth circle.

I have to cut 12 of these circles, so I

have to come up with a better solution. I will do some research on

hole saws.

I finally got one piece of pipe with

the end piece smoothed out, and drilled a hole in the plate at the

end of the pipe.

Pipe With End Plate And Hole Drilled

I then tapped out the hole and screwed

in one of the fabricated rings. I now had one of the six pieces of

pipe needed all of 50% fabricated.

Pipe With Fabricated Ring Screwed In

I then set up to weld another small

piece of plate onto the end of a piece of pipe.

Welding Pipe Set Up

I welded the end onto the piece of

pipe, and eventually smoothed down the edges. I drilled and tapped

the hole in the end of the pipe and fabricated another ring. When I

had finished, I decided to do all of this fabrication in a different

way.

Instead of doing one end of a pipe at a

time, I decided to do all of one thing to completion, so I am not

doing so many set ups! I then cut all of the rings for the pipe ends

using the chop

saw. I then cut the remaining 6 pieces of stainless

steel threaded rod so I could fabricate the six rings for the pipe.

This day was over, so I cleaned up the

shop,

put all of the tools back where they need to be, and headed back to

DREAM AWAY.

January 03, Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go to the shop first thing in

the morning due to the cold! It was 3> when I woke up at 0530! I

worked on the computer and did the December Maintenance Log. I also

did some catching up on emails and scanning in documents and greeting

cards.

When it warmed up a bit, I went out to

take some pictures of the broken hinge on one of the gates at the

marina

that is used to gain access to our dumpster and Port-O-Potty.

Kitty got up, we had breakfast, and we

headed over to the Port

of Delcambre office, and finished the clean up. The

Port

of Delcambre had purchased some new shelves, so we put

them together. We moved some furniture around the office, and loaded

the shelves with stuff that had been on the floor or the work tables.

There was more trash and one folding

table we loaded into the Black

Beast.

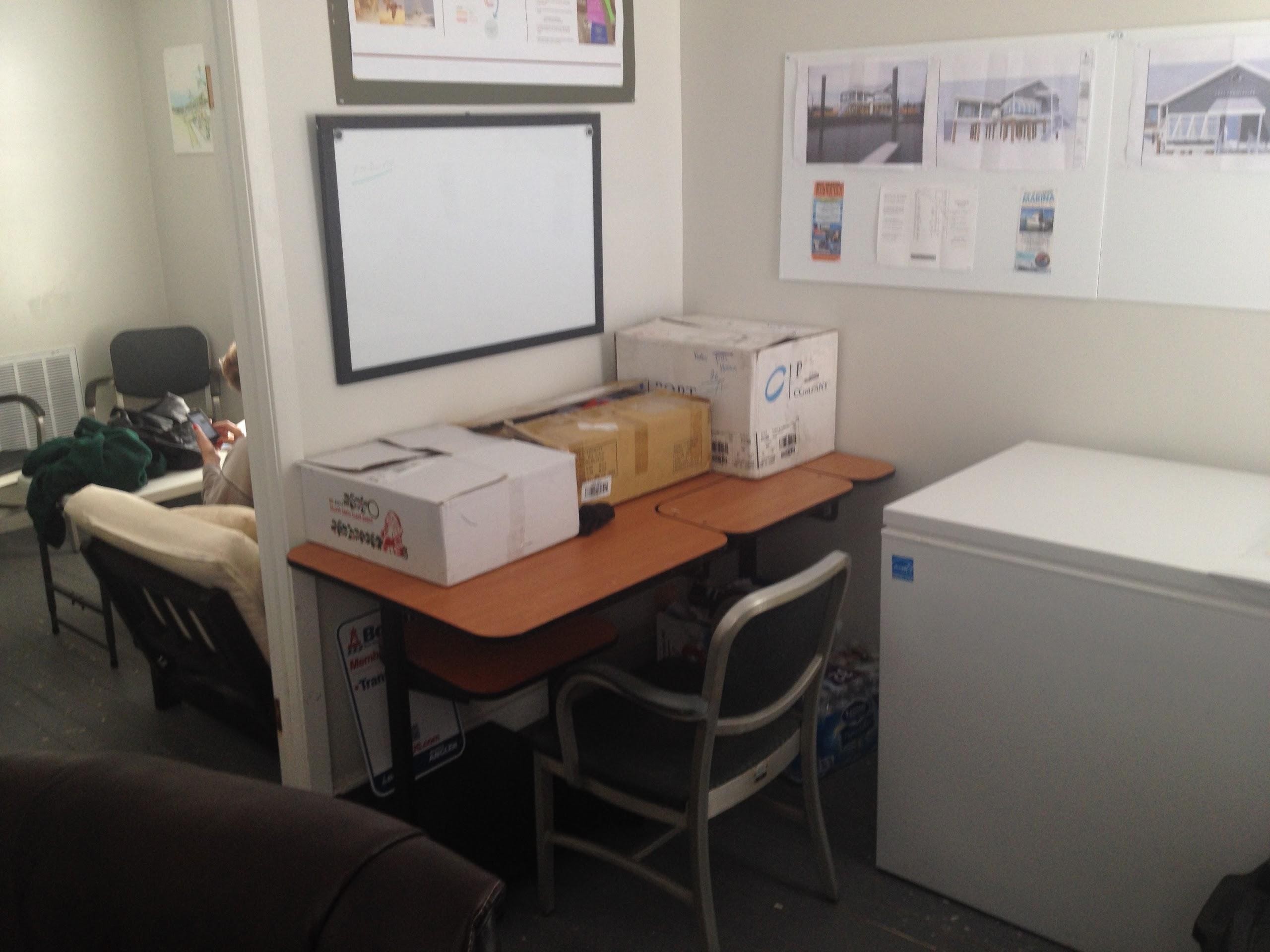

Newly Erected Shelving In Front Office

Other Side Of Front Office

Newly Arranged Back Office

Newly Arranged Back Office

I checked the status of the gelcoat

I had applied yesterday, and it had not completely set up.

I then started working on the mounts I

am building for the hand-holds in the main cabin. We will use these

when we are underway. We had changed our minds about the way we were

going to fabricate these hand-holds.

Initially, we were planning to put up

permanent handholds constructed of stainless steel pipe, and anchored

to the overhead in the main cabin. Since we are actually underway a

very small percentage of the time, we decided to make the hand holds

removeable, so when not under way, they could be stored aboard.

Our new idea is to use a small piece of

stainless steel pipe, about 4” long, with a piece of ¼” plate

welded on each end it. The end pieces will be drilled and tapped. One

end of the pipe will screw into a permanently mounted ½” bolt in

the main cabin overhead. The opposite end of the pipe will have a

fitting to be screwed into the pipe that has a ring on it to

accommodate a piece of large diameter hand-hold line.

This system will be mounted during

passages. Another advantage of the rope system is that the taller

crew members will not have a piece of pipe to bang their heads into,

and the rope can hang down enough for the vertically challenged crew

members to grab.

Now onto the fabrication of the pieces

of pipe. As it turns out, the most difficult part of the fabrication

process is cutting the round pieces to weld onto the end of the pipe.

I initially started out using a

stainless steel blade in my Bosch

jig saw, but the blade was too wide to make the round

cut I needed, so I dispensed with this approach.

Next, I tried a hole saw in the drill

press, and it did cut, but it seemed to be slow, and I was afraid the

hole saw would not hold up.

Setup With Hole Saw On Drill Press

I decided to use the smallest piece of

¼” plate I had, and weld it onto the piece of pipe to see if I

could use the grinder to remove the excess metal.

Setting Up To Weld Pipe To Plate

I decided to work on getting at least

one piece of pipe completed at one end. I cut off a piece of the

stainless steel pipe to be the ring, and I had some left over ⅜”

stainless steel threaded rod that I welded together.

Rod And Ring Ready For Welding

Rod And Ring Welded Together

As it turns out I did not have the taps

with me at the shop,

so I could not complete one of the pipes.

I decided to cut out the six round

pieces of fiberglass

plate that will be needed on the outside of the main cabin to secure

the ½” bolts. My plan is to glass the round pieces to the outside

deck, then drill through the fiberglass

plate and the main cabin overhead through which the bolt can

penetrate. I will then glass the plate onto the deck, and cover the

bolt over with fiberglass,

so there is no chance of leaking.

When it is all finished, it will look

good both inside the main cabin and outside on deck. It will also add

a degree of safety during an offshore passage.

January 03, Thursday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the

shop

and spent some time working on the Sony video camera. None of the

three batteries would take a charge, but the AC adapter plugged into

the camera, and I could load and unload the video tape.

I then broke out my new Stanley

TwinTec ratcheting wrench. I will be using this tool

as much as possible in the coming months to see how it holds up, and

how useful it really is. Time will tell.

The weather was much warmer than I had

expected it would be, so I decided I could apply the first coat of

gelcoat

on the second side of the fiberglass uprights for the hard dodger.

First thing was to sand down the second side of all the uprights,

then wipe them all down with the tack

rag.

Uprights Ready For Gelcoat

Application

Uprights Ready For Gelcoat

Application

Storm Anchor Parts Ready For Gelcoat Application

I then put together all of the items

needed for the preparation and application of the

gelcoat.

I mixed up a small batch of gelcoat

and applied it to the

fiberglass

hard dodger uprights and the storm anchor parts.

First Coat Of Gelcoat

Applied To Hard Dodger Uprights Second Side

First Coat Of Gelcoat

Applied To The Hard Dodger Uprights

First Coat Of Gelcoat

Applied To Storm Anchor Parts Second Side

When that was completed, I went back to

DREAM AWAY and had breakfast. After breakfast, Kitty and I went to

the Port

of Delcambre office, and did some clean up. We

straightened up the office in preparation for some shelf

installation. We also collected and threw away a lot of materials

that were out of date. We then packed up all of the stuff having to

do with the Delcambre

Seafood And Farmers Market, and moved it over to the

Port

of Delcambre storage facility.

When all of the cleaning up, moving,

and trash emptying was completed, the day was pretty much over.

We did pick up two packages that were

delivered, that were late Christmas presents. One present was to

ourselves and it is the

Woll

Nowo 9.5” X 9.5” square frying pan. This pan is

perfect for our small stove in the galley. It gives us more cooking

space in the frying pan than a round frying pan. A very nice feature

of this frying pan is that the handle is removable so the pan can

also be used in the oven as a baking dish. We are really looking

forward to using the frying pan.

The second gift was a box of Candy

Basket salted caramels that I had ordered to give to Kitty for

Christmas.

January 01, Wednesday,

2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

It was a pretty lazy day as it was cold

and rainy all day. I caught up on some more on email, and started the

process of getting the December Maintenance Log up on the web page.

We also watched some football, and did some reading.

Of course being good Southerners, our

first meal of the day included black-eyed peas.

In the evening, we went out to a

birthday party at a friend’s house here in

Delcambre. It was a very

nice party and we enjoyed the food. We increased our chances for more

good luck by having boiled cabbage and black-eyed peas while there.

We came back home to DREAM AWAY, and I

worked on the Maintenance Log while Kitty showered. Then got into our

bed, nicely warmed with the electric mattress pad, and went to sleep.