Maintenance Log April 2013

April

1, 2013, Monday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

I also worked on the March Maintenance Log.

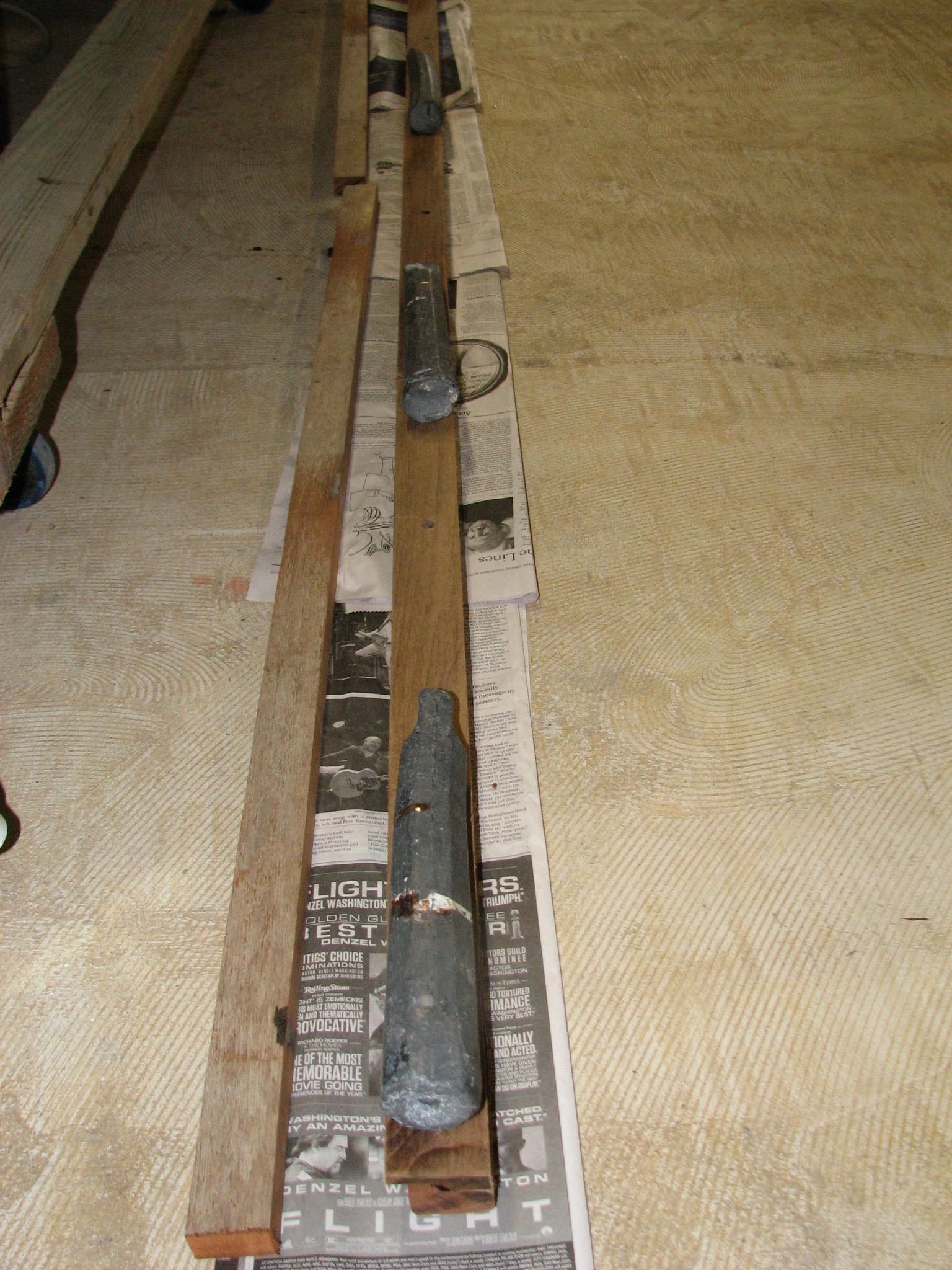

Started

off the day working on the sanding and cleaning up of the name

boards. Very time consuming work. Finally finished all scraping off

all of the old varnish and Cetol.

I still have sanding to do, and fill the old bolt holes with teak

bungs.

Name

Board During Scraping Process

In

my Maintenance Log entry for March

30,

I mentioned I had brushed down all of the teak trim pieces for the

refrigerator/freezer, and the two teak wire covers with the dye

(Agent Orange).

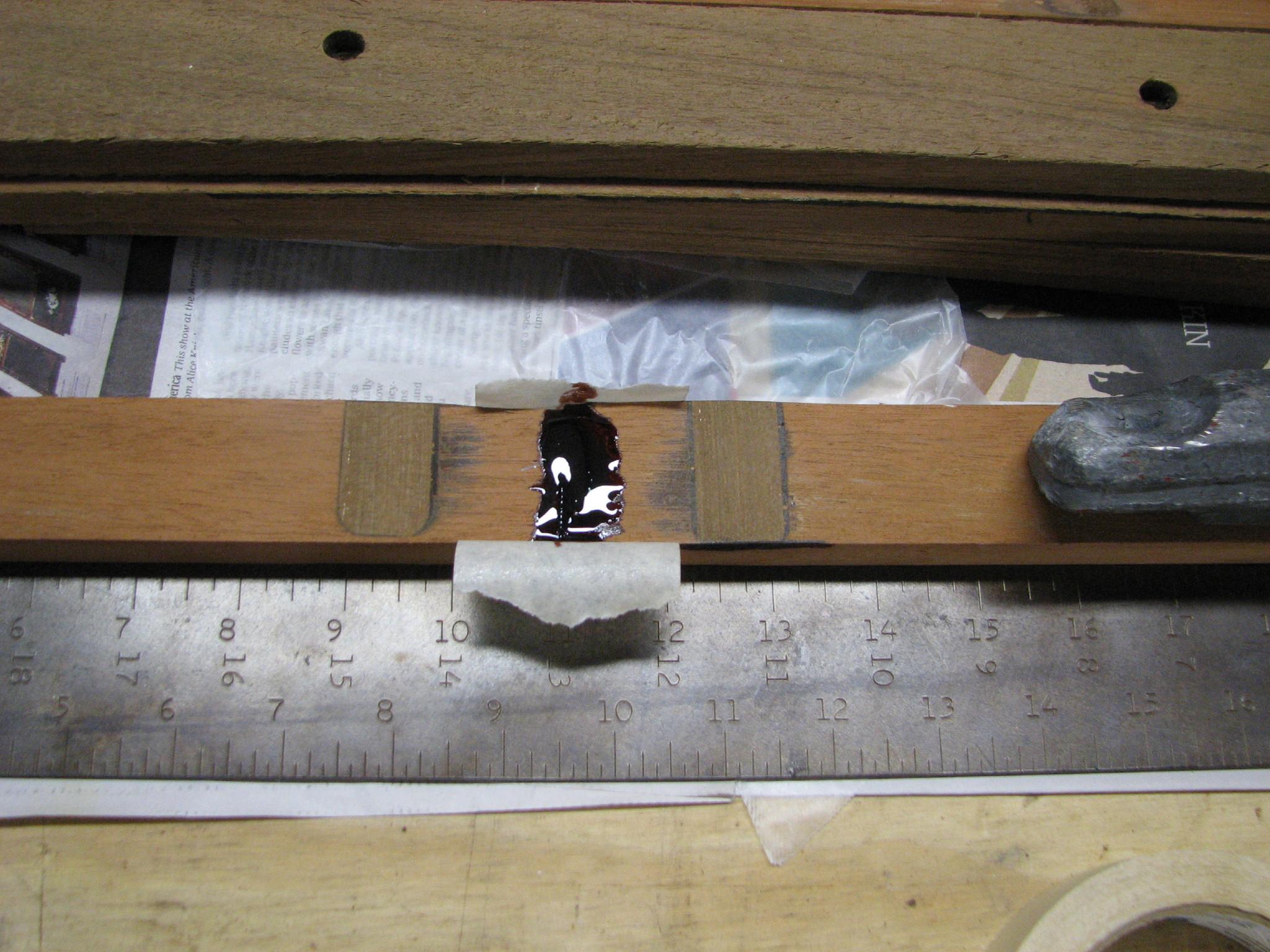

Two

Teak Wire Covers With Dye Applied

Teak

Refrigerator/freezer Trim Pieces With Dye Applied

The

dye had dried so now it was time to apply the Smith’s

penetrating epoxy.

For many years now, I have had a policy of applying Smith’s

penetrating epoxy

to any wood put on DREAM AWAY. The mix is a one to one for the resin

and catalyst. You can see from the picture, I mark all of the

containers, so there is no mistakes made during the mixing process

Mixing

Containers On Work Bench

I

then applied the mixed Smith’s

penetrating epoxy

to the sanded pin rails, the teak trim pieces for the

refrigerator/freezer, and the two teak wire covers. I actually

applied three coats to all of the wood.

Epoxy

Applied To The Pin Rails

Epoxy

Applied To The Teak Trim Pieces For The Refrigerator/freezer

Epoxy

Applied To The Two Teak Wire Covers

April

2, 2013, Tuesday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Had

to go to Lafayette for a doctors appointment, and pet food shopping.

Returned from the trip, and then helped a fellow boater in the marina

move his vessel from one slip to another.

Got

under the aft cabin bunk and removed my bottle of oxygen that goes

with my oxy-propane torch.

Kitty

Holding Down Folded Up Mattress On Aft Bunk

Oxygen

& SCUBA Tank Under Aft Cabin Bunk

April

3, 2013, Wednesday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Also worked on updating the maintenance log.

Today

I did a lot of work on the March

Maintenance Log.

Perfecting a method to get the downloaded file from Google a

viewable file on my web page. I seem to have it going now, just very

time consuming.

Move

some small pieces of stainless steel and aluminum out from under my

storage area under the deck in the galley. I want to have this metal

at the shop when I work on projects in case it is needed.

Washed

down the boat today, all except the cockpit. It is nice to see DREAM

AWAY looking much better. She will sparkle when the sun comes out!

April

4, 2013, Thursday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Also worked on updating the maintenance log.

Went

over to the shop and checked that the epoxy on all of the teak pieces

had hardened. I then moved all of the pieces out of the “work”

area and into Kitty’s Library to get ready for the application of

varnish on interior pieces and Cetol

on the exterior pieces. The picture looks busy, but you can see the

belaying pins and pin rail hanging from various places. Also the teak

reefer trim pieces on a makeshift table, and the wire cover pieces on

Kitty’s computer table.

Teak

Pieces Ready For Varnish And Cetol

Application

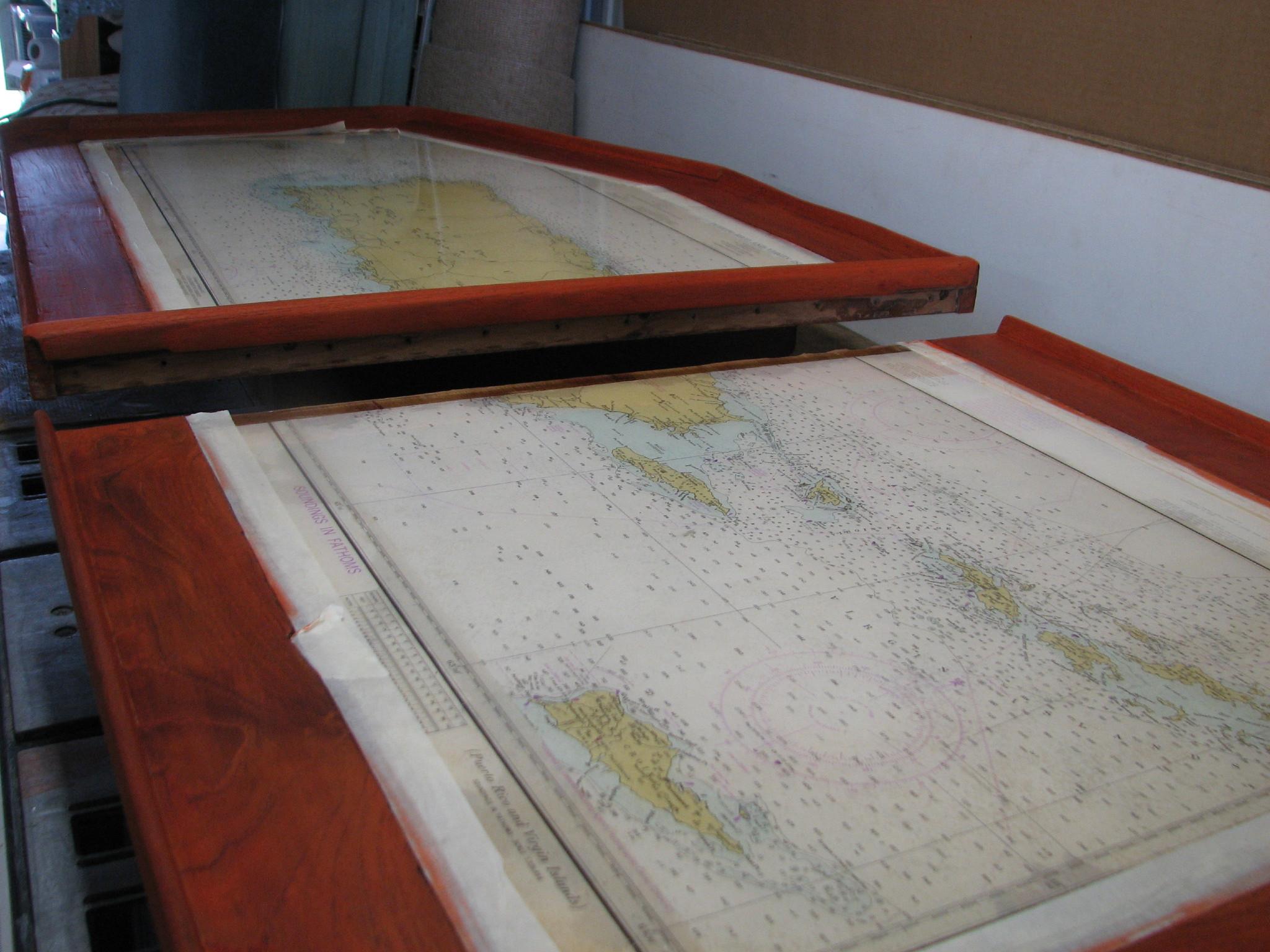

I

knew I was going to be needing the saw table so I moved the main

salon table pieces over to the workbench and leveled them in

preparation for the application of the table resin.

Main

Salon Table Pieces Leveled On Workbench

I

then went over to DREAM AWAY and had breakfast. Before returning to

the shop, I got some help from Kitty, and we emptied out under the

port forward cabin bunk. I had many pieces of teak, stainless steel

and aluminum that might be needed in future projects. I wanted to get

all of the metal and wood I had on hand in one location.

When

I went back to the shop with all of this material, I had to do some

straightening up of the area where I had the metal and wood stored in

the shop. I got this done and all of the new material stored in some

sort of neatness where I can see what is going on.

I

still have some final sanding to do on the name boards, but what is

needed right now are some teak bungs to fill the holes in the name

boards left by the bolts that were used to attach them to the hull.

For that story you can check out the Cap

Rail Project.

Name

Boards Ready For Sanding

I

have the bit to cut bungs, so I chucked up the 1/2” bit into the

drill press, found a small piece of scrap teak, and went to work. I

was able to cut out about 50 bungs for use in the name boards, and

have some for other projects.

Cutting

Bungs On The Drill Press

I

then went back to my fun time project. Trying to get the broken bolts

out of the power head in my spare Yamaha outboard. Every day I apply

either Screwloose

or PB

Blaster

to the broken bolts. Today as every other day, I made no progress on

getting out the bolts. I have about decided to take the power head to

a machine shop to remove the broken bolts. I am afraid if I keep

messing around, I will ruin something, that will make the engine a

pile of junk!

Next

project is building a piece of teak that I can use as a base to cover

up the holes

in the overhead

in the aft cabin. These holes were cut so I could put in backing

plates

for the dinghy davits and the aft cleats. The holes look nasty, and

need to be cleaned up. I need a piece of teak about nine feet long,

by two inches high, and two inches deep. I do not have a piece that

big so I am building one.

I

have had a mahogany wooden ladder that came with DREAM AWAY in the

original purchase. I know I will not use it for its intended purpose,

so I decided to use it to build my hole hiding piece of wood. I did

not take a picture of the ladder before I started cutting. I took the

ladder apart, and cut off the rounded edges on the two ladder

uprights. I then cut the two ladder uprights in half. These four

pieces, plus the addition of four pieces of teak deck boards will be

the hole hiding piece when I am finished.

Teak

Pieces To Fabricate Hole Hiding Piece

Teak

Pieces To Fabricate Hole Hiding Piece

Last

item for the day at the shop is applying the Cetol

and the varnish. I do this as the last item of the day, so at least I

will not be raising any dust to land on the wet surfaces.

I

will go into the gory detail of application, then when I add another

coat I will reference this day for the details. First thing,

especially with the varnish is to sand between each coat with 220

grit sandpaper. For the Cetol

applications, I sand every three coats. The Cetol

goes on the exterior pieces, and I typically apply seven coats if

using a bristle brush. If using a foam brush nine coats. For the

interior varnish, I apply only five coats.

I

use separate containers to apply the material from. I use a cone

filter as I pour the liquid ( varnish or Cetol

) from the can into the plastic container. While the liquid is

draining out of the filter, I wash the brush I am using in acetone to

make sure the brush is clean. I then apply the liquid to the pieces,

hopefully checking under strong light, that there are no runs, and

the liquid is applied evenly. After the application, I pour the

liquid out of the plastic application container, and into its

original container. I then wash out the brush in acetone, until

clean. When I have finished the application of both the varnish and

Cetol,

I lock up the shop and leave for the day.

First

Coat On The Teak Pieces

April

5, 2013, Friday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

I also worked on the March Maintenance Log.

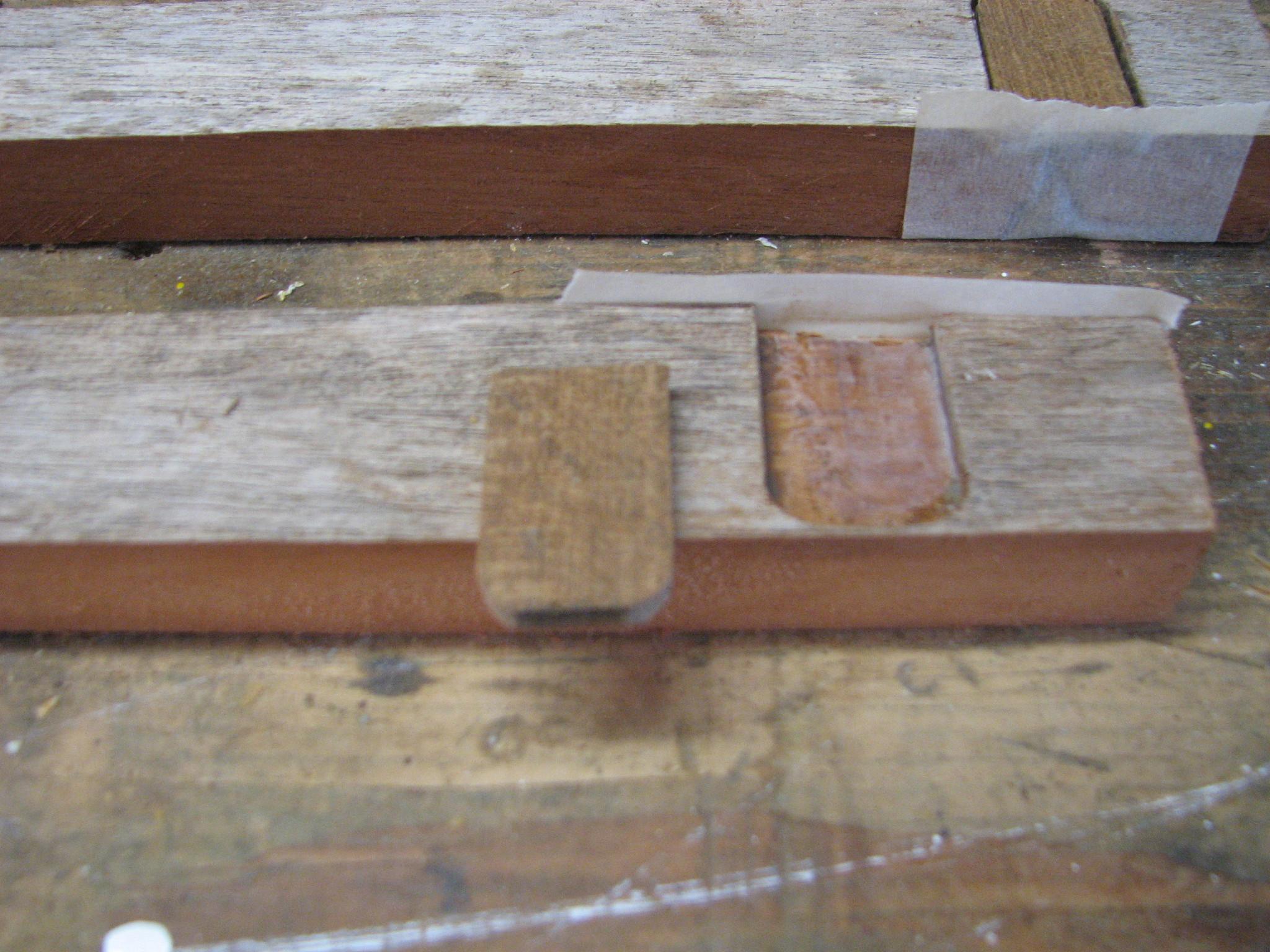

After

I had cut up the ladder pieces for the hole hiding piece, there was

still some indentations in the wood, where the step used to fit, that

needed to be filled. Here again I had some scrap wood that I was able

to cut and fit into the indentations. Once I got all of the pieces

cut and fitted, all that remained was to epoxy the pieces together. I

was going to wait and do the epoxy on the morrow.

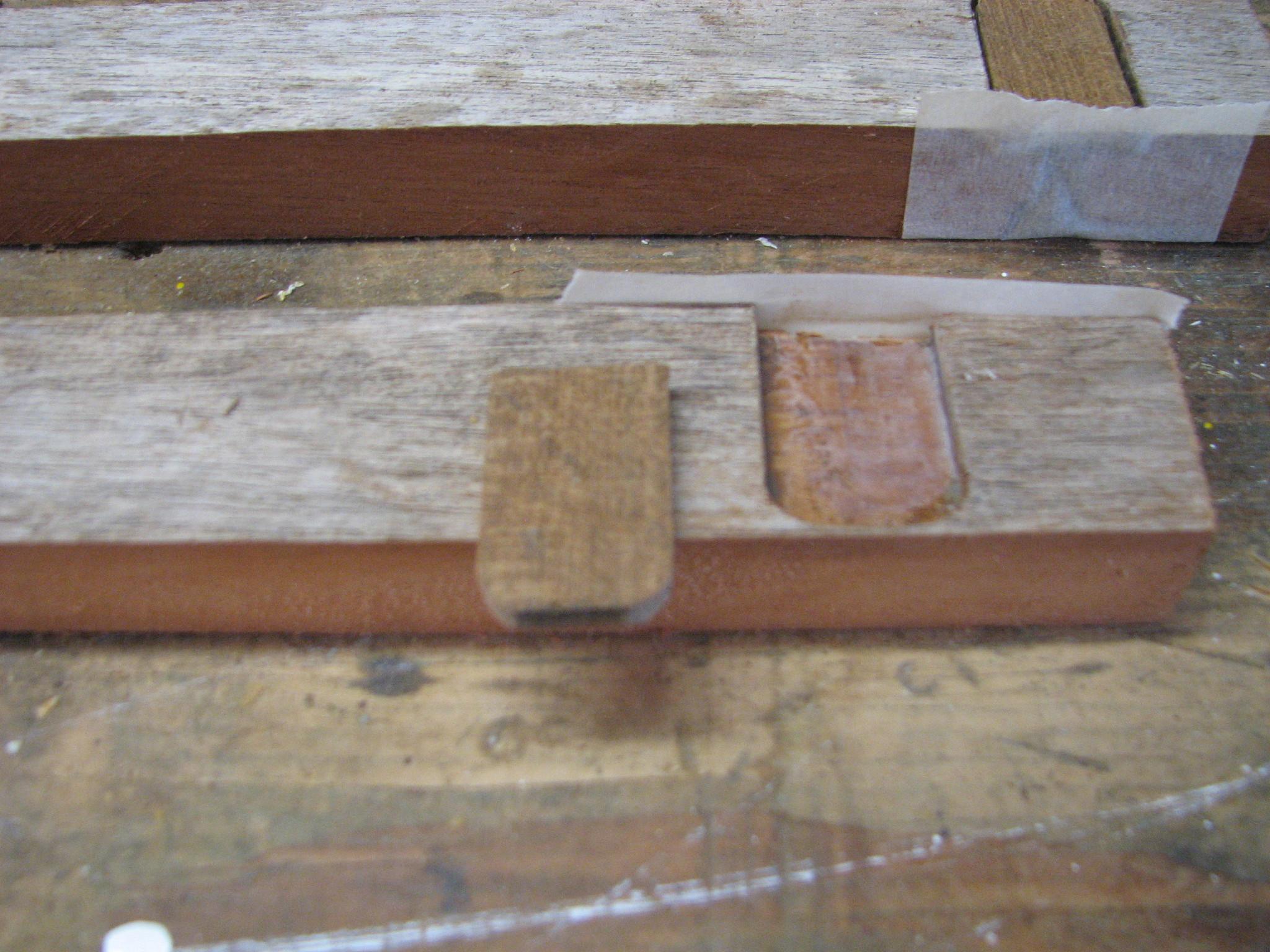

Hole

Hiding Piece With Cut Fill Pieces

With

the help of another boater here in the marina, we looked at the rear

brakes on the Black Beast.

The passenger side we got to and adjusted

with no problem. The drivers side however, has a problem with the

brake adjuster. It is corroded so it will not adjust. Something I

will have to look into in the near future.

While

I was on DREAM AWAY, I started to sand and scrape the teak piece

under the main mast step. All of my sanding and scraping tools were

over at the shop, so did not get very far.

Went

back to the shop, and got to work on adding some pieces of mahogany

to one of the companion way inserts. We have doors for our companion

way, but we also have two other options. We can remove the doors, and

put in an acrylic insert in some tracks installed for that purpose.

If

the weather is cold or wet, we can put another acrylic insert on top

of the initial insert. If the weather is fine, we can install a

screen on top of the initial insert.

Companionway

Doors From Interior

First

Acrylic Insert

First

Acrylic Insert And Screen

First

Acrylic Insert And Second Acrylic Insert

As

you can see from the following picture, there is a huge gap at the

top of the acrylic insert, that allows in various bugs.

Top

Corner Of Second Acrylic Insert

This

gap needed to be repaired, so I cut some pieces of mahogany that I

will be able to epoxy to the second acrylic insert to fill the huge

gap. I have one side cut, now I have to get the second piece cut.

When

I rewired DREAM AWAY many years ago, I put all of the electrical

wiring easy to access. To accomplish this task I used Panduit

wire duct

throughout the boat. This is a great product, and really keeps all of

the wires organized. The problem with the Panduit

wire duct

is the front cover is gray, great on a battleship, but not too cool

on a yacht.

Many

years ago I purchased a roll of 2” teak tape with an adhesive

backing. The teak tape is neat. You cut the size you need and put it

where you want it, and then run a standard iron on the teak side, and

the iron melts the adhesive, and attaches the tape to the surface you

had chosen.

Roll

Of Teak Tape

The

intended use of the teak tape was to cover the Panduit

wire duct

covers. I started the process of covering the Panduit

wire duct

covers with the teak tape and then varnish the teak tape.

Panduit

Wire Duct

Cover

At

the end of the day, I put the second coat of varnish and Cetol

on the appropriate parts, and the first coat of varnish on the

Panduit

wire duct

cover.

April

6, 2013, Saturday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

When

I went to the shop I prepared the hole hiding pieces and the name

boards for the epoxy application. This preparation involves making

masking tape dams to keep the excess epoxy from running all over. On

the name boards I use masking tape on the back of the name boards to

keep the excess epoxy from running.

Hole

Hiding Pieces With Insert And Masking Tape Dams

Back

Of Name Boards Before Masking Tape Application

I

then mixed up a batch of epoxy and epoxied in the teak inserts on the

hole hiding pieces.

Applying

Epoxy And Inserts To Hole Hiding Pieces

Completed

Hole Hiding Pieces

When

the hole hiding pieces were finished, I then started on the name

boards. Apply epoxy in the hole in the name board, apply epoxy to the

bung, then insert the bung into the hole in the name board. Repeat 19

times for each name board!

Name

Board Before Inserting Bungs

Name

Boards After Epoxy Application And Bung Insertion

I

had talked to one of my storeroom neighbors, Huey, earlier in the day

asking if he knew of a welder or machine shop that could help me

extract the broken bolts out of the power head of my spare Yamaha

outboard. Huey called me during the epoxy process, and told me he had

a friend who was an aircraft welder, and was in his shop right now,

and was expecting me.

I

got the power head, put it into the

Black Beast, and headed to the

welders house. It turns out the mans name is Arthur Leblanc. Leblanc

is one of the most common names around Delcambre. Arthur got right to

work and was able to weld a nut on the top of each broken bolt. We

then tried to extract each bolt, but each one broke off again pretty

even with the power head. Arthur apologized for not being able to

extract the bolts. It looks like I am going to have to purchase some

left hand bits, and drill out the bolts and use an easy out to get

the bolts out. This is turning out to be a lot of trouble just to get

a good spare outboard engine.

I

know I will change my tune when I eventually get the job done. When

you are out cruising, your tender and outboard are the only way to

get from your anchored boat to the beach or to town.

I

started another project today. In the middle cabin, I built an

electronics shelf to house my printer, the DREAM AWAY WiFi network

router, a print server, and my 1 TByte back up drive. It worked great

until the HP

printer I had died, and I replaced it with an Epson

printer. Naturally the Epson

printer was a different size than the HP

printer. So the Epson

printer did not fit on the shelf properly, and could fall off of the

shelf

Electronics

Shelf Before Modification

I

took the measurements of the present shelf, and then what was

necessary to accommodate the Epson

printer, and took them to the shop. I found a piece of plywood, and

some teak trim that will fit the bill nicely. I cut out the plywood,

and prepared the teak trim.

New

Shelf Piece And Teak Trim

Tomorrow,

I will remove the old electronics shelf from the mid cabin, and bring

it over to the shop. I have to get the exact measurements, fabricate

the new shelf, and then paint the shelf, and varnish the teak trim.

At

the end of the day, I put the third coat of varnish and Cetol

on the appropriate parts, and the second coat of varnish on the

Panduit

wire duct

cover.

April

7, 2013, Sunday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Went

over to the shop first thing and sanded down the epoxied hole hiding

pieces, and the name boards. Once all of the sanding is done, I can

fabricate the final hole hiding piece, and put back together the name

boards.

Sanded

Hole Hiding Pieces

Name

Boards Undergoing Sanding Process

I

then went back to DREAM AWAY for breakfast. While Kitty was preparing

breakfast, I got out the mitre saw that will be needed to angle cut

the electronics shelf new teak trim. I also took the current

electronics shelf off of the bulkhead in the mid cabin, and got it

ready to take to the shop.

After

breakfast Kitty and I went over to the shop. We had the old

electronics shelf with us and I put it beside the new cut shelf and

new teak trim. Notice the straps on the old shelf. These are used to

hold the printer on the shelf while we are underway!

Old

Electronics Shelf And New Cut Shelf With Teak Trim

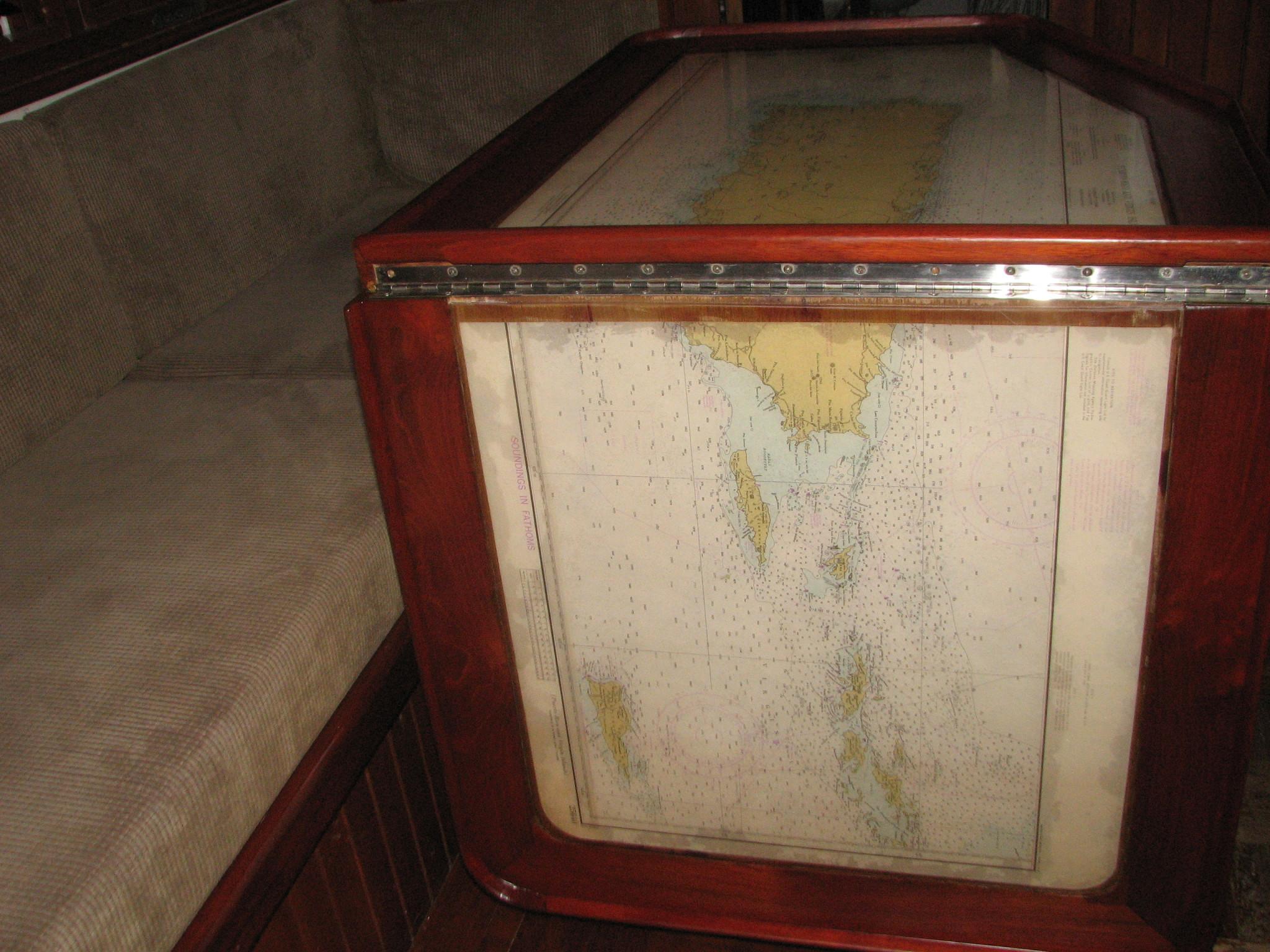

Now

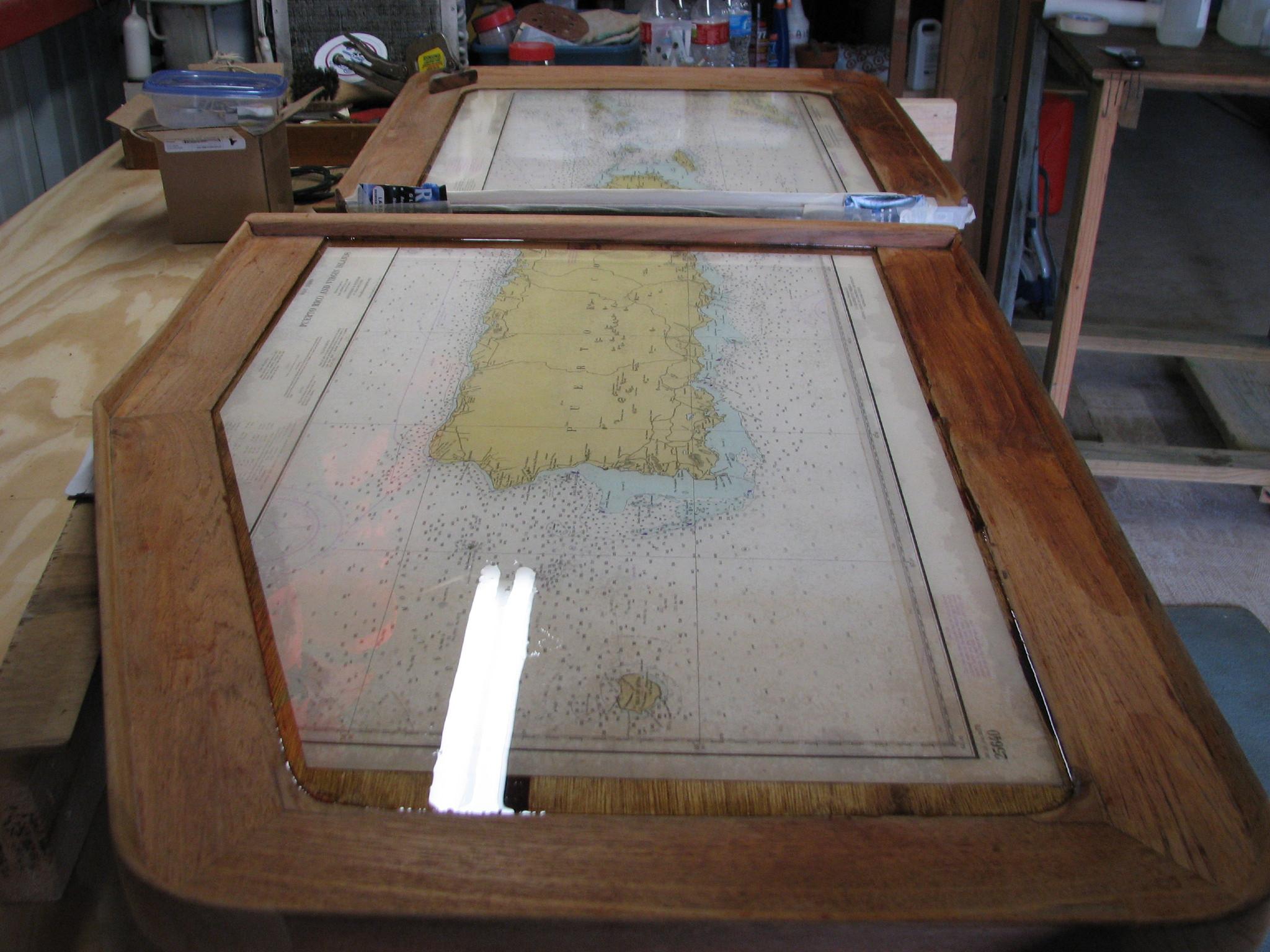

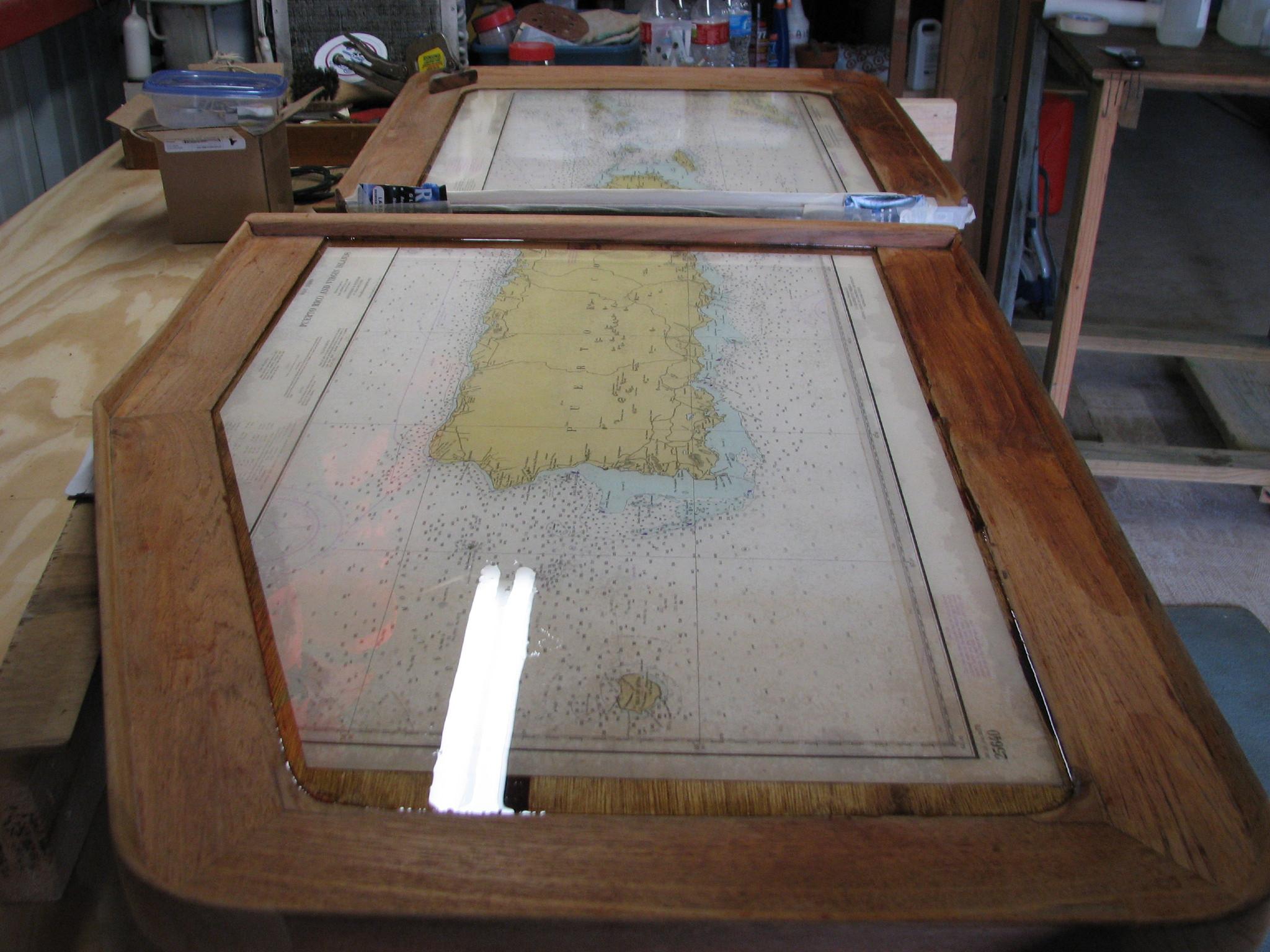

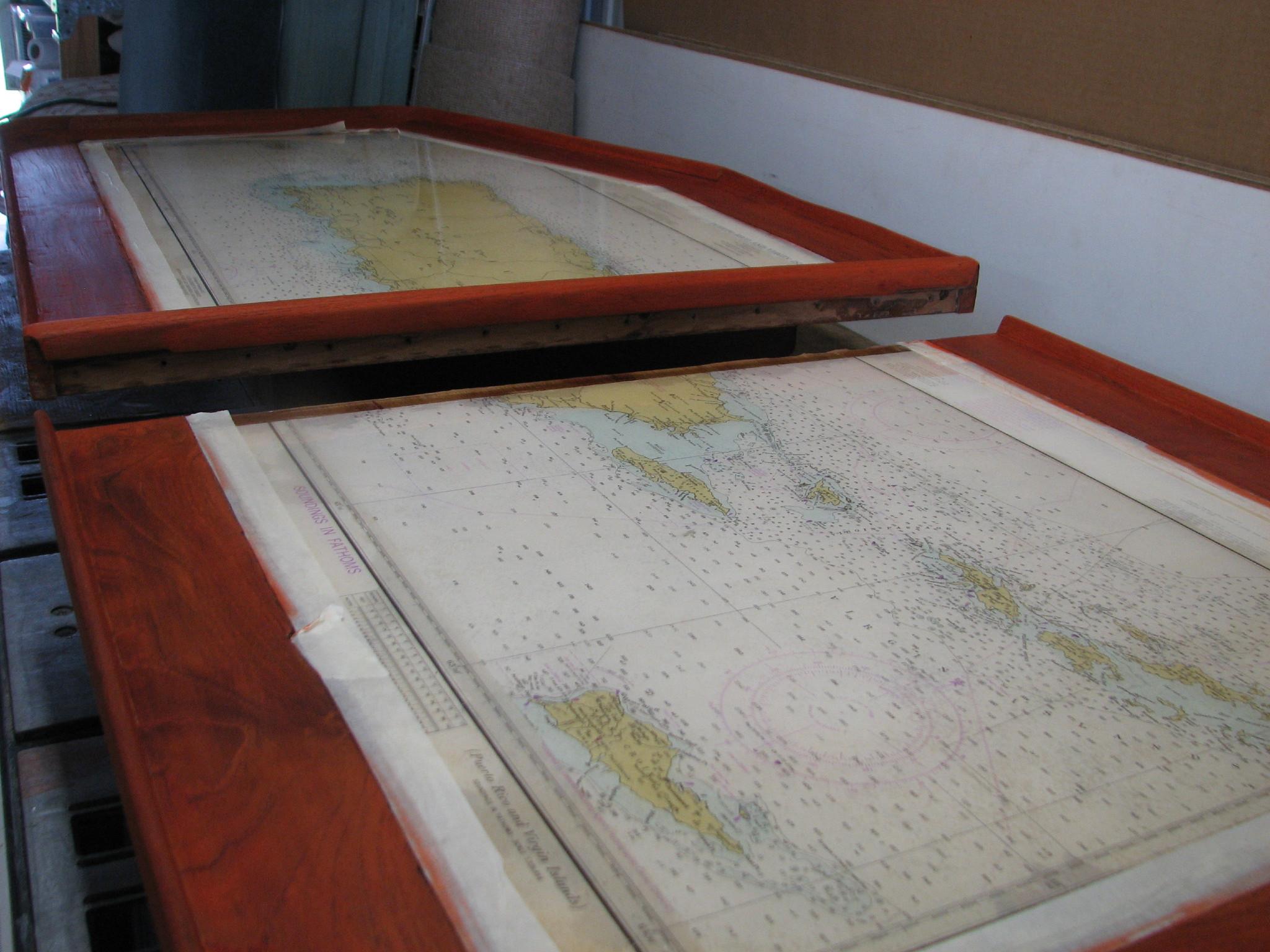

we can finally get the AeroMarine

Products

table top epoxy poured on the main cabin table. From previous entries

you know I have already glued down and sealed the chart of Puerto

Rico onto the table top. We have been delayed from doing the epoxy

application because of schedules and cold weather. I really needed

some help with this process. I could do the mixing and pouring alone,

but if anything went wrong, it is nice to have an extra set of hands.

Once the epoxy is mixed, you can not stop the chemical process.

When

we arrived at the shop we got the application instruction out, and we

both read over them so we had the process straight. We then verified

that the table pieces were level. We then verified we had the proper

mixing containers, heat gun, resin and catalyst all ready to go.

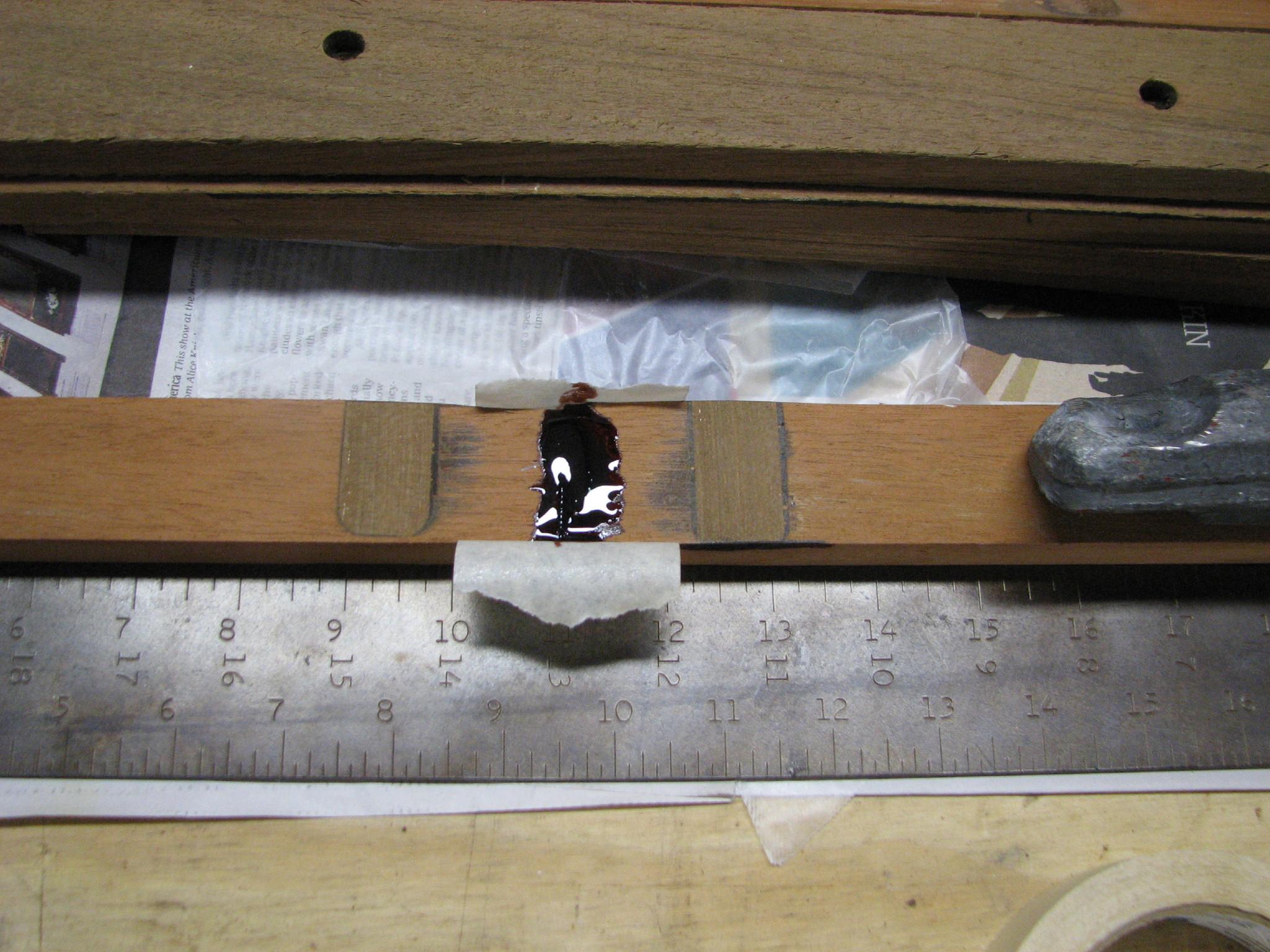

Mixing

Containers, Resin And Catalyst Ready To Go

We

then started the mixing and pouring process. Since Kitty and I were

both involved in the process, and we had protective gloves on we did

not get any pictures taken during the process. After the first batch

was poured, Kitty used the heat gun on the poured epoxy to make the

bubbles disappear. While she was doing that, I was measuring out the

next batch of resin. They recommended a first mixing container, then

pouring that mix into a second mixing container, so that is what we

did. We continued this until both pieces of the main cabin table were

covered.

Main

Cabin Table First Piece With Epoxy Applied

Main

Cabin Table Second Piece With Epoxy Applied

Finished

Main Cabin Table

We

then cleaned up the area, and left the shop. I did not want us to

cause any dust to get into the air that would land and then adhere to

the wet epoxy. I am sure there will be some anyway.

Last

project for the day was not for DREAM AWAY, but for the marina. The

port director had asked me to install two address signs on the marina

mailbox, which I agreed to do after the boat show. Today was the

first really nice day in which I had time, so Kitty and I did the

deed!

New

Address Sign On Marina Mailbox

April

8, 2013, Monday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Also updated the maintenance log.

I

have a doctor’s appointment this morning, but could not stand it. I

walked over to the shop to check on the main cabin table tops. They

look really great. I will let them sit for another 24 hours, then

will apply the dye to the remaining wood, and start the varnishing.

Since the table is so heavily used, I will be putting on nine or ten

coats of varnish.

Got

back from the doctor and errands, that I did not make it back to the

shop. Remainder of day and night catching up on email.

April

9, 2013, Tuesday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Also updated the maintenance log.

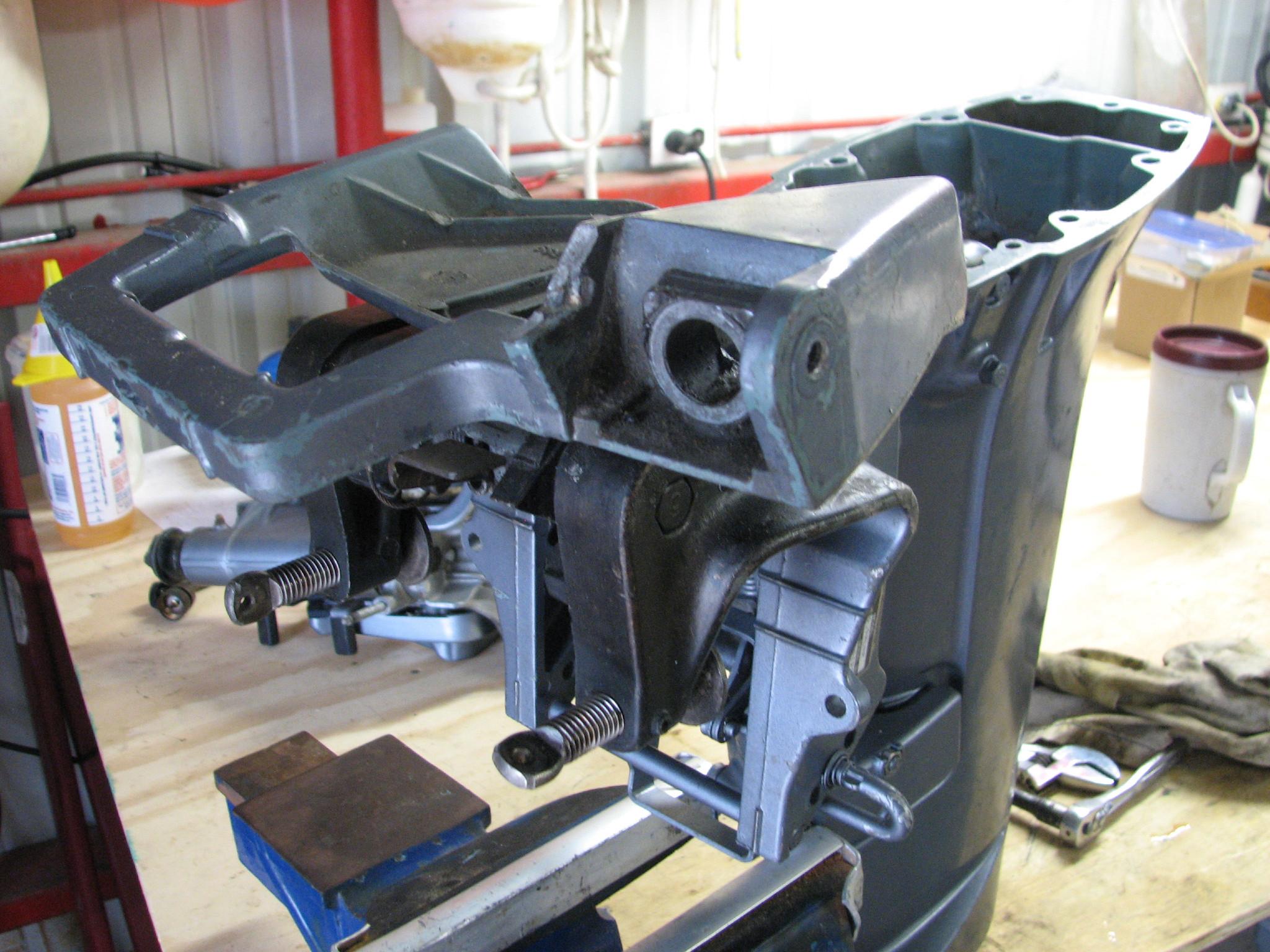

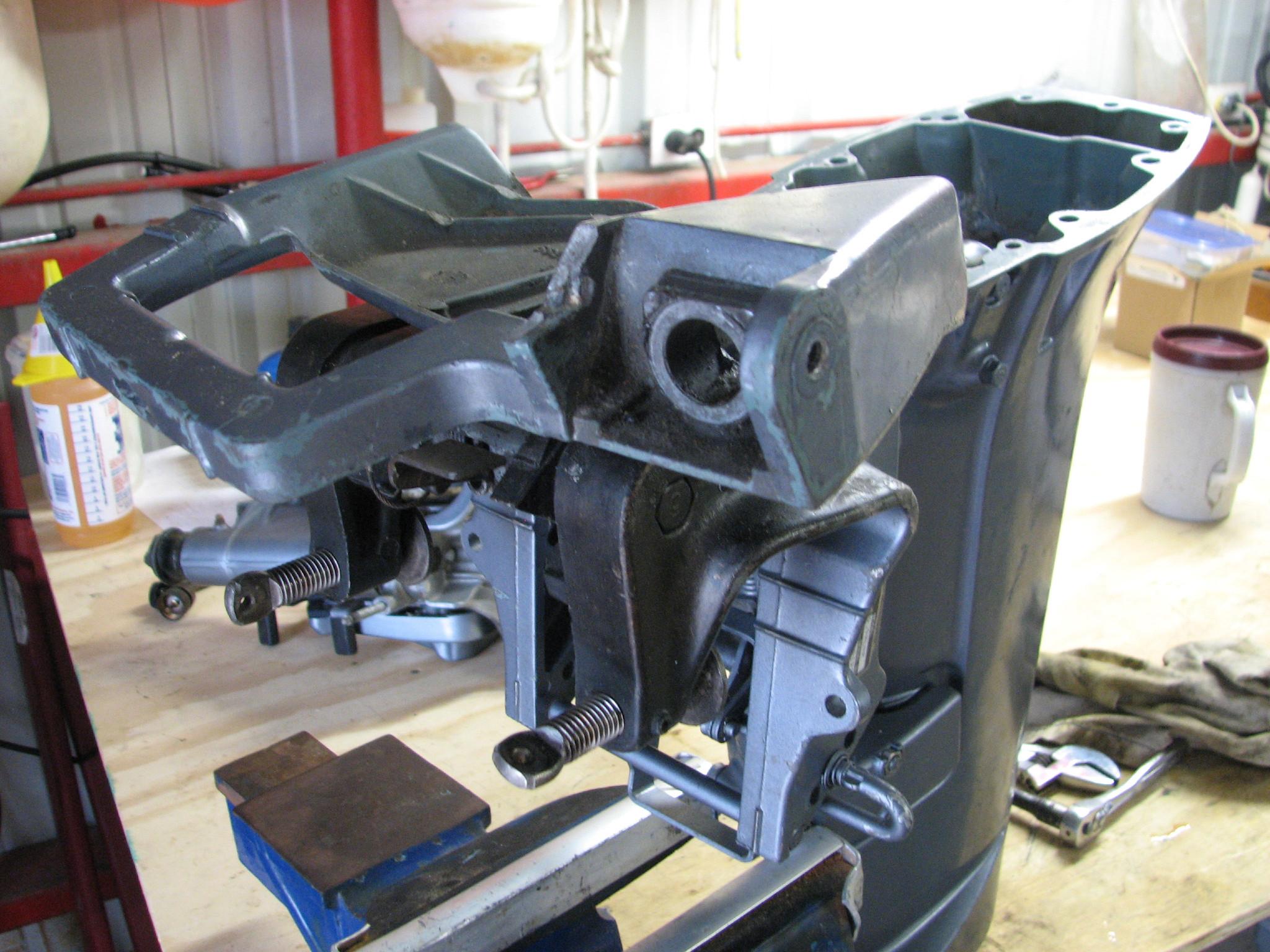

Went

over to the shop and started in on the spare Yamaha outboard. I had

purchased a used bracket

assembly

off of Ebay, and it had arrived yesterday. The bracket

assembly

minus the steering bracket I plan on installing on my outboard. The

steering bracket on the spare outboard is broken, and needed

replaced.

Broken

Steering Bracket On Spare Outboard Bracket

Assembly

I

am still working on the power head for the spare, but have not

purchased the left hand drill bits as yet.

New

Steering Bracket On Spare Outboard

I

went back to DREAM AWAY, and had breakfast. I also picked up the

mitre saw, and the tool used to put screens into frames. When I went

back to the shop, I started in on the aft cabin screen.

The

screen had been damaged, and the screen and the rubber holding in the

screen needed replaced. I had purchased both yesterday while we were

in Lafayette running errands.

I

cut the screen to the approximate size, and then using the proper

tool, put the screen back together. Having the screen repaired will

be important very soon as it gets warmer here in Louisiana, and all

nature of bugs are out!

Screen

Under Construction

Next

on the project list was to cut the teak trim pieces for the new

electronic shelf. I used the mitre box and saw to get the exact 45

degree angles. Once I cut the trim pieces, and dry fit them to the

piece of plywood, I cut a notch at the back of the plywood piece for

cables. This will be for the power cable for the printer, once the

shelf is back in the mid cabin. I then sanded down the shelf and

applied paint, one coat at a time on both sides of the shelf. I am

using a latex paint on this shelf, so the paint dries very quick.

Mitre

Box, Saw, And Trim For Shelf

Painted

Shelf Drying

When

I came back from breakfast on DREAM AWAY, I also brought back another

piece of Panduit

wire duct

cover from the galley, and the iron. I ironed on another piece of the

teak tape to the Panduit

wire duct

cover.

Panduit

Wire Duct

Cover With Teak Tape

The

hole hiding pieces had been sanded down, so I spent some time working

with the pieces to figure out how they would go together, and make a

strong piece to use to hide the holes. I have a plan, but the real

problem is getting the room to put a 9’ piece of wood together.

Hole

Hiding Pieces On Workbench

The

epoxy on the main cabin had set up enough, the I was able to trim up

imperfections, and sand down the exposed wooden surfaces. I also

sanded down the electronics shelf trim pieces, and the latest piece

of teak tape covered Panduit

wire duct

cover. After completing the sanding, I dusted off all of the pieces

with air, then went over everything with a tack

rag.

Now it was time to apply the dye to all of the teak. This included

the two main cabin pieces, the Panduit

wire duct

cover, and the trim pieces for the electronic shelf. After the

application of the dye, I only had to wait 30 minutes, before

applying the varnish. I wiped down all of the parts with a tack

rag.

I put the fourth coat of varnish on the reefer teak trim, and the

teak wire covers. I put the second coat of varnish on the first

Panduit

wire duct

cover. I then applied the first coat of varnish to the two main cabin

pieces and the second two Panduit

wire duct

covers.

Dye

Applied To The Two Main Cabin Table Pieces

April

10, 2013, Wednesday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Also updated the maintenance log.

After

the ritual, I went over to the shop and started working attaching the

teak trim to the new electronics shelf. I came up with a method to

attach the pieces with epoxy, and then using clamp and boards and

other pieces of wood.

I

did a dry fit for the electronic shelf, and I also set up the first

two pieces of wood in the hide hole piece I am fabricating. I got it

all tested out, and then mixed up a pot of epoxy. I got the epoxy

applied to the electronics shelf, and it all clamped down, and

applied the epoxy to the hide hole piece.

Applying

Epoxy To The Electronics Shelf

Electronics

Shelf Clamped Up With Epoxy Applied

Epoxy

Applied To Hide Hole Piece

When

I had completed this task, I realized I had used up all of my table

space, and could not do any more with other projects. I needed to do

some more sanding, but I like to do the sanding outside on one of the

rolling tables, and they were all in use.

Oh

well, another project had come to mind yesterday while I was putting

the aft cabin screen together. I had replaced the rubber O-Ring like

material they use in the screens, so I had the old O-Ring material.

The center hubs on all of the wheels of the

Black Beast were loose,

and at slow speeds, they all rattled, and that drove me crazy. So I

jacked up one wheel at a time, removed the tire and wheel, and took

off the hub. I cleaned the hub, then put grease on the O-Ring

material to hold it in place, put the hub back into the wheel, and

then the wheel back on the truck. I only did this one one side so

far, but it solved the problem! Will probably do the passenger side

tomorrow. The Beast is a 3/4 ton four wheel drive Suburban, so moving

the wheels around is no small matter. These are the times I need a 30

year old helper!!

I

completed the hub project on the drivers side, and went back to DREAM

AWAY for breakfast. After breakfast Kitty went off to do the laundry,

and I went to work on the sea

chest.

During the winter months the sea

chest,

strainers and all of the attaching hoses are cleaned about every five

weeks. During the summer months, the cleaning is necessary every

three weeks. Marine growth is extensive.

What

I have on DREAM AWAY is not really a sea

chest,

but a manifold. I have a 1 1/2” input from outside the boat through

a seacock,

then through a strainer, and then to a piece of 4” PVC pipe. Out of

this PVC pipe, I have hoses running to the raw water foot pump at the

galley, the aft air conditioner cooling pump, the ice maker cooling

pump, the raw water washdown pump, the forward air conditioner

cooling pump, and the refrigeration cooling pump. With this

arrangement I have only one hole in the boat instead of six.

What

I do is remove the 1 1/2 strainer and the manifold from DREAM AWAY

and take the parts out on the dock and clean them out thoroughly. Not

too much of a problem now, but in the summer there are a lot of

mussels and other growth that must be cleaned out. When the strainer

and manifold are all cleaned, I reinstall them back into position.

Now on each individual hose I have a second strainer to further

prevent debris from getting into the pumps.

I

bring the fresh water hose down from the dock into the boat, and

after cleaning each individual strainer, I connect the dock hose to

the hose that was connected to the manifold. I then run the fresh

water through the system to clean out the complete hose run and the

pump to the overboard drain. I do this for each hose except the one

for the raw water foot pump at the galley. When I am all done

cleaning out the hoses, I re-connect them back up to the manifold,

and actuate the seacock

to allow raw water back into the system. I verify that all of the

pumps have been primed, and we are back to normal.

Strainer

Housing With Strainer Removed, Pumps In The Background

Hoses

And Connections On Manifold

Went

back over to the shop and started working on the electronics shelf. I

tried to take apart the old electronics shelf, and realized the shelf

had been screwed and epoxied to the base. There was no way it was

going to come apart.

What

I decided to do was to cut off some of the teak trim on the old

shelf, and just add the new shelf on top of the old shelf. With my

trusty saw, I cut off the excess trim, and then sanded it down flat.

I tested the new shelf on top of the old shelf and it was going to

work. Not beautiful, but accomplished the task.

Old

Electronics Shelf With Trim Removed

New

Shelf On Top Of Old Shelf

The

corners of the teak trim on the new electronics shelf, had some

spaces that needed to filled with epoxy. I used masking tape, and

built dams around the area so the epoxy would not leak out all over.

New

Electronic Shelf WIth Dams And Epoxy Applied

The

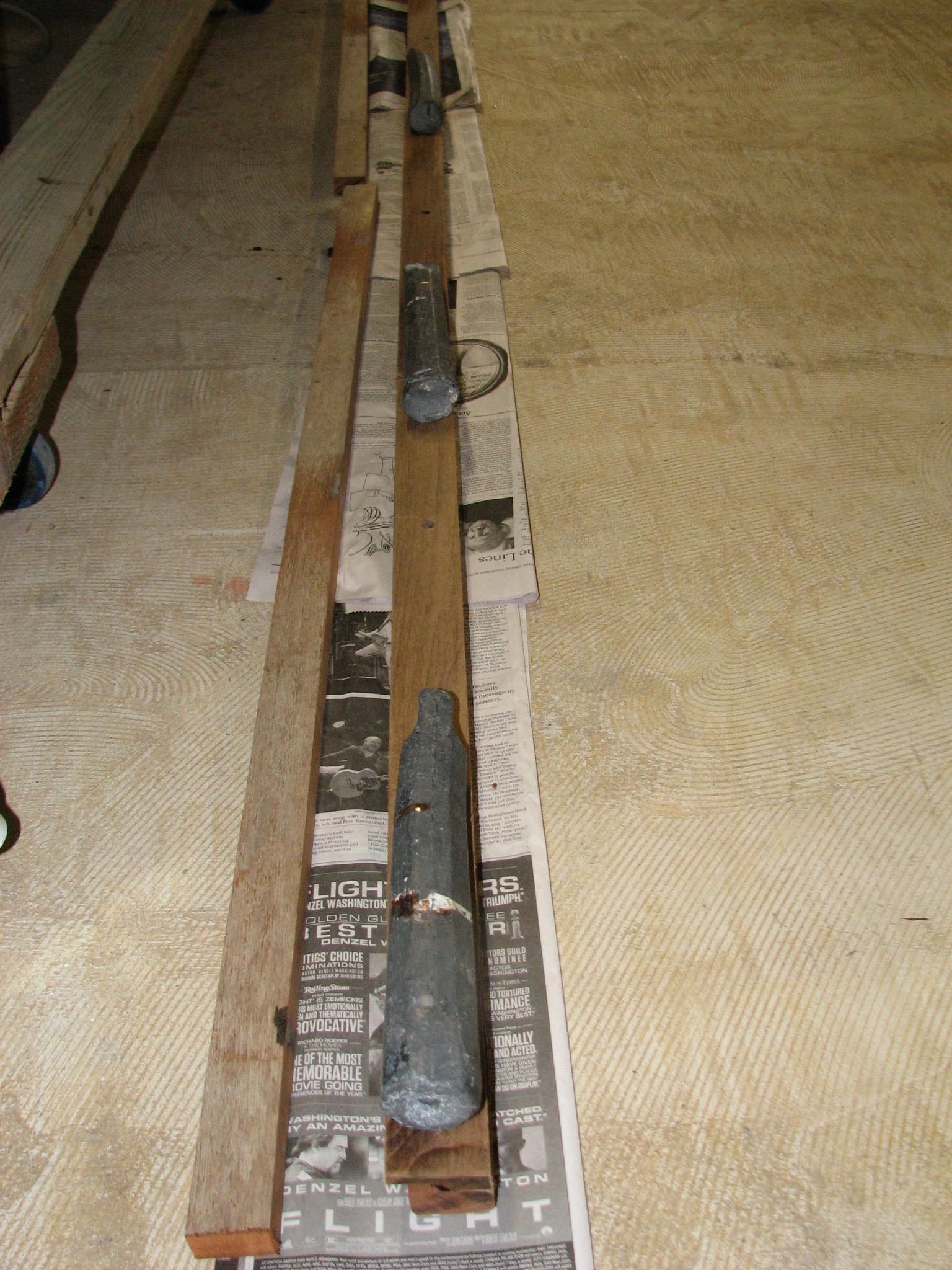

epoxy that I had applied in the morning to the two hole hiding pieces

had set up. I now moved the single piece to the largest flat surface

I had, the floor, so I could add the middle teak pieces. These pieces

were short pieces, so I am laminating this eventual single piece

together into one piece. I mixed up some epoxy and put the pieces

together, and put weights on top so it would all stick together.

Bottom

Mahogany Piece With Teak Pieces On Top And Weights

Bottom

Mahogany Piece With Teak Pieces On Top And Weights

I

put the fifth and last coat of varnish on the reefer teak trim, and

the teak wire covers. I put the fourth coat of varnish on the first

Panduit

wire duct

cover. I then applied the second coat of varnish to the two main

cabin table pieces and the third coat on the two Panduit

wire duct

covers. Last I applied the fourth coat of Cetol

to the pin rails and belaying pins.

April

11, 2013, Thursday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Also updated the maintenance log.

Went

over to the shop and started off with the new electronics shelf. I

removed the masking tape dams, and the sanded down the hardened

epoxy. I sanded down the shelf again to remove any imperfections. I

then masked off the teak wood trim, so I could put another coat of

white paint on the top of the shelf. I applied the coat of white

paint, and went back to DREAM AWAY for breakfast.

When

I returned to the shop, I removed the masking tape from the teak trim

and attached the new electronics shelf on top of the old electronics

shelf. I masked off the new shelf so I could re-apply the dye to the

teak trim, and so it would be ready to apply varnish. Once the

masking tape was applied the shelf was ready for varnish.

New

Shelf With Dye Applied

New

Shelf On Top Of Old Shelf

Now

I started in on the hole hiding piece. I had two layers epoxied

together, so now it was time to add the third and last layer to the

piece. I did a dry fit, and made sure I had all of the necessary

clamps available. I mixed two batches of epoxy and applied it on top

of the two layer piece, and added the pieces for the third layer. I

alligned all the pieces, and clamped it all together.

Hole

Hiding Piece Clamped Together

The

last item for the day before varnish and Cetol

application, was to finish up the sanding of the nameboards. I have

finally got them all sanded down. When I took the nameboards off of

DREAM AWAY, they were too long to store any where on board, so I cut

them into two pieces. Now I will have to get them back together. That

will be done in the next couple of days.

Nameboard

In Two Pieces

I

put the fifth coat of varnish on the first Panduit

wire duct

cover, the first coat of varnish on the electronics shelf, the third

coat of varnish to the two main cabin table pieces and the third coat

of varnish on the two Panduit

wire duct

covers. Last I applied the fifth coat of Cetol

to the pin rails and belaying pins.

April

12, 2013, Friday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Also updated the maintenance log.

I

have been frustrated by air bubbles appearing on the first Panduit

wire duct

cover to which I applied the teak tape. These bubbles did not appear

on the two subsequent Panduit

wire duct

cover to which I applied the teak tape.

Bubbles

Appearing Under The Teak Tape

Teak

Tape Removed

I

then cut a new piece of teak tape, heated up the iron, and prepared

to apply the teak tape to the Panduit

wire duct

cover.

Ready

To Apply The Teak Tape

I

then applied the teak tape to the Panduit

wire duct

cover using the iron. I went back and forth several times to make

sure all of the glue on the tape was melted, and no air bubble would

appear. When the piece had cooled down, it appeared there would not

be any bubbles.

I

decided to wait until tomorrow before I applied the dye. I wanted to

see if any air bubbles appeared.

The

mahogany pieces I have been trying to fit for the large acrylic

insert has not been going well. I have been sanding down the pieces

to fit, but they were getting very thin, and I was getting

frustrated. Just to be sure, I took the large acrylic insert over to

the shop, and put the carpenter’s

square

on it. Just as I thought, one side was flat, but the other side was

not.

I

got out a sander, and sanded down the side until it was flat. Now

both side of the acrylic insert are flat.

I

trimmed up the hide hole piece to try and do a dry fit on DREAM AWAY.

I loaded up the hide hole piece, the acrylic insert, and the mahogany

pieces that go with it, some other small pieces of teak I am going to

use to repair the louvers on a door, and a piece of teak to add to

the Cutco

knife holder in the Black Beast,

and went over to DREAM AWAY with all

of the parts.

Kitty

and I measured the hide hole piece, and it was too big to try a dry

fit. We took a measurement, so I could cut the piece when I took it

over to the shop.

Next

Kitty and I did a dry fit of the large acrylic insert, and the

mahogany pieces I am using to fill the huge gaps. Making both sides

of the insert flat made the difference! What we discovered was the

area that needed to be filled was different from one side of the

insert to the other. I cut a second template, and will use the

template to add a piece to the port side piece. At least now I know

what size pieces I need, and can get them ready for a final dry fit.

The

small pieces of teak I for the louver repair, will work. I just have

to sand them down to a close 1/2 round, just very small!

The

piece I brought over to modify the Cutco

knife holder was not large enough. Will have to find a larger piece

in my stash of spare teak wood.

After

breakfast, I worked on the electrical wire covers I had varnished. I

did a dry fit of the cover, then drilled the necessary holes in the

cover, and the fiberglass, and installed the starboard side cover.

Starboard

Side Wires Exposed

Starboard

Side Wire Cover Installed

Port

Side Wires Exposed

Port

Side Wire Cover Installed

Main

Mast Step Before Sanding

Main

Mast Step After Sanding

I

then went over to the shop to do the varnish and Cetol

application.

I

put the the second coat of varnish on the electronics shelf, the

fourth coat of varnish on the two main cabin table pieces and on the

two Panduit

wire duct

covers. Last I applied the sixth coat of Cetol

to the pin rails and belaying pins.

April

13, 2013, Saturday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Also updated the maintenance log.

Went

over to the shop and got out the sanders to work on the mahogany

pieces to fit the large acrylic insert, and the pieces to repair the

louvers in the door.

Mahogany

Pieces For Large Acrylic Insert

Teak

Pieces For Louver Repair

The

new application of the teak tape to the Panduit

wire duct

cover has been successful. I applied the dye to the cover, and made

it ready to apply a coat of varnish late this afternoon.

I

loaded all of the mahogany pieces for the insert, the louver repair

pieces, the piece of teak wood to use to modify the Cutco

knife holder, and the Smith’s

penetrating epoxy,

and the mixing buckets in the Black Beast

and went to DREAM AWAY for breakfast.

The

newly sanded pieces for the acrylic insert fit perfectly. Now all I

had to do was add a small piece of wood to the top of the piece for

the port side. I am now ready to epoxy the extra pieces to the

acrylic insert, and fill the gap.

I

tried the piece of wood I brought over to expand the Cutco

knife holder. It looks like it will work. I made a template so I can

cut out the size pieces I need. We have purchased two new knives to

add to our Cutco

knife collection. We have a five knife holder, but can not find a

seven knife holder. Of course I have some pretty narrow space

requirements, so it seemed easier to modify the holder we already

have.

Cutco

Knife Holder In Galley

When

we had completed breakfast I got to work on applying the Smith’s

penetrating epoxy

to the main mast step. I mixed a small batch of the epoxy and applied

it to the step.

I

then started in on the main cabin table base. Way back in 2009 when

we made the Gulf crossing from Houston to Isla Mujeres, Mexico, my

good friend Jim, did a stress test on the main salon table. The table

failed the test, and Jim did not come out very well. Jim hit his

head, and shoulder, and broke the table loose from the floor.

The

weather was not great, I did not have another place to store the

table, so we decided to just do a fix and put the table back where it

came from. We made sure Jim was not permanently hurt, but was able to

help with the repair. Kitty was at the helm, while Diane and I got

the table mount back together, and we got the table put back in

place. In fact the new mount was much stronger than the original. The

issue with the fix was all of the screws were not countersunk, and

the teak bungs inserted.

Since

I am refurbishing the top of the main salon table, I decided to

finally repair the table mount.

Main

Salon Table Mount With Screws Exposed

Kitty

and I removed the table from its mount. this made the project very

easy. I then removed all of the screws from the table base, and

drilled out the holes for the screws about 3/8” deep, and 3/8”

wide. This was the size of the teak bungs I am using. I then put all

of the screws back into the mount. I mixed up a batch of epoxy, and

used that to insert all of the teak bungs on top of the countersunk

screws.

Main

Cabin Table Base With Bungs Installed

After

the bungs were installed, Kitty and I put the table back in place. In

a day or so when the epoxy has hardened, We will take the table off

of the mount again, and I will sand down the base so it is ready for

varnish when we do the floor.

Main

Salon Table Back On Base

I

went back over to the shop to epoxy the hole hide piece, and to epoxy

the nameboards back together. I cut the hole hide piece to the 8 1/2’

size needed to fit in the aft cabin.

I

taped up the hole hide piece and the nameboards so the epoxy would

not leak out all over the place. I mixed up four batches of the epoxy

and applied it to the hole hide piece and the nameboards.

Nameboards

With Epoxy Applied

Hole

Hide Piece With Epoxy Applied

I

put the third coat of varnish on the electronics shelf, the fifth

coat of varnish to the two main cabin table pieces and on the two

Panduit

wire duct

covers, and the first coat on the repaired Panduit

wire duct

cover. Last I applied the seventh coat of Cetol

to the pin rails and belaying pins.

April

14, 2013, Sunday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Also updated the maintenance log.

Worked

all day doing computer work, maintenance log. email and financial

issues.

I

did however go over to the shop late in the afternoon and I put the

fourth coat of varnish on the electronics shelf, the sixth coat of

varnish on the two main cabin table pieces and the second coat on the

repaired Panduit

wire duct

cover. Last I applied the eighth coat of Cetol

to the pin rails and belaying pins.

The

two Panduit

wire duct

covers that had their fifth of varnish applied yesterday, I took them

over to DREAM AWAY and installed them in the galley.

April

15, 2013, Monday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Also updated the maintenance log.

Went

over to the shop and started in on the hide hole piece. I had done

the last epoxy application on Saturday, and it has set up great. I

ran the hide hole piece down the table saw to get the edge I had

epoxied smooth. When finished cutting, I still needed to add some

more epoxy to fill in the holes that were remaining in the piece.

I

had purchased a small piece of oak when I was at Lowe’s

on Sunday to use on the Cutco

knife holder. I had decided that using teak wood to make the

extension to the knife holder would not match that well. I used the

template I had made and measured and marked the new piece of oak I

had purchased. I used the table saw to cut out the pieces. Now I have

to figure a way to cut out the place for the knife, since I do not

have a router.

Cut

Pieces For Cutco

Knife Holder

I

cleaned up the table saw area, and put the saw back into the shop.

Cutting on the table saw makes so much dust, I roll the table saw

outside to make all of my cuts, weather permitting.

Now

I dry fitted the two pieces I am adding to one side of the large

acrylic insert. When I was satisfied with the dry fit, I mixed up

some epoxy and epoxied the two pieces to the large acrylic insert.

Dry

Fit Of Two Additional Pieces On Large Acrylic Insert

Two

Additional Pieces Epoxied On Large Acrylic Insert

After

sanding and trimming down the hide hole piece, there were still some

holes to be filled. With the epoxy that was mixed for the large

acrylic insert, I filled these holes on the hide hole piece.

Second

Application Of Epoxy

I

now completed the sanding of the front of the name boards. They are

getting close to getting varnish applied

Sanded

Name Boards

I

had put on the sixth coat of varnish on the two main cabin table

pieces, and I plan to have at least nine coats. Because of this it

was time to remask the pieces. This is to prevent excessive build up

on the masking tape. I removed the old masking tape, and applied the

new masking tape. The two pieces were now ready for the next coat of

varnish.

Table

Piece With Tape Removed

Pieces

Drying Or Epoxy Kicking Off In The Sun

Next

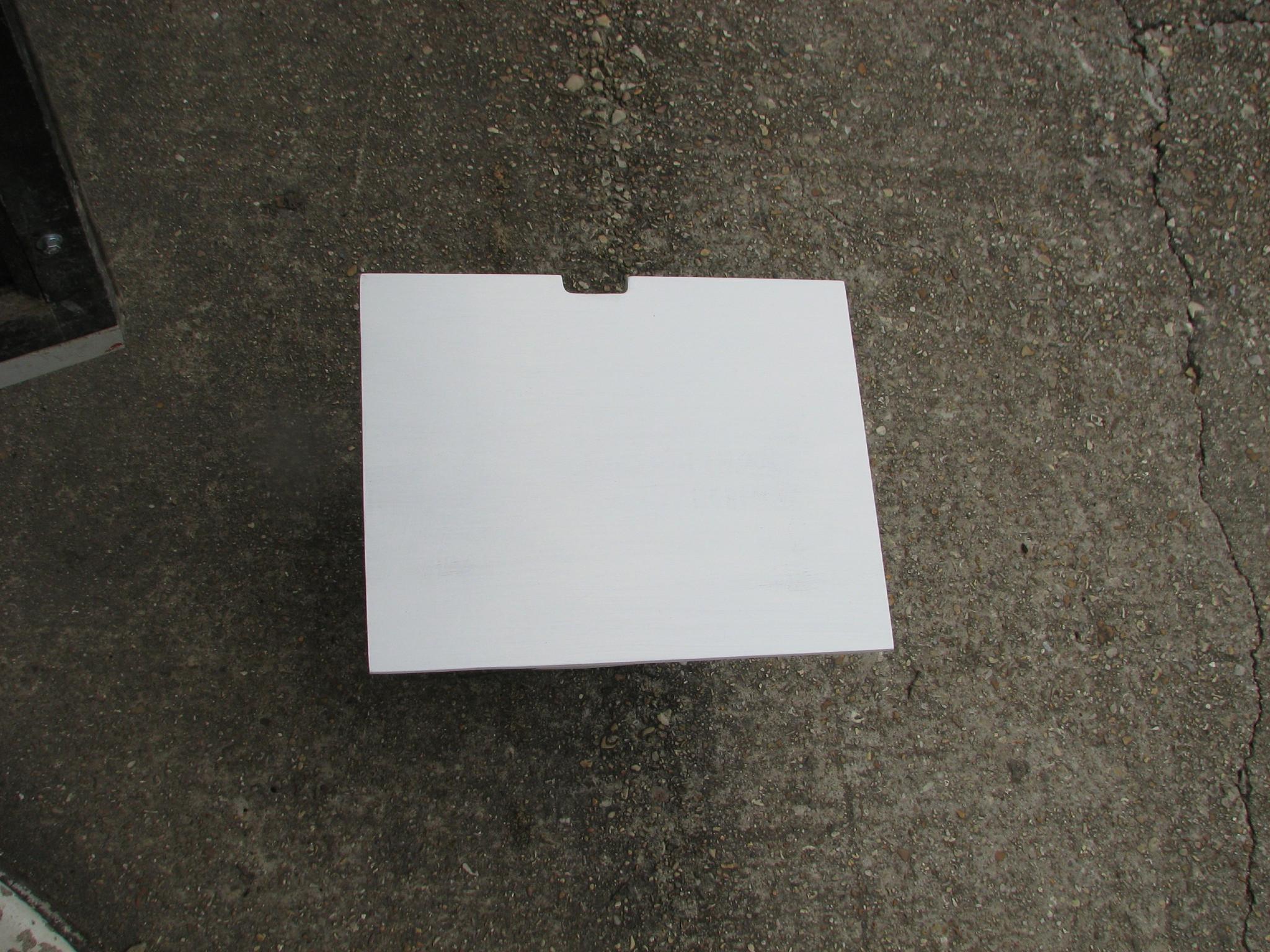

I got out some plywood to build a temporary hatch. Some folks off

another boat here in the marina had recommended to us a product for

the teak deck called Watco

Teak Oil Finish.

We had purchased a pint on our last visit to Lowe’s.

We decided to give it a try.

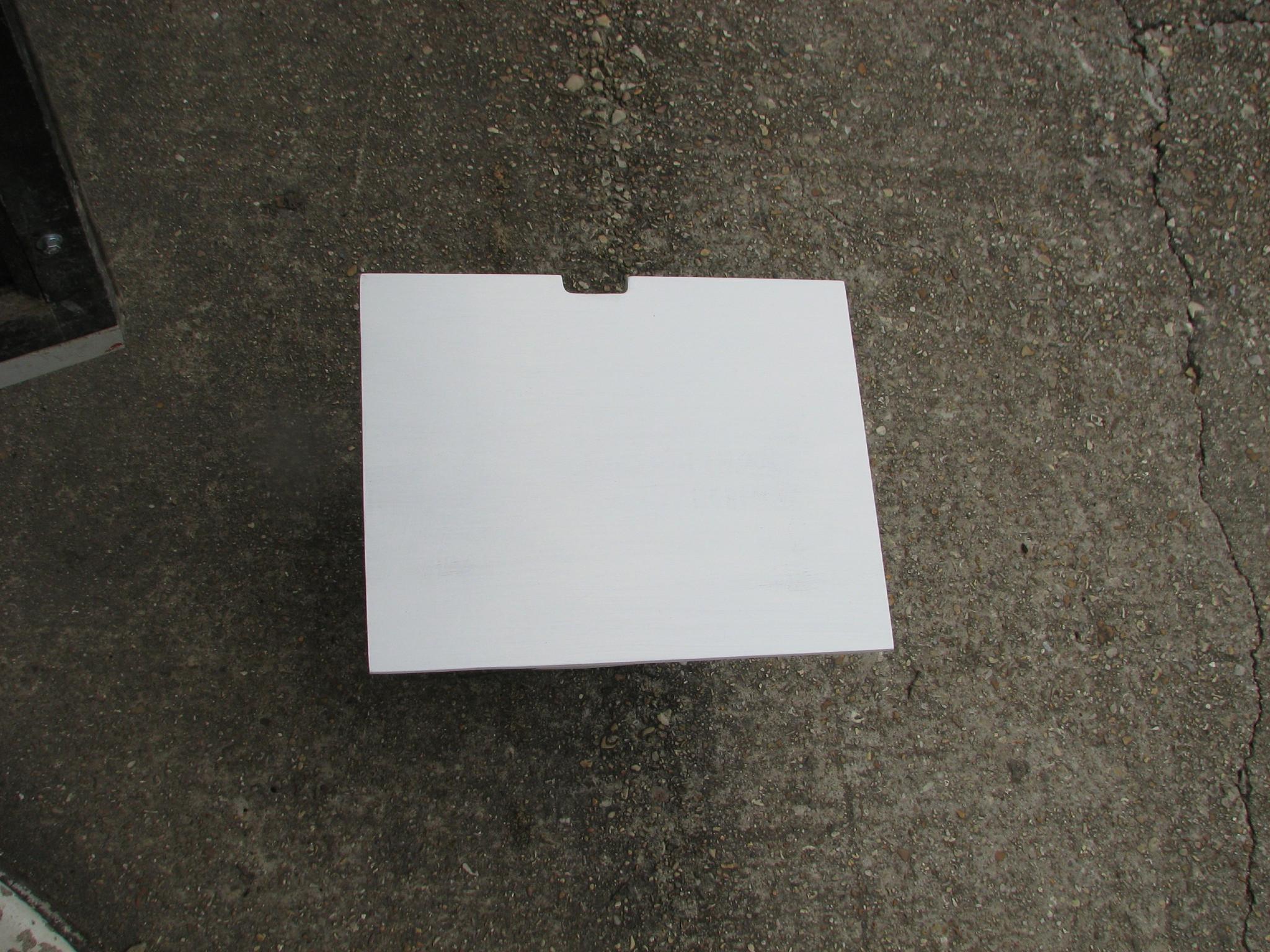

Plywood

Pieces For Temporary Main Cabin Hatch

We

have a hatch in the main salon that gets a lot of traffic, so we

decided to do the Watco

Teak Oil Finish

test on this hatch. To enable me to take the hatch over to the shop,

I had to build a temporary hatch.

When

I took the hatch over to DREAM AWAY, and did a dry fit, it did not

fit properly, so a couple of adjustments would be necessary. I also

discovered I had left no way to get the hatch out of the floor, once

it was installed, so I would also need to cut a notch in the hatch

for a finger hold.

We

then drove over to the Rip

Van Winkle Gardens

at Jefferson Island with two transient cruisers, Larry and Linda.

They saw the gardens, and enjoyed the tour of the Joseph Jefferson

House.

When

we returned from Rip

Van Winkle Gardens,

I went over to the shop. I put the fifth coat and last coat of

varnish on the electronics shelf, the seventh coat of varnish on the

two main cabin table pieces and the third coat on the repaired

Panduit

wire duct

cover. Last I applied the ninth coat of Cetol

to the pin rails and belaying pins.

April

16, 2013, Tuesday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Also updated the maintenance log.

Went

over to the shop and “adjusted” the temporary hatch for the main

cabin. This means I cut it to actually fit the hole. I also cut a

finger hole so you could remove the hatch without tools. Later, I

took the temporary hatch over to DREAM AWAY and it fit perfectly.

Temporary

Hatch In Floor On DREAM AWAY

I

sanded down the hide hole piece and the large acrylic insert. I had

to get them ready for another epoxy application. When I finished the

sanding, I did a dry fit of the pieces to add to the large acrylic

insert. I then mixed up a batch of epoxy and filled the remaining

holes in the hide hole piece, and added the new pieces to the large

acrylic insert.

Third

Application of Epoxy To The Hide Hole Piece

Epoxy

On Large Acrylic Insert

Two

Pieces Epoxied To Large Acrylic Piece

I

installed the printer tie-downs to the completed electronics shelf,

so the electronics shelf was now ready for installation.

Electronics

Shelf With Tie-downs Installed

I

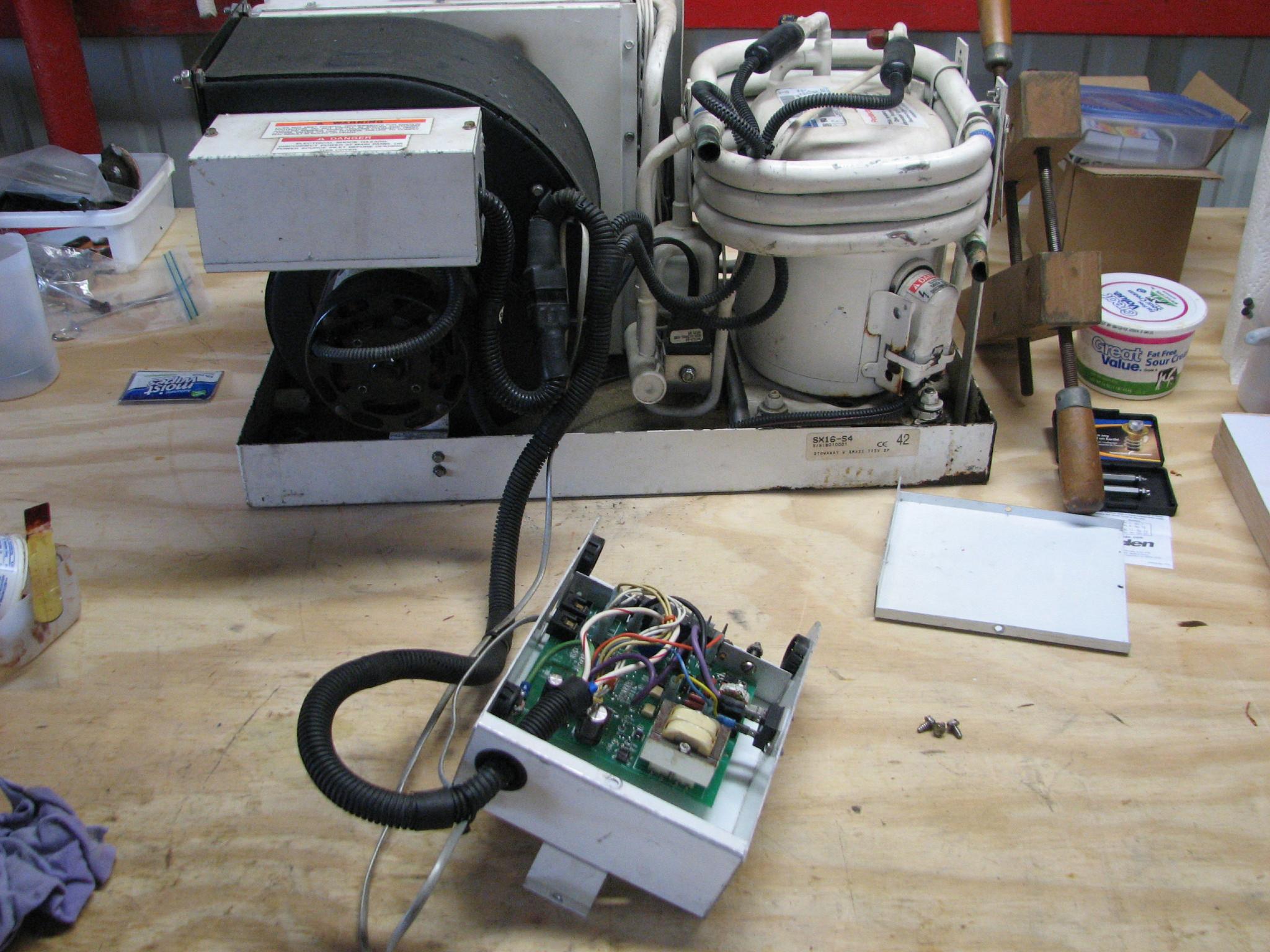

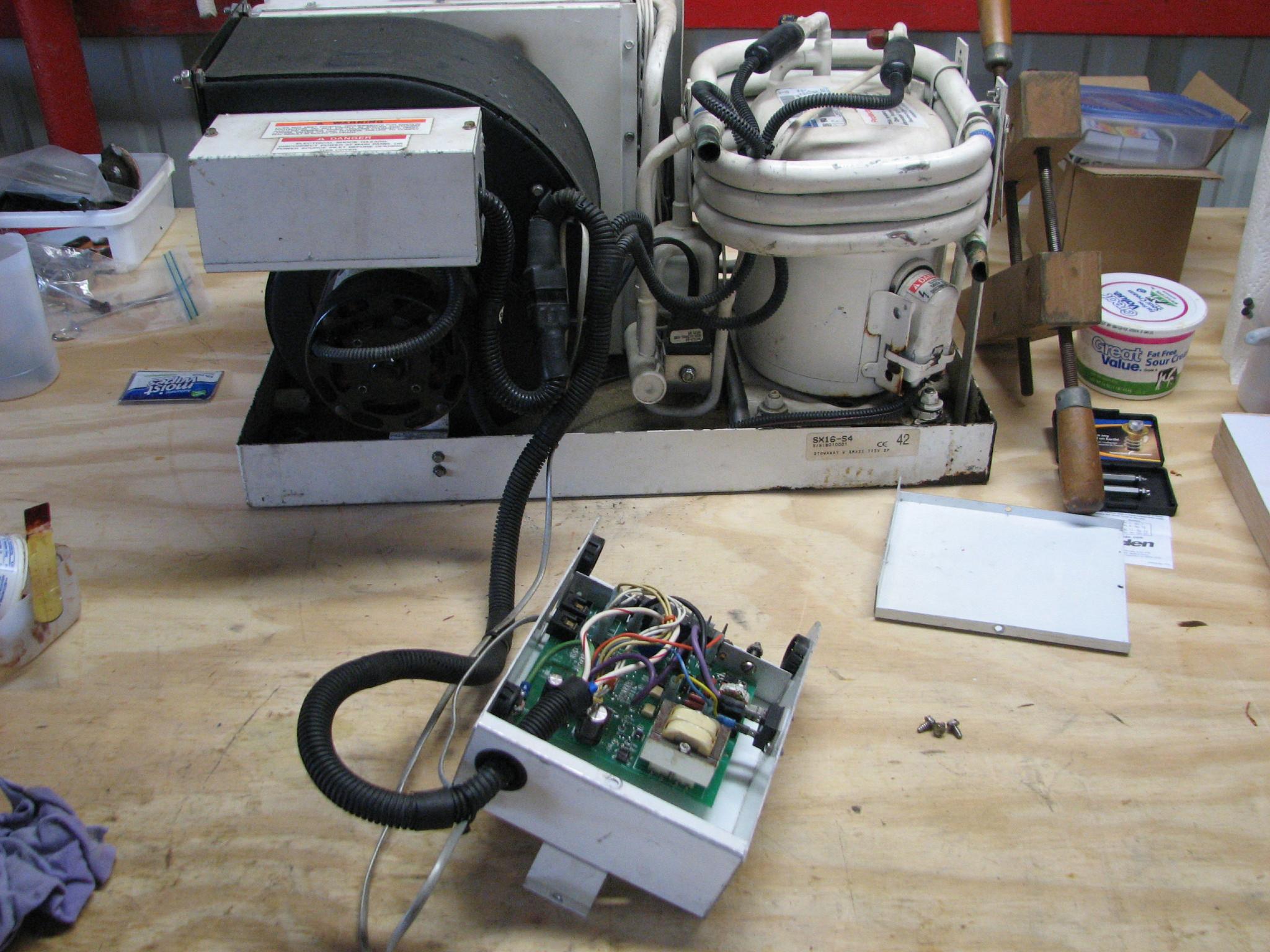

started investigation of how I was going to repair the used air

conditioner I had purchased and shipped to Delcambre. When it arrived

in Delcambre the unit was damaged. I have parts from the failed air

conditioner on hand, that I will use to repair the damaged unit.

The

problem I am having is with the control unit. Two different

connection types, so it will take some investigation.

Used

Air Conditioner With Control Box Apart

I

went back over to DREAM AWAY to have breakfast. After breakfast,

Kitty assisted me with the remove the radar reflector from the mizzen

mast project.

This

project was very necessary as a pair of mourning

doves

had built a nest in the radar reflector. The mess they were making

on deck was just too much. The good news was by the time I got up the

mast to the radar reflector, the nest had been abandoned. We decided

to remove the radar reflector until we go on our next offshore trip,

that way we will have no more problems with birds nests.

April

17, 2013, Wednesday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Also updated the maintenance log.

I

went over to the shop and did a major bunch of sanding. I sanded off

the final application of epoxy on the hide hole piece. I then sanded

down the epoxy applications on the large acrylic insert. I also

sanded down the new pieces added to the large acrylic insert to make

the insert sides as smooth as possible.

Large

Acrylic Insert After Sanding

Next

on the sanding list is the hatch from the main cabin. I used

scrappers to get most of the old varnish off, and then finished off

the hatch with a sander.

Main

Cabin Hatch With Sanding Underway

Finished

Main Cabin Hatch

Went

back to DREAM AWAY, and tested the large acrylic insert. It needs

more sanding to make it thinner, but during the process I broke off

one of the new pieces, so it will have be epoxied back on.

After

breakfast I installed the rebuilt electronics shelf into the

mid-cabin.

Mid-Cabin

Before Electronics Shelf Installation

Rebuilt

Electronics Shelf Installed

Helped

a new transient sailboat into the marina, and did the welcome basket,

and took several pictures.

Went

back over to the shop and got started on a new teak wire cover for

the wires behind the new electronics shelf. I cut the pieces from

already fabricated wire covers. I used the mitre saw to cut the

pieces, and then used masking tape to hold the pieces together for

the application of epoxy.

I

masked up the large acrylic insert for the application of epoxy. I

then applied the epoxy to the teak wire cover and the large acrylic

insert.

Epoxy

Applied To Large Acrylic Insert

Epoxy

Applied To Teak Wire Cover

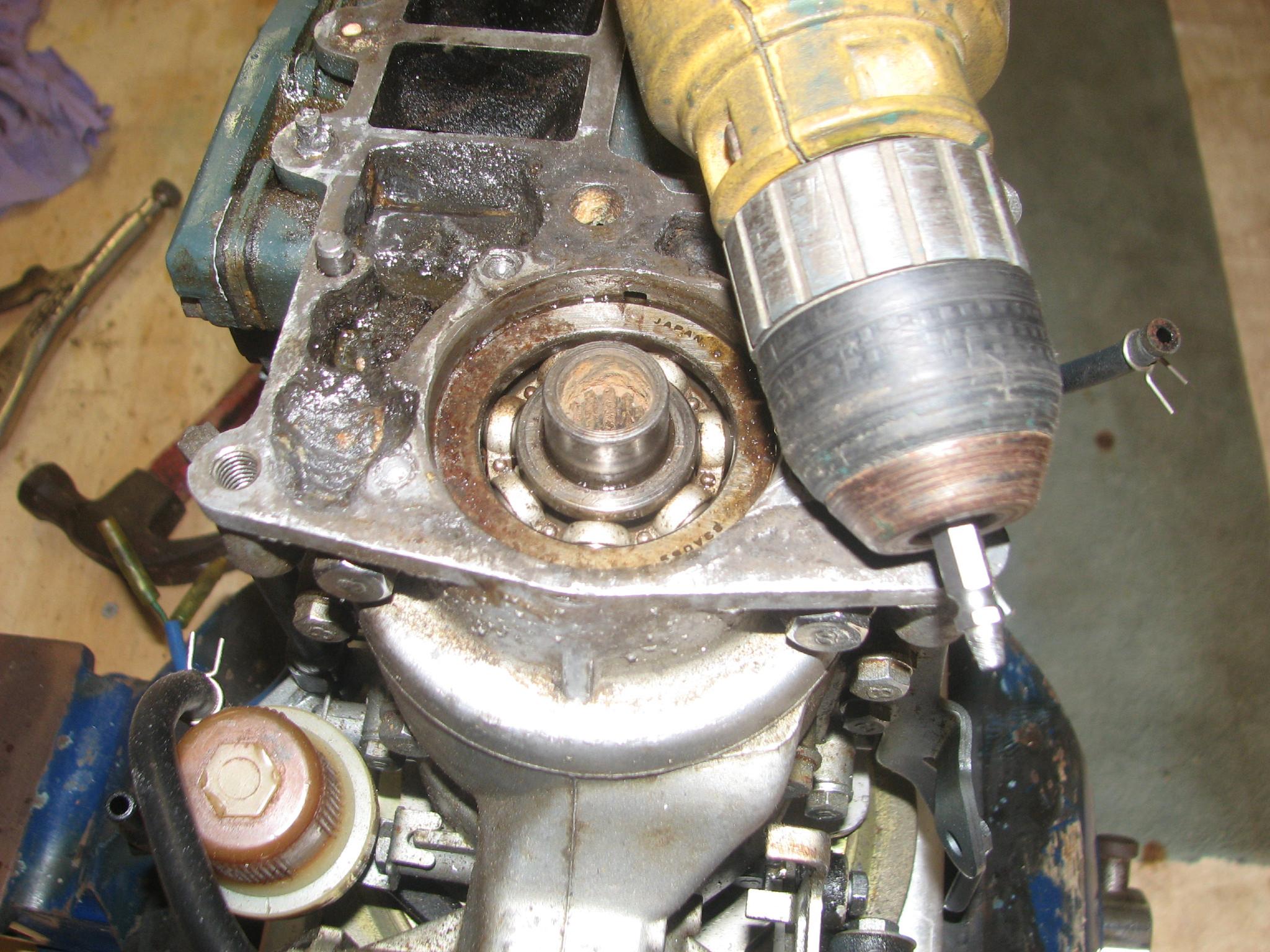

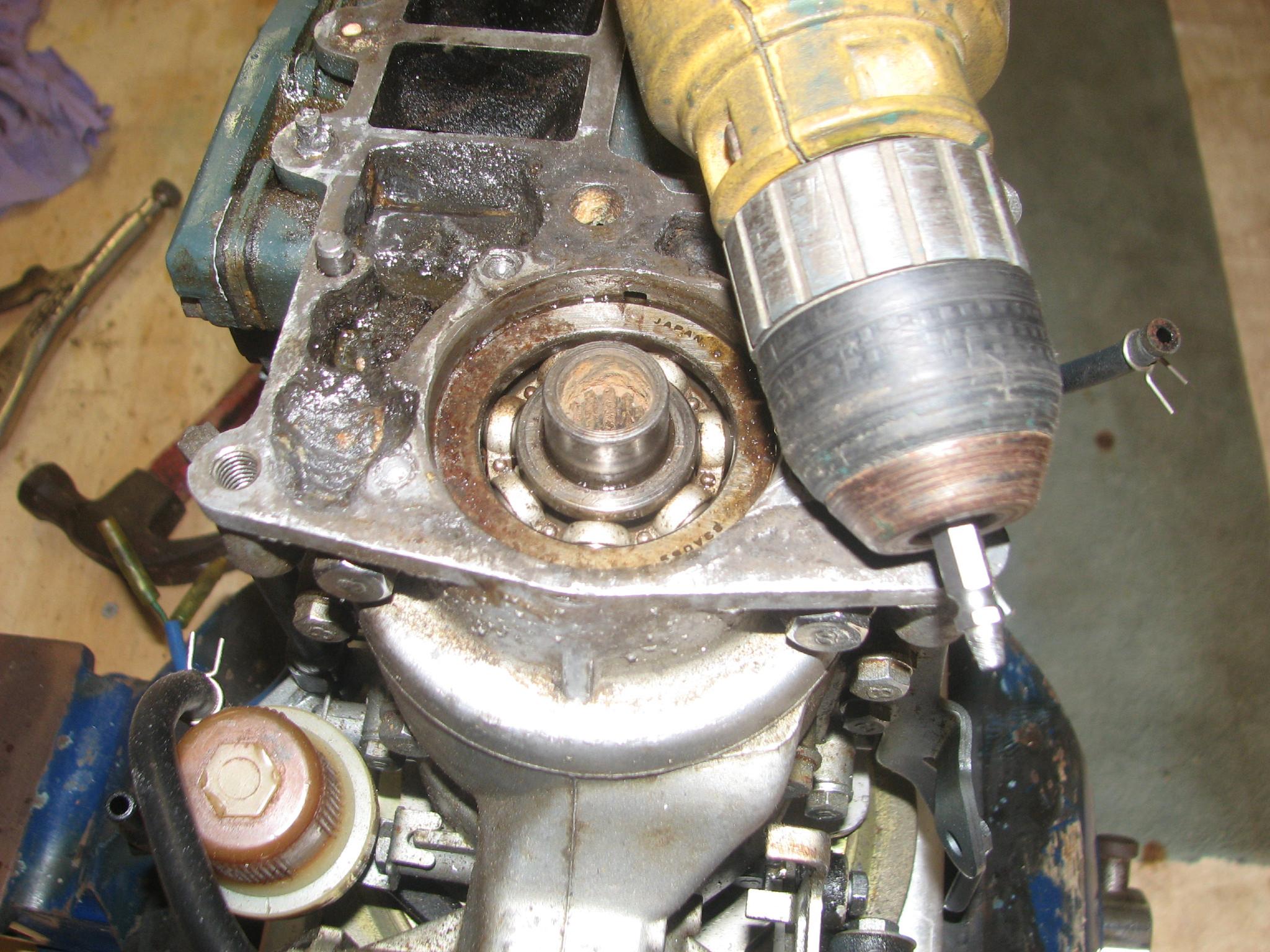

Now

it was time to try the the new Grabit

screw extractor.

I followed the instructions by first drilling the hole in the top the

broken bolt on the spare Yamaha power head. This part seemed to work

pretty well, so I continued on with the second part which uses the

actual screw extractor. This part did not work. It did not remove the

bolt, and stripped the Grabit

screw extractor.

After

this failure, I did some research on the tool, and nowhere does it

mention removing bolts. So it looks like I am back to getting a left

hand drill bit and using an Easy

Out.

If that does not work, then I will have to drill out the holes

oversize and use Helicoils.

Top

Of Power Head With Broken Off Bolts

Before

doing the varnish application, I applied a coat of the dye to the

main cabin hatch.

Main

Cabin Hatch With Dye Applied

I

put the ninth coat of varnish on the two main cabin table pieces and

the fifth coat and final coat on the repaired Panduit

wire duct

cover.

April

18, 2013, Thursday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Also updated the maintenance log.

Went

over to shop and sanded down the large acrylic insert to make the

insert fit in the companionway. I then sanded the last epoxy

application on the hide hole piece. I also sanded the teak wire

cover, and got it ready for the dye application.

Panduit

Wire Duct

And Teak Wire Cover Ready For Dye

Panduit

Wire Duct

And Teak Wire Cover With Dye Applied

I

brought an empty cat litter container over from the shop. I filled it

with water, and heavy bleach. I then dropped in all of our plastic

cutting boards for cleaning. By the time I returned from the shop

after applying the varnish, the cutting boards were VERY clean.

I

went over to the shop and applied the tenth and final coat of

varnish on the two main cabin table pieces.

April

19, 2013, Friday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Also updated the maintenance log.

Went

over to the shop, and did an additional wipe down of the Watco

teak oil finish

that had still not soaked into the main cabin hatch.

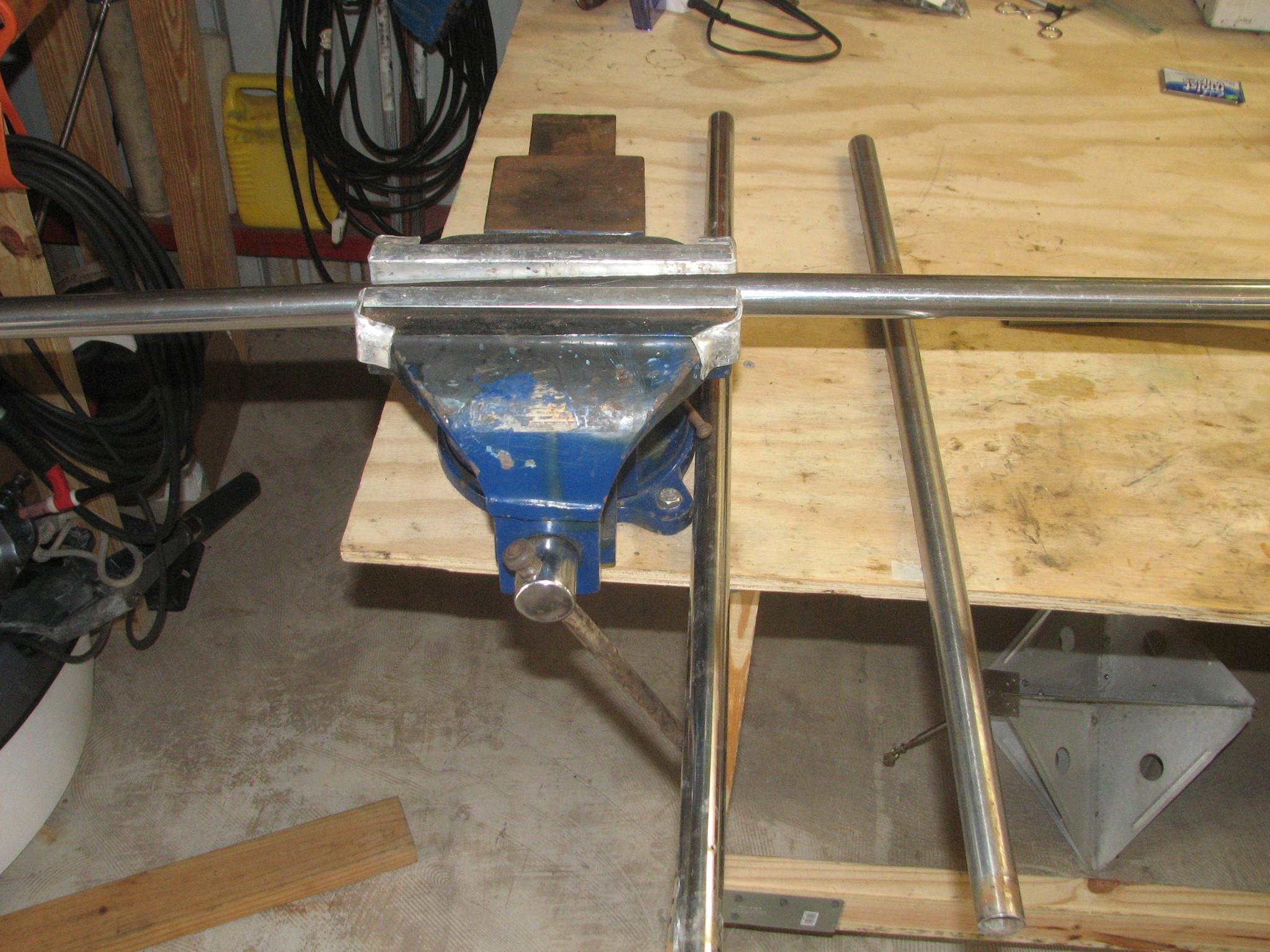

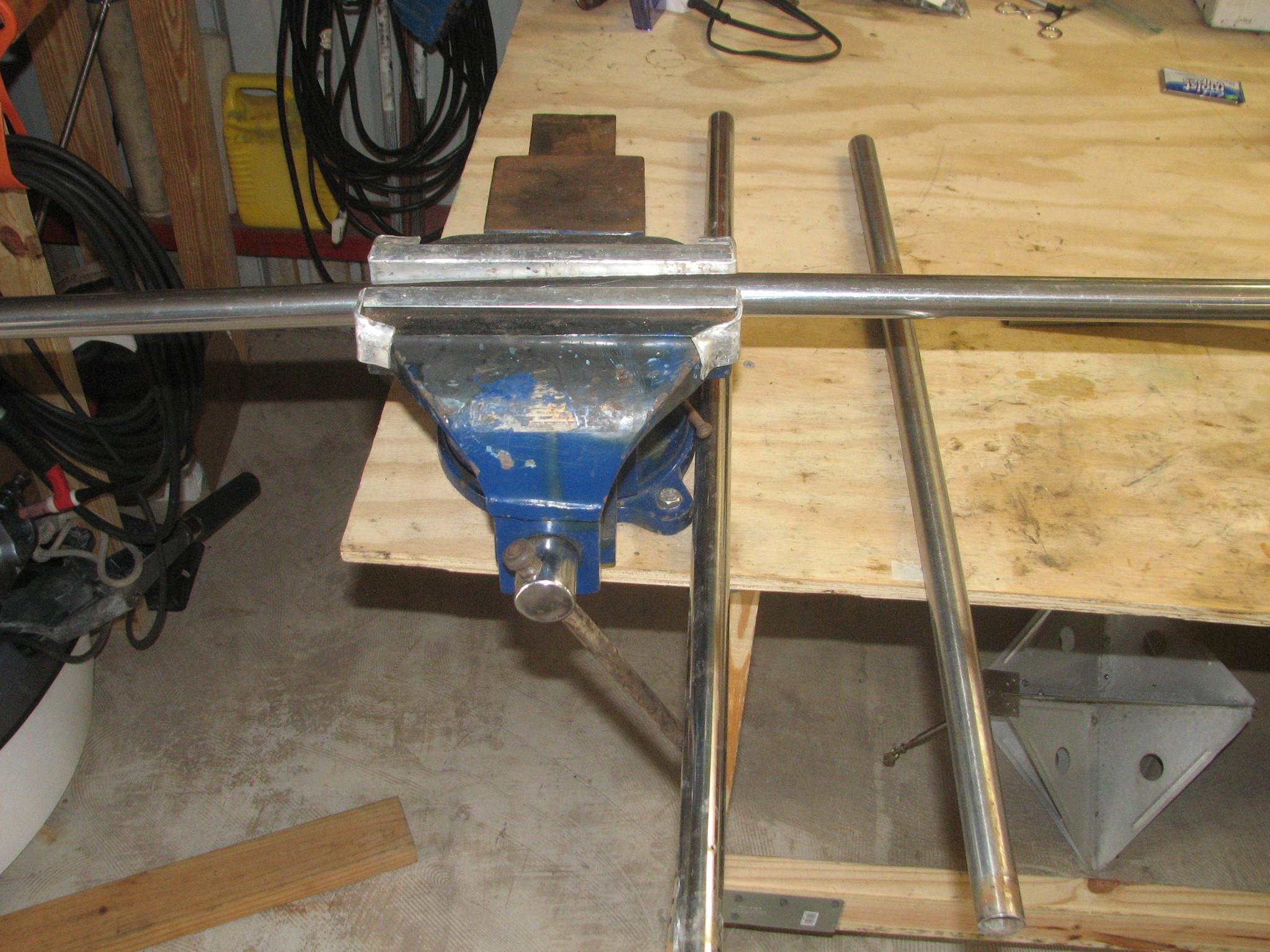

I

started in on a project that needs to be done before we go offshore

again. That is fabricating and installing handrails in the main

cabin. These will be fabricated from 1” stainless steel tubing, and

bolted to the overhead in the main cabin.

Stainless

Steel Tubing To Be Used On Main Cabin Handrail

April

20, 2013, Saturday

I

arrived at the Shrimp

Festival Grounds

to direct traffic for the Delcambre

Seafood & Farmers Market

at 0600. Venders were arriving when I arrived. We closed the gates at

0745, then I spent the remaining time the market was open, 1300,

working at the registration booth. Kitty arrived at the market around

0800 and also worked the registration booth until closing. When the

market closed down, I helped with the breakdown of all of the tents,

tables and chairs. We then loaded all of the tents, tables and chairs

onto a trailer, then took them over to the Port

Of Delcambre’s

storage facility and unloaded them.

I

got back to DREAM AWAY around 1600. A really long day.

April

21, 2013, Sunday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

I continued working on the computer all morning. I got caught up on

email, and got most of the financial stuff completed.

We

were having a potluck marina party in the afternoon, so I made a

pasta salad for the potluck. The party in the afternoon was a great

success, way too much to eat!

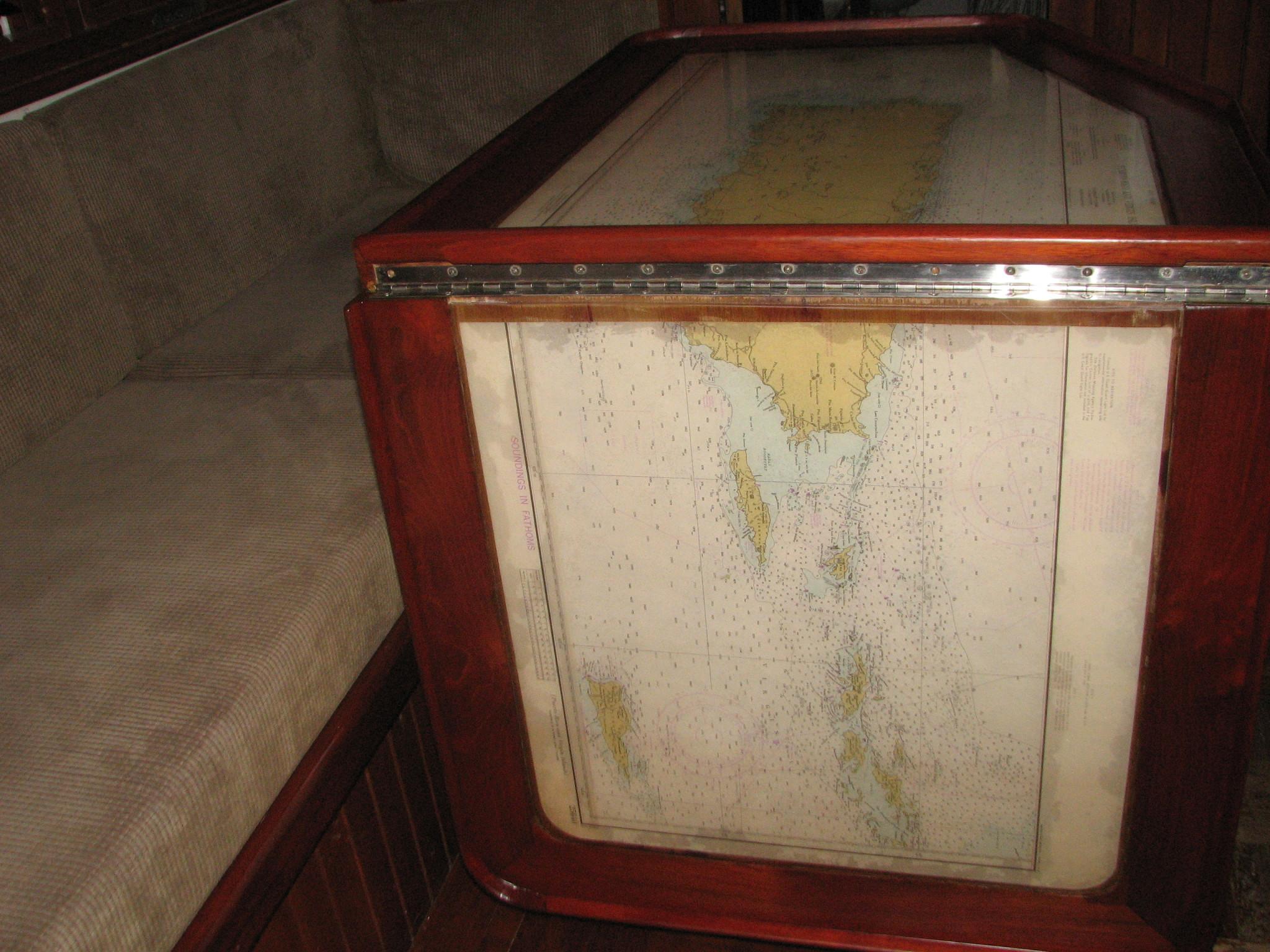

Our

English friends were arriving from Guatemala late this evening, so I

had to install the refurbished table in the main salon, and the

“test” hatch also in the main salon.

New

Table Ready For Installation

Temporary

Table Ready For Removal

Table

Base Ready For New Table

Temporary

Table Removed

New

Table Installed With Drop Leaf Down

New

Table Installed With Drop Leaf Up

Hatch

Installed In Main Cabin

April

22, 2013, Monday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

After

breakfast, we all headed to Lafayette for my appointment with the

dermatologist. We had lunch at the Hai-Nam

Chinese Buffet,

and then returned back to DREAM AWAY.

Noel

and I went to work to change out the Heart

Freedom 25

inverter/charger due to a perceived problem. We installed the spare

inverter/charger, and the problem did not change. I was able to get

the batteries charged, but I am still not comfortable. I think there

is some problem in either the DC system or the AC system that is

causing the inverter/charger to draw too much current.

We

decided to leave the spare inverter/charger installed. The really

good news is that I now know I have a completely operational spare

Heart

Freedom 25

inverter/charger

April

23, 2013, Tuesday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Today

we decided to do a swamp tour at McKee’s

Landing

in Henderson, Louisiana. It was a tour of the Atchafalaya

basin

and was pretty interesting. We did get to see a couple of big

alligators.

Alligator

In The Basin

On

the way back to DREAM AWAY, we stopped at the

Acadian

Museum and Memorial

in St. Martinsville, Louisiana. We found the museum interesting and

informative.

April

24, 2013, Wednesday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Today,

after breakfast and the storms from the passing cold front we went to

Avery Island to visit the Tabasco

Factory

and take the tour. While on Avery Island we also took the driving

tour of the Jungle

Gardens and Bird City.

April

25, 2013, Thursday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

As

we were going back to DREAM AWAY, we met up with Nicola’s niece,

Anna, who had arrived to visit and spend the night.

April

26, 2013, Friday

Started

off the morning by making a pot of coffee for Nicola and Noel, and

getting them under way by 0600. They had to drive back to Houston to

catch their plane to Manchester, England.

When

Nicola and Noel departed, the Admiral (Kitty), went back to bed, and

I got to work catching up on email and the maintenance log. Anna is

still sacked out!

Spent

the entire day getting the boat put back together after Anna had

left. We then went out and did the laundry.

April

27, 2013, Saturday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Today

was spent just catching up. I did put a second coat of Cetol

on the main mast step. The pin rails that were completed, I installed

on DREAM AWAY. Now that project is finally completed.

Pin

Rail & Belaying Pins Installed

April

28, 2013, Sunday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Went

over to the shop, and unloaded several projects to work on. The first

was a screen on one of the forward main cabin hatches. One of our

Kittens, Jordie,

tried to lie in the screen when he was outside, and pulled the screen

loose. The screen did not tear, so all I had to do was put the screen

back in the frame.

Screen

Frame And Screen On Work Bench

Screen

And Frame Back Together

I

brought over to the shop three more of the Panduit

wire duct

covers. I cut the teak tape for the covers and then applied the tape

to the Panduit

wire duct

covers. When that was complete, I applied the dye to get all of the

covers ready for the application of varnish.

Next

on the list was the repair of the large acrylic insert with epoxy.

One of the newly installed tabs had broken off and needed to be put

back on with epoxy.

Large

Acrylic Insert With Broken Tab

Large

Acrylic Insert Epoxy Repair

Since

I had a pot of epoxy mixed, I had also planned to fill in the holes

that I had made in the temporary table in the main cabin. The

starboard hatch in the cockpit has some rot in it, and needs repair.

My plan is to use the piece of plywood I had used for the temporary

table in the main cabin, as the temporary cockpit hatch. Because I

had drilled some holes in the piece, I needed to fill the holes so

there would be no leak issues. I masked the back of the piece with

masking tape, and then applied the epoxy.

Plywood

Before Epoxy Application

Plywood

After Epoxy Application

I

had again brought the hatch from the main cabin deck over to the

shop. Of course I inserted the temporary hatch in the deck. I needed

to apply an additional coat of Watco

Teak Oil Finish

to the hatch in the main cabin floor. I sanded the hatch with 320

grit sandpaper, then wiped it down with a tack rag. I then applied a

coat of the Watco

Teak Oil Finish.

Main

Cabin Hatch Before Sanding

Headed

back to DREAM AWAY to have breakfast. After breakfast I started in on

the check DC wiring project. On April 22nd when Noel and I swapped

out the Heart

Freedom 25

inverter/charger and starting using the spare, there still seems to

be some problems. For one, when the battery charger is in max charge

mode, 130 amps DC, it seems like the unit is pulling too many AC

amps, almost 30. Checking with the Heart

Freedom 25

inverter/charger manual, it states when in max charge mode the unit

draws 26 amps, AC. I was having trouble with the main panel circuit

breaker, 30 amps, popping. That would make sense if anything else was

on the AC power system.

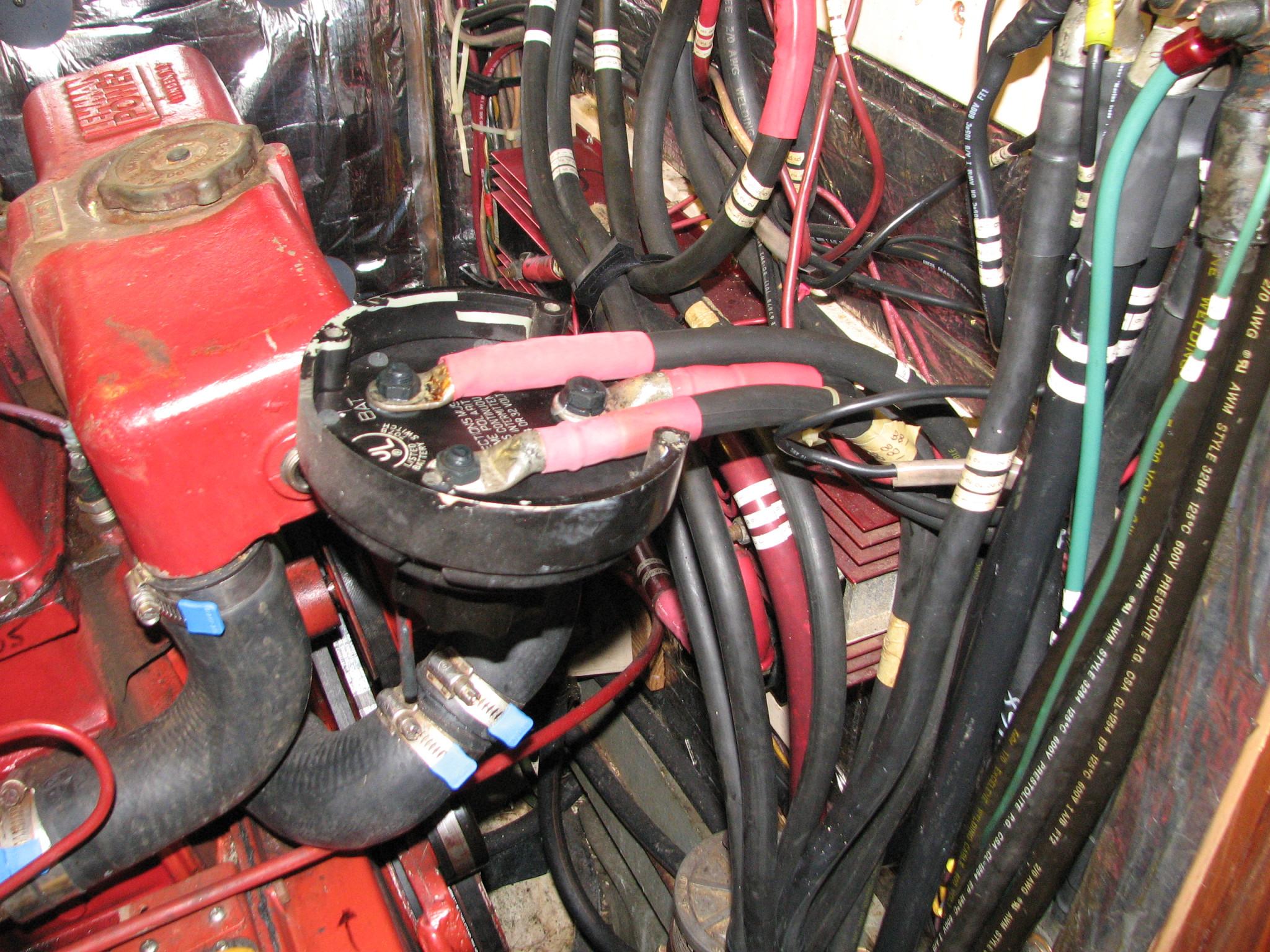

Any

way to make sure there was not any other problems, I decided to

completely check out all of the DC battery connections. I knew this

needed to be done, as I mentioned previously that the bolts on the

battery clamps had a steel bolt in them and they were rusting.

I

am sure I have said it before. but I get so upset with “Marine”

parts suppliers selling parts that do not work in a marine

environment. Case in point, West Marine selling marine battery

terminals that uses a steel bolt to clamp the terminal to the battery

post.

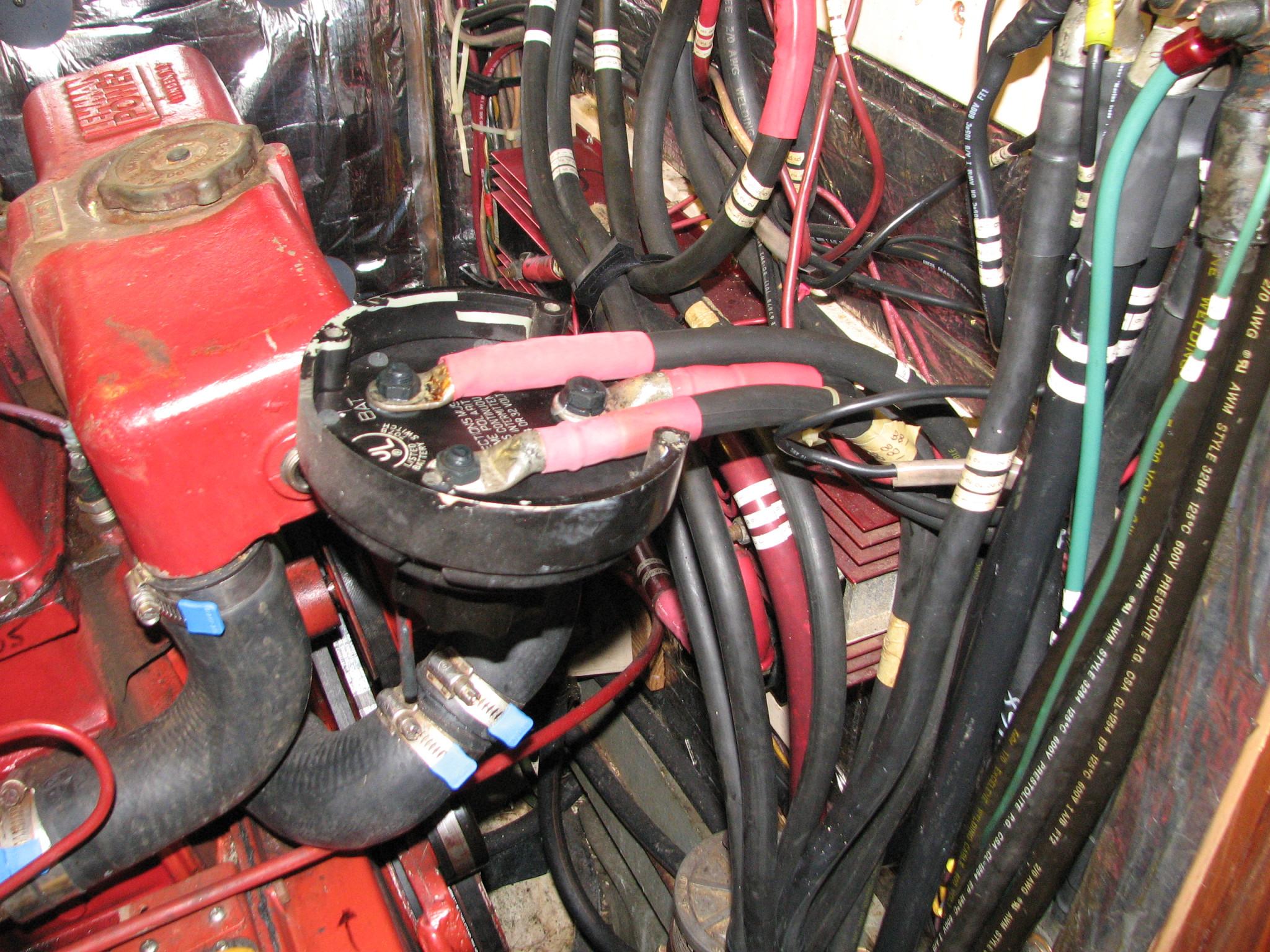

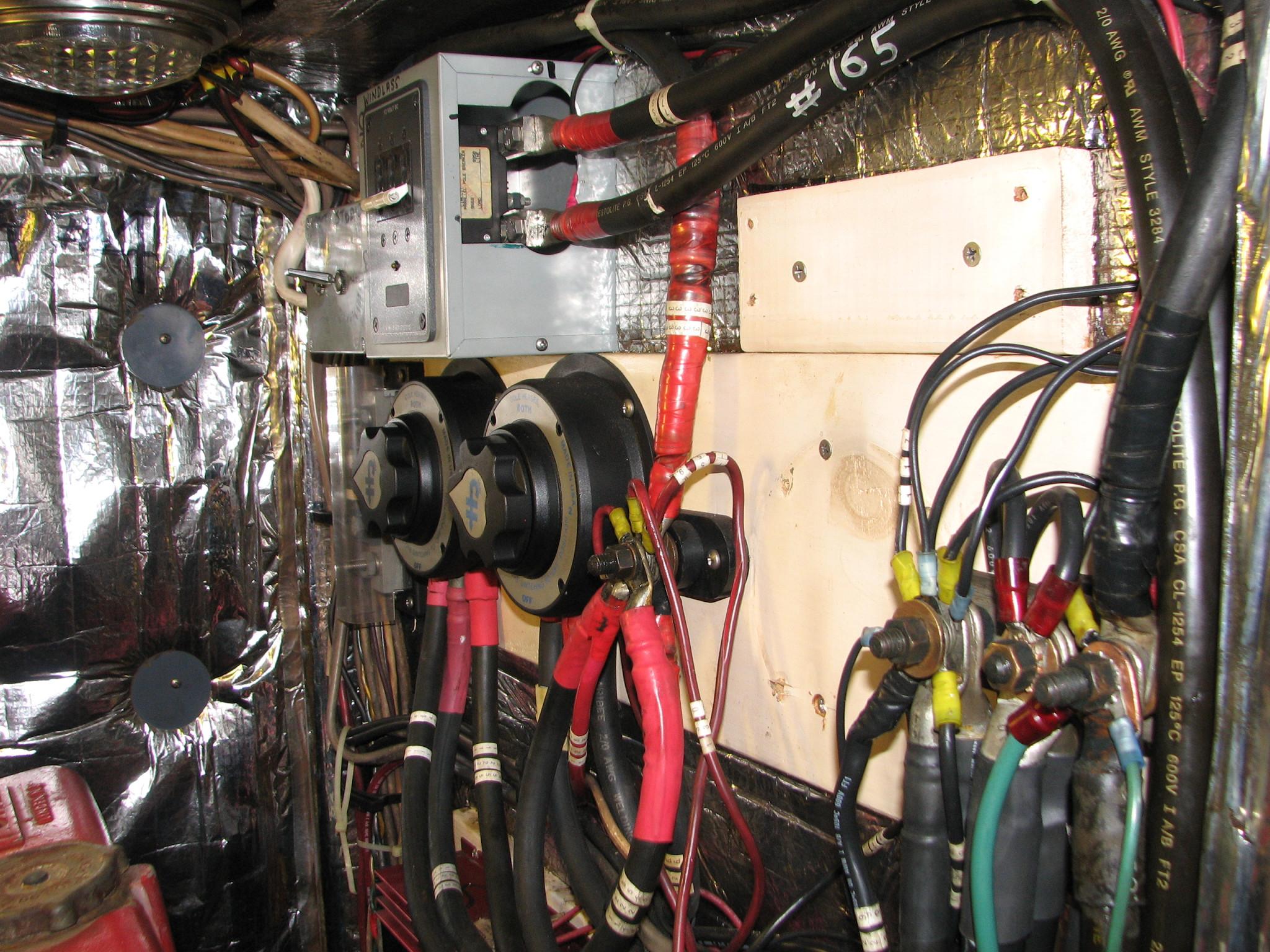

Off

my pedestal, and back to real life. I took off all of the ground

connections on the ground buss, located in the engine room, and

cleaned all of the connections. I also took the battery switches off

of the bulkhead in the engine room and checked and cleaned all of

those connections.

When

that was completed, I started in on the seven 8D batteries in my

system. Six are in the house battery, and the seventh is the main

engine and generator start battery. I took off all of the connections

and cleaned them. I also removed all of the battery terminals, and

replaced the clamp bolts with silicon bronze bolts and nuts. I also

measured the voltage in all of the batteries. The voltage ranged from

13.48 to 13.42 volts. Not bad for four year old batteries. Bottom

line all of the connections looked good. The work was more

preventative maintenance than fixing or finding a problem.

I

also checked the AC connections at the inverter/charger end, and

found no problems there. I am still having an issue with the spare

inverter/charger. It is working fine, and charging the batteries, but

it’s function is not displaying on the LINK 2000R battery monitor.

Also the inverter/charger seems to switch from float mode to accept

mode at random. I will probably swap in the other inverter/charger

and see if it reacts the same way.

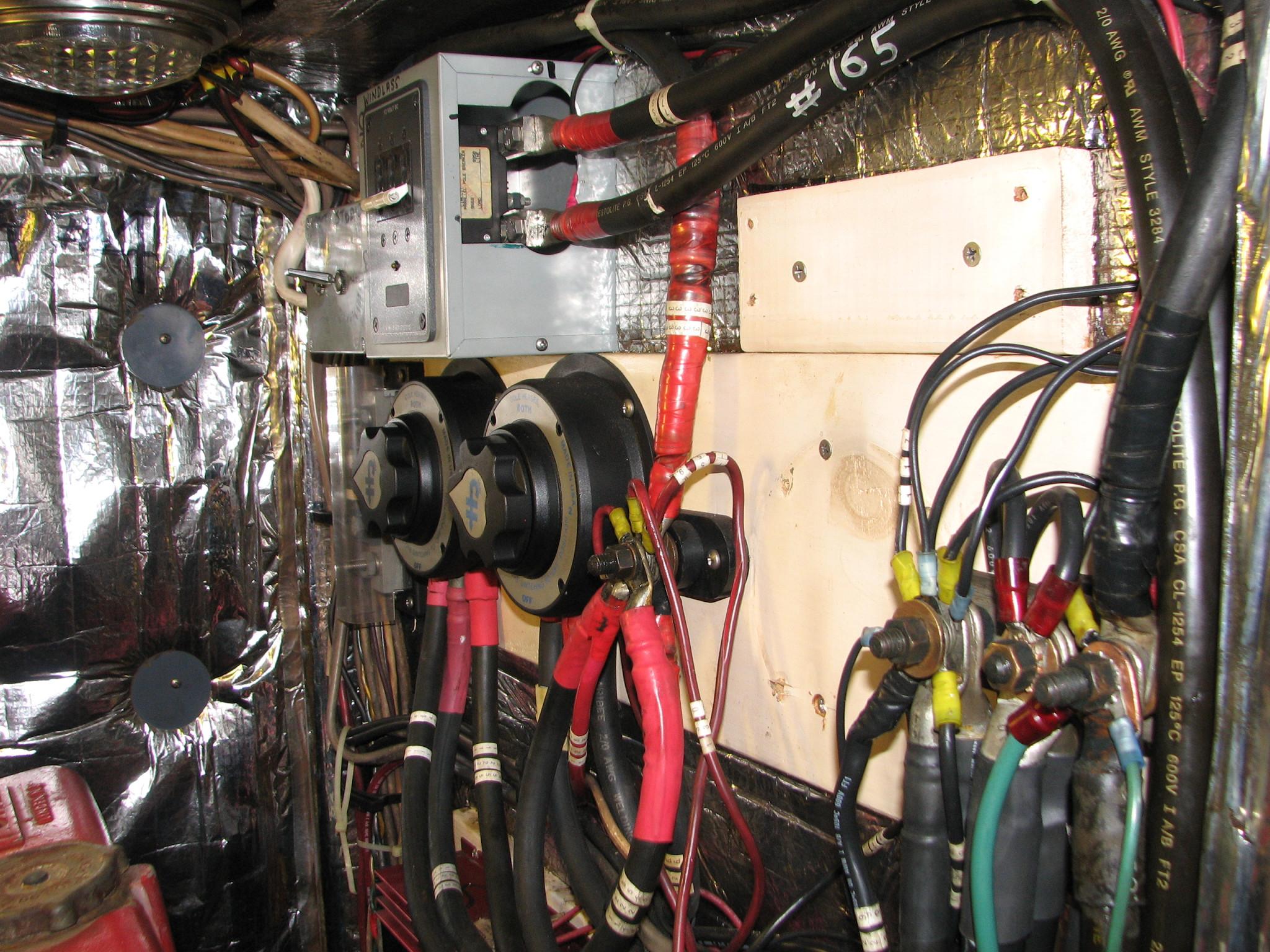

Ground

Buss In Engine Room

Battery

Switch Off Of Bulkhead

Battery

Switches, Anchor Windlass Switch, And Ground Buss

Start

Battery Connections, Notice Steel Bolts On Terminal

So,

after four of work, it seems I have very good connections in all of

my DC system, and good connections in the AC system that powers the

inverter/charger.

What

I do have is a problem with one inverter/charger not reading

correctly, and going from accept to float for no apparent reason. The

second and the original inverter/charger has a problem with it

popping the 30 amp breaker on the unit itself.

April

29, 2013, Monday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Sanded

off the epoxied area on the large acrylic insert. Also sanded down

the new temporary hatch and loaded the large acrylic insert and the

hatch into the Black Beast.

I

had the two pieces of oak already cut out for the Cutco

knife holder. Now I had to cut out each piece, such that, when the

pieces were attached to the Cutco

knife holder, there would be a slot for the additional knives to drop

into. I do not have a router, so I had to setup the table saw to cut

the slots. Not a difficult task, just had to be careful during the

process.

Table

Saw Setup To Cut Slots

Knives

In The Newly Cut Slots

I

finally got all of the Panduit

wire duct

covers completed and dyed, so they are ready for varnish. The Teak

wire cover is also ready for varnish. I moved all of the parts to the

paint area of the shop. This happens to be mostly in the Admiral’s

library, but it is the only area available.

Panduit

Wire Duct

Covers On Computer Table

Panduit

Wire Duct

And Teak Wire Cover On Book Shelves

Nameboards

Ready For Varnish

I

left the shop and went back to DREAM AWAY for breakfast. After

breakfast, I had to check one last set of connections in my DC

battery system.

I

had forgotten there is a large fuse in the positive DC line between

the inverter/charger and the battery. I had neglected to check those

connections yesterday, so I completed that task today. Like

yesterday, the connections looked great, but I disassembled the

connections, cleaned them up, and then put them back together.

Fuse

Holder With One Wire Disconnected

I

checked the fit of the large acrylic insert, and it fits nicely. I

put one screen, and the insert in the Black Beast

to go back to the

shop for varnish. I also removed the starboard cockpit hatch, and put

it into the Black Beast.

I put the temporary plywood hatch in the

cockpit to cover the hole left by the removal of the starboard

cockpit hatch. Then I went back to the shop.

First

item was to put a third coat of Watco

Teak Oil Finish

on the main cabin hatch. The key now is to get the Watco

Teak Oil Finish

to dry. I wiped off all of the excess with a rag, following the

instructions, so we shall see.

Next

project was working on the cockpit hatch. This took up the remainder

of the afternoon, except for the varnishing. The filler material has

to be removed from between the teak pieces on the top of the hatch,

and then all cleaned out. I also have to dig and cut out the rotten

wood on the underside of the hatch. This will be an on-going project

for a few days.

Top

Of Hatch

Underside

Rotten Area Of Hatch

Last

Item for the day was the varnish. I applied the first coat on the

nameboards, the teak wire cover, and all of the Panduit

wire duct

covers.

April

30, 2013, Tuesday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

worked

some more on cockpit hatch; checked shakepeare antenna

Went

over to the shop with the Cutco

knife holder. I measured where I wanted to put in the screws to

attach the new pieces to add to the Cutco

knife holder. I am going to screw and glue (epoxy) the cut pieces to

the Cutco

knife holder. I used screw starter bits to make sure I did not split

the wood in any of the pieces. I was working with some thin areas.

Drilling

And Fitting the New Pieces To The Cutco

Knife Holder

When

I got all of the hole drilled in both pieces, I did a dry fit before

applying the epoxy.

Dry

Fit Of Additional Pieces To The Cutco

Knife Holder

The

dry fit went well, so I took off the pieces, mixed a pot of epoxy,

getting ready to put the pieces and Cutco

knife holder back together.

Pieces

And Mixed Epoxy

I

then applied the epoxy to one piece, screwed it to the Cutco

knife holder, then epoxied the second piece and screwed it to the

first piece. When it was all together I put the Cutco

knife holder in the vice, so if there was any epoxy drips, it would

not harden in the hole cutouts for the knives.

Completed

Cutco

Knife Holder

I

then spent some time working on the cockpit hatch, scraping out the

area between the teak boards.

Last

item before going to DREAM AWAY for breakfast was to work on two

Shakespeare

SeaWatch 2025

Marine TV antennas. I have acquired two of the units, and the

previous owners said they do not work. I thought perhaps I could get

at least one to work. I have two antennas, but only one control box.

I

took both antennas apart, and made sure that all of the parts were

inside, and all of the solder joints were still good. I put the

antennas back together, and put them in the Black Beast.

Shakespeare

Antenna And Controller

I

went back to DREAM AWAY, and did not do much the remainder of the day

as far as project go. It was our 44th anniversary. We had planned to

go out to eat in New Iberia, but Kitty found two 1 ½” thick

Porterhouse steaks on sale, and bought two we were having dinner in

tonight. What a wonderful meal it was! It consisted of cajun surf and

turf!! Porterhouse steak, seafood patti (shrimp, crab meat &

tilapia), grilled eggplant, and corn on the cob. Dessert was Kitty’s

rum cake!

The

Meal

Happy

Participant

Happy

Participant