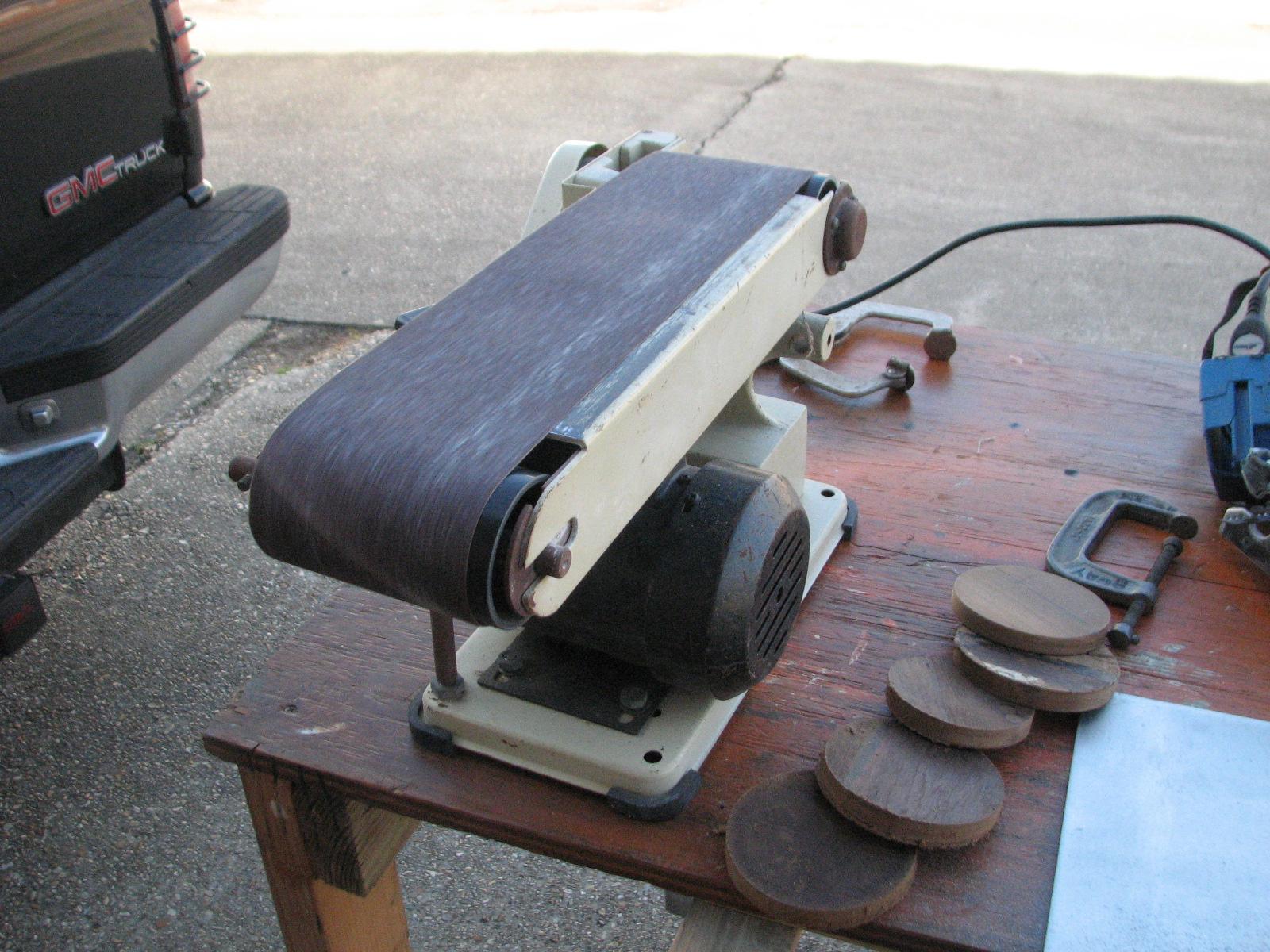

Cutting Circles Out Of Teak

Wood Piece

Yesterday while at LeBlanc Oil, I had

picked up a package for our friends

Nicola & Noel

who are coming to visit from England. I

opened the package to check for physical damage, and took photos to

send to them. We will check out the electronics once they get here.

At that time

Johnal

called. RUTHIE was out of the water and he was able to look at the

damaged rudder. The good news is the rudder can be repaired while in

the boat. The bad news is there is a big chunk out of the rudder that

needs to be repaired. He asked if I could help, and I agreed.

I drove over to

GEO shipyard, and parked next to

Johnal & Cindy'sboat, RUTHIE.

Johnal

had already cut the bad place out of the rudder. It looked like an

alligator had taken a bite out of the rudder.

Rudder With Bad Spot Cut Out

We cut out a piece of the

Extren

sheet fiberglass that matched the cutout in the

rudder. We left the remainder of the sheet attached to use as a

handle, and it would be cut off later.

We then mixed up a batch of the

Dyna-Hair

filler, and put some of it on the rudder. We then shoved in the cut

piece of Extren

sheet fiberglass mushing it into the Dyna-Hair

filler. Before the filler had a chance to kick off, we applied more

of the filler to each side of the sheet in the rudder. We also made

the filler as smooth as possible.

Kitty and I got to the meeting around

1245. We had a great meeting, and we are all very enthusiastic about

setting up a youth boating and safety program. We ended the meeting

with an early dinner at Shuck’s

in Abbeville.

After dinner we came back to DREAM

AWAY. Kitty worked on the boating course. I changed clothes and I

went over to the shop.

I finished wiping down the boom gallows and instrument pod parts with

the tack

rag, and applied the first coat of

Cetol

teak treatment.

I then went back to DREAM AWAY and did

some more catching up on email and the maintenance log.

February 19, Wednesday,

2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Cruising yacht RUTHIE, left the dock at

0700 sharp. They are going to the GEO

shipyard in the

Port

of Iberia to get hauled out and

to get some work done on their rudder. They should be back by the

weekend.

I went over to the

shop,

and was surprised that the

Smith’s Penetrating Epoxy had not

set up. This was rather disappointing. I still have seven coats of

Cetol

teak

treatment to put on the boom gallows and instrument pod parts.

I decided to get out more stuff that I

am planning to auction on eBay

in the near future. I got out an old Sony Cybershot camera that works

very well, but sometimes the off/on switch does not cooperate.

Charging Batteries On The Sony Cybershot

Heater On Instrument Pod Parts

Still Wet Boom Gallows Hanging In The

Shop

Went back to DREAM AWAY and had

breakfast. Yesterday I had purchased a ⅝” stainless steel

shackle

that I wanted to put on the storm anchor in conjunction with the

stainless steel chain gripper. If I ever have to use this anchor, I

do not want the attaching parts failing.

About this time

Cindy and Johnal

called and they had arrived at the GEO

shipyard, but there was not enough water in the

haulout slip to get RUTHIE out of the water at that time.

On the way to the GEO

shipyard we stopped at Harris Castile in

New

Iberia. I dropped off my three injectors and the

injector pump for them to check out, and to explain why one injector

was different from the other two.

We continued on to the GEO

shipyard and picked up Cindy.

She offered to take us to lunch, so we stopped at the Golden Wok in

New

Iberia. While we were eating lunch, the folks at

Harris Castille called and said the parts were ready, and they

checked out OK.

After lunch, we went to Harris Castille

to pick up the parts. I was told the three injectors were good and so

was the injector pump. The issue with one of the injectors was, when

I removed that injector, the spacer also came out with it. The spacers

did not come out with the other two! The issue with the two different

numbers was the casting numbers.

While there I also purchased a

temperature switch for the

generator,

as I had used my spare.

We drove back to North

Pier Marina, and on the way stopped at LeBlanc Oil to

pick up my filled argon

bottle. I am now back into the welding business. Cindy

got her car and went back to GEO

shipyard, and I went to DREAM AWAY to work on the

generator.

I removed the spare injector pump from

the generator,

and installed the pump that was just checked out. I also installed

the injectors and the fuel return lines.

February 18, Tuesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian and Jordan,

and spend time with them brushing their beautiful coats.

Went over to the shop

and finished cutting out the pieces from the

Structoglas.

Sanded down the edges of the cut pieces of

Structoglas

to keep from getting cut. Set cut out pieces of

Structoglas,

and put the remaining pieces of

Structoglas

away. Cleaned up shop, and vacuumed shop to get all of the debris

from the cutting removed.

Next I hung the boom gallows from the

shop

overhead so I would be able to apply the

Smith’s Penetrating Epoxy and the

Cetol

teak

treatment to all four sides at one time. I also did this to the

instrument pod pieces also.

Boom Gallows Hanging From

Shop

Overhead

Instrument Pod Housing Hanging From

Shop

Overhead

I removed the three injectors from the

engine. They all seemed to be in good shape, but one of the injectors

had a shim or spacer that the other two did not, and the part number

stamped on it was different. This could be my problem with the

generator

not starting.

Three Injectors - Different One In The

Middle

Three Injectors - Different One In The

Middle

Kitty had left DREAM AWAY while I was

working on the

generator

to run a couple of errands. One of which was to mail the second box

to our friends in New Zealand. She also stopped by the welding supply

store with our argon

bottle to get it filled with gas.

Now all we have to do is find someone

with a pickup truck to bring the argon

bottle back to the shop. The gas supply companies will not allow a

high pressure tank to be transported in a closed vehicle

When I finished the injector removal

project, I started the second electrical outlet in the galley

project. A couple of days ago when the single outlet in the galley

failed we both realized it would be great to have a second outlet. We

decided to put the second outlet on the other side of the

galley

stove.

Aft Side Of Galley Stove Area

I removed one of the plastic bins from

the bulkhead and moved the second bin up. This second bin is a

storage area for clothes pins and coffee filters. I then installed

the teak

frame for the electrical outlet.

“All” that remains is to run the AC

electrical wire, and drill the holes in the bulkhead for the new wire

run.

New Bulkhead Layout

February 17, Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Took the Black

Beast over to Ray’s

Auto Repair here in Delcambre,

to have the engine oil cooling lines replaced, and the upper ball

joints replaced. Ray brought me back to the North

Pier Marina, and I walked to the shop

from there. I started in on sanding the boom gallows, and the teak

piece I epoxied

together. I finished sanding the boom gallows, but it was obvious I

would have to apply more thickened epoxy

to the teak

piece, and epoxy

to the top of the boom gallows.

Epoxy

Applied To Top Of Boom Gallows

I loaded up a bunch of template

material (cardboard) into the Black

Beast and drove over to DREAM AWAY to have breakfast.

After breakfast, I brought all of the template material down to DREAM

AWAY.

Kitty and I made a template for the

after bulkhead in the head, and the underside of the deck in the main

cabin. I will use these templates to cut out the pieces of

Structoglas.

When the pieces of

Structoglas

are all fitted I will then apply Liquid

Nails to put them in place.

The pieces in the main cabin are sorely

needed to cover up some not so nice looking places.

Took all of the templates just created,

plus one other template I had cut two or three months ago for the

underside of the deck in the head over to the

shop.

Templates Leaning Against Work Bench

I got out a sheet of

Structoglas

panel from my stash of five, and laid it out on the floor. I then

worked with the templates to get the best usage of the sheet, and

have the most left over. When I came to a solution, I marked the

sheet with a black Sharpie

for all of the templates

I said great, come to the

marina

and pick me up. I left the shop

and went over to the marina

to meet Ray. He had called earlier in the day and told me he had

looked at the brakes, and found the problem with them.

He could not adjust the drum brakes on

the rear passenger side, because the adjuster was stuck. When he

pulled the wheel, he discovered the adjuster was stuck, and the brake

was adjusted all the way open. He also found the rear wheel cylinders

leaking.

When he unstuck the adjuster, he was

able to adjust the rear drum brakes perfectly, and he also replaced

the seals in the wheel cylinders. Now I can just barely tap the brake

pedal, and the truck stops. Also the emergency brake really holds the

truck still in both forward and reverse.

So now the front end in the

Black Beast is in good

shape with the replacement of the

upper ball joint on both sides. There is no leaking engine oil,

because the leaking cooling lines have been replaced, and the brakes

are working perfectly. I am a happy camper.

February 16, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian and Jordan,

and spend time with them brushing their beautiful coats.

Went over to the shop

and discovered that the epoxy

I had applied yesterday did not set up completely. That was a bit

disappointing.

There is always something to do, so I

set about cleaning and straightening up the area of the shop which is

the library/exercise room and sometimes paint room. I put away a lot

of items into the storage boxes on the shelves.

I got out some of the items I plan to

sell on eBay.

I cleaned them up and took several pictures of each item. I got down

boxes that I keep instead of throwing away, and measured them to use

for shipment of the items. Then I got the idea to use flat rate boxes

from the Post Office. That will be simpler for me if I use the Post

Office rather than another carrier which is in another city.

I decided to sand down the boom gallows

and scrape off the unset up epoxy.

I assumed I had mixed an incorrect batch, and will apply more

epoxy

this afternoon.

When I got to DREAM AWAY, I had

breakfast, and immediately following breakfast, I got to work on the

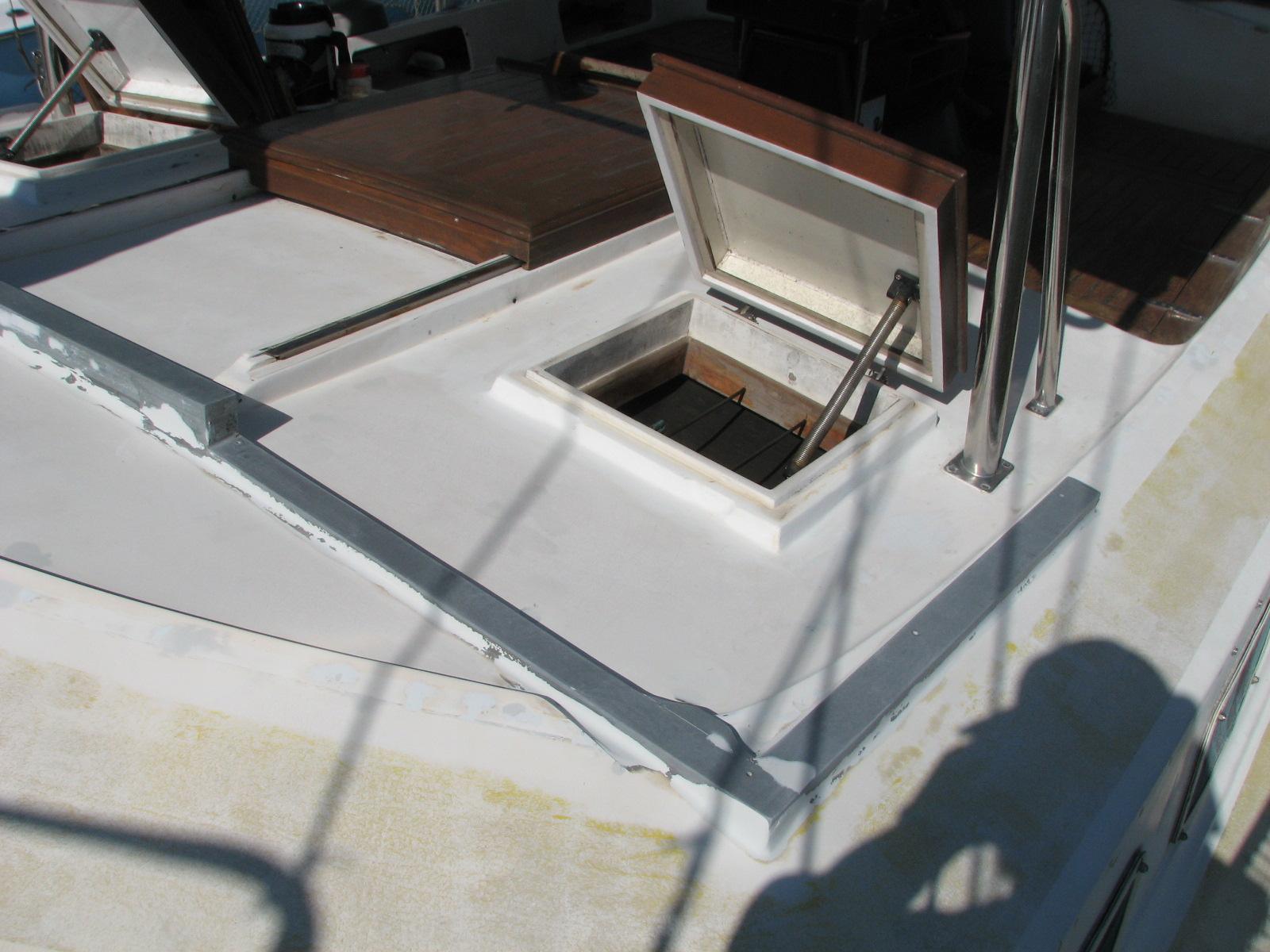

starboard cockpit hatch.

I had put off finishing the

installation of the hinges on that hatch for several months for

various reasons. I had scraped out the rotten wood under one hinge,

and treated the surrounding wood with Smith’s

Penetrating Epoxy. Now it was time to mix up a very

small batch of finishing

putty and fill the hole in the wood. I filled the

hole, and had a bit of the finishing

putty remaining, which I applied to some other areas

around the cockpit.

Finishing Putty Applied To Cockpit

Next on the list was to dry fit the

piece of Structoglas

to the overhead in the head. This is no small task. First of all the

piece of Structoglas

would not fit into the overhead. Too many edges, overhangs and

corners. Kitty and I decided to cut the piece of Structoglas

into two pieces and then cover the seam with the teak

wood tape I have. Once the tape is varnished, it will look very

professional.

The other fun part of the dry fit is to

be able to hold the piece of Structoglas

up to the overhead while the Liquid

Nails is drying. Getting all of the boards, supports

and wedges to get this done, and then remember what you did so you

can take it all down, and put it back up again after the application

of the Liquid

Nails, is a real challenge.

With the dry fit complete, it was time

to spread the Liquid

Nails onto the back of the Structoglas

and put it up on the overhead, and put all of the boards and supports

back up until the Liquid

Nails drys.

I went out to the cockpit and the

finishing

putty had dried. I sanded down smooth the finishing

putty, and drilled a hole into the finishing

putty for the hinge screw. I then installed all three

of the hinges into the cockpit hatch, and that project is finally

finished. I even got the approval of Jillian.

Jillian Inspecting Cockpit Hatch

Completion

Now it was time to see if the teak

wood I had added to the top of the boom gallows, would

allow the boom to clear the future solar panel installation on top of

the hard

bimini. Kitty and I put the boom gallows in place, and

then put the boom on the boom gallows.

We would have plenty of room to install

the solar panels, and any mechanism I can come up with to raise and

lower the panels to face the sun more directly.

We took the boom gallows off of DREAM

AWAY, and I loaded it into the Black

Beast, along with the unused wood supports, small

pieces of wood, and the “Box

O’ Resins”.

It was back to the shop,

and I unloaded all of the wood, “Box

O’ Resins”, and the boom gallows.

I did some more sanding on the boom

gallows in preparation of another application of

epoxy.

Boom Gallows Ready For Epoxy

Application

I did not have any teak

pieces big enough to cut out circles to cover the holes I cut in the

overhead of the head. I found some smaller pieces that I could

epoxy

together and then cut out the hole covers.

Dry Fitting Two Pieces Of Teak

To Make One

I mixed up a plain batch of epoxy

and applied it to the two pieces of teak,

and clamped them together, and added weights to keep both pieces

flat.

With the remaining mixed epoxy,

I added in some teak

dust as a thickener, and applied it to the boom gallows.

Epoxy

With Thickener Applied To The Boom Gallows

I cleaned up all of the material used

with the epoxy

application, and went back to DREAM AWAY.

It had been a good three to four hours

since the Liquid

Nails application on the overhead piece of Structoglas

in the head. I felt confident I could remove the wood supports. Then

I had to put back all the teak

coverings for the light, and other pieces on the overhead. I also had

to put in new hooks to hang the shower curtain.

Overhead In Head Complete Except For

Hole Covers

Overhead In Head Complete Except For

Hole Covers

I still have to fabricate the hole

covers and fabricate the wire cover for the head overhead.

February 15, Saturday,

2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

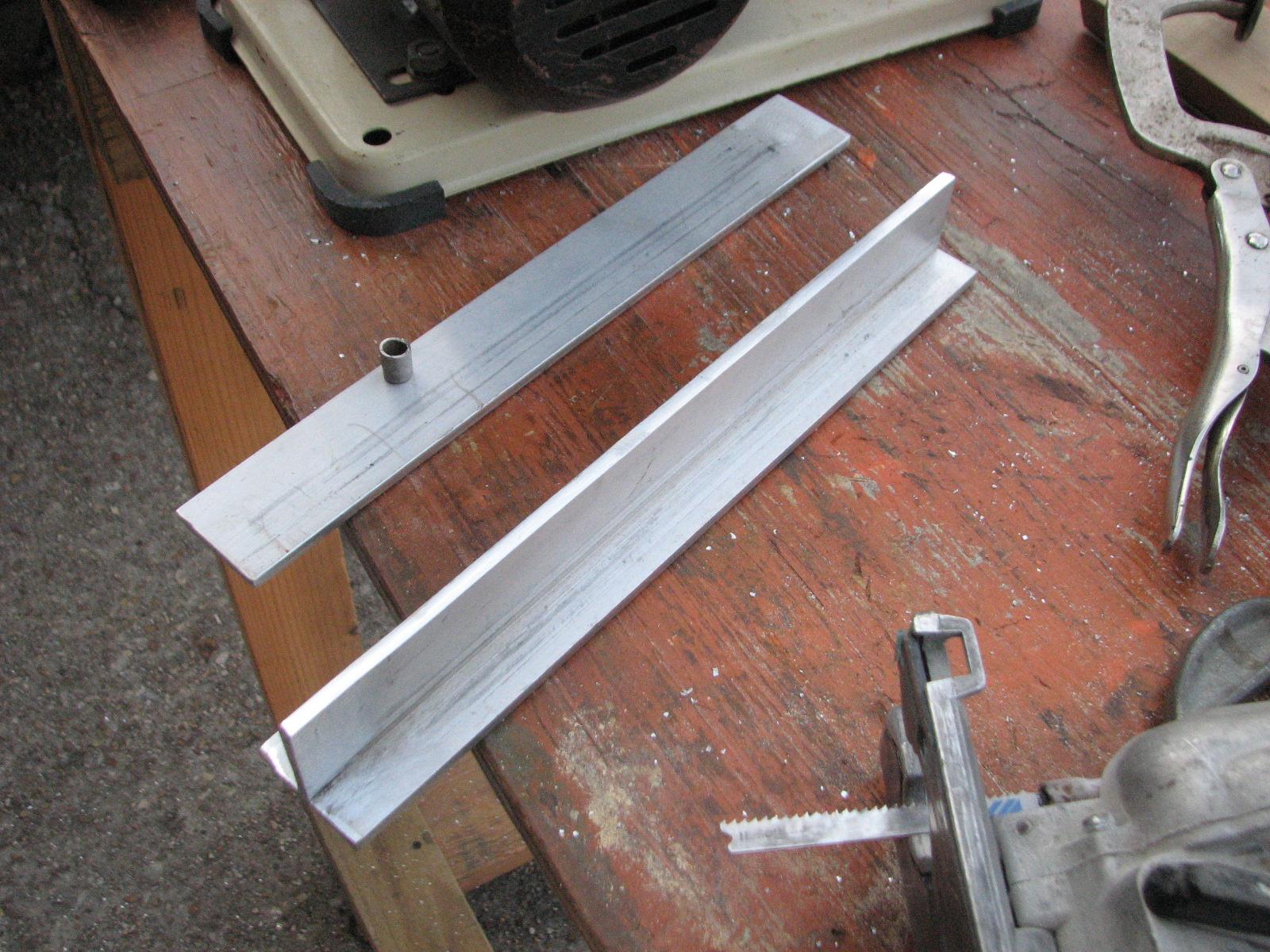

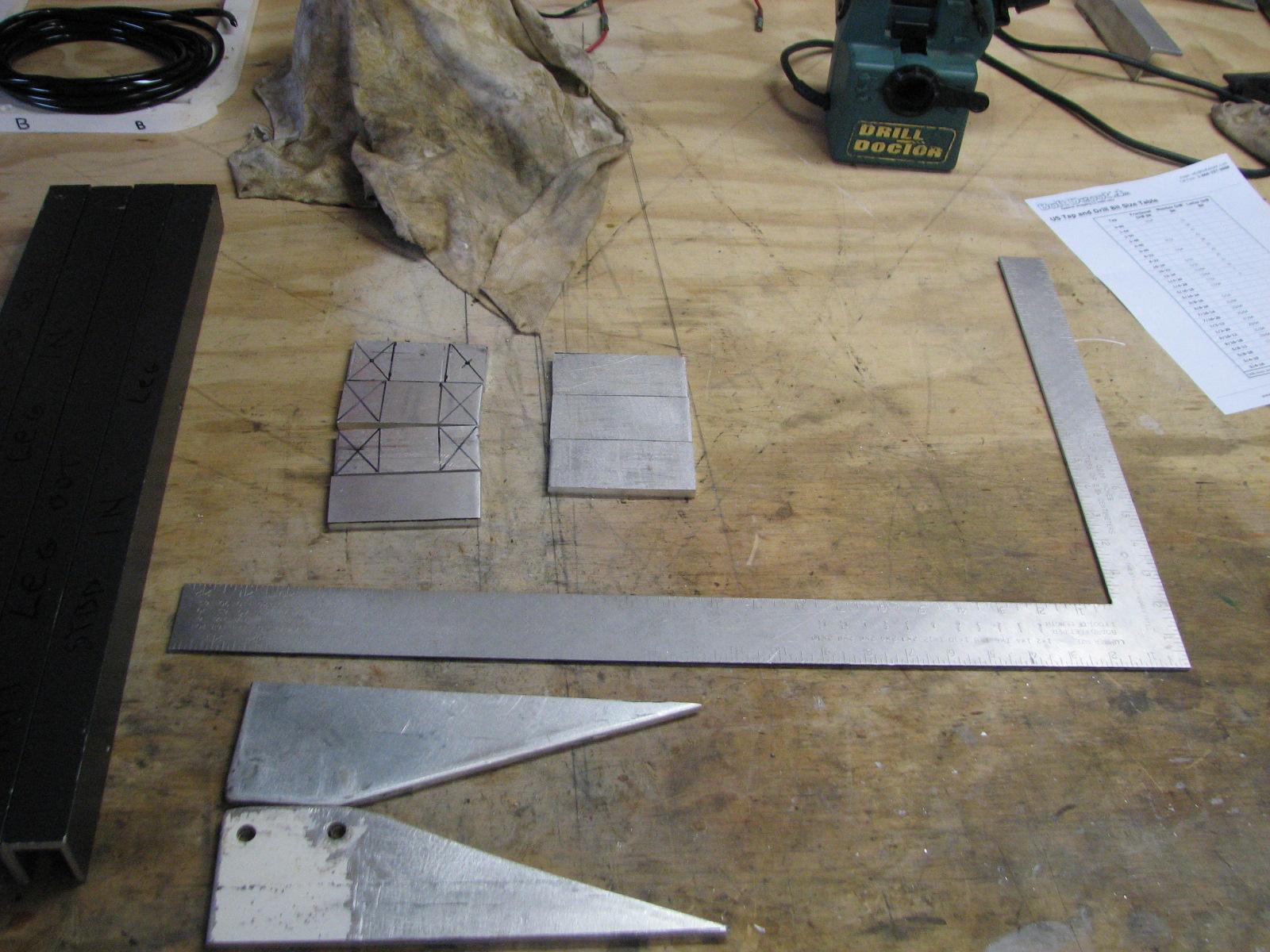

Went over to the shop

and inventoried all of the pieces I will be using on the top of the

legs for the sail handling platform (SHP).

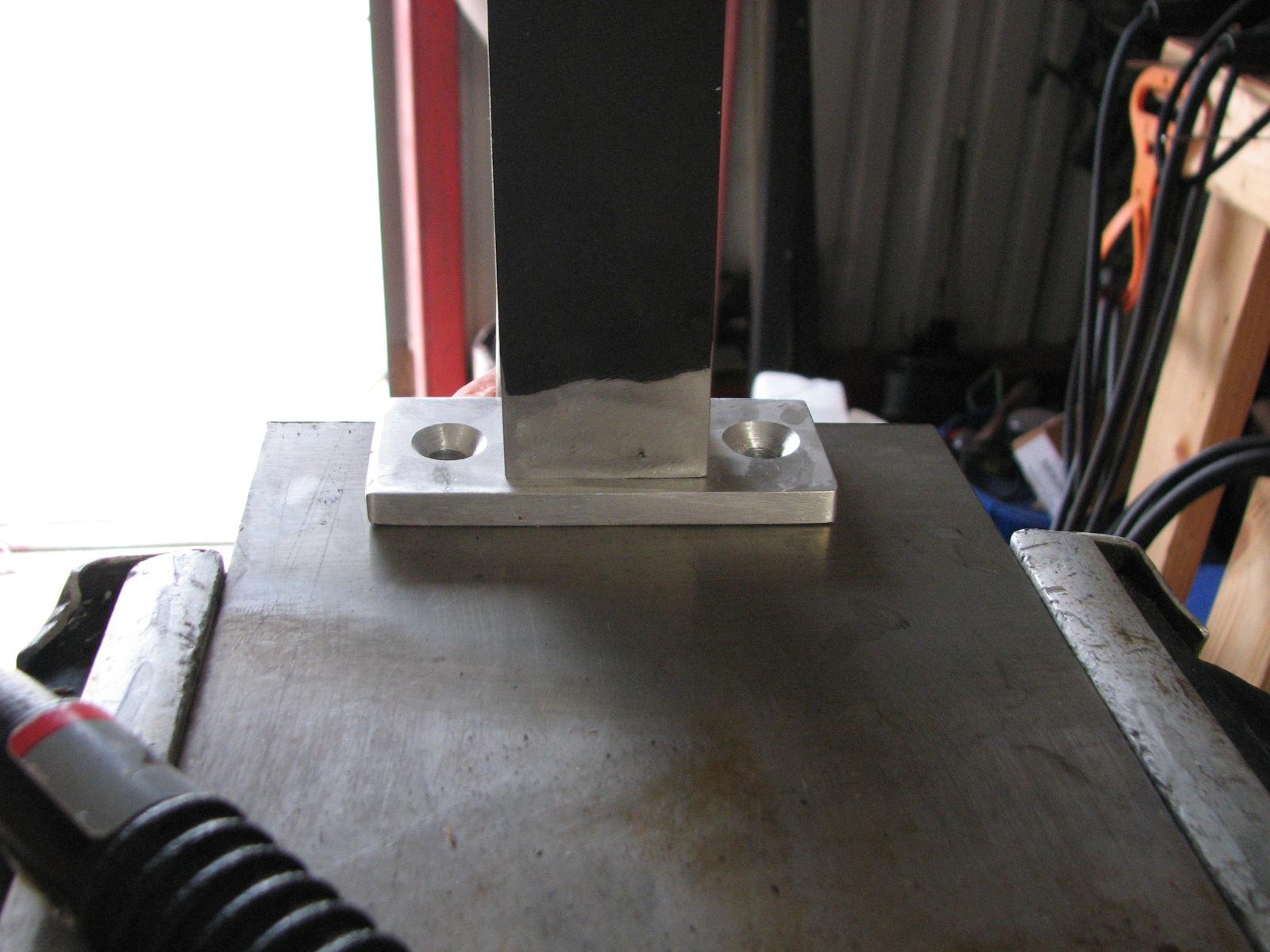

Aluminum Pieces Inventoried

Next was to get to sanding and scraping

on the boom gallows. I knew it would take some effort to get the boom

gallows smooth again, and hopefully the side I applied the

epoxy

mixed with the teak

dust did not have any voids. I was correct, that it did not. The

other side did need an application of epoxy

mixed with the teak

dust. It was still a little cool, so I would do the epoxy

application lated in the afternoon.

Sanding And Scraping The Boom Gallows

Smoothed Out Boom Gallows

Sanding And Scraping The Boom Gallows

Today is the day we were finally going

to get the Structoglas

panel put onto the overhead in the head. I loaded up the panel, and

all of the pieces of wood of varying lengths that would be required

to hold the panels in place after the Liquid

Nails adhesive was applied.

When I got to the marina,

I unloaded all of the wood supports, the necessary tools and the

Structoglas

panel, and brought them all down to DREAM AWAY.

First thing to be done was to cut out

some holes in the overhead interior pan. There is a

teak

grab rail on the coach roof outside that is just over the head. We

are going to remove the teak

grab rail and replace it with a maintenance free stainless steel grab

rail.

The teak

grab rail has through bolts holding it to the deck, so we needed

access to the underside of the deck to get to the bolts for removal.

We will also need access to the underside of the deck to install the

new grab rail.

Three Holes Cut In Overhead

Now I had to clean out all of the

debris from inside the holes. This is another fun feature of this

Hardin.

Debris In One Of The Overhead Holes

Now that the holes were all cleaned out

of debris, I placed old newspapers over all of the exposed surfaces

under the overhead in the head. When this was done, I sprayed

insulation foam in all the areas I could reach between the

fiberglass

coach roof and the interior fiberglass

pan.

This foam will help deaden the noise,

but the main purpose is to stop the condensation that occurs between

the fiberglass

coach roof and the interior fiberglass

pan. The newspaper I put down was to capture any of the foam that

squeezed out while it was setting up.

It was obvious we were not going to get

the piece of

Structoglas

panel installed today. I closed off the head to prevent our cats from

getting in and playing with the wet foam. I loaded everything back

into the Black

Beast, and went back to the

shop.

I got out the pink book, and checked

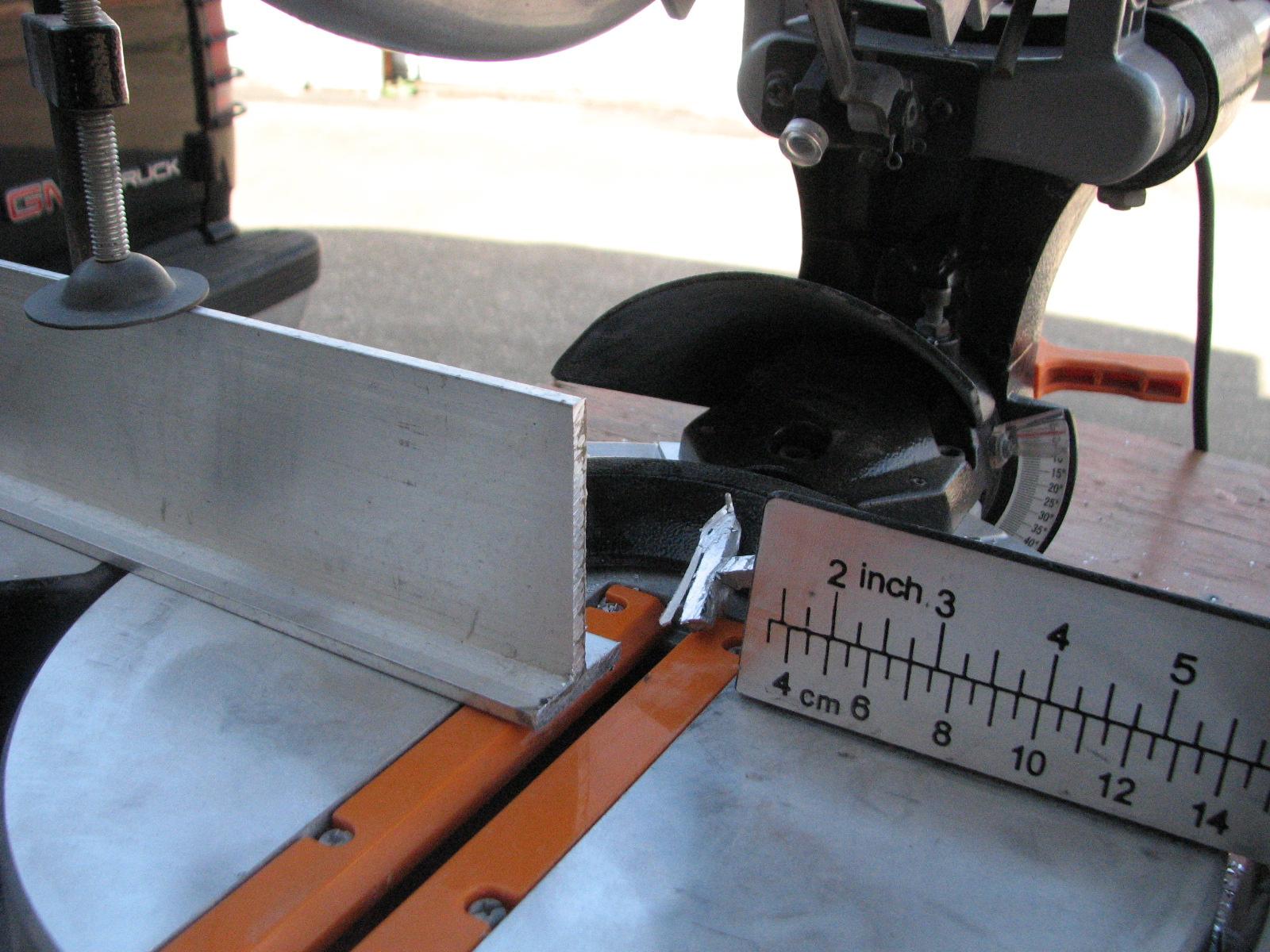

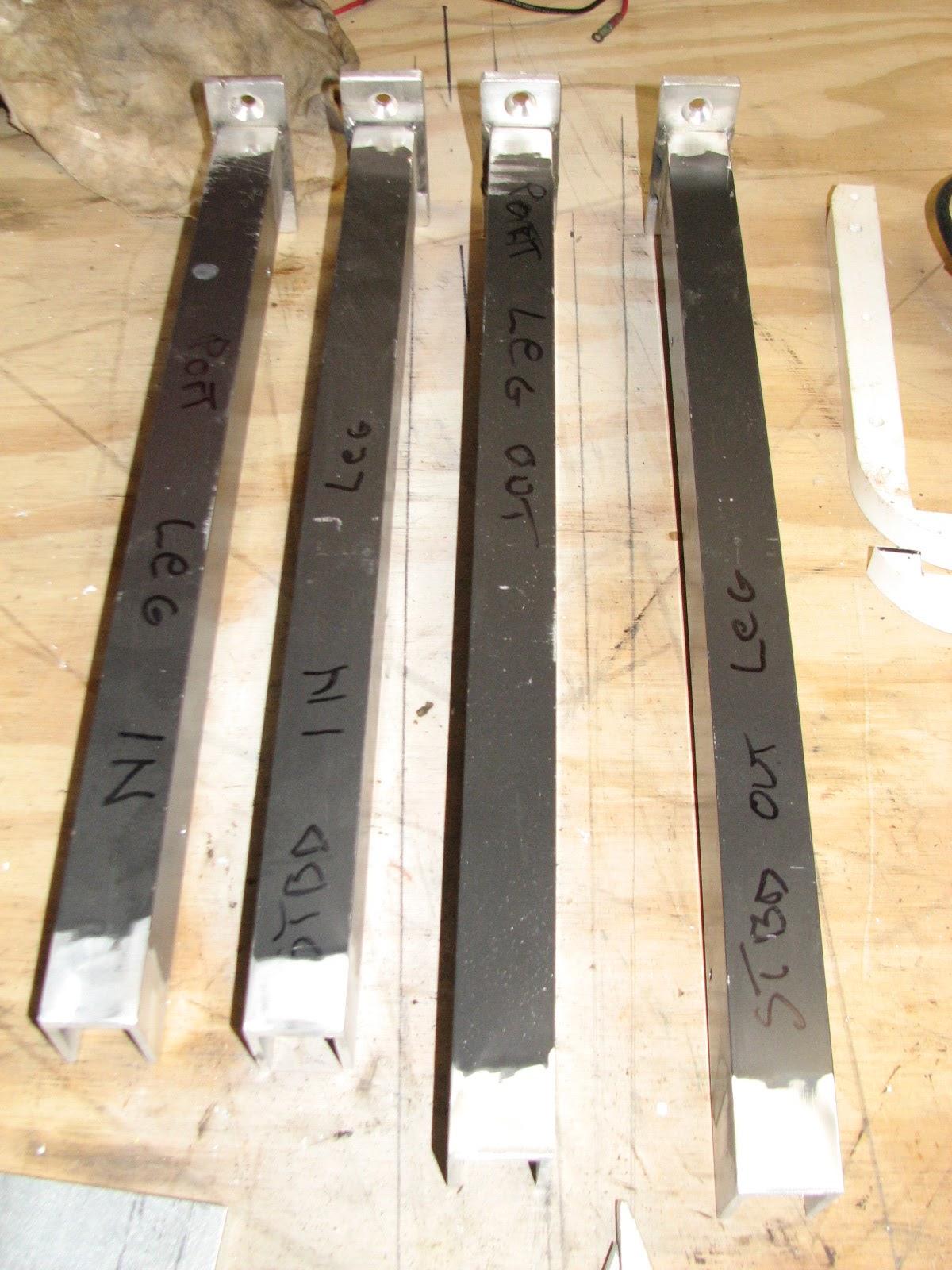

the length required for the legs of the sail handling platform (SHP).

I wanted to cut the legs that I have welded the base plates to. When

I get my new bottle of argon,

I want to weld the top support plates onto the legs. The leg length

includes the base plate and the upper support plate.

I put the metal cutting blade into my

Bosch

jig saw, and cut off all four of the SHP support legs.

Four Cut Legs

Four Chopped Off Pieces

Now it was back to DREAM AWAY to clean

up the foam in the head. The foam had hardened, so it was easy to cut

off the excess, and clean up the newspaper. When I finished the

cleanup, I was done for the day.

February 14, Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Went over to the shop

this morning, but stopped by Dollar

General and purchased wrapping paper and a Valentine’s

card. When I go to the shop I wrapped two gifts I had for Kitty, and

signed the card.

Before I left DREAM AWAY, I had printed

out the customs form for the second package to be sent to our friends

in New Zealand. I put a copy of the customs form into their box and

packed up the box. I will send out the second box on Monday, and get

it on it’s way.

Second Box Ready For Shipment To New

Zealand

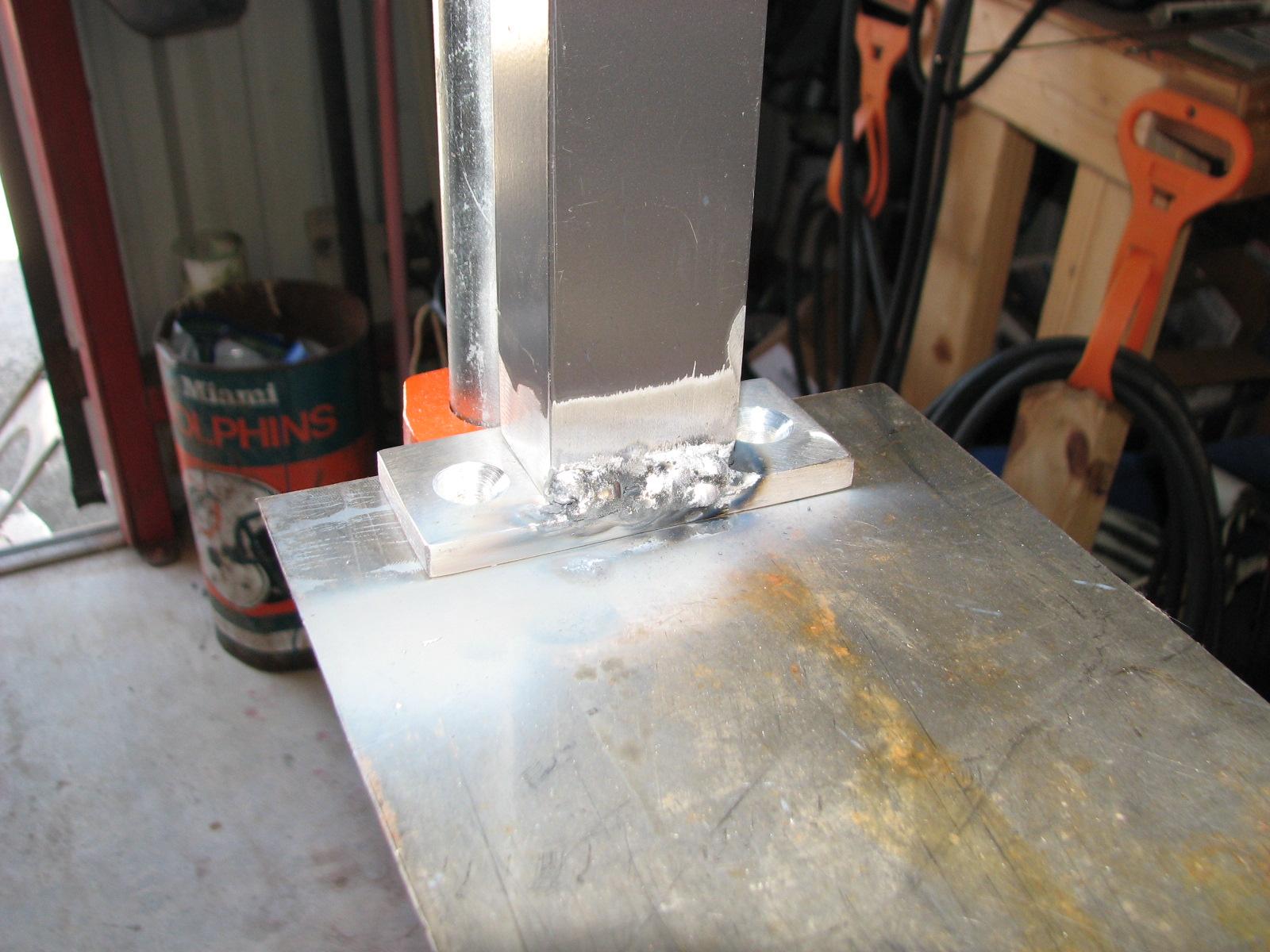

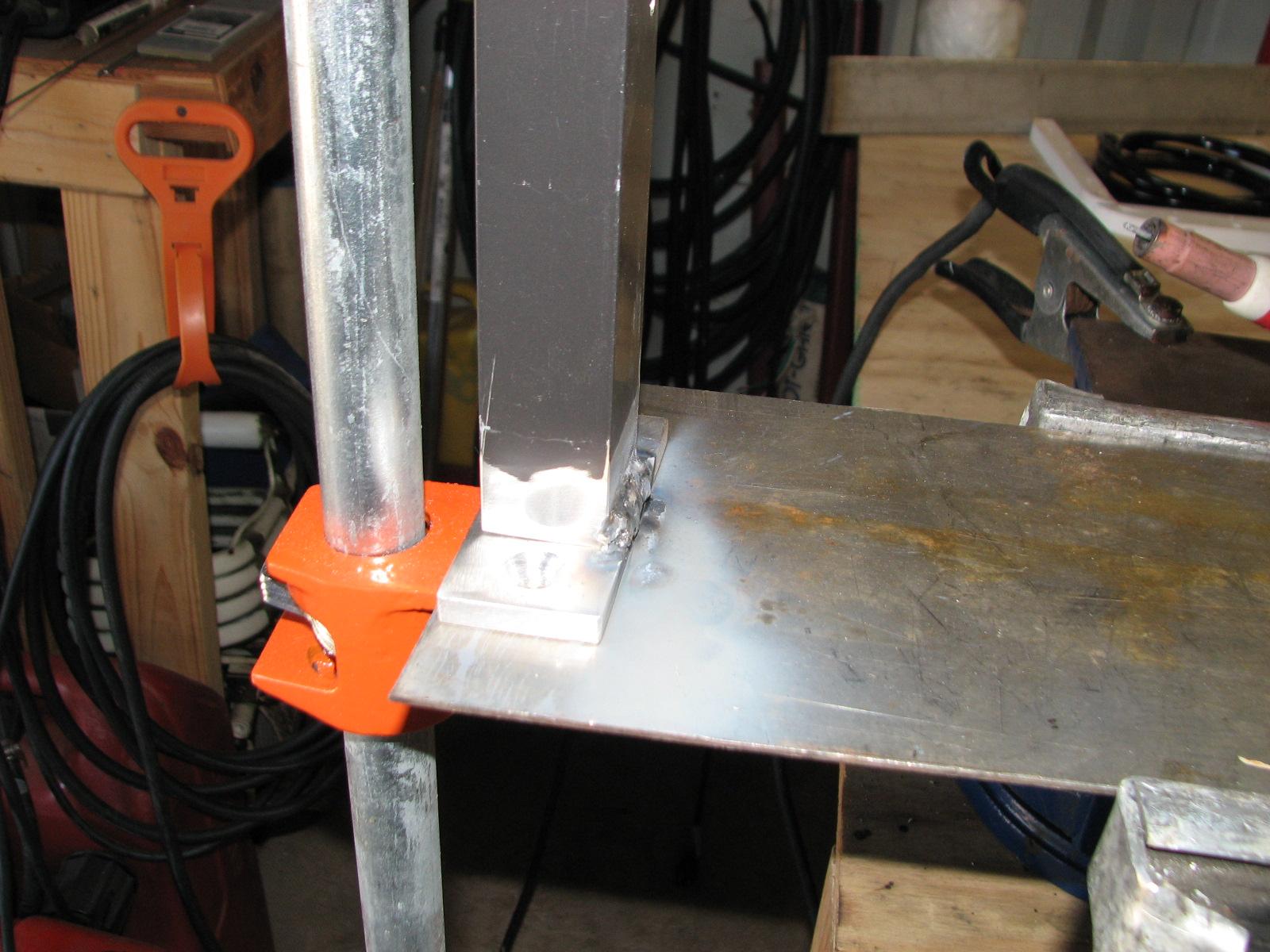

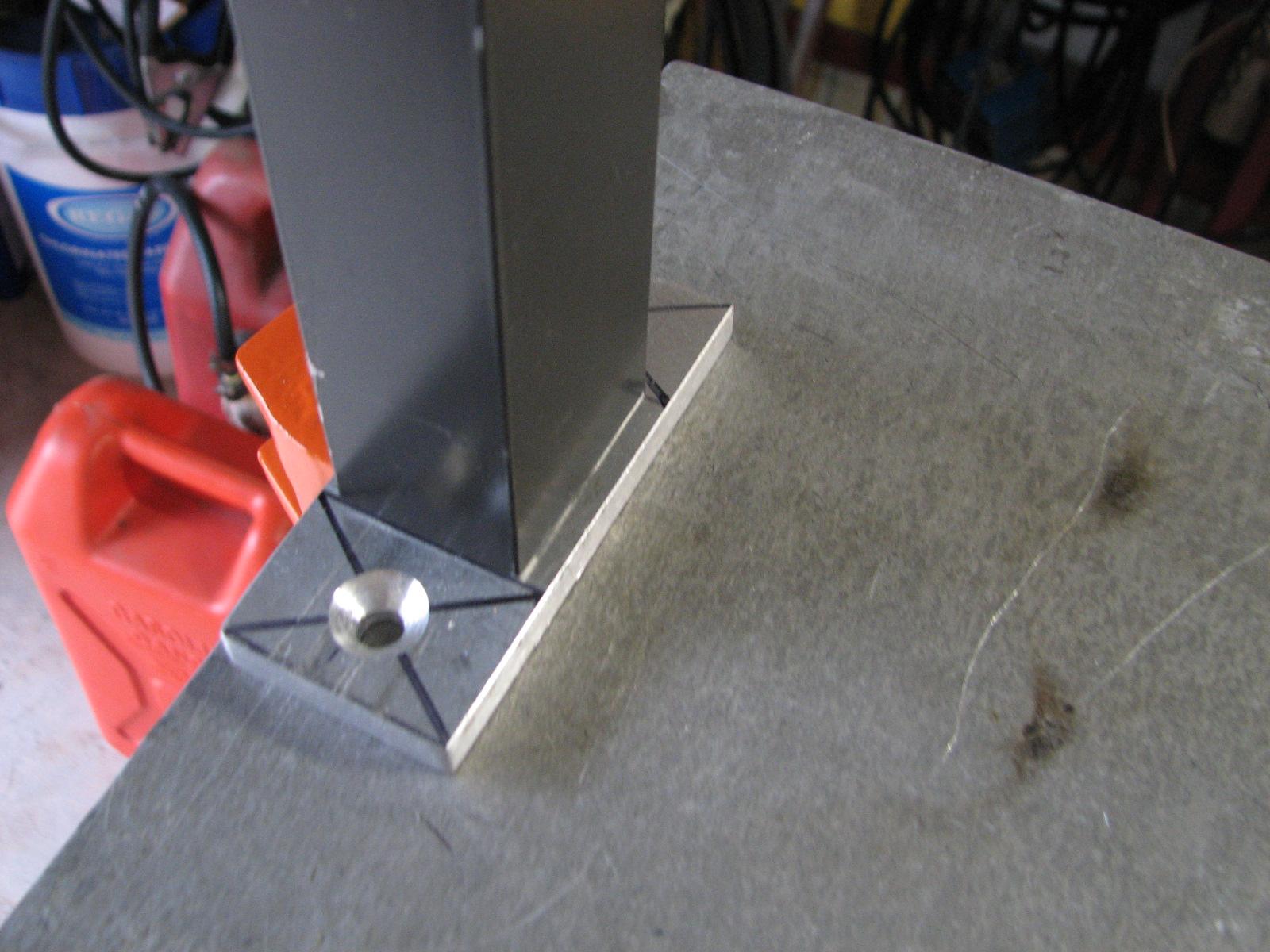

I do not have much Argon

left, but I wanted to get the base plates welded onto the bottom of

the legs on the sail handling platform (SHP). I completed two legs

yesterday. I set up the welder and the, and the base plate and leg. I

would tack weld the two together, then lay down the leg to complete

the welding.

Setup To Weld Base Plate To Leg

I completed the remaining two legs, and

that ran me completely out of Argon.

I found out I can get my tank filled, because I have a receipt to

prove the tank is mine, but I have to have an open bed truck to transport the

filled tank. They will not put a full tank into an enclosed vehicle.

Base Plate And Leg Welding Complete

I have been working on a panel to install

in the aft cabin to place the

Aft

Security Panel (ASP) and the replacement aft

air conditioner controls into. The panel I am going to use is a white

piece of ¼” acrylic plastic. I am doing this to so I can move the

ASP

from a horizontal configuration to a vertical configuration. In this

new configuration, I can label all of the circuit breakers.

The ¼” acrylic plastic had to be cut

to the proper size, so I put the proper blade into the jig saw, and

cut the plate needed.

Plate Measured For Cutting

Kitty was awake, so I went over to

DREAM AWAY to have our valentine breakfast, and to exchange presents.

Kitty At Valentine Breakfast Table

Jim At Valentine Breakfast Table

After breakfast the plan was to work on

the aft cabin leak in the area of the aft port cleat. Earlier in the

morning while making coffee, and making my frothy milk, I discovered

the GFCI

receptacle in the galley was not functioning.

Having a 120 VAC outlet in the galley

was pretty important, so I got into the replacement of the outlet.

Fortunately I have a couple of spare

GFCI

receptacles.

Removing Defective

GFCI

Receptacle

New GFCI

Receptacle In Place

With the new GFCI

receptacle in place it was time to get to repairing the leaks in the

aft cabin. The first item on the list is to removing all of the

bedding and mattress from the aft cabin bed. I knew I was going to be

chopping into fiberglass,

I did not want any of the debris in our bedding.

There was some foam and a patch of

fiberglass

putty around the backing plate for the port aft cleat, so I removed

all of that so I would have good physical and visual access to the

backing plate. The leak was coming from around the backing plate.

Backing Plate With Debris Removed

After the debris was discarded I removed

all of the nuts on the cleat bolts, and attempted to remove the

bolts. This was very difficult. When I initially installed this new

cleat I used rope

caulk weatherstrip. This is great stuff, and I have

been using it for many years to bed almost everything on DREAM AWAY.

Since the bolts were so difficult to

remove because of the rope

caulk weatherstriping, I deduced that the leak was not

around the bolts holding the cleat to the deck.

I attempted to remove the backing plate

for the cleat, but ran into the same problem. I could not get it

unstuck from the deck. I again deduced that the leak problem was not

there.

When I checked on deck at the cleat, I

noticed a couple of cracks between the fiberglass

riser I had glassed to the deck and the deck. I assumed this might be

the source of the leak.

When this was finished, I cleaned up

and vacuumed the aft cabin, and Kitty and I put the bed back

together.

I went back to the shop

and applied another coat of epoxy

resin mixed with teak

dust to the boom gallows.

Now it was back to DREAM AWAY to get

showered and cleaned up for our valentine’s dinner at the

Little River Inn.

February 13, Thursday,

2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the i

shop

first thing, again because of the temperature. It was 31° when I

woke up. Worked most of the morning on the computer trying to catch

up on email.

Kitty had to go off to a doctor’s

appointment here in Delcambre.

When she returned we had breakfast. When breakfast was finished it

was warm enough outside that I did go over to the

shop.

First thing I did was inspect the

painting of the new propane tank. It looked great, so I removed all

of the masking tape and paper, and then set the tank aside. It will

not go into use until we use all of the gas out of the second older

tank.

Propane Tank On Bench WIth Masking

Still Applied

Propane Tank Ready For Use

Next on the list is to inspect the

epoxy

application on the boom gallows. As expected there are some places

where I will need to apply more epoxy.

It is still not real warm, so I will not chance the

epoxy

application today. Tomorrow it will be warm enough to apply more

epoxy.

Boom Gallows With Epoxy

Applied and Set

Boom Gallows With Epoxy

Applied and Set

Because I was not able to continue

working on the boom gallows, I got back to work on the aluminum

pieces for the sail handling platform (SHP).

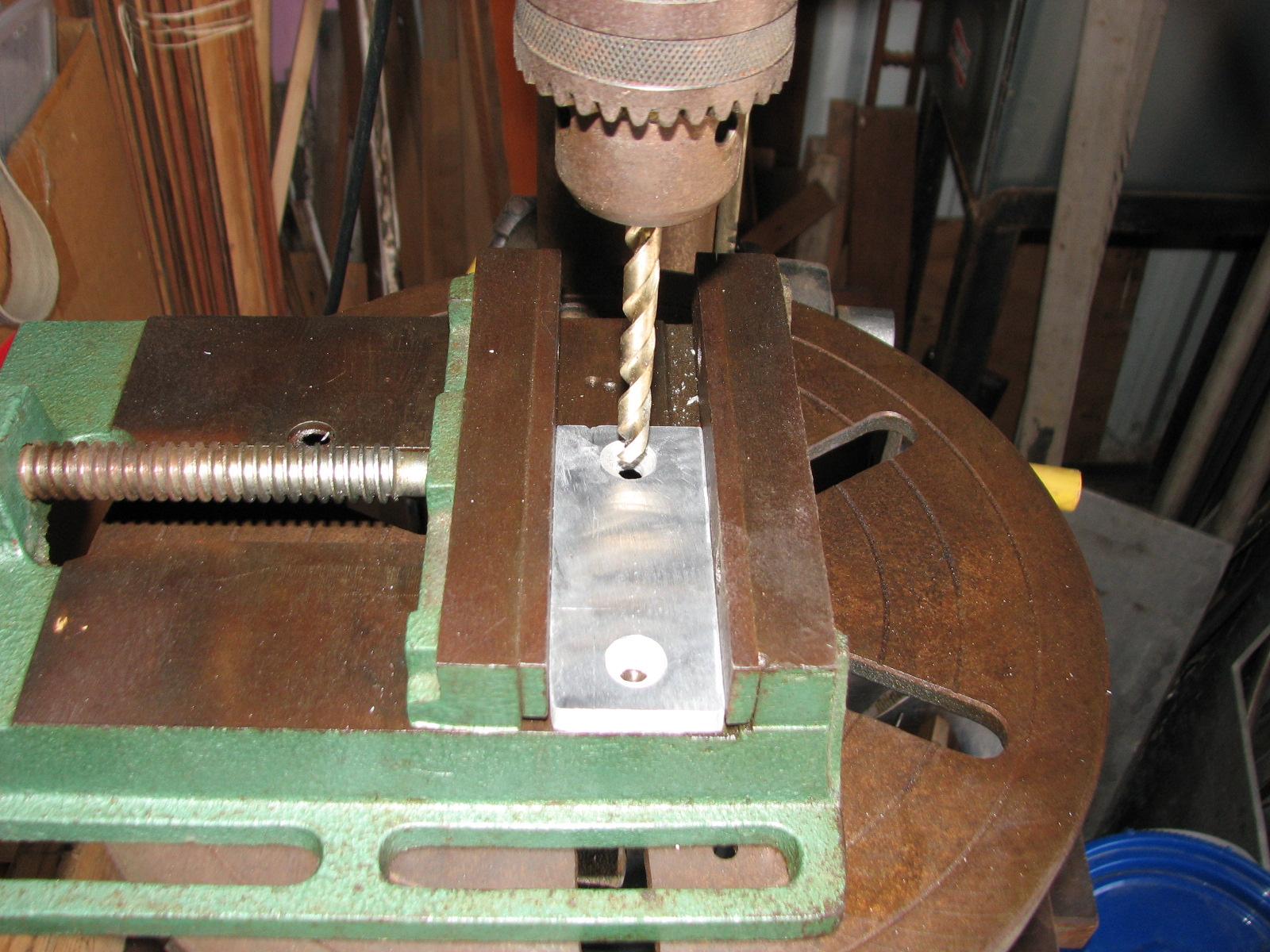

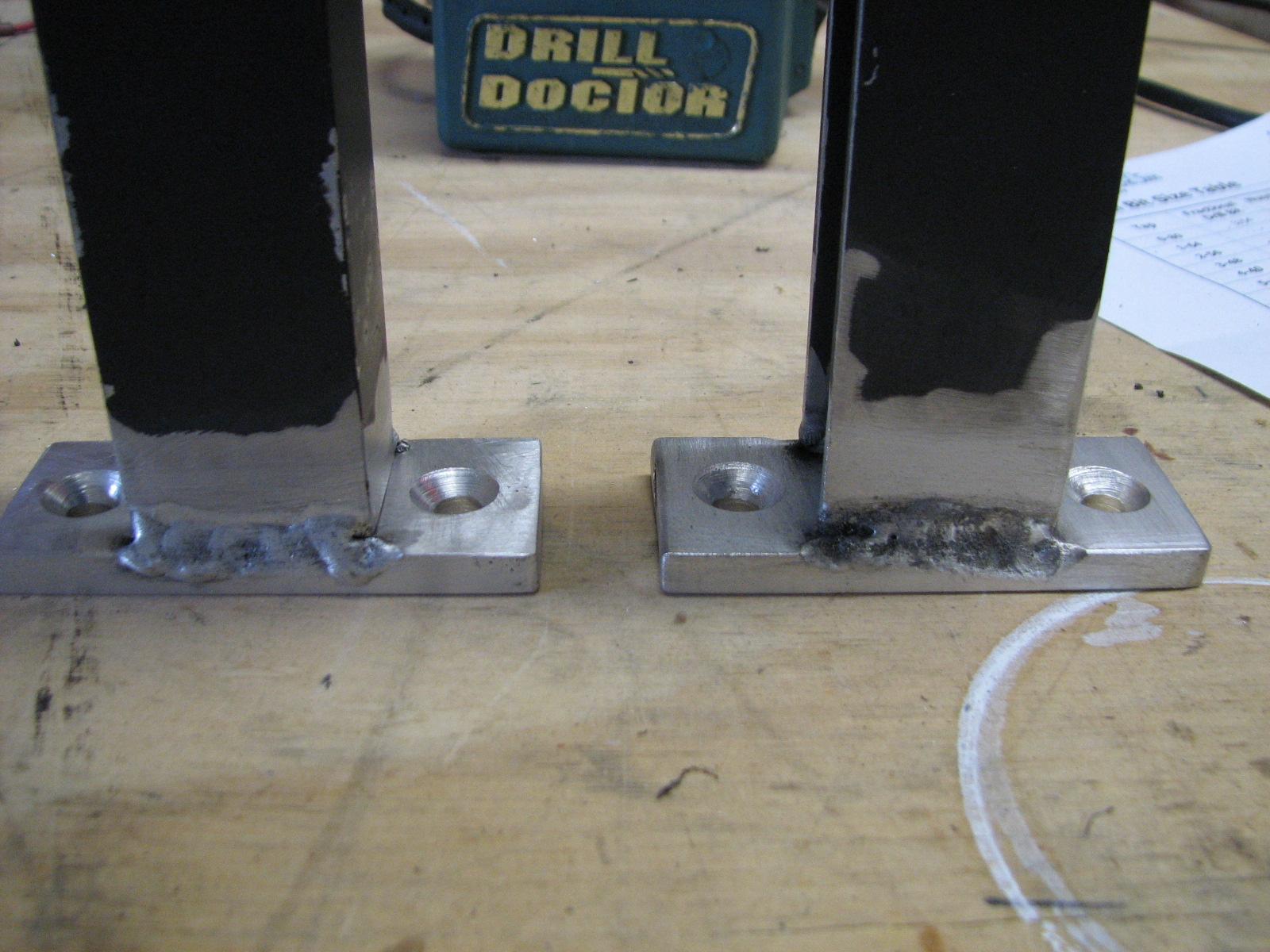

The base plates for the legs supports I

had drilled out for ¼” bolts, but I will be using 5/16” bolts.

The necessitated me drilling out the holes in each base plate to the

larger size, and again counter sinking the holes.

Drilling Out Holes In Aluminum Base

Plates

Four Base Plates Drilled And

Countersunk

When I completed the work on the bases,

I started welding the legs to the bases, and was able to complete two

base to leg welds. I am getting real low on Argon,

so I will have to start looking for a supplier.

Welding The Leg To The Base

Welding The Leg To The Base

Maybe not the prettiest welds, but they

will not come apart, either.

Two Legs And Support Bases Completed

I left the shop

and went back to DREAM AWAY. I wanted to do a project that has been

bothering me for months, probably years.

The stove in the galley is gimballed,

so when you are underway the top of the stove is always flat. When in

port or at anchor, there is a lockdown on the stove to keep it from

moving. When I installed the lockdown, the stove was not quite level.

It was not a level surface to cook on, and it was annoying.

Today I was fixing the problem. In the

following picture, you can see the stove is not level relative to the

counter beside the stove.

Stove Not Level

I moved the lockdown block, and using a

level got the stove level. Now all of the cooking surfaces will be

level. I am a happy camper.

Stove Is Now Level

The remainder of the day I spent

measuring the hard

bimini top for solar panels, and then talking to

Johnal,

from the yacht RUTHIE about his solar panel installation. We also

discussed tenders, outboards and electronics.

February 12, Wednesday,

2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Woke up to a temperature of 33°, so

did not go to the shop

this morning. Actually, did not go to the

shop

at all today. The high temperature was only 37°! The good news seems

to be, after tomorrow we will have at least five days of good working

weather.

We did welcome some new cruisers that

came into the marina

yesterday while we were at the workshop. We presented them with the

official North

Pier Marina welcome basket. They said they are only

staying two nights, so will be leaving tomorrow. The cruisers, Carol

and Eric lived in Morgan

City for eight years, so they are pretty familiar with

this area. Their niece Terry, is also sailing with them.

Eric, Carol, And Niece With Welcome

Basket Items.

I did get some progress made on inside

computer projects. I got our 2013 taxes finished and filed. I caught

up on all of my scanning, now I have to get caught up on emails.

One of the neatest things that happened

was a new hatband for me. It actually happened yesterday, but I did

not get the hat band on my hat until today.

One of the presenters, Benny Welch,

from yesterdays workshop explained how he now has a whole business

from the waste of alligator harvesting. As it turns out the alligator

farms that harvest the meat and skins from the alligators do not use

everything.

The feet, the heads, and what they call

the backstrap are all thrown away. In fact the farms have to pay to

have all of the waste thrown away. The backstrap is the portion of

the skin that runs down the alligators back. The lumps on that part

of the skin are too big and hard to use commercially.

Benny takes all of these “waste”

products and makes alligator souvenirs from them. He uses the teeth

from the head to make hat bands, necklaces and so on. Most of the

bones in the head of the alligator are solid bone, no marrow, so the

bone can be used for scrimshaw and other types of carving.

He makes a knife and handle out of

bone, and the scabbard out of hide from the feet and backstrap.

When he showed the workshop all of

these products, I mentioned to Kitty that the headband would look

really cool on my hat. After the workshop was over, and Benny was

packing up his items, Kitty asked him if she could buy the headband.

He said no, because he does not sell directly, he sells all of his

souvenirs through brokers.

Kitty talked to him some more, and then

Benny just gave her the hatband, and would only accept a thank you as

payment! That hatband is a $300.00 item. The actual band is made from

the backstrap, and the teeth are glued to the hatband. Benny guessed

the gator the teeth came from was probably between eight to nine

feet.

Jim With New Hatband

February 11, Tuesday, 2014

We attended the workshop in

Lake Charles for

the Twin Parish Port District. We enjoyed

the workshop, and got

some great ideas for implementation in our area. We also got some

great contacts to help us put together some eco-tourism or

agri-tourism plans.

February 10, Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Went to the

shop

and got started in on the propane tank upgrade. Yesterday I had

painted the bottom of the tank with the DREAM AWAY orange paint. Now

I had to put on the plastic automotive door trim. Hopefully the door

trim will prevent rust from starting on the bottom of the tank. Only

time will tell, but I will have to keep a closer eye the bottom of

the new propane tanks.

Starting To Apply The Automotive Door

Trim

Automotive Door Trim Installed

Now that the door trim was installed, I

masked off the new propane tank to paint the green stripe around the

top of the tank. This green strip serves no practical function other

than to make the tank unique. I do not want someone to say this new

tank is theirs.

Propane Tank With Strip Masked Off

Picture Of Package Being Sent To New Zealand

Now that the small projects were out of

the way, I got back onto the boom gallows. Yesterday, I got a little

carried away with the epoxy

resin application. I had not masked off properly, so I had a lot more

epoxy

than I needed.

I did a lot of sanding and scraping to

get the boom gallows prepared for the next row of teak

pieces to be added to the boom gallows.

Sanding The Boom Gallows

Sanding The Boom Gallows

Once the boom gallows was all sanded, I

did a dry fit of the last row of teak

pieces, and made sure it was masked properly for the

epoxy

application.

I mixed up a pot of epoxy,

and applied it to the boom gallows and the teak

pieces, and then fitted them together. I then added more epoxy

to fill in all of the space and imperfections in the teak

pieces I added.

I applied the green paint to the

propane tank, as it was still warm enough to use the spray paint, but

the temperature was falling.

I did not take any pictures of the

above actions.

I went back to DREAM AWAY and we packed

our stuff, loaded it into the

Black Beast, and drove to

Lake Charles so we

could attend a workshop for the

Twin Parish Port District.

This workshop was to familiarize us with eco-tourism and agri-tourism.

February 09, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian and Jordan,

and spend time with them brushing their beautiful coats.

Went to the

shop

and got started in on the propane tank upgrade. As mentioned before I

had purchased a second new propane tank. I wanted to get the bottom

of the tank painted to keep rust from forming. Additionally I planned

to put some plastic door trim on the bottom of the tank. This will

protect the paint from chipping.

I had done the same thing to the

previous new propane tank.

Propane Tank Masked And First Coat

Applied

Now it was back to the boom gallows and

getting the wood that is being added to the top of the boom gallows

fitted. The wood needs to be cut, and then a dry fit done before

actually epoxying the wood to the boom gallows.

The teak

pieces I am using are left over pieces of deck boards. These pieces

were removed from DREAM AWAY almost 15 years ago.

Teak

is so expensive, I keep all I can carry. It comes in very handy in

times like these.

Dry Fitting Teak

Pieces To The Boom Gallows

Dry Fitting Teak

Pieces To The Boom Gallows

Dry Fitting Teak

Pieces To The Boom Gallows

I loaded up the

Black Beast and went over

to DREAM AWAY to have breakfast,

and to get the second coat of gelcoat

applied to the hard dodger base area. We finally have a day where the

temperature and humidity are cooperating.

I sanded down the base of the hard

dodger where it was required, which was not much. I then used a

tack rag to wipe down the whole

area. I then mixed up a batch of

gelcoat

and applied the second coat to the hard dodger base.

It is hard to tell the difference

between the before and after pictures of the

gelcoat

application, but I really did apply a second coat.

Hard Dodger Base Before Second Coat

Application

Hard Dodger Base After Second Coat

Application

I cleaned up everything I was using for

the hard dodger base gelcoat application, loaded it all into the

Black Beast, and went

back to the shop.

Once there I unloaded the

“Box O’ Resins”, and got back

into working on the boom gallows.

I had done the dry fit of the teak

pieces I was adding to the boom gallows, so I mixed a batch of

epoxy.

I applied it to the boom gallows and the new pieces of

teak

and then screwed and glued the pieces of

teak

to the boom gallows.

I filled in the spaces with additional

epoxy.

Now we just wait for the chemical reaction to take place, and I apply

the second layer of teak

pieces.

Installing The Teak

Pieces To The Boom Gallows With Epoxy

Installing The Teak

Pieces To The Boom Gallows With Epoxy

February 08, Saturday,

2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Went to the shop

and got started straightening up the area, and getting projects

organized to make some progress. First on the list was to get the

boom gallows organized, and the instrument cluster taken apart.

As mentioned previously, the Watco

teak oil finish experiment was a bust. It seems to

hold up well indoors, but it does not hold up well outdoors. I will be

sanding down the gallows and the instrument cluster housing and going

back to Cetol

teak

treatment. I also have to add some wood to the boom gallows to accomodate the

solar panel installation.

Instrument Cluster Housing Before

Taking Apart

Taking Instrument Cluster Housing Apart

Boom Gallows Ready For Sanding

Next on the list was to repack some

caulking to be shipped to New Zealand. We have some friends who live

in New Zealand who needed some caulking for their wood boat that was

only available here in the USA. They asked me if they had the

caulking sent to me, would I repack the product into USPS

international flat rate boxes and send it to them. Of

course I agreed.

We received the caulking last Wednesday

afternoon, but it was too cold to go to the shop and do the

repacking. I got the repacking done today. The USPS

international flat rate boxes have a limit of 20

pounds, so each box is under that limit. All that is remaining is to

fill out the customs forms and get them sent.

Inside Of One Packed Box

Outside Of Packed Box

I got the old shackle off of my Bruce

anchor that I use as my pony anchor and put on the new cast stainless

chain gripper. This item is so cool, I just had to have two.

Old Attachment Shackle

New Chain Gripper On The End Of The

Chain

Close-up Of New Chain Gripper On The

End Of The Chain

Sorry about that, I just had to do the

closeup, because this chain gripper is just the coolest thing.

Earlier in the week I had purchased a

new water filter housing to replace the one that Winter

Storm Kronos took from me. I connected the hose barbs

to the new housing with new teflon tape. When I go back to DREAM

AWAY, I will put the new housing into the fresh water system. This

filter allows me to filter the fresh water coming onto DREAM AWAY

before it even gets into the onboard tanks.

New Filter Housing

Hose Barbs And Hoses Attached To Filter

Housing

Was a month behind on one of the

shop

calendars, so made the adjustment to February on the construction

babes calendar.

Now We Have February

I had brought over to the

shop

my fuel filter to filter some diesel fuel a cruiser had given me. He

had pumped some diesel into his water tank, and when we pumped out

the diesel he gave it to me. All I had to do was filter out the

water, and I should have some good diesel.

Using Filter To Clean Diesel Fuel

I had purchased another new propane

tank to replace the present tank, because of rust issues. Really

concerned that I could have some problems with my present tank. They

have lasted a good 15 years, so there is no saying I have not got

good use out of them. I plan to paint the bottom of the new tank and

put the door trim on the rim to keep the rust from getting to the

tank.

New Propane Tank And Old Propane Tank

Kitty called and she was up, so I went

over to DREAM AWAY and had breakfast. After breakfast, I got to work

on installing the new water filter housing into our fresh water

system.

New Water Filter Housing And Hoses Ready For Installation

New Water Filter Housing And Hoses Installaled

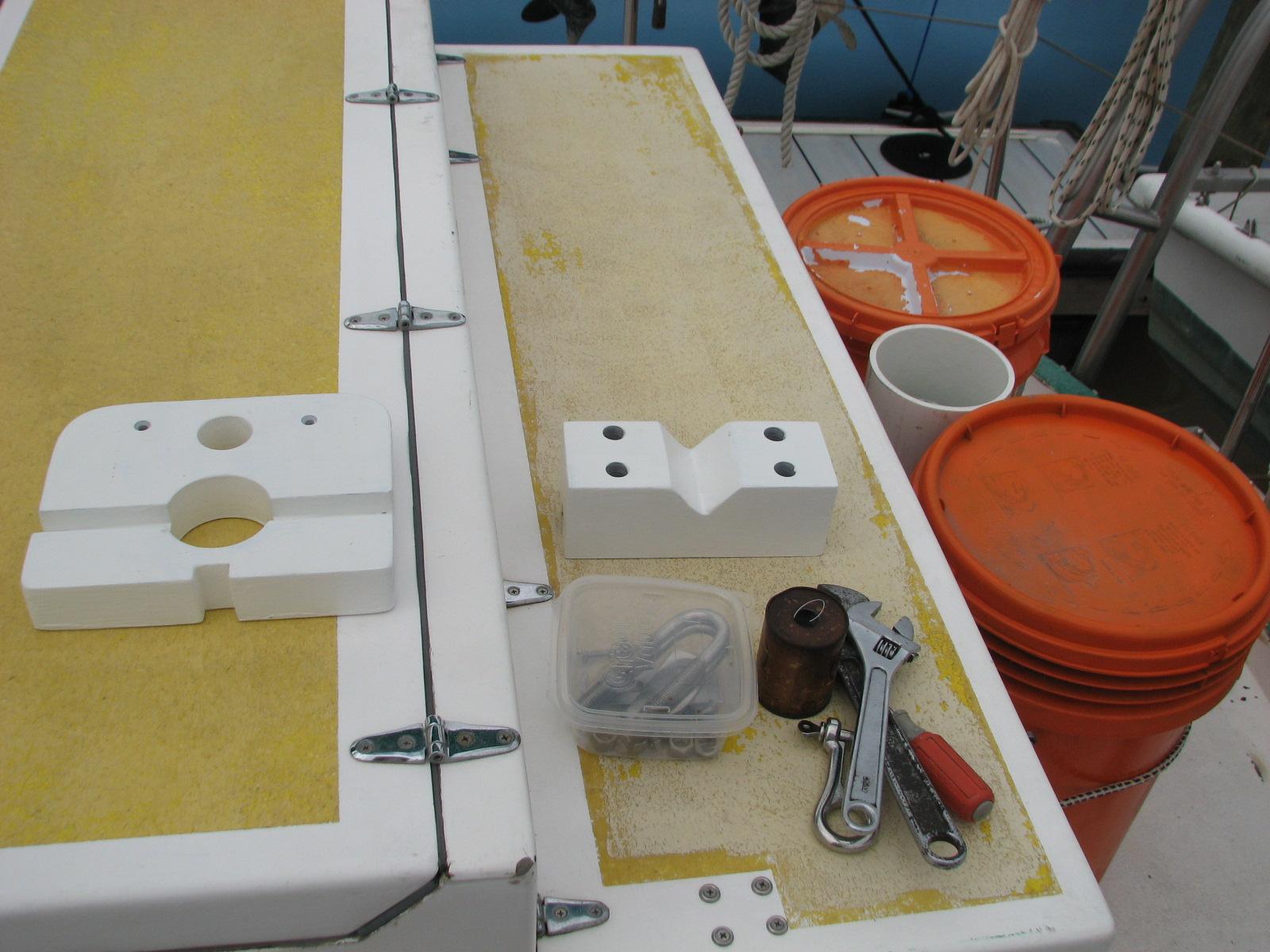

Now it was FINALLY time to finish off

the storm

anchor support project. The storm

anchor on the stern of DREAM AWAY used to have

supports made from wood, which equaled maintenance. I had fabricated

the replacement anchor supports out of fiberglass a couple of months ago, and

applied the gelcoat.

It just seemed like I could not get the

parts over to DREAM AWAY and get them installed. Today it happened.

Storm Anchor Tied To Life Rail

Bottom Of Storm Anchor Sitting On Stanchion Base

New Storm Anchor Supports Ready For Installation

New Upper Storm Anchor Support Installed

New Lower Storm Anchor Support Installed

I cleaned up from the storm anchor

support project, then back to the

shop

to continue work on the boom gallows and the instrument cluster

housing.

I had to sand down the boom gallows and

the instrument cluster housing to remove all of the Watco

teak oil finish before I will be able to apply the

Cetol

teak

treatment.

I am also fitting some teak

pieces to the top of the boom gallows, that will raise the boom. This

is in preparation of the installation of the solar panels on the top

of the hard hard

bimini.

Sanding The Boom Gallows

Fitting The Teak

Pieces To The Boom Gallows.

Fitting The Teak

Pieces To The Boom Gallows

February 07, Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the

shop

because of the weather, another cold day! Same reasons as yesterday.

We did go out to our dental

appointments, then back to DREAM AWAY. Worked at computer most of the

day, and did some domestic chores.

We did enjoy a bit of a milestone as it

was the 22nd anniversary of Kitty and I purchasing DREAM AWAY. We had

friends over for an indoor picnic dinner, and watched the movie “All

is Lost”, about boating.

February 06, Thursday,

2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the

shop

because of the weather! The high today was 36°, and it was sleeting

by 0800. Not the kind of weather in which to be working outside or to

be working at the shop

with no heat.

I spent most of the day on the computer

finishing off the January update and also working on my 2013 taxes.

I did go outside to check the fuses on

the Black

Beast. I checked them and could not determine the

problem, but I still had some kind of problem.

I went back to DREAM AWAY and finished

the inventory of the generator

spare parts. When I had finished that project, I called Ray at Rays

Auto Repair to see if he could help with my electrical problem on the

truck.

I drove over to his shop, and he was

able to find and fix the problem, which turned out to be the main

headlight switch. He replaced the switch and now all is well.

It is supposed to get into the high 20s

tonight, so I went to the end of all three piers and started the

water trickling to prevent pipes from freezing.

February 05, Wednesday,

2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the shop

because I had an appointment at 1100 with my dermatologist. I stayed

on DREAM AWAY and, you guessed it, worked on my computer. I did some

catching up on emails and started filling out my 2013 taxes.

We went to the dermatologist in

Lafayette

and ran a bunch of errands afterwards. We got home in time to unload

the Black

Beast and have a bite of dinner, and then I went off

to the Marine

Corps League meeting in

Abbeville.

Before the meeting I stopped at Stine’s

as I am still trying to find 10 X 32 threaded rod. Still no luck.

On the way home from the meeting, the

dash lights in the Black

Beast went out. Then a Delcambre

cop pulled me over and told me the back lights were out. They let me

off with a warning, and I only had about ½ mile to go to get home.

Now I have an electrical problem to look into on the Black Beast.

February 04, Tuesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

I went to the shop

after coffee and spending time on the computer. I started working on

the legs and pads for the sail handling platform (SHP).

I realized I needed to drill holes in

the pieces of aluminum I am using for the pads to which the legs are

going to be welded. Once the legs and pads are welded together, there

was not room to drill and countersink the holes. I drilled ¼”

holes in all four pads, and then countersunk the holes.

Set Up For Drilling The Holes

When that was finished, I set up to

start welding the legs to the pads. I know this will be interesting

because the pad is ⅜” thick, and the legs are only ⅛” thick.

I will have to be careful.

I did the setup for the welding, and

started to weld. It was then I realized the legs all have paint on

them. The welding process was not going well. So, I sanded off the

paint at the ends of the legs to which I will be welding.

Setup To Weld Pads And Legs

I then had another realization that I

was not sure whether the bolts I will be using are 1/4” or 5/16”,

so I decided to not do any welding until I know what size holes I

need in the pads.

I went back to DREAM AWAY and had

breakfast, and just after that the heavens opened up. I knew then it

was time to get back on the computer and do more email, and research.

I also checked the two leaks we had.

One was in the head where there is a backing plate for the turning

block on deck. I was sure it was fixed as I had rebedded the turning block

about two months ago. We have not had a real hard rain since

then, so it hadn’t had a true test. There was no leak, so the fix has been a success.

Backing Plate On Underside Of Deck In

The Head

The second leak is in the after cabin

around the backing plate for the aft port side cleat. Water was

running out at a good clip, so I will have to rebed the two after

cleats. They were both installed at the same time, so there is a good

chance the starboard cleat will start leaking, to.

Aft Cabin Cleat Backing Plate Leaking

The rain finally stopped. Although it

was very wet outside, I went to work on removing the boom gallows. It

is being removed for two reasons. First reason is that the Watco

teak oil finish I used on the boom did not hold up, so

I am going back to Cetol

teak

treatment. The second reason is to prepare for the installation of

solar panels.

I am going to be installing solar

panels on top of the hard

bimini, so must add about 1 1/2” of teak

wood on top of the boom gallows to make sure I have plenty of

clearance between the boom and the solar panels.

I got everything removed from the

gallows, and all of the bolts removed or disconnected. When Kitty

came home from her errands, we removed the boom gallows.

Boom Gallows And Accessories On The Way

To The Black Beast

I took the newly painted propane tank

to LeBlanc Oil and had it filled. I purchased another 30 pound

propane tank to replace the second one that was rusting out! I also

picked up two chain grippers that I had ordered. These will be used

to attach my poney anchor or storm anchor to the primary anchor, when

it is deployed.

New Chain Gripper

I ended the day by getting all of my

scanning done. This included all of my tax documents. Now I can get

started on filing my 2013 taxes.

February 03, Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian & Jordon,

and spend time with them brushing their beautiful coats.

Did not go to the shop

today. I had an 0815 doctor’s appointment to draw blood, and to be

honest, it was very cold again this morning. It was 36°, and the

wind was blowing 15-18 knots.

When I got back from the doctor’s, I

spent the remainder of the day on the computer catching up, and not

getting any other projects done. I also cooked up some of food for

our two cats, Jillian

and Jordan.

I had an appointment with the eye

doctor at 1530, so the day was pretty much gone. Tomorrow should be

warmer, but rainy.

February 02, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

I went over to the

shop

first thing and continued cutting out the base pieces for the legs of

the sail handling platform (SHP). Yesterday, I cut out five of the

base pieces for the legs of the sail handling platform (SHP).

Today, I continued with the project. I

cut out three more base pieces so I had for pieces for the bottom of

the legs, and pieces for the tops of the legs. I also measured out

the bottom base pieces in which I must drill holes so that I can

attach them to the deck after the leg is welded to them.

Four Base Pieces Cut Out, Measured

Plate For More Pieces

Cutting Plate Using Fence For

Jig Saw

Cut Base Plates On Work Bench

I sanded down all of the base pieces,

and went back to DREAM AWAY. I have/had still more computer work to do.

I made a dip for the Super Bowl party

to which we were going, and started cooking the next batch of food

for our two cats, Jillian

and Jordan.

February 01, Saturday,

2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Did not go over to the

shop

first thing this morning. Kitty had plans with Cindy, of the cruising

yacht RUTHIE. They were going to the Teche

Farmers Market in New

Iberia, then attending a presentation at the Library

in Jeanerette.

I decided to wait until she got up, then we had breakfast together.

I unloaded the Black

BeastI

cleaned the sanders I had used yesterday and put them all back. I

also cleaned up the spatulas and other items I had used yesterday to

apply the finishing

putty.

I searched out some aluminum pieces I will be needing for the main mast

sail handling platform. The sun had finally come out and was warming

things up. I left the shop

and went over to DREAM AWAY to start the preparation to apply the

first coat of gelcoat

to the hard dodger base.

When I went to wipe down the area with the tack

rag, I realized I had left the rag at the shop.

I checked in the garage on DREAM AWAY, but I had none there. I walked

back to the shop,

got the tack

rag, and walked back to DREAM AWAY.

I wiped down the area of the hard dodger base, then mixed up a batch

of gelcoat.

I applied the first coat of gelcoat to the hard dodger base and to a

bit of the surrounding area. The coat looked good. Now I was hoping I

had added enough MEKP

hardener to the mix so it would kick off before night fall.

Hard Dodger Base Before

Gelcoat Application

Hard Dodger Base Before

Gelcoat Application

Hard Dodger Base Before Gelcoat

Application

Hard Dodger Base After Gelcoat

Application

Hard Dodger Base After Gelcoat

Application

Hard Dodger Base After Gelcoat

Application

I put the

“Box O’ Resins”

away, and started in again on cutting

out the zippers from the old soft dodger. Hopefully, these zippers

will come in handy in the future.

Cutting Old Zippers Out Of Soft Dodger