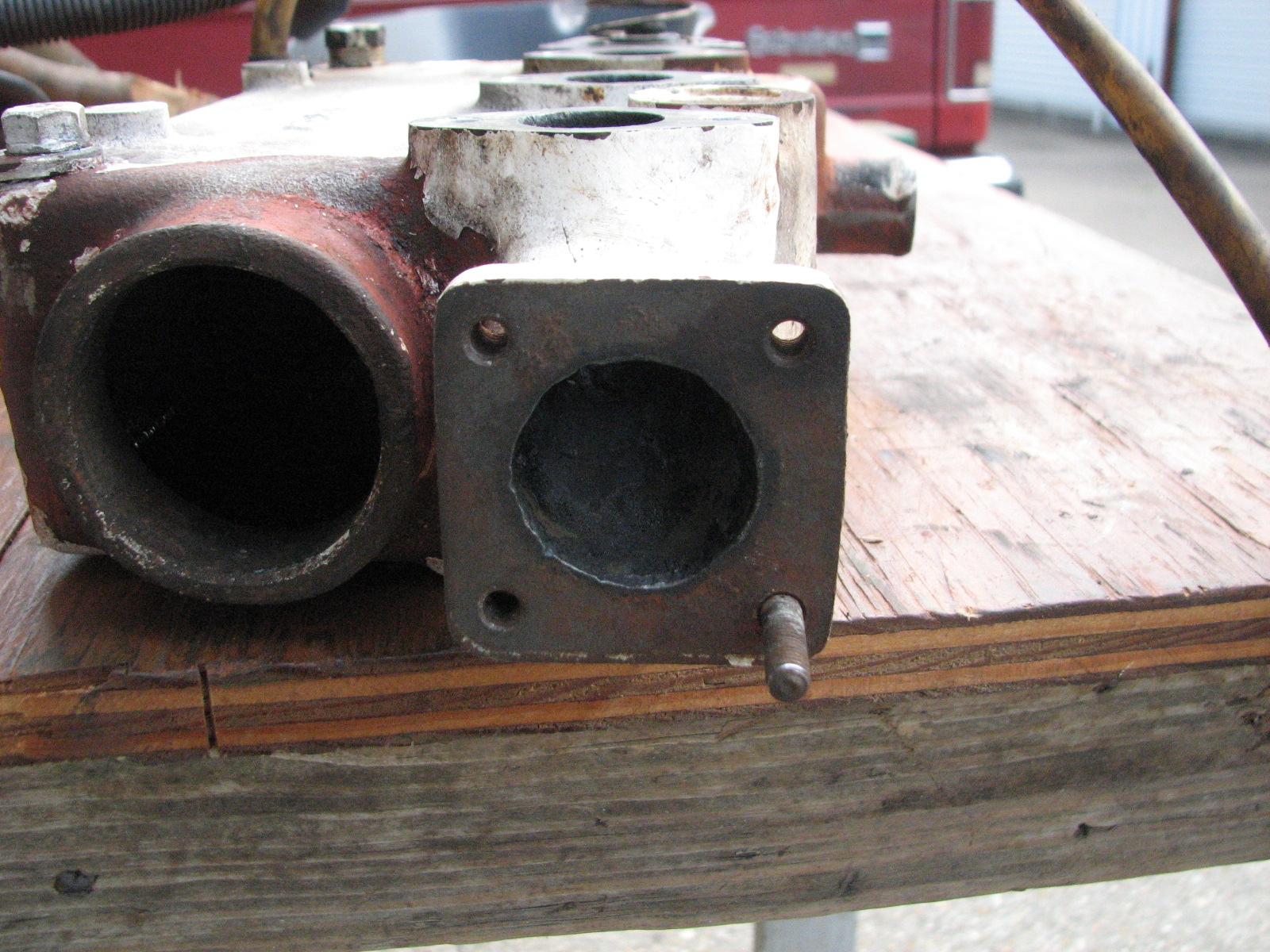

Cleaned Out Exhaust Elbow

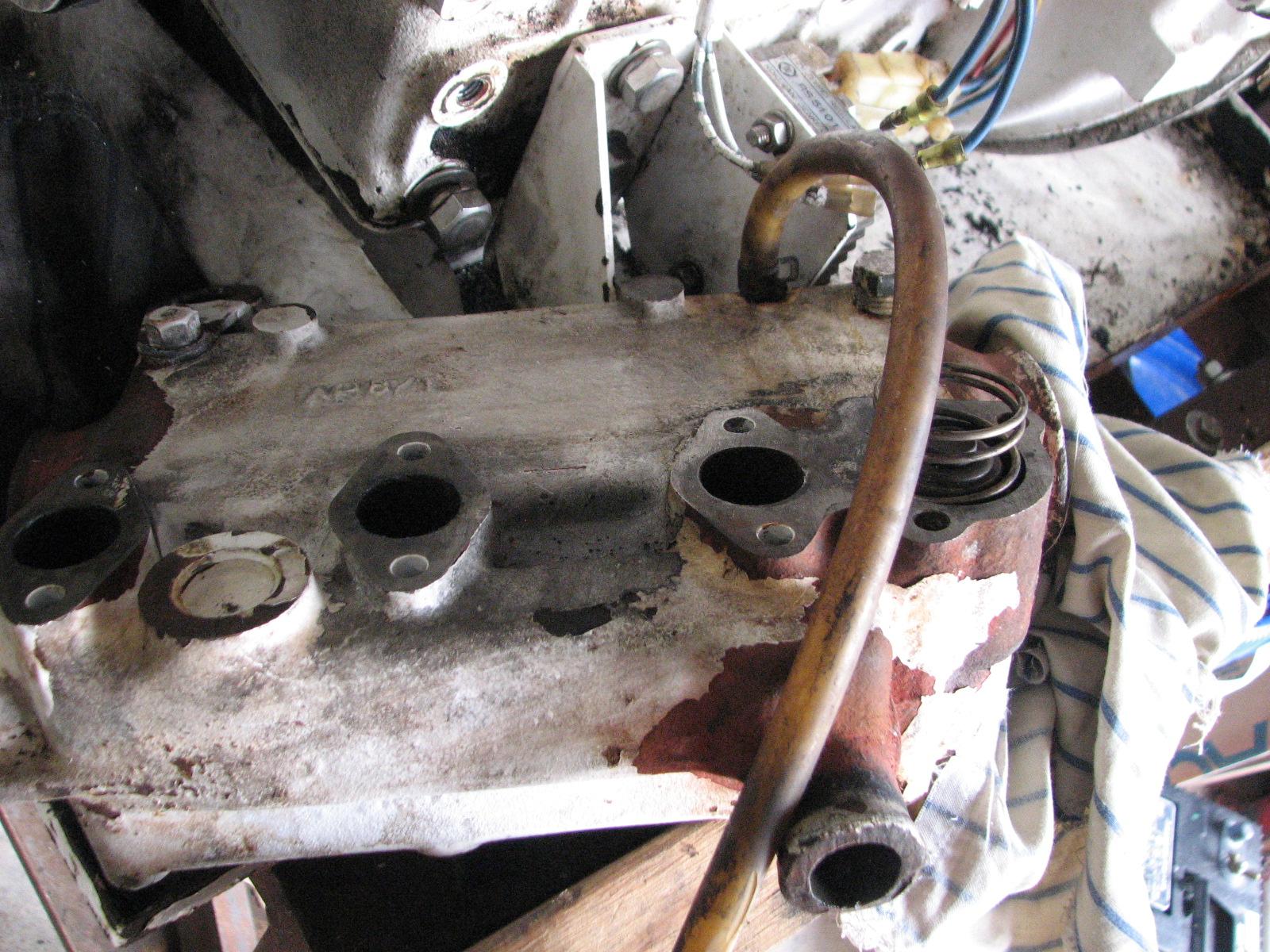

Clogged Exhaust Manifold

Clogged Exhaust Port In Manifold

Cleaned Exhaust Manifold

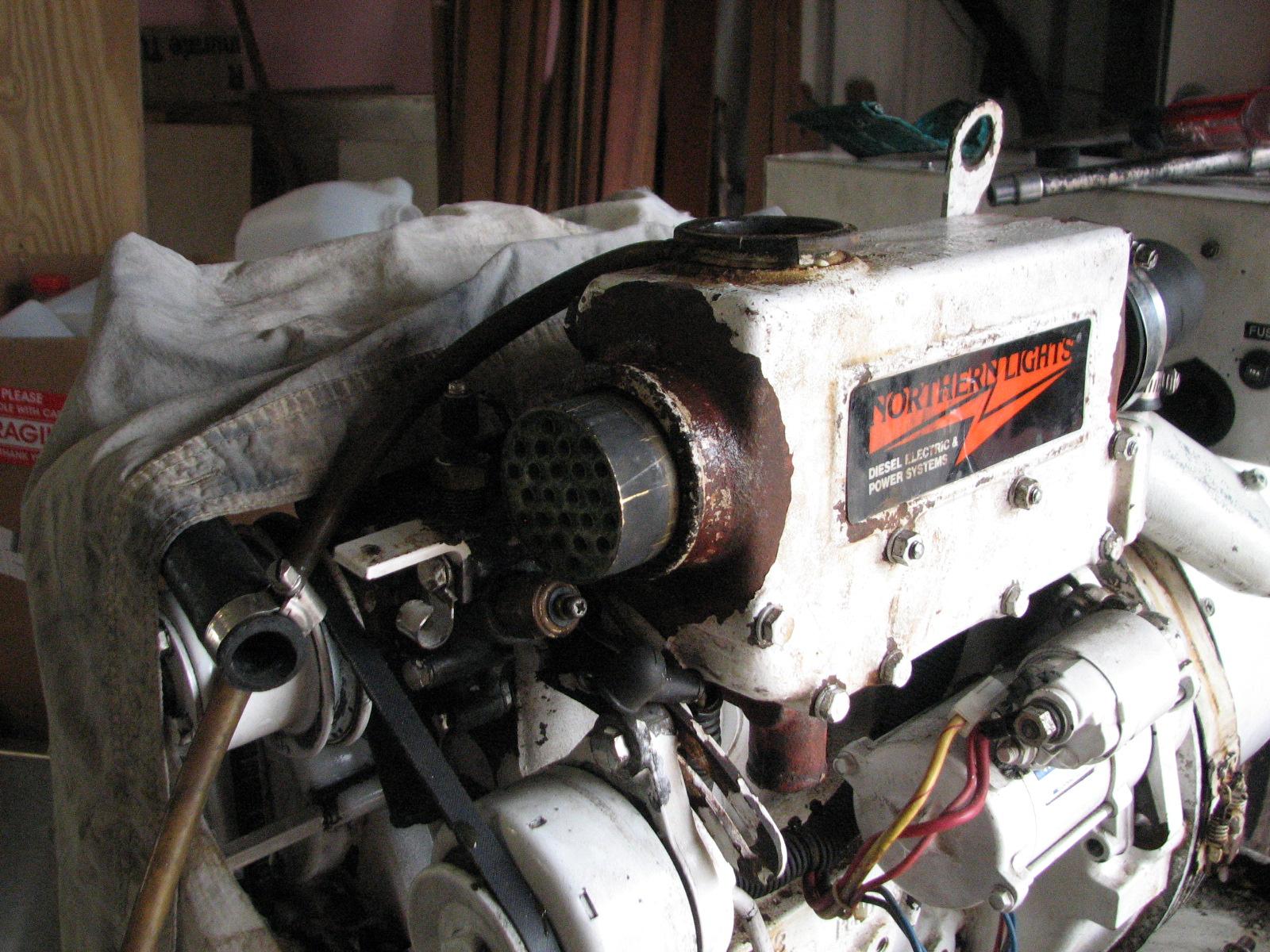

When that major cleanup job was

complete, I installed the exhaust manifold on the head, the exhaust

elbow on the manifold, and finally inserted the heat exchanger into

the exhaust manifold. The last item for this installation was the

rubber fittings at either end of the exhaust manifold to separate the

raw water from the fresh water used to cool the engine.

Head Ready For Manifold Installation

Exhaust Manifold Ready For Installation

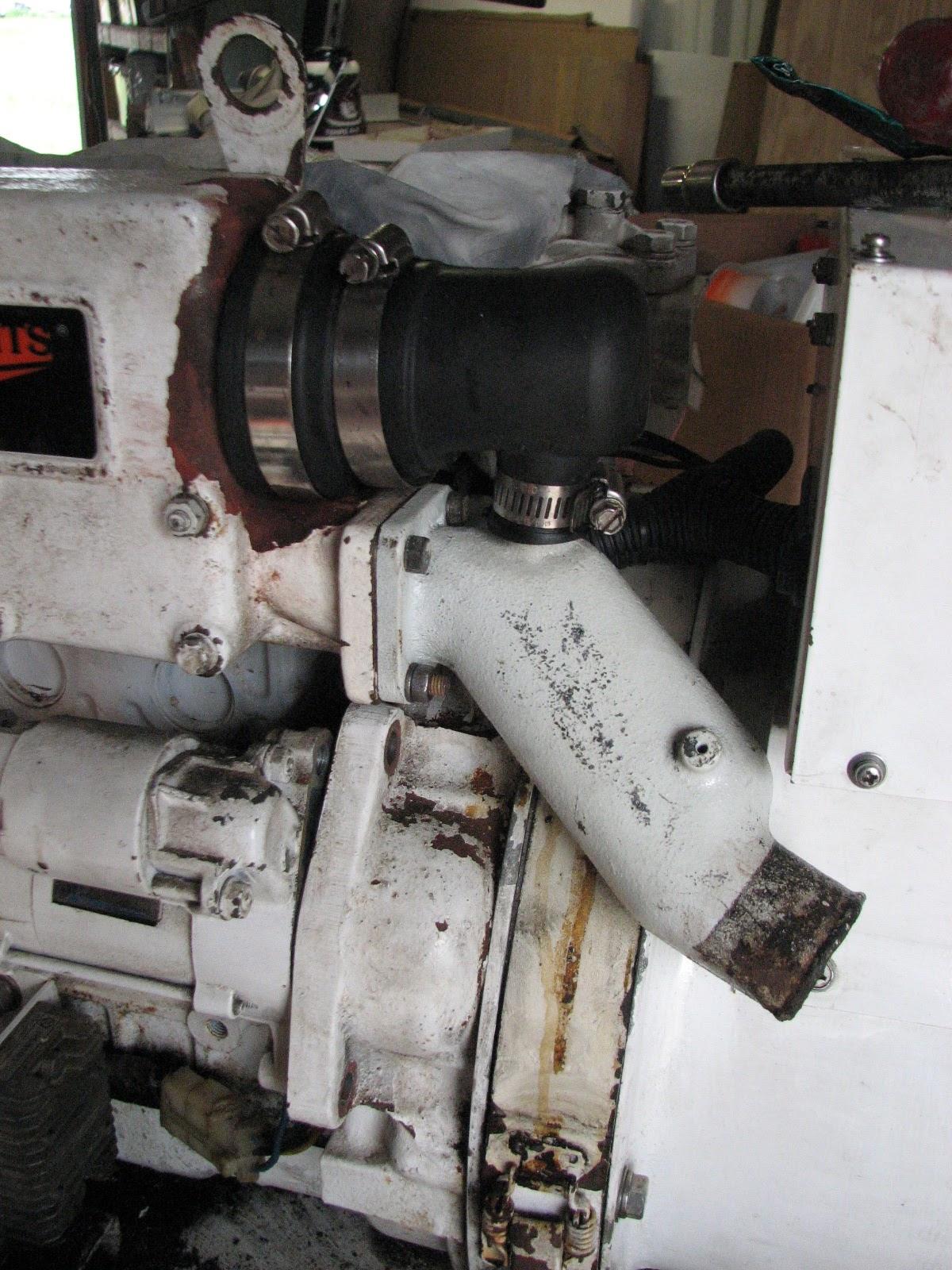

Exhaust Manifold Installed, Heat

Exchanger In

Exhaust Elbow Installed On Manifold

That was it for today, back to DREAM

AWAY for a well deserved shower and adult beverage!!

March 22, Saturday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee.

Worked on computers, ordered 2 new

PC’s; will load Linux and run virtual machines; drove Red Beast

(Ruby)

home to Delcambre, no problems encountered

Before Jim got up in the morning, I had

ordered two Toshiba

PC’s off of eBay,

and I was on my way! Jim burned me a couple of DVD’s with Suse

Linux on them to take home with me so I could install

it when the PC’s arrived.

We did some working on Ruby,

and also fluid checking before I headed out to Delcambre.

Jim and I went to the local Waffle

House for breakfast. Jim went back home, and I headed

out to drive home. In total it was about an eight hour drive.

Jim In Front Of Ruby

Before Heading Home

Jim In Front Of Ruby

Before Heading Home

When I returned to Delcambre, Kitty had

a present for me - Fuzzy Dice!

March 21, Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee.

Jim and I got up early in the morning

and we worked on the old Gateway computer of mine. We also discussed

possible solutions to my long term computer needs.

One solution that we came up with was

to order two new PC computers that are exactly the same, and run

Linux

on them. Having two machines exactly the same means there is no

problem having a backup computer.

If I run Linux

I would be able to run my navigation software in a Windows virtual

machine. Hopefully all the other utilities and programs that I have

become accustomed to on the Mac will also be available on the PC

running Linux.

Jim and I then headed south, after a

breakfast at the local Waffle

House. We drove to

Fairfield, Texas, and picked up Ruby.

We drove back to Dallas, and Ruby

performed with no problems.

Jim and I talked more about the two PC

solution to my computer problems, and Stacy liked the idea, and was

behind it 100%.

March 20, Thursday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Spent most of the morning working on

the Gateway computer trying to get it up and functional as a useful

computer. This Gateway has a lot of broken pieces on it so do not

know how long it will last as the main navigation computer or as the

backup. Time will tell.

Kitty took me to the airport in

Lafayette

so I could fly to Dallas.

I will be spending a couple of days with my good friend Jim Bates. We

will definitely be talking about computers, and he is driving me down

so I can pick up my new truck (toy). We did call it the

Red Beast but Kitty likes

Ruby

better, so that is what she will be called in the future. The name

actually comes from Red Beast = RuBy.

Had an uneventful flight to Dallas and

Jim picked me up with no problems.

Jim made some great ribs for dinner

with all of the fixins’, and we talked about our past careers, and

what I am going to do about my computer situation.

Jim Working On The Ribs While Cooking

Jim Working On The Ribs While Cooking

The Finished Product We had For Dinner

I just had to throw in a photo of Jim’s

Granddaughter.

Braylyn Laying On The Couch

March 19, Wednesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

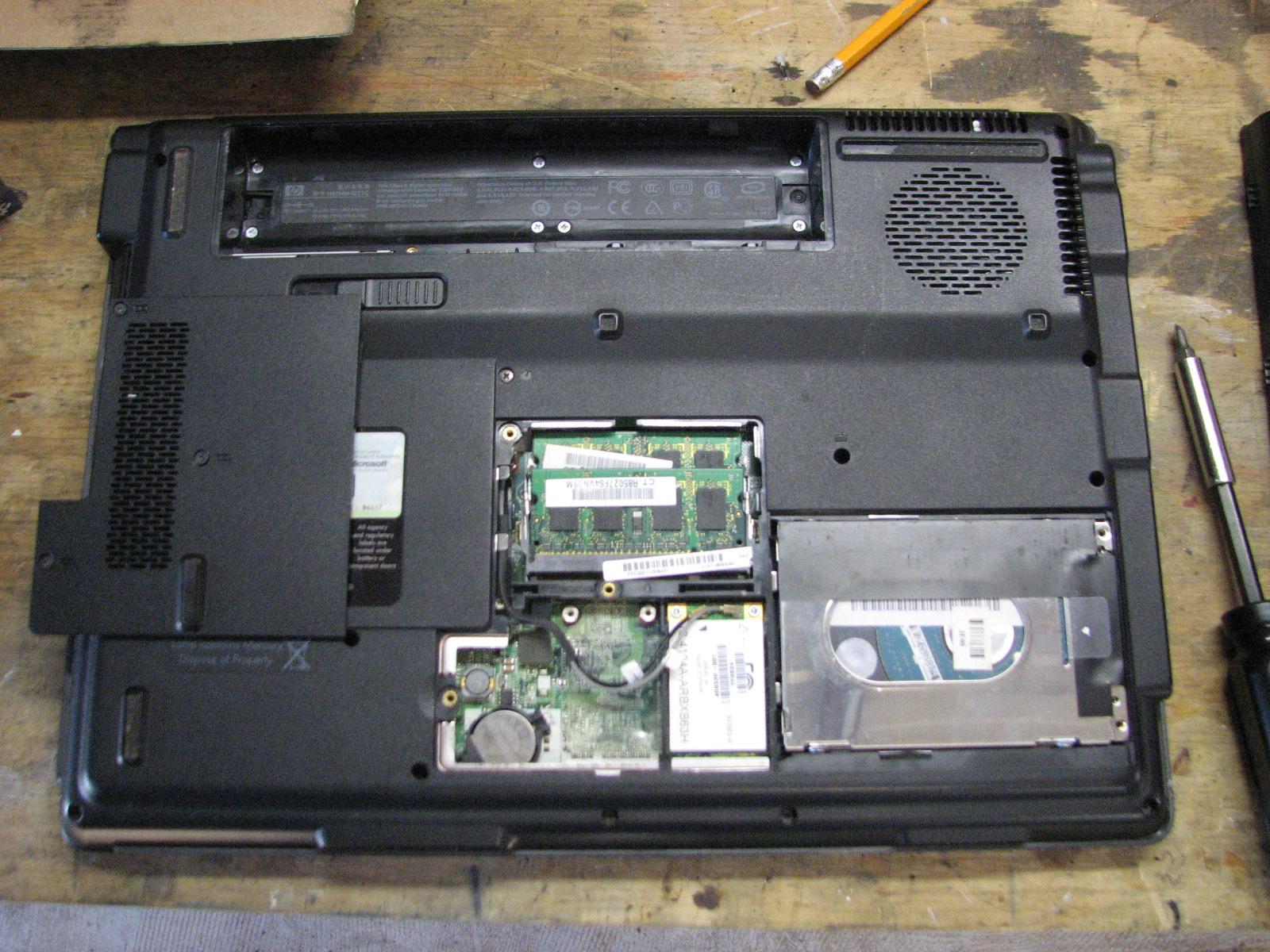

Went over to the shop

this morning and removed the WiFi card out of an old PC we had stored

there. I am taking the WiFi card back to DREAM AWAY to put into the

Gateway PC to see if it will fix the WiFi problem on it.

XXX

Removing WiFi Card From Old PC

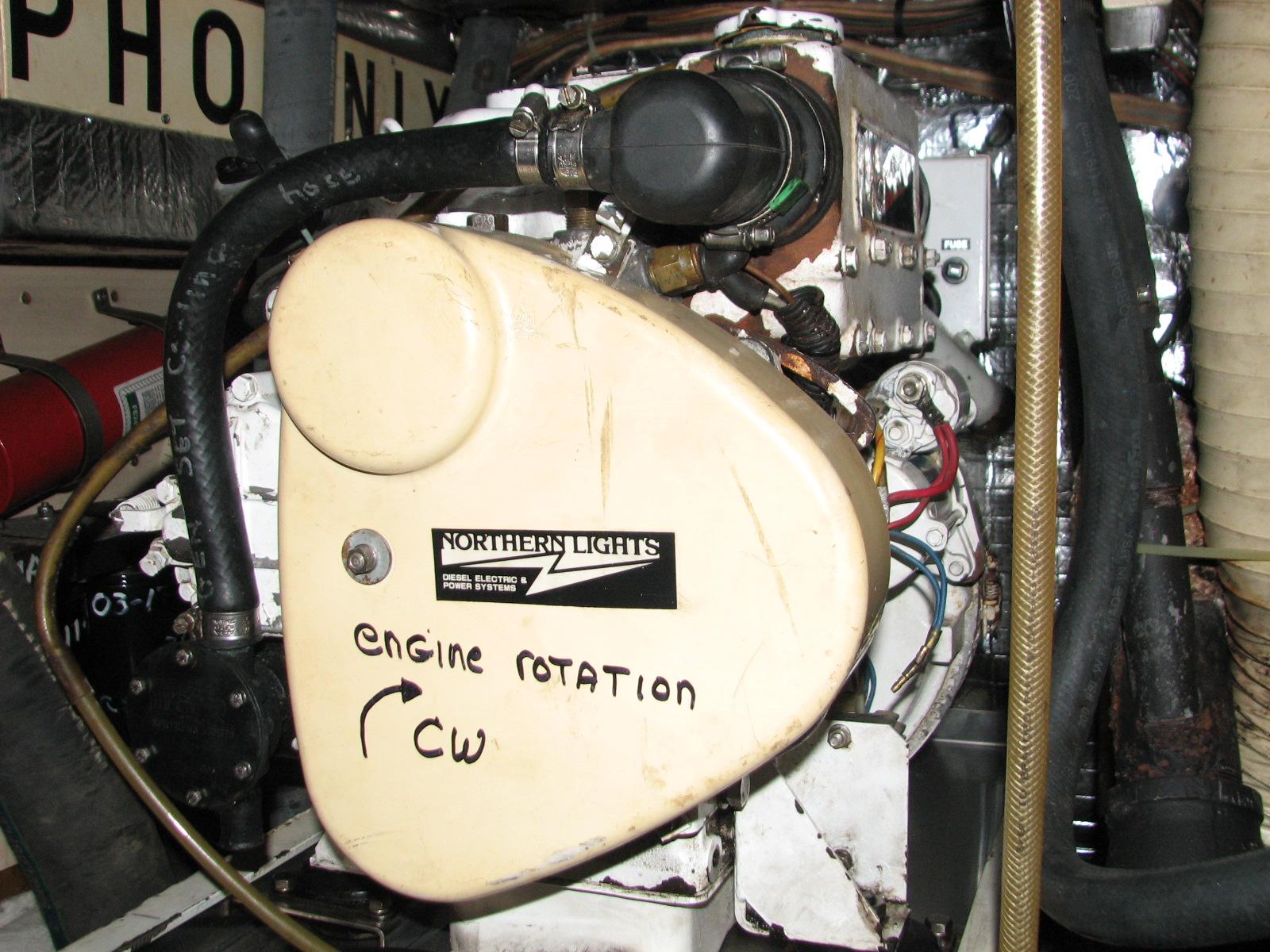

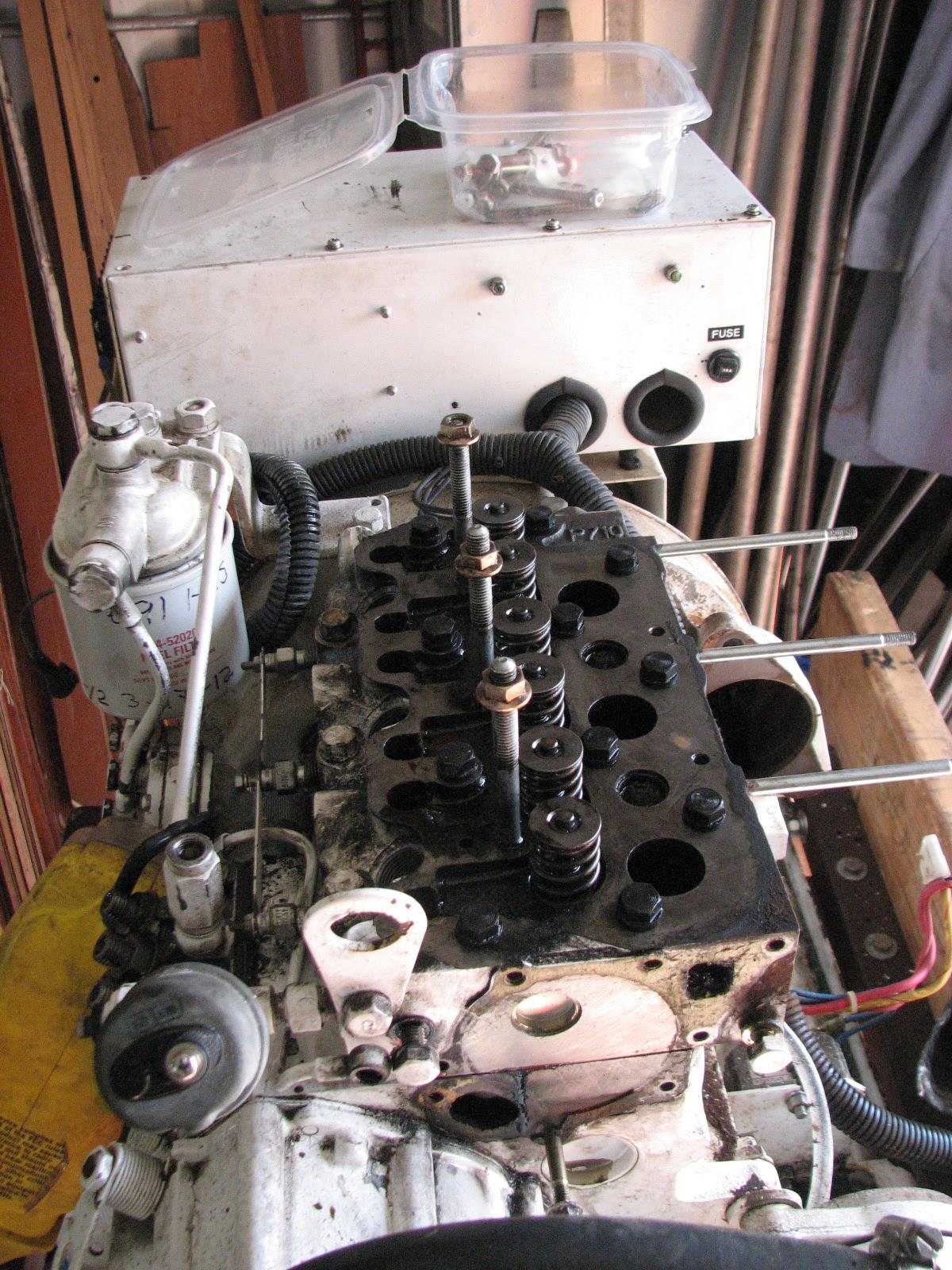

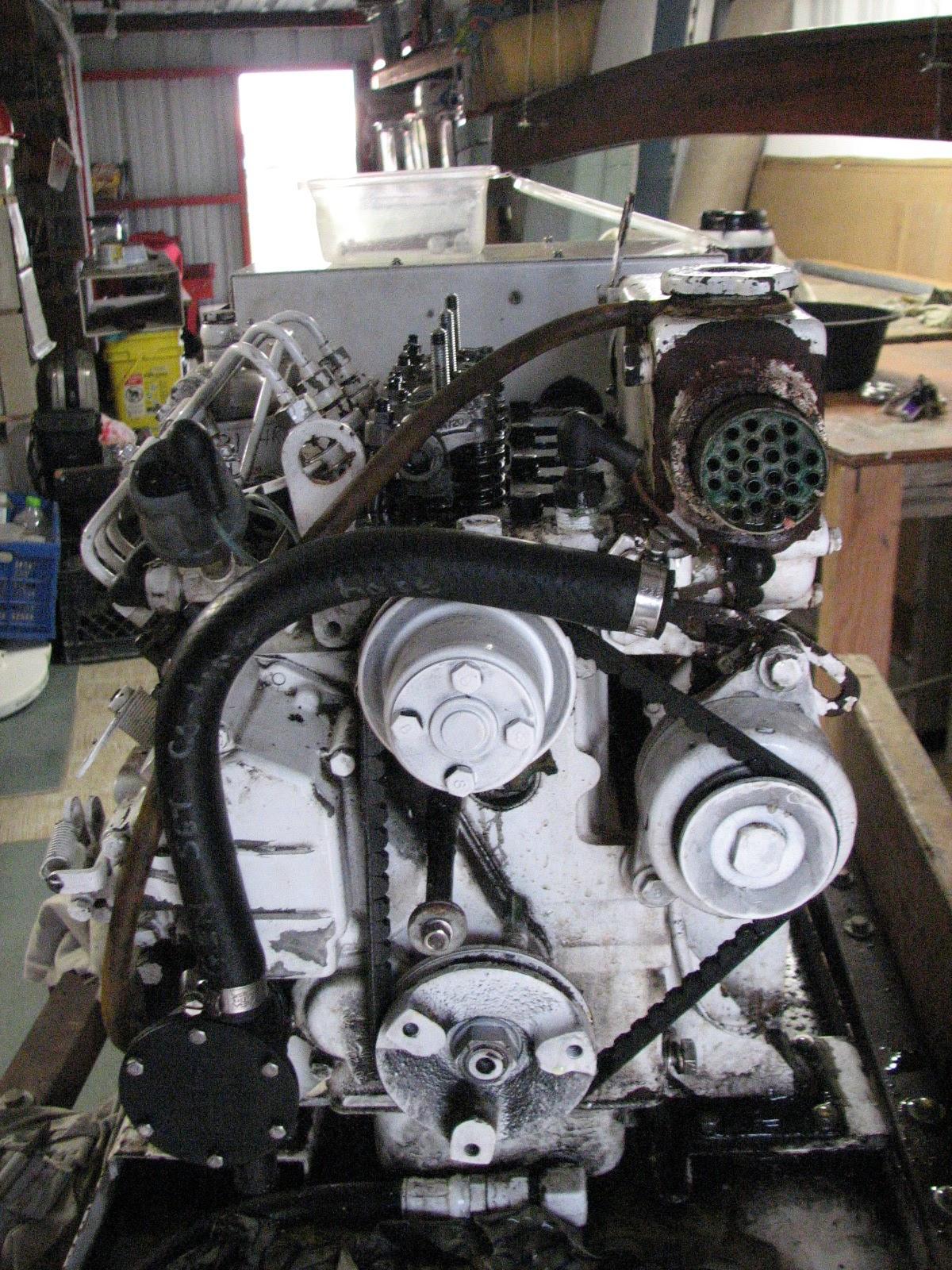

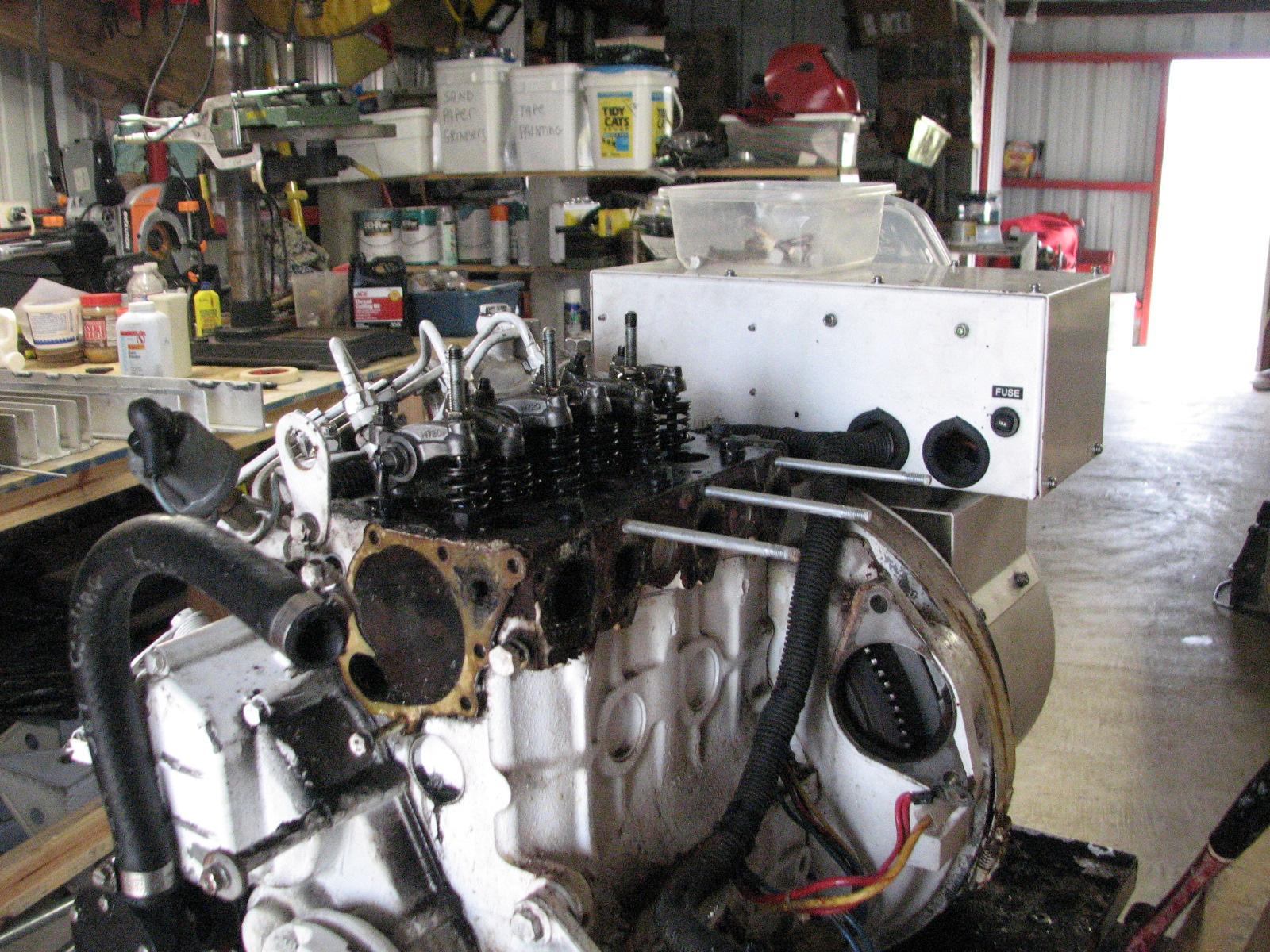

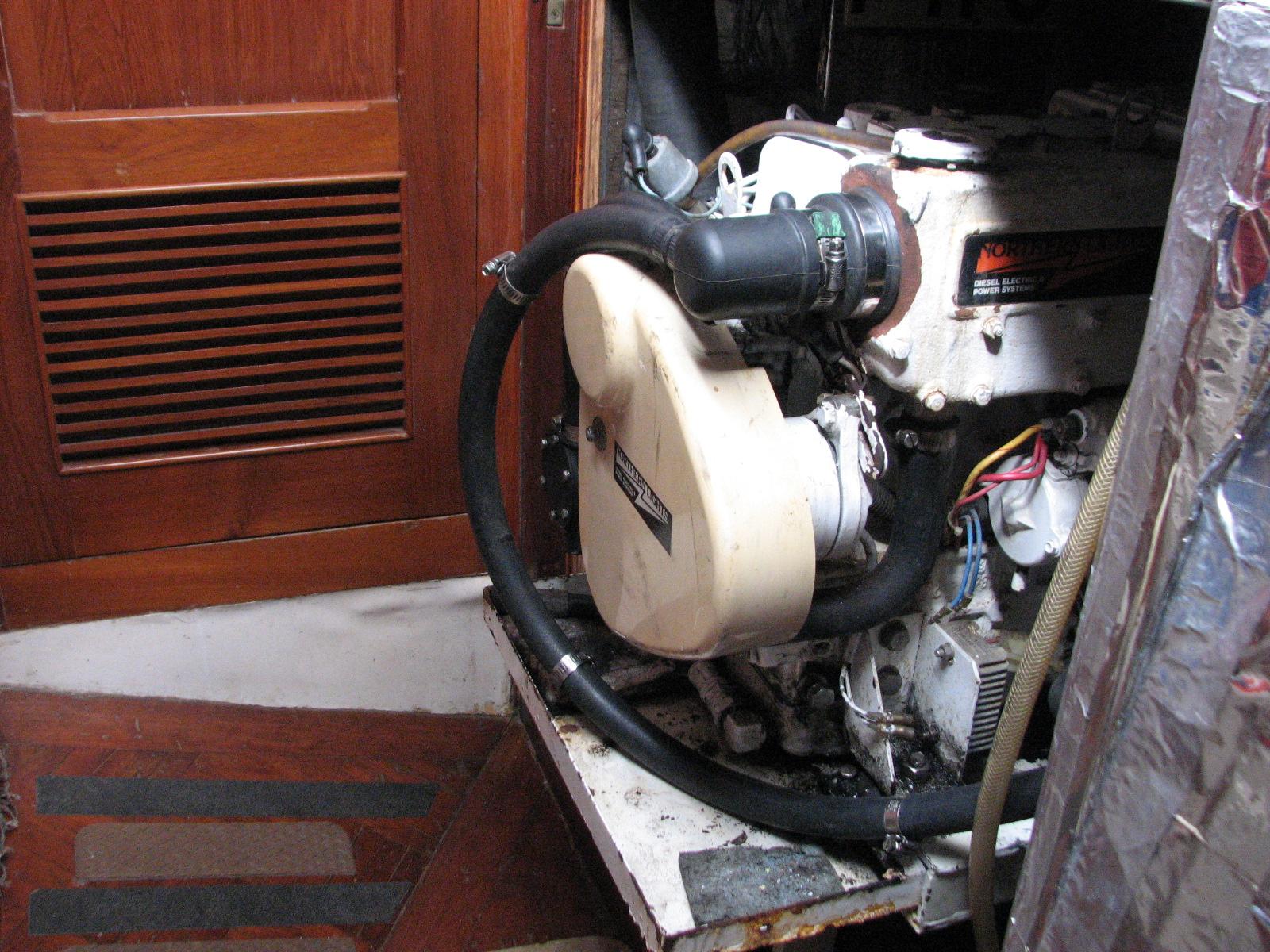

I next put the generator head back

together, and then installed it onto the generator.

I had the service manual for the generator

on my iPad so I was able to look up the necessary torque

specifications.

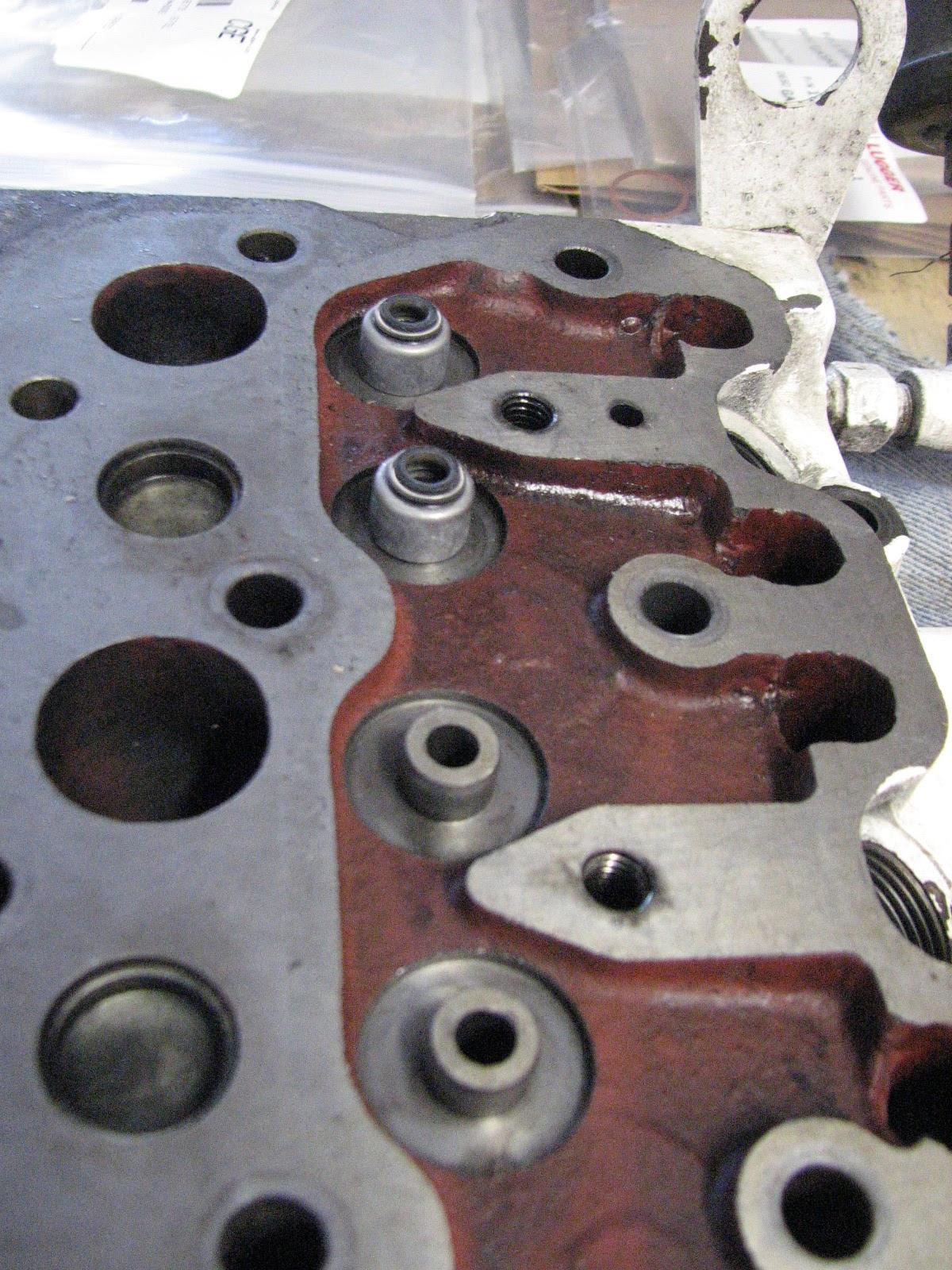

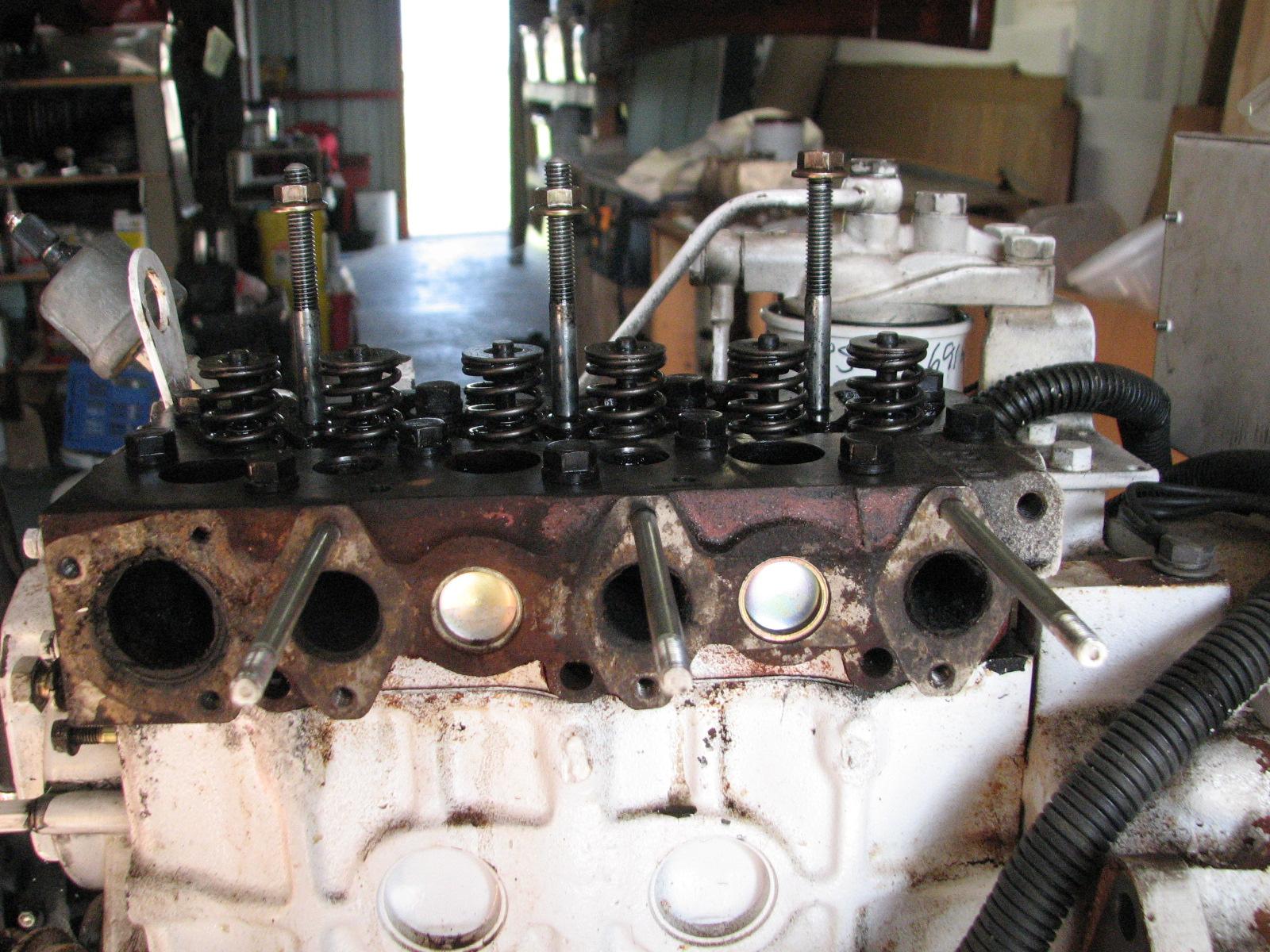

Cleaned Generator Head Before Assembly

Cleaned Valves Ready For Installation

Valve Seals Installed On Head

Installing Valves Into Head With Valve

Spring Compressor

Head Installed On Generator

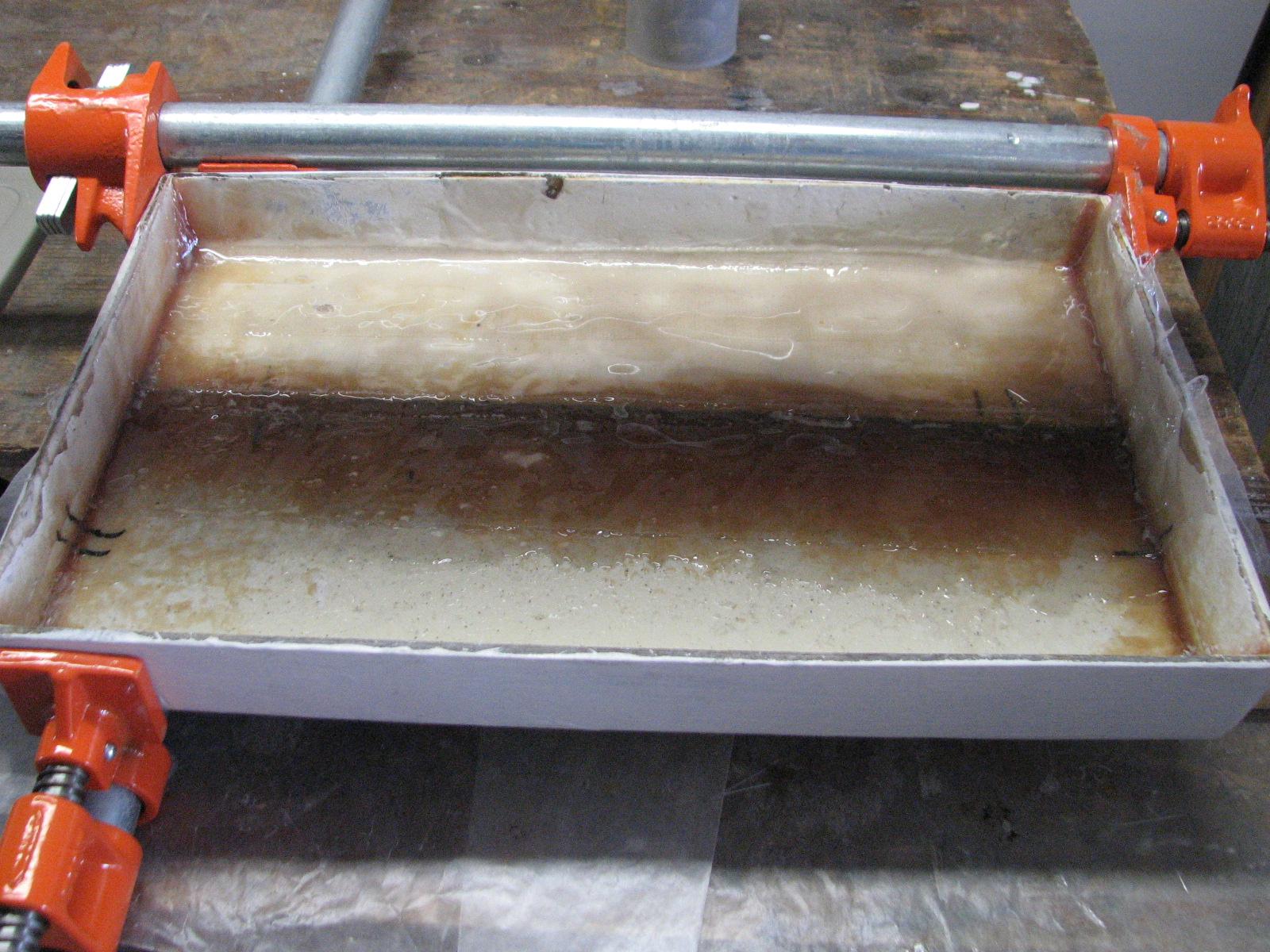

I had to fiberglass the top to the

tender

battery cover. I had stepped on the battery box in the

tender,

and the top cracked. When I had originally fabricated the top, it was

made from two pieces of spare fiberglass.

I used some fiberglass

tape I had and repaired the battery box top.

Fiberglass

Tape To Be Applied To Battery Box Cover

Tape And Resin Applied To Battery Box

Cover

I applied the third coat of varnish to

the teak

wire covers, and went back to DREAM AWAY and had breakfast.

After breakfast I drained the holding

tank in the

shower trailer.

With so many cruisers in and taking showers,

the tank fills up pretty fast.

I then put the

tender back onto the

davits. I knew we would not be using the

tender for a couple of days,

so it was good to get it out of the water.

Spent the remainder of the day working

on the Gateway computer getting it to the stage where it will be a

useful computer. I am able to send and receive emails. I am also

learning that there really is no comparison between the Windows and

Apple GUI. Windows is very clunky!!

March 18, Tuesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Booted up the Mac first thing and

worked on the machine until we had breakfast. That was from

approximately 0530 until 0930, and had no problems with memory

overheat issue. While we were having breakfast the Mac hung! I am

lost!

We called an Apple repair company, In

and Out Phone Repair, and they said they would look at

the Mac and see if they could find a problem. We drove to Lafayette,

and went to the store. They kept the machine for well over an hour,

and could find no trouble. It was then I decided to switch over to

the Gateway as my backup computer.

When we got back to DREAM AWAY, I did

all of the backups on the Mac, and then loaded all of the data onto

the Gateway. Since the wireless card on the Gateway is not working, I

am using a USB wireless card, and I can get to the Internet using

that option.

A major problem using that USB card is

that it drops the connection every five to six minutes, and I have no

idea why. Another feature of my computer experience.

I will use the Gateway as my main

computer until I can get the Mac back to the Snow Leopard OS-X.

March 17, Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go to the

shop

today, but basically spent the whole day working on computers. I

booted up the Mac and it ran with no problems, but I was hopeful the

problem was fixed. I had good backups of the Mac and all of my data.

I took a break from computers and went

out and drained the holding tank in the

shower

trailer at the

marina.

When I got back on DREAM AWAY, the

Gateway backup PC on board wireless card was not working! Nothing I

did would get it working, so I decided to stick with the Mac. I then

started catching up on emails and the Maintenance Log.

I worked the remainder of the day on

the Mac with no trouble. It looked like my computer problems were

solved.

March 16, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

I booted up my Mac first thing, with

both of the 2 Gbyte memory cards in the computer, and it crashed. I

removed one of the 2 Gbyte memory cards, and booted up the Mac, and

it crashed again. I am pretty well convinced the problem is

overheating memory.

I left DREAM AWAY, and went out to the

military breakfast at the Marine

Corps League Campout. The breakfast consisted of

scrambled eggs, SOS, bacon and coffee. I helped with the cleanup and

breakdown of the tables and chairs. It was a good weekend and well

worth the $30.00 donation per couple.

When I finished the cleanup at the

campout, I went back to DREAM AWAY, and got myself cleaned up to go

to the SPAMalot

play in New

Iberia. It is a parody of Monty Python’s Search for

the Holy Grail. We went with Cindy

and Johnal, and had a great time. By the time I left

the theatre, my stomach was hurting because I laughed so hard!

We had dinner on the way back to DREAM

AWAY. When we got home, I replaced the 2 2 Gbyte memory cards in the

Mac with the original 2 1 Gbyte memory cards, and booted up the Mac.

It came up with no problems. I might have found the problem!

March 15, Saturday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the shop

and I applied the second coat of varnish to the

teak

wire covers.

Varnish Applied To Teak

Wire Covers

Varnish Applied To Teak

Hole Covers

I then inventoried all of the gaskets

we had purchased from Harris Castille for the generator.

I wanted to make sure when I started putting the generator

back together, I would have no problems.

Inventoried Gaskets On Work Bench

I then went back to DREAM AWAY, and

started in working on the problems I was having with the Mac. Because

my frustration level was very high, I called Stacy. We made a lot of

progress, and it looked like I was going to be able to boot up the

Mac.

We had to go to the Marine

Corps League Campout, not only to enjoy the food and

camaraderie, but we had committed to man the ticket booth for two

hours in the afternoon. Kitty and I drove out to the Campout. The

other cruisers would be out later in the day for the dinner.

Kitty and I had a great time visiting

with a lot of Marines from our detachment in Abbeville.

When the other cruisers arrived it was just in time for dinner which

consisted of a spit roasted pig and fried turkeys with vegetables and

rice dressing. Everyone enjoyed the meal and had a great time.

Enjoying The Campout Camaraderie

Enjoying The Campout Camaraderie

Enjoying The Campout Camaraderie

We all left the Campout, after helping

some with the cleanup and went back to DREAM AWAY. I was able to boot

up the Mac normally, so was very happy about that. I started running

backups, so if the Mac did not come back all the way, I would have

all of my data saved. It had been a long day so when the first backup

finished I went to bed to continue the the backup process in the

morning.

March 14, Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the shop

and did a couple of cleanup items. Tried to get everything ready to

be able to put the head back on the generator,

and then start the generator

while it is in the shop.

I also inventoried the stainless steel

chain grippers I ordered to replace the two galvanized chain grippers

I use on the anchor

snubbers.

Two Stainless Steel Chain Grippers On

Work Bench

Our friend Cindy

was going to do some shopping in Abbeville,

so I decided to go with her. I needed to find some scraper blades and

exchange the polyurethane

for varnish.

We then stopped at Wallyworld,

so Cindy

could do her grocery shopping. I also checked there for the scraper

blades, but they did not have them either. We left Wallyworld

and stopped at Tractor

Supply to see about the scraper blades, and they did

not have them either!

Our last try, just as we were entering

Delcambre,

we stopped at Otto Hebert Lumber Yard. I went in and they had both

types of scraper blades I was looking for. I purchased two of each.

We then drove back to the marina.

I went over to the shop

and continued to clean generator parts. I also applied the first coat

of varnish to the teak

wire covers.

I walked back to DREAM AWAY and started

getting all of the required stuff we thought we would need for the

Marine

Corps League Campout. When Kitty finally returned from

her tour guide function, I had a couple of the guys from WIND ORCHID

go with me to the storeroom. We loaded up chairs, tables and a tent

into the Black

Beast, then headed back to the marina.

Everyone got all of their coolers,

coats and blankets loaded into the Black

Beast, and we headed off to Maurice to the Campout. We

had a great dinner, and the band was outstanding. We all returned to

the marina

around 2200.

March 13, Thursday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

I took the passerelle out to the new

cruisers boat, WIND ORCHID, and they put it on the dock and their

boat to get to the dock until the water comes in and they can tie up

WIND ORCHID properly.

I then went to work weeding the front

gardens at the marina.

They were in really bad need of it. The cold weather seems to really

bring out the weeds.

While they were out playing the tourist, I drained the holding tank in the

shower trailer

at the marina.

When that was complete I went over to the

shop

to get to work on the generator

head. I called Harris Castille and ordered the necessary parts to put

the head back on the generator, and see if it will start.

Before getting on the oily work on the

head, I put the instruments back into the instrument pod face. I am

hoping that in between all of the social activities of the weekend, I

can get the boom gallows put back on DREAM AWAY, and the instrument

pod is just part of it.

Instruments In Instrument Pod Face,

Covers On

Instruments In Instrument Pod Face,

Covers Off

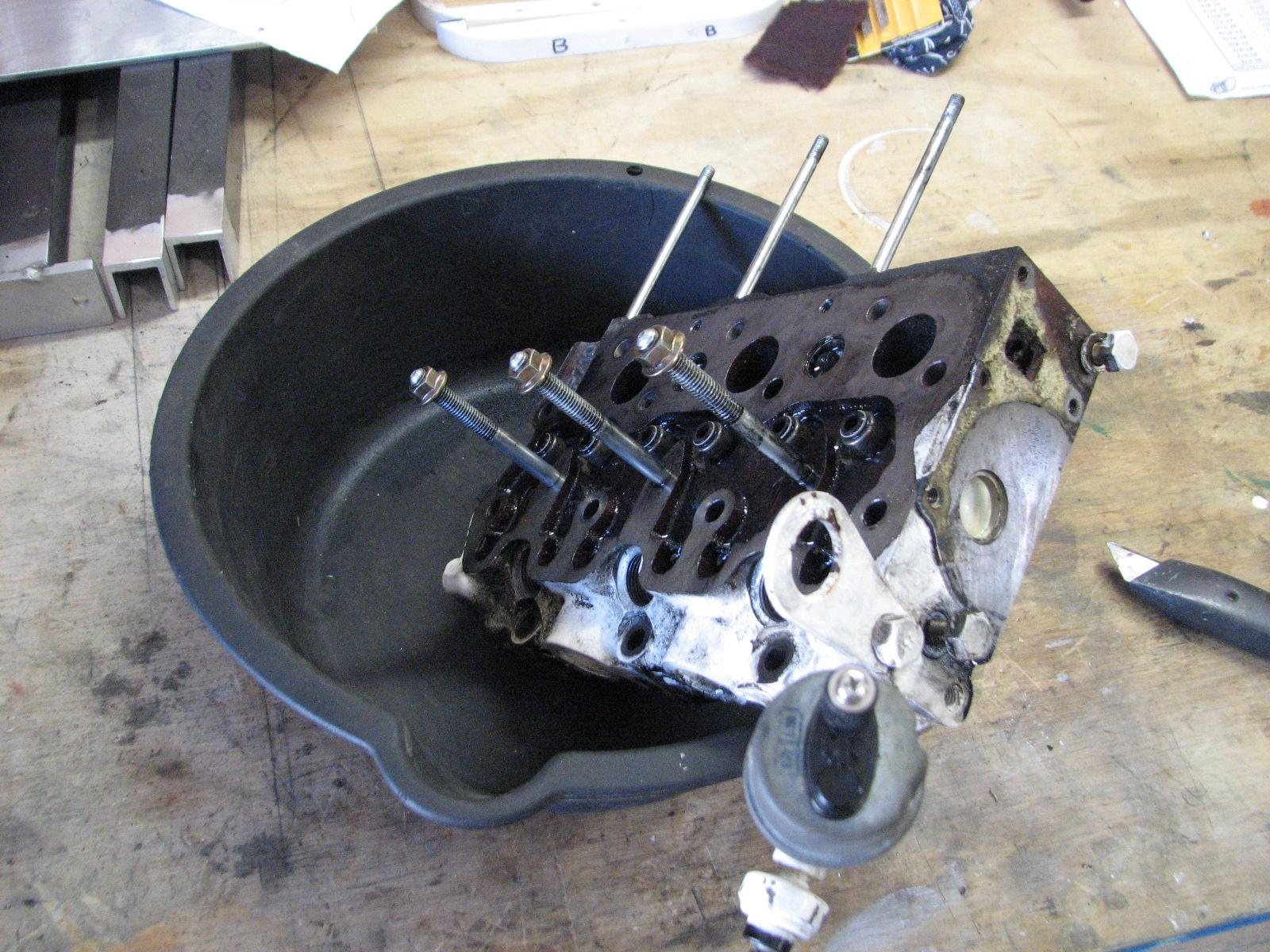

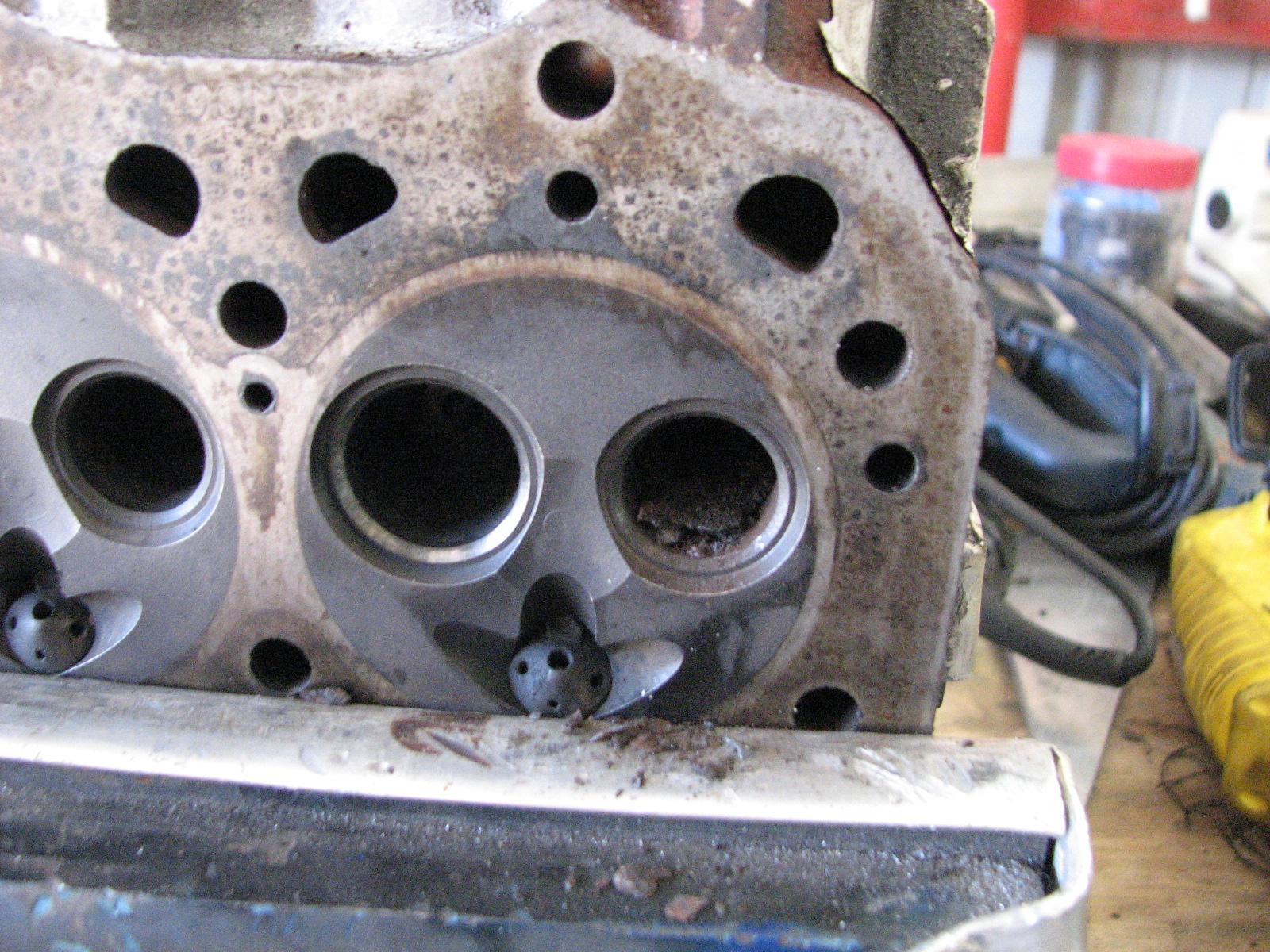

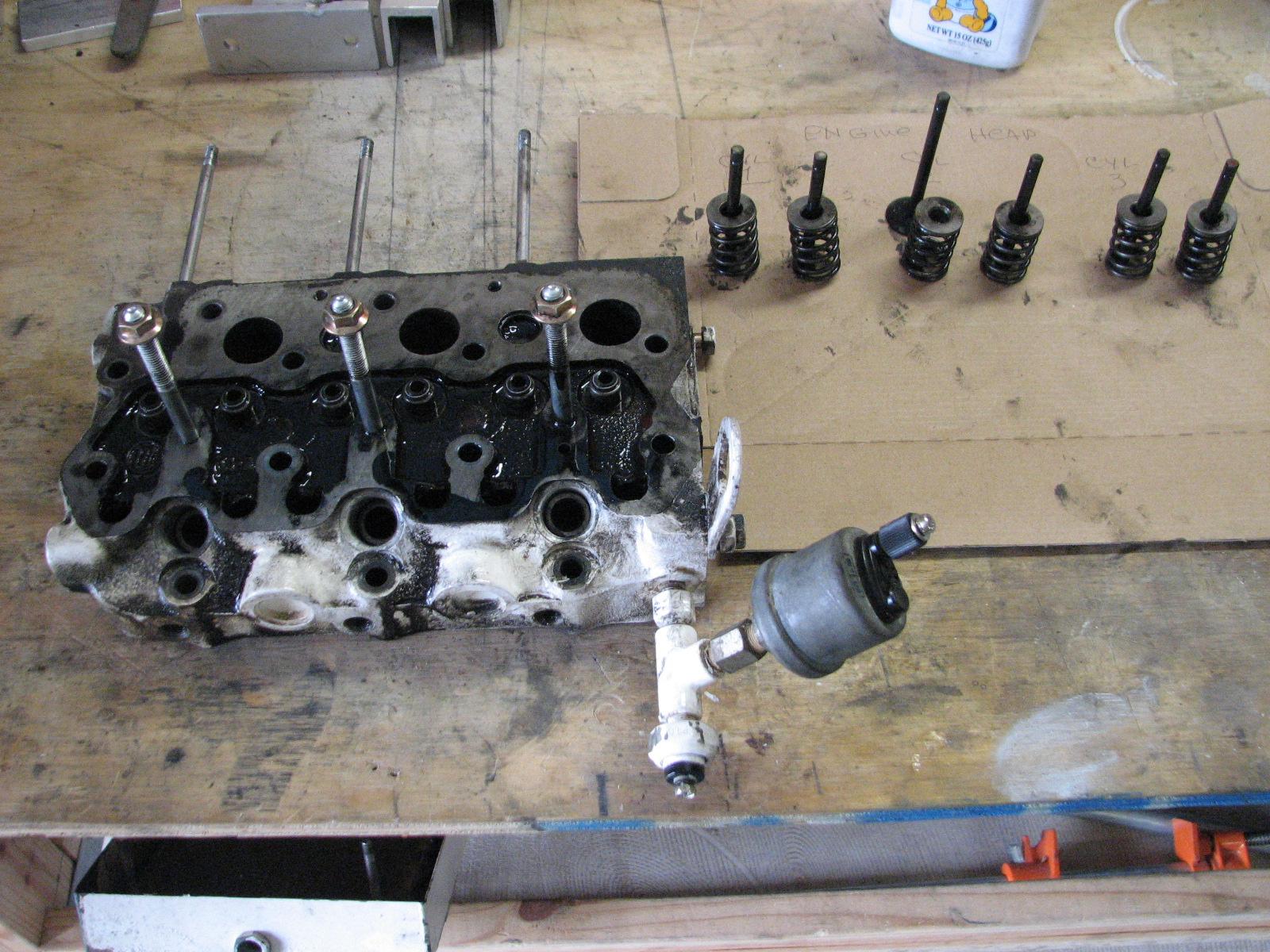

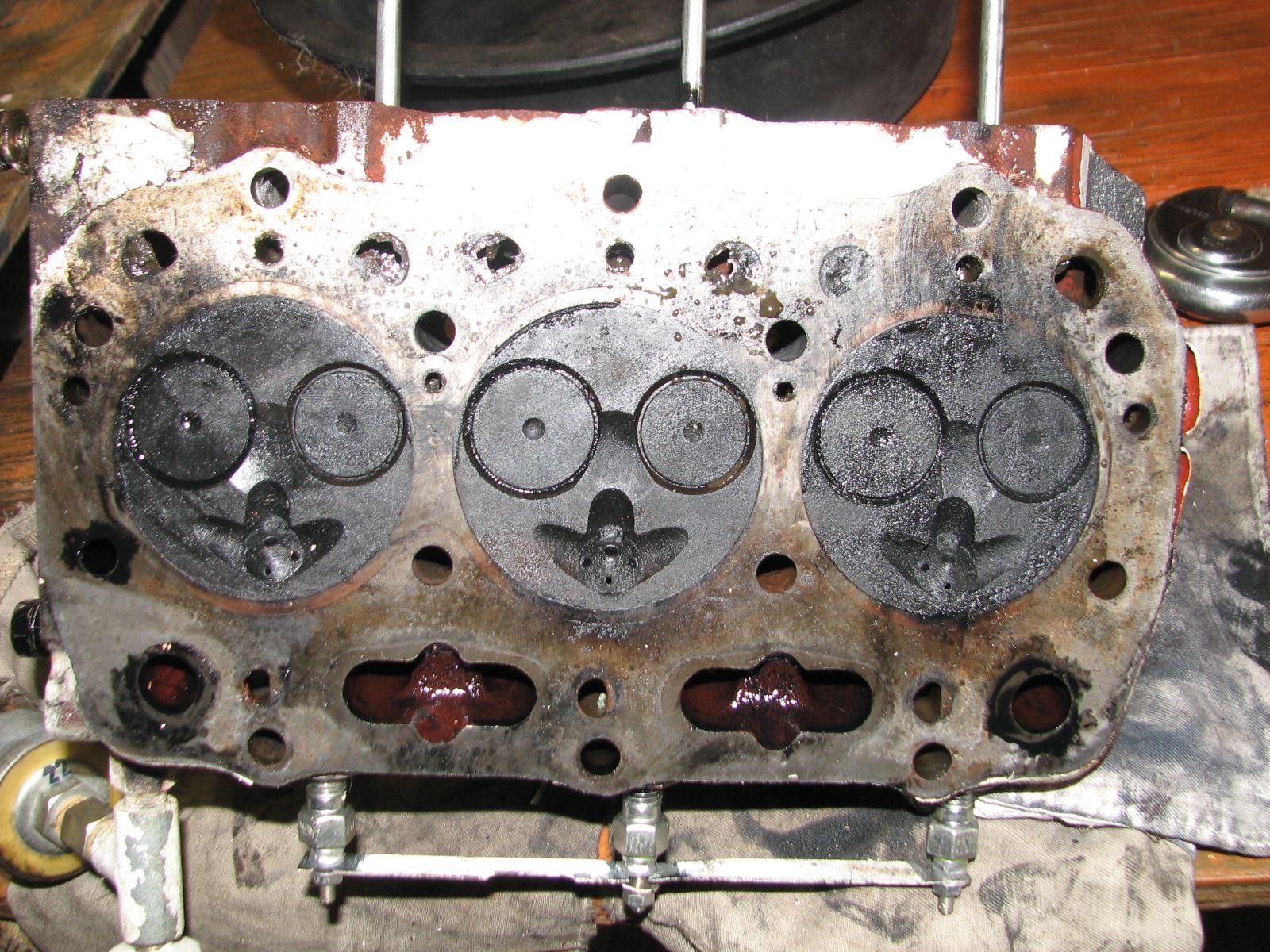

Now it was into the dirty work. I got

at the head and with some clean gasoline, and cleaned up the head.

This included cleaning out the number three cylinder exhaust port

which was really heavy in carbon buildup. Not really sure why?

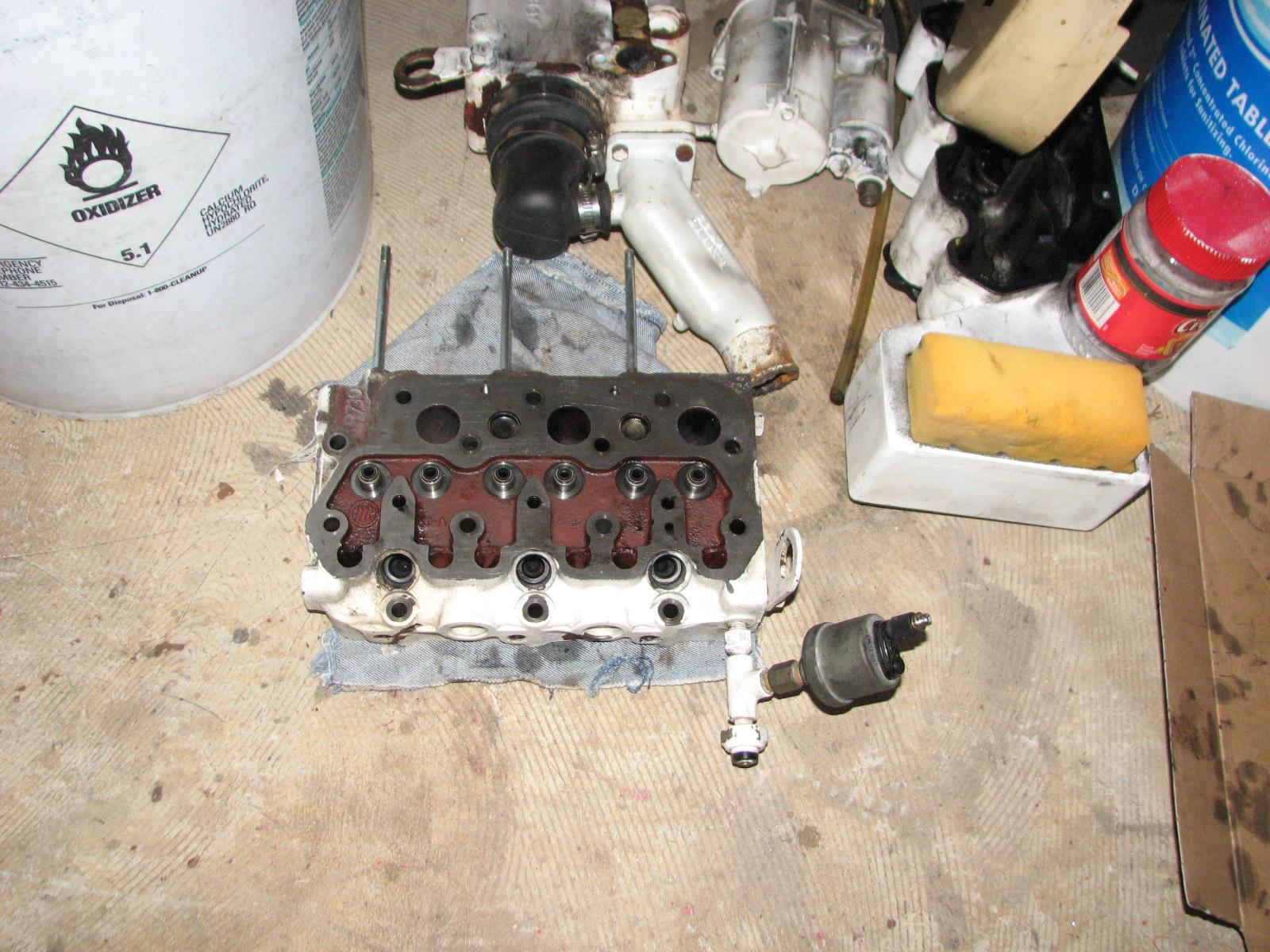

When the head was cleaned up and blown

dry, I then cleaned up all of the valves and springs, and then did

the valve grinding on all of the valves.

Head In The Cleaning Bucket

Dirty Number Three Exhaust Port

Completed Head On Floor

Completed Valves And Springs On Floor

The last item for the day was to apply

varnish to the teak

wire covers. When I got out the varnish to apply, I discovered the

“varnish” is actually polyurethane. I will have to return the

polyurethane and get the semi-gloss varnish to apply.

I closed up, and went back to DREAM

AWAY. I got showered, and Kitty and I and the new cruisers went to

Shuck’s

for dinner.

March 12, Wednesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Stayed on DREAM AWAY in the morning,

and attempted to catch up on email and other computer items. Around

noon we drove to Lafayette

for Kitty’s doctor’s appointment.

Did some shopping, and then came back

to the marina.

We welcomed new cruisers, John, Mia, Darrell, and Simon. They are on

a cruise bringing John’s boat from

Annapolis

to Houston,

Texas.

New Cruisers, Simon, Darrell, John, Mia

& T-Boy With Welcome Basket

We got the new cruisers secured and

sort of tied up. The water was real low, so we had to drag the

sailboat as close to the dock as possible.

I did get a list of the gasket prices

in an email from Harris Castille. It will take two or three days to

get most of the gaskets, and the cost will be about $350.00.

Kitty and I then left for New

Iberia where we participated in the Rotary

Club Red beans and Rice fundraiser.

March 11, Tuesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the shop

to start work on the generator

to finish the compression test. I had brought along my big jar of

hydraulic fittings so see if I could come up with a solution. I found

one fitting that was a 90° turn. I connected this fitting to the oil

outlet, and then put a container under the outlet to capture the oil.

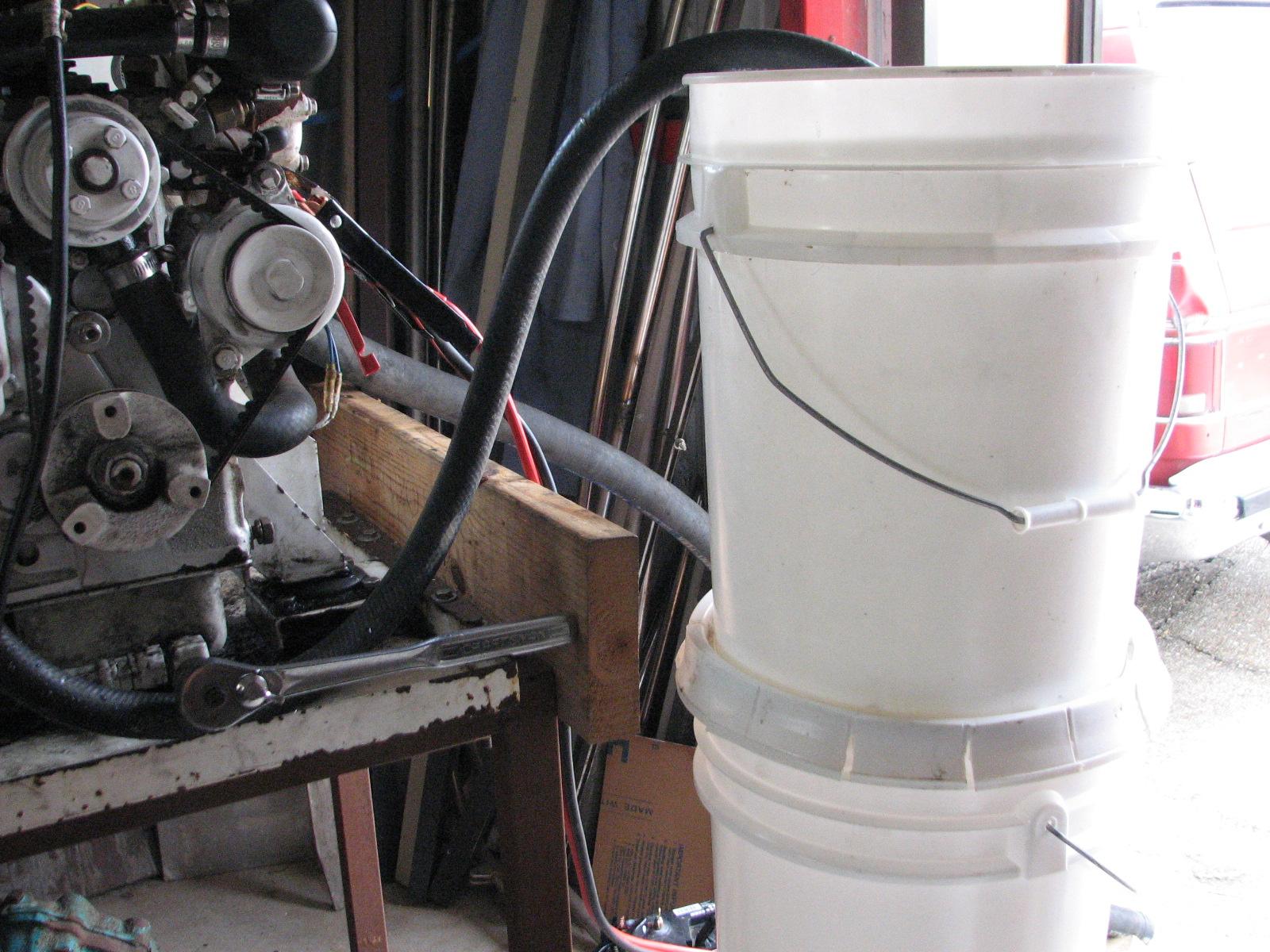

After each test, I could pour the oil

in the container back into the engine so it would not run dry.

I had to remove the fuel filter from

the engine to connect the tester to the number three cylinder. I then

brought the

Black Beast

as close to the door of the shop

as I could, and connected one end of the jumper cables to the

Black Beast

battery, and the other end to the starter on the

generator.

I used the trusty steel screw driver method to activate the

generator

starter.

This proved successful, and I got a

reading of 500 PSI on the number three cylinder. I also got ½ a

quart of oil in my container, so I poured the oil back into the

engine. I moved the compression tester to the number two cylinder,

and checked it. I got 500 PSI from that cylinder.

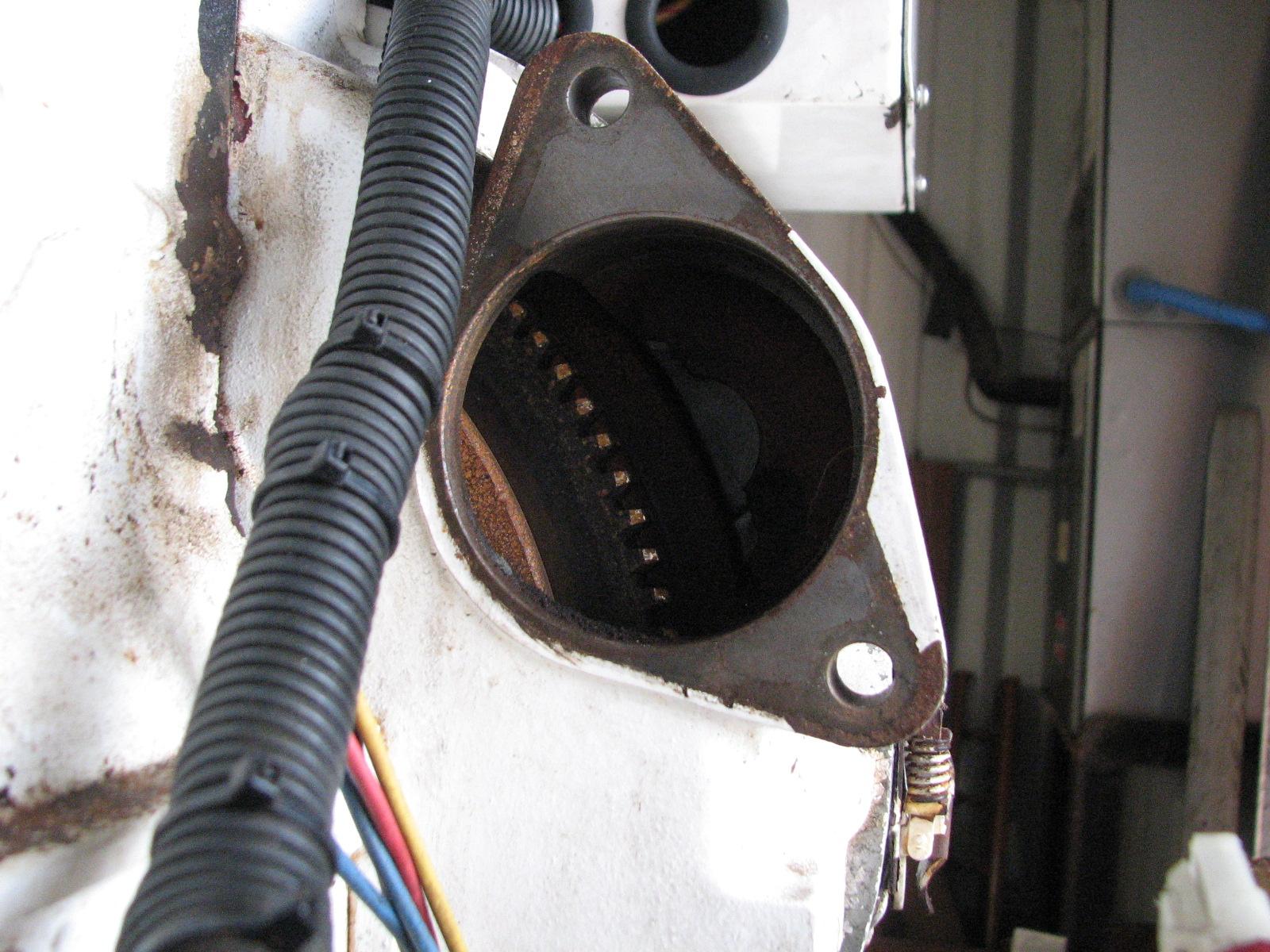

To check the number one cylinder, I had

to remove the injection pump, which I did. I connected the

compression tester to the number one cylinder, and got a reading of

420 PSI. Later when I removed the injector from that cylinder I

realized I forgot to use the copper gasket to seal the injector, and

that is why number one cylinder is low. The low reading is well with

is specs, so I am not worried about it.

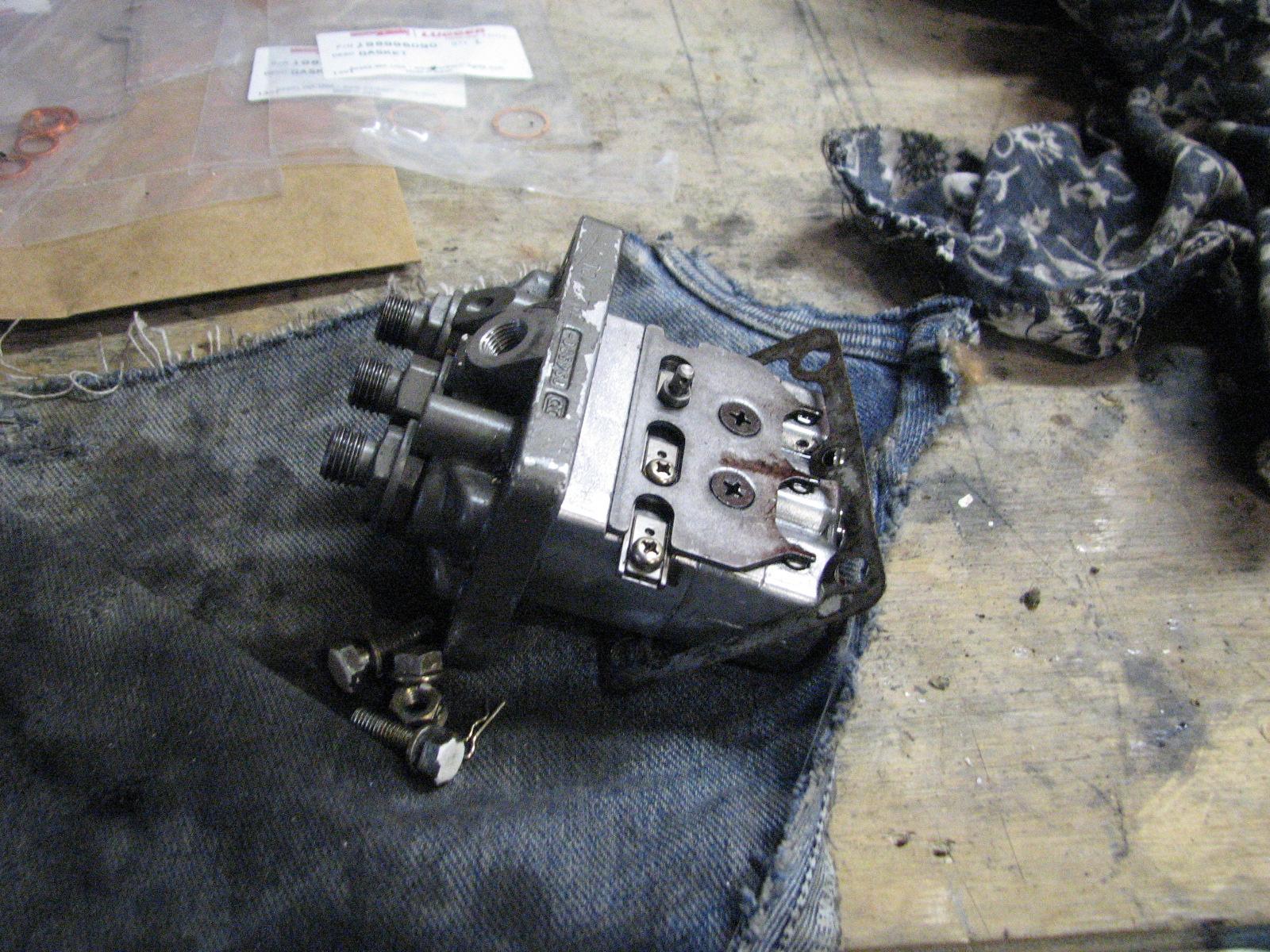

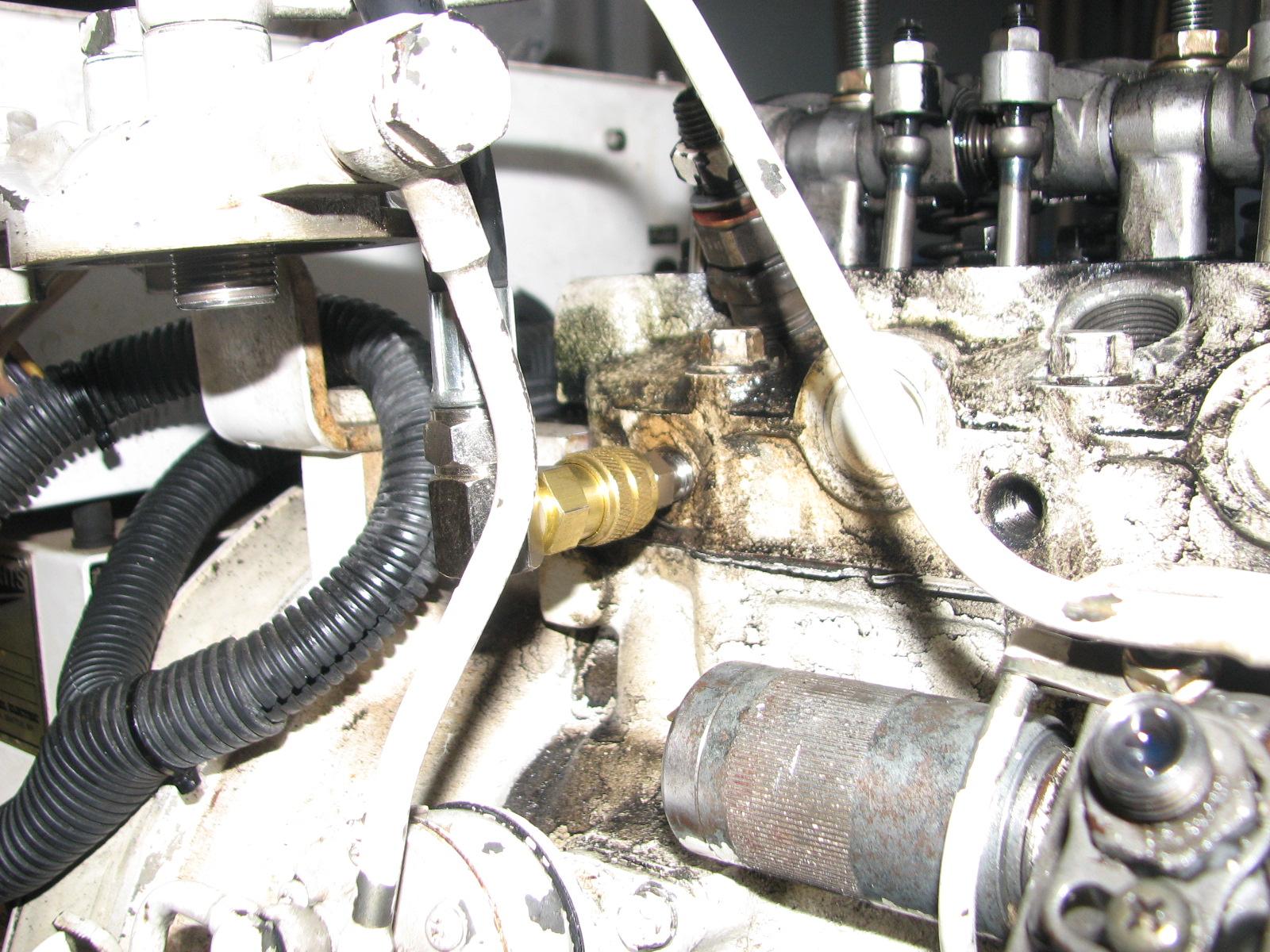

Since I had the injector pump out, I

verified the operation of the stop lever/spring system. It seemed to

work properly.

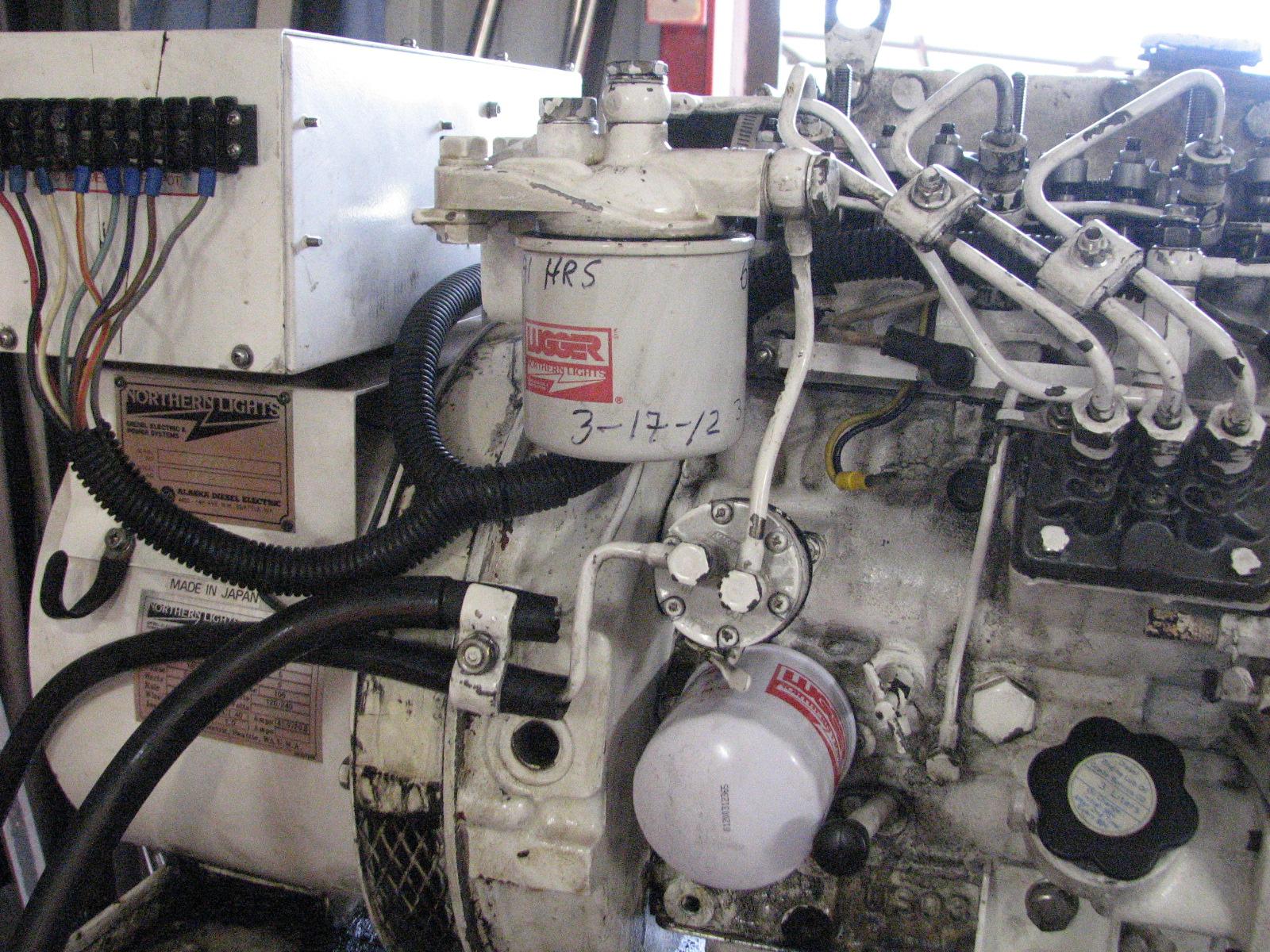

Compression Tester In Number Three

Cylinder

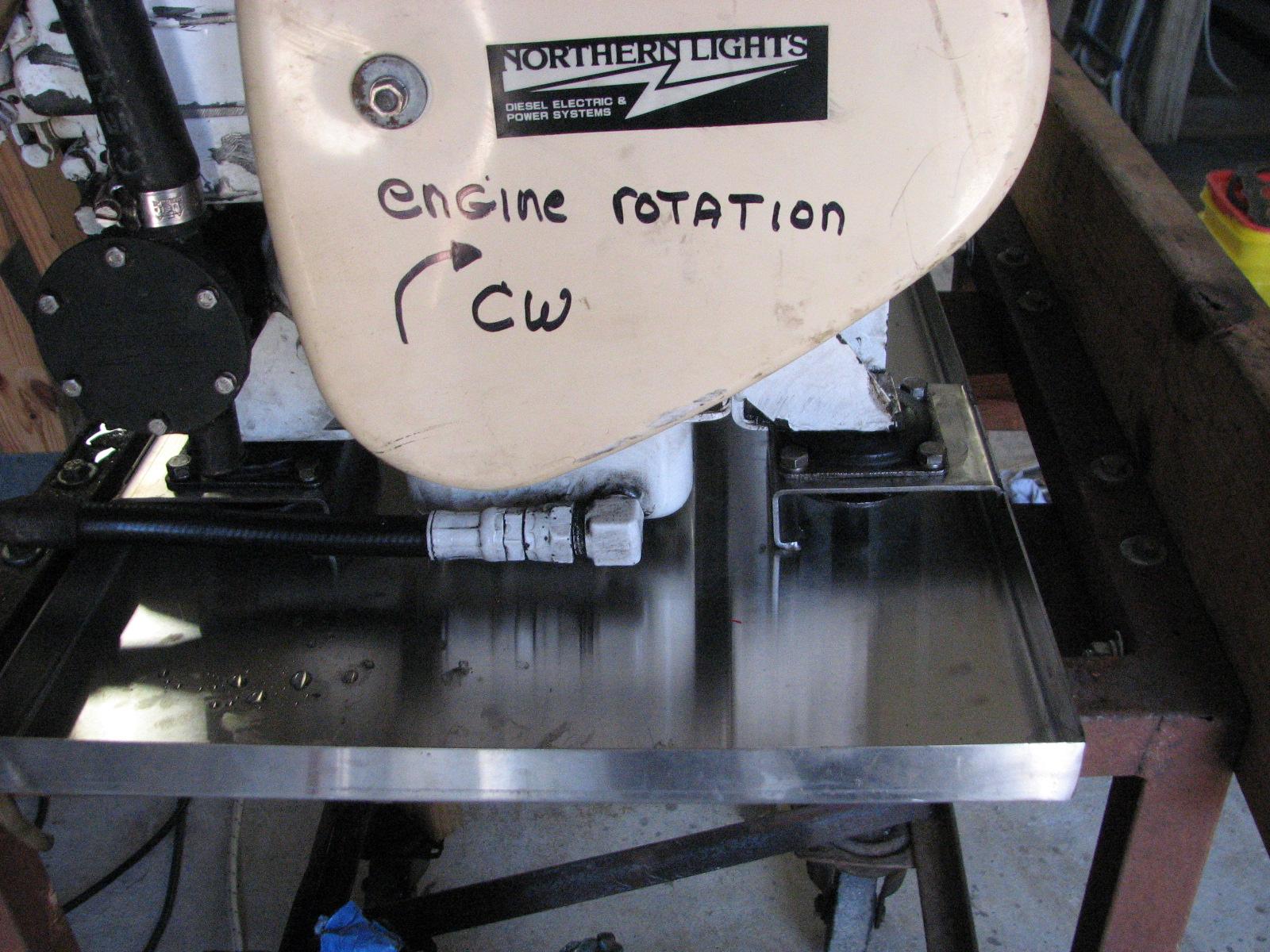

Engine Ready For Test

I changed gears, and put the orange dye

on the pieces of teak

I needed to varnish. Two pieces were the round covers to cover holes

in the head overhead. One piece is the wire cover for the head

overhead. The last piece, is a wire cover from the navigation

station that had to be trimmed so the navigation

station cover

would close.

Orange Dye Applied To The Teak

Pieces

Orange Dye Applied To The Teak

Pieces

By this time Kitty had called, so I

went over to DREAM AWAY to have brunch. Today is a diet day, the meal

consisted of a piece of pork and a big salad.

After breakfast I looked into my box of

electrical wire looking for a short piece of 10 ga. black wire. I

wanted the wire to connect the battery in the

tender

to the echo-charge

feature of the

Freedom

25 Inverter/Charger. I found a piece of wire, and put

the proper connections on the ends.

I then moved the battery in the tender

to the area where the house batteries and main engine start battery

are located and connected it to the echo-charge

feature of the Freedom

25 Inverter/Charger. Tomorrow will tell if this is the

method I will use to charge the battery in the tender.

While looking for the black wire in the

electrical wire box, I found a long length of 8 ga. duplex wire that

would be perfect for the solar panels if it was long enough. I decide

to take it over to the shop and measure it.

Kitty had to run a couple of errands,

so she dropped me at the shop

so I could get back to work. I immediately started on the generator.

I put the injector pump back onto the engine, and replaced the fuel

filter. I again removed the starter.

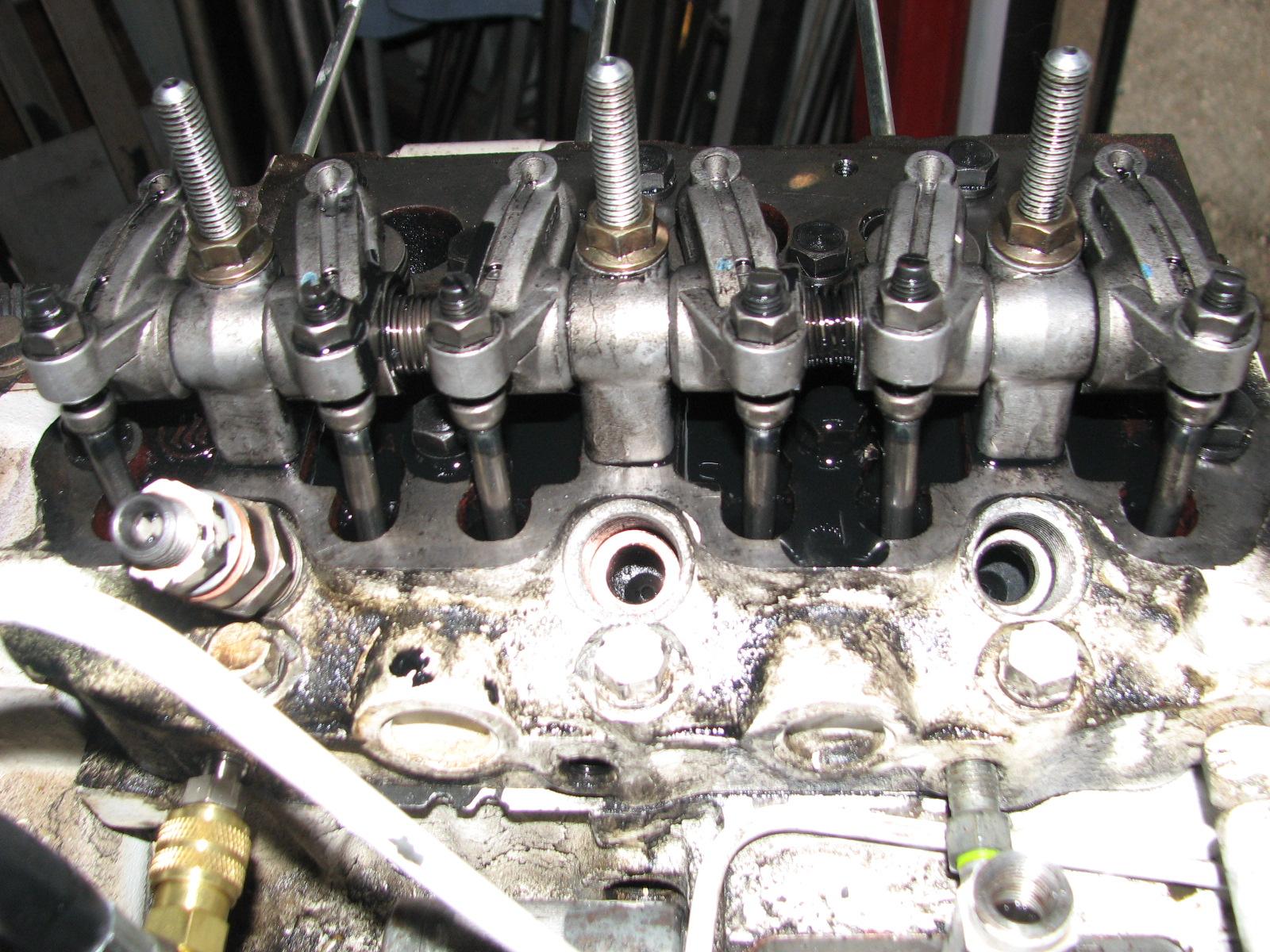

I removed the rocker arm assembly, and

finally the head came off. Johnal

had also loaned me his valve spring compressor, so I removed all of

the valves from the head. This went pretty smooth and all of the

valves looked good except for the number two cylinder intake valve.

It had a really big build up of carbon, which is very unusual. Not

really sure of the source of the problem, except perhaps the valve

guide seal.

I then took all of the valves out of

the spare head, so I could get it ready to be a good spare if this

problem would ever come back.

Valves Removed From Engine Head

Bottom Side Of Head With Valves Removed

Spare Head And Valve Cover

By this time, Johnal

had come over to the shop so I could do some welding on some if his

lifeline parts. He had done all of the fabrication, all I had to do

was weld some ears onto a couple of pieces of stainless steel pipe.

Finished Life Line Parts

Since I had help on had, I had Johnal

help me measure the 8 ga. duplex wire. it turned out to be 30 feet,

which I think will be just right to connect the solar panels to the

controller.

March 10, Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

I went over to the shop

and checked the water I had left in the intake ports of the head from

the generator.

No water had leaked out of ports, so there was no obvious problem

there.

As mentioned yesterday, I put about an

⅛” of oil into the cylinders of the engine. I wanted to see if

one of the cylinders leaked down more than another.

Oil In All Three Cylinders

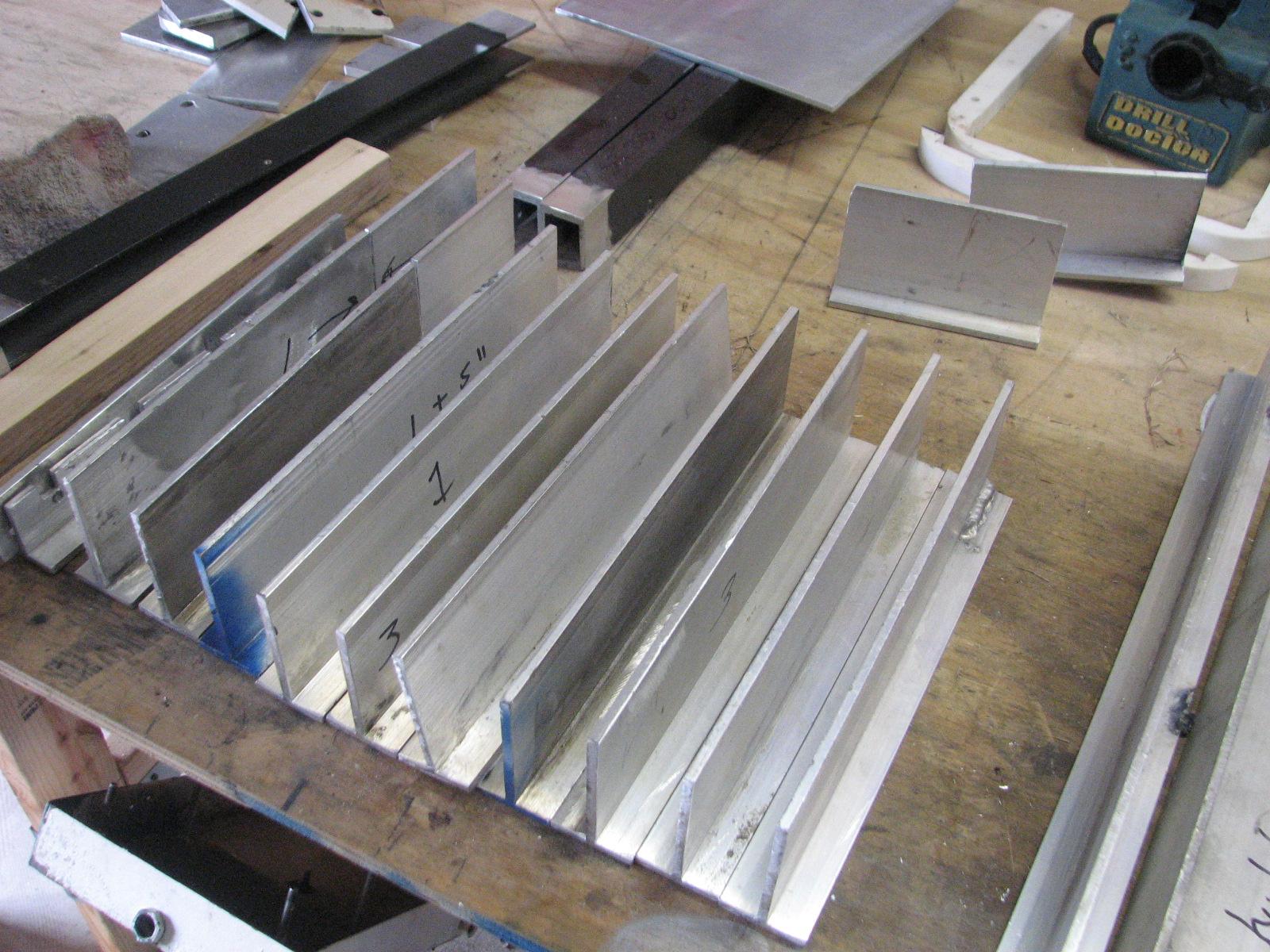

I then continued working on the solar

panel risers I am fabricating. Some of the “T” plate I acquired

from the scrap dumpster was not great, so I am having to do some

extra work to get the last two risers fabricated.

Kitty called, so I went over to DREAM

AWAY for breakfast, and then we left to run some errands and do our

grocery shopping. When we returned, I went over to the yacht RUTHIE

to talk to Johnal

about my generator

problem.

During our discussion, Johnal

said he had a compression tester, so we decided I would put the head

back on the generator

engine, and we would run a compression test.

I went over to the shop

and cleaned up the head, and the gasket. The oil in th three

cylinders, did not seem to have leaked down at all, so I was pleased

with that. I cleaned all of the oil out of the cylinders and put the

head back on the engine.

Head Back On The Engine

Head Back On The Engine

Johnal

came over to the shop

with his compression tester. We proceeded to connect the tester to

one of the cylinders. We had to connect the tester through the glow

plug port instead of the injector port. I turned the engine over by

hand, but could not get a reading on the gauge. On issue that did

come up as I was turning the engine over by hand, I was pumping oil

out of the engine into the tray!

Again Johnal

and I talked over the issue, and we decided the engine needed to be

turned over with the starter. Before we could do that, I would have

to “fix” the oil pumping out of the engine. I will have to come

up with some way to save the oil or put it back in the engine. Will

work on that problem tomorrow.

March 09, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

At 0715 I walked out to the end of Pier

“C” to help the cruisers off of MISS JAZZ get going but they were

no stirring as yet. At 0745, when I went over to the shop,

MISS JAZZ had departed.

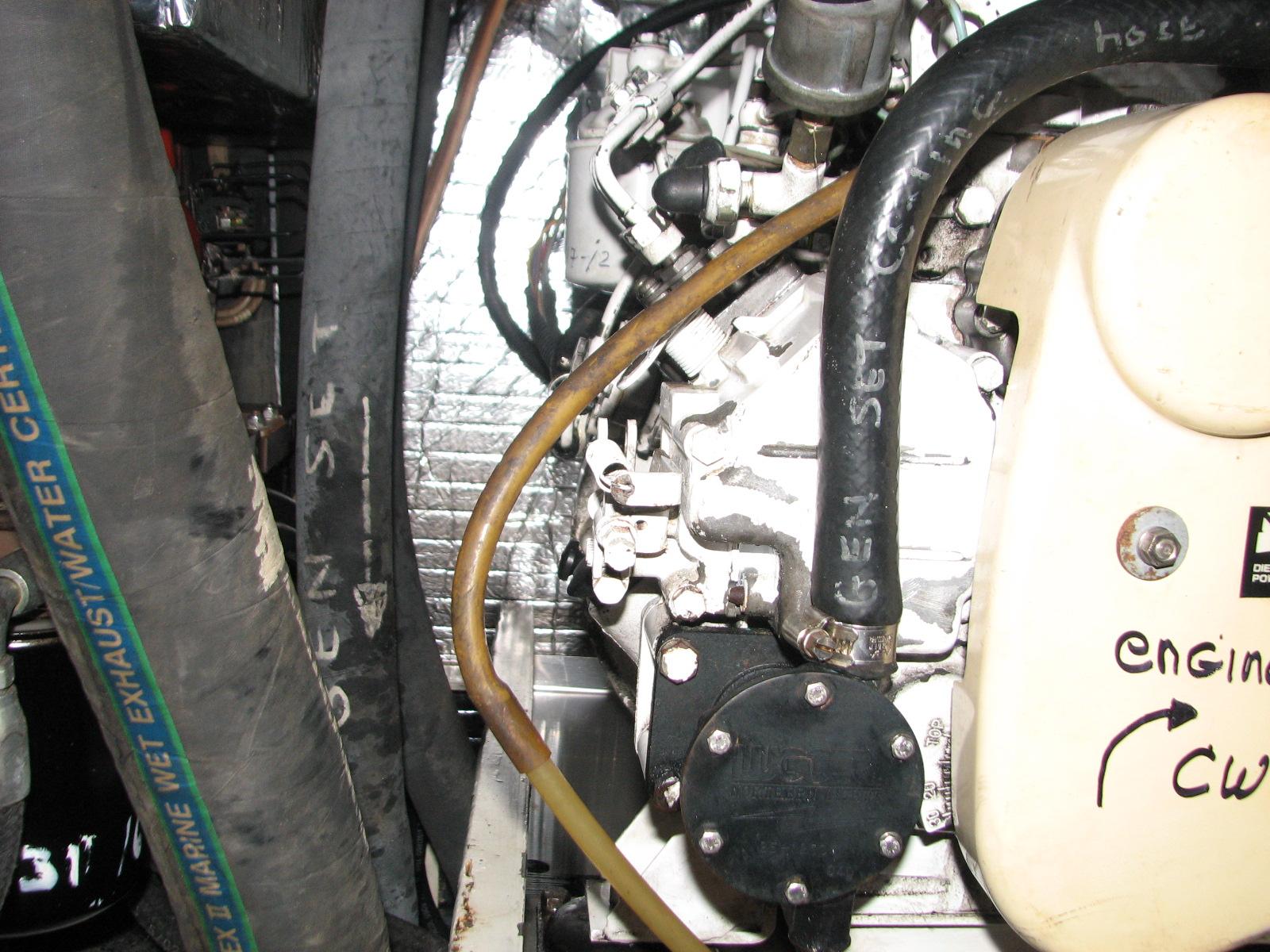

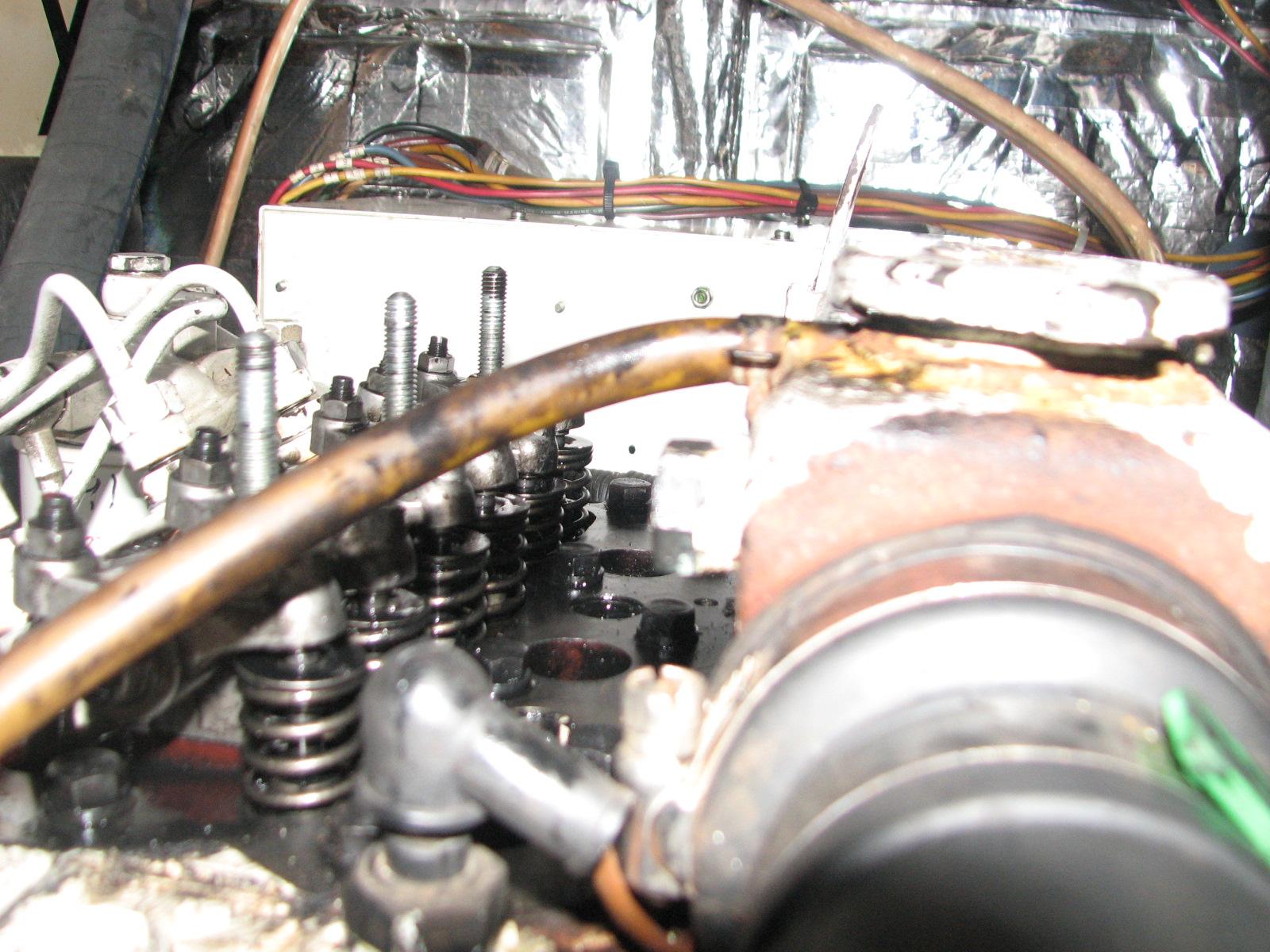

When I arrived at the shop,

I immediately started in on removing the head from the generator.

The teardown was not too difficult, just had to remove several parts

before the head could be removed.

Cooling Hoses Removed Exposing Heat

Exchanger

Water Pump Removed

Exhaust Manifold & Heat Exchanger

Removed

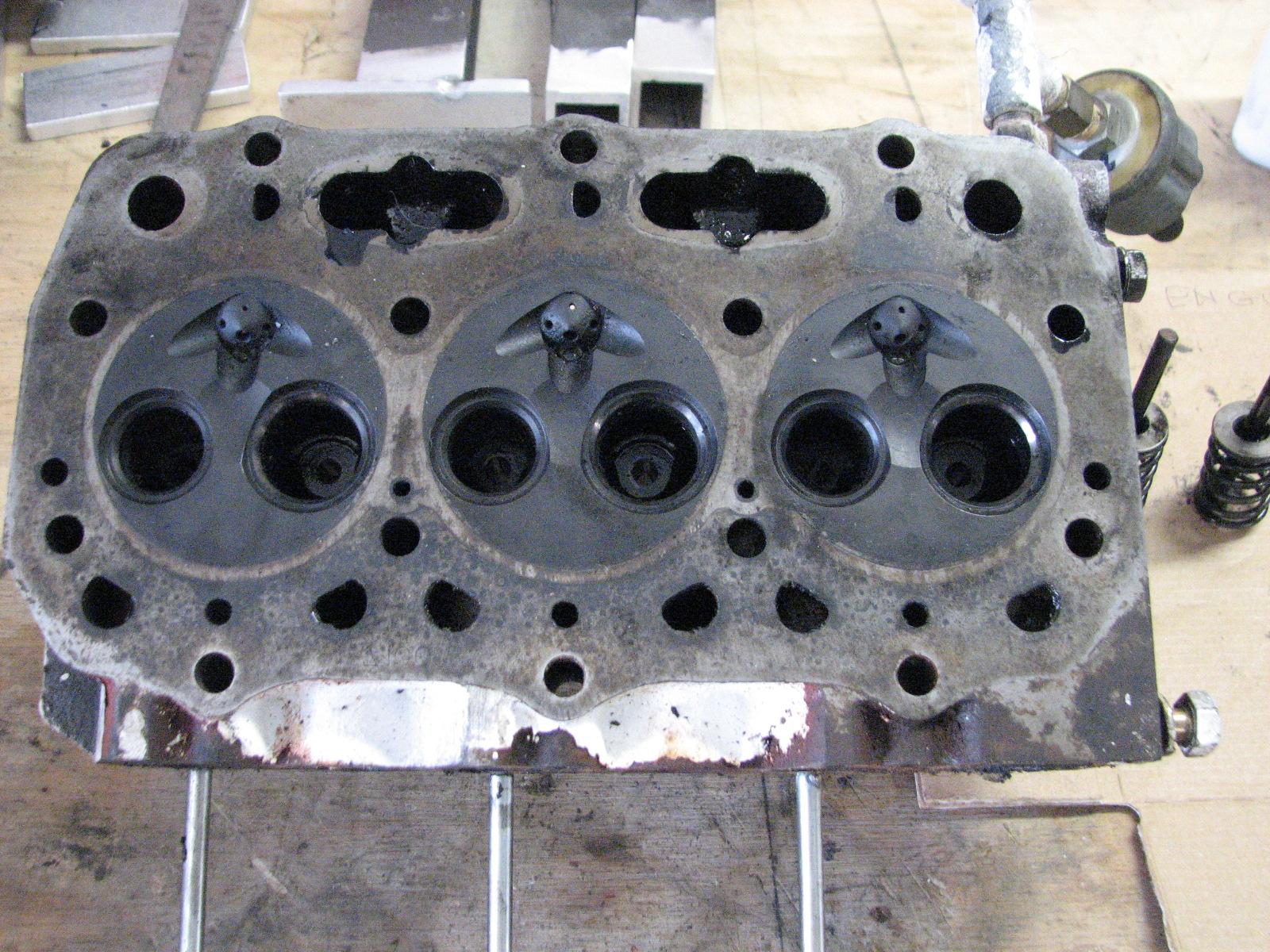

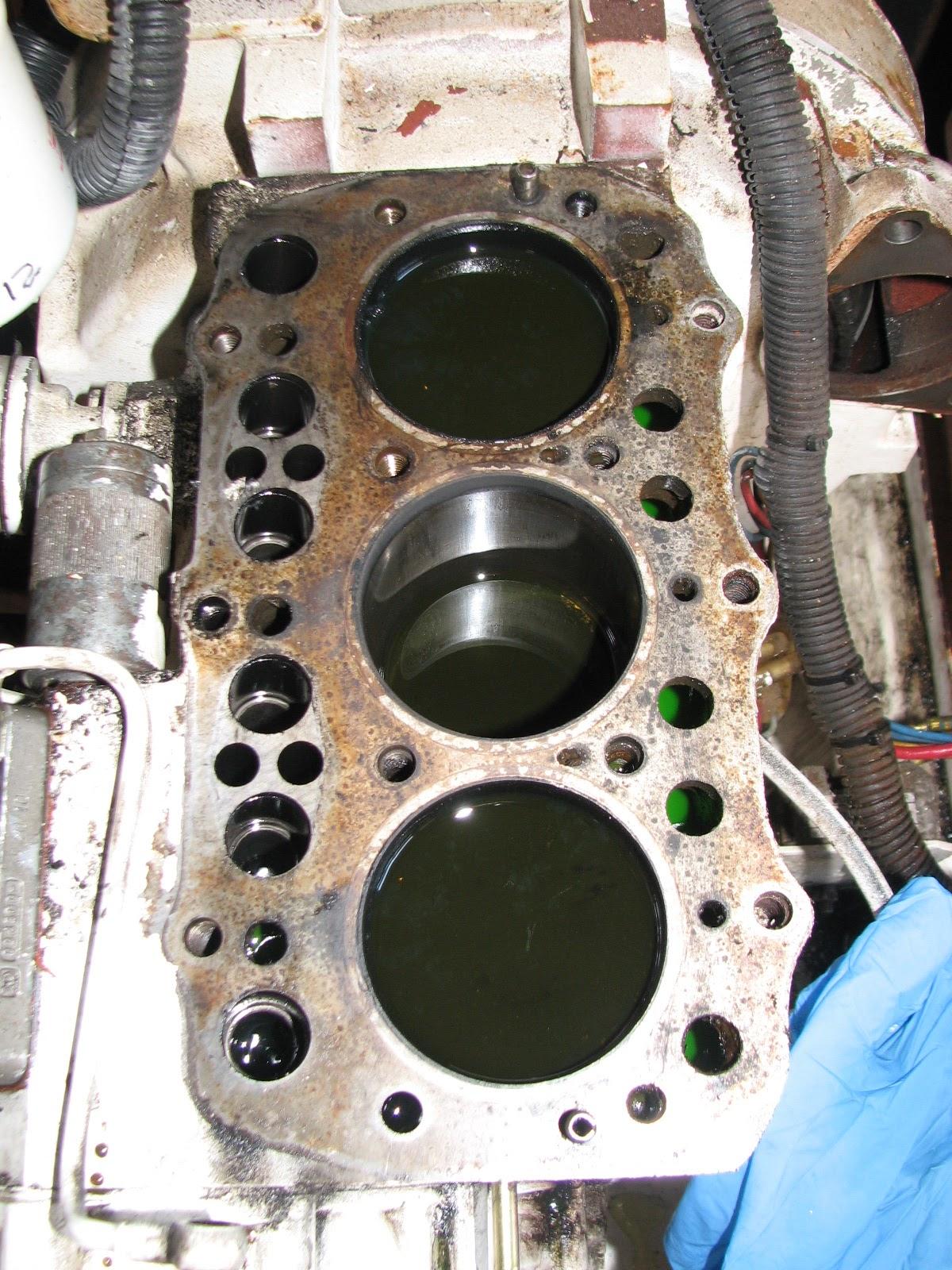

When I did finally get the head off, I

could not find an obvious problem. This was very disconcerting. The

valves in the head looked good, and all three cylinders looked very

good. I set the head on the bench, and poured water into each of the

intake ports, and no leaks were detected. I left the head in that

condition over night, just to see if there is a leak.

Head Removed From Engine, Topside

Head Removed From Engine, Bottom side

The Three Cylinders In The Engine Block

Water Sitting In The Three Intake Ports

I did not do it today, but tomorrow I

will pour oil into the cylinders and see if one leaks down faster

than the other.

I went back to DREAM AWAY, and Kitty

and I got in the tender

and went for a ride down the bayou. We wanted to check out some land

the Port

of Delcambre owns. We had looked at the land from the

landside, but wanted to see how it looked from the waterside.

Kitty and I are trying to get the Port

of Delcambre to use this property as a nature walk for

birders.

Land From The Waterside

Bird Nesting On The Mud

We continued our ride down the bayou,

to give the Yamaha engine on the tender

a good workout.

March 08, Saturday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian and Jordan, and spend time with them brushing

their beautiful coats.

Did not go over to the shop

first thing in the morning. Worked on the computer until 0900. At

that time, Nicola

& Noel called from Guatemala and we discussed the

issues involved with the repair of the main mast step on TANTALUS.

We are deciding what materials we will need to purchase here in the

states, and that we will bring down to Guatemala to do the repairs.

Kitty and I had breakfast, then I got to work on getting the

generator

out of DREAM AWAY.

First item on the list was we had to

move the hard Bimini from over the cockpit to the front of the boat.

Because I already had the boom gallows off of DREAM AWAY the task was

reduced. I had to disconnect the DC wires for the cockpit reading

lights, and the external antenna for the Globalstar

satellite phone.

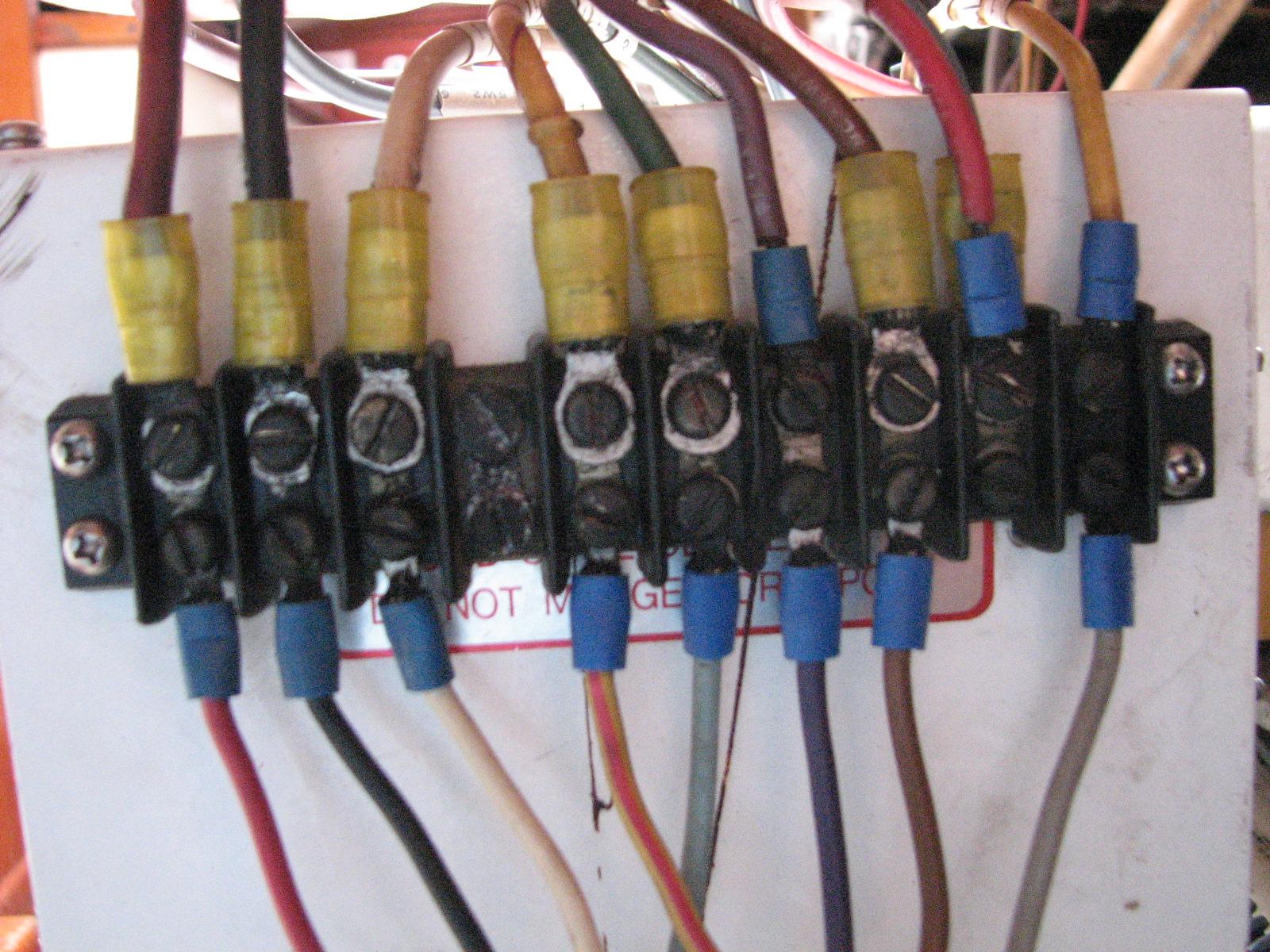

When I got all of the wires

disconnected, I attached ropes to the Bimini so we could lift it out

of the way. I then removed all of the bolts that had the Bimini

bolted down to the cockpit.

Now I had to get the generator

ready to remove. The fuel, water, and exhaust were disconnected, and

then all of the DC and AC wiring were disconnected. I removed the

bolts that held the generator

tray bolted to the stand. The generator

is ready to go!

I got Cindy

and Johnal over to help, and then with Kitty and I

helping, we got the Bimini up and moved to the front of DREAM AWAY.

Bimini Wires Disconnected

Bimini Ready To Lift Off Of Cockpit

Bimini On The Front Of DREAM AWAY

Next was the removal of the generator.

I have no photos of the actual removal because all four of us were

involved in the removal, and no one could take pictures of the event.

Johnal Getting Ready For Work

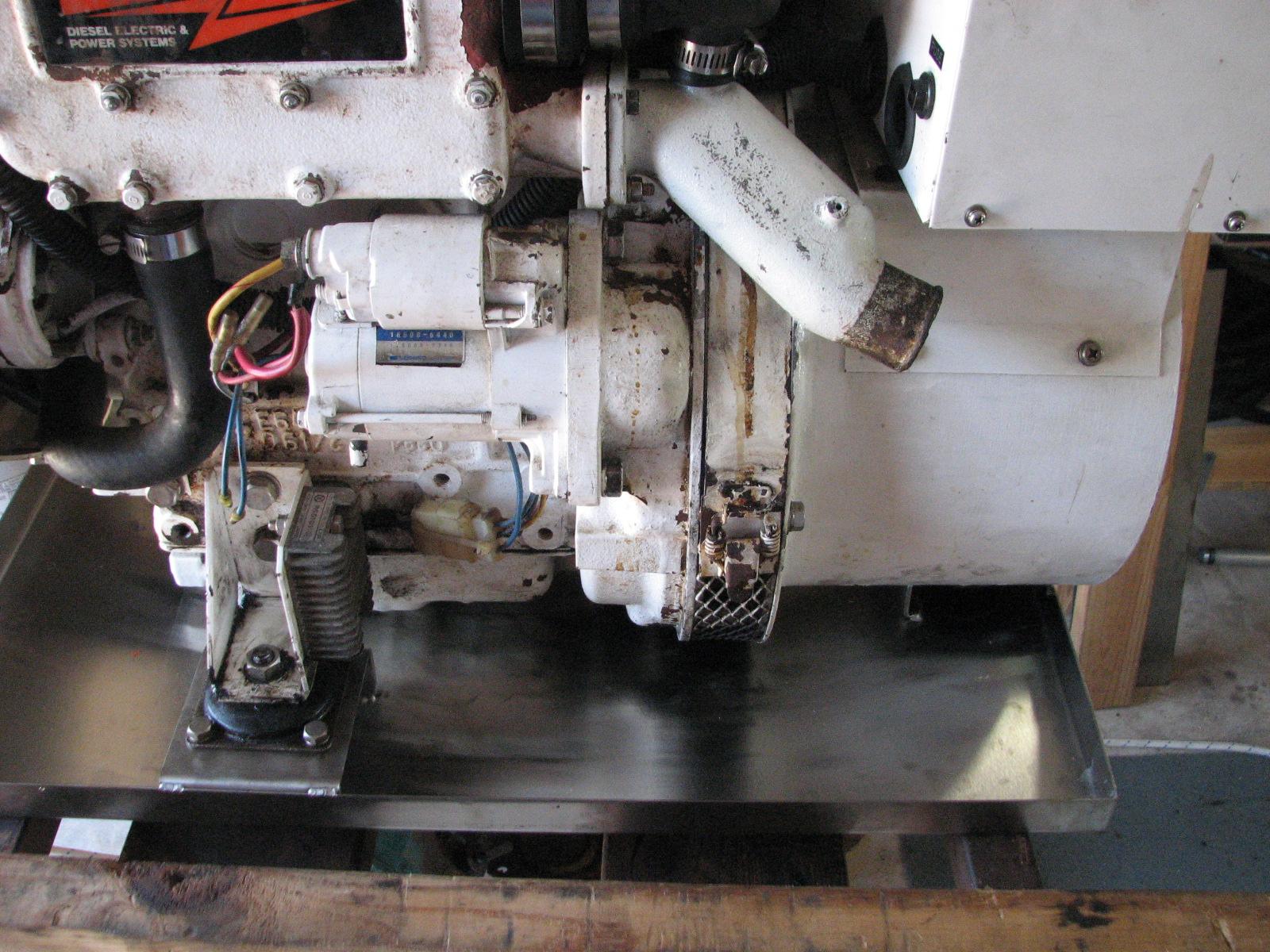

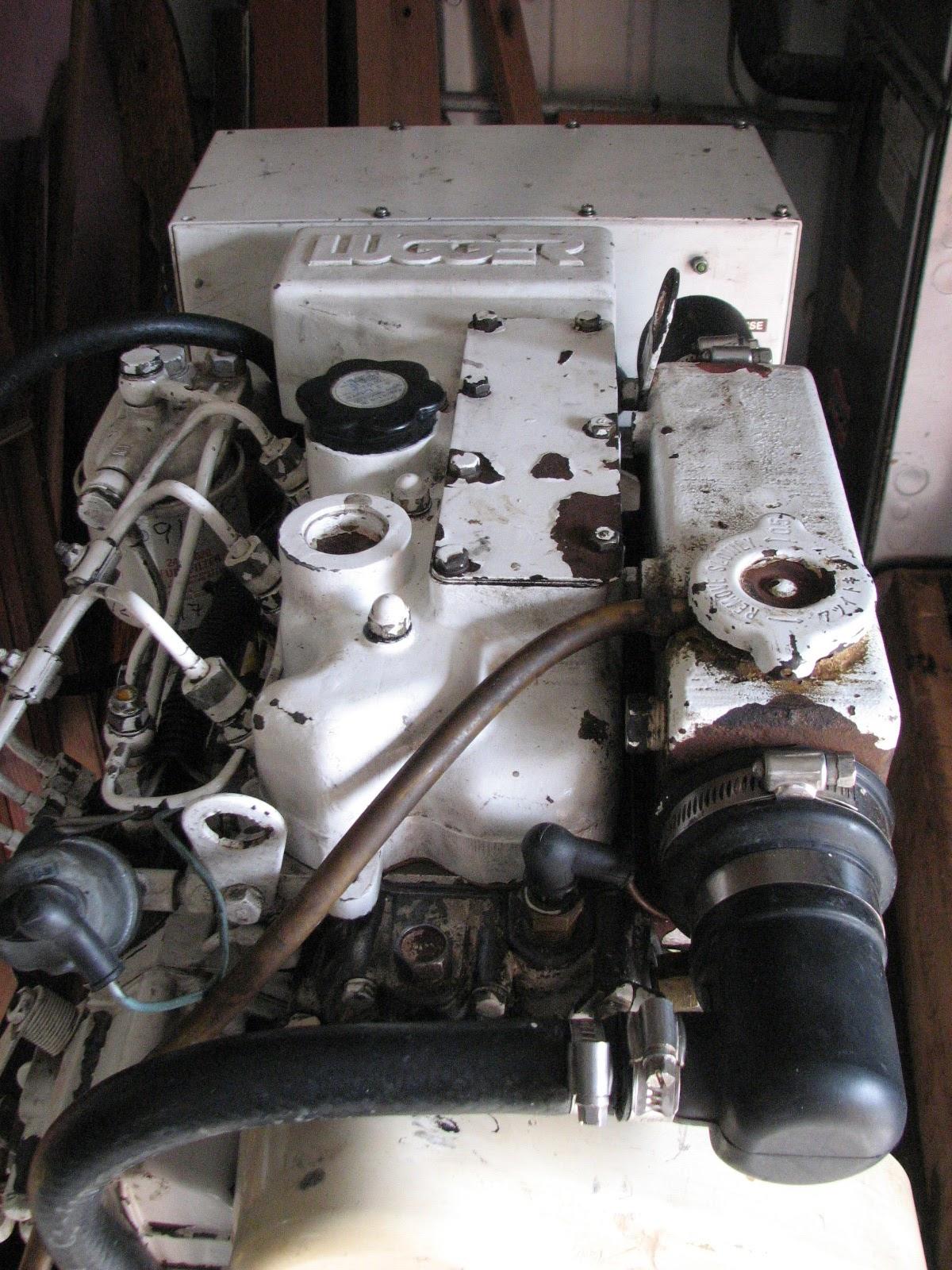

Generator & Johnal In The Shop

Drill Press Moved To Work Bench

We then went back to DREAM AWAY. Johnal

went over to his boat to get back on his projects, and I straightened

up the garage, put all of the tools and various items away. I also

straightened up all of the lines, sheets and halyards we used and put

the main sail cover back on.

I went over to the

shop

and applied the seventh and final coat of

Cetol

teak

treatment to the boom gallows and the instrument pod pieces.

March 07, Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian and Jordan, and spend time with them brushing

their beautiful coats.

Went over to the shop

first thing this morning as the temperature was in the high 40’s

and climbing.

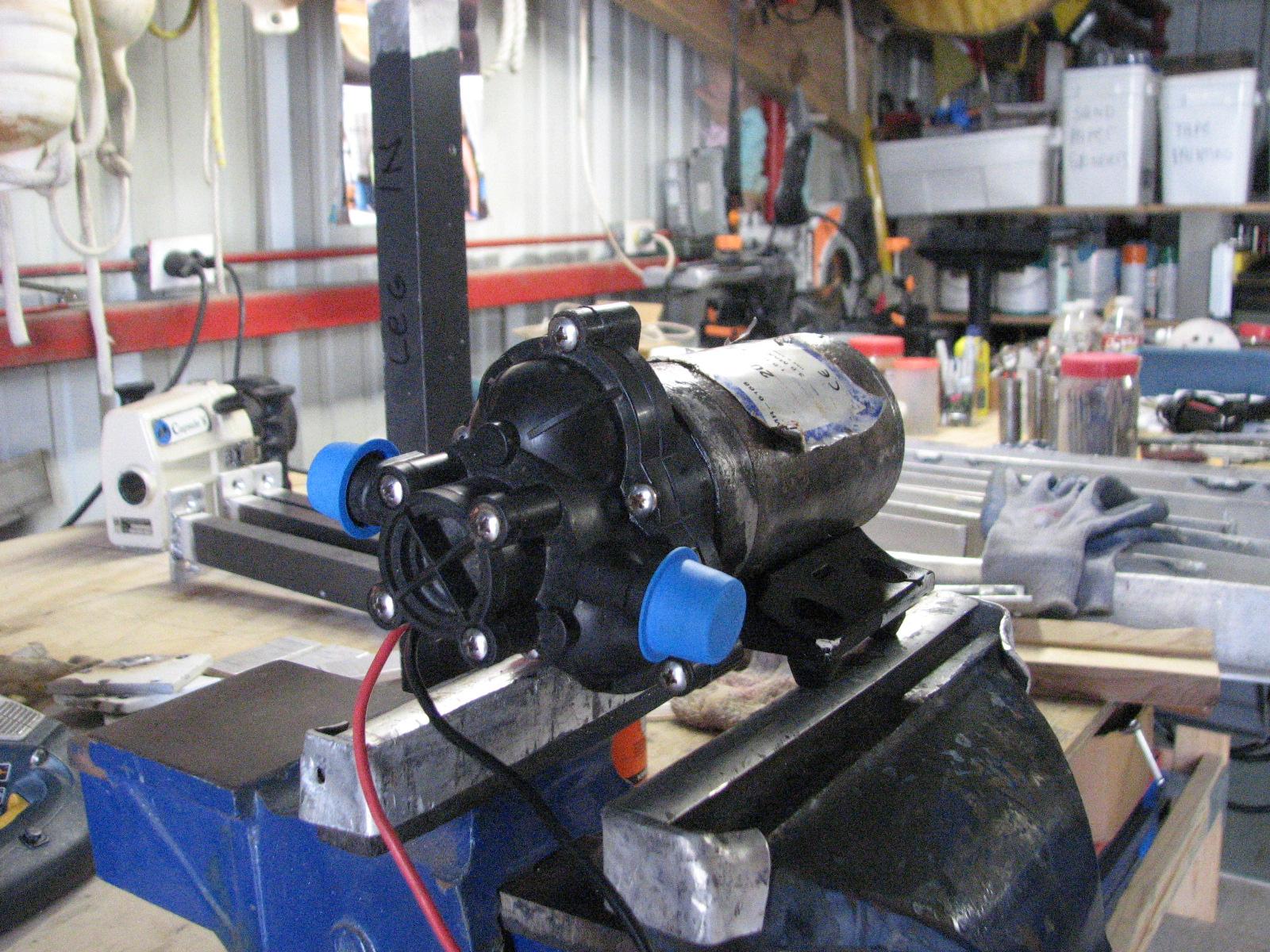

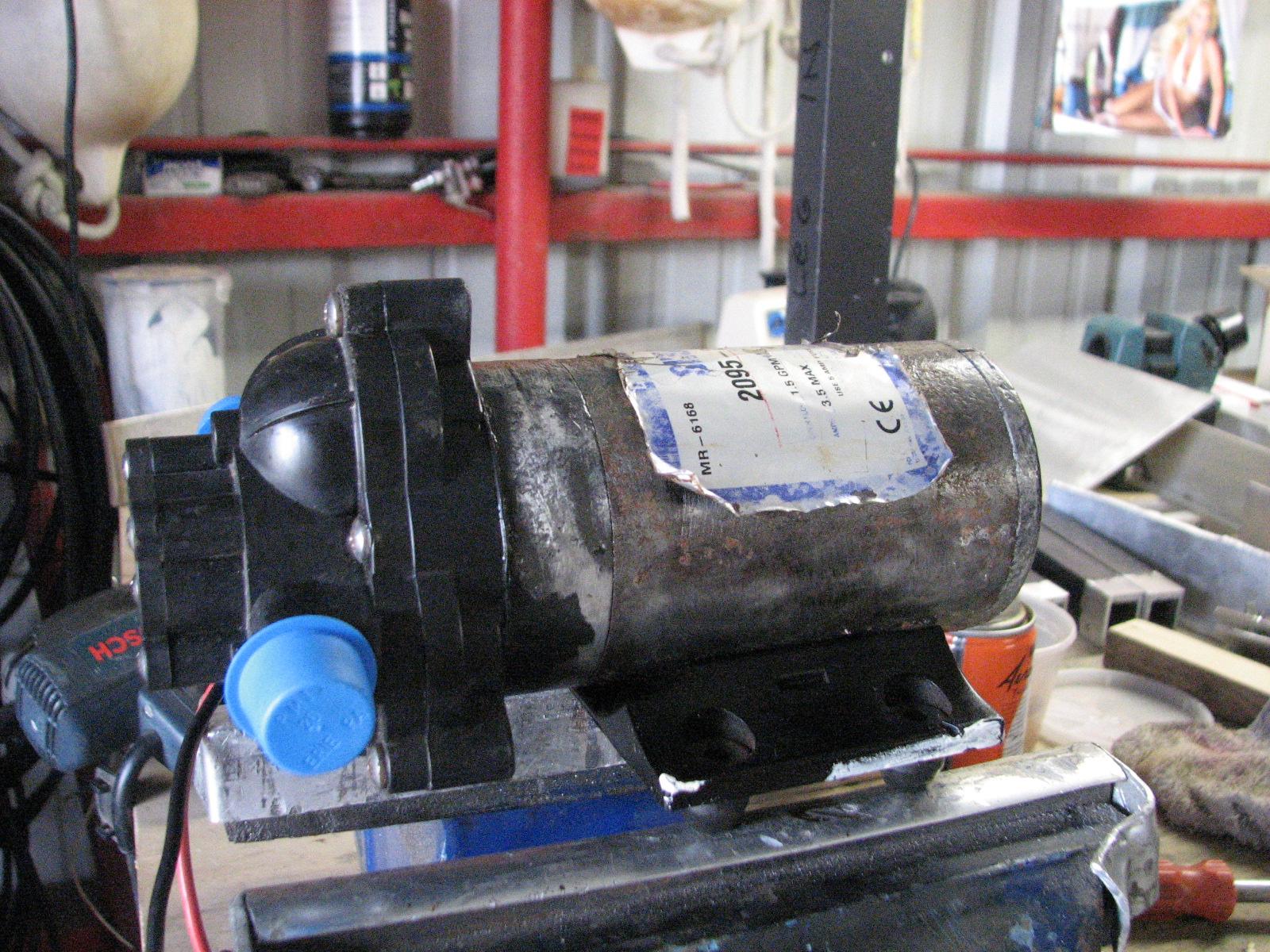

I had remembered the nuts and washers

for the refrigerator cooling pump, so I put the motor back together,

and tested the motor using the battery in the

Black Beast. The

motor worked pretty good. The bearing in the motor still sound rough,

but it will do as a good spare for now. Before going out cruising

again, I will probably purchase a new pump.

Motor Back Together

I then put the pump parts back onto the

motor and tested the complete unit again using the battery in the

Black Beast.

Worked fine, but still have the bearing problems.

Pump Head On Motor

Pump Head On Motor

The last coat of Cetol

teak

treatment to the boom gallows and the instrument pod parts had dried,

so I sanded down all of the parts with 220 grit sandpaper. This will

be the final sanding before I apply the last two coats.

Sanded Boom Gallows

Sanded Instrument Pod Front

Sanded Instrument Pod Housing

I then wanted to start welding on the

legs for the sail handling platform (SHP). I would like to get going

on that because I might be able to get the SHP completed before our

planned cruise to the Mermentau

River at the end of the month.

SHP Leg Setup For Welding

I also have some aluminum welding that

needs to be done on the solar panel risers. It would be more

efficient to do all of the welding at one time with only one setup.

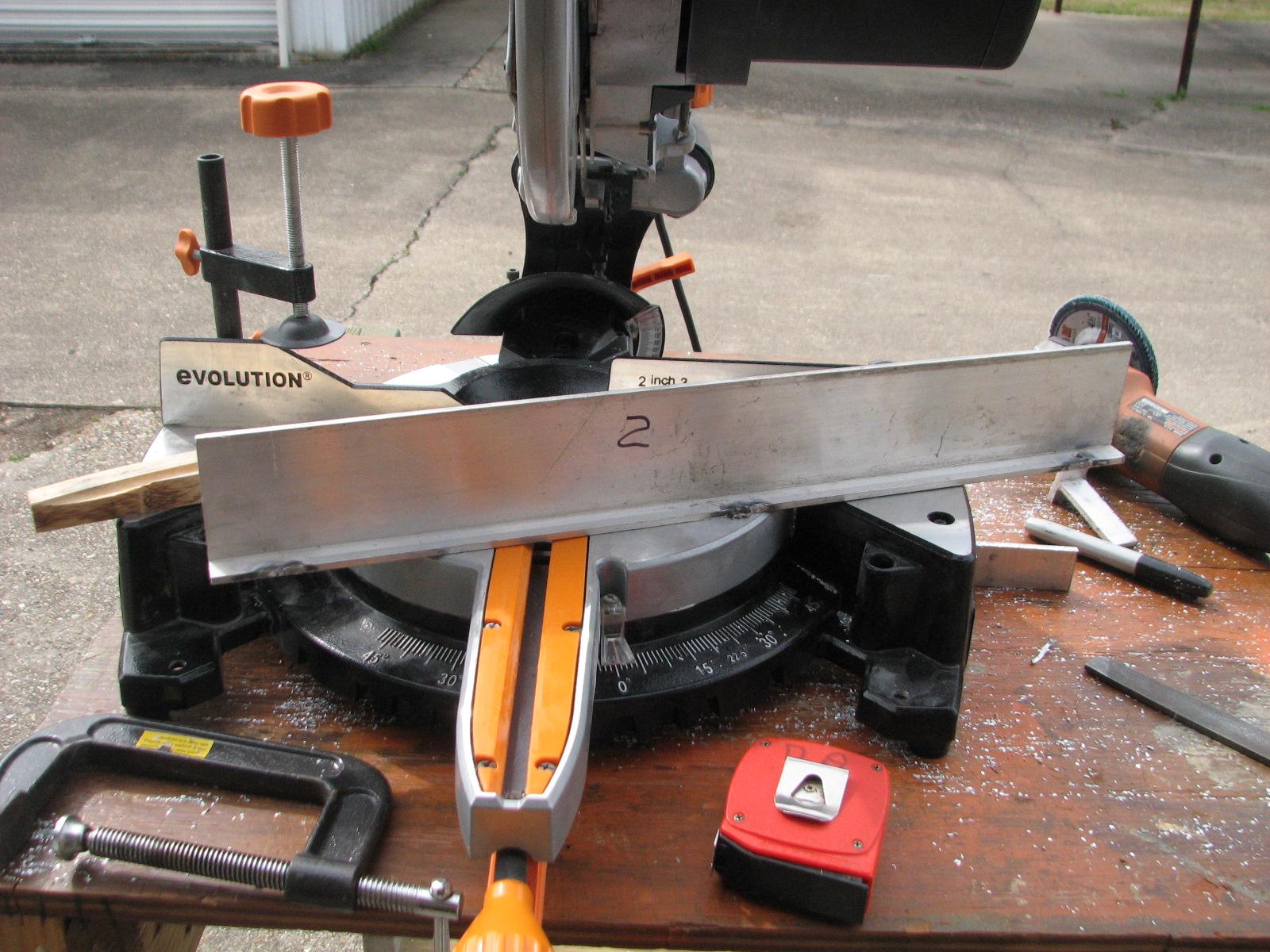

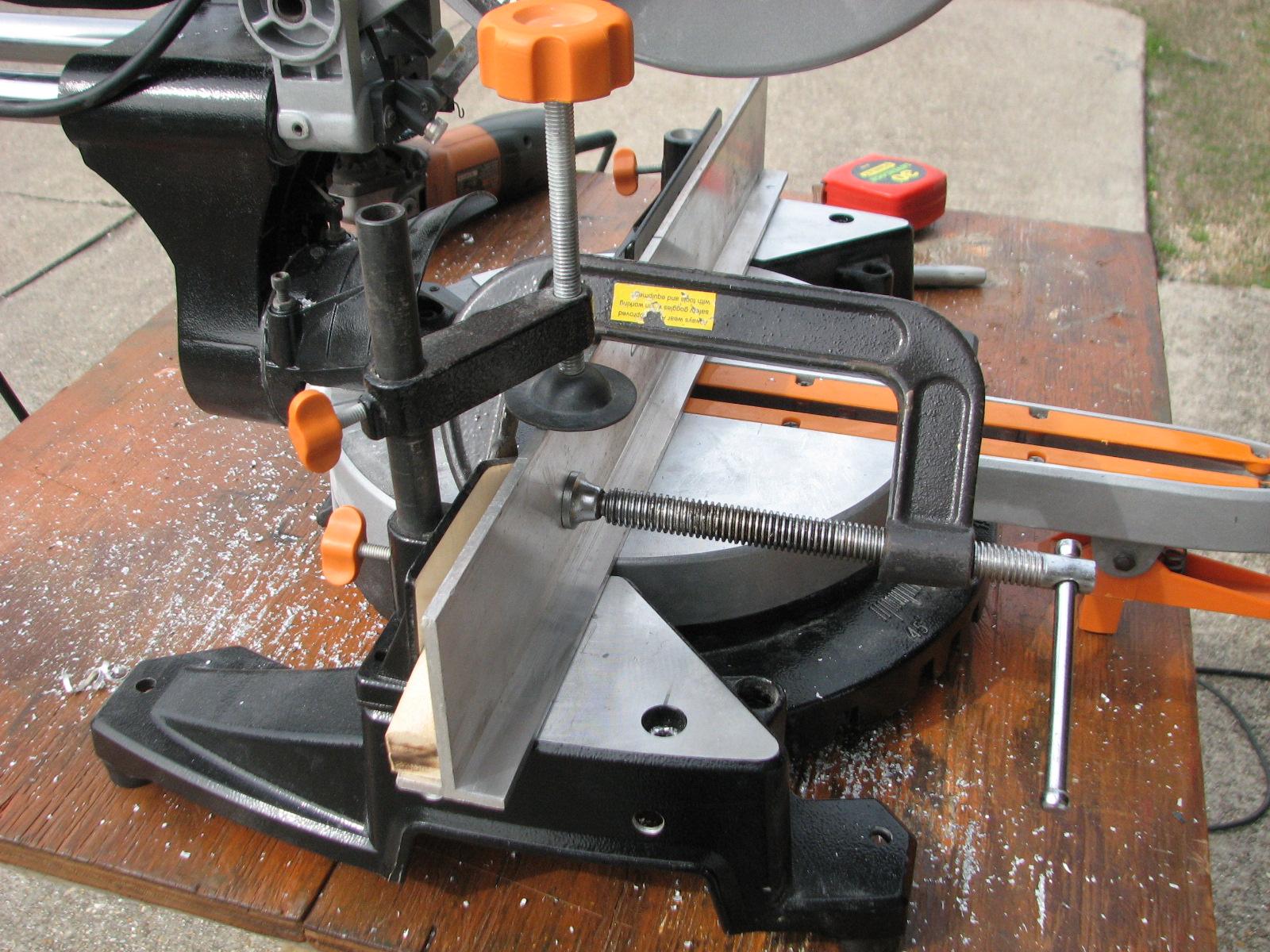

I then got busy cutting and measuring

the “T” plates for the solar panel risers.

Measuring And Cutting The “T”

Plates

Kitty called and was up, so I went over

to DREAM AWAY to have breakfast. After breakfast, I went back to

Xtreme Marine and talked to Travis about the generator.

I told him about the different switches on the generator

and they had no effect. He suggested that I remove the air

intake/valve cover and verify that all three cylinders are sucking

air on the intake. I told him I would, then headed back to the shop.

I worked more on cutting the “T”

plates for the solar panel risers. I am working to get all 16 risers

cut to 11” long and then the adjustable piece cut off of the “T”

plate.

“T” Plates On Work Bench

Setting Up For A Cut Of The “T”

Plate

Setting Up For A Cut Of The “T”

Plate

At about 1530, I stopped cutting on the

“T” plates, and wiped down the boom gallows and the instrument

pod parts with the

tack rag. When I finished,

I then applied the sixth coat of

Cetol

teak

treatment to the boom gallows and the instrument pod pieces.

I cleaned up the application materials,

and put everything away, and headed back to DREAM AWAY.

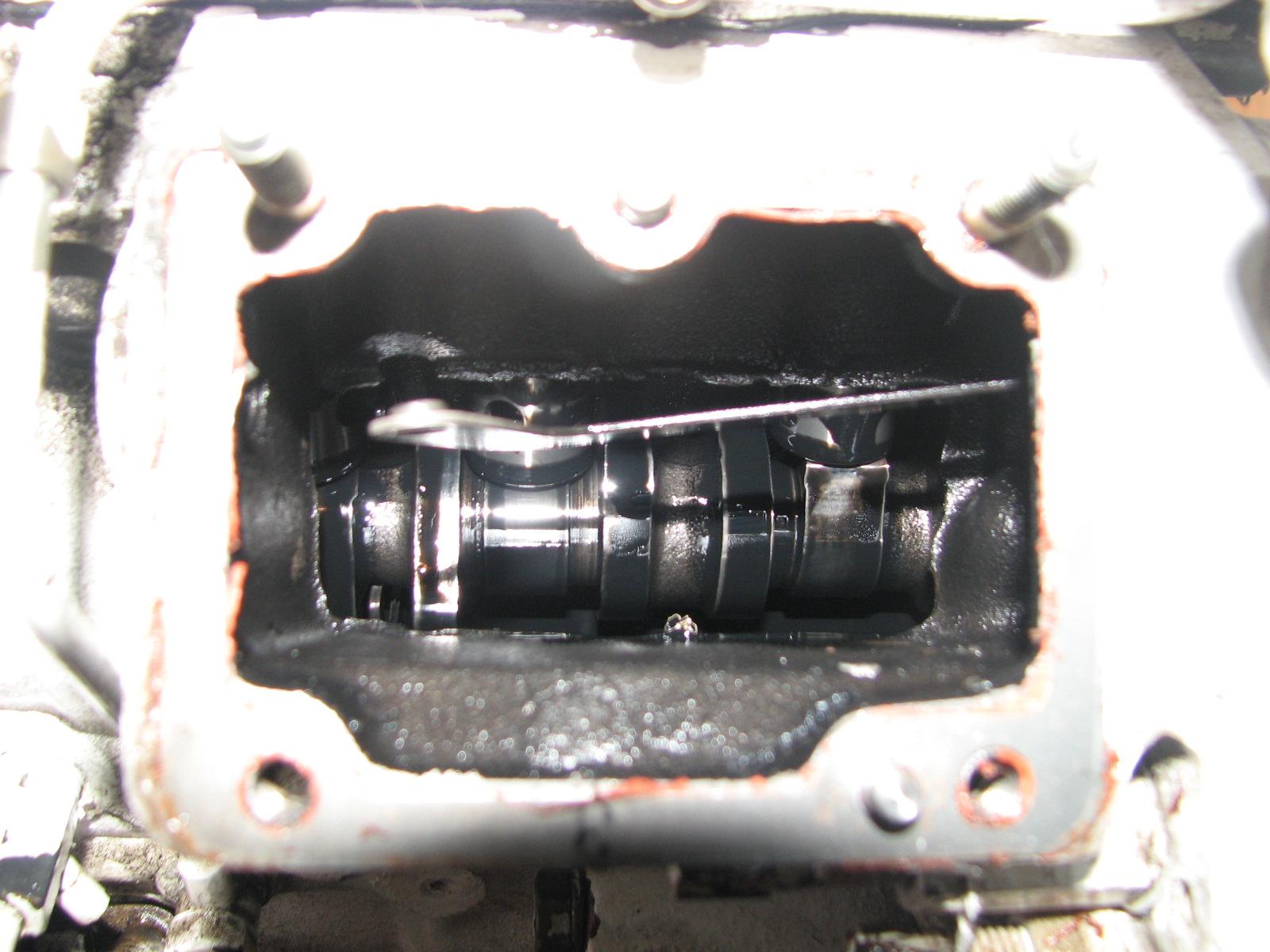

When I got back I started in on the

generator.

I removed the air intake/valve cover, and was surprised to see a

large amount of oil in the air intake half of the cover. I then had

Kitty turn the engine over with the control panel start switch. The

good news is the valve train seems to be operating properly. The bad

news is there is oil being blown out of the number two cylinder!

I decided then it was better to take

the generator

out of DREAM AWAY and take it over to the shop to work on. Very easy

access, and make the overall project go a lot better. It will also

make it much easier to clean out and clean up the bilge.

March 06, Thursday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian and Jordan, and spend time with them brushing

their beautiful coats.

Did not go to the shop

this morning, as it was still pretty cold, windy and overcast. The

high temperature for the day was only 43°. I stayed on DREAM AWAY, forever catching

up on email and computer projects.

After breakfast I went up to see Travis

and Xtreme Marine and talk about my generator,

and the problem I am having getting it to start. He suggested disconnecting the

exhaust temperature switch, and even the oil pressure switch and the

water temperature. If any one of these switches are bad, he said it

would prevent the engine from starting.

I went back to DREAM AWAY, and went to

work on the generator.

As it turns out, my generator

the M643-5N, does not have the exhaust temperature switch. I did

disconnect the temperature switch and the oil pressure switch, and

the engine still will not start. I am really running out of ideas! I

will try and see Travis again tomorrow, and see if he has any good

ideas.

The holding tank in the

shower trailer

at the marina

was full, so I drained it into the sewer system. I have to keep a

good watch on the level, because the tank watch system is not working

properly. Even with the tank completely empty, it is showing ¾ full.

More fun than I need.

When I cleaned up from that task, I

went over to the shop.

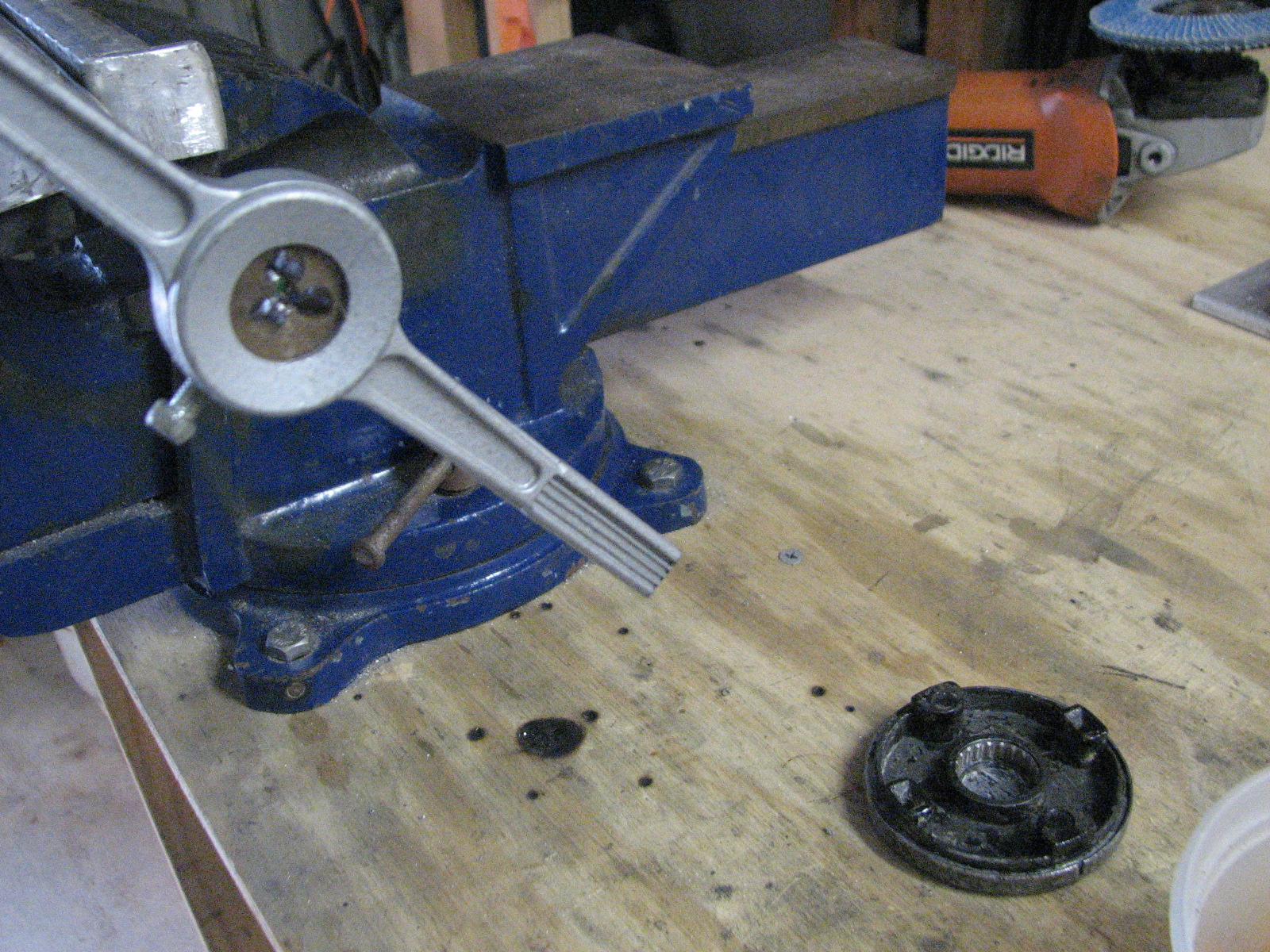

I had finally remembered to take over my 10 X 32 die, so I could

fabricate the long bolts to put back together my spare refrigeration

cooling pump.

I got the piece of steel rod in the

vice, and cut the threads at one end. I screwed that end into the

motor end cap, and calculated the length of the bolt, and then cut

the rod. I cut a second piece of the steel rod, and the cut the

threads in each end of the rod.

I put the motor back together, but I

had forgot to bring over the nuts and washers to complete the

project.

Cutting The Threads In The Steel Rod

Motor Back Together, No Nuts On Bolts

Went back to DREAM AWAY, and while

preparing dinner, some new cruisers arrived. They are Francis and

Helene of of the trawler MISS JAZZ. They are from Quebec in Canada,

and are presently cruising the Louisiana coast.

They heard about us on The

Active Captain, and came into the dock. They joined us

for dinner, and they will be out touring the area with some friends

from New

Iberia.

Helene And Francis On MISS JAZZ

March 05, Wednesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian and Jordan, and spend time with them brushing

their beautiful coats.

Around 0830 went over to Pier “C”

to help Chris and Melanie on MIDNIGHT SHADOWS get off. They went up

to LeBlanc Oil for fuel, then they were on their way back to Kemah,

Texas.

When that task was completed, Kitty and

I drove to a Credit Union in Lafayette

so I could get the cashier’s check for theasdasdas

. We got the check, then to the Post

Office, and got the check off to the owner of the Red

Beast.

On the way back top DREAM AWAY, we

stopped at a grocery store and purchased some groceries.

After a quick lunch, I defrosted the

freezer and cleaned out the refrigerator. It had been some time since

the last defrost,and the ice buildup was quite large. The

refrigerator was definitely in need of a cleaning.

Freezer With Some Ice Removed From

Holding Plate

Ice Removed From Holding Plate

Ice Removed, And Food Back In Freezer

Finished off the refrigerator-freezer

cleanup and defrosting, and went over to the shop.

I then applied the fifth coat of

Cetol

teak

treatment to the boom gallows and the instrument pod pieces.

March 04, Tuesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian and Jordan, and spend time with them brushing

their beautiful coats.

Did not go to the shop

today as it was bitter cold with sleet and freezing rain until the

late afternoon. The high for the day was 34° and the low was 31°.

Not a good day to be outside, and I wasn’t!

Spent the day on the computer. Almost

finished the February Maintenance Log, caught up on paperwork

scanning, and catching up on computer work.

March 03, Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the shop

at all today, cold all day, with no chance of warming. Worked all

morning on computer, catching up on emails and doing general family

stuff. Making plans to get the Red

Beast paid for and picked up.

In the afternoon, I worked on the

generator.

I took out all three glow plugs and checked them, they all glow! To

get one of the glow plugs out I had to partially disassemble part of

the fuel system. Once I got the glow plugs back into the system, I

finished putting the fuel system back together

Kitty helped me by operating the start

switches, and we bled the fuel system up to the injectors. fuel was

squirting out of the injectors. The generator

still would not start. I am running out of ideas!

I thought the generator

might have a timing problem, so I sent an email off to Northern

Lights, and asked about how to set the timing. The

wrote right back and said timing was set with shims under the

injection pump. I did not change the shims, so should not be a

problem. He also said that if the timing was off, the engine my run

rough, but timing would not keep the engine from running.

I am going to have to talk to Travis at

Xtreme Marine here in Delcambre

to get some ideas.

I then went into the head and cut the

teak

wire cover to fit over the wire to the overhead light in the head.

One piece will do the job, so I do not have to epoxy

a couple of pieces together.

I went back to the computer and

continued work on it, still trying to catch up.

March 02, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan,

and spend time with them brushing their beautiful coats.

We had a very nice farewell breakfast,

including Mimosas! Nicola

& Noel were leaving this morning, as they were

continuing their trip to Guatemala to spend a couple of months on

their yacht, Tantalus

.

We drove to the airport in Lafayette

and dropped off Nicola

& Noel. We are hoping to meet up with them this

December or next January in the Rio

Dulce.

We drove back to DREAM AWAY. Kitty

worked at getting the front cabin squared away, and I went over to

the shop.

Before going over to the shop,

I put in a low bid on eBay

on a truck I really like.

This truck is a 1988 Suburban with a

Cummins engine conversion, and a dually conversion also. Right now I

am referring to it as the Red

Beast!

When I got over to the shop,

I worked on the risers for the solar panels that will be installed on

DREAM AWAY. The slight modification will be much easier to adjust the

height of the panels as the sun moves across the sky.

I then applied the fourth coat of

Cetol

teak

treatment to the boom gallows and the instrument pod pieces. I did

some cleanup in the shop

and came back to DREAM AWAY.

When I came back to DREAM AWAY, I

checked on eBay,

and my offer was accepted. I am now the owner of a 1988 Suburban

dually, Cummins conversion. Now all I have to do is figure out out to

get money to the owner, and how I am going to pick it up and bring it

back to Louisiana. That is a later or tomorrow project. Informed both

kids of my new purchase! The fun begins!!

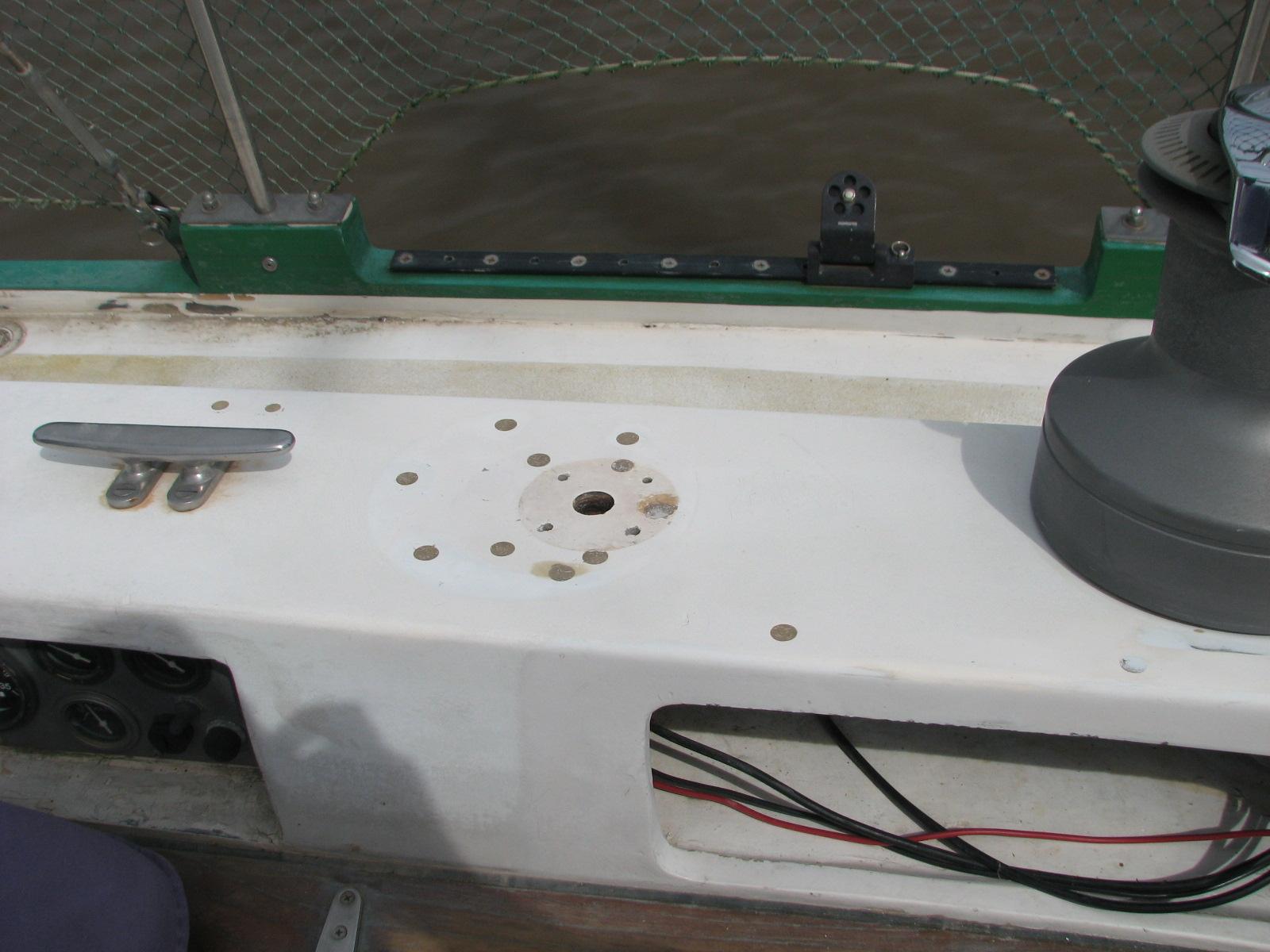

Kitty had some items for me to take

over to the shop,

and I had to pick up some sealant, so over I went. When I returned to

DREAM AWAY, I applied some silicone sealant around the after port

cleat. We are supposed to have a lot of rain tonight or tomorrow

morning, so I am hoping to stop the leak!

March 01, Saturday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan

and spend time with them brushing their beautiful coats.

Did not go over to the

shop

this morning, we ate a wonderful breakfast, and then headed up to

Broussard, Louisiana. Kitty and I with

Nicola & Noel in one car, and

Cindy and Johnal

in their car. We were heading to the

Parish Brewing Company for their

tour and the tasting room.

The “Computer Room” Before Breakfast

We sampled a couple of their beers. I preferred the

Canebrake beer. It is brewed the

traditional way, but they add

some Steen’s Molasses during the brewing process, and for me it

adds a nice flavor. Many opinions about the different beers as you

can imagine, but we had a great time.

We all enjoyed the tour, and interacting with all of the other folks

in the tour.

Front Of The Brewery

Brewmaster Giving Us The Tour

Post Tour Photo

Tapping A Keg Of Black Currant Beer

We all had small lunches, but the food was wonderful. We all

thoroughly enjoyed our meals.

We left

Prejeans Restaurant and had a great adventure getting to the

Bayou Teche Brewing location. One of the roads was being

repaired and nothing but a dirt track. Loads of fun, but we finally arrived!

We walked into the taproom, and were told there would not be a tour

because their was a funeral of a very close friend of the town, and

all but one employee were attending the funeral. The brewmaster

explained how they ran the tap room.

They have eight beers on tap, and we could purchase a beer flight for

$4.00, and this would give us a sample of all eight beers. It seemed

like a good idea so Kitty, Nicola, Noel and I purchased one flight.

Once everyone purchased their flight the brewmaster explained each

beer, how they were made and what they were made from. My favorite

was one of their best products.

Boucanee.

It tasted like you were drinking smoked ham. This beer would go very

good with a hard cheese.

Brewmaster Pouring The Beer Flights

The Gang And Brewmaster Before Departure

We departed the brewery, and headed back to DREAM AWAY were we had a

wonderful T-Bone steak dinner with Dijon string beans and baked

potato.