Went

back to DREAM AWAY, and verified the propane connection for the

Hummer

Grill at the propane tank.

It seems if I do not really tighten the connection, the propane leaks

out. I will have to replace the original POL

valve with the newer QCC

valve.

I

had finished off the large acrylic insert for the companion way

several days ago, but did not put in the before and after photos of

the improvement.

Large

Acrylic Insert, Before Modification

Large

Acrylic Insert, After Modification

May

12, 2013, Sunday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Worked on web page and maintenance log until Kitty awoke.

Spent

Mother’s Day with Kitty, and did not work on DREAM AWAY.

May

11, 2013, Saturday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Went over to the shop

and mixed up a batch of Smith’s

penetrating epoxy and

applied it to the bottom of the cockpit hatch. I also applied a good

soaking to the bottom of the wooden boat hook.

Cockpit Hatch With

Epoxy Applied

Wooden Boat Hook End

Soaked In Epoxy

Continued working on

the companionway screens. I had decided to scrape all of the varnish

off of the screens, rather than do a couple of maintenance coats.

When the screens were down to bare wood, I planned to apply the

Smith’s

penetrating epoxy to them,

and then apply the Watco

teak oil finish. Hopefully

this combination will be easier to maintain.

Sanding Screens

Continued to get the

letters on the name boards. Not as easy as it might seem. The letters

were all individually drilled to put the screws in them, so trying to

get the correct letter lined up in the correct position was proving

more difficult than expected! Most letters I only had two choices,

but the “A” I had six to choose from!

Letters On Name Boards

Went back to DREAM AWAY

and had breakfast. After breakfast, I re-installed the instruments

back into the cluster under the main boom gallows.

Before putting putting

the instruments in their proper position, I made sure all of the

connecting wires had the proper connectors on them. I had previously

purchased connectors for just that purpose, as I did have to replace

several connectors.

I also wanted to check

out my wind instrument. It had not been working correctly. I wanted

to see if the actual instrument was bad, or the wiring on the

anemometer at the top of the main mast. I had a spare masthead

anemometer and the wiring, so I could connect the spare directly to

the instrument while the instruments were not in the pod.

The wind Instrument

functioned normally connected to the spare masthead anemometer, so

the actual instrument was not the problem. I would have to do some

more troubleshooting. In the meantime, I put all of the instruments

back into the pod.

Instrument Pod And

Wiring

Checking Instrument

Connections

Instruments Back Into

The Pod

May

10, 2013, Friday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

The rain was amazing, so stayed on DREAM AWAY and worked on the web

page.

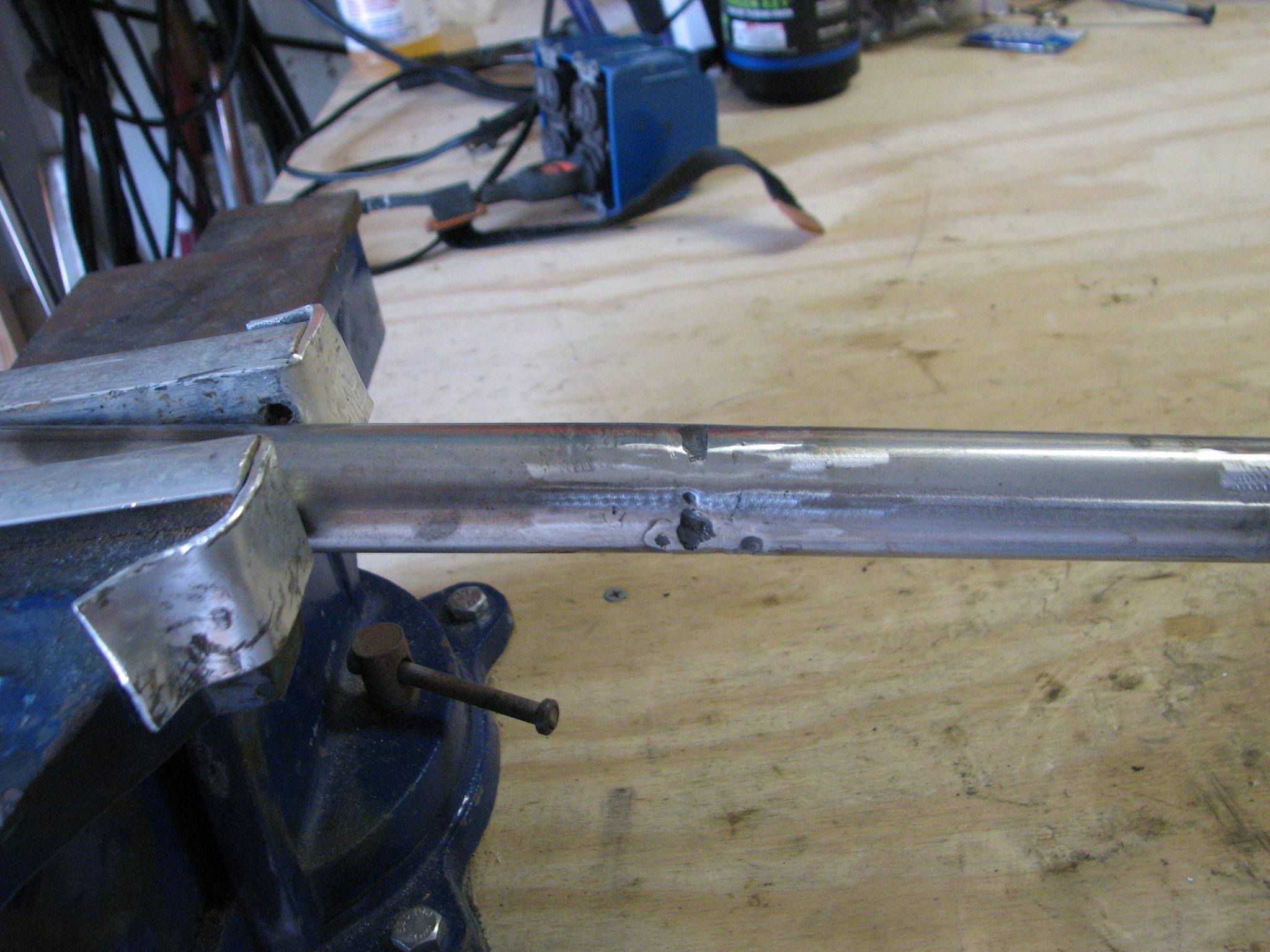

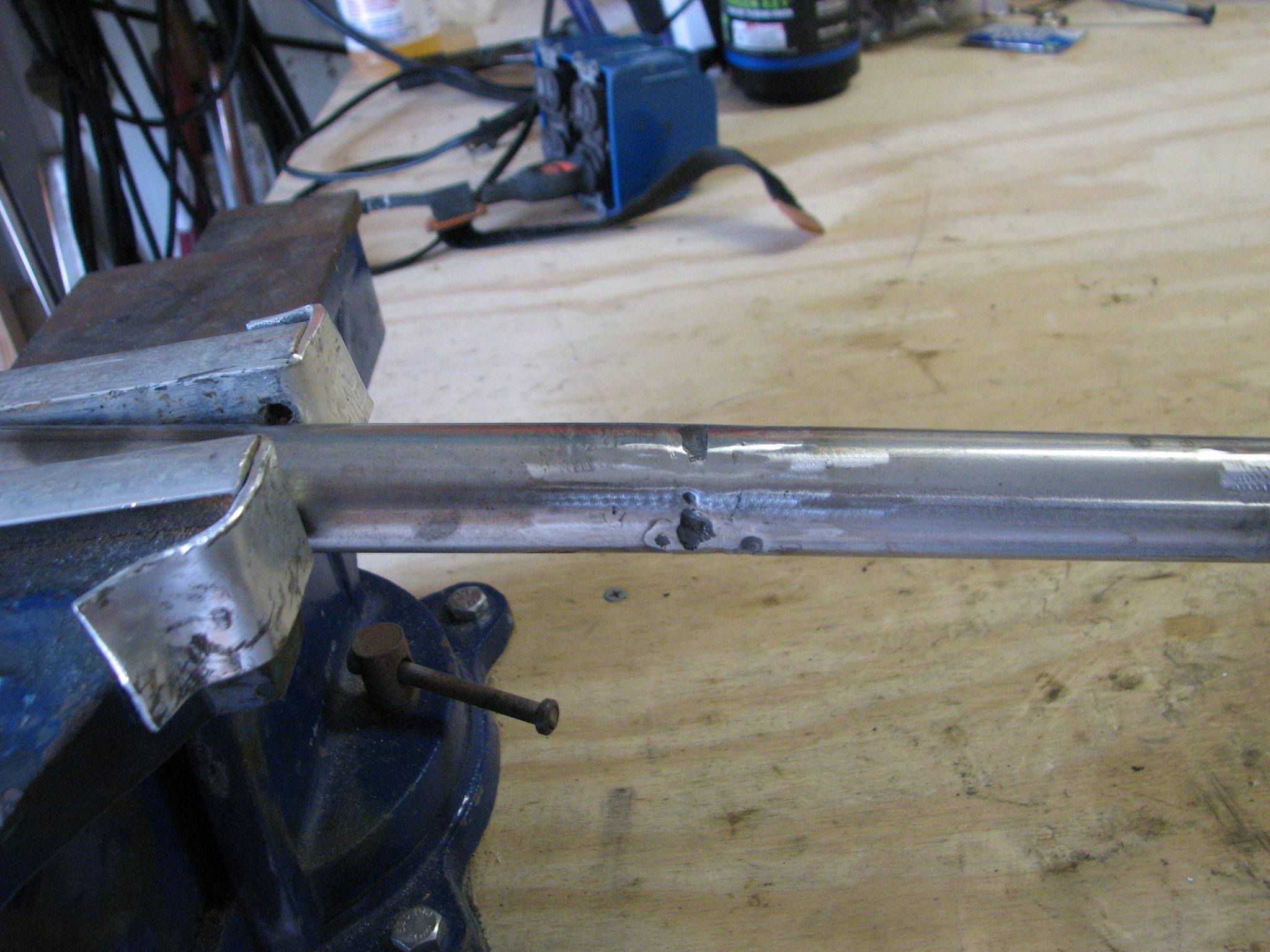

Went over to the shop

in the late afternoon, after the rain had stopped, and the floods had

receded. Did some more welding on the tubing I will be using for the

main cabin grab rail. Trying to do some fill on some of the bad

welds. Trying to get back into the swing of welding, and it is a slow

process.

Did some more work on

the nameboards. I am putting all of the original green letters back

on the nameboards. They will look really good when I am finally

finished.

Got the hole cut in the

panel the cockpit instruments are in. Like everything else, cutting

the hole was easy, getting everything set up on the drill press and

clamped down, took all of the time.

Drill Press Setup To

Cut Hole

Hole Cut In The Panel

All Instruments Back

Into Panel

May

9, 2013, Thursday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Today was not a DREAM

AWAY maintenance day. We went to our Doctor in Delcambre to start the

examinations for our annual physical.

We then drove to

Abbeville to do our laundry, and also stoped by Lowe’s,

and purchased some of the required items for the OpenROV

project coming up at the end of the month.

While at Lowe’s

I also purchased at extension cord, so I can continue with the

installation of the second WiFi router at the North Pier Marina. The

installation did not go well, as the second router seems to be DOA.

May

8, 2013, Wednesday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Worked on web page and email, until it was time to leave for

Dermatologist appointment.

When we returned from

the appointment at the dermatologist, I changed into my work clothes,

and went to work on deck.

The area under the

jerry jugs on the deck of DREAM AWAY, had never been cleaned up

properly, so I got out the brushes, toilet bowl cleaner and elbow

grease. I got the area on both the port and starboard sides all

cleaned up, and looking good.

Had a bit of excitement

at the marina before I went back to the shop.

Kittie,

off of one of the cruising boats at the marina had been stung by a

wasp, and she is highly allergic. Lots of emergency medical folks

came, but the bottom line was, she was taken by helicopter to Iberia

Medical center because of

the wasp sting bite. The good news is she was released after only

being at the Iberia

Medical center for about

three hours.

I

had finally decided to install a new Raymarine

ST-60+ compass in my

instrument

cluster in the cockpit. I

had purchased the compass in April of 2012 to replace the Autohelm

ST-50 compass. It was the last of the original ST-50 system which I

had purchased in 1995. The compass still worked, but I wanted to get

the newer one installed.

When

I got over to the shop I removed all of the instruments from the teak

wood panel. I was preparing the panel to have the hole enlarged for

the new Raymarine

ST-60+ compass.

Instruments

And Panel On Work Bench

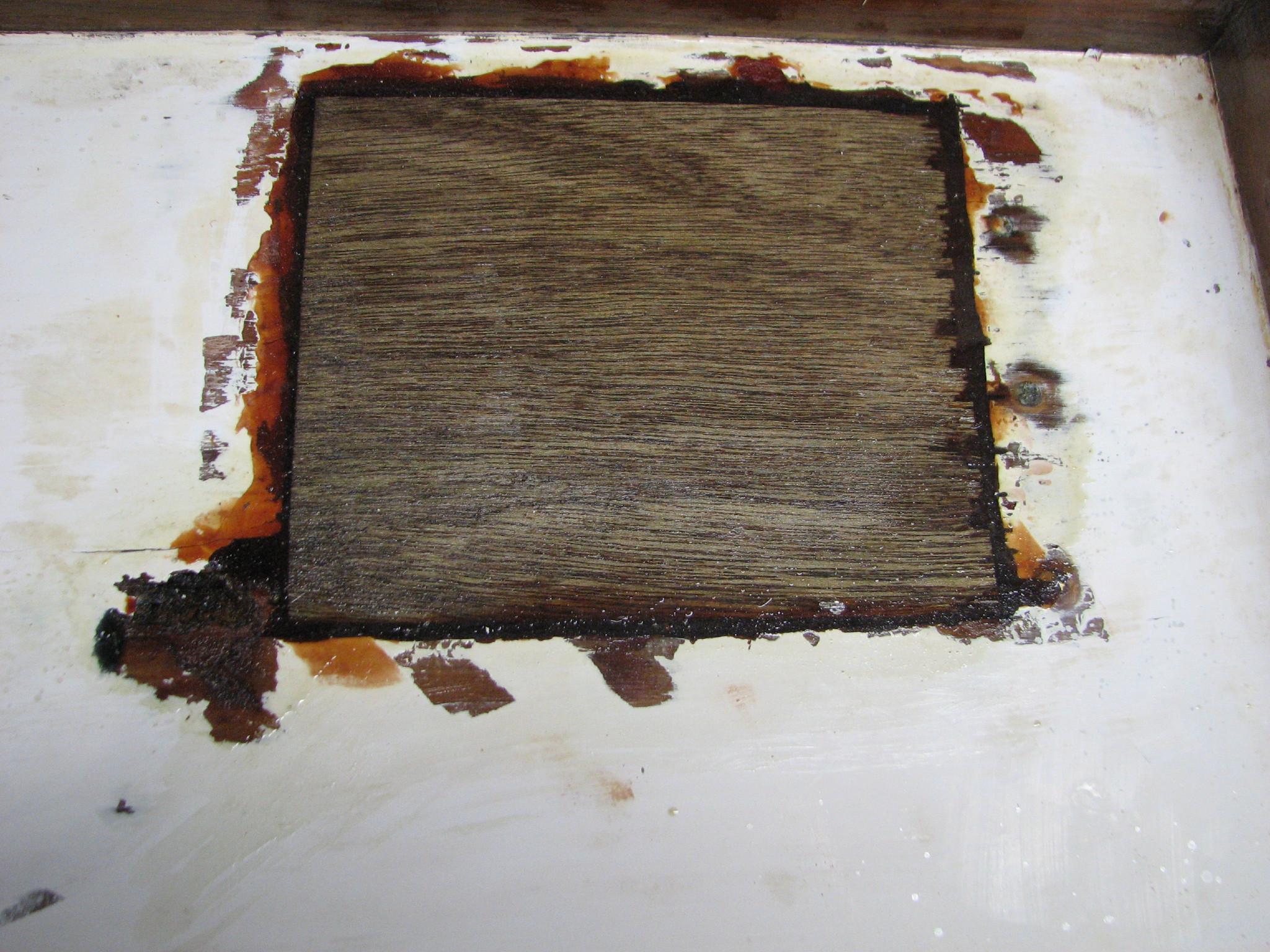

I mixed up a batch of

the epoxy mash mix, and used it to install the filler piece of

plywood on the underside of the cockpit hatch. This is being used to

fill in where the rotten wood was cut out of the hatch

Plywood Installed In

Cockpit Hatch

May

7, 2013, Tuesday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Went

over to the shop, and mixed up another batch of the Smith’s

penetrating epoxy and

applied it to the cockpit hatch. I then put the cockpit hatch out in

the sun to get the epoxy to “kick off”

Epoxy

On Cockpit Hatch

I did the install of

the Cutco

knife holder in the galley, and we were able to install the two new

knives we purchased at the boat show in March. We had ordered the

Traditional

Cheese Knife and the Petite

Santoku

knife to add to our

collection. That is why the Cutco

knife holder had to be modified.

Cutco

Knife Holder Installed In The Galley

When I finished the

laying out of the grid, I went back to the shop and mixed up a third

batch of the Smith’s

penetrating epoxy and

applied it to the cockpit hatch.

I took my high speed

grinder over to the shop and worked on the stainless steel tubing I

am going to use for the main cabin hand hold.

Sanding On Stainless

Steel Tubing

Last Item for the day

was the varnish. I applied the seventh coat on the nameboards. I

applied the second coat of

Watco

Teak Oil Finish to large

acrylic insert.

May

6, 2013, Monday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Worked on computer getting caught up with email and working on the

Maintenance Log

brought over finished

the teak wire cover, and all of the Panduit

wire duct covers, and

installed on DREAM AWAY.; applied expoxy to top of cockpit hatch;

welded on tubing; Helped get transients, Connie and Wayne off the

dock and on their way.

Went over to the shop,

and on the way I picked up a 12 VDC battery that was still good, but

Kittie was getting rid of. They had upgraded all of the batteries on

their boat, and some of the old batteries were still good. I needed a

battery for the starter I was installing on the Yamaha outboard for

the dinghy.

When I got to the shop,

I pulled out the electric start kit I had purchased for Kitty, so she

would be able to start the Yamaha. I used the newly acquired

battery, and tested the the starter. It worked perfectly! Now all I

have to do is get the electric start kit installed on the outboard,

and get a battery box installed in the dinghy.

Did a bit more welding

on the tubing for the main cabin hand hold. Working on getting my

steady hand back, and the setup for the welder.

Welded Tubing

Went over to DREAM AWAY

for breakfast. Took over the teak wire cover, and all of the

Panduit wire duct covers.

Now I had to install

the teak wire cover in the mid-cabin. This cover was covering all of

the wires going to the electronic shelf, mid-cabin fan and forward

cabin reading lamp. Before installation could be completed, I had to

remove the printer from the top of the electronic shelf.

When the printer was

removed, I had to move some wires around to make sure I had enough

slack wire to make the angles in the teak wire cover.

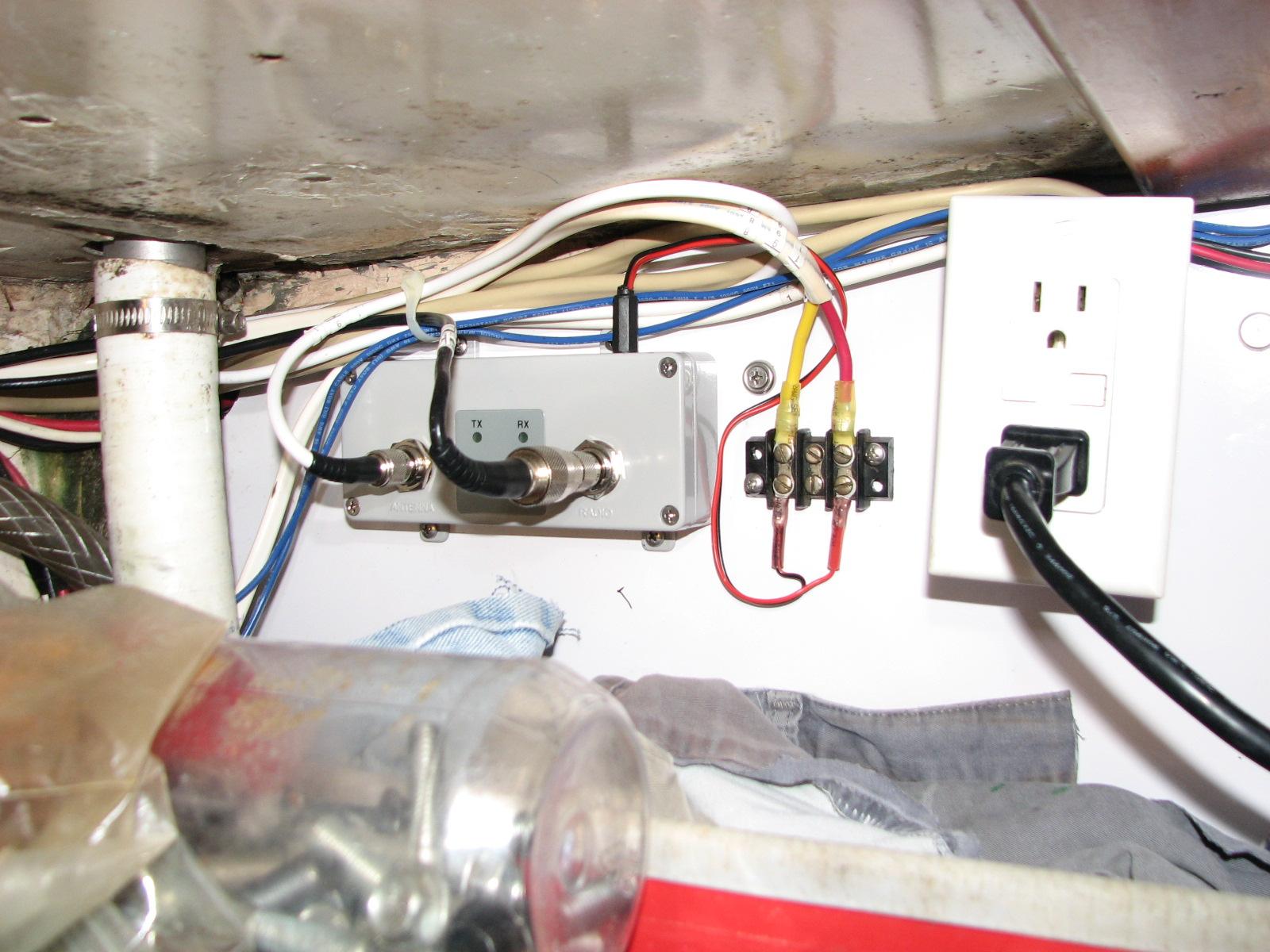

Mid-cabin Wires

Exposed

Last Item for the day

was the varnish. I applied the sixth coat on the nameboards. I

applied the fifth coat of varnish on the

Cutco

knife holder. I applied the first coat of

Watco

Teak Oil Finish to large

acrylic insert.

May

5, 2013, Sunday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Worked on computer getting caught up with email and working on the

Maintenance Log

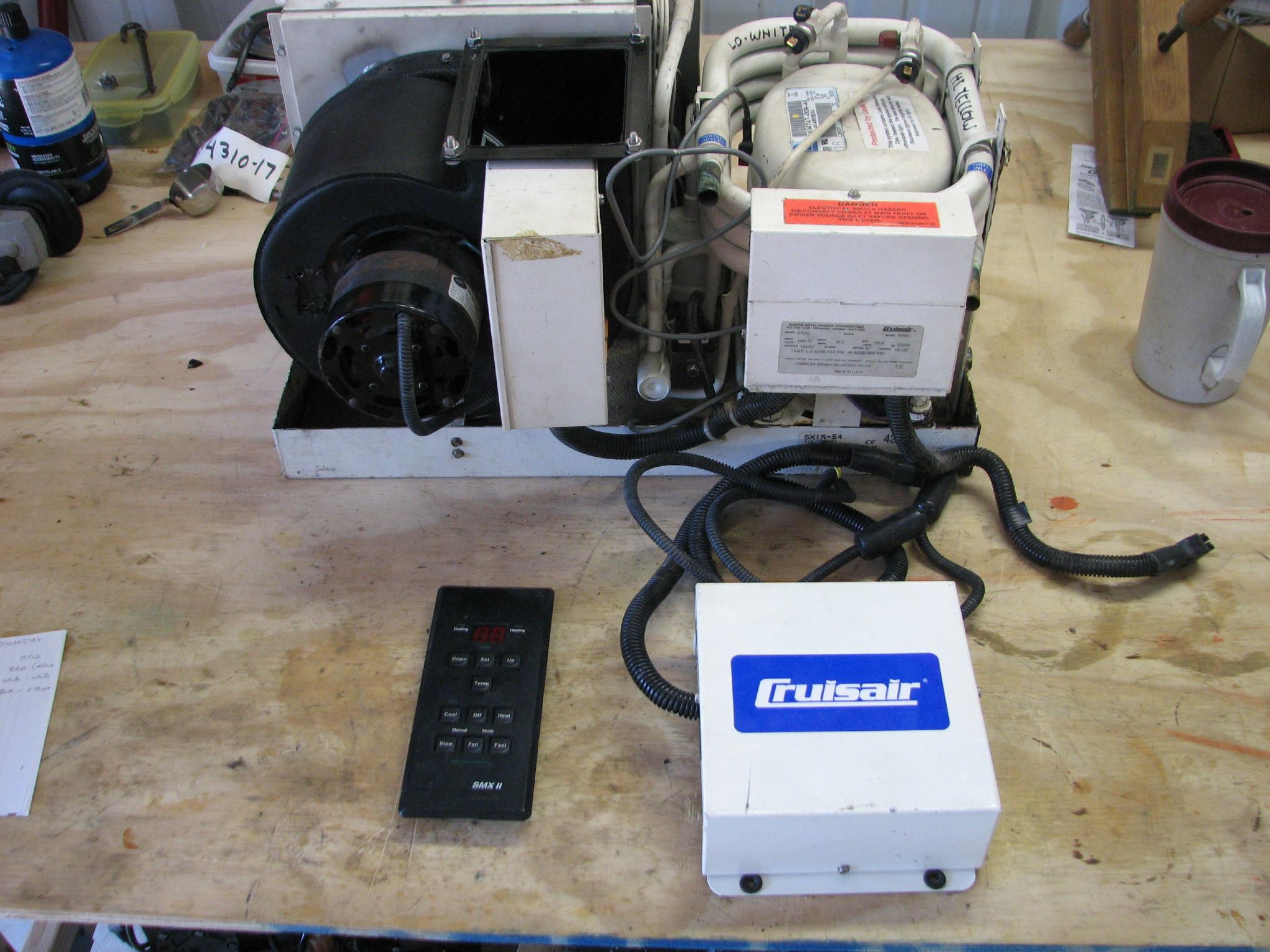

Chris at

Tekris

Power Electronics asked me

to put a paper inside the box with the

Heart

Freedom 25 Inverter/Charger

that had the return shipping information, and an explanation of the

problems with the unit. I printed out this information, and an

address label. I then went over to the shop.

When I got to the shop,

I got out several pieces of scrap foam. I cut and fit the pieces of

foam to completely wrap the Heart

Freedom 25 Inverter/Charger in.

Once I got the foam all

around the Inverter/Charger, I put the information sheet inside, then

closed up and the taped the box. I put the address label on and it

was ready to go. I shipped it out in the afternoon via the

USPS.

Heart

Freedom 25 Inverter/Charger

Ready To Go

Next was the cockpit

hatch. The Smith’s

penetrating epoxy I applied

yesterday had set up very hard, so it was time to epoxy the piece of

plywood into the hole in the hatch.

Hole In The Hatch

I sanded and scraped

out the hole, so that it was smooth and the piece of plywood fit

perfectly. I did a dry fit of the piece of plywood, then I mixed up a

batch of mash mix. The mash mix is a mixture of the epoxy and the

Cabosil

ormicroballoons.

It is about the consistency of peanut butter. I used the mash mix to

put the plywood into the hole in the cockpit hatch.

Ready For Hatch Repair

After the repair was

made I placed three weights on the piece of plywood to insure it

would set up properly.

Weights On Cockpit

Hatch

Last

Item for the day was the varnish. I applied the fifth coat on the

nameboards, the teak wire cover, and all of the

Panduit wire duct covers. I applied

the fourth coat of varnish on theCutco

knife holder.

May

4, 2013, Saturday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Alan and I filled our go cups with coffee, and headed to the shop.

When we got to the shop

we started in. Yesterday I decided to use the newest parts to build

my main engine. That meant I would use the new long shaft lower

housing I had purchased off of eBay on the main engine. This meant I

had to move the whale tail from the old lower

drive to the new lower drive.

While Alan started on

the whale tail project, I looked around the shop for a suitable

platform to attach the Heart

Freedom 25 Inverter/Charger, and make it ready for shipment. I was able to find

a piece of plywood already attached to some 2 X 4’s, that is

perfect to mount the Heart

Freedom 25

Inverter/Charger. I also put two pieces of foam insulation between

the Inverter/Charger and the plywood to act as a cushion.

I got some help from

Alan, and we cut up a cardboard box, and stapled it to the pallet to

form a box around the Heart

Freedom 25 Inverter/Charger. When that was finished, Alan and I got back

changing the whales tail to the new

lower drive.

We measured and looked,

and then measured again. While I was drilling holes in the lower

drive for the whales tail,

Alan was cleaning out the threads in the zincs. There are six bolts

total holding the whales tail to the lower

drive. Two of the bolts

have nuts on the end. The other four bolts are bolted into the zincs.

We scraped the paint off of the area on the lower

drive where the zincs are

bolted to make sure we have good contact. While we were working on

thelower drive, we also took the

water pump apart and checked the impeller, which was good.

Whales Tail Bolted On

We then sanded down the

all of the exposed teak wood on the cockpit hatch, and sanded down

and smoothed the filler that was applied yesterday.

I mixed up a batch of

the Smith’s

penetrating epoxy and

applied it to the hatch and really soaked in the wood around the cut

out. This took some time, as I would pour the epoxy in the hole, let

it soak through, and kept it up until no more epoxy would soak in.

Cockpit Hatch Showing

Epoxy Soaked In

Cockpit Hatch With

Epoxy Applied

May

3, 2013, Friday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Alan and I filled our go cups with coffee and headed over to the

shop.

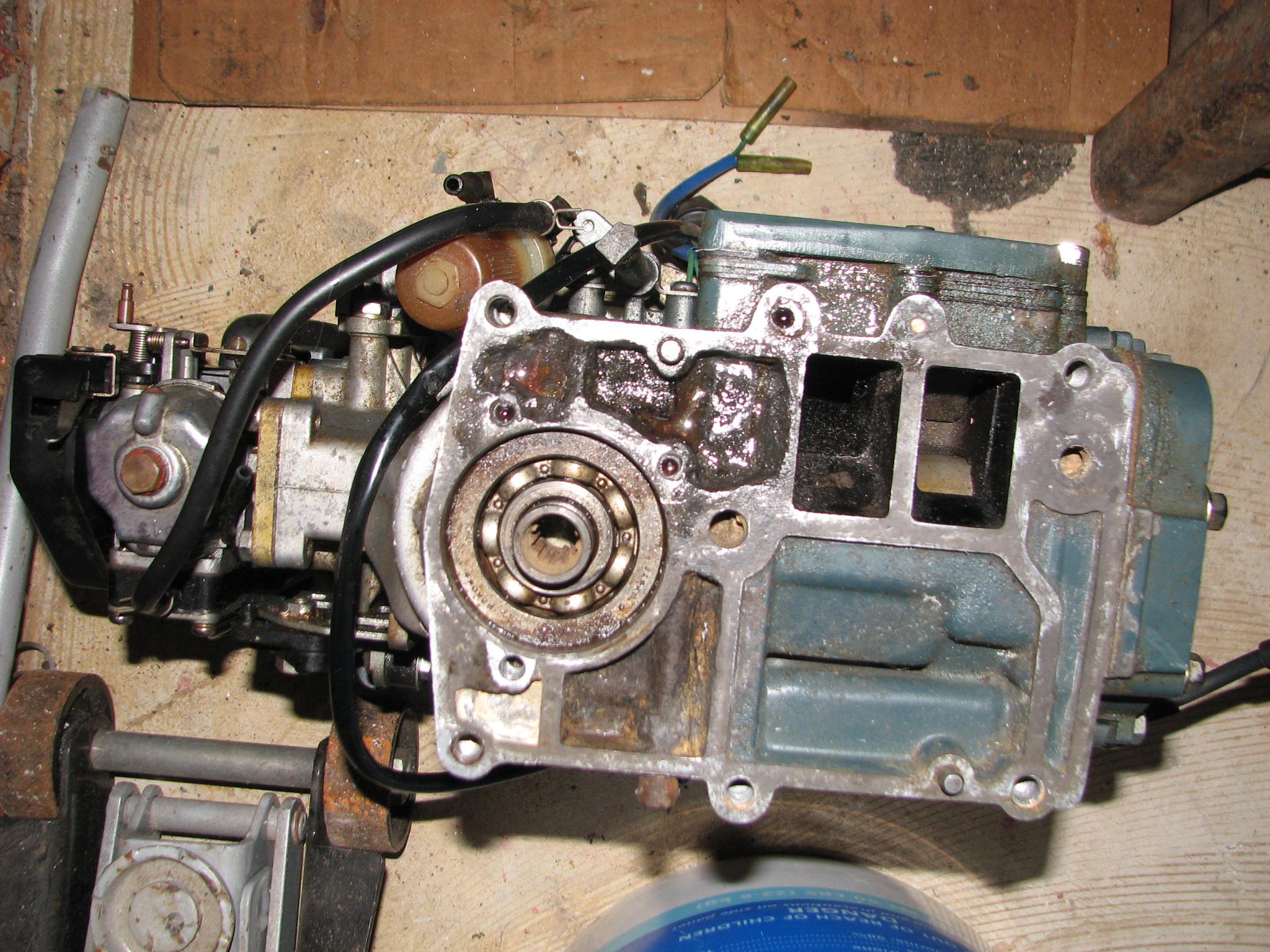

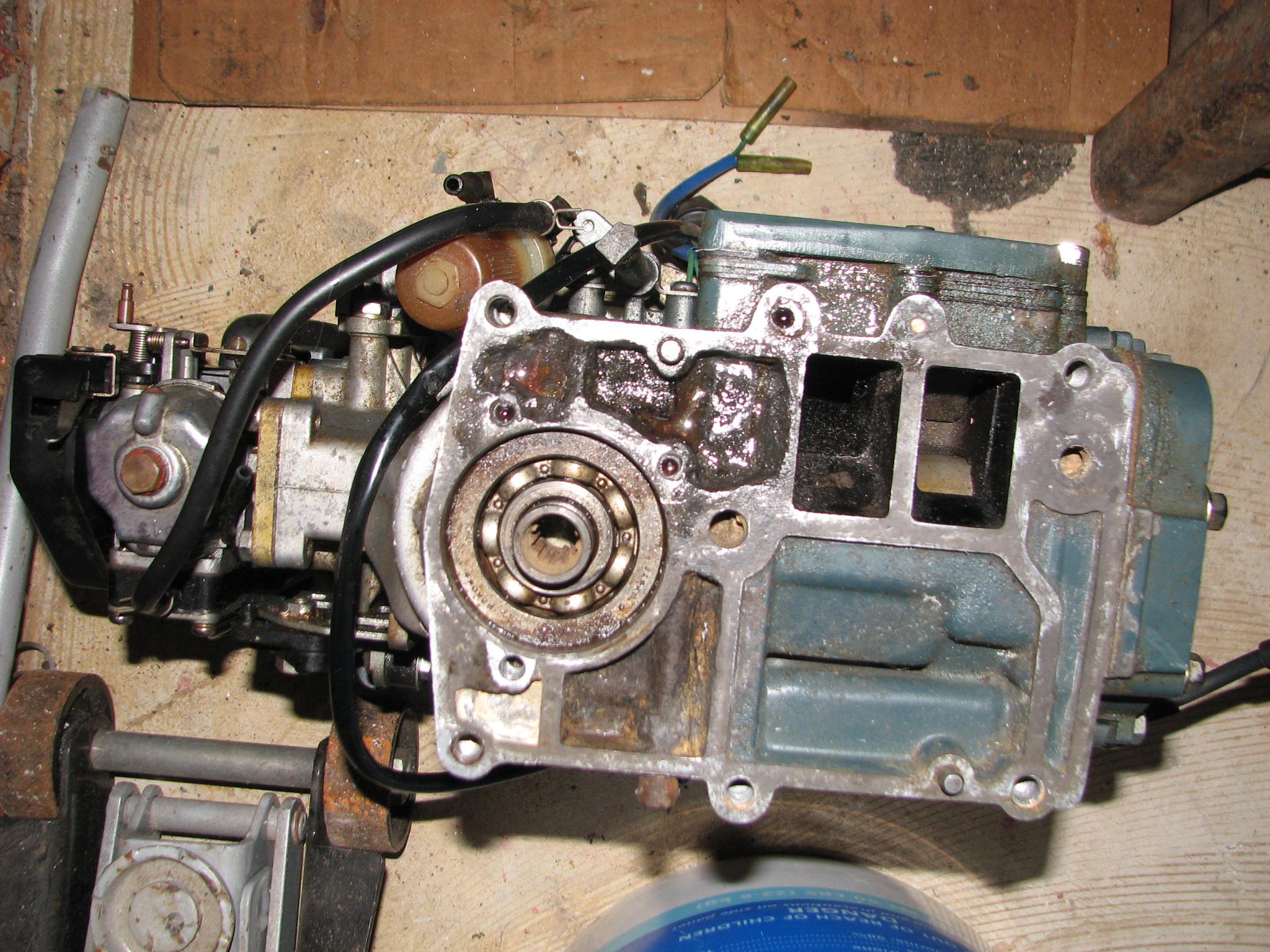

We started in on the

main outboard engine, to replace the

bracket

assembly. As with most

projects of this type, there is a lot of parts that have to be

removed from the engine before you can actually change the

bracket

assembly.

Preparing To Remove

Power Head Bolts From Bottom

Cowling

Basically the engine

has to come completely apart. When we separated the power head from

the bottom cowling, we discovered the oil

seal housing for the drive

shaft, was eaten away, and would need to be replaced.

My storage room

neighbor, Huey, came to his storage area, and I asked him about

getting the cream hardener. He said I should try V & V Auto Parts

in Delcambre. I called them and they did sell the needed cream

hardener.

We then went back to

DREAM AWAY to have our breakfast. We left DREAM AWAY, and stopped by

V & V Auto Parts. I purchased the cream hardener, and went back

to the shop.

Alan continued on with

the disassembly process of the outboard engine. I mixed up a batch

of the Dyna-Glass

filler with the cream hardener, and applied it to the cut out rotten

area in the cockpit hatch.

Cockpit Hatch With

Filler Applied

As we waited for the

filler to harden, I joined Alan in the continuing disassembly

process. I wanted to get the old bracket

assembly off of the engine,

so I could figure out how many new parts I would need to put the main

engine and spare engine back together. The spare engine was already

apart, and I knew what I needed there.

Engine Parts Removed

We were able to make a

list of the items necessary for the reassembly of both engines.

Looking at all of the parts I had acquired for both engines, I

decided I would take all of the newest and best parts, and marry them

with my main power head, and build the main engine. I had the power

head rebuilt in 2010 in Guatemala. I would use all of the older parts

to build the spare engine.

Parts Ordered For Both

Outboard Engines

Last Item for the day

at the shop was the varnish. I applied the fourth coat on the

nameboards, the teak wire cover, and all of the Panduit

wire duct covers. I applied

the third coat of varnish on the

Cutco

knife holder.

I had talked earlier in

the week to Chris at Tekris Power Electronics

discussing the issues I was having with my two

Heart Freedom 25

Inverter/Chargers. When Alan and I went back to DREAM AWAY, I got out

my spareLINK

2000-R voltage monitor, and

connecting wire. We used the wire to attach the

LINK 2000-R

voltage monitor to the currently installed

Heart Freedom 25

Inverter/Charger. I got the same indications, or lack thereof, so I

decided I do have some kind of signal problem with the

Heart Freedom 25

Inverter/Charger.

The otherHeart

Freedom 25 Inverter/Charger

was popping its internal circuit breaker, so I decided to send that

unit to Tekris

Power Electronics for

repair first. I dug the Inverter/Charger from under the forward cabin

birth, and hauled it out to the Black Beast.

Tomorrow, Alan and I

would build a shipping crate for the Heart

Freedom 25

Inverter/Charger.

May

2, 2013, Thursday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Alan and I got a cup of coffee in our go cups and went over to the

shop

Worked more on the

cockpit hatch, sanding and scraping. I need to get all of the old

Cetol

off of the hatch, as I plan to apply the

Watco Teak Oil Finish to the

hatch. This will be done after the rotten area is repaired, and the

whole hatch is soaked in the Smith’s

penetrating epoxy.

I have the polyester

filler I need for the hatch, but all of my cream hardener is very old

and not useable. We drove over to Leblanc Oil, and

Touchard’s Marine looking for the

cream hardener, but were not successful. Will probably have to drive

into Abbeville to find it.

We then went to work on

the spare Yamaha outboard power head. I still do not have the broken

off bolts removed. I had ordered and received a Neiko screw extractor

set. It contained five sizes of left hand drill bits, and five

easy

outs. We drilled the holes

and used the easy

out, but we still did not

get the broken off bolts out of the power head. It looks like to save

this power head, I am going to have to take it to a shop that

specializes in removing broken bolts. I am sure I am going to end up

using a Helicoil.

Bottom Of Power Head

With Broken Bolts

Since we were making no

progress with the spare engine, Alan and I decided to go to work on

the main Yamaha outboard. I had purchased a used bracket

assembly off of Ebay, to replace the

bracket

assembly presently on the

engine. The bracket assembly was in pretty bad

shape, but needed replacement.

We started in on the

project, but a new cruising boat was coming into the marina. I

applied the third coat of varnish on the nameboards, the teak wire

cover, and all of the Panduit

wire duct covers. I applied

the second coat of varnish on the

Cutco

knife holder.

Alan and I closed up

the shop and headed over to the marina, to help the newcomers dock.

When we finished with the docking process, and had some social time,

it was time to quit for the day.

May

1, 2013, Wednesday

Started

off the morning with my normal ritual of getting on the Internet,

answering email, checking the weather, while making a pot of coffee.

Went over to the shop

and started in on doing an inventory of all of the items that arrived

in the

OpenROV kit. I still did

not have the printed inventory with me, but I wanted to make sure all

of the parts in the kit arrived in excellent physical shape.

Everything seemed to be in order, and I even got all of the parts

back into the original box! You can keep up with the kit assembly and

testing on the DREAM AWAY web page with this

link.

The epoxy had set up on

the Cutco

knife holder, so I sanded it all down it preparation to apply thr

first coat of varnish this afternoon.

Sanded Cutco

knife holder

Next I started on the

cockpit hatch. The timing on this project, turned out to be great.

Yesterday on our anniversary, Kitty gave me a new tool. It is a

Rockwell

Sonicrafter Oscillating Tool,

and it is the perfect tool to cut out the rotten wood in the cockpit

hatch.

Installing Blade On New

Tool

I measured off a square

section around the rotten wood on the underside of the hatch, then

used the new tool to make the cuts. It worked perfectly. This is

going to be a nice tool to use in situations just like this.

Tool Laying Near Rotten

Area In Hatch

Cut Out Area In Bottom

Of Hatch

I then cut out a square

of ⅜” mahogany plywood to fit into the cutout of the hatch. I

trimmed and sanded the plywood piece until it fit into square. Now it

was ready to be epoxied into place.

Cut Piece Of Plywood

Fit Into Cut Out Squart

I took the

Shakespeare

SeaWatch 2025 TV antennas

apart, and checked all of the connections. I also took the small

printed circuit boards out of each antenna, and the control box

looking for broken or damaged wires or electronic parts. Needless to

say I could find nothing amiss, so I am afraid we are out of luck

with the attempts to get the

Shakespeare

SeaWatch 2025 functioning.

I started on another

project today, that will not need to be completed until we do a long

passage again. I have been requested by several of our crew to put

some handrails near the center of the main cabin. This is an

excellent idea as there really is nothing to grab onto between the

companion way handholds, and the handholds at the forward end of the

main cabin. Just a lot of empty space.

Grab Rails At

Companionway

Grab Rails At Forward

End Of Main Cabin

I am welding some

pieces of 1” stainless steel tubing together to make part of the

new handrails. When they are complete, they will have mounting plates

at each end, and will be thru-bolted to the deck.

Welded Tubing

Last Item for the day

was the varnish. I applied the second coat on the nameboards, the

teak wire cover, and all of the Panduit

wire duct covers. I applied

the first coat of varnish on the

Cutco

knife holder.