After I got the corners rounded, I

continued with the polishing process. I used my DeWalt

sheet sander starting off with 120 grit paper, then

220 grit paper, and finishing off with 320 grit. It polishes the

surface pretty well, but it is not absolutely smooth.

I then got out the chop

saw and cut a piece of 1” stainless steel schedule

40 pipe in half. This is in preparation to welding the

pipe to the aft ladder stanchions.

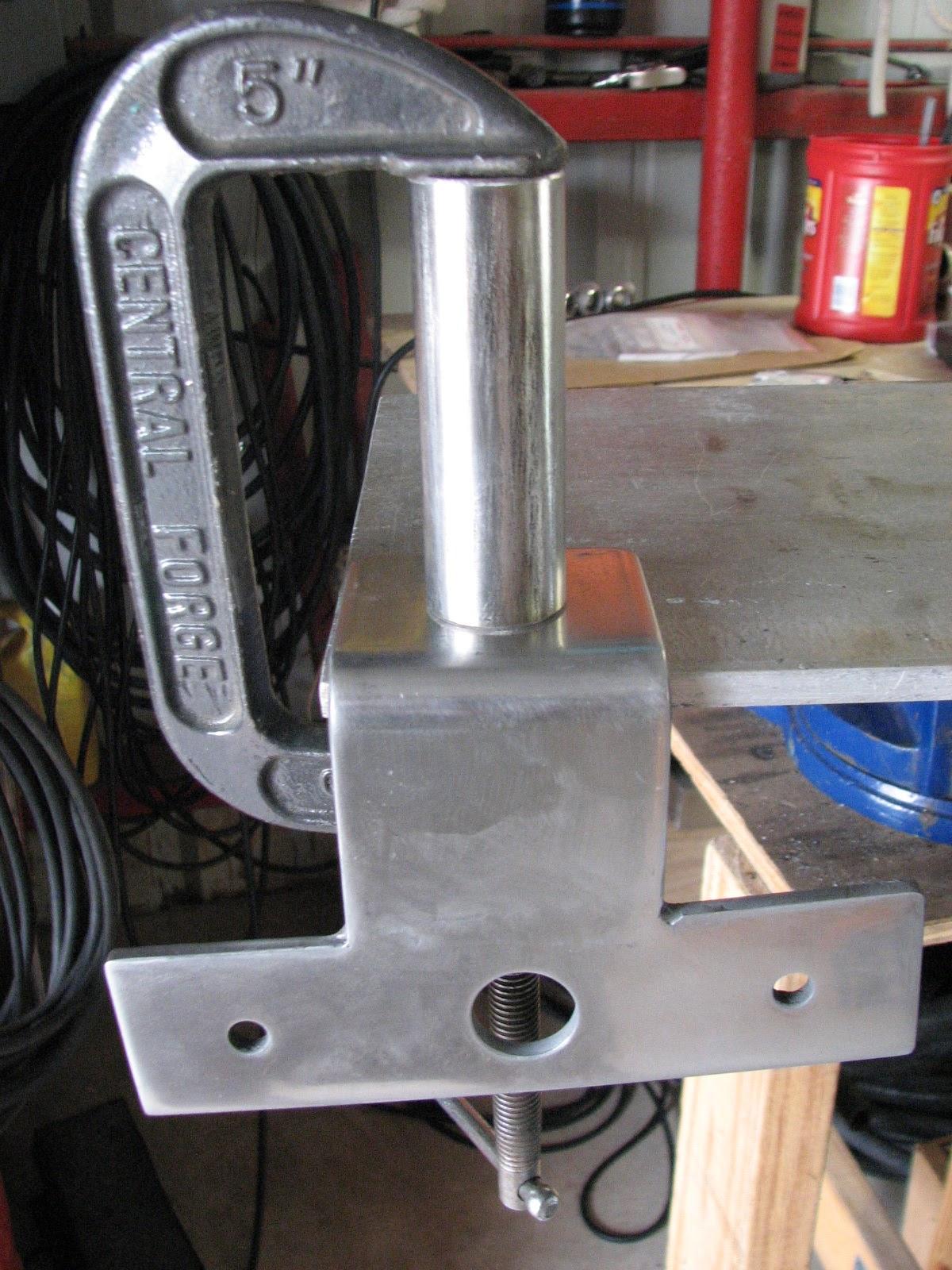

Pipe And Stanchion Pieces Ready For

Welding

Kitty called, and said she was awake,

so I went over to DREAM AWAY to have breakfast. After breakfast, I

got the two tubs we use to wash lines and put them on the front of

the boat. I am planning on running the generator,

but need to get the exhaust outlet out of the water at the stern. To

accomplish this I must put a lot of weight on the front of the boat.

The present method is to fill the tubs

and buckets with water at the front of the boat. I realized I had

forgotten to bring over the buckets from the shop,

so I went back to the shop

and got the buckets. When I had them on the front of DREAM AWAY I

filled them all with water.

I put the

tender into the water, to get

that weight off of the stern, and finally the generator

exhaust outlet was out of the water. I do not want to have the

problems I encountered with the exhaust outlet clogging up!

I started the generator,

and it started just fine and ran it for a total of two hours. During

the time it was running, I changed the ice head in the ice maker.

I was having some serious problems with

the ice head not lifting the ice out of the tray, so I decided to

replace the ice head with the spare. But I found a problem with the

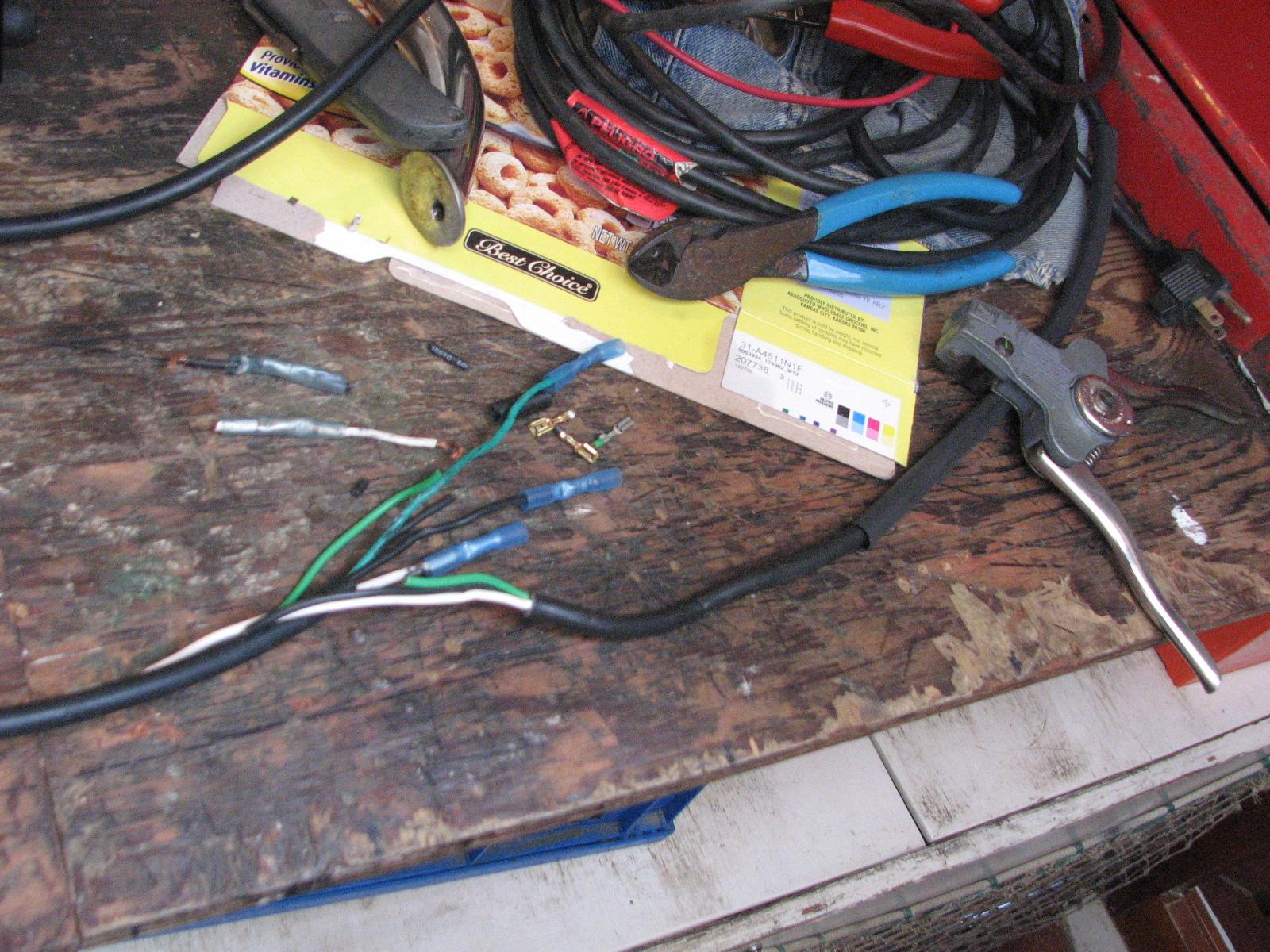

spare. It only had four wires coming out of it, and the one in the

ice maker had five wires.

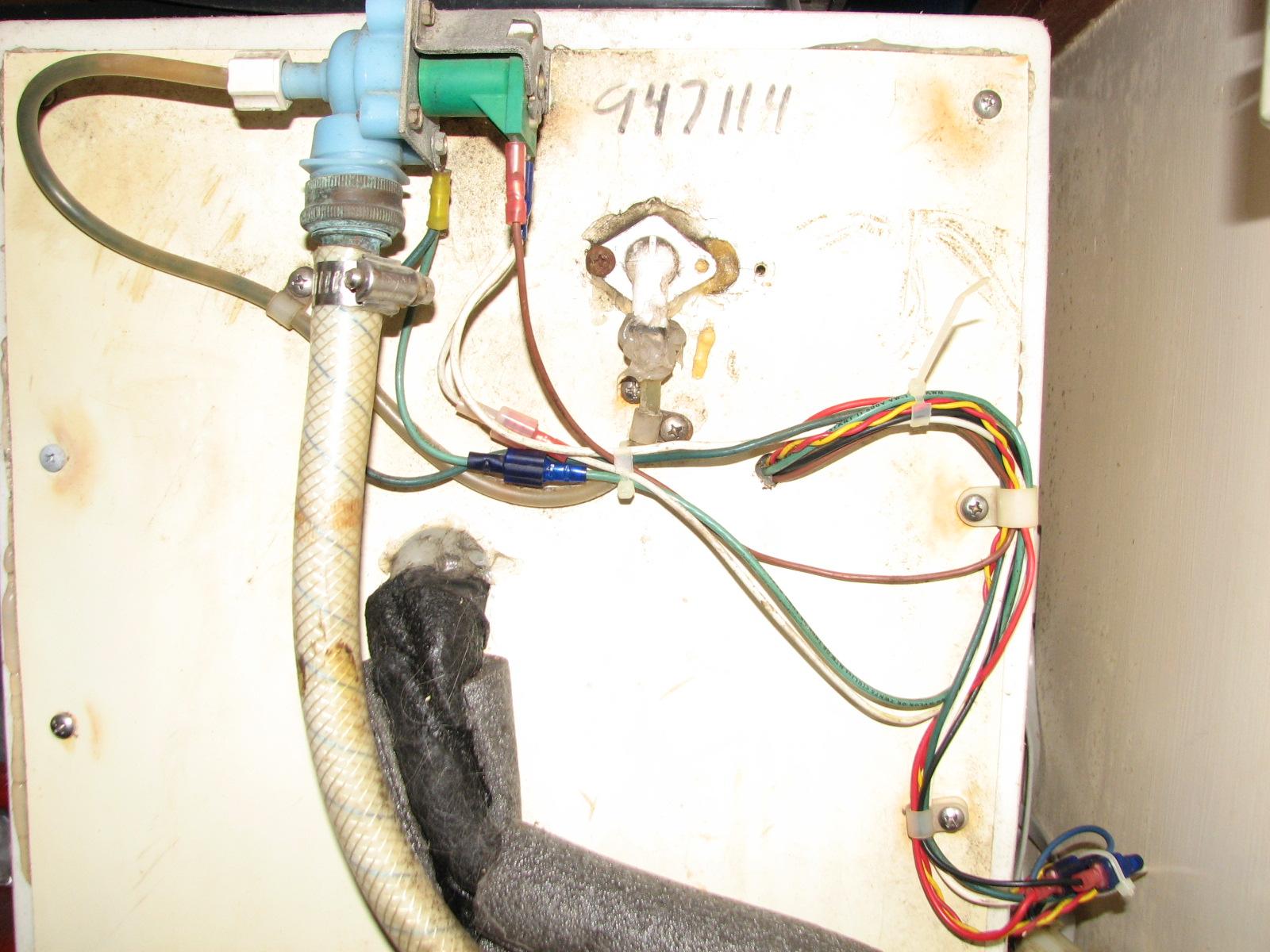

I called David at SeaFreeze

and he told me how to modify the ice head to add the fifth wire. I

made the modification to the spare ice head, after pulling out the

old ice head. I then installed the new ice head, modified all of the

wiring, and started up the ice maker.

New Ice Head In Ice Maker Box

Wiring On Back Of Ice Maker

The ice maker started making ice, and

then would not make any more ice! It was late and I decided to work

on it in the morning! A quick note to fast forward to tomorrow. I

realized during the night that I had in fact turned off the water

supply to the ice maker, instead of turning it on. When I turned on

the water, the ice maker started cranking out the ice cubes!!

Ice Maker Producing

May 25, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go to the

shop

today, but caught up on emails, and the maintenance log. Worked on

the Linux machine to try and get it to be my general purpose and

navigation computer.

Several steps forward and a couple of

steps back. Making progress on the OpenCPN,

but still not satisfied with the application completely.

I was able to get the new Epson

XP400 print working on Linux. I also checked out the

VueScan

software on the unit, and it worked great.

Checking Out Printer Operation

Still working on getting the satellite

phone to make a data call.

May 18 - May 24, Sunday -

Saturday, 2014

We left very early on the morning of

the 18th of May, 0430, and flew to Fort Walton Beach, Florida. We

spent four great days with Stacy and Tina. It was a wonderful

vacation, and we did spend a lot of time working on the computers,

but we were very relaxed.

We then went to Miami, via Fort Myers,

Florida, to attend a Shiva for our dear friend Marilyn who was

murdered by her ex-husband. She and her fiance were murdered two days

before their wedding.

A very sad and unhappy time!

May 17, Saturday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went to the shop

first thing and had to straighten up a bit. Yesterday after I had

helped Troy with his boat, we did not have a lot of time to get to

Norman’s. When I unloaded Ruby,

I just piled everything at the front of the

shop.

Now It was time to put it all away.

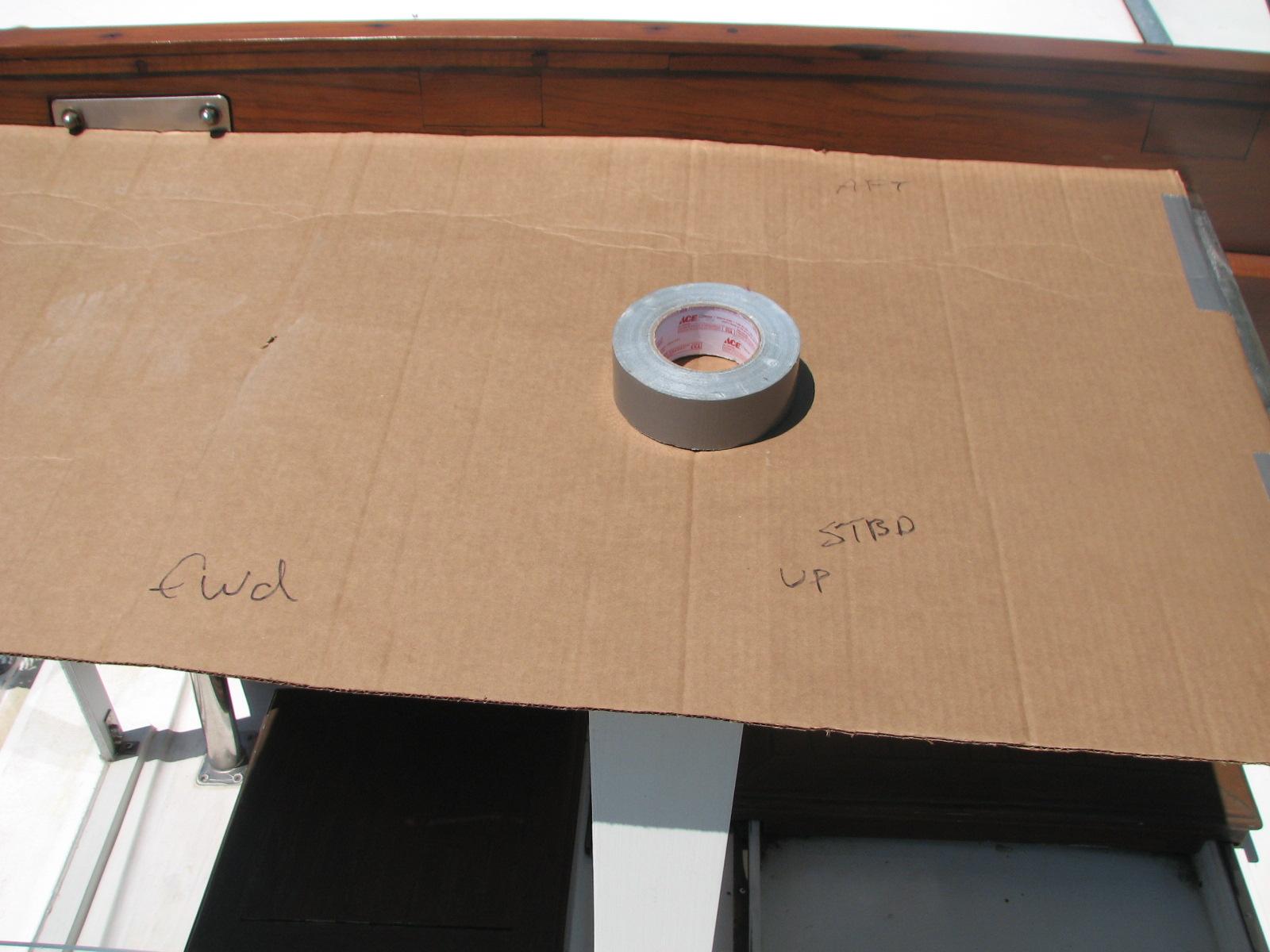

Fenders And Template Cardboard

I had brought over two stainless

steel shackles, that would fit on the two large

shackles at the end of the snubbers, so I made them up to go back to

DREAM AWAY. The big shackle on the second snubber I was not happy

with. There was not enough galvanizing

on it, so I decided to take the snubber over to DREAM AWAY and

replace the big shackle.

Snubber With New Chain Grabber Ready

For Use

I had purchased some ¼” X 20 X 1 ¼”

hex bolts and wing nuts to finish off the risers for the solar

panels. I used the bolts, wing nuts and the spacers I had fabricated

to complete ll of the solar panel risers.

Bolts, Nuts And Spacers On Workbench

Completed Solar Panel Risers

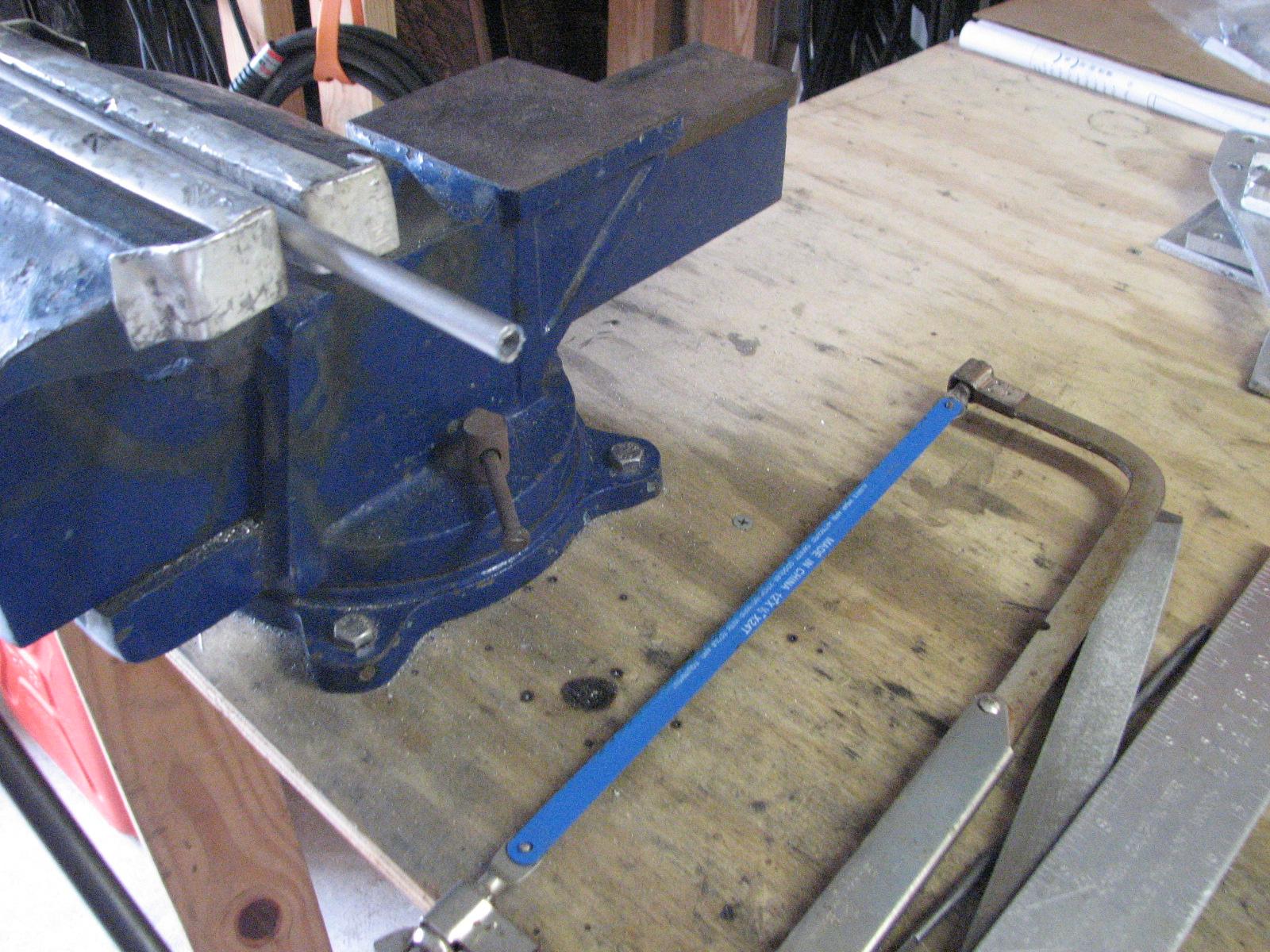

When the risers were finished, next on

the list was bending the starboard stanchion base plate for the stern

ladder. I put the plate in the vice after being marked, fired up the

Oxy-Propane

torch. I heated the plate at the mark and made the 90° bend.

Marked Base Plate In Vise

Plate After The Bend

When the plate had cooled down, I got

out the chop

saw and made the cuts so the pipe can be welded on for

the ladder.

Plates Cut For Installation On The

Stanchion Bases

Plates Cut For Installation On The

Stanchion Bases

Kitty had called, so I loaded up the

snubbers and the stanchion base plates into Ruby,

and went over to DREAM AWAY to have breakfast.

When I had finished breakfast, I dug

out a big shackle, and completed the installation of the new chain

grabbers on the anchor snubbers. I also installed seizing wire on all

of the shackle clevis pins.

Complete Installation Of The Chain

Grabbers On Both Snubbers

Next project is something I had wanted

to do for many months, but like a leaky roof, I never remember when

the propane tank was not in use.

In my aft, aft deck box, the starboard

propane tank is in such a location, it is always difficult to attach

the regulator for the Hummer

Grill. The fix was very easy, just move some stuff in

the propane locker around, and the tank would be at the front of the

locker instead of the back. So I did it, and it fixed the problem.

Propane Tank At Back Of Propane Locker

Propane Tank At Front Of Propane Locker

I then put the outboard motor and the

tender

back aboard DREAM AWAY so they would be out of the water while

we are on our trip to Florida.

The remainder of the day was spent

packing for our trip. We are flying out tomorrow morning on a 0615

flight so we are getting up at 0400. We also attended a Luau Saturday

evening at our next door neighbor’s house.

May 16, Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go to the shop

this morning, but helped my neighbor, Troy, move his boat to the

shrimp dock so we could remove one of his engines. We got the one

engine removed and loaded onto a trailer, and then secured his boat

to the shrimp dock. The hope is he will have the engine repaired and

be able to get the engine back into the boat within a week.

I next helped another neighbor, Hollis,

pressure wash the side of his boat using my

tender.

When all of that was finished, I went

over to the shop

to unload Ruby.

It was back to the marina

to get cleaned up.

We drove Ruby

over to Norman’s Auto Diesel repair, because he is going to change

out the NV4500 manual transmission in Ruby.

Kitty and I then drove into New

Iberia so we could have a late lunch and purchase a

new printer for DREAM AWAY.

We got back to DREAM AWAY after

stopping for a couple of more errands around 1630. We had to make

some plans around our trip to Destin to visit with Stacy and Tina,

and to plan the trip to Miami for our dear friend’s funeral.

May 15, Thursday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the shop

with the remaining two windows from the hard dodger. I also took over

a more coarse file to file off the rough edges of the Optix

acrylic window. I set up and drilled the necessary

holes in the Optix

acrylic windows.

I closed up the shop,

and drove down to the Port

of Delcambre’s storage room and loaded up all of the

cleat project gear. I already had my ½” drill in Ruby,

plus the extension cord from the shop,

so I drove over to the marina.

T-Boy, the dockmaster, showed up so we

loaded all of the gear in the dock trolley, and headed out to Pier

“C”. Once we got the hang of the cleat installation we made

pretty good progress. We installed about eight of the cleats.

We did discover one problem. When I

measured the thickness of the boards on the pier that we had to drill

through, I was at the north end of the pier. The boards were 8 X 8's.

When we started drilling into the boards at the south end of the

pier, they used different boards, 12 X 12's! We will have to get 16”

bolts to complete the cleat project at the south end of the pier.

T-Boy and I worked about two hours, and

then quit that project for the day. We plan to get back onto it

tomorrow afternoon.

When I got back to DREAM AWAY, I

removed the two aft stanchion base plates from the stanchion bases. I

will be using these plates to weld on the aft ladder I am

constructing.

Stanchion Base Plates At The Shop

I had purchased two stainless steel

chain grabbers several weeks ago for the anchor line snubbers, but

never installed them. I decided now was the time! As it turned out

the clevis pins in the shackles were so rusty, I could not get them

loose, so this is a project for the big vice at the shop.

I loaded the stanchion base plates and

the snubbers into Ruby,

and went back to the shop. I was able to get the clevis pins removed

from the shackles holding the old rusty chain grabbers from the

anchor line snubbers.

As is common with these situations, the

clevis pin would not go through the hole in the new stainless steel

chain grabber. This is because I am using 1” nylon rope for the

snubber and the thimble for the eye requires a large shackle. I will

have to use a smaller size shackle to be able to attach the new

stainless steel chain grabber to the anchor line snubber.

Anchor Line Snubbers On Floor In The

Shop

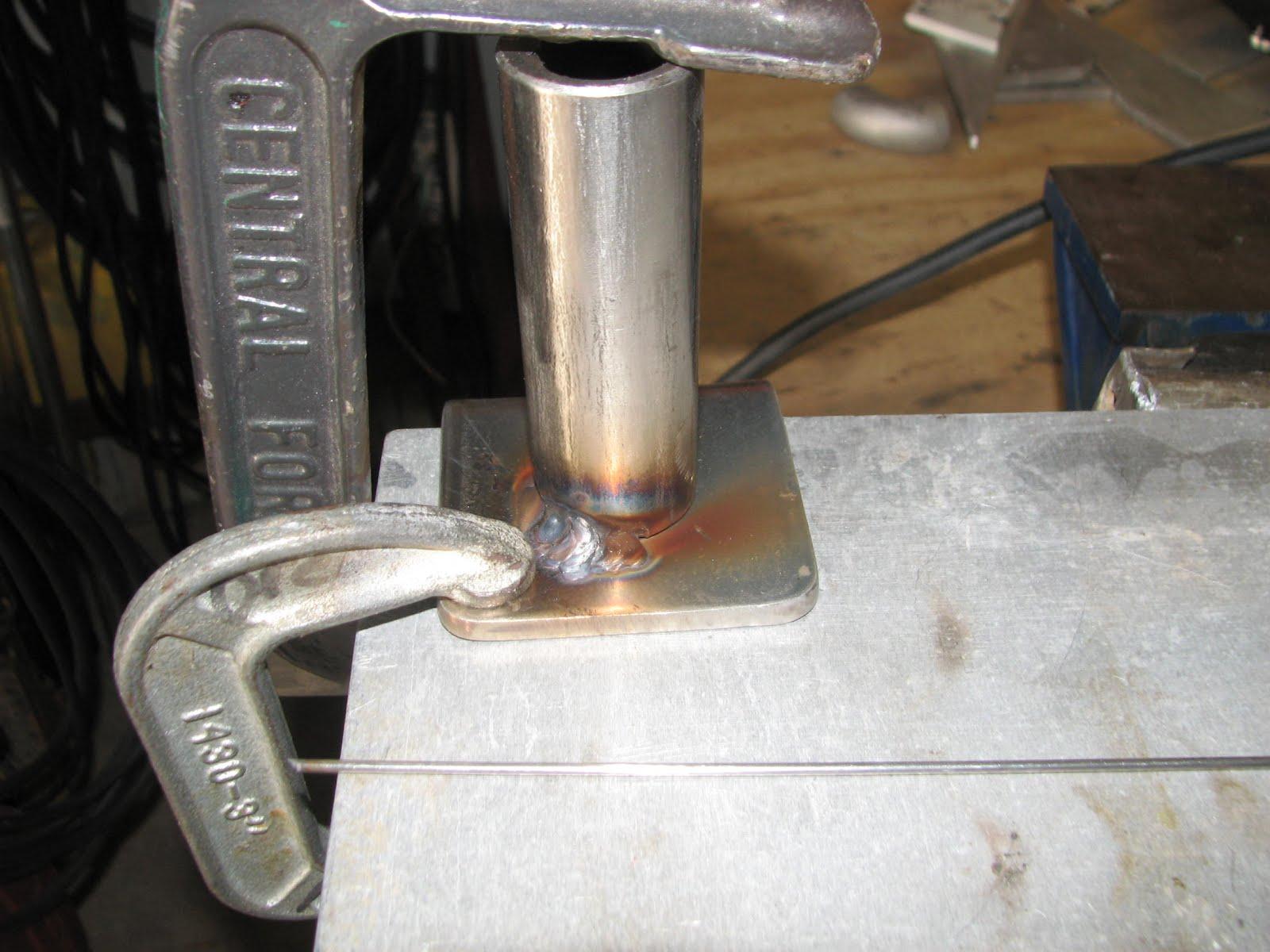

I then got to work on the aft ladder

project. I cleaned off the stanchion base plates, and cleaned a piece

of ¼” X 3” stainless steel flat bar I have. I am welding the

flat bar to the stanchion base, then heating the flat bar and bending

it 90°. On the bent piece of flat bar I will be welding the pipe for

the ladder.

Flat Bar Welded To Stanchion Base Plate

Bent Piece Of Stainless Steel Flat Bar

Last item for the day was the console

varnish

project. I applied fifth coat of

varnish

to console base, second coat to bottom of cup holders, and first coat

to lid bottoms.

The day actually ended on a major

downturn. We got a telephone call that a very dear friend’s former

husband had shot and killed her and her fiance two days before their

wedding.

May 14, Wednesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Before going over to the shop

I took a picture of the magnolia blossoms I had picked yesterday.

While I was trimming and cutting the grass yesterday at the marina,

I cut off three of the magnolia blossoms that were growing on our

trees and gave them to Kitty. She was very happy with the gift, but

we were not sure the blossoms would open!

This morning they were opening, and the

scent was magnificent!

Magnolia Blossoms Opening

I then headed to the shop

around 0800 with one of the windows from the hard dodger. I set up

the drill press to drill the holes in the Optix

acrylic window from the hard dodger. The drilling went

fine, and had no real problems. I also used a fine file to file some

of the rough edges left on the Optix

acrylic window.

Took the Optix

acrylic window over to DREAM AWAY, and when we

returned from the doctor’s appointment, I used

Super Glue to glue in

the grommets.

I applied the fourth coat of varnish

on the console base, and the first coat of varnish

on cup holder bottoms.

While waiting for Kitty to call, I

finally finished filing down all of the spacers for the solar panel

risers.

Finished Spacers In Bowl With A Couple

Of The Bolts

Went back to DREAM AWAY when Kitty

awoke and had breakfast. Right after breakfast went over to Hollis’

boat and helped him find his two air conditioner evaporator’s. We

took the coverings off in case access was needed. He is having an air

conditioning man come over tomorrow to have a look at his A/C

systems.

Kitty and I then headed off to

Lafayette for a

doctor’s appointment for Kitty and to run a couple

of errands, which included some grocery shopping.

When we returned to DREAM AWAY in the

late afternoon, we dropped our

tender into

the water and put the engine on. We will be needing the

tender tomorrow for the cleat

project on Pier “C” in the marina.

May 13, Tuesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the shop

around 0800. I started working on the console for Ruby.

I had to work on the stand-offs for the bottom of the cup holders.

Yesterday, one of the errands was to pick up the fasteners needed for

the console cup holders.

I had also fabricated new stand-offs

for one of the cup holders, so I needed to drill holes through them

for the screw to go through.

Sanded Cup Holder Bottoms & Other

Console Parts

Hardware Ready For Cup Holders

Drilling Out Cup Holder Stand-offs

I got all of the parts ready for the

next coat of varnish,

but the remainder of the day ran so late, I did not get back to the

shop

to apply the next coat of varnish.

The next project is an experiment. We

have decided on the method of raising and lowering the windows on the

hard dodger. We are planning on drilling holes in the bottom of the

windows, and install a brass grommet in the hole. We will pass a line

through the hole, and use small line to raise and lower the windows.

I was not sure how the drilling of the

hole would go, so I drilled out a scrap piece of the acrylic.

I had no problems. No cracking or splitting. I went to install the

grommet into the hole, but the width of the grommet was not

sufficient to install the grommet properly. We decided to use our old

stand by, and Super

Glue the grommet in place. We are going with this plan

for the hard dodger windows.

Experimental Drilled Acrylic

With Grommet

I closed the shop,

and went to the Port

of Delcambre’s storage room and picked up the lawn

mower and fuel tank. Then back to the

marina

to weed all of the gardens. When I had weeded all of the gardens, and

trimmed the grass at the edges of the parking lot and gardens, I

mowed the lawns in the

marina.

These activities took the remainder of the day.

May 12, Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian and Jordan,

and spend time with them brushing their beautiful coats.

Went over to the shop

around 0800 and put several pieces of stainless steel tubing up out

of the way. I was successful in this effort, although the process was

very time consuming.

Area Where Stainless Steel Pieces Will

Go

Stainless Steel Pieces On The Way Up

Stainless Steel Pieces Up And Stored

When that was complete, I sanded down

the console for Ruby

in preparation for the fourth coat of varnish.

I loaded the old TV antennas into Ruby,

and some template material to be used to make a template for the hard

dodger top. I then drove over to DREAM AWAY.

After breakfast, I took a shower in

preparation of running some errands, and we had to deliver 100 Lbs of

fresh frozen catfish to the supplier in

Lafayette

.

When we returned to DREAM AWAY around

1630, we tested out the four TV antennas we have. The two Shakespeare

Seawatch 2025 antennas did not work, but the other two

we have did. I will be getting rid of the two that do not work!

May 11, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Continued working on the computer,

catching up on

Maintenance Logs until

0830. At that time I drove the

Black Beast

over to the boat landing in

Delcambre.

T-Boy Renard, the dockmaster, met me there.

We then prepared the

shower trailer

for transport back to the

marina.

This included disconnecting the electricity, and putting all the

steps up in the transport mode.

We moved the shower

trailer back to the

marina

and set it up for use. We put all of the steps down, and the railings

on. We emptied the holding tank, and attached the electricity and

water to the shower

trailer. T-Boy emptied all of the trash containers and

put new liners in the trash cans, while I mopped out all three of the

stalls. We are now back in business.

The remainder of the day was spent on

the computer scanning in documents, which I actually finished!

The end of the day was spent preparing

Kitty one of her favorite meals for Mothers Day, grilled steak with

grilled eggplant.

May 10, Saturday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

I went to the shop

around 0800, and inventoried the package that had arrived with toilet

parts for Nicola and Noel.

Toilet Parts On Table

Yesterday while working to get the ice

maker back functioning again, my drop light quit working. I brought

the drop light over to the shop to find the problem.

I suspected the actual light to be the

problem, but when I used my DVM (Digital Volt Meter) there was only

17 volts getting to the light. I then suspected the connection I had

done to the input electrical cord. The original light had come with

only a five foot cord. I had spliced in a 20 foot cord to make the

use of the light more practical.

I cut the light cord off from the

extension cord, and tested just the light, and that was good! So the

problem had to be in the actual extension cord. I suspected the problem was the

plug, but that was not the case. I cut off the plug, then used the ohmmeter to

check the actual wires, and that is where the problem is!

My vacuum cleaner had died, the motor

is dead, so I need a replacement. I cut the electrical cord off of

the vacuum cleaner, and tested it with the light. it all worked!

Drop Light On Workbench

Light Wire Connected To New Extension

Wire

I did not have all of the tools and

parts necessary to do a proper splice, so I took the extension cord

and light back to DREAM AWAY.

Next item is to drill the broken easy

out out of the handrail end. I did get it drilled out, but that cost

two drill bits. Rather than drill and tap the handrail end, I have

decided to weld a bolt onto the handrail end. This is much easier

overall, and a more secure fitting.

Kitty called and said she was up, so I

loaded the new ice maker head into

Ruby,

and went over to DREAM AWAY.

After breakfast, I got out the butt

connectors and shrink tubing necessary for the light and extension

cord project. I was able to successfully complete that project. I now

have a working drop light with a 20’ extension cord.

Putting The Light And Extension

Together

Next item was to replace the ice maker

ice head. When I got out the replacement, I discovered that ice head

currently in the ice maker has five wires, and the replacement ice

head only has four wires. Now I do have a problem!

I have to do more research to figure

out what ice head I need for my ice maker.

New Ice Head

Ice Head Currently In The Ice Maker

So I still have no properly functioning

ice maker!

May 09, Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

It had rained all night and was still

raining in the morning, so did not go to the

shop.

Kitty had a dental appointment at 0900, so I dropped her off at the

dental office in

Delcambre,

and I drove

Ruby

to Winmill Tire in

Abbeville

to get the four new tires installed.

I got the four new tires installed and

then drove back to Delcambre,

picked Kitty up and went back to DREAM AWAY.

I stayed in the remainder of the day

mostly working on the computer getting the

Maintenance Logs updated

and ready for a DREAM AWAY update.

I spent some time working on the ice

maker, but without very much success. I will probably end up

replacing the ice head.

I also prepared the

shower

trailer to be moved to the

Delcambre

boat landing for the Poker Run tomorrow. I emptied the holding tank,

and put all three steps up in transportation mode. I hope we get the

shower trailer back by Sunday!!

May 08, Thursday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Kitty and I both had an appointment at

the doctor’s to draw blood at 0845 in New

Iberia, so we left DREAM AWAY around 0750. When we

finished at the doctor’s we headed out to Abbeville.

We stopped at a place called Auto-Go

Transmission. I am looking for someone who works on manual

transmissions or someone who will supply a manual transmission. We

talked to Jim Reed at Auto-Go, but he was not able to find anyone to

help me get a NV-4500

transmission for Ruby.

It looks like I will be purchasing a

rebuilt transmission online, and having Norman’s Diesel install it

for me. From Auto-Go, we went to Winmill

Tire, also in Abbeville

to see about some new tires for Ruby.

I had one size tire in the front of

Ruby,

and a different size in the rear, and the spare was not a light truck

tire! Brandon, a former Marine, worked it all out for me at a drive

out price of $500.00. That was four new tires on the road and the

proper size tire for a spare. He did not have the required four tires

in stock, so I will be back in the morning to get the tires

installed.

Went back to DREAM AWAY, and drove the

Black

Beast over to the shop

with all of the necessary tools I thought I would need.

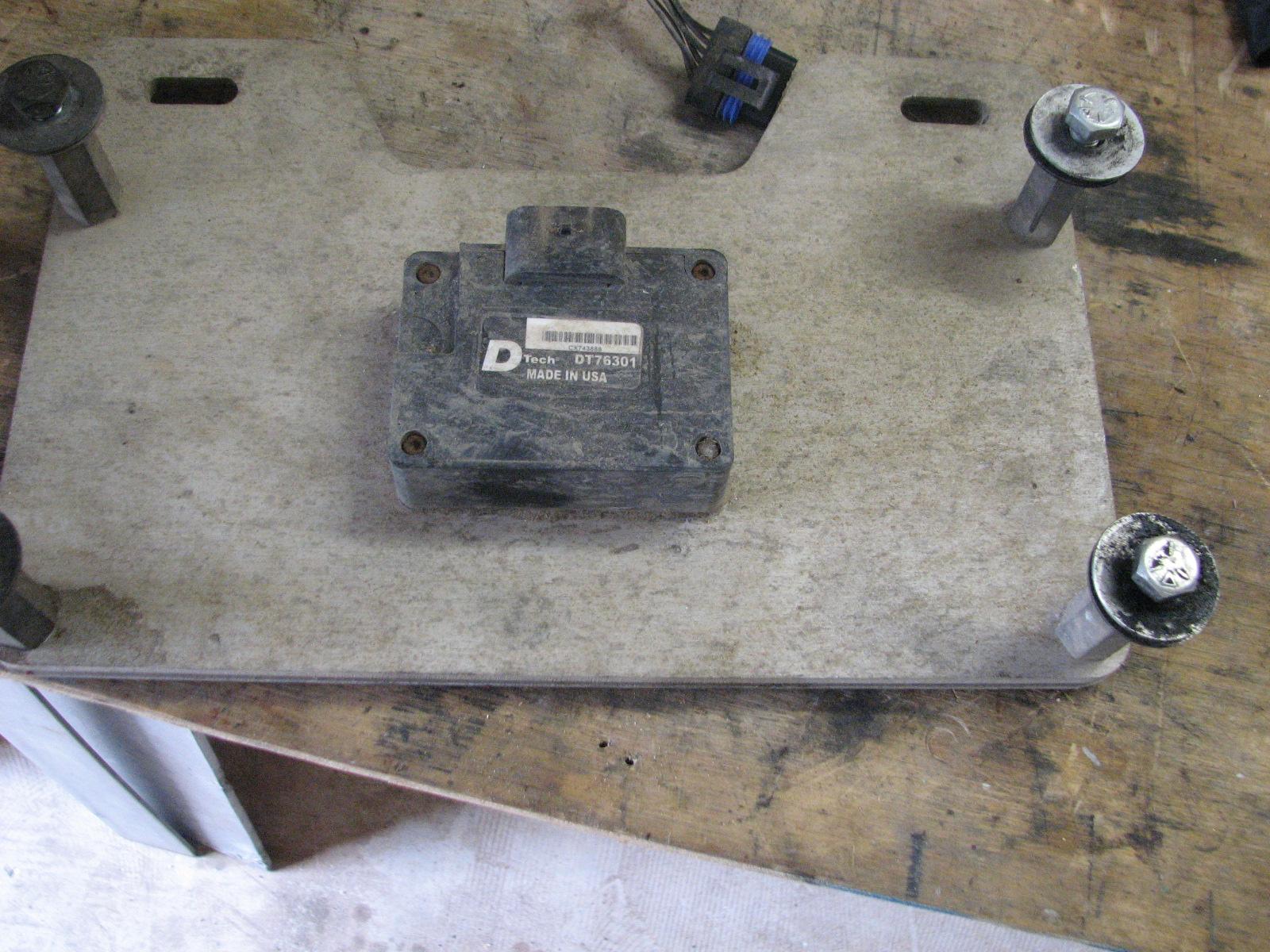

First on the list was to actually

connect the original PMD (Pump Mounted Driver) to the new cable on

the engine of the Black

Beast. After connecting it to the system the engine

started right up, so I was on the correct path.

PWD Module In Original Configuration

I installed the original PMD on the

heat sink, and then installed it on the engine in the Black

Beast. It started right up, and so far is running

fine.

Original PMD On New Heat Sink

Next I attempted to repair the broken

off stud on the handrail end that was on the hard dodger. I drilled

it out, and of course the easy out broke off in the hole! One step

forward two back!!

Broken Stud In Hand Rail End

I applied the second coat of

varnish

to the console and the console parts.

May 07, Wednesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the shop,

and started off with sanding the main console and console part I had

repaired yesterday afternoon. I got both parts sanded smooth, and put

them on my paint table ready for a coat of varnish

this afternoon.

I finished cutting all of the spacers

for the solar panel risers. Now I have to trim each one of the

spacers, and remove all of the sharp surfaces, so they are all

useable.

We got everyone in contact with each

other, and it looks like the

US

Customs and Border Protection boat will be kept on our

Pier “C” about 10 days out of the month, so they can do their

Vermillion

Bay patrols from here. I think it will be good

publicity for our marina.

I spent about an hour working in the

gardens at the marina

with the never ending battle to get the weeds under control.

I went over to the shop

in the Black Beast. When I

arrived I cleaned all of the mag wheels on the

Black Beast.

They were in pretty sad shape because of all of the brake dust.

I then tried to connect the original

PMD (Pump Mounted Driver) from before the replacement of the PMD.

This was an issue that happened late in 2012. I was having problems

with the Black

Beast stalling. I had someone replace the PMD module,

and that did not help, so I replaced the injector pump. That solved

the problem unit the last couple of months.

The Black

Beast is stalling again, and I suspect the PMD. Anyway

I could not change the PMD because of the connector issues, and I did

not have the proper tools with me.

I had another fender on the front deck

of DREAM AWAY that I had found floating in the

marina,

so I cleaned it off, and rinsed it, and hung it up to dry.

I then started the varnish

ritual! Put on nitrile gloves, get out the

tack rag,

and wipe down all of the parts to be varnished. Pour some

acetone

into a clean container, and wash out the brush. Open the can of

varnish,

and pour the varnish

through a medium cone filter into a clean cup. I then apply the

varnish

to the job, which in this case in the console and console parts.

I normally do the painting or

varnishing just before I leave the

shop

in the afternoon to keep the chances of disturbed dust to a minimum. Also the truck

traffic is way down in the late afternoon, so that tends to keep dust

down!!

May 06, Tuesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

I was feeling much better this morning,

so went over to the shop

and started in on the projects. Had to do some straightening up, as I

left things a bit of a mess when I left almost two weeks ago!

First on the list was a fender

I found floating in the marina.

Before we left on the Puerto Rico trip, I had left the fender

in the sink in soapy water. The fender

was mostly clean, but I scrubbed it down. It looked very nice and

serviceable, so I rinsed it off, and hung it in the sunlight to dry!

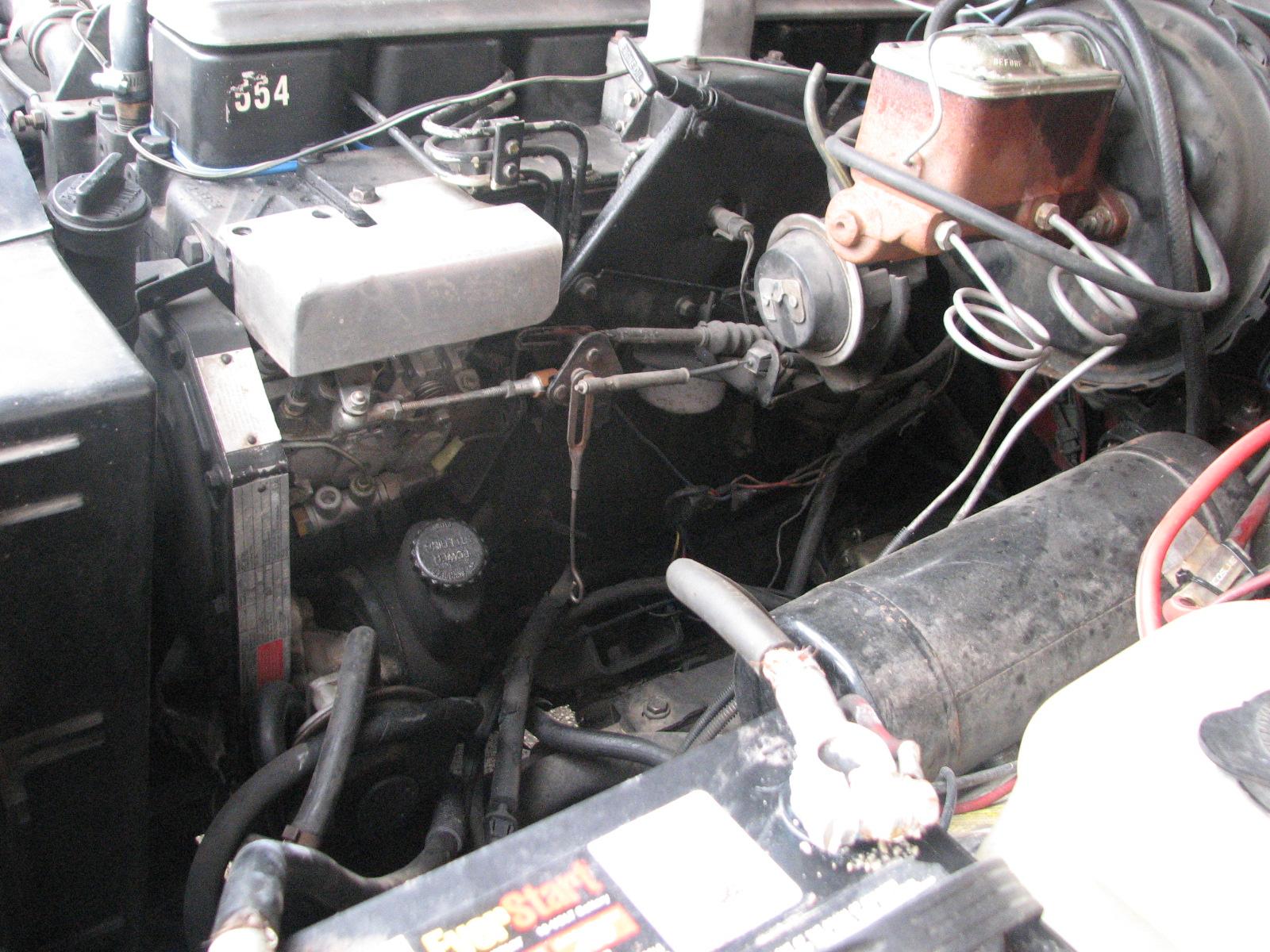

I have a new toy, Ruby,

which is a 1988 GMC

Suburban. Because it is over 25 years old, it

qualifies to be a classic truck in Texas. I therefore ordered classic

truck plates for Ruby,

especially since there was no additional charge. The plates had come

in, so I installed them on Ruby.

I also took a couple of photos of the engine compartment.

Engine Compartment Showing Cummins

Diesel Engine

Drivers Side Engine Compartment

Engine Compartment Passenger Side

The next project was to change the

three calendars I have hanging in the shop. It is a new month, so the

calendars must keep up to date!

Change Miami Dolphins Cheerleader

Calendar From April

To May

Change The LeBlanc Fuel Construction

Workers Calendar From April

To May

Change The LeBlanc Fuel Beach Calendar

From March

To May

We had received the three

Lumateq Spreader Lights I had ordered for

Tantalus.

I opened the box and verified the lights were in good physical

condition. Now all that remains is to check out the light operation.

I had already cut about 10 spacers for

the solar panel risers, but I needed at least 32, and probably a

couple more as spares. I am sure I would lose a couple over time as I

adjusted the solar panels. I used a hacksaw to cut off ¾” pieces

off of a piece of stainless steel tubing to make the spacers.

Tubing In Vice From Which I Am Cutting Spacers

I cut an angle on a 3” piece of

stainless steel flat bar as the start of the stern ladder project,

but it needed to be straightened out just a bit. I used the Chop

Saw to make the cut, and the high speed grinder to

smooth out the cut. I will take the piece of flat bar over to DREAM

AWAY to verify the angle.

Cut Made On 3” Stainless Steel Flat

Bar

Kitty got up, so I went over to DREAM

AWAY to have a small breakfast, as today was a diet day. After

breakfast I removed all of the handrail fittings, reading lights, and

external satellite phone antenna from the hard

Bimini. This is in

preparation of replacing the King

Starboard on top of the

Bimini.

I was a bit disappointed when I removed

the external satellite phone antenna. The metal in the bottom of the

antenna is a pot metal, and it had a stainless steel screw in it, in

a marine environment. Not good to try and attach the antenna back on

the new

Bimini.

Reading Light On Underside Of

Bimini

Reading Light & Antenna Wire On

Underside Of

Bimini

I then installed a water regulator on

our water connection on the dock, and set it for 200 gallons. This is

a safety device that will shut off water flow to DREAM AWAY after 200

gallons, then it will have to be reset again. When we run the

icemaker, we leave the water on even if we leave the boat. If there

was a pipe leak or something, it could sink DREAM AWAY.

Water Regulator Installed On Dock

Pedestal

As I was securing all of the removed

parts, our neighbor Joel, came over. He said he had purchased a large

piece of fresh watermelon, and would we like to share? We said yes,

so we went up to the marina

picnic area and enjoyed our watermelon. Officially, I believe this is

the first picnic of the year!

Kitty And Joel Enjoying The Watermelon

When we finished with the watermelon, I

went back over to the shop

to apply the first coat of varnish

to the console and parts that belong in Ruby.

When I looked at the parts, I realized

one part I had repaired and come apart again, so it would need

repaired before I could start the varnish.

This time I would pin the two pieces together using bamboo

chopsticks. I have used chopsticks on several occasions on DREAM AWAY

to put together two pieces of wood!

I drilled, cut and fitted until I was

satisfied with the fit, and then mixed up a pot of epoxy

thickened with teak dust. Since I was mixing up a pot, I decided to

apply some of the epoxy

to a seam on the main console that had been neglected.

Main Console With Epoxy

Applied To Seam

Console Piece Fitted Together

It will have to wait until tomorrow to

apply the first coat of varnish

on the console!

May 05, Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go to the shop

today, but stayed busy all day. When I woke up I did not feel great,

but pressed on!

Kitty was up at 0800, and we were under

way by 0900 to Lafayette.

We were meeting Ben who was driving from

Baton Rouge, so we

could deliver 20 Lbs of shrimp, and seven

Lbs of catfish. Ben is running an online grocery store, and they are

going through the shrimp and catfish very quickly.

When we dropped off the product and we

spent the remainder of the day going to two doctor’s appointments

in New

Iberia, and running several errands.

We arrived back on DREAM AWAY around

1600, and I went right to bed. Kitty took care of everything else!

May 04, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go to the shop

today, but stayed on DREAM AWAY, getting caught up after the trip to

Puerto Rico. We arrived at DREAM AWAY about 2300 last night. Not much

accomplished then.

I did some catching up on emails and

other computer work. I then went to Shawn’s

Cajun Meats Too to stock up on various meat items.

Kitty and I then got organized and went into New

Iberia to take our dirty laundry and to do our grocery

shopping.

We returned to the marina

around 1700. We got all of our mail and groceries down to DREAM AWAY.

Kitty put all of the groceries away, and while she was doing that, I

went up and finished setting up the shower

trailer, so I could use it to take a shower.

May 01 - May 03, Thursday

- Saturday, 2014

The dates of our trip to Puerto Rico,

which will be covered in a DREAM AWAY update.