Maintenance Log April 2014

April 24 - April 30,

Thursday - Wednesday, 2014

The dates of our trip to Puerto Rico,

which will be covered in a DREAM AWAY update.

April 23, Wednesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Today is going to be a busy day, so I

got started early. I went over to the

Port of Delcambre's

storage room and pick up the lawn mower and fuel tank. Then back to

the marina

to weed all of the gardens. When I had weeded all of the gardens, and

trimmed the grass at the edges of the parking lot and gardens, I

mowed the lawns in the marina.

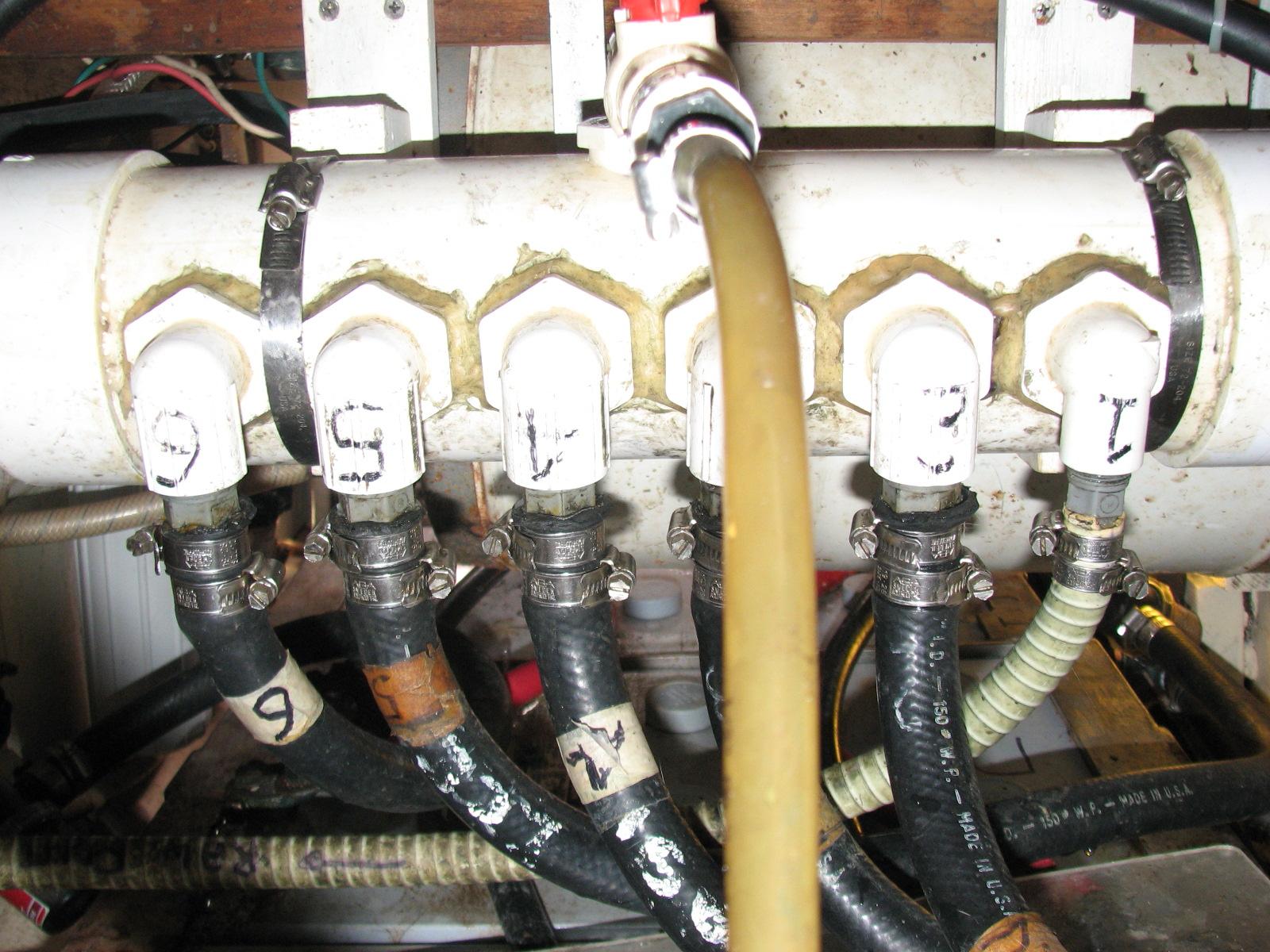

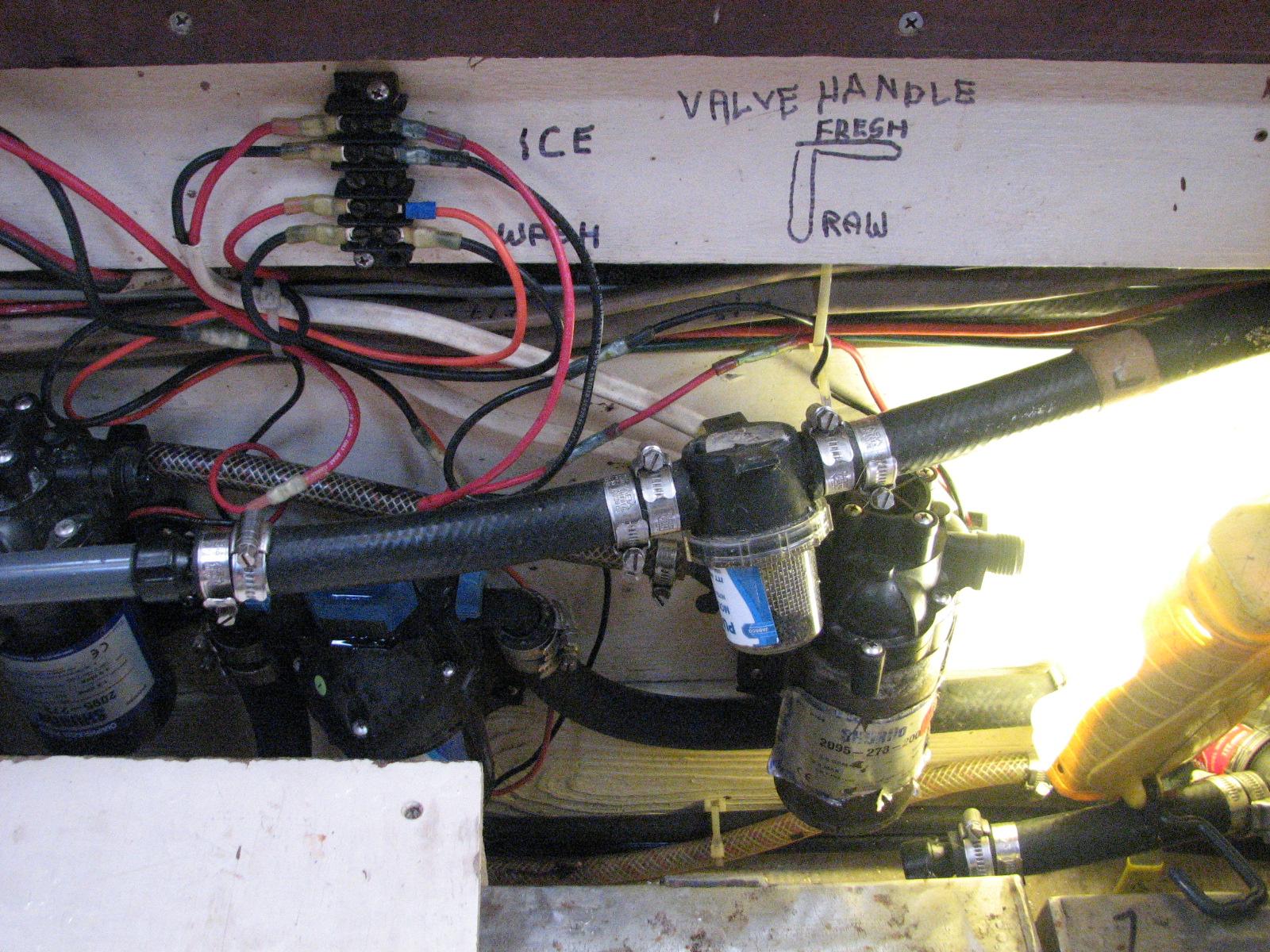

When T-Boy had left, it was time for me

to get busy cleaning out all of the raw water strainers and manifold.

Since we will be gone for ten days to Puerto Rico, I did not want to

have any issues with these systems.

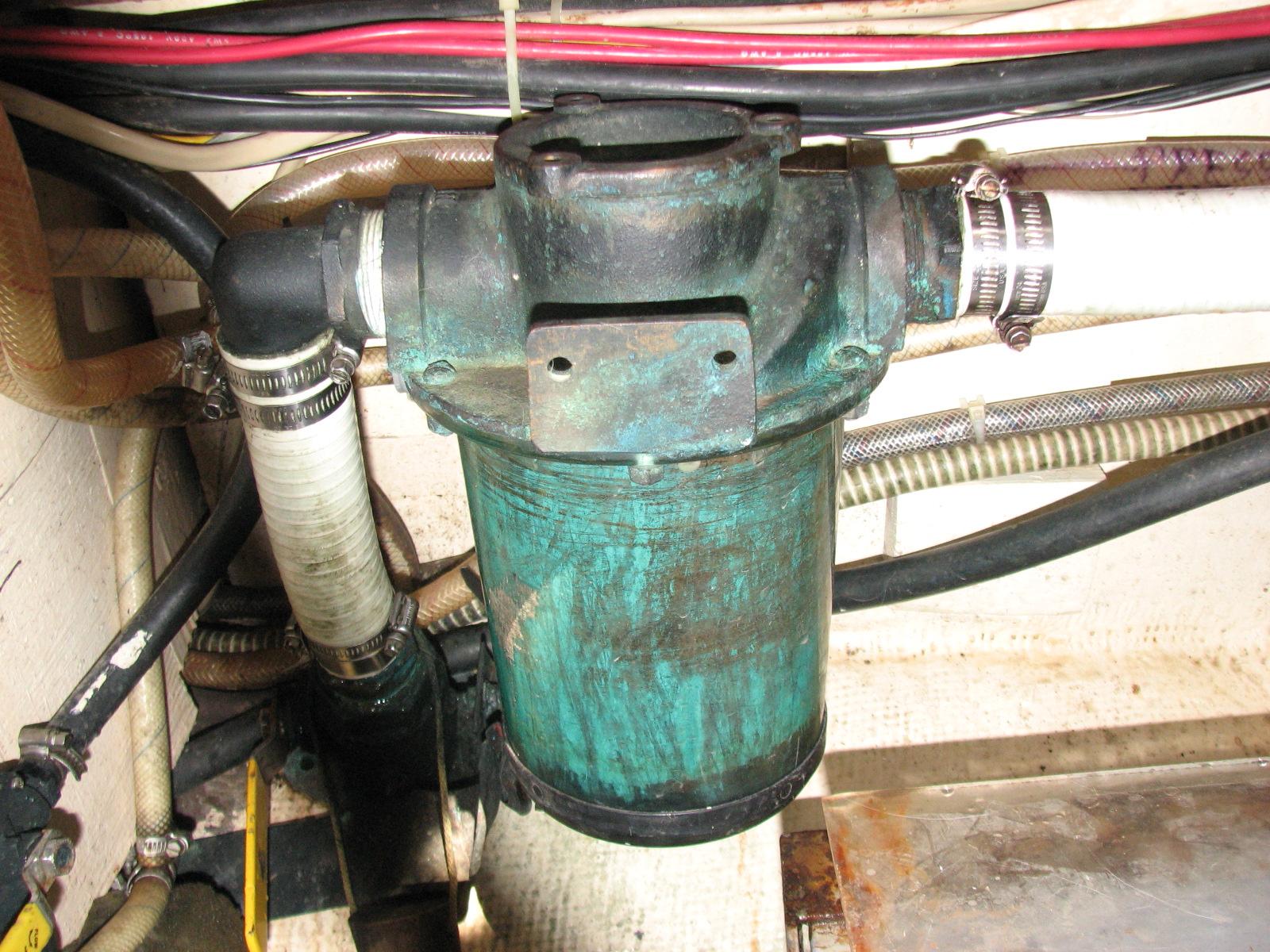

I cleaned out the main strainer for the

manifold (Sea Chest), and the manifold (Sea Chest). Also cleaned out

the strainers for the ice maker cooling pump, the refrigeration

cooling pump and the forward air conditioner cooling pumps. During

this cleaning process, I also cleaned out the hoses for all of the

cooling pumps using high pressure water from the dock.

Main Strainer For The Manifold (Sea

Chest)

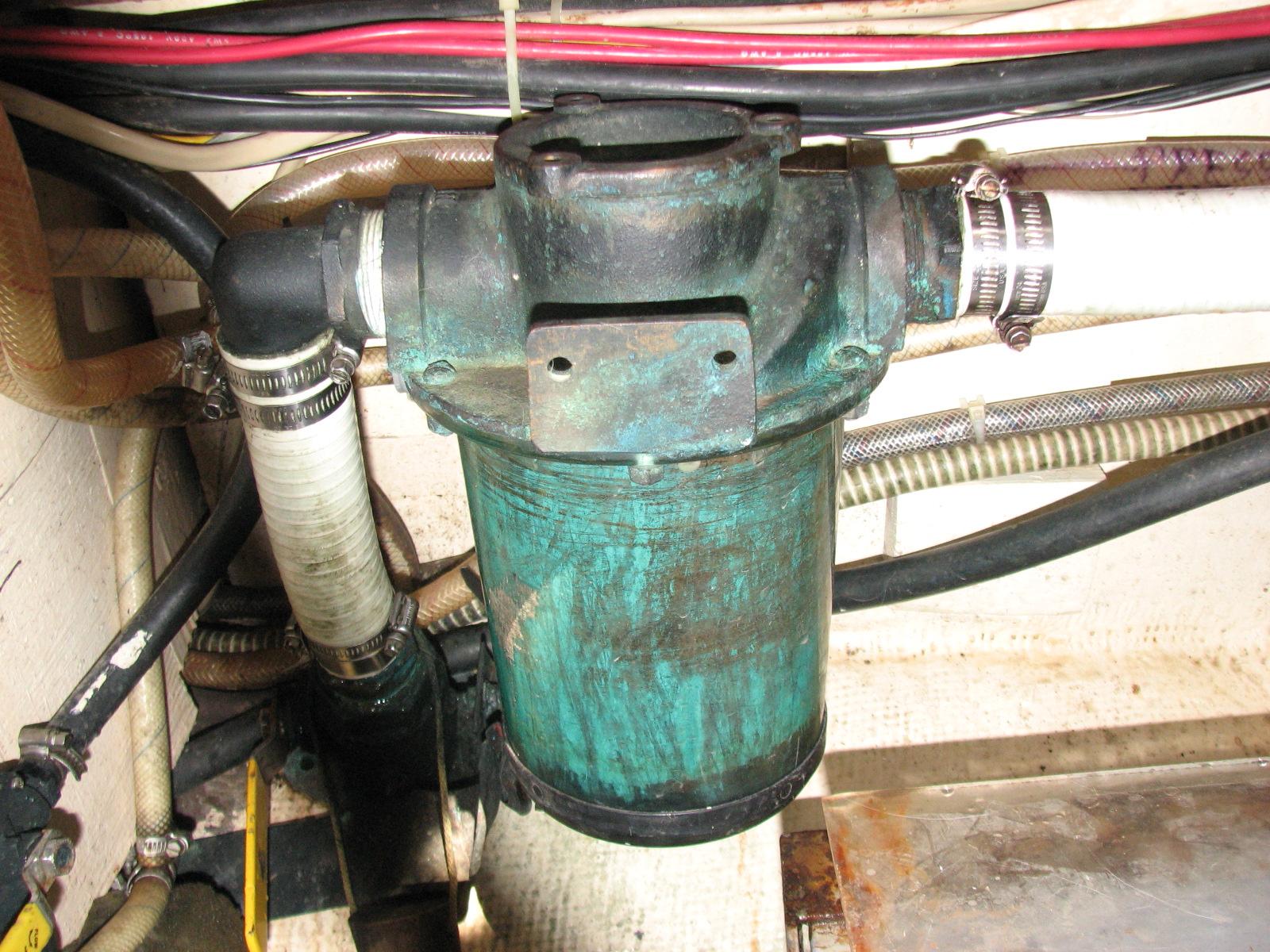

The Manifold (Sea Chest)

I took apart the the refrigeration

cooling pump head and made sure it was clean, then put it back into

service. I also moved the original ice maker cooling pump back into

the system and removed the spare cooling pump.

Ice Maker Cooling Pump

Refrigeration Cooling Pump With Hoses

Being Cleaned

By the time this project was finished

it was time to prepare dinner and get packed for the trip to Puerto

Rico. We have to drive to

New Orleans tomorrow leaving

Delcambre

at 0600!

April 22, Tuesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go to the

shop,

but stayed on DREAM AWAY and worked on the computer and

scanning in papers.

Drove into New

Iberia to the hospital so Kitty could get her annual

reclast IV. To make a long story short it did not happen. It will

have to be looked into to see what the issue is with her kidneys.

On the way back home, the

Black Beast

died on us! It was touch and go, and then we

decided to call the

GM Motor club.

They could not help us, so after waiting an hour, the

Black Beast

had cooled down a bit. I started the

Black Beast and it

ran fine. We drove it to the mechanic and left it with him. I am sure

it will not fail for him, so he will not be able to find the problem!

When we finally got back to DREAM AWAY,

we unpacked some of our stuff, and then went off to Abbeville

with our good friend Bonnie to a concert at the Vermillion Parish

Public library. It was a wonderful treat!

Back home after a dinner at Shuck’s,

I then prepared the food for the cats while we are on our trip to Puerto Rico. Bonnie

will be feeding Jillian

and Jordan while we are away.

April 21, Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go to the

shop

first thing, but stayed on DREAM AWAY and continued working on

email and the Maintenance Logs. I am making progress, emails are at

an acceptable level, and I am working on finishing up the March

Maintenance Log.

After breakfast, I started work on an

experiment. Yesterday, I had loaded several empty buckets and kitty

litter containers into Ruby,

which I brought down to DREAM AWAY. I also brought down two tubs that

we keep at the marina

in which to wash lines.

The experiment is to put all of these

containers on the bow of DREAM AWAY and see if the generator

exhaust is out of the water enough that I could move the exhaust. I

also lowered the tender into the water to take that weight off of the

stern of DREAM AWAY.

The experiment was successful in that

the exhaust for the generator

is completely out of the water, but not enough to do a replacement

while DREAM AWAY is still in the water. Exhaust outlet work will have

to wait until I have DREAM AWAY out for a bottom job.

Tubs And Buckets On Bow Of DREAM AWAY

I emptied all of the bucket and tubs,

and returned them to their proper location. I left the tender in the

water, as I needed it to work on the leak in the aft cabin.

We had located the source of the aft

cabin leak a couple of days ago, so now I was going to fix it. Along

the stern of DREAM AWAY, where the hull to deck joint is, is a crack

in the fiberglass.

This is the source of the leak.

I had to scrape out the crack to get to

good solid fiberglass

on either side of the crack. My goal was to clean out all of the

area, even though some of the crack was not leaking at the time. Sort

of some preventive maintenance.

Captain In The Tender Working On The

Crack

Source Of The Aft Cabin Leak

Source Of The Aft Cabin Leak

Other Areas Of The Stern That Were

Cleaned Out

Once I got all of the crack cleaned

out, I wiped down the area with acetone,

and then applied

Bondo

Glass short hair filler putty. This is a filler putty with short

fiberglass

strands in it, so it is a structural filler putty rather than a

finishing putty.

Structural

Bondo

Glass Filler Putty Applied To Repair Area

Structural

Bondo

Glass Filler Putty Applied To Repair Area

Since the point of this exercise was to

repair a leak, I had Kitty get in the aft cabin where the leak is

(hopefully was) and keep an eye on the area while I ran water from

the hose over the area. Previously, when I ran water over the area,

the water appeared in the aft cabin within 15 seconds. This time I

ran water over the area for three full minutes, and no leak!! This is

great news.

I put the tender back onto the davits,

cleaned up the area, put all of the tools and stuff away, and hit the

shower!

April 20, Sunday, 2014

I slept in this morning until 0700.

Must be the effects of the cold and medicine. Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee. When the

coffee is started, I feed our two cats,

Jillian and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the

shop first thing, but

stayed on DREAM AWAY and continued working on

email and the Maintenance Logs. We had a very late breakfast, as

Kitty slept in until 1030. She is recovering from her cold also.

After breakfast, I tested the new

Autopilot control head friends Nicola and Noel ordered, and had sent

to us. It worked perfectly here in the slip. When we get to some open

water, will have to check it again to make sure it actually steers

the boat!

Raymarine ST7000+ Control Head Powered

Up

I went over to the shop

got to work on the console for Ruby.

I sanded down the bottom of one of the lids on the console.

Theoretically, I am ready to put on the first coat of varnish when I

leave the shop

today.

Sanded Cover Bottom From Console

Seam In Console Before Epoxy

Application

Seam In Console After Epoxy Application

Next, I got started cutting the spacers

required for the solar panel risers. I have to cut 36 ¼” spacers

from a piece of stainless steel tubing. Once I cut them off with a

hacksaw, they have to be filed down to make all of the edges smooth.

Cutting Spacers From Stainless Steel

Tubing

I did not finish cutting all of the

spacers, but I did finish trimming and polishing all 16 of the risers

for the solar panels. I still must get some more bolts and wing nuts

to finish that part of the project. The next part will be to drill

four holes in each riser, so I can attach the risers to the hard

Bimini.

I went to get the console pieces ready

for the varnish application. When I looked at the console, I decided

I needed to fill more of the gaps in the bottom with the thickened

epoxy.

I taped up the seams in the console, and then mixed up a pot of

thickened epoxy.

I applied the epoxy

to the seams, so it will have to wait until tomorrow for the varnish.

April 19, Saturday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the

shop first thing, but

stayed on DREAM AWAY and worked on email and

the Maintenance Logs. The email situation is getting to a manageable

level, and I am caught up on the April Maintenance log.

I decided not to work on the leak in

the after cabin today, because of wind and tide conditions. Tomorrow

the wind will be out of the south, which will blow the dust away from

the boat. Also, late in the morning, and all afternoon, the tide will

be incoming, so that will tend to keep the tender from banging into

DREAM AWAY.

After breakfast, I went over to the

shop

and started in on the console for Ruby.

I got all of the sanding done, but decided to add more of the

thickened epoxy

to the console.

Bottom Of Sanded Console

I decided to add the thickened epoxy

mixture to the seams in the bottom of the console. This would keep

small objects from falling out , and also make the total unit

stronger. I also added some battens to increase support.

Spaces Can Be Seen In The Bottom Of The

Console

I then taped up the seams, mixed up two

pots of the epoxy,

thickened, and applied it to the console.

Console With Epoxy Added And All

Clamped Together

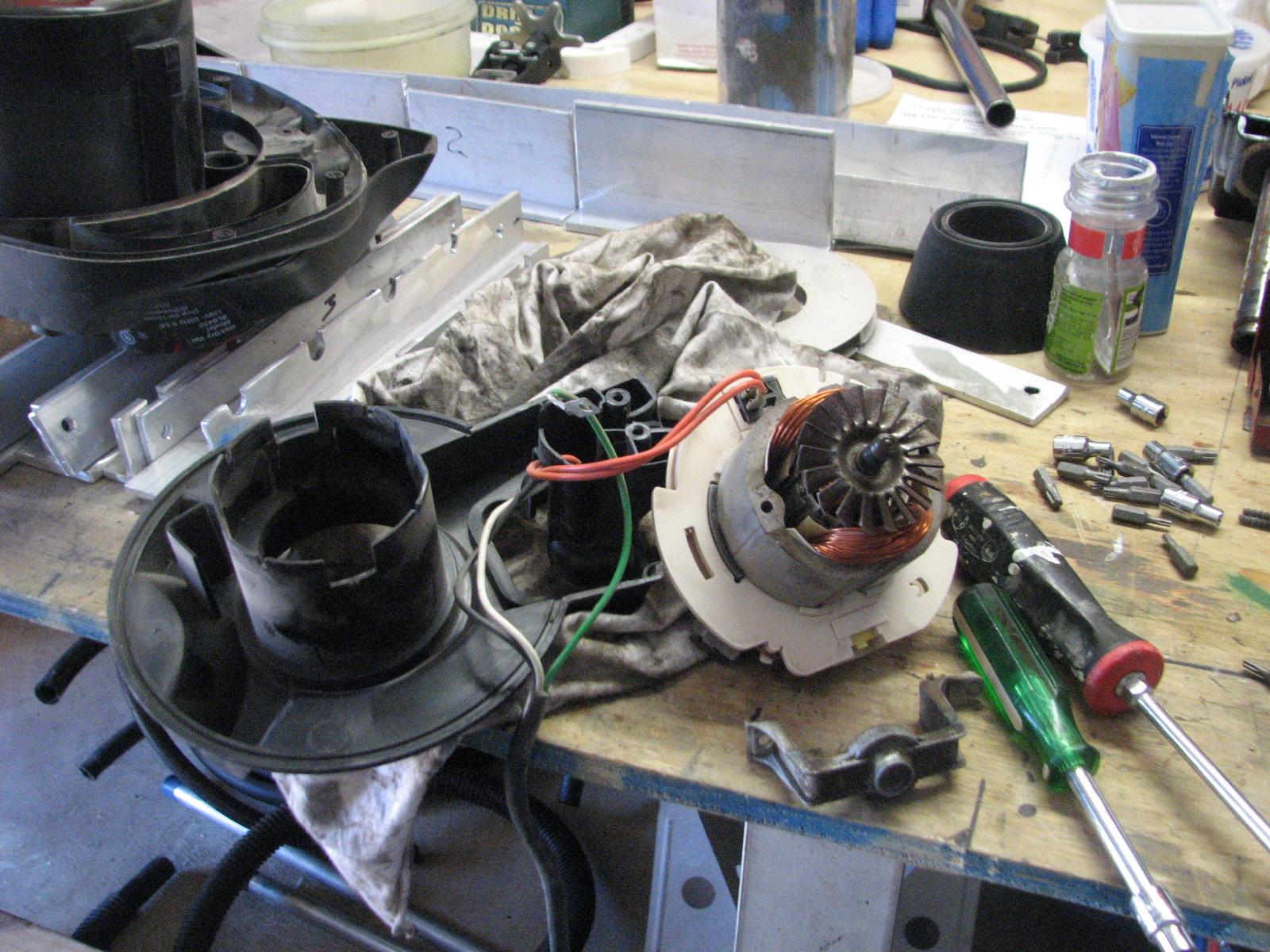

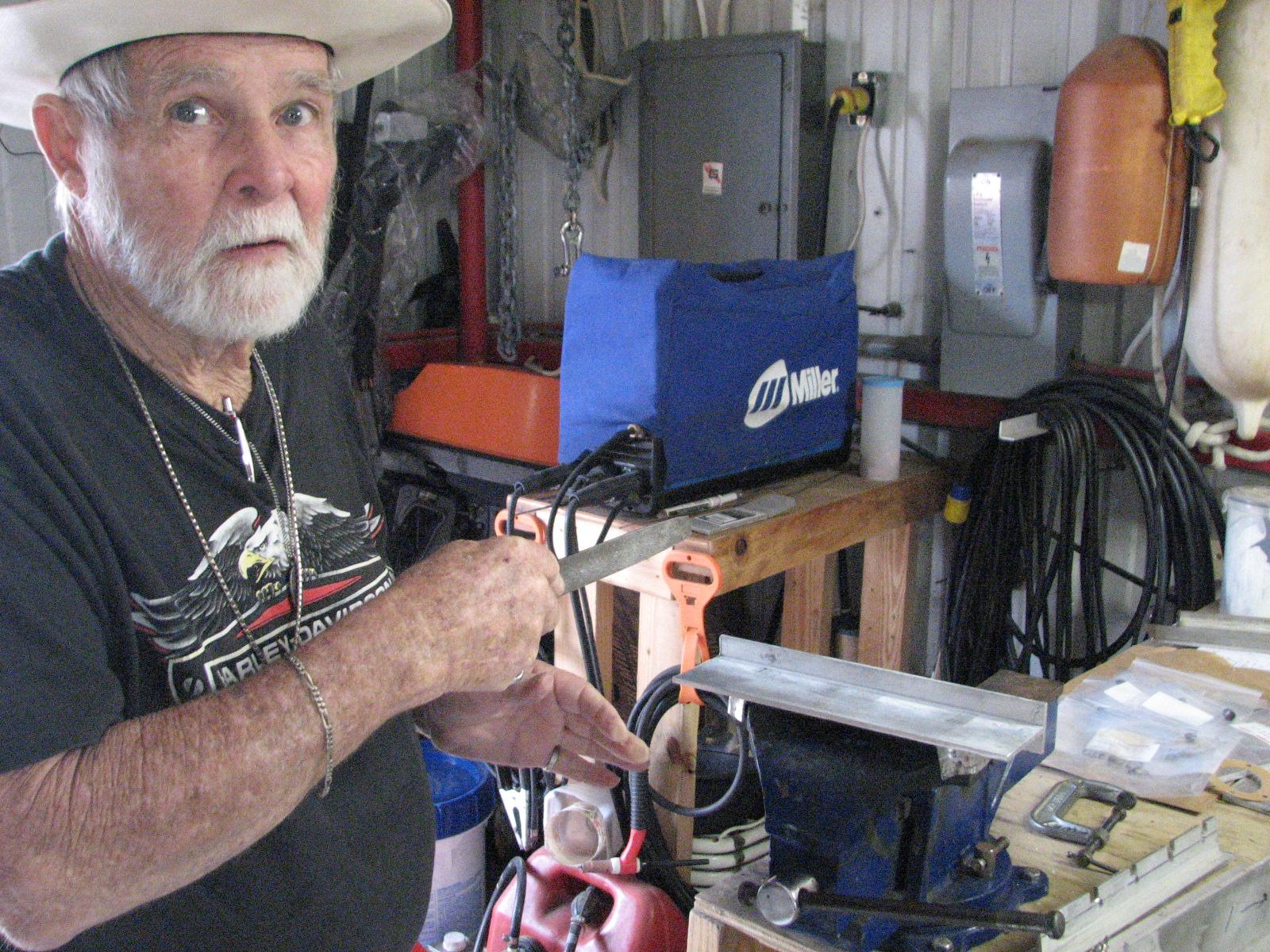

Next, I worked on the vacuum cleaner. I

really miss having it, as I like to keep the shop

clean. I took the motor assembly apart, and verified that I was

getting power past the Off/On switch. The problem must be somewhere

in the brushes. I took the motor apart and cleaned the brushes and

the armature. When I put it all back together, it still would not

run. It looks as if I will have to purchase a new one.

Vacuum Cleaner Motor All Apart

Next, I started working on the risers

for the solar panels. I had come up with a method to duplicate the

notches needed in the riser bases using the drill press and the drill

press vice. I continued with this method, and finished all 16 riser

bases and the adjusters. I finish the notches in the riser with a

file, so that is all done.

Filing Out Notches On Solar Panel

Risers

I still have to drill the mounting

holes in all of the riser bases, and do some minor finish work on all

of the pieces, but I should be able to get that all completed this

week.

The last item for the day was to put

the JB Weld

repaired raw water cooling pump back together.

Raw Water Cooling Pump In Pieces

I put the pump back together and tested

it using the battery installed in Ruby.

The pump worked, so now I will have to install it back into the

system to see if will continue to work.

April 18, Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

I went to the shop

first thing and worked on sanding down the console for

Ruby.

I made significant progress, but did not finish completely sanding

the console.

Back Of Console

Side Of Console

Next I worked on the drilling out the

notches on the base for the solar panel risers. Yesterday I had

successfully drilled out a notch in the riser, so I continued with

that same set up. The three remaining notches did not go as well. I

still have to work on a method that is repeatable. As you can see

from the photo, not one notch is the same as the other.

The Four Notches Drilled Into The Solar

Panel Riser Base

I went back to DREAM AWAY for

breakfast, and after breakfast I started to work on the raw water

cooling pump for the ice maker. I had noticed this morning that the

ice maker was working fine, but the raw water cooling pump was not

coming on. This needed to be looked into and repaired, or it could

burn out the ice maker compressor.

I turned off the ice maker and then

started it again to be sure the pump was being turned on by the ice

make electronics. This was not happening. I verified that I was

getting the 12 VDC to the ice maker, but it was not switching the

12VDC to the raw water cooling pump.

I disconnected the raw water cooling

pump from the ice make circuit and connected it directly to the

battery, the pump still did not work. The good news is I had repaired

the spare raw water cooling pump, so I verified its operation by

connecting it to the battery.

I removed the old pump and installed

the spare replacement pump. I started up the ice maker again, and

still it did not switch the 12 VDC from the ice maker to the raw

water cooling pump. I had two problems, and now I have one problem.

The solid state relay in the ice maker is not working, so I will have

to troubleshoot that problem. I will take the removed raw water

cooling pump over to the shop

and see what the problem is with it.

While I was working on the ice maker

problems, Kitty took our laundry into New

Iberia, and she had now returned. We were now going to

see if we could track down the source of the leak near the port cleat

in the aft cabin. I used a hose, and we were able to pinpoint the

source of the leak.

The leak is a crack in the fiberglass

on the very stern of DREAM AWAY just under the stern anchor. Now that

I have located the leak, all I have to do is fix it! It would not be

today, so we cleaned up the area, and I went back to the shop.

When I got over to the

shop,

I decided to inventory the fasteners Kitty had picked up from LeBlanc

Oil. These fasteners are going to be used on the

Tantalus

mast step project early next year.

Bolts, Washers, And Nuts For The Mast

Step

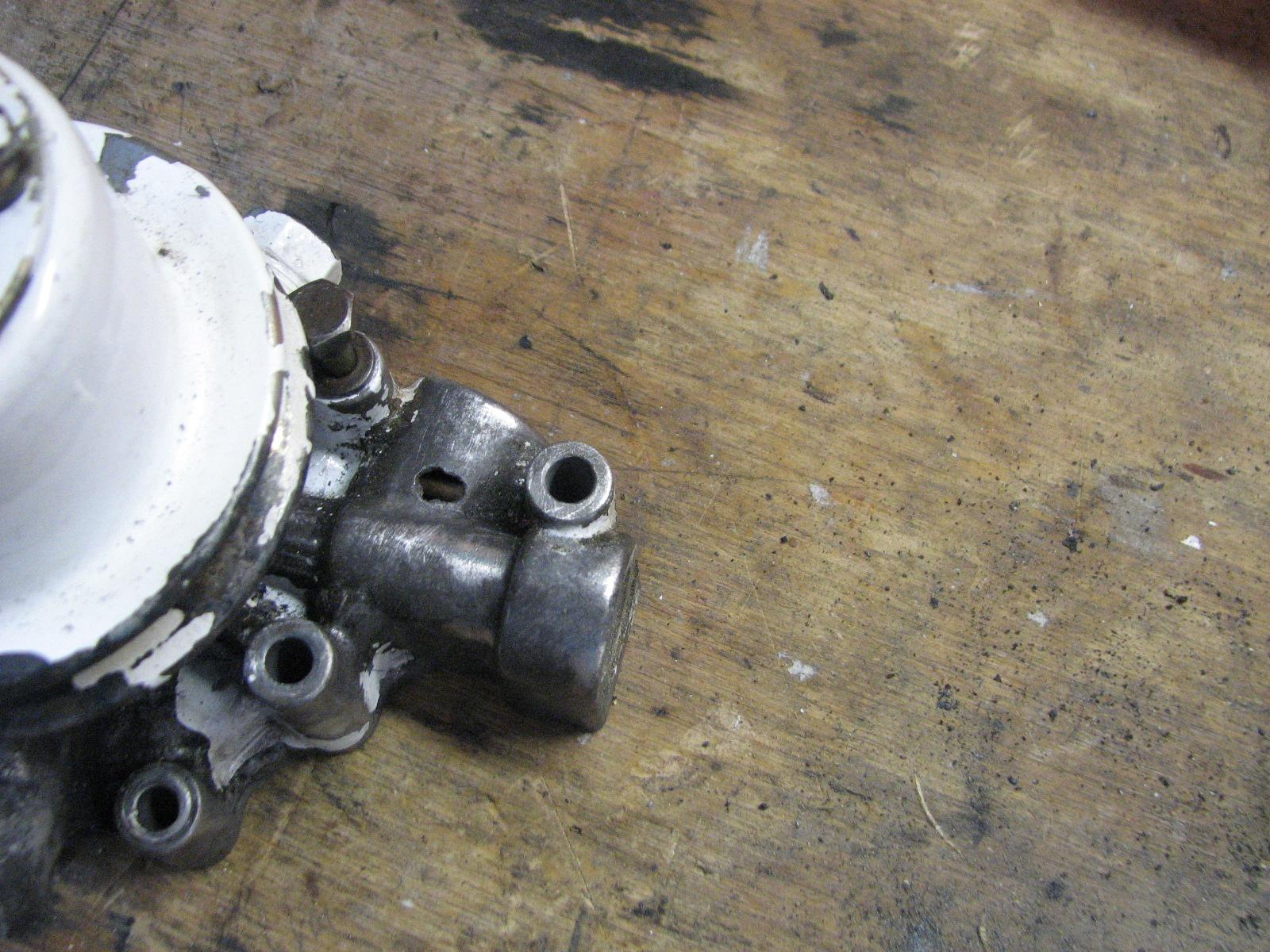

I then started work on the raw water

cooling pump for the ice maker. This pump can also be used for the

refrigeration system cooling pump. I took off the pump head , and of

course it was very dirty. The water here in the

Delcambre Canal is not

very clean, so it does tend to clog up diaphragm pumps.

I took the motor out to

Ruby,

and connected it to the battery, and the motor worked just fine. I

then went in and took apart the pump head, and that is when I

discovered the pressed fitting in the bearing was just turning inside

the bearing race, and not turning the pump.

I concluded that my only attempt to

repair the problem was to use JB

Weld. I cleaned up the fitting and the bearing race. I

then mixed up a very small batch of JB

Weld, and applied it to the parts. I hope it will fix

the problem, but I must check to see if I have a spare pump head.

Raw Water Cooling Pump With JB

Weld Applied

I next got the four aluminum cleats I

will be using on the hard dodger sliding windows, and cleaned them up

with the stainless steel wire wheel.

Four Cleats Polished Up For Use

Now it was time to get back to the

issue of drilling out the notches in the risers for the solar panels.

I had come up with a plan to use the drill press vice to hold the

riser, and prevent the drill bit from moving away from the riser.

I did the deed on one riser, and it was

successful. After drilling out the notches, I used a file to finish

the notch, and then cleaned up the riser with 120 grit flap disk on

my high speed grinder.

Drilling The Notches In The Riser

Finished Riser With Adjuster, Side View

Finished Riser With Adjuster, Top View

This method proved itself, and I was

able to do four more risers before the afternoon was gone. I will

finish off the risers tomorrow.

April 17, Thursday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the shop

first thing this morning. I stayed on DREAM AWAY and worked on

getting caught up on emails and the Maintenance Logs. Getting really

close on the emails. I have the April Maintenance Log caught up, now

I have to get the March Maintenance Log finished.

After breakfast, I went over to the

shop

and started in on the console for Ruby.

The work I had done yesterday looked great. I sorted through the

console parts and selected the ones I would need to complete the

fabrication of the console. I sat them aside, to be sanded and

prepared for varnishing.

Console Parts Set Aside For Varnishing

I had one more seam I had to fill with

epoxy

so I got that prepared. I mixed up a pot of epoxy

thickened with teak dust and applied it to the seam, and then clamped

the console together.

Console Clamped Together

The Actual Seam Filled With Thickened

Epoxy

I took the selected console pieces,

and took them outside and scraped and sanded them down. As soon as

the main console box is sanded, we are ready to apply varnish.

When I was vacuuming the tablesaw area,

to clean up after working on the console parts, I realized I needed

to lubricate the vacuum cleaner motor. It was making some strange

sounds due to the fact that some of the dust ends up inside the

motor.

I took the motor housing apart,

lubricated the motor bushings, and then put it all back together. Now

the vacuum runs perfectly again.

Vacuum Motor Assembly

Vacuum Motor Assembly All Apart

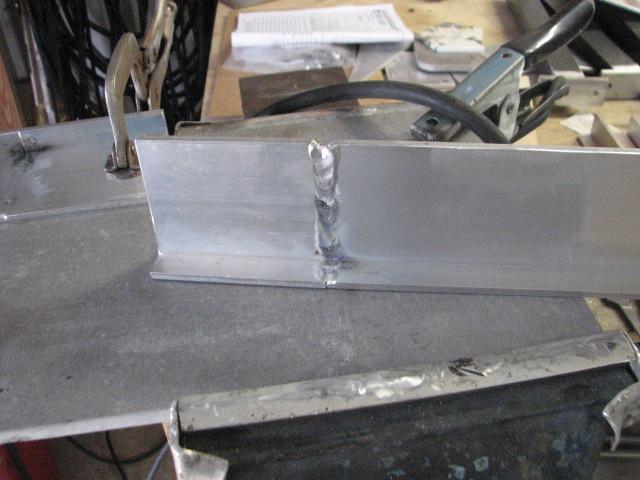

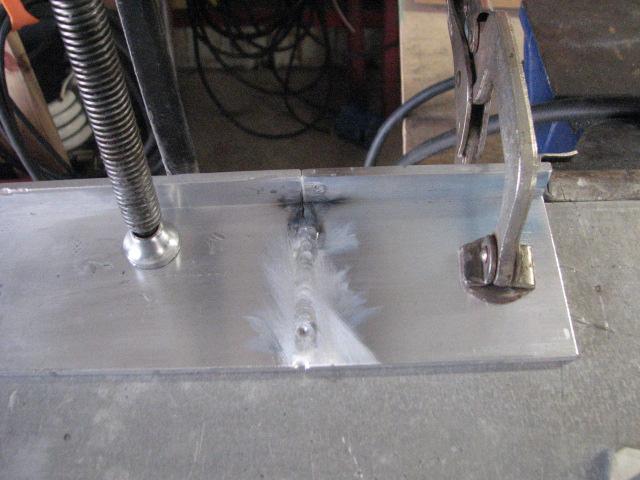

Now it was back to working on the solar

panel risers. I cut the last two aluminum pieces lengthwise. Now I

had to weld some pieces together to create a riser. Originally I did

not have enough scrap pieces to make all 16 risers. I was able to

weld two pieces together to create a riser . I did this twice.

First Welded Riser

Second Welded Riser

When I completed the welding task, it

was necessary to cut the two risers to their required 11” length. I

did this with the Evolution

Rage III miter saw.

When the tow fabricated risers had been

cut to their proper length I got out the

Bosch Jig Saw

and cut the risers lengthwise.

Now I had all 16 risers fabricated and

cut lengthwise. I now had to try and see if I would be able to drill

out notches in the riser base for the actual riser to set in. I set

up the drill press, and did a test drill. A couple of very small

problems, but I was able to drill out a very nice notch in one of the

riser bases.

It was time to head back to DREAM AWAY,

but now I only have 63 more notches to drill out.

April 16, Wednesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go to the shop

first thing this morning. I stayed on DREAM AWAY and worked on

getting caught up on emails and the Maintenance Logs. It was a bit

cold to do any outside work, but it was supposed to warm up in the

afternoon.

I did go over to the shop

after Kitty got up and we had breakfast. Kitty went off to get her

hair done, and I went to the shop.

First item to work on is the console

out of Ruby. I sorted

through all of the parts that I needed to put back

on the console, and did a dry fit of those parts.

Console Ready For Epoxy

Application

I mixed up a pot of epoxy

thickened with some teak dust, and applied it to all of the places I

had dry fit console parts. After I applied the epoxy

mixture, I clamped the parts together.

Console With Epoxy

And Clamps Applied

I started in again on cutting up the

risers I am fabricating for the solar

panels that I will be purchasing. We have decided to

order the panels while we are in Puerto Rico, that way they will be

delivered just when we return from the trip.

I have cut the the risers to their 11”

length, but now I am cutting all of the risers lengthwise to give me

the base and the riser. I did manage to get half of them cut.

I left the shop around 1530 and went by

LeBlanc Oil to see if the bolts had arrived that I am ordering for

the Tantalus

mast step project. They had not arrived, so I went back to the

marina,

and worked in the gardens.

April 15, Tuesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian and Jordan,

and spend time with them brushing their beautiful coats.

Did not go to the shop

this morning. I stayed on DREAM AWAY and worked on getting caught up

on emails and scanning in documents. Still not caught up, but making

progress.

The day did clear up , and I went into

New

Iberia for a doctor’s appointment. When I returned,

it was back to computer work. I left again around 1700 to pick Kitty

up at the Amtrak

station in New

Iberia.

April 14, Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Alan had not been feeling very good

yesterday, and the cold was getting to him. He decided he wanted to

go home, so we made reservations on the Amtrak

train for this morning. Kitty is accompanying Alan to make sure he

gets home with no problems.

Cheryl, his caregiver, has made a

doctor’s appointment for Alan tomorrow.

Did not go to the shop

this morning, but stayed on DREAM AWAY and worked on getting caught

up on email and other computer work.

Around 1100 we went to the train

station in New

Iberia, and Kitty and Alan headed to Houston.

I went back to DREAM AWAY and worked on more emails, scanning and the

Maintenance Logs.

No projects done today, as the weather

turned bad, rainy and cold - again!

April 13, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Alan and I went over to the shop

we started in on the console fabrication for Ruby.

I have already done all of the cutting, now it is time to get it back

together.

I mixed up a pot of thickened epoxy,

and applied it to the console where I am putting the side of the

console back together. I also applied some of the epoxy

between two pieces of wood on the back of the console.

Thickened Epoxy

Applied To Console

Next on the project list is continue

work on fabricating the risers for the solar panels to be installed

on top of the hard Bimini.

I did the major cutting with the power tools, while Alan did the fine

work with a file. I am having issues cutting a straight line with the

Bosch

jig saw. I will get that worked out.

Alan Filing Aluminum Pieces

Kitty called and said she was awake, so

we cleaned up the area, put the tools and tables away, and went over

to DREAM AWAY for breakfast.

After breakfast we got to work on

several small projects. The first on the list was to install a new

Taylor

weather station. this is an indoor/outdoor wireless

unit. The base station is indoors, and it will support up to three

remote sensors. The system comes with just one remote sensor, but I

will be ordering at least one more for the engine room, and probably

one for the refrigerator. I installed the base unit beside the

barometer and the analog clock.

Now it was time to get to work on the

ice maker. It was giving me a few problems lately. It would not pop

the ice out of the tray, and I know what the problem is. The

electrical connections in the unit are just a press connection,

nothing very positive. These connections tend to be a problem in the

wet environment they live in.

I took the front of the ice head off,

and cleaned all of the connections, then put it back together. That

fixed the problem, so now it is happily making lots of ice!

Ice Maker After Repair

Next project on the list was to install

the backing plate and cover for the turning block on deck that had

the bolts coming through in the head. I finally got the leak fixed,

so I felt good about putting it all back together.

It is a two man job as we need one

person on the outside deck holding the head of the bolt, and a second

person inside putting on the nuts and tightening the nuts.

Backing Plate Installed And Decorative

Cover Installed

I had finished varnishing the teak

wire cover for the head, but had not got it installed. This again is

pretty much a two person job. One person to do the drilling, and the

second person to hold the vacuum cleaner to keep the mess to a

minimum.

Electrical Wire Hanging In The Head

Teak Wire Cover Installed Over Overhead

Wire

Jim And Alan Working On Wire Cover

Installation

Jim And Alan Working On Wire Cover

Installation

The remainder of the day was spent on

applying the sealant around the outside and inside of the windows in

the hard dodger. When I got to applying the sealant on the inside of

the windows, I did not use masking tape, and the application went

very well.

Sealant Applied To Outside Windows,

Starboard Side

Masked Windows Port Side

Masked Windows Port Side

The non sliding windows on the hard

dodger are all sealed in. Now we have to decide on the handles for

the moving windows, and all of the windows will be complete.

Next big project will be to get the top

put on the hard dodger.

April 12, Saturday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Alan and I went over to the

shop

and unloaded

Ruby.

We had to make room in the

shop

to store the

grating

and the

Extren

fiberglass plate. After we got the

grating

and the

Extren

fiberglass plate moved into the

shop,

we had to put back all of the material we had moved to make room in

the first place.

Unloading The Extren

Fiberglass Plate

Unloading The Extren

Fiberglass Plate

Grating Unloaded And In The Shop

We worked on Ruby

a bit. I adjusted one of the hood studs so the hood looked liked it

closed. I also put water into the windshield washer reservoir, and it

did not leak. That was the good news, the bad news is the windshield

washer outlets do not squirt any water on the windshield, so that

will have to be worked on.

The lock button on the back passenger

door had come out so we took that door apart to fix that problem,

which we did.

We then got out the Optix

acrylic sheet, as we had to cut a new window. I had

trimmed one of the stationary windows too small so I had to have it

redone. I also had to trim the center stationary window for the hard

dodger as it was not even across the top.

When we finished the cutting, we loaded

the two new windows into Ruby,

and went over to DREAM AWAY for lunch. After lunch, Alan took a nap,

and I worked in the marina

gardens.

We then started with applying the

BoatLife

LifeSeal sealant to the fixed windows on the hard

dodger. First item is to mask off the area where the sealant is being

applied with masking tape. When the tape is applied, then you apply

the sealant, smooth it out with a wet, soapy finger, then remove the

masking tape. Of course the idea is to keep the sealant only where it

is applied. Keep a good supply of paper towels handy!

I got the BoatLife LifeSeal sealant applied to the outside of the

starboard and forward windows. I ran out of time before I got the

sealant applied to the port windows.

April 09 - 11, Wednesday -

Friday, 2014

We had no trouble or any problems with

Ruby,

except I must have the transmission looked into. It jumps out of

reverse gear, and that is a real problem.

We picked up our good friend Alan while

in Clear

Lake Shores and brought him with us to

Delcambre.

He will be helping me with some projects on DREAM AWAY for the next

week or so.

On the way into

Delcambre

we stopped by Rays Auto Repair and picked up the

Black Beast. Ray

had repaired the broken oil cooling line that had ruptured. When he

replaced both lines last month, one of the lines had rubbed against

some metal and wore a hole in the line. Ray fixed it all for no

charge, so we are good to go there.

One event that happened while we were

in Clear Lake Shores, our cruisers

Cindy

and Johnal left

North

Pier Marina to continue east. They arrived at the

marina

in December of 2013, and we really have enjoyed having them around.

They are good company with social activities and good help with

various projects. They will be missed.

April 08, Tuesday, 2014

Attended business plan workshop in

Chalmette,

Louisiana. After the workshop drove home to

Delcambre.

We made the trip in the

Black Beast.

When we arrived at the marina,

there was a large amount of oil leaking out from under the engine.

We moved all of the tools and supplies

from the

Black Beast to

Ruby,

and took the

Black Beast

over to Ray’s automotive. He is going to look

at the problem while we make the trip to Houston to pick up the

Strongwell

Extren fiberglass plate, and some grating.

April 07, Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Worked on the computer most of the

morning trying to get caught up on email and getting the Epson

NX330 flatbed scanner to work on Linux. I downloaded

the VueScan

software for Linux, and was able to perform a scan using the Epson

NX330 scanner.

Kitty got up early, so we had

breakfast, and then went over to the

shop.

We had two more pieces of

Optix

acrylic sheet to cut out for the hard dodger windows.

We finished cutting out the pieces, and cleaned up the

shop.

We loaded all of the window pieces we had cut out into

Ruby,

and drove back to the marina.

Cut Acrylic Ready To Be Put Into Truck

Set Up For A Cut Of Acrylic

Acrylic Pieces Loaded Into Ruby

Before we left the shop,

I checked to see if the “new” console would fit in the area of

Ruby

between the two front seats with the back seat down. The console fit

great, now all I have to do is put it completely back together.

Captain Testing Console Fit

We brought all of the cut window pieces

down to DREAM AWAY, and started to fit the windows into the hard

dodger uprights. It was obvious, I had been generous in cutting out

the windows for the hard dodger, and I would need to “adjust” the

windows. It was also obvious I would need to get some tools and

equipment from the shop

to be able to continue.

I drove back to the shop

and loaded into Ruby,

my Bosch

jig saw, some clamps, a long piece of aluminum flat

bar, a piece of plywood for a table, and two large plastic buckets. I

went back to the marina,

and hauled all of this stuff down to the dock next to DREAM AWAY.

Kitty and I then set up on the dock and

started “adjusting” the windows to fit into the channels of the

hard dodger up rights. When we were finished I had “adjusted “

nine of the ten just right, but I had cut one window too small. I

would have to cut another piece of the Optix acrylic sheet to fit the last window.

Captain Adjusting A Window To Fit

Captain Sitting By Fitted Windows

Captain Preparing Another Cut

Windows Installed In Hard Dodger Frame

Windows Installed In Hard Dodger Frame

Windows Installed In Hard Dodger Frame

Windows Installed In Hard Dodger Frame

Windows Installed In Hard Dodger Frame

Windows Installed In Hard Dodger Frame

Windows Installed In Hard Dodger Frame

When we return from our various travels

this week, I will finish the job. I also have to fabricate the

handles for the sliding windows in the hard dodger.

We cleaned up around the dock, and I

hauled all of the stuff back to

Ruby,

and then back to the

shop.

When I got back to the

marina,

I then had to empty holding tank in

shower trailer.

When that task was completed, I took a

shower, Kitty and I packed up, and we drove over to Chalmette,

Louisiana, so we could attend a workshop tomorrow morning.

April 06, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Worked on the computer most of the

morning trying to get caught up on email and getting the printer and

scanners to work on Linux. I was successful with our Epson

NX330 network printer.

I was actually under a hundred emails

in my inbox when we left for the shop

after breakfast. Kitty and I went over to the shop,

as we were going to be using the templates to cut the pieces for the

hard dodger out of a 4’ X 8’ sheet of Optix

acrylic sheet.

Handling a 4’ X 8’ sheet of

anything is difficult for one person, so having some help makes it

much easier. Using the templates we marked and measured until we got

the best usage of the first sheet of Optix

acrylic sheet. We then set up a fence on all of the

cuts so we would be cutting a straight line using my Bosch

jig saw. We made significant progress, but had to

leave the shop

at 1330.

Pieces During Cutting Operations

Captain Doing The Cuts

Admiral Getting Ready To Cut

Went back to DREAM AWAY and got ready

to go to New

Iberia to see a locally performed play, Tuesdays with

Morrie. It was a great play, sad most of the time, happy at times and

insightful most often. We went to the play with Cindy

and Johnal, and after the play, we stopped and had

dinner.

April 05, Saturday, 2014

Kitty and I did take a break and

strolled through the market and of course purchased some goodies to

eat.

After the market shut down, we got the

shower

trailer ready for transportation. This means draining

the fresh water tank, removing the railings for the steps, and then

folding the steps up to transport mode. We moved the shower

trailer back to the marina, and got it set up there.

We got the water turned on, the

electricity connected, and then changed out the trash bins in each

room. Kitty cleaned up each room, and then I mopped out each room.

We then drove over to the Port

of Delcambre

store room and unloaded all of the accessories that I had removed

from the folding tent storage bags.

It was back to the marina

and down to DREAM AWAY with the final template for the hard dodger.

We measured and cut and got the fitting of the template perfect. Now

we have all of the templates cut for all of the hard dodger windows.

Hopefully we can get them cut out tomorrow.

April 04, Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go to the shop

first thing this morning, but stayed on DREAM AWAY working to catch

up on email, scanning and the Maintenance Logs.

We set up the shower

trailer, filled the fresh water tank, but did not put

down the steps. I will do that tomorrow morning when I arrive at

the Shrimp

Festival grounds at 0515.

I then went over to the shop

and cut the last template needed for the hard dodger windows.

Cardboard Ready To Cut Out Template

I then got to work on the wooden

console for Ruby.

I had already cut it apart, now it was time to start putting it back

together. The very back of the console had previously been broken, so

I started with repairing that not very good repair. I mixed up a pot

of epoxy

and applied it to the two pieces and clamped it together.

Back Of Console Epoxied And Clamped

When I was taking the console apart, I

discovered one of the cup holders was split into two pieces, so I

applied epoxy

to each half and clamped them together.

Cup Holder Epoxied And Clamped

April 03, Thursday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the shop

and removed the console from Ruby.

I had measured the allowed length of the console by putting the rear

seat down. I then cut out a length of the console and pretty much

took the console apart. Now it will just be a matter of getting the

console all back together, taking maximum advantage of the space

allowed.

Now I got out all of the big pieces of

cardboard that we will be using for the hard dodger window templates.

I cut out all of the templates, and added a little bit on each side

so that I would have plenty of material. I did not want to come up

short.

Went back to DREAM AWAY, and after

breakfast, Kitty and I did the final fitting of all of the templates.

It was a lot of fun doing the work, as the wind was really blowing.

It made it difficult to try and fit a piece of cardboard into a small

space with the wind trying to blow the cardboard away.

Cardboard Templates In Hard Dodger

Frame

Captain Cutting Templates For Fit

Captain Cutting Templates For Fit

We finished all of the cutting and

fitting, I took the templates up to

Ruby.

Taking Templates Up To Ruby

I then took a shower, got cleaned up

and we went to New Iberia to see a movie and have dinner with Cindy

and Johnal.

April 02, Wednesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Spent most of the day working on Ruby.

I did not take any new photos of her, but I promise to do so soon.

The truck was very dirty inside, so I did a pretty thorough cleaning.

I cleaned as many surfaces as I could get to, and vacuumed most of

the truck also. It still needs more cleaning up, but that will come

as time goes on.

I removed the third seat and hung it up

in the shop

out of the way. I also removed the front console, as it was too long.

I could not put down the back seat to get my space needed to haul

boat parts. I will have to cut up the console, epoxy it back

together, and then varnish it up properly before it goes back into

Ruby.

Dashboard And Steering Wheel Of Ruby

I checked the oil and water in Ruby,

and applied a good coat of Rain-X

to all of the windows.

I then went over to the marina

so I could get Kitty’s help fixing the window and tailgate in Ruby.

The window in the tailgate would hang when you put it down or up, and

the tailgate was very difficult to open.

I removed all of the panels from the

tailgate so I could see and watch the window mechanism work. The

problem is once the tailgate is closed, I can not operate the window.

That was Kitty’s job. Working together, I was able to find the

problem and fix it for now. It still needs some work.

The window had bent the opening

mechanism for the tailgate. Once I bent the correct piece back to

where it was supposed to be, the tailgate opened properly, and the

window did not hang up any more. Another problem fixed.

Kitty and I then went down to DREAM

AWAY and made the final measurements for the templates for the hard

dodger windows.

When that was complete, I got a much

needed shower, and we both got dressed and went to the monthly

meeting of our detachment of the Marine

Corps League.

April 01, Tuesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the shop

and looked into the repair of the spare generator

fresh water pump. As mentioned yesterday, there is a hole in the

pump. I mixed up a batch of JB

Weld and applied it to the hole and some other bad

areas of the pump.

Water Pump With Hole Showing

I need to mow the grass at the marina,

so I got the lawn mower from the Port

of Delcambre’s storage room. I removed the blade

from the mower, and sharpened the blade. Hopefully this will make the

grass cutting go much easier.

Johnal

had replaced his Raymarine

radar system on his boat, and gave me the old unit. I am going to see

if I can get it working, or salvage some parts from it to use on my

Autohelm

Radar.

My next door neighbor on the dock had

got rid of some drawers from his boat, so I also took them over to

the shop.

I just might find a use for them!

I then loaded all of the fiberglass

uprights for the hard dodger into Ruby,

and the lawn mower and gas can, and drove over to the marina.

I weeded the gardens and mowed the

grass at the marina.

It looks very good for the residents. The weeds seem like they are

taking over the area.

I then hauled all of the hard dodger

uprights down to DREAM AWAY, and installed all of them. The good news

is they all fit, even after so long. Now we have to make the

templates out of cardboard so I can finally get the windows in place,

and hopefully finish the job.

Hard Dodger Uprights Starboard Front

Hard Dodger Uprights Starboard Side

Hard Dodger Uprights Port Side Front

Hard Dodger Uprights From Cockpit

Starboard Side

Hard Dodger Uprights From Cockpit Port

Side

When that was complete, I loaded the

lawn mower back into Ruby

and went back to the shop.

I put the lawn mower back into the Port

of Delcambre’s storage room, and I did some more

work on cutting and trimming the adjuster’s for the solar panels.