Maintenance Log June 2013

June 30,

Sunday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

The tender was still in

the water after working with PERELANDRA, so I put the engine back on

the lifelines, and the tender back onto the davits.

I washed the mainsheet

in a mild soap and bleach solution to remove built up dirt and

mildew. Rinsed it off and then hung it out to dry. Continued

scrubbing the cockpit sheet nets. They are slow to get clean. May

have to resort to the laundromat.

Worked on the computer

to get caught up on email and scanning in receipts and documents.

Welcomed Transients To

The Marina

Went and took a shower,

then drove to New Orleans to Get Kitty after her trip to see friend

Kathy. Got back to DREAM AWAY around midnight!

June 29, Saturday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went over to the shop

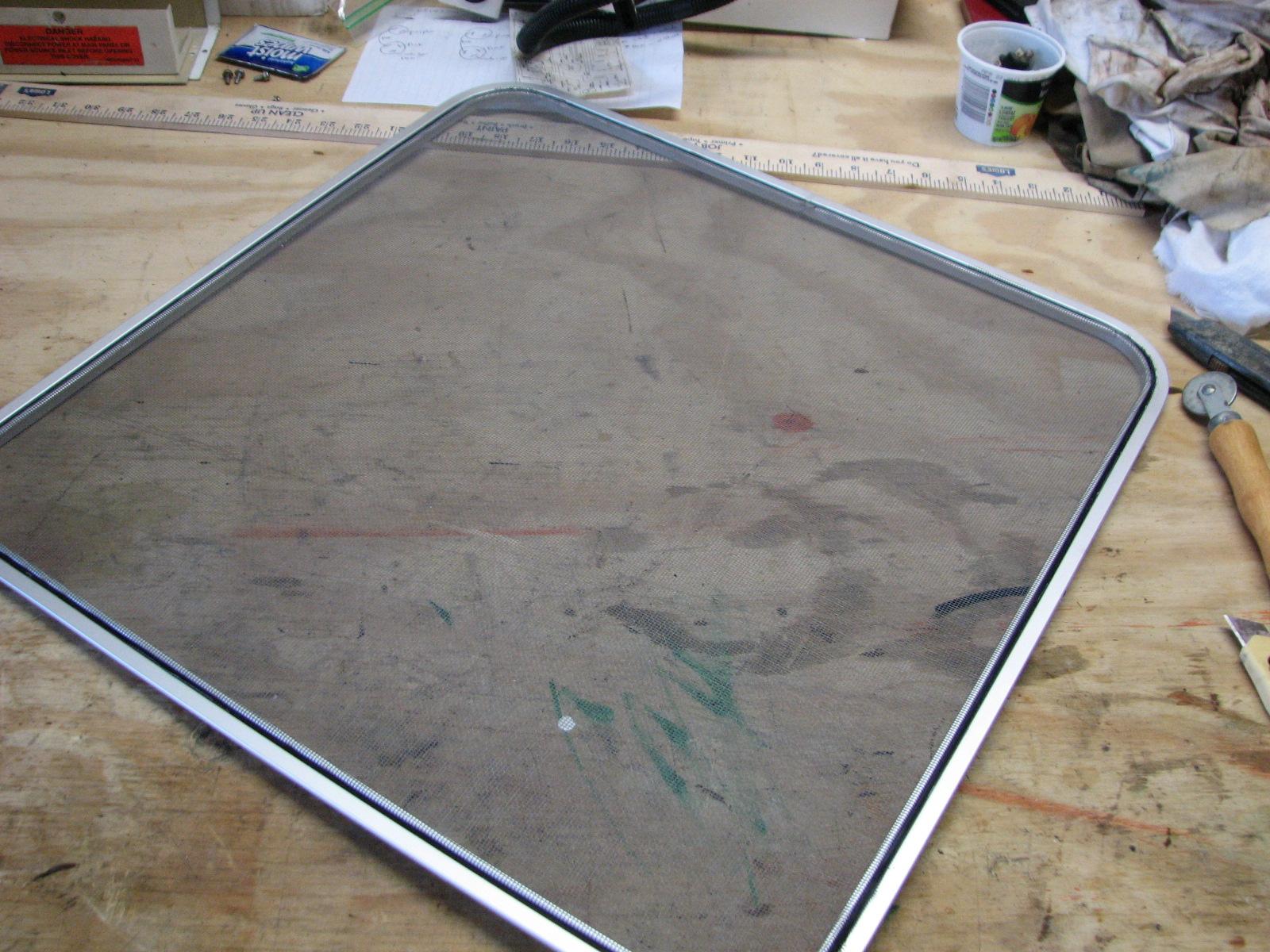

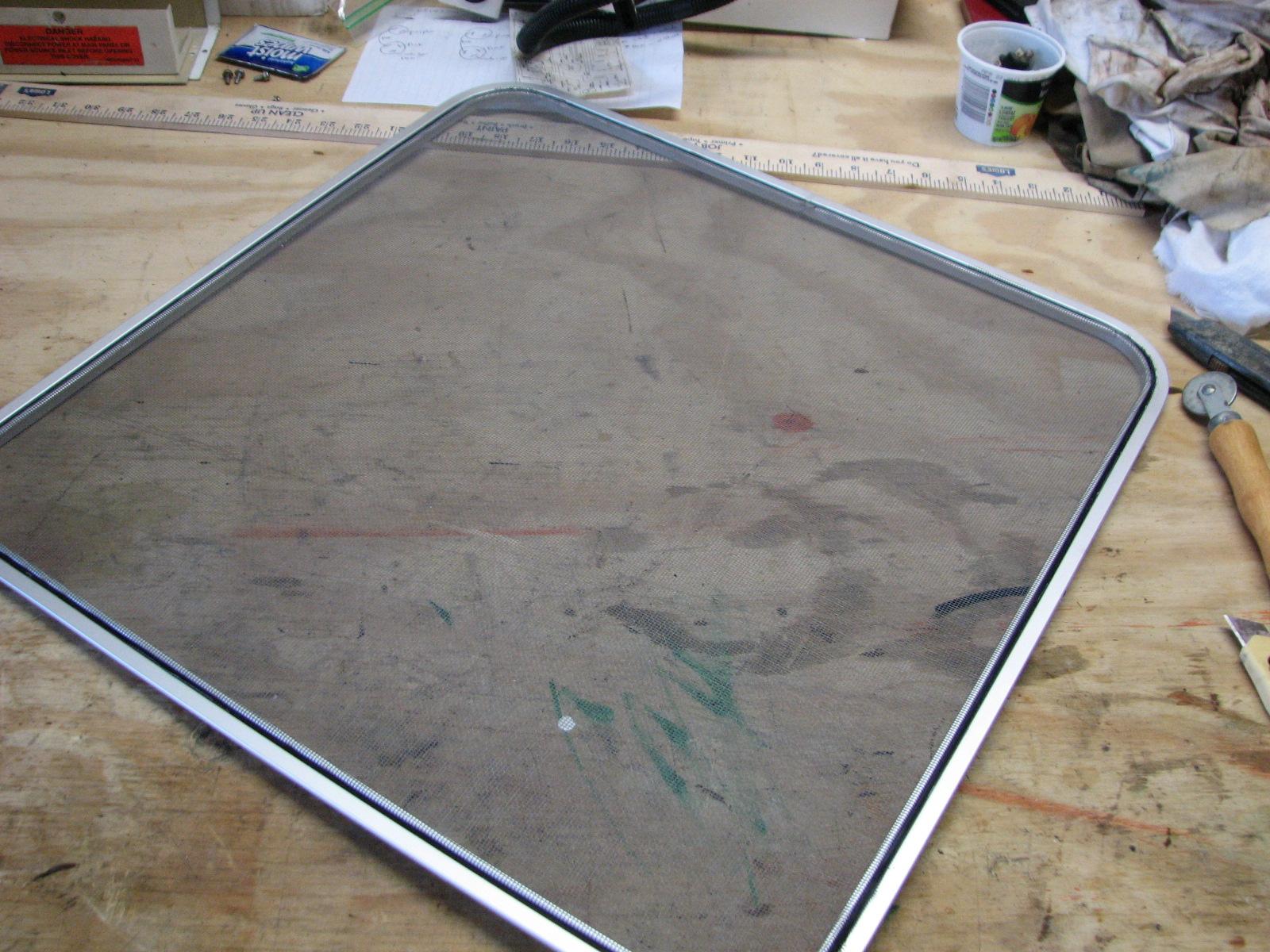

and repaired the screen from one of the main cabin hatches. The

screen I repaired yesterday was larger than the main cabin hatch, so

I was able to use the old screen to repair the screen for the main

cabin hatch.

Repaired Main Cabin

Hatch Screen

I checked out the

window air conditioner I have and verified it worked properly. Mark

and Kittie are having issues with their on board air conditioner.

Before I offered them the window unit, I wanted to make sure it

worked.

I sanded the V-Berth

insert, and the Panduit

wiring duct covers. I masked the V-Berth insert in preparation for

the application of varnish.

I applied the first

coat ofSmith’s

penetrating epoxy on the

shelf for under the stove in the galley, the batten for the front of

the shelf, and the two supports for the shelf.

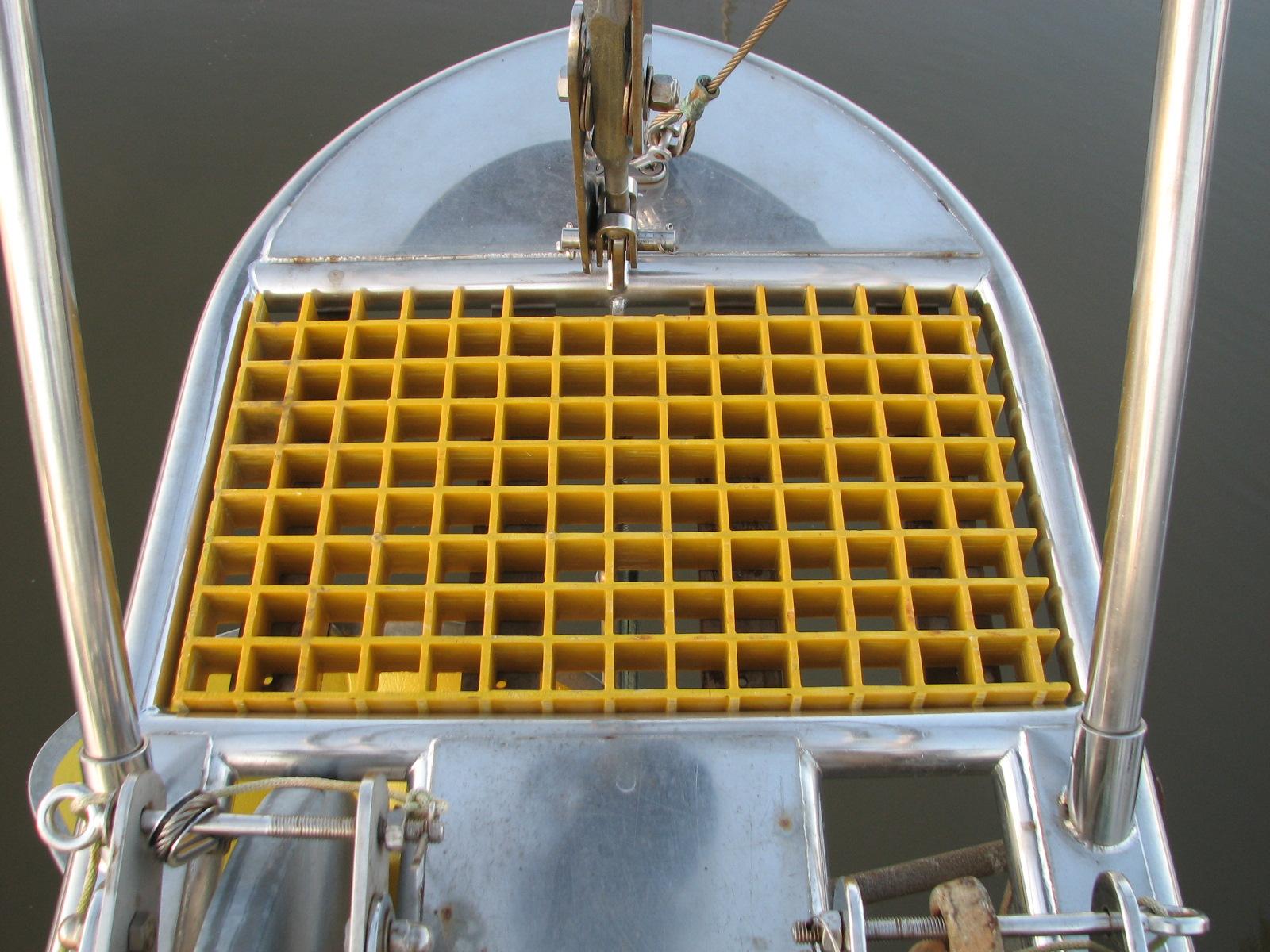

Went back to DREAM

AWAY, and removed the wood deck in the anchor area of the bow pulpit.

Fit the fiberglass grating, but still needed some trimming for the

perfect fit. Marked the grating for cutting.

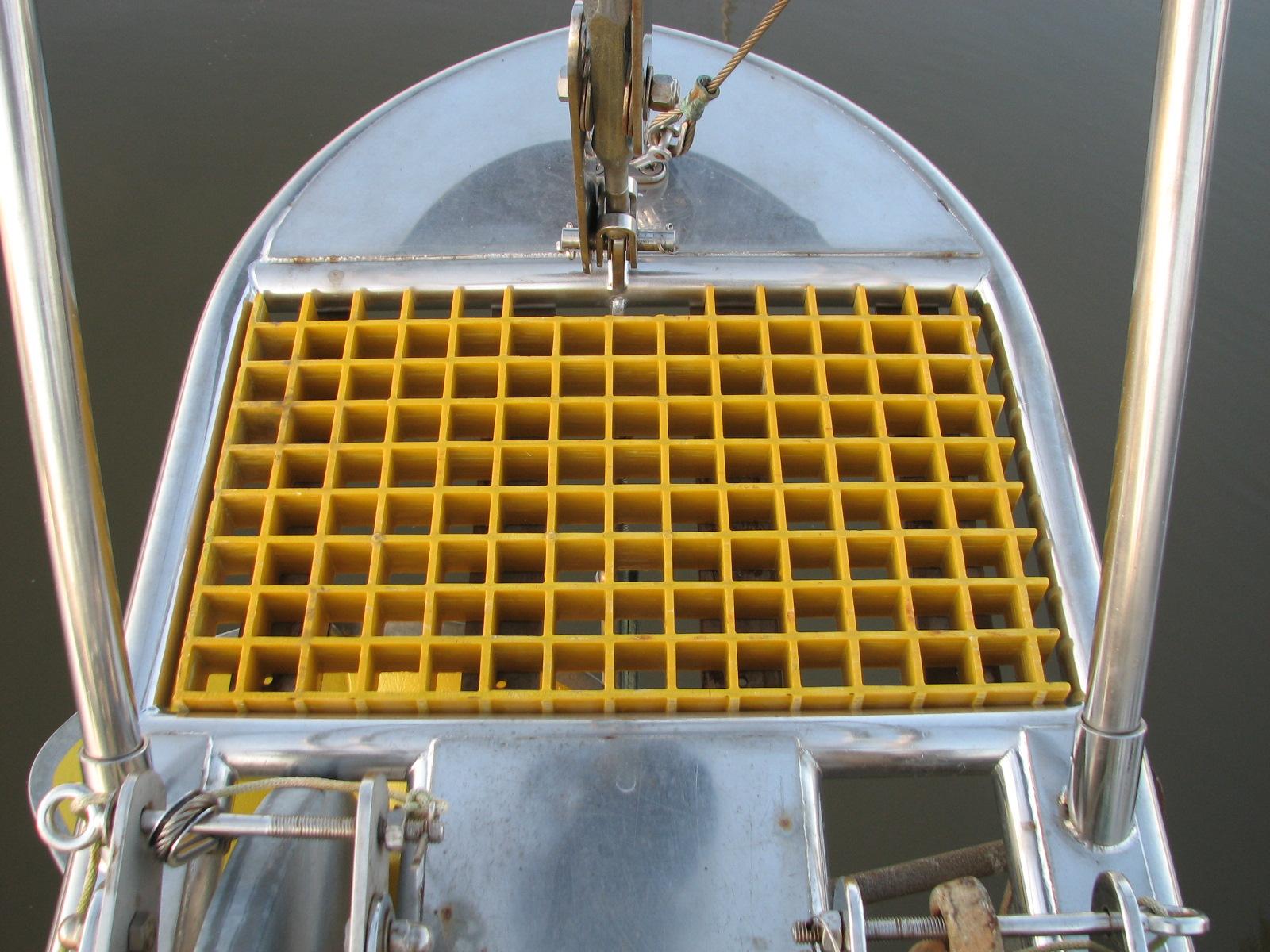

Deck From Anchor Area

On Bow Pulpit

Back into spring

cleaning mode. I cleaned the main cabin, including both lockers on

either side of the settee shelves.

Went back to the shop

and cut the fiberglass grating to the adjusted measurements.

Fiberglass Grating

After Adjustments

I nailed the batten

onto the front of the shelf to be put under the stove in the galley.

The batten is to keep pans from sliding off of the shelf.

I applied the second

coat of varnish to the Panduit

wiring duct covers, and the first coat of varnish to the V-Berth

insert.

Varnish Applied To

Panduit

Wiring Duct Covers And V-Berth Insert

Went back to DREAM

AWAY, and fitted the fiberglass grating to the deck of the anchor

area on the bow pulpit. It is a perfect fit.

Fiberglass Grating On

Bow Pulpit

All that remains is to

purchase J-bolts to secure the grating to the bow pulpit.

June 28, Friday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went over to the shop

and repaired the screen for the aft cabin. Had to cut new screen

material, and insert the screen into the frame.

Frame With New Screen

Material

I brought over two butt

connectors, so I connected the blower on the spare air conditioner to

the power controls. I powered up the unit, and everything functioned

normally. Now all I need is a small piece of hose, and I can check

the system out with the cooling water running through the system.

I applied the dye to

the Panduit

wiring duct covers. When they dry they will be ready for varnish.

I cut the wood for the

shelf I am putting under the stove in the galley. I also cut the

fiberglass grating to be used on the bow pulpit anchor area.

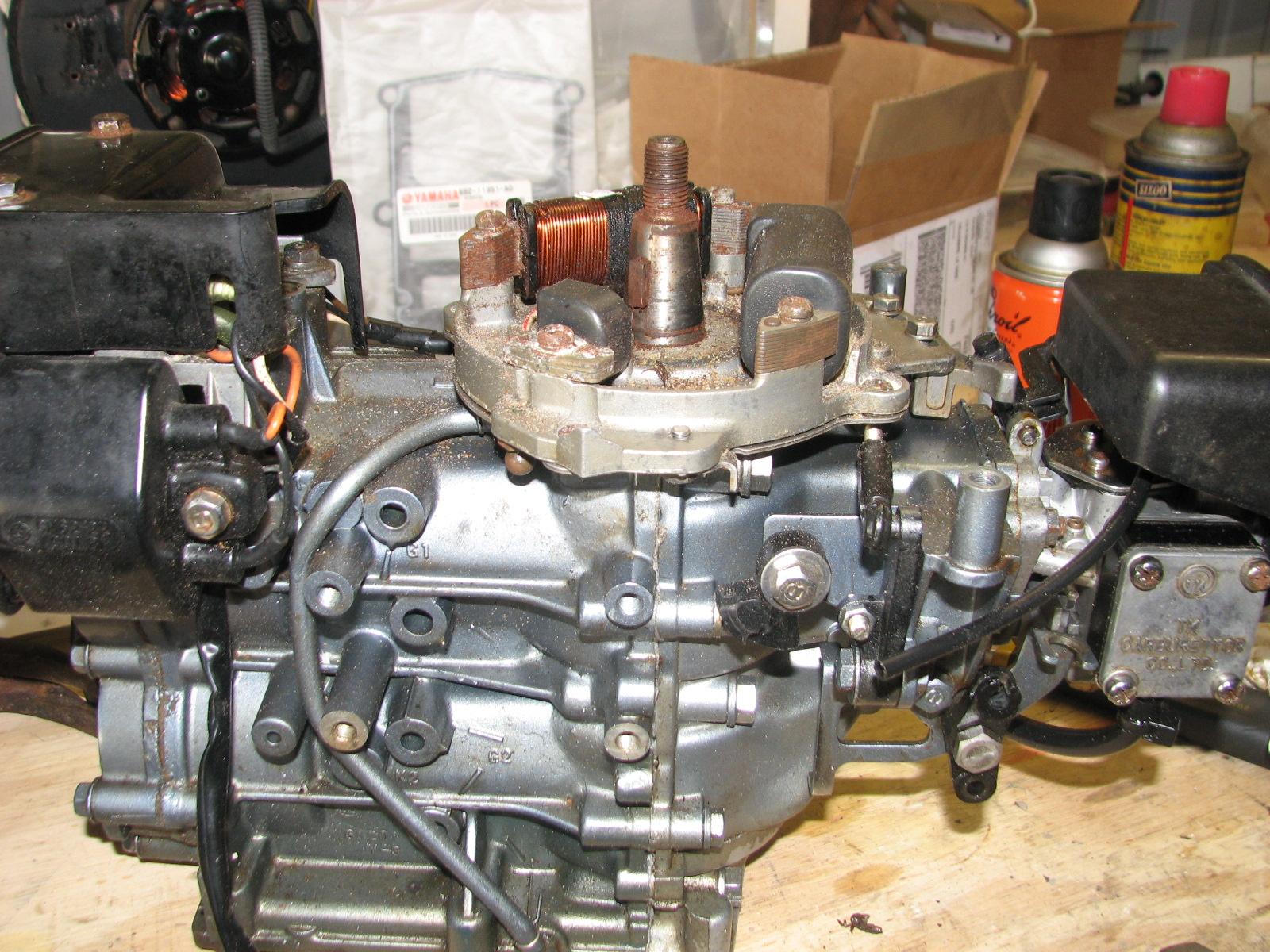

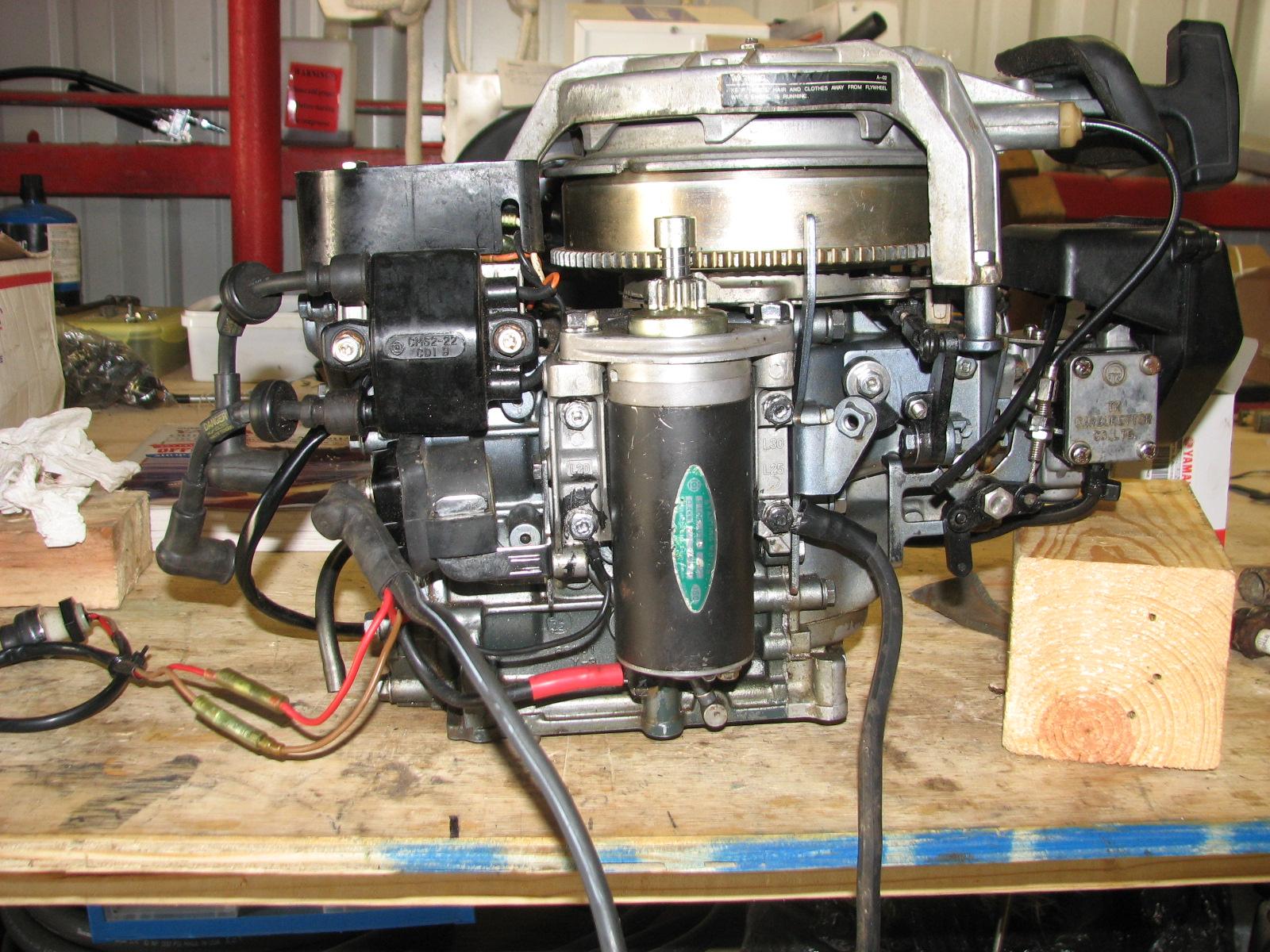

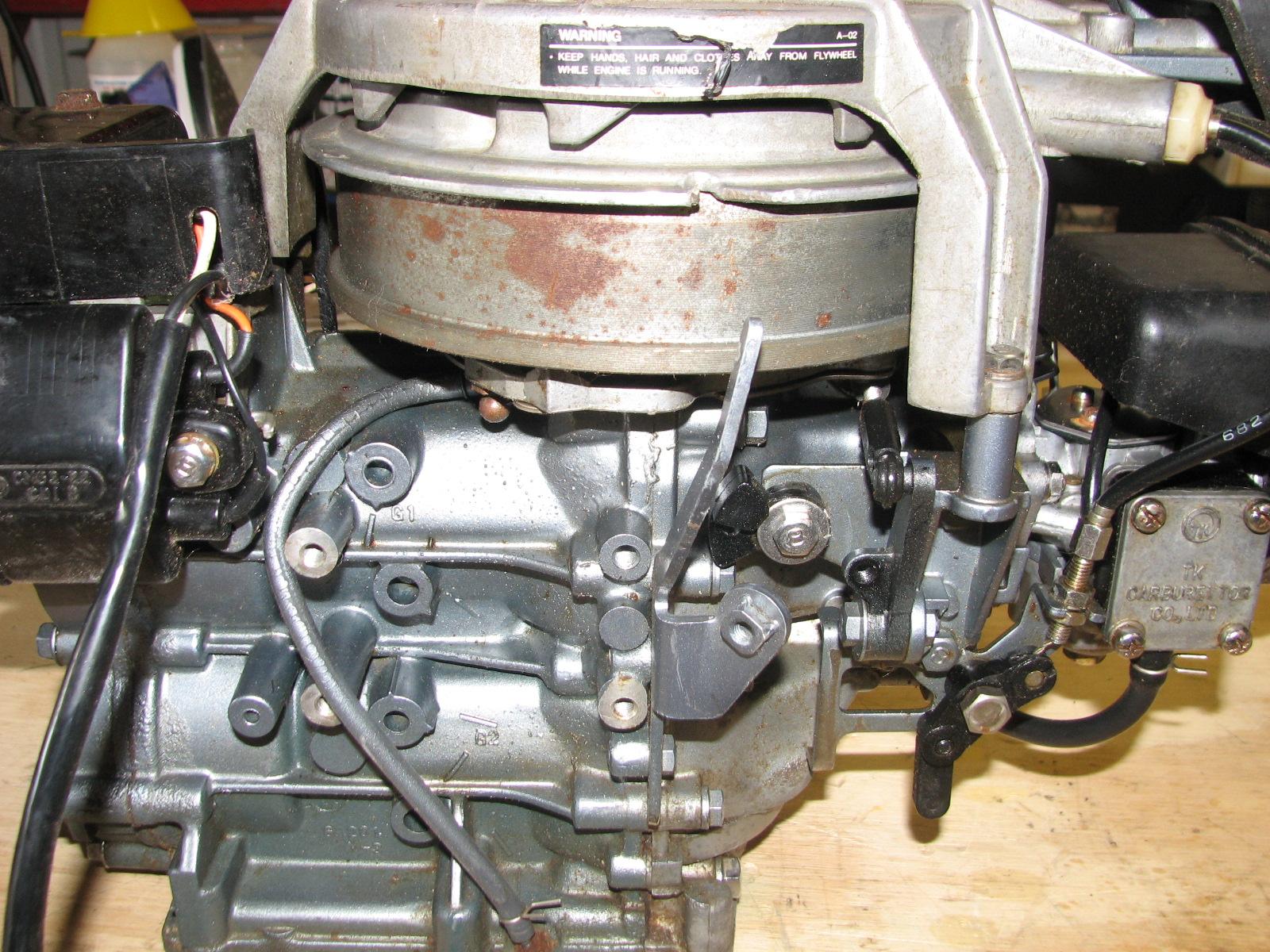

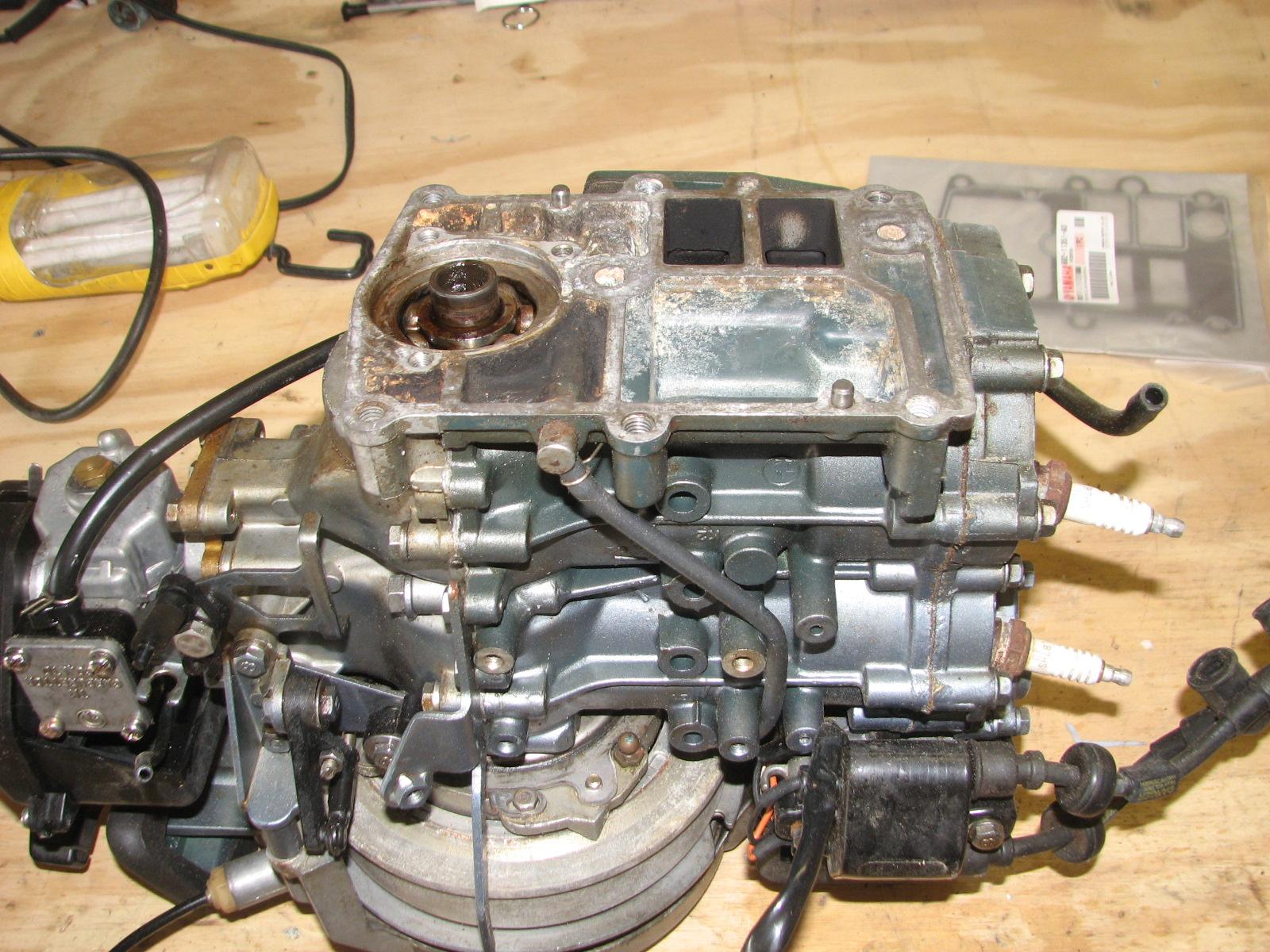

Before leaving the

shop,

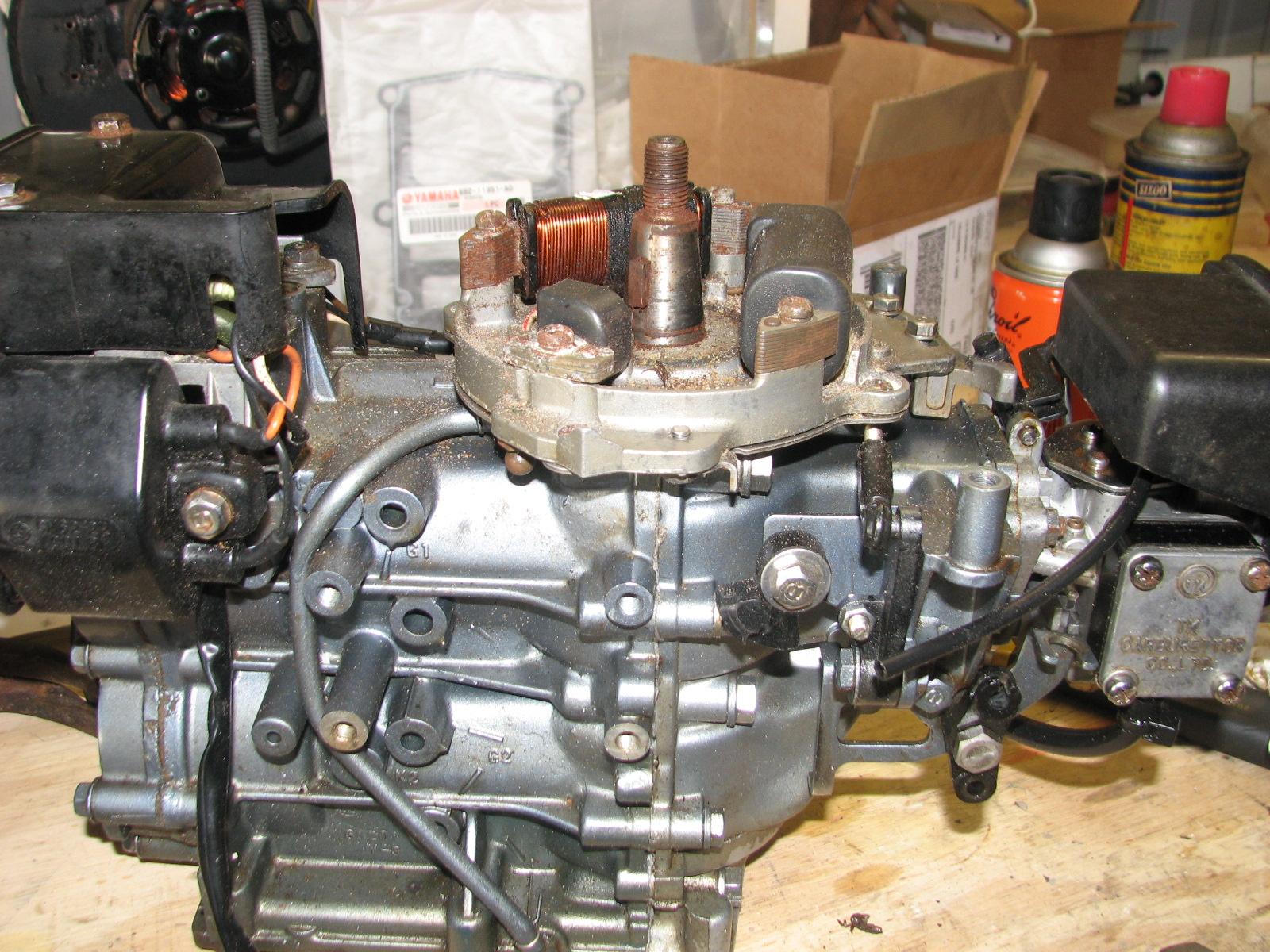

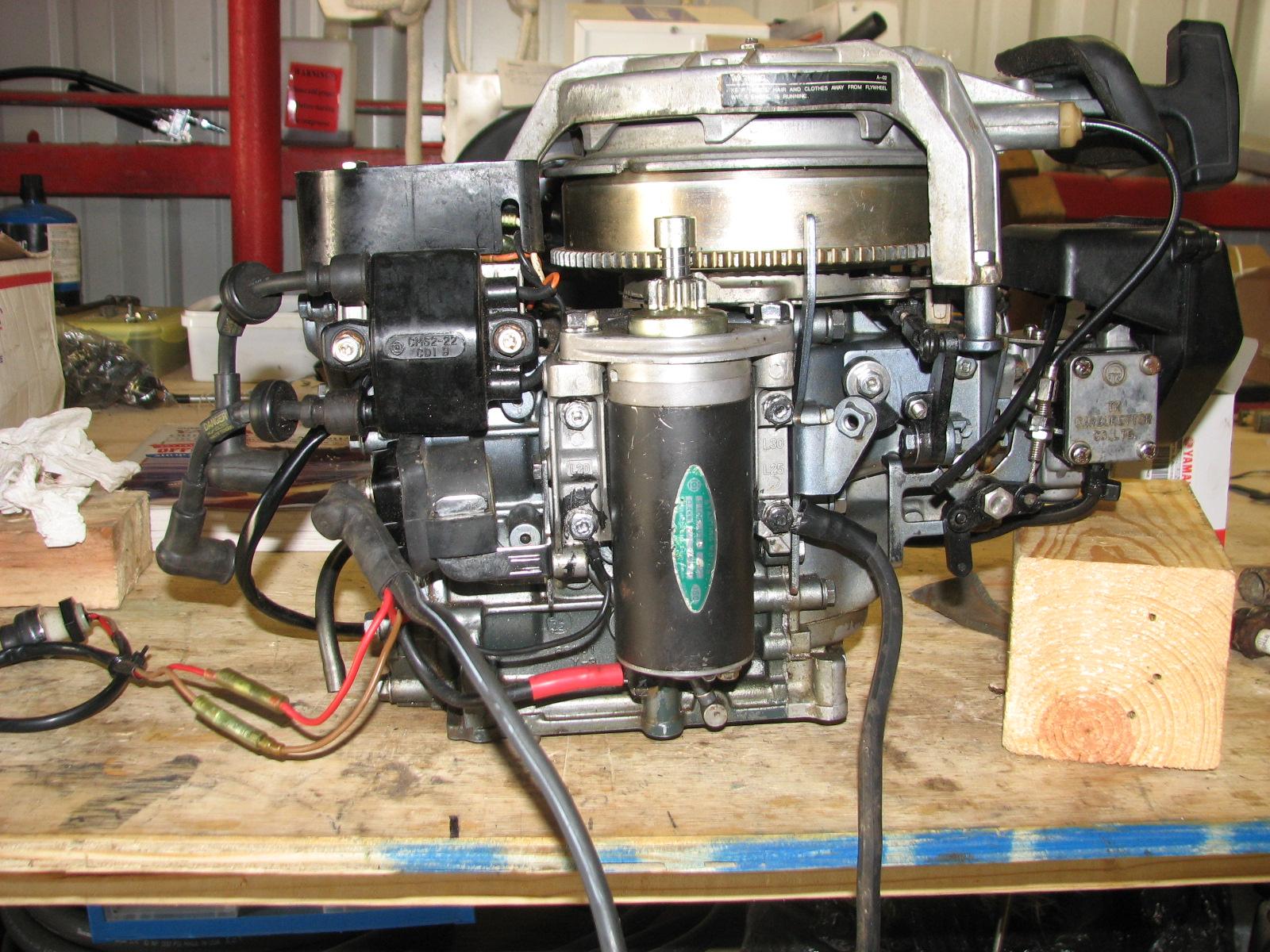

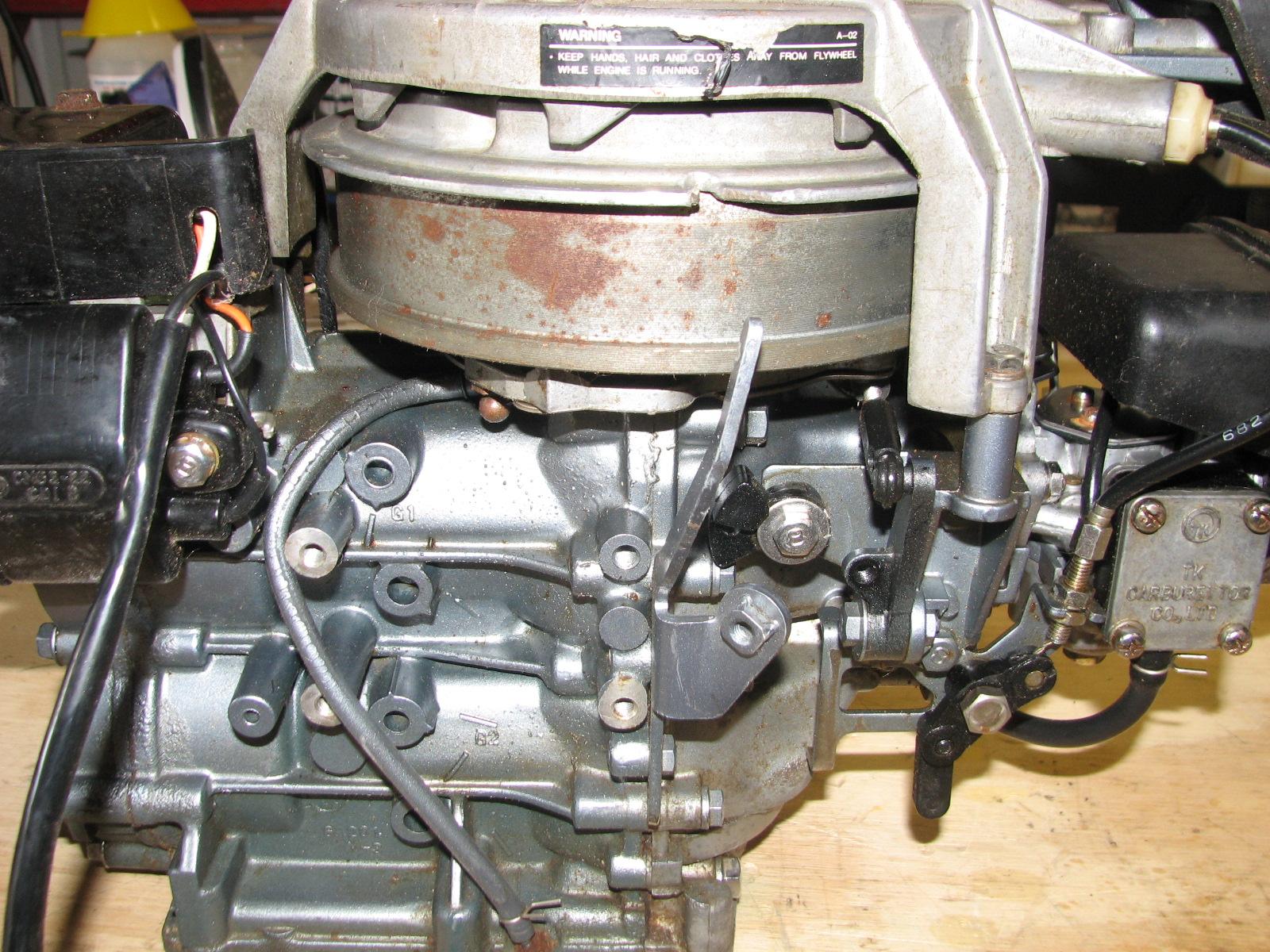

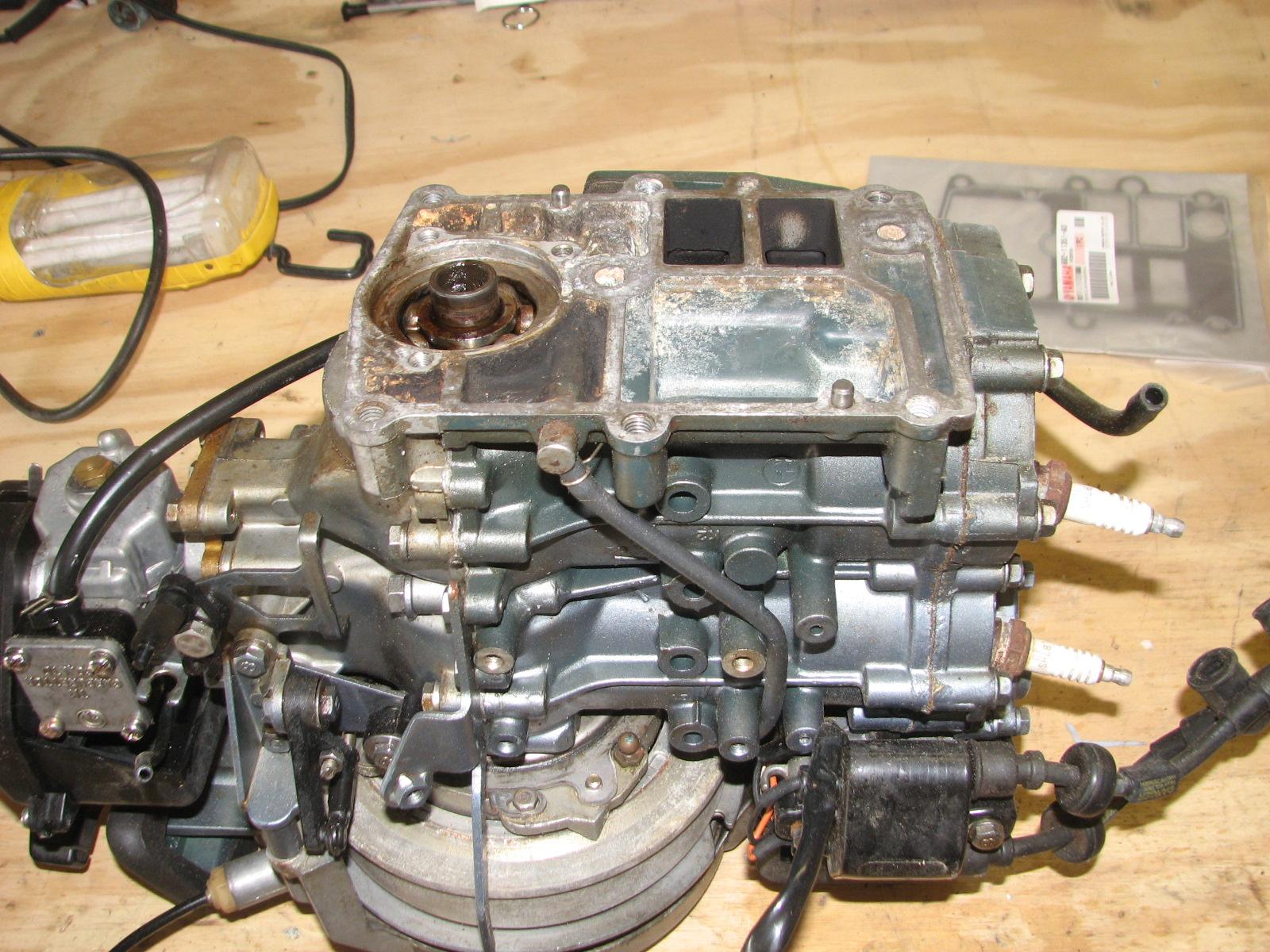

I took a couple of pictures of Mark’s diesel engine that is in the

shop

along with a bunch of parts he ghad stripped from the engine.

Engine From The Back

Engine From The Front

Parts Removed From

Engine

Went over to DREAM

AWAY, and fitted the shelf under the stove in the galley.

Went back into spring

cleaning mode. I cleaned the pot and pan storage area under the

microwave in the galley. Took the doors from the aft cabin, and the

door from the main cabin to the mid cabin out on deck and washed and

rinsed them.

I then cleaned the head

and the storage area under the head sink. When that was finished the

doors on deck were dry, so I put them back in their respective door

jams!

I went back over to the

shop

and applied the first coat of varnish to the Panduit

wiring duct covers.

It was then back to

DREAM AWAY for a shower and adult beverages!

June 27, Thursday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Mark and I drove into

Abbeville to get parts and wood for Mark and his engine project. The

plywood and 4X4’s Mark purchased was to support the engine hoist in

the main cabin of PERELANDRA, and to spread the load of the weight of

the engine. Returned to the marina,

dropped off Mark and his wood, and I went over to the shop.

I removed the old power

and electronic controls from the spare air conditioner, and

reinstalled the original power and electronic controls. I also got

the pump connected all but one hose, which I will get later.

Long story here, but I

could just cut off a short piece of the ¾” hose I have. My plan

though, is to use that long piece of ¾” hose to run from the raw

water washdown pump on DREAM AWAY to the raw water outlet on deck at

the bow. I already have a hose run, but it has been cut into for

fittings that are not needed now. That piece I want to remove from

DREAM AWAY, and I will use that short piece for the air conditioner

test.

I got all of the

electrics and electronics connected except for the blower motor. I

did not have two butt connectors. I powered it on and the unit

started to cool. With no water to cool the unit, I shut it off, as I

did not want to cause another problem.

Spare Air Conditioner

Connected Up

Knew I was going to be

using the tender today to move PERELANDRA to and from the shrimp

dock, so I cleaned out the fuel filter on the tender fuel tank.

Fuel Filter Before

Cleaning

Cut the teak wood tape

for the two Panduit

wiring duct covers I brought over to the shop yesterday. I then used

the iron, and ironed the teak wood tape onto the Panduit

wiring duct covers.

Teak Wood Tape Cut For

The Panduit

Wiring Duct Covers

Teak Wood Tape Applied

On The Panduit

Wiring Duct Covers

Loaded Troys wood into

the Black Beast, then went back to the marina.

I put Troys wood out in the sun on DREAM AWAY.

I then went into spring

cleaning mode and finished cleaning under the galley sink and the

galley stove. While under the galley sink, I also exercised the

seacocks located there.

Under The Galley Sink

I took measurements for

a shelf in the area under the galley stove. We need a shelf there to

keep some of the large pans and the waffle iron from sliding down the

hull every time you remove something in front.

The remainder of the

day was spent helping Mark get the engine out of his boat. I was

deeply involved, so was not able to take any pictures.

We used the tender as a

tug, and moved PERELANDRA to the public dock in Delcambre. Mark had

arranged to have Mike From Leblanc Oil come to the dock with his

forklift. Mike drove the end of the attachment on the forklift into

the main cabin of PERELANDRA. We attached the engine (short block) to

a shackle on the fork lift. Mike very carefully lifted the engine,

and the backed it out of the main cabin on PERELANDRA.

When the engine was on

the dock, Mike walked back to Leblanc Oil. ark drove the forklift

over to the shop,

and we put the engine in the back entrance to the shop.

Mark drove the forklift back to Leblanc Oil, and the came back to

PERELANDRA. We used the tender again and got PERELANDRA from the

public dock back to her slip on Pier “C” at the marina.

Mark cleaned up the

inside of PERELANDRA to get it back to a live aboard boat again. His

work was cut out for him. Good for him that I had the shop

available for him to use to rebuild his engine.

June 26, Wednesday,

2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went to shop

with my digital DVM. Measured the input AC, and it seems good.

Something must be different in the controls from the failed AC to the

controls from the spare AC. Will have to do the exchange of all of

the electrical controls.

Sanded the teak board I

epoxied to use to cover the holes in the aft cabin. Needed to mix

another batch of epoxy but the can of hardener was empty. I have a

new can of hardener, but I could not get the pump out of the old can

to put in the new can. I ended up destroying the old pump, so will

have to purchase a new pump before I can mix any more epoxy.

Took most of Troy’s

wood over to DREAM AWAY to sit out in the sun. This will accelerate

the drying process.

Took eight doors from

the aft cabin, galley and head outside on deck and washed them down

with soap, water and high pressure water. Left them out in the sun to

dry.

Performed the spring

cleaning on the aft cabin. Removed two Panduit

wiring duct covers to take to the shop,

and glue on the teak tape.

Got on the computer and

finally caught up on emails!

June 25, Tuesday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went to the shop,

and got to work on the spare air conditioner. Got the blower

connected, and applied power to the unit, but it would not power up!

Very disappointing. I was hoping the controls out of the failed unit

would work on the newer unit. I will have to bring over my digital

VOM to verify the power.

Worked on the epoxied

teak I will be using to cover the davit holes in the aft cabin. Mixed

up a batch of epoxy and filled in any gaps in the teak that I had

missed yesterday.

Teak Piece To Cover

Davit Hole In Aft Cabin

I applied another of

Watco

teak treatment to the backside of Troy’s wood.

Went back to DREAM AWAY

to work on the fresh water pump. The pump in the system was leaking,

so I had to install one of the spare pumps. I carry two spare fresh

water pumps, so I am pretty covered!

Freshwater Pump Removed

From System

Leaking Pump Removed

From System

Spare Freshwater Pump

Installed Into System

Spent the remainder of

the day spring cleaning the galley.

June 24, Monday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Started fabrication of

a piece of wood to use to cover the holes left by the davit

installation in the aft cabin. I am using several pieces of teak wood

that was removed from the deck of DREAM AWAY many years ago. I lay

all of the pieces on a flat surface, apply mixed epoxy to all the

edges, and then clamp them all together.

Teak Wood Strips

Clamped And Epoxied Together

Worked on getting all

the necessary connectors on the water pump and the spare air

conditioner so it can be tested properly.

Water Pump And Spare

Air Conditioner

Went back to DREAM

AWAY, took a shower. Kitty was packed, so we loaded up and I drove

her to New Orleans so she could catch a flight to go visit friend

Kathy. I returned back to DREAM AWAY arriving well after dark.

June 23, Sunday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee. Alan left this

morning to go back home to Houston.

Went over to the shop

and added more tension on the puller attached to the flywheel of the

spare yamaha. Smacked the puller with a hammer, and the flywheel came

off! I removed the flywheel and the magneto under the flywheel. Now I

had the power head ready to go the machine shop.

I put the first and

second coat of Watco

teak oil finish on back

side of Troy’s wood.

Worked on old air

conditioner to remove parts off of the drip pan. Getting the drip pan

ready to send to Stacy’s friend to fabricate a new drip pan out of

stainless steel for the spare air conditioner.

Took outboard off of

tender and put on DREAM AWAY. Pulled tender out of water and washed

down the exterior and bottom of the tender. Also cleaned up all of

the stainless steel rails and fittings on the exterior. When

finished, I put the tender back on the davits.

June 22, Saturday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went over to shop

and checked the puller on the flywheel of the spare outboard engine,

it had not come loose. We applied some more Aero

Kroil, tightened the bolts

a bit more, and tapped the puller with a hammer. The flywheel

remained fixed. We then set the power head aside. A few times during

the day we would tap the puller with a hammer, and tighten up the

bolts from the puller to the flywheel. When we left at the end of the

day, the flywheel remained fixed.

We then started in on

the main outboard engine. As mentioned yesterday, we had an almost

complete engine. All that remained was putting the lower

drive on the engine, which

we did.

I also took pictures of

the new serial numbers, and engine type since I used parts from a 9.9

HP outboard. It is still a 15 HP, it will be listed as a 9.9 HP.

New Serial Numbers And

Engine Model And Year

The model I created

with all of the new parts is:

15 ELG

15 = horsepower

E = Electric Start

L = 20"

G = 1988

The parts I used for

most of the upgrades is:

9.9 MLHP

9.9 = horsepower

M = Manual Tilt Manual

Start

L = 20" (Long

Shaft)

H = Tiller

P = 1991

Complete Engine Ready

For Use

We loaded the complete

engine with the battery and the fuel tank into the Black Beast and

went back to DREAM AWAY. We lowered the tender into the water from

the davits, and then put the “new” long shaft 15 HP motor on the

back of the tender.

We put the battery into

the tender and connected it to the motor. We also connected the fuel

tank that had very fresh gas in it with no alcohol in it. I tried to

start the engine manually and with the electric start, but no go!

Then I remembered I did not have the dead-man switch activated. I

attached the dead man switch, and the engine started right up with

the electric start. I also tried the manual start and that worked

also.

It was so great to

finally have the long shaft motor running. I had been saving parts

off of eBay

for over two years to get this accomplished. That was the good news.

The bad news is there is no water running out of the Pee tube. This

means the water pump is not working.

I decided rather than

try to take the motor apart on the dock, we off loaded the motor from

the tender and took the motor back to the shop

in the Black Beast.

We took the lower

drive off the motor. That

is when I discovered I had not aligned the water tube coming out of

the water pump up to the power head. We put the lower

drive back on the motor

being very careful to get the proper alignment of the water tube.

We took the motor back

to DREAM AWAY, put the motor on the tender and started it up. We had

water pumping out of the Pee tube! What a relief. Alan and I took the

tender down the channel and when we were past the docked the shrimp

boats, I opened it up. Right up on a plane with both Alan and I in

the boat.

We went back to DREAM

AWAY and got Kitty in the tender. Did the same trip again, and when

the tender got up on a plane there was some cavitating. I adjusted

the angle of the motor in relation to the transom of the tender. Went

down for another ride, and it was almost perfect. I finally can get

the tender up on a plane with three people in the tender.

We took the tender back

to DREAM AWAY, and locked it to the dock. We took showers and had an

adult beverage in celebration.

June 21, Friday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Alan and I had our

coffee, and then went over to the shop to get started on the outboard

engines again. We put together the puller with the proper bolts and

bolted it to the flywheel on the spare engine.

As noted previously, I

was trying to strip all of the parts off of the spare power head

which included the flywheel and the magneto under the flywheel. I

also had to remove the flywheel off of the main outboard so I could

install the electric start kit I had purchased for Kitty. For the

electric starter to function, I had to install a new flywheel.

We put the puller on

the flywheel of the spare engine, and attempted to pop off the

flywheel. We used muscle, a small hammer and liberal application of

Aero

Kroil. It was not going to

work, as hard as we tried.

Well we went to plan

“B”. We removed the puller from the spare flywheel, and attached

it to the main flywheel. We applied some Aero

Kroil, and then tightened

down on the puller. After a few minutes of applying pressure, the

flywheel popped off!

Old Flywheel With

Puller Attached Beside New Electric Start Flywheel

Main Power Head with

Flywheel Removed

We now knew the puller

actually worked as designed. We put the puller back on the spare

engine flywheel, and tightened up the puller as much as we thought

reasonable. We applied some Aero

Kroil, and then set the

power head aside. A few times during the day we would tap the puller

with a hammer, and tighten up the bolts from the puller to the

flywheel

Now we could get

serious about putting the main outboard engine back together,

starting with the power head back. We installed the new flywheel and

the starter. We also installed the manual start mechanism just in

case!

Power Head With Starter

Installed

When the power head was

complete, it had to be mated with the bottom

cowling. We did all of this

using never seize with all of the bolts. We also had to clean the

bolts, and some of the parts as we went along.

Alan Working On Tiller

Control

June 20, Thursday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Alan and I went to the

shop

and worked on the two outboard engines. While Alan and I were getting

all of the parts for each engine straightened out, we started putting

the main outboard back together. Kitty went and purchased the

required bolts to use my puller on the outboard flywheels, and also a

tube of never seize.

I wiped down all of

Troy’s wood, and put them outside in the sun to dry. I applied a

coat of Watco

on the cockpit hatch, and also put it outside to dry.

Wood Parts Outside To

Dry

Wood Parts Outside To

Dry

When Kitty came back to

the shop with the bolts and never seize, Alan and I had to regroup! I

decided I wanted to apply never seize to all of the bolts on the

parts we had already put together on the main outboard. So now we

took apart the bracket

assembly and put it all

back together with never seize.

June 19, Wednesday,

2013

Alan and I got up, had

coffee, and hit the road, with a breakfast stop at a Whataburger.

We drove up to Porter,

Texas, to Diamond

Composite Structures. The

man running the company, Vince Pena, remembered me from previous

purchases. I purchased some pieces of the ¾” plate fiberglass for

the hard dodger, and the main mast step. I also purchased fiberglass

grating to replace the teak wood on the anchor area and the seat in

the bow pulpit.

I asked vince about

fiberglass rod of very small size that I am thing about using for

security on the hatches on DREAM AWAY. He had a pile of carbon

fiber tubes that he had

used for arrows. I felt this would be perfect, because of the

strength. He just gave me about 20 of the tubes!

We got all of the

fiberglass parts loaded in Alan’s little FIAT

500, and

drove back to

Delcambre. When we got to Delcambre we unloaded his car and headed to

DREAM AWAY.

June 18, Tuesday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

The folks off of the

cruising boat that came in from Texas this past Saturday, Sammy and

Dick, were heading back to League City today. My friend Alan was

coming over from League City to visit for a couple of days, and I

needed some structural fiberglass from Diamond

Composite Structures.

I made arrangements

with Sammy and Dick to ride over to League City with them. I made

arrangements with Alan to spend the night with him, and then on

Wednesday drive up to Diamond

Composite Structures in

Porter, Texas, on our way to Delcambre.

The plan worked! Sammy

and Dick dropped me off at the West Marine in League City, and Alan

picked me up there. We went to Alan’s apartment, and I worked on

his two computers to get them back up and functional. Alan and I had

dinner and a couple of adult beverages, and hit the sack.

June 17, Monday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Had to run errands in

Abbeville, so I took my spare Yamaha power head along to stop at an

outboard shop. We stopped at a shop in Erath, and the owner told me

he did not drill out and install helicoils.

I would have to take the power head to a machine shop. He recommended

a shop in Abbeville.

We finished up our

shopping errands, and then went to the machine shop. I told to one of

the technicians there, and he told me he could do the job, but I

would have to strip all of the parts off of the power head. Now I had

another project.

We went back to

Delcambre, and I went to the shop to strip all of the parts off of

the power head. I took many photos, so hopefully when the time comes,

I will be able to get all of the parts back on the power head.

Power Head Before Parts

Removal

I got all of the parts

stripped from the power head except the flywheel. Of course I did not

have the required bolts for my puller. As it turned out I needed 2 ½”

long 5 mm metric bolts.

I got the new tube of

BoatLIFE

LifeSeal, and I finished

applying it to the cockpit hatch.

Went back to DREAM AWAY

to look for the required bolts, but of course did not have them.

I did call Boats.net,

and talked to a person in the parts department. The o-ring I needed

was listed as obsolete, but they had 15 in stock. I order three of

them. One for my main outboard, one for the spare outboard, and of

course a spare just to have!

June 16, Sunday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Spent a lazy day on

fathers day. Worked on the computer trying to catch up, and spent

time just reading. Kitty and I talked over our future plans, and

pretty much decided to not stick to a hard a fast date to leave

Delcambre. When I feel comfortable with DREAM AWAY, we will continue

our cruise.

Since it was Fathers

Day, Kitty asked me what I would like for a treat. I told her I would

like her very good rum cake. She made me a rum cake, and we both

enjoyed snacking on it and for dessert!

Finished Rum Cake

Pouring On The Rum

Sauce

June 15, Saturday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Started to work on

getting the outboard motor back together. I had all of the parts to

build a stock long shaft motor. When I went to put the oil

seal housing (use link to

my own pdf file) back on the engine, I realized I did not have an

o-ring that was required. I then went through all of the parts and

gaskets on hand to verify I did have all of the necessary parts,

except one!

Later in the day, when

I went back to DREAM AWAY, I looked on my parts list and got the

necessary part number. I then went on the Internet, to Boats.net,

and discovered the part number is obsolete. This will take more

investigation!

Bottom Of Motor Where

Oil Seal Housing Attaches

Original And New Oil

Seal Housing

Went back over to the

marina

to welcome two cruising boats into Delcambre. One boat was from

Texas, and the other boat was from Franklin, Louisiana.

Texas Cruisers Welcomed

Into North

Pier Marina

Louisiana Cruisers

Welcomed Into North

Pier Marina

June 14, Friday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went over to the shop

and started in on Troy’s wood. Did the final sanding on all of the

pieces. Arranged all of the pieces so that I could get to them and

apply the Watco

teak oil finish. I wiped

all of the pieces down with a tack

rag, and then applied the

first and second coat of the Watco

teak oil finish.

June 13, Thursday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went over to the shop

and spent a couple of hours working on Troys wood. He had two fishing

pole hangers that really took a lot of time to sand out. Lots of

holes and curves!

Applied the BoatLIFE

LifeSeal to the masked off

cockpit hatch. Could not do the complete hatch because the tube of

BoatLIFE

LifeSeal had

hardened at the bottom of the tube. Was able to return the tube for a

new one, but it delayed the completion of that part of the project.

Cockpit Hatch Waiting

For More BoatLIFE

LifeSeal

Went back to the

Marina,

and welcomed another cruiser to the dock.

New Cruiser Tied Up To

Pier C

June 12, Wednesday,

2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went to shop,

and straightened up all of the stuff we brought back from Atlanta,

and some other stuff I had acquired. Had to put it all away and out

of the way, to get the shop

back into full production.

Finished masking out

the cockpit hatch, so it is ready for the application of BoatLIFE

LifeSeal.

Went back to DREAM

AWAY, to have breakfast. After breakfast, I defrosted the freezer,

and cleaned up the condiment trays in the refrigerator.

Ice Scraped Off Of

Freezer Holding Plates In Freezer

Ice On Expansion Valves

Ice Removed From

Expansion Valves

When I finished

cleaning up from the defrosting project, went back to shop

and started sanding on Troys wood for his boat, and the teak pieces

for the navigation lights on the tender.

Troy’s Pieces Sanded

And Ready For Watco

Application

Went back to DREAM AWAY

and welcomed two transient boats to North

Pier Marina. When we got

the two boats all settled in and properly welcomed, I went to work on

the second router at the North

Pier Marina.

Welcome Transient

Boaters

Welcome Transient

Boaters

June 11, Tuesday 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went to shop

started masking top of cockpit hatch. Have to get the hatch masked

off so I can apply the BoatLIFE

LifeSeal between the teak

boards on top of the hatch

Hatch Partially Masked

Off

Chris And Sarah On

PENDANA

PENDANA Leaving the

Marina

I worked on marina

landscaping, weeding the gardens for about 30 minutes. The remainder

of the day was spent working on web page other computer activities.

Kitty and I attended

the monthly Port meeting that evening starting at 1800.

June 10, Monday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went over to the shop

and masked off the bottom of the cockpit hatch and the V-Berth insert

for the forward cabin. Did the preparatory sanding, and the the

wiping down with the tack

rag. I mixed up a batch of

the two part white paint from Guatemala, and applied a coat to the

cockpit hatch and the V-Berth insert.

Masked V-Berth Hatch

Painted V-Berth Insert

Masked Cockpit Hatch

Painted Cockpit Hatch

The remainder of the

day was spent taking Kitty to the doctors and the hospital for a

test, that did not work out as planned. On the way back from

Lafayette, we stopped and shopped for groceries.

June 9, Sunday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Spent the remainder of

the day working on the computer to catch up on email, maintenance

logs, and scanning in papers.

Kittie and Mark, on

PERELANDRA, left to start their trek to Florida.

PERELANDRA Leaving

North

Pier Marina

That was the good news

for them, and we will miss them. The bad news is they were back that

afternoon with a blown engine! They had proceeded about 20 miles down

the GIWW,

when the engine froze up! An initial diagnosis was that the number

six cylinder had overheated and froze. They had to be towed back to

North

Pier Marina. Needless to

say they are very down and disappointed. This will be an ongoing

issue.

June 8, Saturday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went over to the shop

and unloaded the Black Beast. We had brought some material and tools

from Atlanta to help with the ongoing projects on DREAM AWAY. I also

brought back some stuff that I am going to sell on eBay. I have been

meaning to do this for a long time but never got to it.

Sanded on bottom of

cockpit hatch to get it ready for paint. Also sanded on the V-Berth

filler brought back from Atlanta, and the tender navigation light

holder. The light holder really needed attention.

Sanding On Cockpit

Hatch

Sanded V-Berth Filler

One other group of

parts I brought from Atlanta was my exhaust elbow for the main

engine. When I had to replace the exhaust elbow several years ago, I

purchased all of the parts to have a spare (Overkill!!). When we left

Texas in 2009, I did not take the spare with me. It is four years

later, so I decided it would be a good idea to have the spare with

me.

I verified all of the

parts fit together and looked like it should when fitted to the

engine. I am considering welding the whole fitting together or

keeping the parts separate. If the parts are separate, they are much

easier to store, but then a far amount work ro put it together with

hi-temp pipe dope. If I weld the whole thing together, it is a bear

to find space for, but can be put in place with little effort. The

jury is still out.

Exhaust Elbow In Vice

DREAM AWAY Dressed

Ship

May

29, Wednesday, to June 7, Friday 2013

Went

on a driving trip from Delcambre, to Atlanta to visit with our

children. While in Atlanta, we drove to Tampa to visit family and to

attend my sisters memorial service. We came back to Atlanta, spent

more time with our children, then drove back to Delcambre.

Recording

Serial And Model Number Before Shipment