Now

it was time to start with getting the Formica

off of the first piece of the main salon table. With patience and

time, I got all of the Formica

off f the first piece of the main salon table.

First

Main Salon Table Piece With Varnish And Formica

Removed

As

with the other piece, some of the plywood came off with the Formica.

So I will have to repair the two pieces before I can put the Puerto

Rico chart on the table.

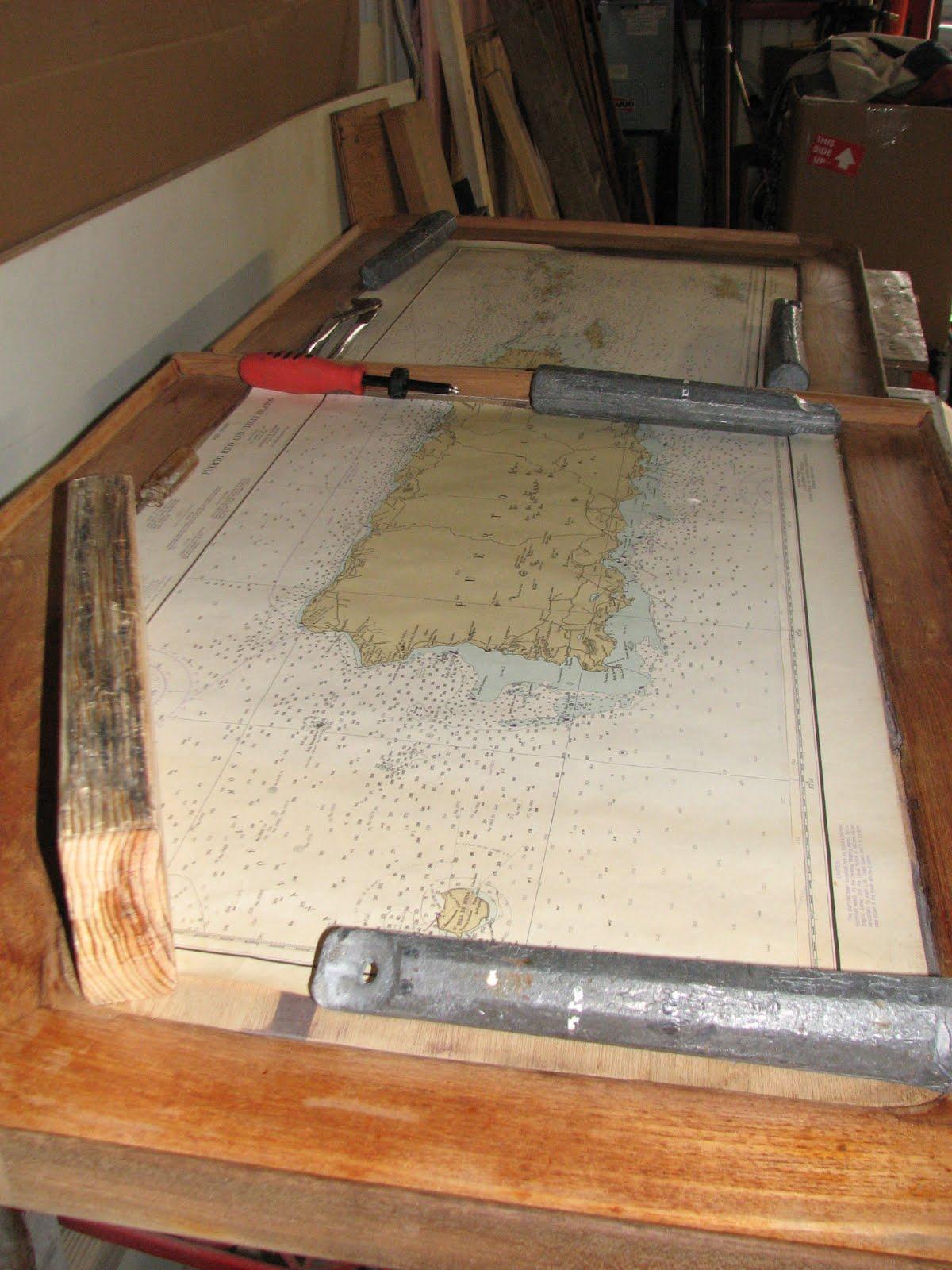

Main

Salon Table Pieces Ready For Epoxy Repair

I

got the two table pieces set up, and ready to go. I mixed up a batch

of epoxy, and added some Cabosil

as a thickener. I then applied the mix to the table tops, and filled

in the imperfections as good as possible. Based on past experience, I

will probably have to apply the epoxy filler two or three times to

get the tops really smooth.

Next

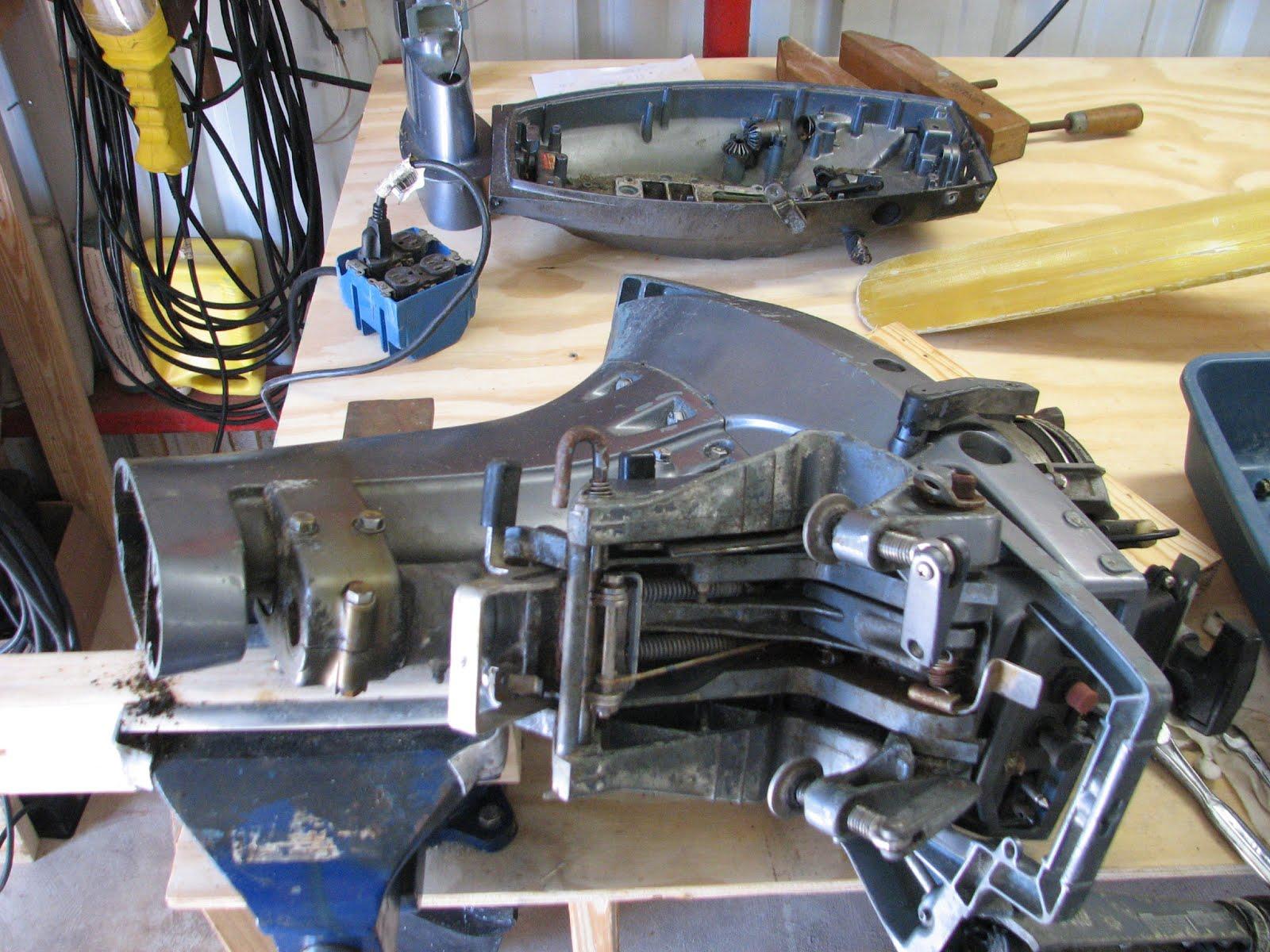

I started back working on the spare outboard motor. I have discovered

that the repair manual I have for the motor, does not cover replacing

the parts I wish to replace. So I will have to go it alone, but I am

pretty sure I will be able to get the job done. I have to remove and

replace the upper casing, and also remove the bracket. Today I

started the disassembly, but some of the stainless steel bolts were

very tight in the Aluminum casting. I stopped and sprayed all of the

bolts down with Screwloose.

Outboard

Engine And Parts On Work Bench

March

11, 2013, Monday

Started

off the morning with my normal ritual of getting on the Internet,

answering email and checking the weather.

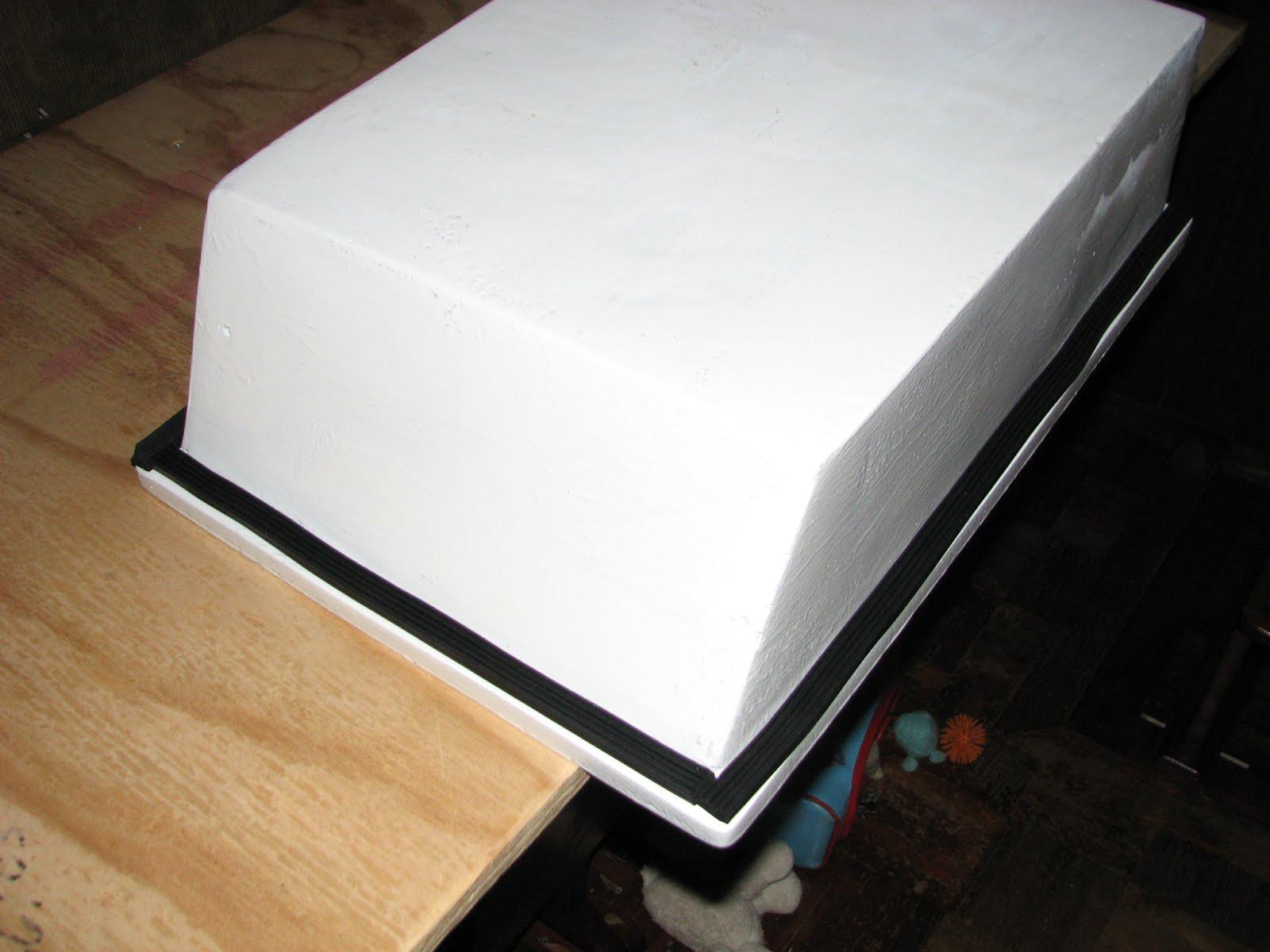

Went

over to the shop and first looked at the freezer top. It had reached

room temperature, so it was ready to paint. The problem is it was too

cold in the morning, so waited till noon when the temperature was

warmer. I used the same two part epoxy paint I had used on the

refrigerator top. I added more thinner to this batch, and it went on

very nice. Tomorrow when the paint is dried, all I have to do will be

to add the weather stripping.

Started

in again on the second main salon table piece, and finally got all of

the Formica

removed from the table top. By the end of the day, I had removed all

of the Formica

from the table top, and all of the varnish. I will have to do a

couple of repairs to the wood on the table piece because of some

gouges made while removing the Formica.

The first main salon table piece is now ready for the Formica

removal.

Second

Main Salon Table Piece With Varnish And Formica

Removed

First

Main Salon Table Piece Ready For Formica

Removal

March

10, 2013, Sunday

Started

off the morning with my normal ritual of getting on the Internet,

answering email and checking the weather.

Went

over to the shop and checked on the painted drawer and the painted

refrigerator top. Both looked good, and dry. I then cut the

weather stripping and applied it to the underside of the refrigerator

top.

Refrigerator

Top With Weather Stripping Applied

Started

in on removing varnish from the first piece of the main salon table.

I used scrapers rather than a heat gun, but I may give the heat gun a

try, and see if it is any easier.

Removing

Varnish From First Main Salon Table Piece

Went

back to DREAM AWAY for lunch, and took the painted drawer and the

finished refrigerator top. I put the refrigerator top back into its

place after removing the temporary top. I also put the newly painted

drawer back into it’s place, and all of my T-Shirts back into the

drawer. Before leaving DREAM AWAY to go back to the shop, I put the

temporary top in the freezer, and took the freezer top back to the

shop.

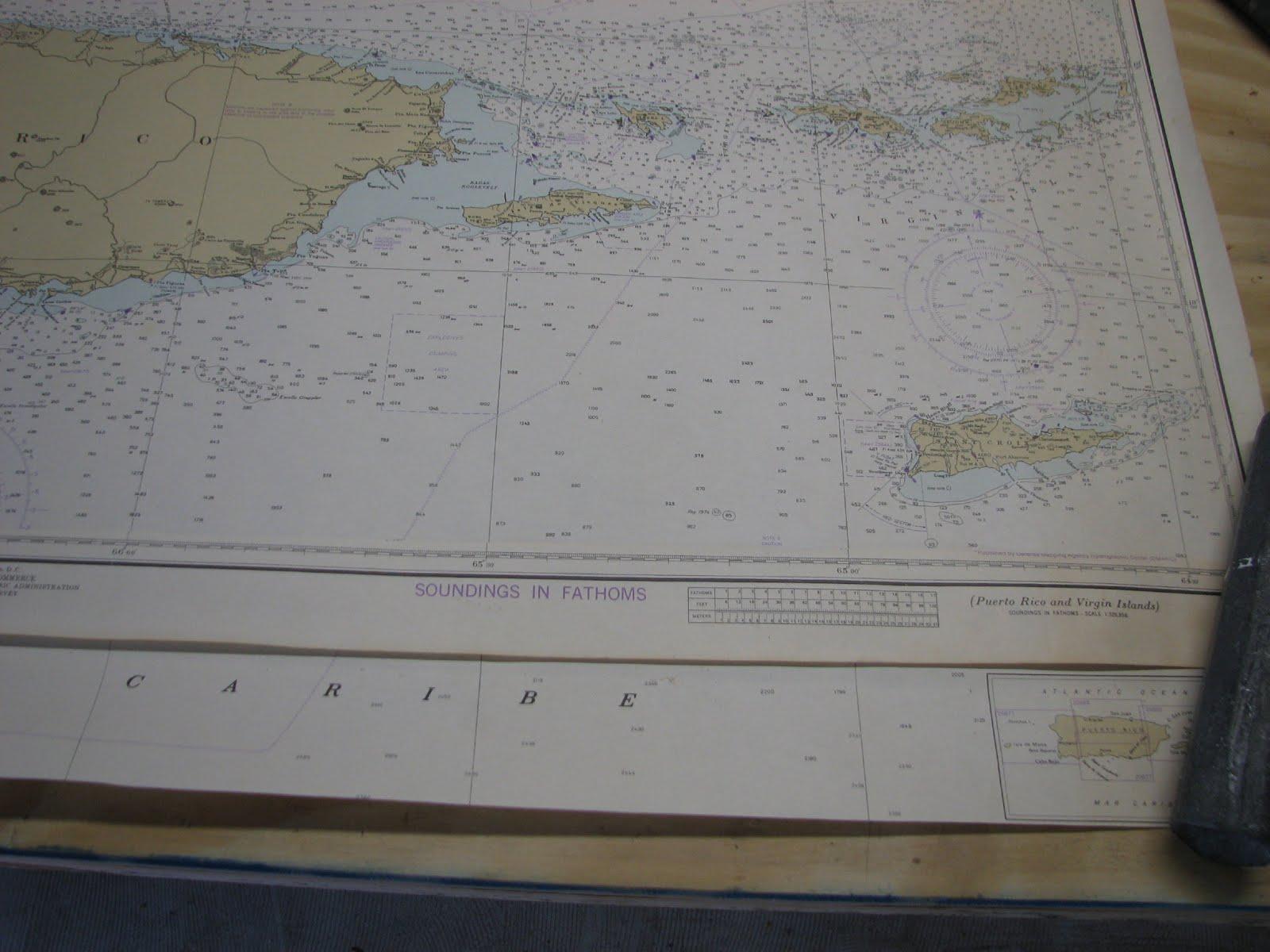

I

finished the varnish removal on the first piece of the main salon

table. I started in on the second piece of the main salon table. I

removed all of the epoxy and the chart from the table. While doing

this, I discovered the table top was actually covered with Formica.

This was probably why the epoxy did not stick to the table. I started

in removing the Formica

from the table top. This was much harder than removing the epoxy.

Removing

Formica From Second Main Salon Table Piece

It

is more effort, but I believe the epoxy will stick much better to the

wood than the Formica.

I

was not able to paint the freezer top because it never reached room

temperature. With any luck, I will be able to paint the top tomorrow.

Freezer

Top Coming To Room Temperature

March

9, 2013, Saturday

Started

off the morning with my normal ritual of getting on the Internet,

answering email and checking the weather. I also had a bunch of

scanning to do and updating spreadsheets.

I

had brought over to DREAM AWAY the new temporary reefer top, and the

new temporary table. After breakfast, I installed the new temporary

top in the reefer. Easy to do, pull out the original, and insert the

temporary.

Temporary

Top Installed

Next

was to remove the original main salon table and install the temporary

main salon table. This was a more time consuming, as the table is

bolted down to the table base. I got the job done and we now have a

fine new unfinished plywood table in the main salon.

Table

Base With Table Removed

Table

Top Pieces Removed From Table

New

Table Top In Main Salon

Now

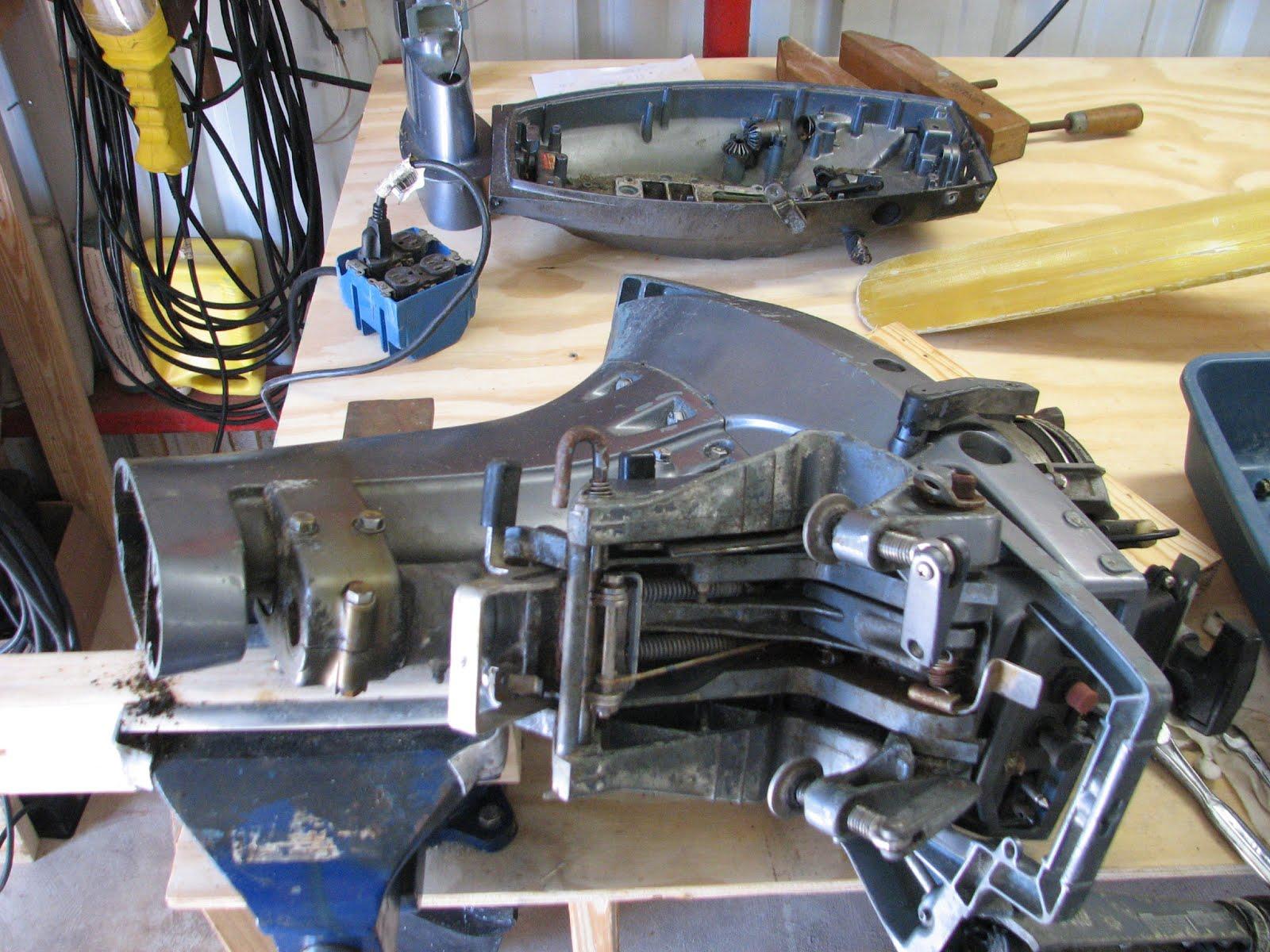

I loaded the main salon table parts and the old reefer top into the

Black Beast, and took them over to the shop. When I got to the shop,

I had to change priorities. I was last working on the spare outboard,

but that will have to be put on the back burner until I get the

reefer/freezer tops and the main salon table finished.

Outboard

Parts On Work Bench

First

on the agenda was to get the reefer top cleaned up and ready for

painting. This was pretty easy to do. Scrape the old weather striping

off of the top, then wipe the top down with acetone. Then I sanded

down the top so it was nice and smooth, and again wiped it down with

acetone.

Reefer

Top Ready For Paint

Now

it was time to work on the main salon table top. First was to remove

all of the old epoxy and chart that was on one half of the table. If

you remember the main salon table is a drop

down table, so the top is

actually in two pieces. This was not too bad, as the epoxy came off

pretty easy. I finished the first piece of the table, and cleaned up

from that. Pieces of broken epoxy went all over.

Removing

Epoxy From Table Top

Now

it was time to prepare for the painting. Because I do all type of

work in the shop, I do the painting last, so I get get the shop

cleaned up and allow the dust to settle. So far it seems to be a good

plan.

I

decided to try painting the reefer top. I have had good luck with a

two part epoxy paint I had purchased in Guatemala, so I decided to

use it on the reefer top. I checked the drawer that I had painted

yesterday with a water base latex paint. It looked real good, so I

used a tack rag and wiped down the inside of the drawer, and the

reefer top. I then mixed up the two part paint, and was ready for the

application phase.

Reefer

Top Ready For Painting

Drawer

Ready For Second Coat

I

the applied the two part epoxy paint to the reefer lid. The paint

went on very well, but I think I could have used more thinner. When I

do the freezer lid, I will add more thinner.

Painted

Reefer Top

Cleaned

up the area and the brushes from the reefer top application, and the

applied the second coat of paint to the drawer.

Drawer

With Second Coat Of Paint

Cleaned

up the area and the brushes from that project, closed up the shop and

went back to DREAM AWAY. When I got back to DREAM AWAY, I mixed up a

batch of soap and water, and scrubbed out the tender. It was in

pretty bad shape, very dirty, so it needed attention. I wanted it

cleaned out so I can get the upgraded Yamaha outboard on it and

tested.

I

also scrubbed down the back ¼ of DREAM AWAY. The whole boat is in

need of a cleaning. I will finish that job tomorrow or the coming

Monday.

March

8, 2013, Friday

Started

off the morning with my normal ritual of getting on the Internet,

answering email and checking the weather.

Spent

the whole day in the shop except for a breakfast break.

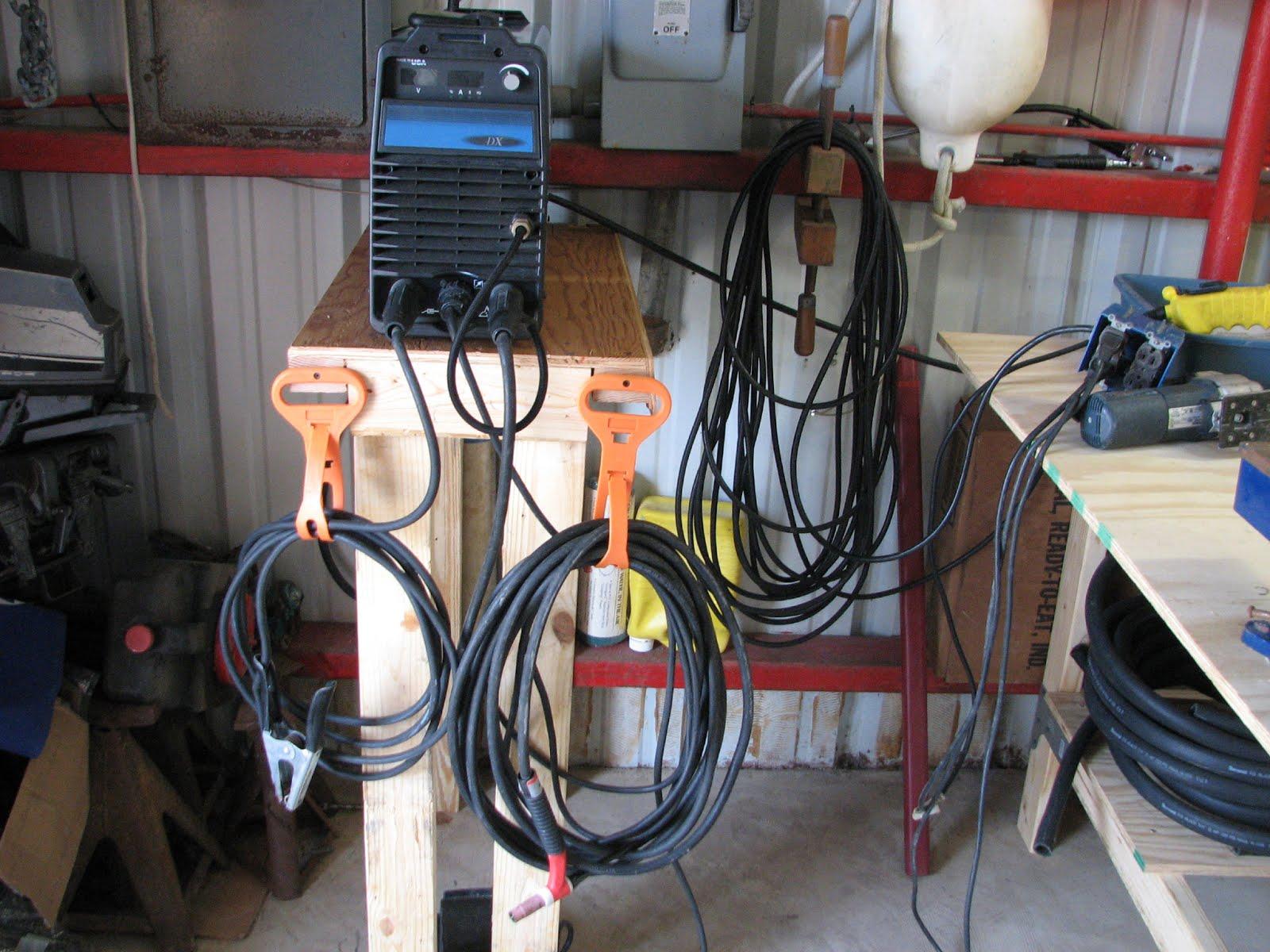

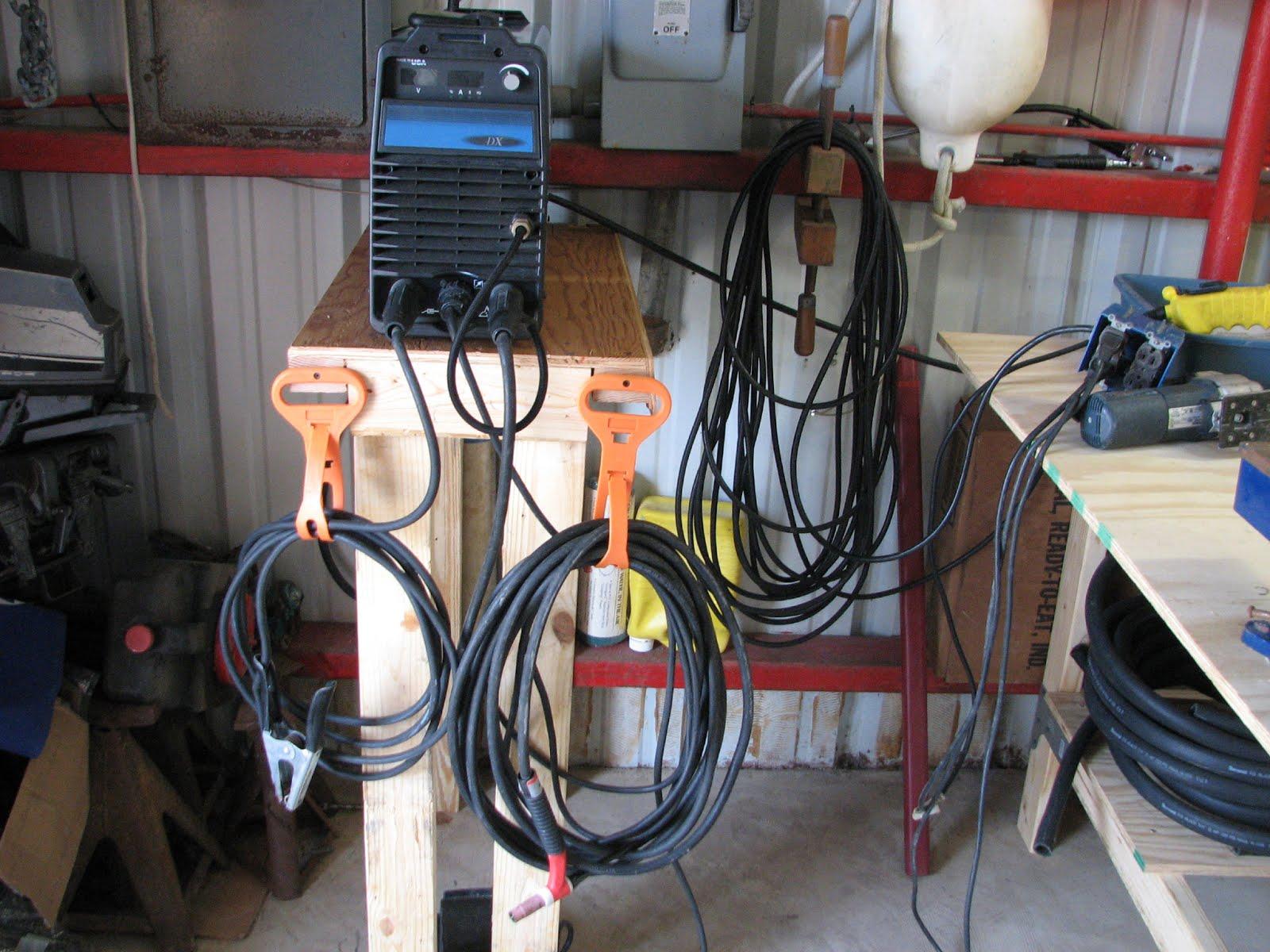

First

item on the agenda was to finish the welder table, and get the welder

set up. I completed this task and also checked out the welder to make

sure it functioned. I was able to draw an arc on stainless steel. The

welder and the auto darkening helmet functioned perfectly.

Table

With Welder Set Up.

The

next project was to get the small table for the hand power tools to

set on. I have a roll around table, but when I want to do some dirty

work, I take the roll around table outside to do the work on, but I

have to set all of the hand power tools on the floor. Not a good

solution. I built a small table and used empty plastic containers as

the legs.

Small

Tool Table

The

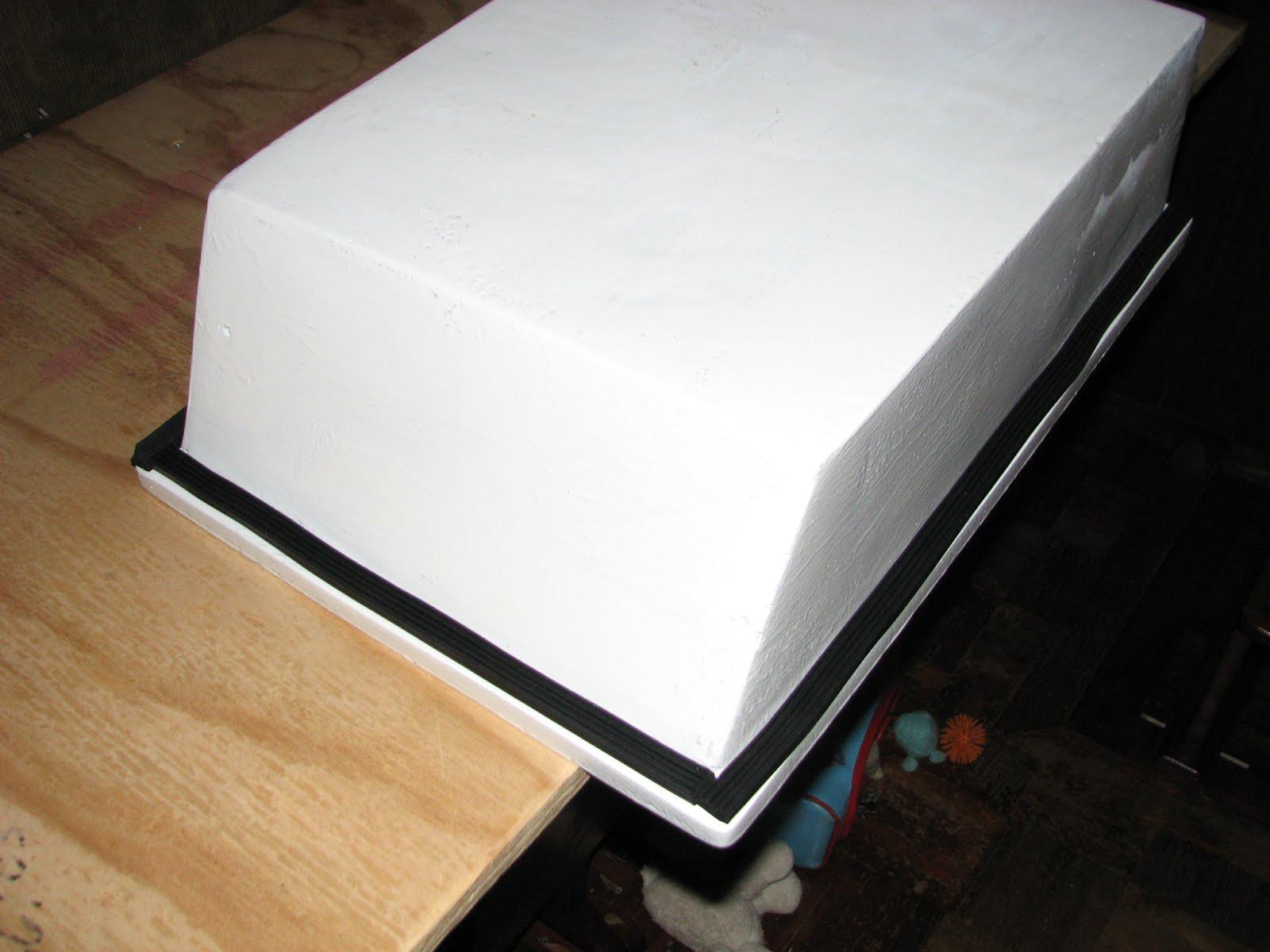

next project was to complete my “temporary” tops for the

refrigerator/freezer. I have to replace the sealing strips around the

tops, but to do that the tops have to be dry and reach room

temperature. I need “temporary” tops to fill the space while I am

working on the real tops. I calculate I will need a day or two to

complete the sealing upgrade to the tops. I decided to use ½”

pieces of insulation glued together with Liquid

Nails. I finished

fabrication of the “temporary” top, and I am ready to get the

real tops over to the shop and finished as quickly as possible.

Fabricated

“Temporary” Top

Next

on the list for today was to get a T-Shirt drawer off of DREAM AWAY,

so the interior of the drawer could be painted. We have discovered

over the years, that if you leave the teak inside of drawers

unpainted the oils in the teak will leach into the clothing, and ruin

it. I have been slowly taking drawers off of DREAM AWAY, and getting

the drawer interior painted.

This

picture is of scraping the old paint out of a drawer.

Another

project have been wanting to get under way is to repair the table in

the main salon. As you may remember I refinished the main salon table

several years ago.

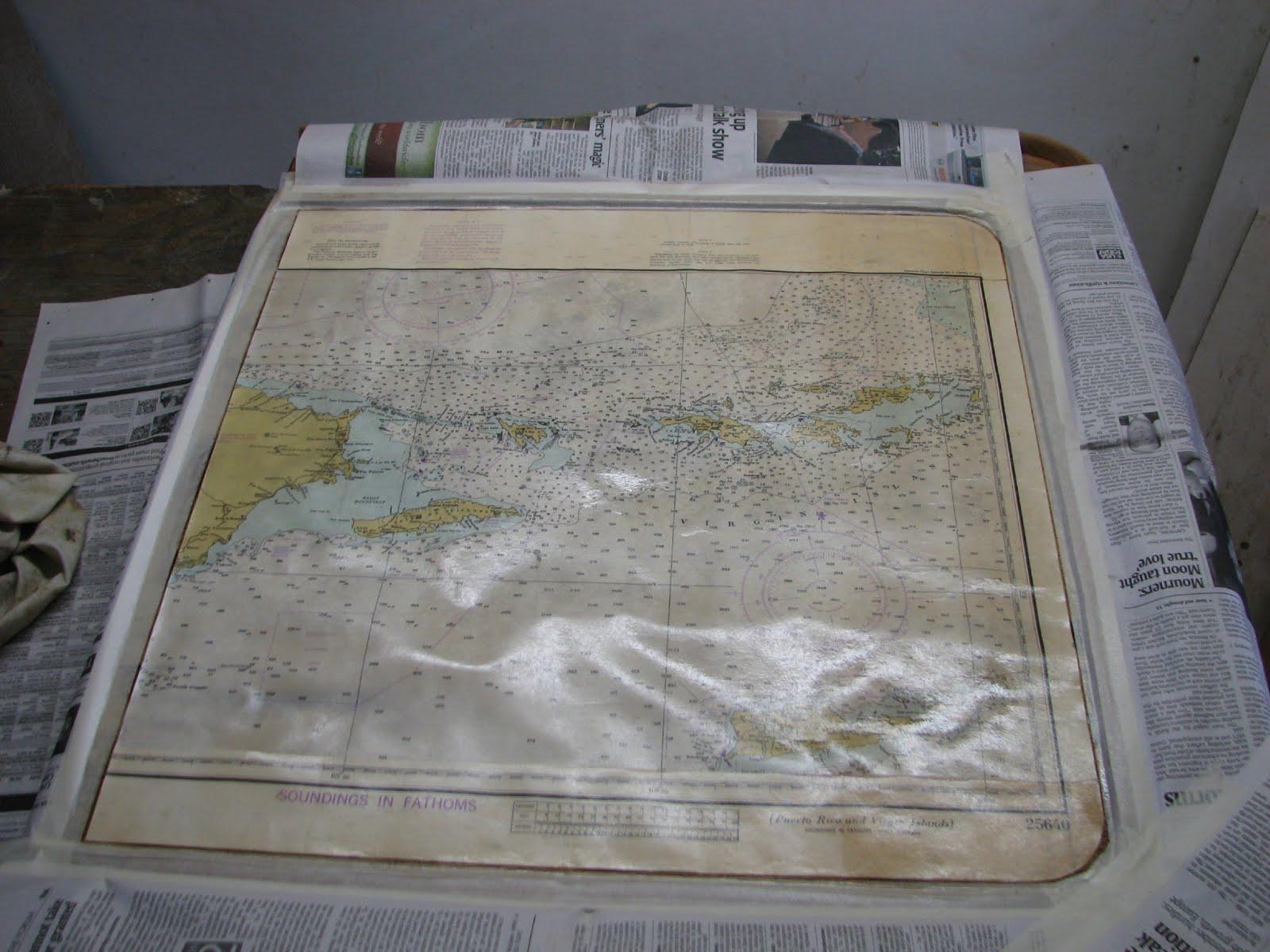

Main

Salon Table

I

put a chart of Puerto Rico on the table, and covered the table with

an epoxy resin. I did not use the proper resin, and the layer of

epoxy has lifted off of the table. Now I have to redo the chart on

the table, and also varnish the table.

The

bar top epoxy I ordered from AeroMarine

Products arrived today.

This is the resin I will use on the table to cover the chart of

Puerto Rico.

Because

I am taking the table out of the main salon, I constructed a

“temporary” table to use while I am working on the refit of the

original table. It will probably take two to three weeks to get the

table done. It will take five or six days just for the varnish!

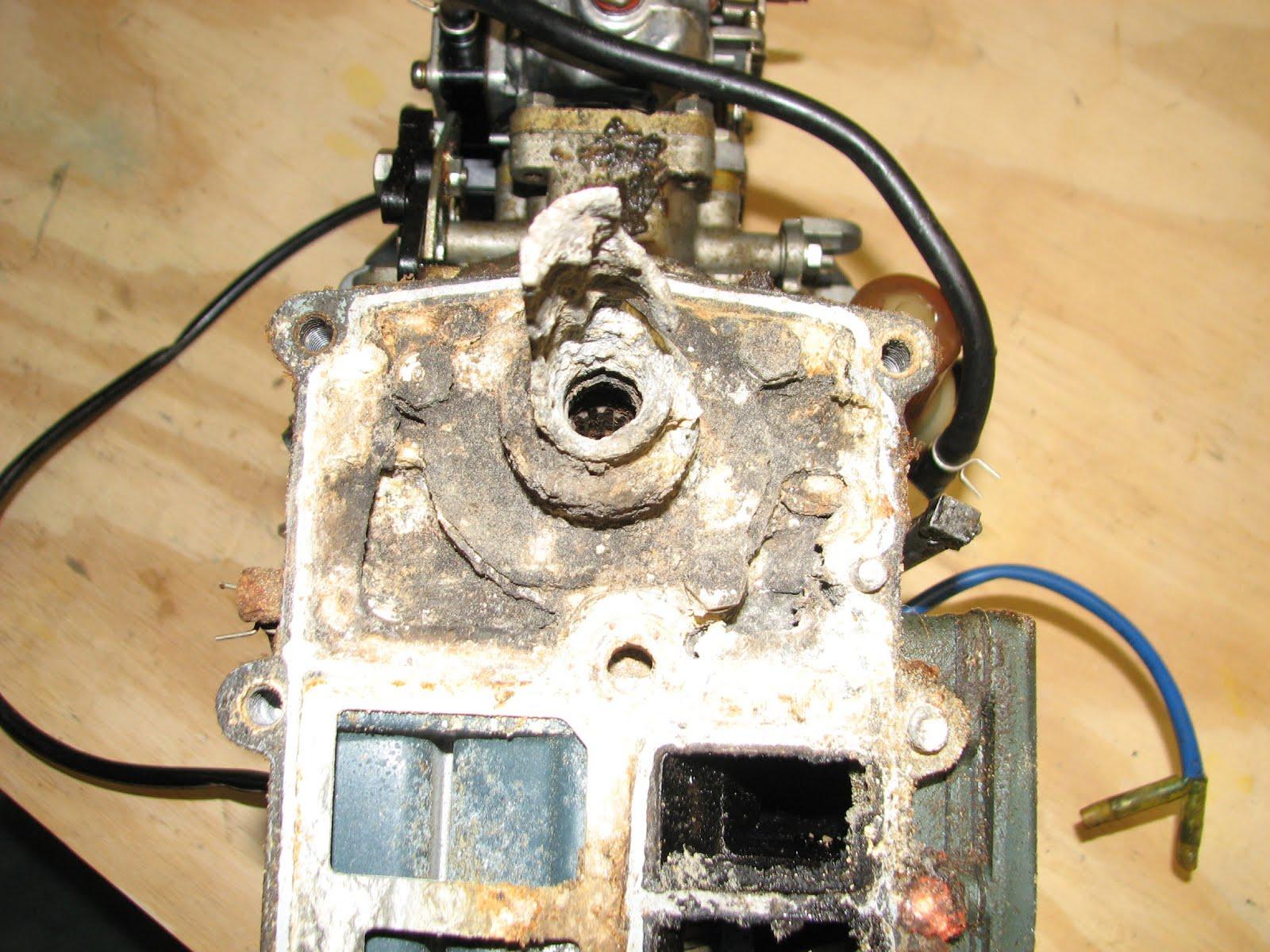

The

last project I worked on today was starting on the upgrade of my

spare Yamaha 15 HP outboard. I will not bore you with the whole

story of how I ended up with the extra outboard, I just did.

The

spare outboard had some damage in shipment, and needed the upper

casing replaced. Because of

my experience with the original outboard, I knew I needed to make a

long shaft out of the outboard, so it could be used with our

Livingston

tender.

Being

the patient sort, I have been obtaining all of the necessary parts I

would need for the repair and the upgrade from eBay. It has taken a

couple of years, but I have them all together.

I

sorted through all of the parts, and I have been spraying down all of

the bolts on the motor with Screwloose

so I would not have any problems with backing out all of the bolts.

I

checked out the new lower

drive unit, and verified

the water pump impeller is good. Everything else in the lower

unit seems to be good. I

have not checked the oil in the lower

unit, but will get on that

tomorrow.

Before

leaving for the day, I applied the first coat of paint to the drawer

I cleaned out, and sanded in preparation for the painting process.

March

7, 2013, Thursday

Started

off the morning with my normal ritual of getting on the Internet,

answering email and checking the weather.

I

then went over to the shop and got the damaged air conditioner ready

for pickup. The unit was damaged in shipment from Tampa to Delcambre.

It really was not packed very well, and resulted in damage. This is a

Cruisair

air conditioner I purchased off of eBay as a spare in case the new

one I purchased fails. The original Cruisair

unit lasted 18 years, so I have confidence in their systems.

I

had a store room mate give me some seats he was throwing away. I

wanted to salvage the foam and the wood. Not sure what I would use

them for, but did not want to throw them away.

I

decided I needed to use the wood to build a table to put my welder

on. I wanted the welder up, and out of the way, but also easy to

access when I start the welding projects. I spent the time stripping

the seats getting the foam and wood separated.

We

had to drive to New Iberia, and on the way I went by Xtreme Marine,

and saw they had a pallet out by their dumpster. I told Kitty when we

come back, and the pallet is still there I want to get it. We came

back, it was there, I got it. We took it to the shop, and I went to

work on taking the pallet apart. Bottom line is I have enough wood to

build the welder table and another table to put my small electric

tools on. This will get them up and out of the way. Tomorrow I hope

to finish the tables, and work on temporary lids for the

reefer/freezer.

March

6, 2013, Wednesday

Attended

a Seafood

Academy session in the

morning. It was a worthwhile effort, and I learned a lot of

information about the seafood industry in general, and the shrimping

industry in Louisiana. We also met a couple of new friends that came

over to DREAM AWAY and visited.

Worked

in the forward cabin, and got out the bottle of argon, and all of the

other welding parts. I have to run the wiring, and build a small

table, but hope to get the welder operational very soon.

March

5, 2013, Tuesday

Attended

a Seafood

Academy session in the

morning, and then helped Kitty with errands and chores getting ready

for the Southwest International In The Water Boat Show.

March

4, 2013, Monday

Nice

warm day when I went over to the shop. Messed around with the Yamaha

outboard, but still could not figure out why the outboard is

difficult to shift. Played around with electric start kit, but first

have to remove the flywheel. Will need some way to hold the flywheel,

and loosen the bolt, and then will need a puller.

Messed

around with the wood I will need to fix up and cover the area in the

aft cabin where the backing plates are for the aft cleats and the

dinghy davits.

I

sanded down all of the pieces of teak wood on which I had put the

fourth coat of varnish. I wiped down all of the parts with a tack

rag. I then filtered the varnish, and applied the fifth coat to the

teak wood pieces. I will probably put on a sixth coat of varnish and

call it quits. After all this is inside wood, so six coats applied

with a brush should be adequate. If the wood was exterior, it would

require at least 12 coats, and a tape change every four to five

coats.

March

3, 2013, Sunday

Another

cold day but very sunny, and warmed up as the day went on. I went

over to the shop, and continued with the Yamaha long shaft extension

kit installation. I installed the studs and all of the extension

pieces. Before I put the gear housing back on the engine I took the

water pump apart and made sure the impeller was in good shape. It was

so it all went back together. The gear housing went back on the

engine with no problems. I am anxious to get the engine on the dinghy

and test out the long shaft.

I

still have to install the electric start option, but that will come

as soon as I can get some drawings to show exactly how all the parts

go into and attach to the engine. I also spent some time trying to

figure out why the shift mechanism is so hard to shift. I was not

able to come to a resolution. The shift mechanism is not mentioned at

all in my Yamaha manual, so I will have to see if I can find another

manual that cover this issue.

Next

I worked on the vice. The vice jaws are steel, and very hard. I had

some pieces of angle aluminum which I cut to the size of the jaws and

hammered them onto the jaws. Now I can put wood and soft metals into

the vice without having to worry about damaging it.

I

had sanded all of the teak wood pieces yesterday, so I wiped down all

of the parts with a tack rag. I then filtered the varnish, and

applied the fourth coat to the teak wood pieces.

March

2, 2013, Saturday

Today

was a cold day here in Delcambre, so did not go over to the shop

until around noon. In the morning I spent my time on the computer

checking weather, and scanning in paperwork by the pound! Eventually,

I will get most of the paper off of the boat and onto electronic

media.

When

I did get over to the shop, I was able to install the second shop

light I had purchased this past Thursday. I had to go to the hardware

store and purchase a plug, but got the light up and working over the

workbench. I must remember to bring my camera with me to take photos

of the progress.

I

had sanded the teak wood pieces yesterday, so all I had to do was

apply the fourth coat of varnish to all of the teak wood pieces.

I

then started into working on my primary 15 HP Yamaha outboard. On

this motor I am installing an extension kit from Bay

Manufacturing who makes a

specific extension kit to make the engine a long shaft. I had been

applying PB

Blaster to all of the bolts

on the engine, so they would be easy to remove. As I thought the

bolts came right out, so I was able to remove the gear housing from

the motor. Hopefully installing the extension kit will be pretty

easy going. Once that project is complete, I have to install the

electric start kit on this engine.

By

1500 in the afternoon, I was getting cold, so I headed back to DREAM

AWAY, and continued with paperwork scanning project.

March

1, 2013, Friday

We

got some domestic chores taken care of, and then I went over to the

shop. I finished getting all of the stuff from Alan’s storeroom put

away, and generally straightened up the area to make the shop more

productive, and easier to use.

I

was able to get one of the shop lights installed over the saw table.

The second light I was not able to install, because I did not have a

power plug for it. The good news is when I left the shop, the first

light was still working.

I

sanded down all of the pieces of teak wood on which I had put the

third coat of varnish. The sandpaper I used was 320 grit, so I was

just preparing the surface for the next coat. It was late in the

afternoon, and getting cold, so I did not apply the fourth coat of

varnish.