We did start the prop cleaning project

with Joel. It did not go well, but we are moving forward. Joel did

not have a BC, so we dug out mine under the aft bed.

June 22, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go over to the shop

today, but stayed on DREAM AWAY working on the computer and visiting

with Judy.

Made some good progress on the

Maintenance

Logs and email. Kitty, Judy and I had a good time

playing dice and card games.

Our friends, Cindy

and Johnal, stopped by for dinner on their way to

Houston. They are staying with their daughter for about a week, then

they will be heading to Montana to spend the summer. They will start

cruising again in the fall, so we are hoping to meet up with them

again in the Florida Keys.

June 21, Saturday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the shop,

and the first thing on the list was to unpack my new Ridgid

WD1450 wet/dry vac for the shop. I got it all

unpacked, set up and turned it on! It was wonderful, I was able to

vacuum the shop. The only disappointment was the canister filter from

the old vacuum was not the same size, so I was not able to salvage a

lot from the old vac.

Inside Of Old Vacuum

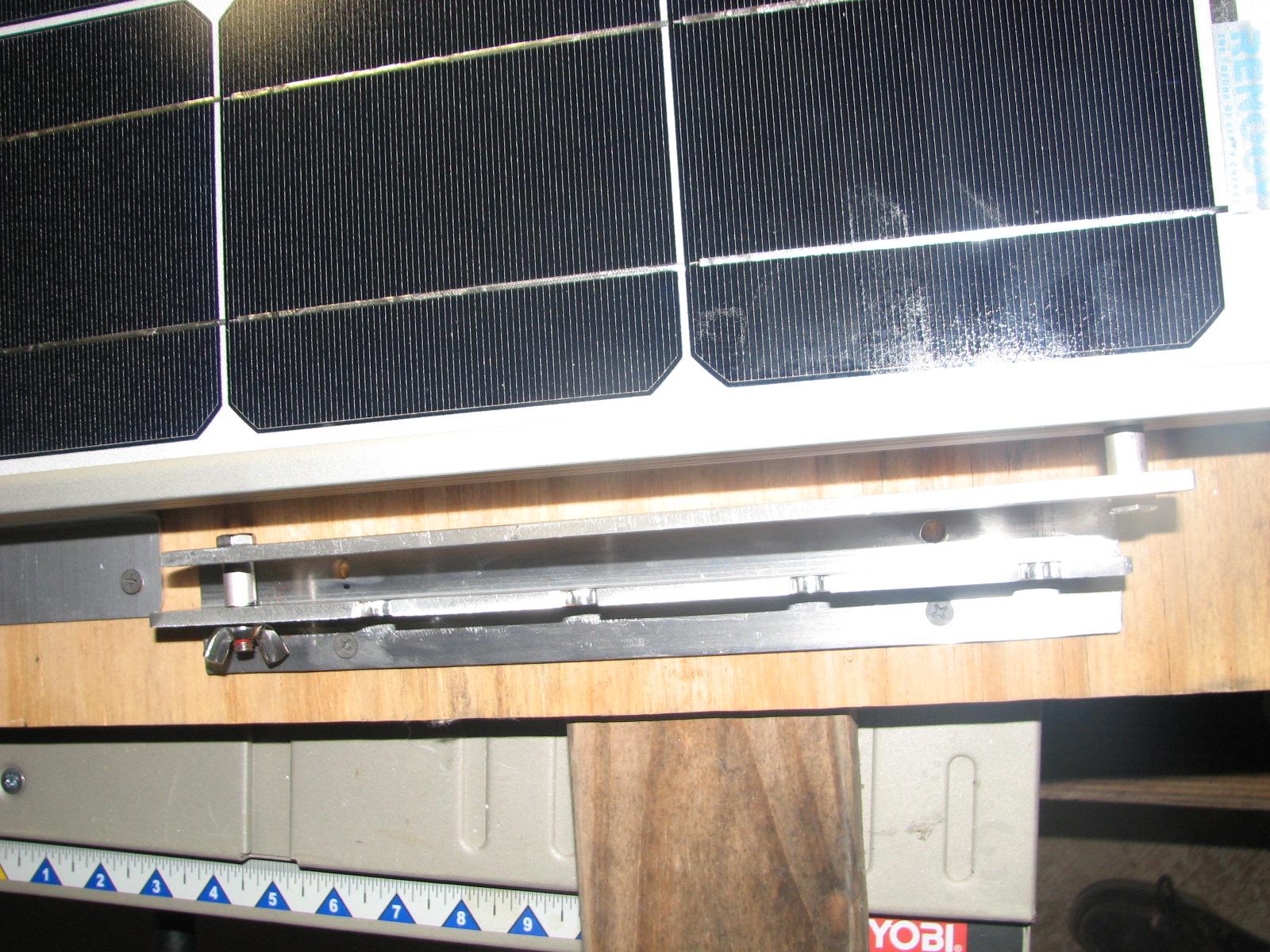

Now it was time to get busy with the

mockup of the installation I am planning with one of the four Renegy

100 watt solar panels I had purchased. This is a

mockup of how the panel will be installed on top of the hard

Bimini.

I have built risers for each panel so I could angle the solar panels

more towards the sun as the day progresses.

I built the risers not knowing if they

would actually work, so I thought I would test four of the risers on

one of the solar panels. The first thing I had to do was drill a hole

in the solar panel frame at each corner. I was surprised at how well

the panel is constructed.

After the holes were drilled I attached

the leg of a riser to the panel.

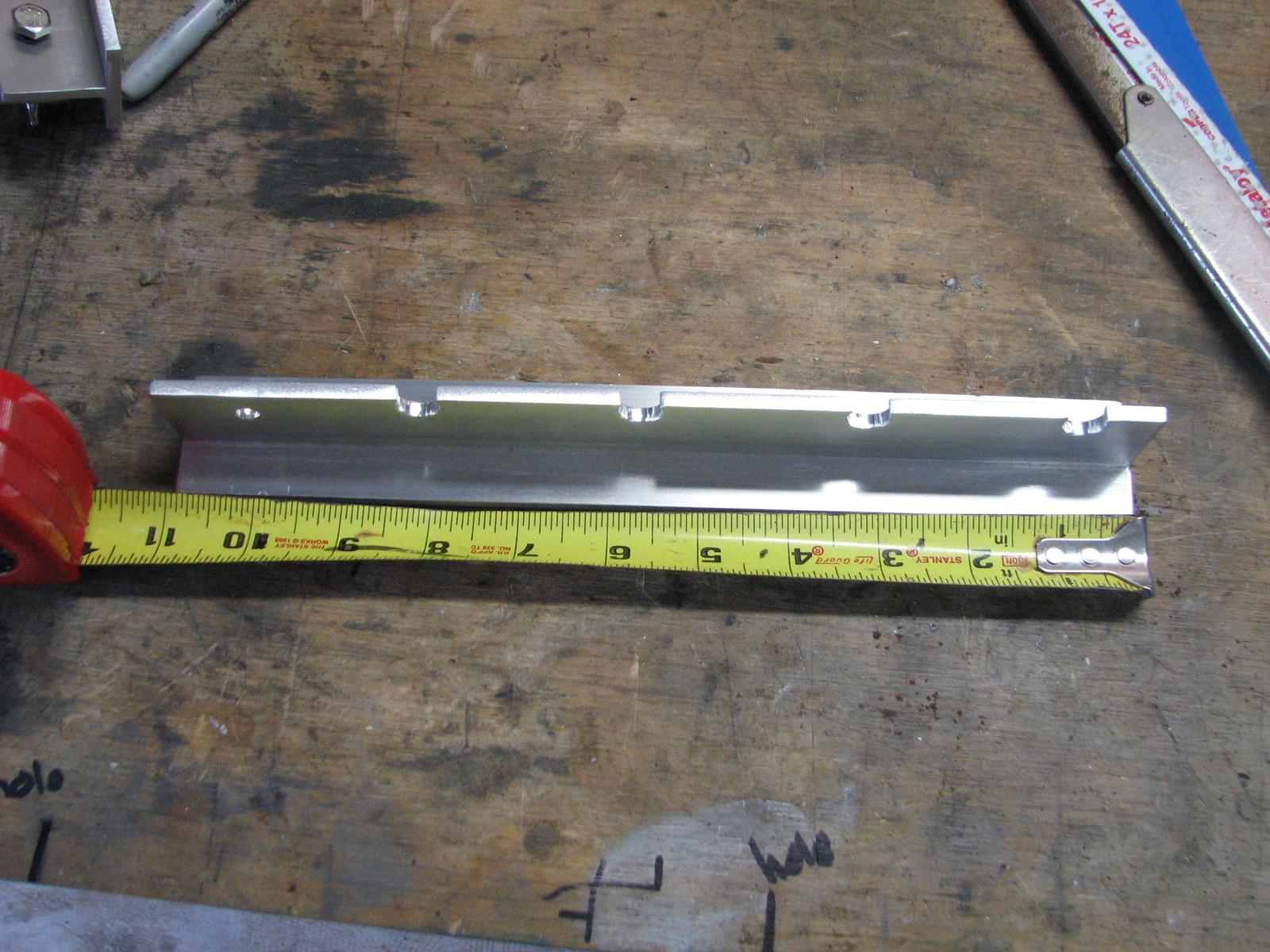

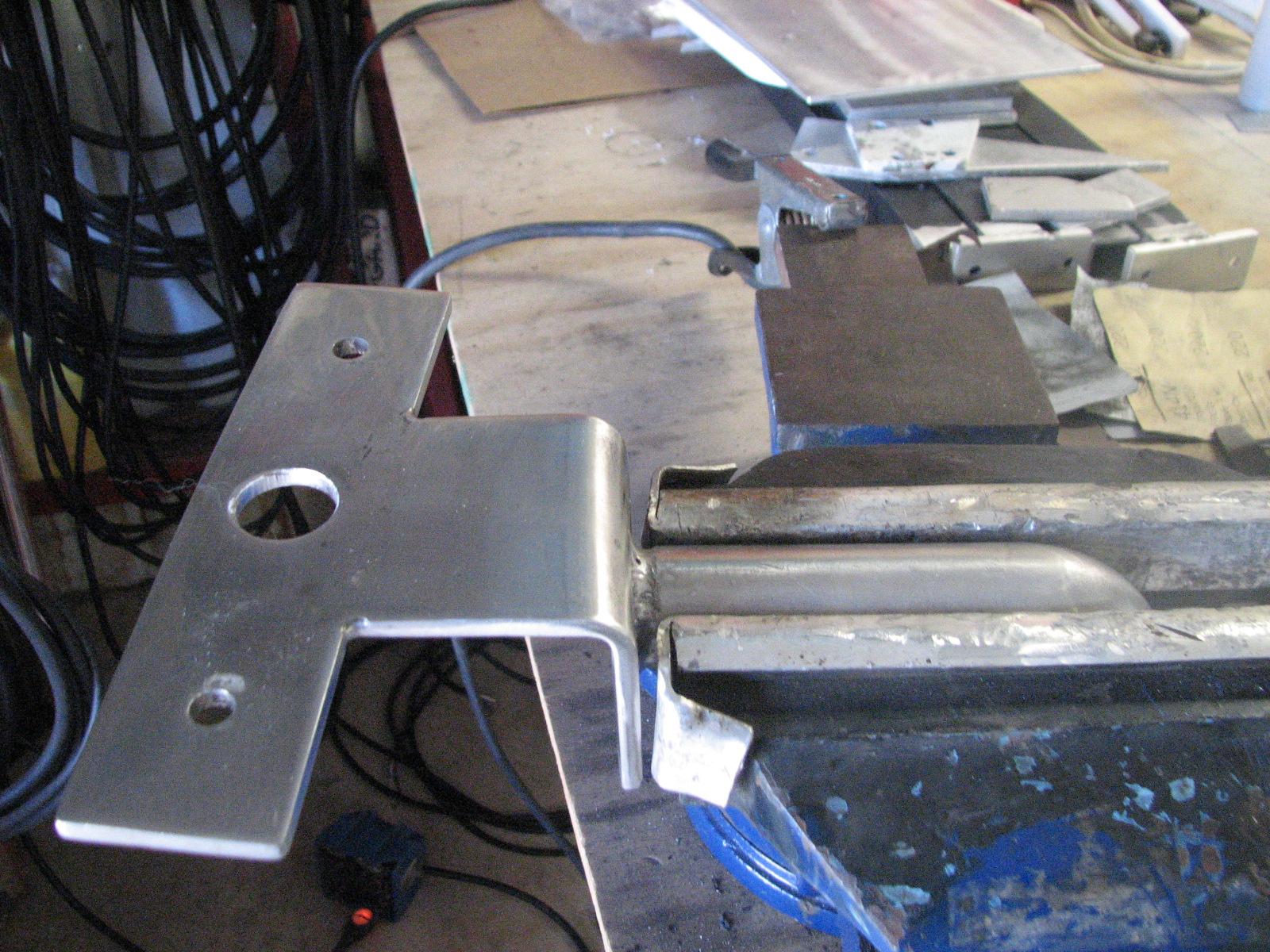

Riser Leg With Riser Base Attached To

The Solar Panel

When I got the riser legs attached to

all four corners of the panel, I moved the panel to my piece of

plywood with the Z

brackets already screwed down to the plywood. When I

had the solar panel fitted into the Z

brackets, I aligned the riser bases on the plywood,

and screwed them to the plywood.

Now came the test to see if the riser

would actually do the job. I did a test, and the theory is good. The

only issue is the spacer on the bolt that attaches the riser to the

solar panel frame. The spacer needs to be longer so I can remove the

bolt that attaches the riser to the riser base. I cut some longer

spacers, but did not have the longer bolts with me.

Riser On Solar Panel At Highest

Position

Static Riser On Left, Raised Riser On

Right

Another View Of Riser Mock Up

I finished cleaning up , and went back

to DREAM AWAY. The remainder of the day was spent with Judy, and

making a lazy day for Kitty. It was her 70th birthday, so she

deserved some time off. It was a very relaxing day.

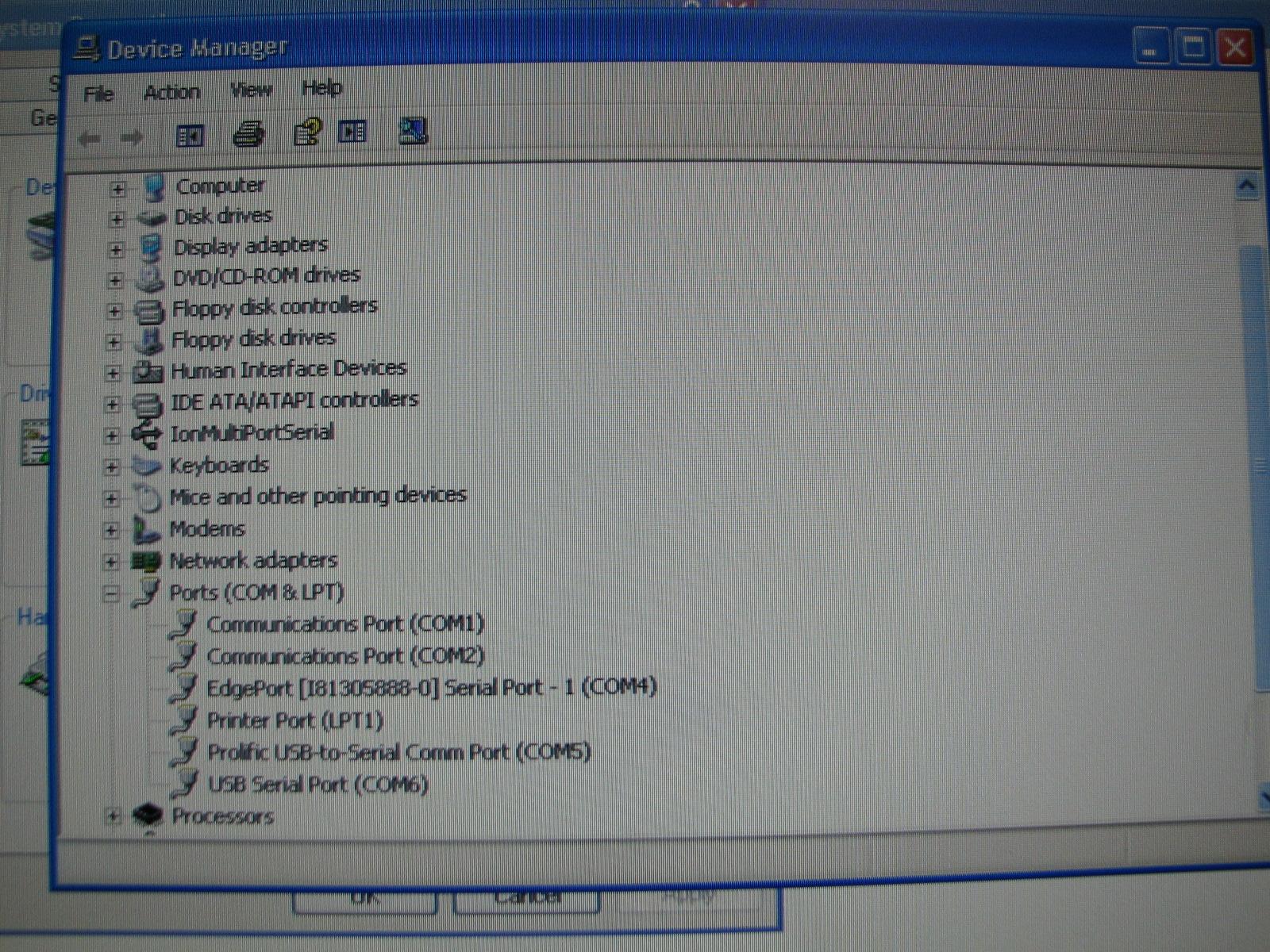

While Kitty and Judy were resting, I

was able to install the CAPN

software on my virtual Windows XP operating system on the PC with the

host OS of Linux

Mint. I was able to get the GPS info to the CAPN,

so I was very pleased about that. Still more work to do, but I am

making progress!

Screenshot Of Windows XP And Status Of

COM Ports

June 20, Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go over to the shop,

but stayed on DREAM AWAY, and worked on the Maintenance

Logs and email.

After breakfast we headed to the

Lafayette

to pick up Judy, our daughter, who will be staying with us for a few

days. After picking her up we ran a bunch of errands. One of which

was stopping at Home Depot to purchase a wet-dry vac for the shop.

This was my birthday present! Today I hit the big seven oh!!

We finally all arrived back on DREAM

AWAY around 1700. We settled in and had a great steak dinner with

corn on the cob, and rum cake for dessert! We all were able to sit in

the cockpit, enjoy a Rum Wookie, and I had a cigar. My first one in

about a year!

It was a good day, and it was great to

see Judy again.

June 19, Thursday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

I went over to the shop

and started in on a test of the solar panel risers. There is nothing

more I can do about the stern ladder until I can get the first step

tack welded onto the ladder. That means I need time and no wind in

the morning to do the setup.

So my thought is to set up a solar

panel on a spare piece of plywood in the shop, and actually test out

my plan for the risers I had fabricated for the solar panels.

Before I got seriously into the solar

panel project, I finished up cleaning all of the fasteners that I

will be using to attach the hard dodger top to the frame. Hopefully I

will be able to get most of that completed today.

Fasteners All Clean And Ready To Go

OK, back to the present. First thing I

did was use the Z

brackets that came with the solar panel system to lift

the solar panel off of the mounting surface.

When I do a dry fit of my risers, I

realize I must drill mounting holes in the base of the risers to

attach the risers to the mounting surface. I do some measuring, and

then center punch where the holes must be placed and drill the holes

into four of the riser bases.

Using Drill Press To Drill Holes Into

Riser Base

When I finished drilling the holes in

the riser bases, I realized I did not have the additional fasteners

to attach the riser to the solar panel frame. Because I did not have

the fasteners, I was not willing to drill the necessary holes in the

solar panel frame until I have the fasteners on hand.

Setting Up Risers On Solar Panels

Setting Up Risers On Solar Panels

Kitty called to say she was awake, so I

headed over to DREAM AWAY to have breakfast. After breakfast, Kitty

drove into

New Iberia to drop off laundry, and run a few errands.

I started in on the top installation on

the hard dodger. Right away I realized I needed a sander and some

clamps that were over in the shop,

and got my milk crate with three sanders in it and four of my clamps.

I headed back to DREAM AWAY to get started on the top installation.

I had previously fitted the pieces of

Starboard

to the frame so there was almost no issue there. I did find one

problem, and on the starboard side I had to sand down one of the

uprights of the hard dodger. When I had sanded down the upright, it

was time to clamp down the piece of Starboard

to the starboard side.

I am using the 10 X 32 X 1 ½” bolts

from the old hard

Bimini

to bolt down the top to the frame. The hard dodger frame is stainless

steel, so the drilling and tapping is a bit more time consuming.

The process is to drill a hole in the

Starboard

that has clearance for the bolt. When that bit notches the stainless

steel frame, I change to a smaller bit to drill through the stainless

steel. After I make the hole I use a 10 X 32 tap to make the threads.

Captain Drilling The Holes

While I was tapping out the second hole

in the frame, the tap broke! I called Kitty and asked her to stop by

Lowe’s and pick up two of the taps. While waiting

for Kitty to come back from running her errands, and bringing my new

taps, I worked in the marina

gardens.

When Kitty returned, she told me that

Lowe’s

did not have the taps, and she ended up purchasing the two taps at

LeBlanc Oil here in Delcambre.

That was the first place I called when I broke the tap! Oh well!

I now had a new tap so I got back to

installing the starboard side top on the hard dodger. I finally

completed the starboard side.

Equipment Necessary To Drill And Tap A

Few Holes

Equipment Necessary To Drill And Tap A

Few Holes

While I was working on the hard dodger

tops, Kitty was down below on the phone getting the second

transmission coordinated to be sent to Norman’s. Hopefully this

will be the one that work’s!

Kitty Hard At It On The Phone

Now I started on the port side top. I

got it all set up, but was not able to clamp it down anywhere. I got

Kitty to come out and hold the top in place while I drilled and

tapped two holes. Once the two holes were completed and the fasteners

installed, The port piece of Starboard

was secure, and I was able to continue on without Kitty’s help.

I was not able to complete the port

side of the top, as I simply ran out of time. By the time I got all

of the tools put away it was 1800. I will have to finish the port

side installation tomorrow or Saturday!

Port Side Top Of Hard Dodger

Starboard Side Top Of Hard Dodger

Underside Of Hard Dodger Top

I washed down DREAM AWAY, and then took

a shower myself. Today is a diet day, so no adult beverages!

June 18, Wednesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

At 0700, T-Boy, the dockmaster, picked

me up at the marina.

We drove down to Jeanerette,

Louisiana, to pick up some boards! We had a good sized trailer, and

we did not know how big the boards were, but we knew we were to pick

up 100 of them.

When we arrived at the proper location

we discovered the boards we were to pick up were 2” X 8” X 8’

treated lumber, and most of the boards were wet and heavy. We got the

100 boards loaded and brought back to a second store room right next

to the original Port

of Delcambre’s storage room. We unloaded the 100

boards into the second storage room, and I was back at the marina

by 0945.

In the meantime Kitty had gone into the

Iberia Medical Center to get her scheduled Reclast IV. This time it

went off without a hitch.

I went over to the shop

and picked up the three awnings for DREAM AWAY. They are not in the

best shape, but they will do until I get the time to fabricate new

one’s.

I was able to get all three awnings put

up on DREAM AWAY. Not only will this make it much cooler down below,

but I will be able to finish up the Hard Dodger, and Hard Bimini

in the shade.

When I had finished the awning

installation, Kitty had arrived home, so we had a late lunch. I took

a shower after lunch, and then spent the remainder of the day working

on my computer and scanning in documents.

June 17, Tuesday, 2014

Started off the morning with my normal

ritual of feeding our two cats,

Jillian

and Jordan.

Kitty and I had a doctor’s

appointment at 0700, so we left DREAM AWAY at 0645. Both our

appointments were at the dermatologist. Kitty was having a small cyst

removed from her face, and I was having two basal cell carcinomas

removed from my left arm.

While at the dermatologist’s, Kitty’s

blood pressure went sky high, so we went to the

Heart Hospital of

Lafayette’s emergency room. We got the situation under control, and

Kitty was released in the afternoon, and we went home and stopped at

the vegetable stand on the way!

Kitty is back on blood pressure

medicine, and has an appointment with her cardiologist next week.

Kitty was feeling much better, so she

accompanied me to Auto Go transmission in Abbeville.

I wanted to have a real transmission man check the problem I am

having with the new transmission I had put into

Ruby.

Jim and Jerry, of Auto Go Transmission,

took Ruby

out for a road test, and confirmed my suspicions. There is a bad

bearing in the transmission, and needs to be replaced.

More delays, more fun and more expense!

I called Norman at Norman’s Auto Diesel, and he agreed to do the

transmission again. I called Smart

Parts Automotive and told them about the problem.

I talked with Jeff, he said he would

call the guys at Auto Go Transmission, and then get back to me

tomorrow. He also said he would check the status of my core. Based on

previous promises of call back and tracking numbers from Jeff, he

will not call me back, and I will have to hound him until I get my

new transmission.

Kitty and I went back to DREAM AWAY.

Kitty got settled in and lay down to try and get her headache under

control, I worked on the computer trying to get caught up.

June 16, Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee.

When we got ready to leave so we could

go to the USCG office, I had Johnal have a listen to the transmission

noise or growel in Ruby.

We decided it is definitely not the throwout bearing, but something

in the transmission.

Kitty and I went to the USCG office,

and I submitted all of my paperwork for the renewal of my USCG

master’s license. That all went very smooth. They

are four days behind, so by the end of this week, I should be in the

system, and be able to get my new license very soon.

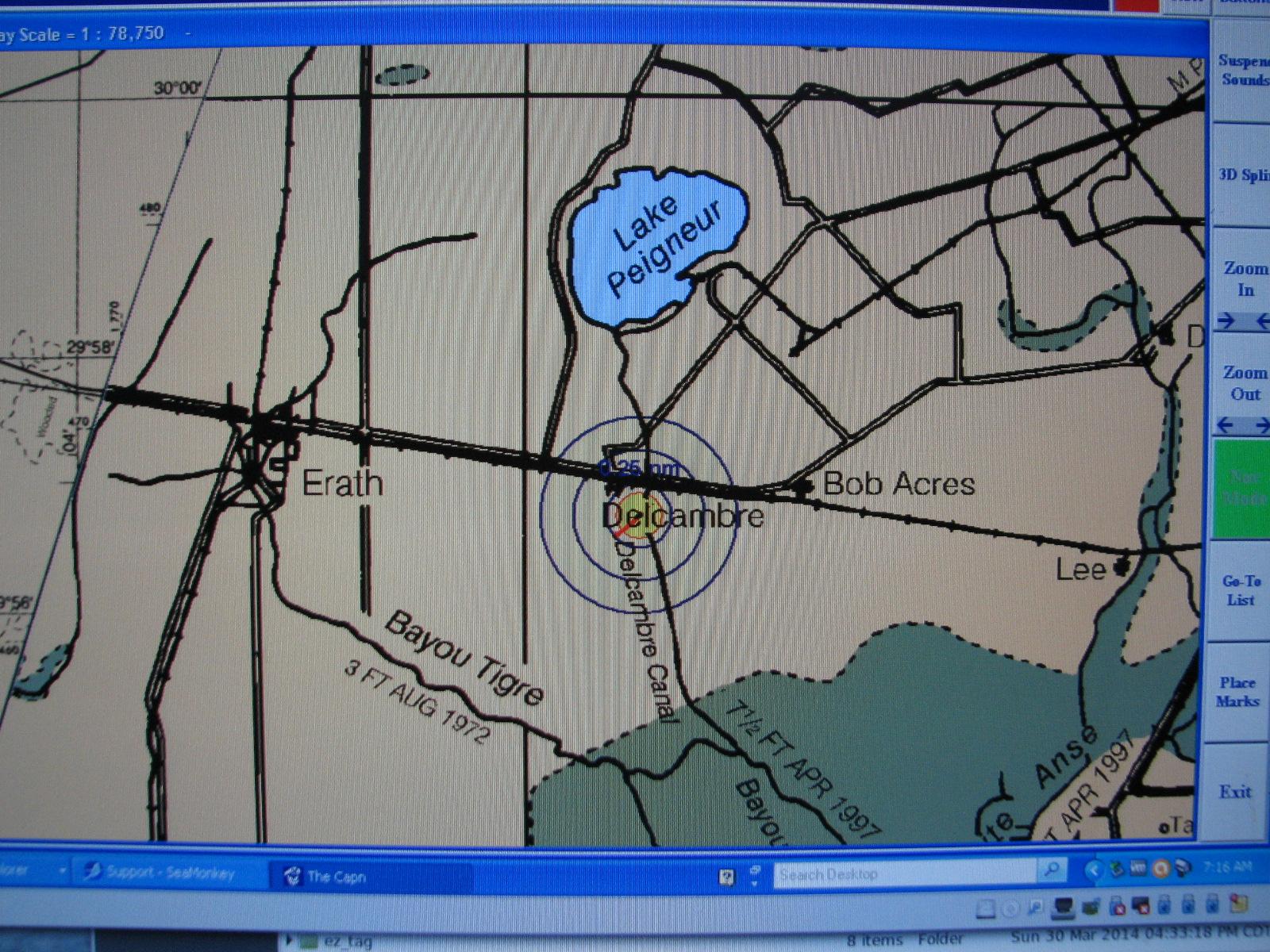

We had an uneventful drive back to

Delcambre,

and as usual were glad to get home and see our cats.

June 15, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the

shop,

and unloaded the long extension cord. I cleaned all of the windows on

Ruby.

I then applied Rain-X

to all of the windows.

I then polished another of the

stainless steel steps I had cut for the stern ladder. I am pretty much

at a standstill on the stern ladder until I can get the first step

tack welded with the stern ladder bolted onto the stern.

I then went to the Port

of Delcambre’s storage room and unloaded two tables

I had in the back of Ruby

just in case they were needed for the National Marina Day

Celebration.

When that was complete, I went back to

DREAM AWAY and took all of the flags down and put them away. Kitty

and I packed all of the stuff we would need for an overnight and

loaded them into Ruby.

We left extra water and food for our sweet cats, Jillian

and Jordan, and headed out to Mandeville,

Louisiana.

I had decided to drop off all of the

necessary forms required for the renewal of USCG

master’s license in person so there would be no loss

of documentation. This had to be done at the office in Mandeville,

so we decided to stay with our friends Cindy

and Johnal who had their boat docked in Mandeville.

When we arrived they had some other friend’s there who they knew

from Kemah.

We had a wonderful visit. The new friends had to leave due to a

commitment, so we played Mexican

Train and Farkle,

until late in the evening. We finally hit the sack around 2200.

June 14, Saturday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the

shop

first thing in the morning, and checked out Ruby.

The transmission was working fine, but I think the clutch needs some

adjustment, and I was trying to see how that works. It was not

obvious, so I will have to look that up on the Internet and see how

it is done!

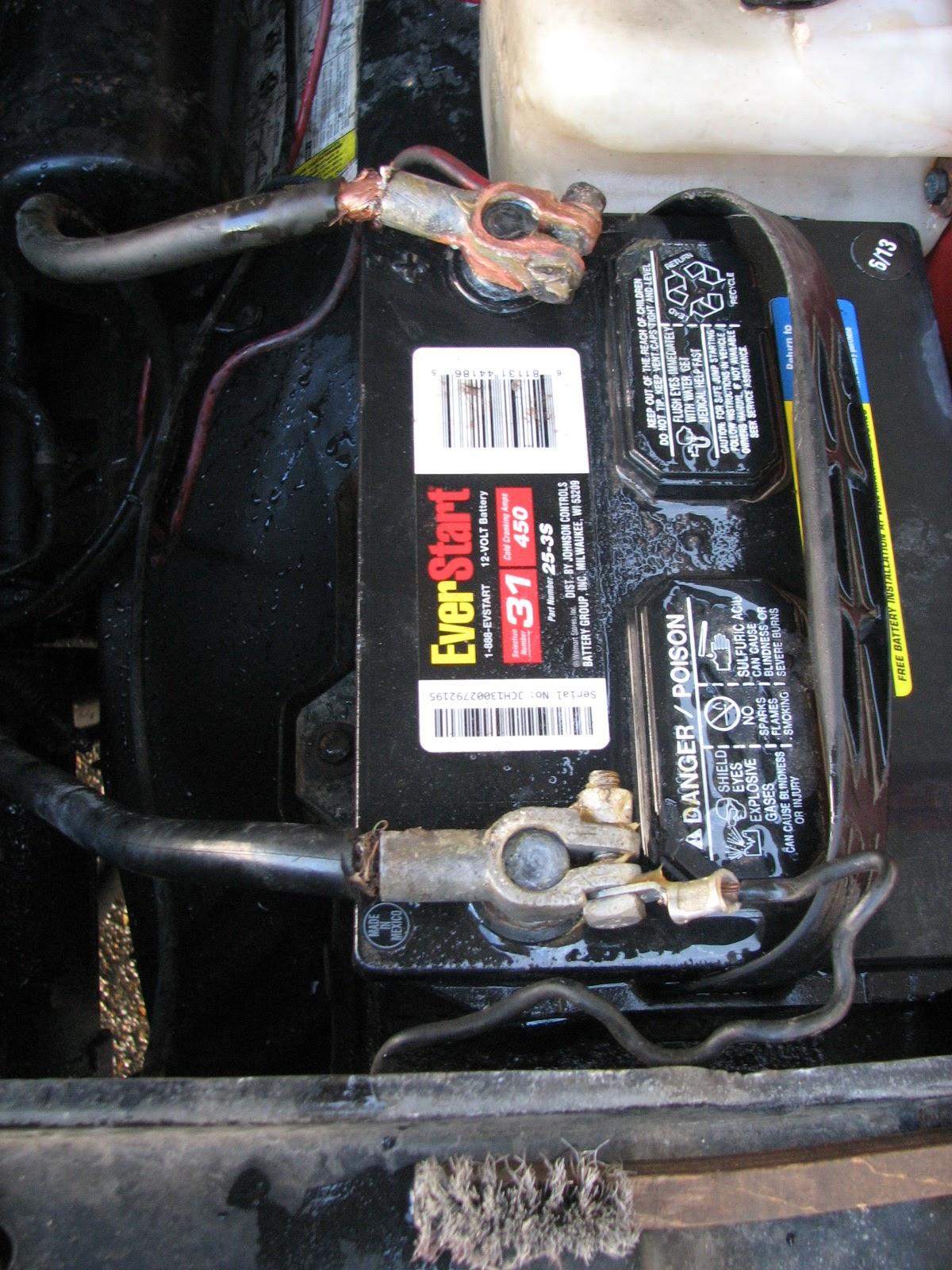

I then cleaned the battery posts on the

battery. They were looking pretty bad. In fact I could not get the

positive post off of the battery. I was afraid if I got too physical

with it, I would ruin the battery! I got the posts cleaned as good as

possible, and then covered them with grease.

Battery Posts During Cleaning Process

Battery Posts After Cleaning; Grease

Applied

Finally after all of this time,

re-construction, and coats of varnish, it was time to put the console

back into Ruby.

Console In Shop

Ready For Installation

Area Between The Front Seats Before

Console Installation

Area Between The Front Seats After

Console Installation

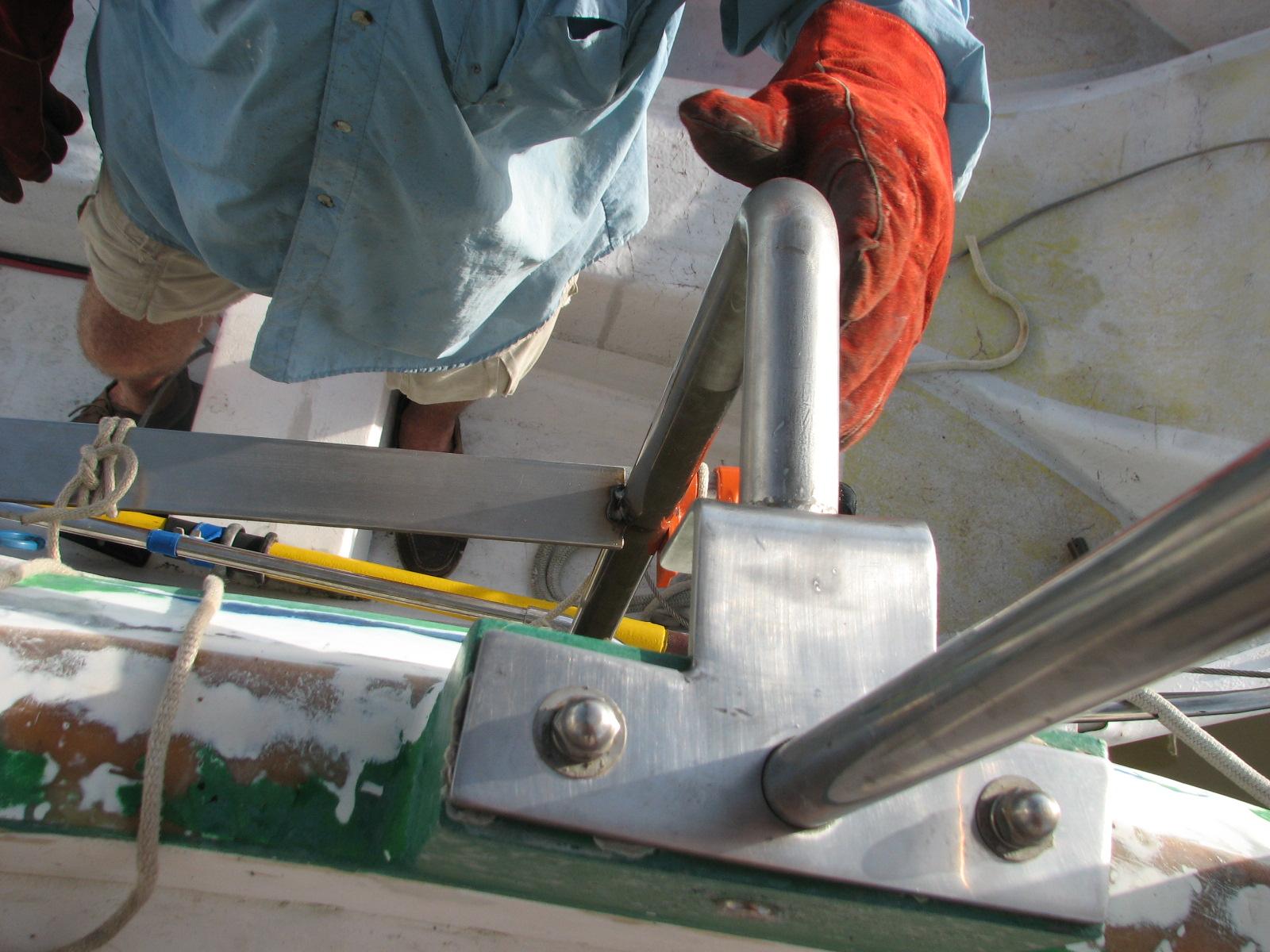

With that one project finally completed

on Ruby,

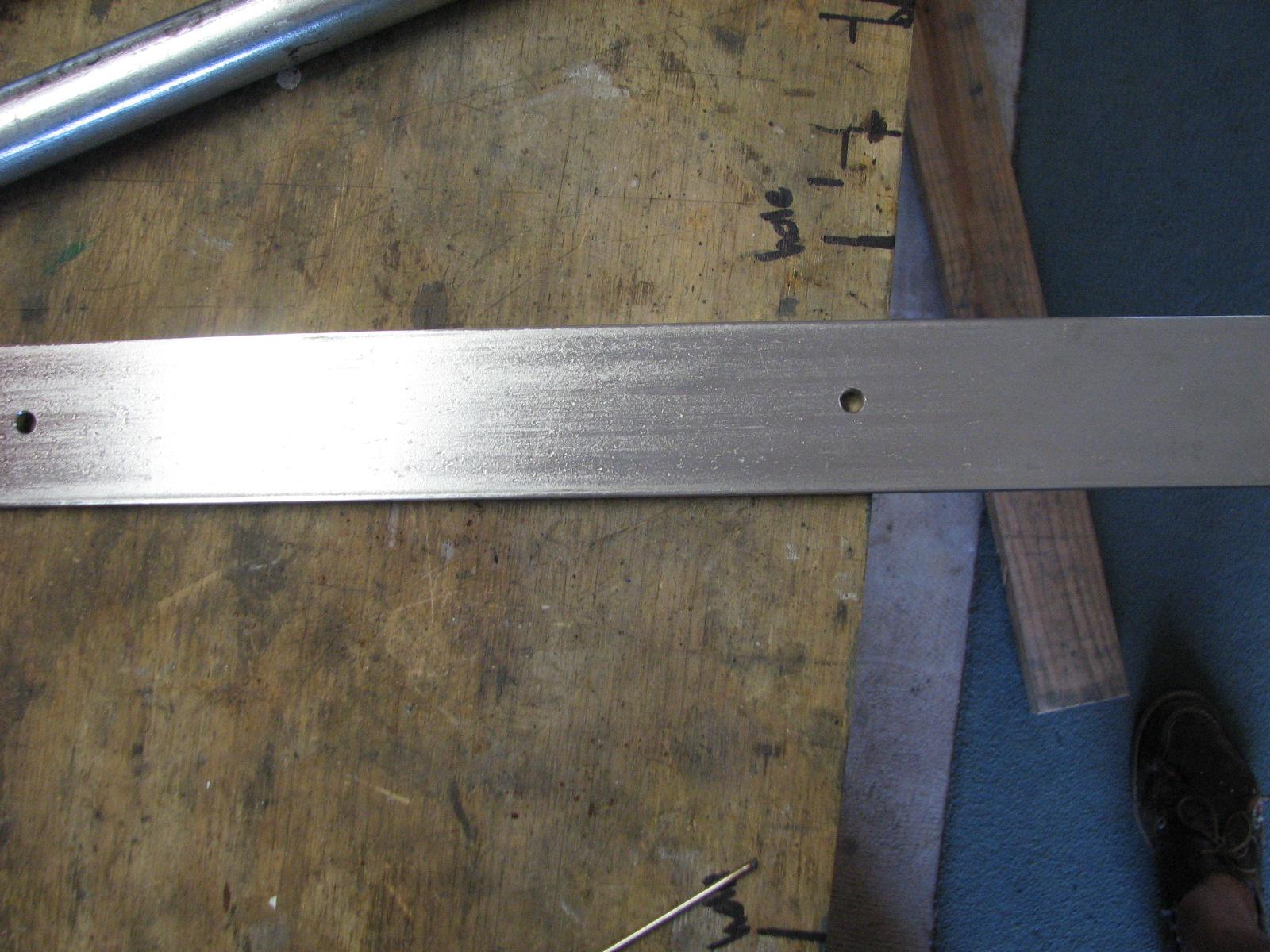

I got back onto polishing the 2” stainless steel flat bar I am

going to use for the steps on the stern ladder.

Polishing Stainless Steel Flat Bar

I came back to DREAM AWAY, and after

breakfast got busy cleaning out all of the raw water strainers and

manifold (Sea Chest). I cleaned out the main strainer for the

manifold, and the manifold (Sea Chest). Also cleaned out the

strainers for the ice maker cooling pump, the refrigeration cooling

pump and the forward air conditioner cooling pumps. During this

cleaning process, I also cleaned out the hoses for all of the cooling

pumps using high pressure water from the dock.

I put up all of the code flags on DREAM

AWAY, and all of the normal flags I put up for events. That would

include, Texas flag, A&M flag, Marine Corps flag, SSCA flag,

ships flag, and the Flag of the United States.

The remainder of the day today was

spent getting ready for the National Marina Day celebration. I

participated in the setup, worked the beer booth during the event,

and helped with the take down.

The event was from 1600 to 2000, so it

made for a long day. We finally finished at 2130.

June 13, Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go over to the

shop

today. I had promised a neighbor I would help him move his boat, and

then help stab (put in) a new engine. That took up most of the

morning.

LORRAINE D Ready To Receive Her New

Engine

New Engine Ready To Go

Getting Ready To Stab Engine With Troy

Driving Forklift

Chad Attaching Engine To The Clutch

Inside The Engine Room

Troy and Chad had the situation under

control, so I went back to DREAM AWAY, had a quick breakfast, and

then Kitty and I drove into

New Iberia,. We went to

Norman’s Auto Diesel Repair, and drove

Ruby

home with her new transmission. It was wonderful to have reverse

again!

When we got back to DREAM AWAY, we

packed up Jordie,

our male cat to go off to the Veterinarian. He was off his feed, and

that is very unusual for him

June 12, Thursday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the

shop

and started in on cleaning the fasteners for the hard dodger roof.

Was not able to finish the cleaning.

I met T-Boy, the dockmaster, and we

removed a piling from Pier “C” using a chainsaw

and the help of Bradie. We got the piling removed and then installed

a cleat where we had removed the piling.

First Piece Of Removed Piling

Last Two Pieces Of Piling Being Cut

I then rode along with T-Boy to clean

out the stable of his young filly, Apollo.

T-Boy’s Young Filly, Apollo

We returned to the marina,

and continued with the cleat project out on Pier “C”. This was

the hard part, as we were drilling through 12’ X 12”’s, and

inserting 16” bolts. It was hot work and finally T-Boy had had

enough. T-Boy had not brought his hat, and had no water to hydrate

himself!

T-Boy Working On The Cleats

T-Boy went home, and I cleaned up and

put everything away. Kitty came home after running several errands,

we had a bit of lunch, I took a shower, and then got into catching up

on emails for a couple of hours.

One of Kitty’s errands was to pick up

two pieces of T-Bar that I will be using for the center piece on the

hard dodger roof and the Bimini

roof.

June 11, Wednesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go over to the

shop

first thing in the morning. I stayed on DREAM AWAY, and worked on the

computer almost all day. I was able to get the June Maintenance Log

up to date, and got a good chunk taken out of the emails. I started

the morning with 170 emails. and finished off in the evening with

only 87. Still a way to go, but making progress.

Just after noon, Wayne & Connie

came by DREAM AWAY, and then we went over to the shop.

They had come over to help with getting the two sheets of Starboard

for the hard Bimini

from the shop

to DREAM AWAY. We had loaded one sheet onto their small SUV, when

Jeff showed up in his pickup.

This was great, four people to move the

sheets of Starboard,

and a pickup truck to take the sheets over to DREAM AWAY. We moved

the one sheet from Wayne & Connie’s SUV into the pickup truck,

and then loaded the second sheet into Jeff’s pickup truck.

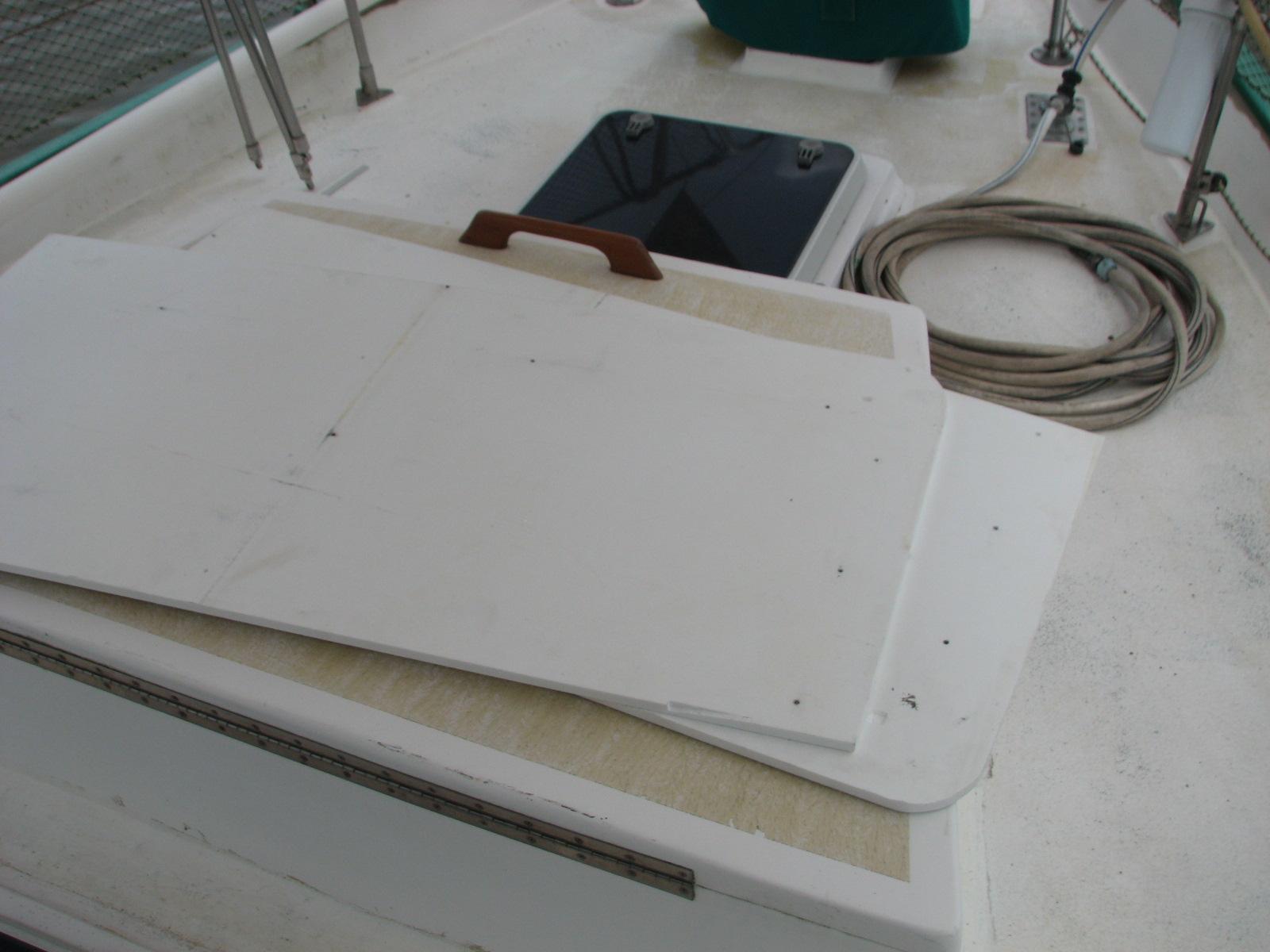

We all went over to DREAM AWAY, and

then hauled each sheet down to DREAM AWAY and put it on top of the

hard Bimini

frame. I tied the sheets to the frame, because I did not want them to

blow away. Now the pressure is on to get the sheets fitted and bolted

down to the frame.

Of course since we were all involved in

the lifting and moving, I have no photos of the project, just the

finished product.

Kitty had returned from her grocery

shopping with a very nice watermelon just as we had finished the

sheet moving. We all helped getting the groceries from the Black

Beast down to DREAM AWAY. The watermelon was sliced

and we all sat around the main cabin table eating watermelon, and

drinking a special beer that Kitty had brought for Wayne.

All of my workers soon left, so I went

and took a shower, and got back on working on emails. I did this

until we left DREAM AWAY around 1700. We were going over to Jeff and

Janice’s house for homemade red beans and rice. Wayne and Connie,

and Wayne’s mother were also there, so we had a great meal and good

company.

June 10, Tuesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the

shop

and packed up the round top shifter so it could be sent back to Smart

Parts Automotive. They had sent the square top shifter

to put on their new transmission.

Bottom Of The Round Top Shifter

Top Of Round Shifter

When the box was packed and taped shut,

I manhandled a sheet of new Starboard

for the hard Bimini

up onto the saw table. I used the old piece of Starboard

as a template plus the other measurements I had made to mark the

lines on the new sheet Starboard.

When all the measuring has been done,

then it is time to set up the fence, and get it in the proper place

to enable a straight cut with the Skil

saw.

Fence In Place - Ready For Cut

Cut Made Along The Fence

Post Cut Mess

I made all of the cuts on both sheets

of Starboard.

They were now ready to take over to DREAM AWAY, and I even had some

muscle lined up to help me, but!!

Look Out The Front Of The Shop

Look Out The Back Of The Shop

As you can see, the weather had

something to say about our plan. I was stuck

in the shop,

so I continued working on projects.

I did call Kitty, and she checked on

our leaks. It seems the one in the aft cabin has been fixed. The

underside of the deck in the head did not leak at all! It seems to

only leak when I put on the backing plate on. That will be the next

course! The leak in the companionway doors, had slowed down a lot,

but there is still a leak that must be found and repaired.

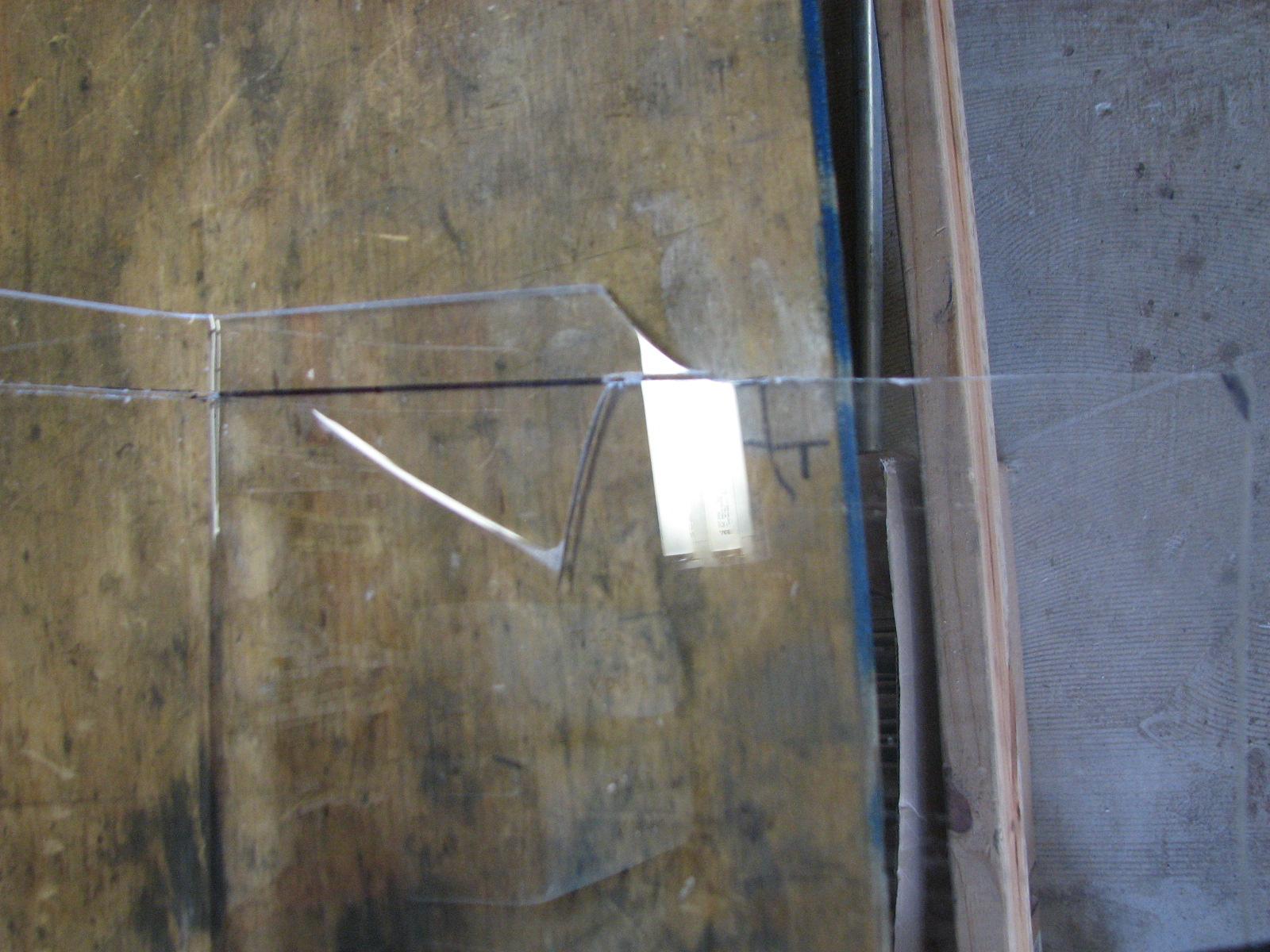

I got the selected piece of the Optix

acrylic sheet I am going to use to make a second

moisture cover for the solar panel charge controller. First I clamped

the piece of acrylic sheet to my work table with the area that will

be bent just off of the table. I then applied heat from the heat gun,

and slowly bent the piece of acrylic to a 90° angle.

Set Up To Bend The Piece Of Acrylic

Piece Of Acrylic After 90° Bend

I then made a small 45° bend as

additional protection from moisture. I then did the set up to cut off

the piece of acrylic, and made very sure it was clamped down

properly.

Acrylic Piece Before Cut

I cut off the piece of acrylic, and

then smoothed out all of the sides, and rough places I could find.

The moisture cover is ready for installation.

Next project while waiting for the rain

to cease, was to polish the two pieces of pipe and the two steps I

had cut for the stern ladder.

Pipe In Vice Ready For Polishing

You know the drill by now, start with

80 grit sandpaper, then 120 grit, 220 grit, and finish off with the

320 grit. I did this with both pieces of pipe and the two steps.

Piece Of Pipe After Polishing

The rain had finally stopped, so I went

over to DREAM AWAY, and had to pump out the

tender.

Then it was hit the showers, and off to dinner with Connie, Wayne and

his mother. We went to Shuck’s

in Abbeville,

and then we left them to head out to the Port

of Delcambre’s monthly meeting.

June 09, Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the

shop

and started work on the solar panel controller moisture cover. The

cover was too wide, so I decided to cut off one inch on the width.

Unfortunately, I did not properly secure the acrylic piece while

cutting, and cracked the piece making it unusable for the solar panel

controller moisture cover.

Cracked Solar Panel Controller Moisture

Cover

Salvaged Regulator Moisture Cover

Salvaged Fuse Panel Moisture Cover

Now all that remains to to make another

solar panel charge controller moisture cover. I got out another piece

of the Optix

acrylic sheet, and verified I could make a new

moisture from it.

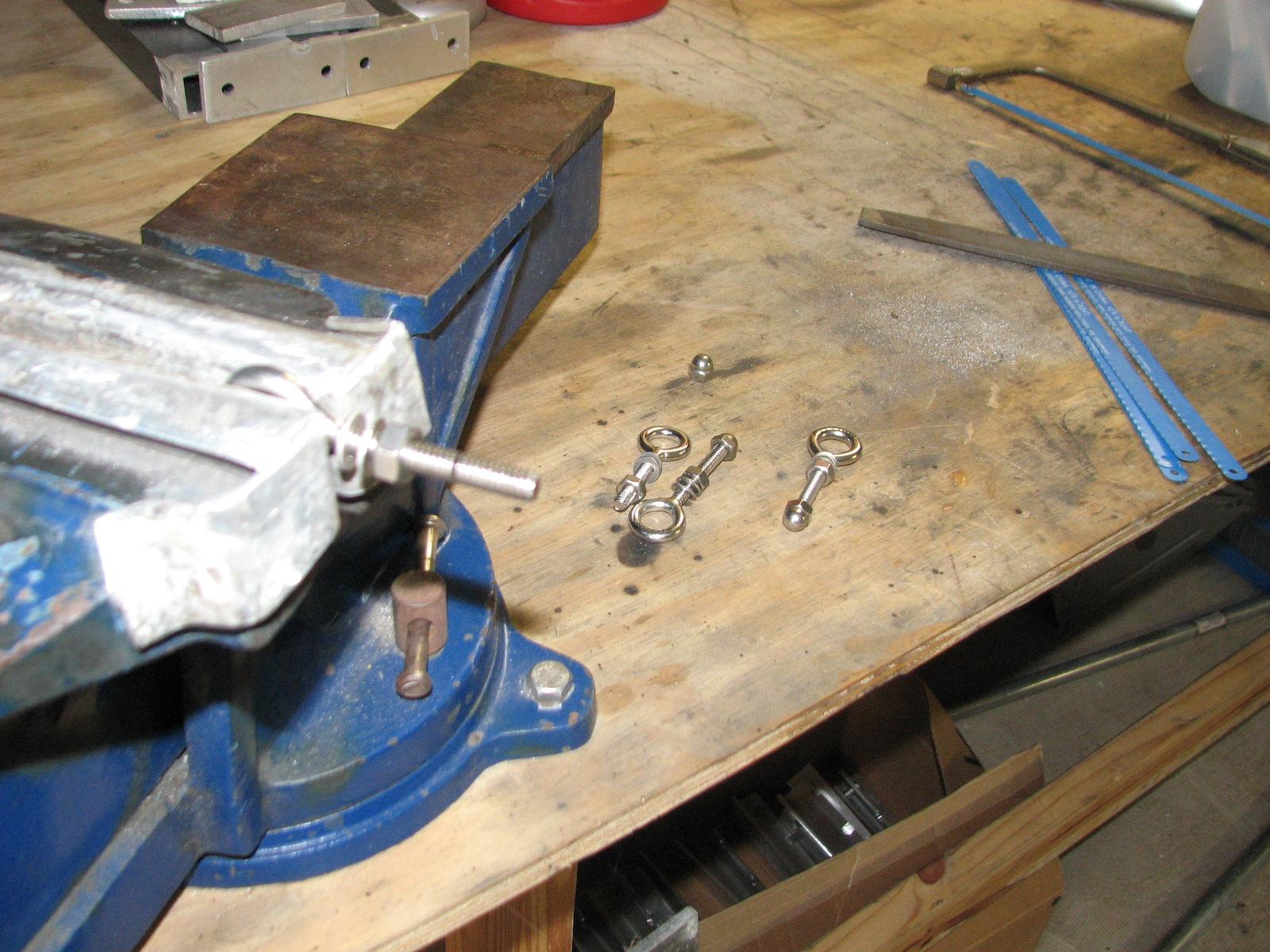

Next was to select a piece of the 1”

stainless steel pipe from which to cut the two pieces I needed to go

from the stern ladder back to the transom for the stern ladder

support.

Stanchion Supports & Stern Ladder

Pipes Set Up On Bench

Two Pipes Cut And Ready For Polishing

I had the chop

saw set up to cut the pipes, so I used it to

cut the first step that will be welded to the stern ladder. I

selected a piece of 2” stainless steel flat bar, and cut the step.

There is enough metal remaining, I will be able to cut a second step.

I cut the step just a bit long, and I

then notched the step to give me more of a bite to weld the step

to the pipes of the stern ladder.

Notched Flat Bar Of First Step

When Kitty got up, I went over to DREAM

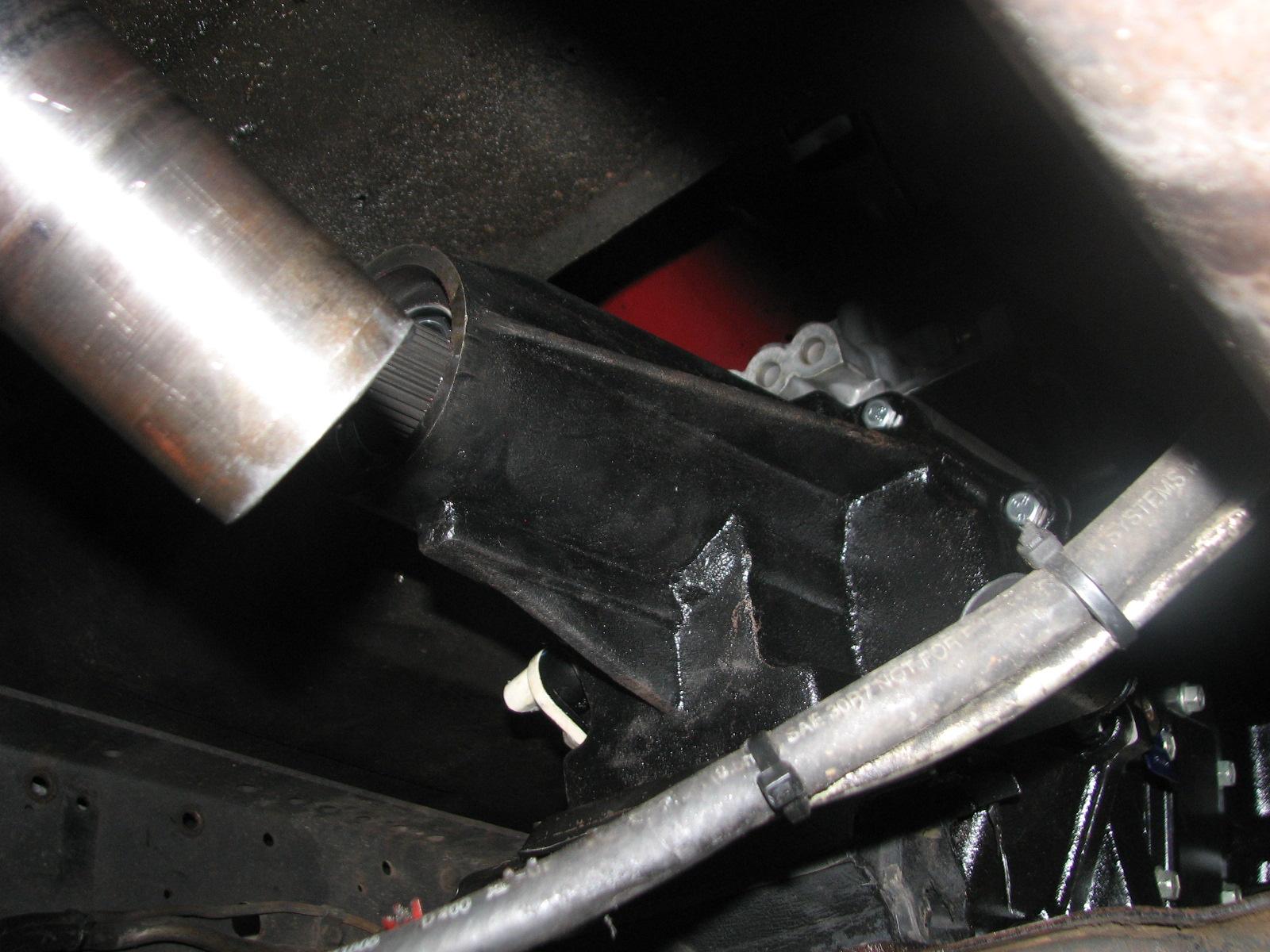

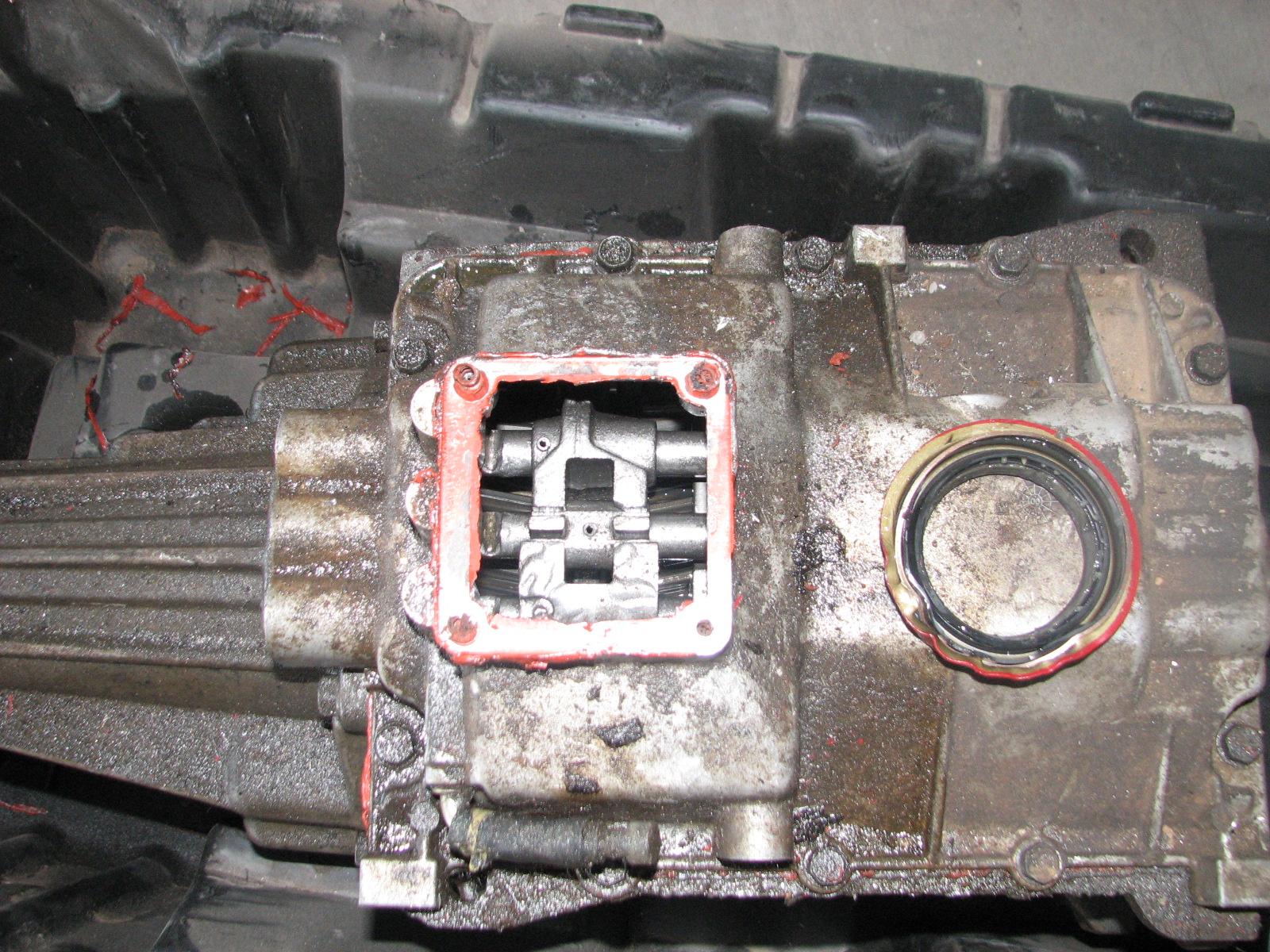

AWAY and had breakfast. We then went over to Norman’s Auto Diesel &

Repair. Norman wanted to ask me about a rear seal issue on the new

transmission. He explained the situation to me, and I decided to go

ahead with the new seal. While there I took several pictures of the

underside of Ruby.

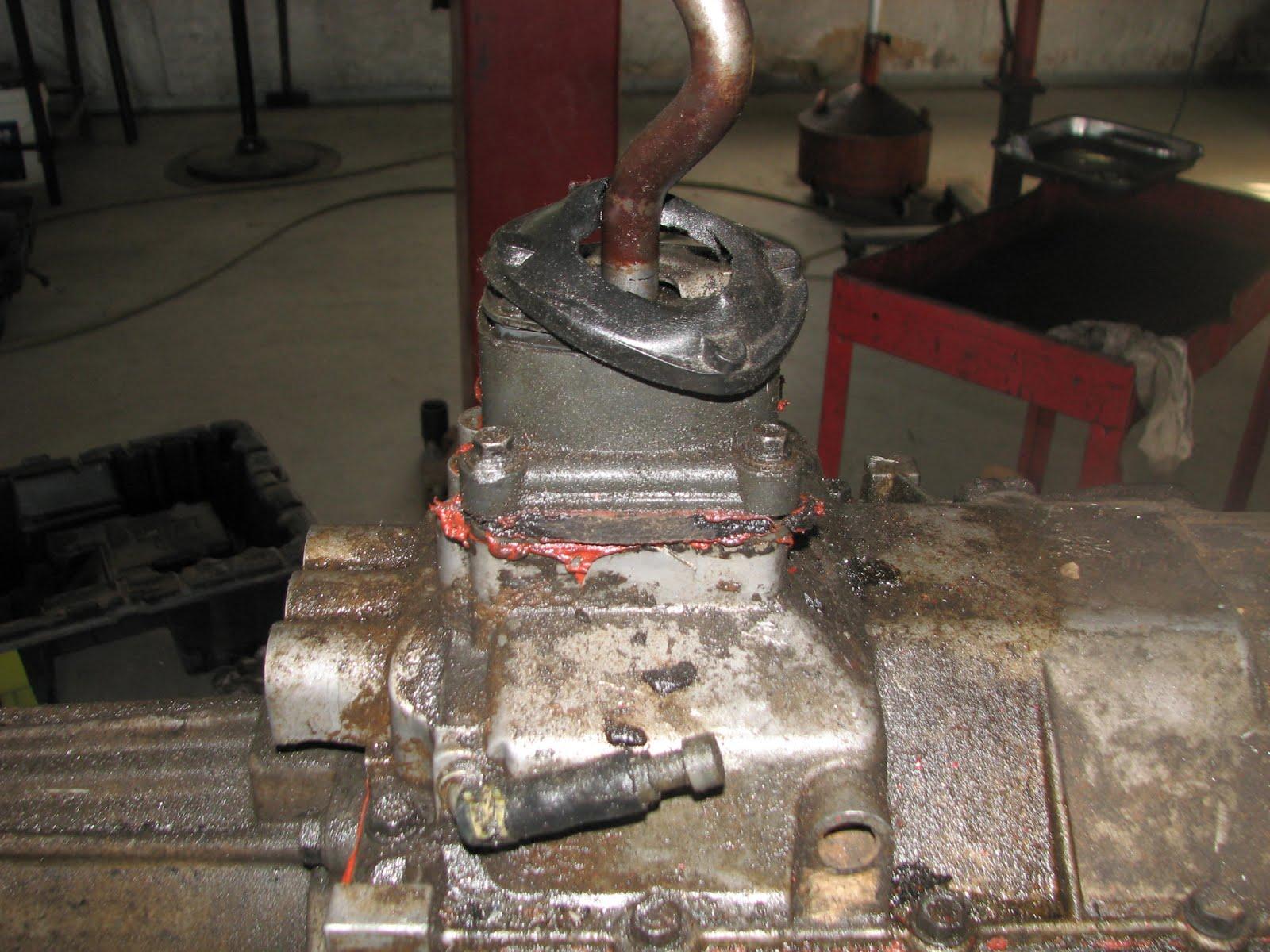

Rear Of Transmission And Drive Shaft In

Ruby

Round Top Shift Plate

Top Of Old Transmission

When we left Norman’s, we drove down

to Sterlings

Upholstery & Fabrication to see if they had or

could order the T-Track I need for the hard Bimini.

The men in the fab shop were gone, so we had to come back.

When we returned from Norman’s, I

went over to the Port

of Delcambre’s storage room and picked up the

pressure washer and the fuel can. I brought them back to the marina,

and pressure washed dock line I had been cleaning.

I also washed all of the power

pedestals on Pier “A”. When that was done I returned the pressure

washer and the fuel can to the Port

of Delcambre’s storage room.

I came back to the

marina,

and took a shower. We then went back to

New

Iberia to meet Connie & Wayne at Jeff &

Janice’s house. We did a tour of their house, and then went to

Duffy’s

Diner for a great dinner. We then parted company, and

we returned to DREAM AWAY.

June 08, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

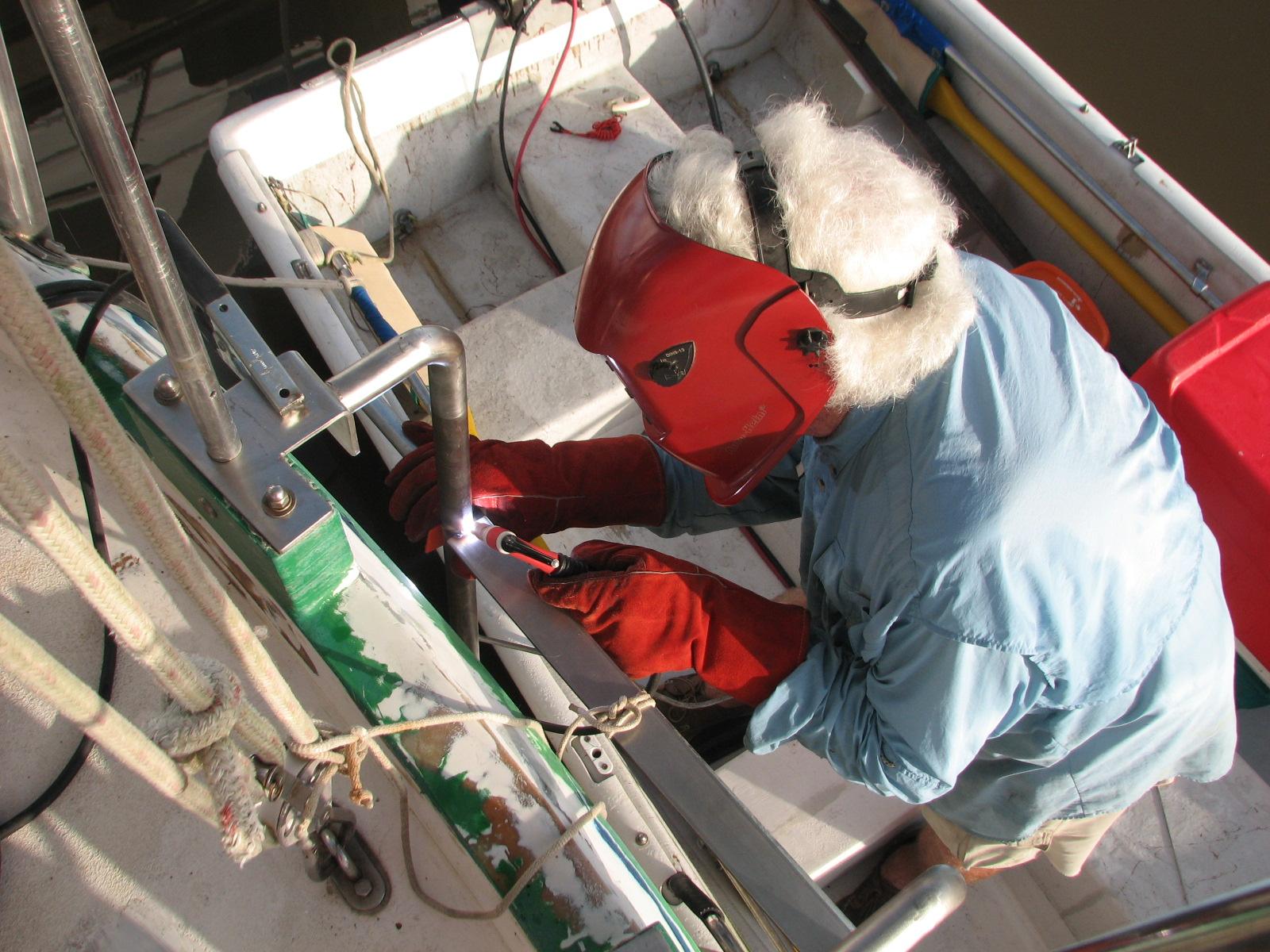

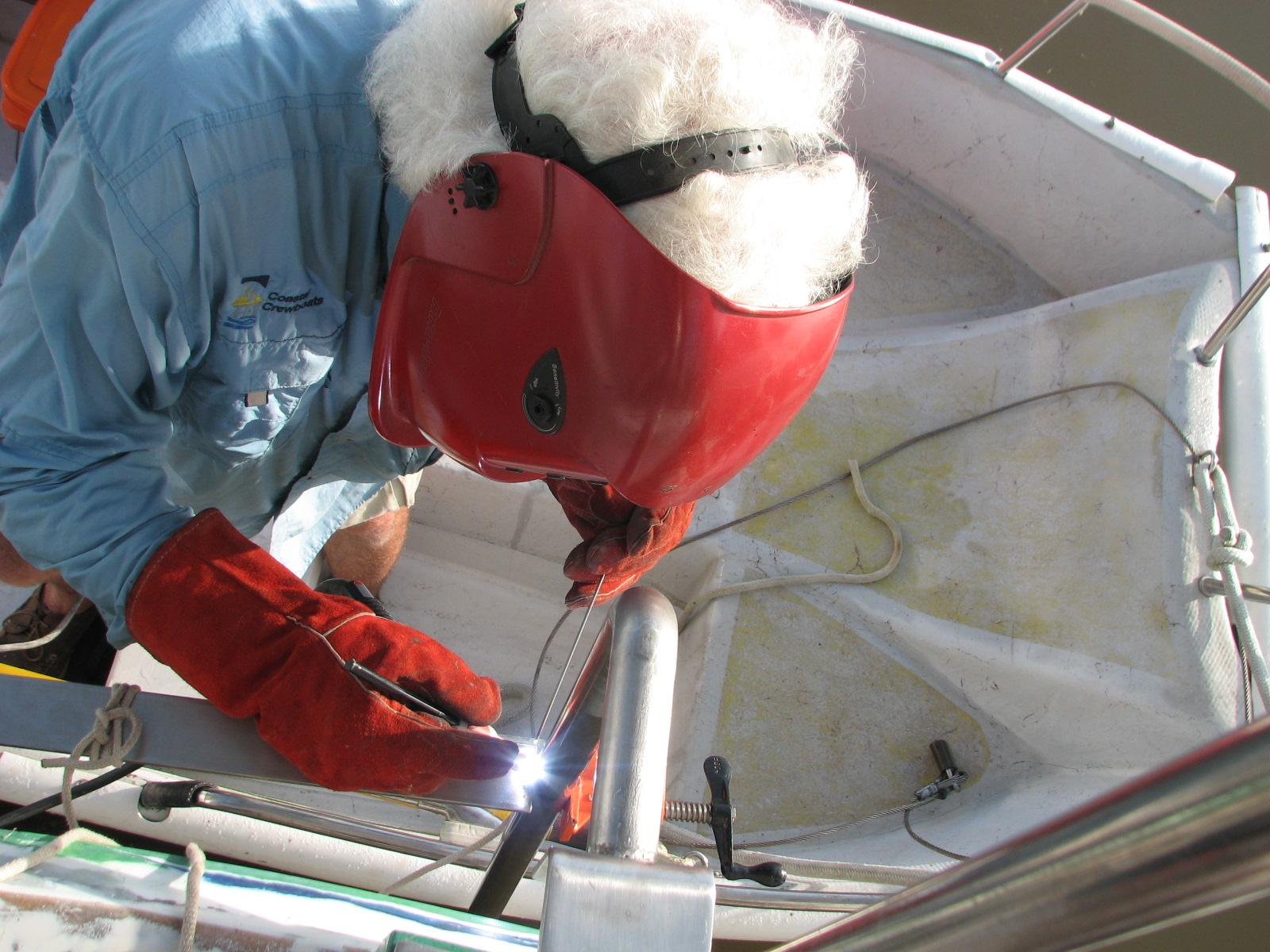

Went over to the

shop

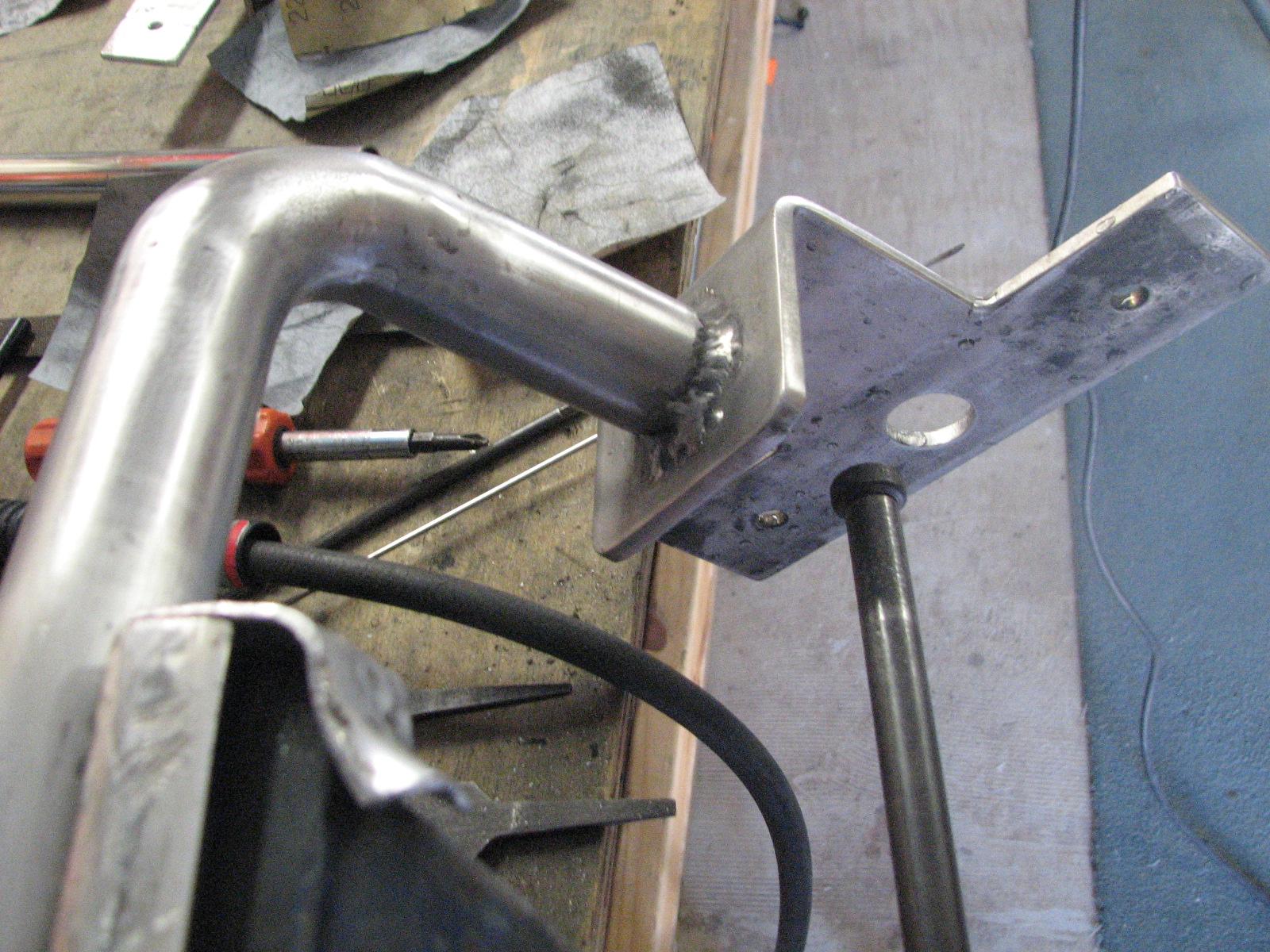

and set up the second aft stanchion base and pipe. When I got the

setup where I liked it, I welded the stanchion base and the pipe

together.

Second Pipe With No Stanchion Base

Pipe And Stanchion Base Welded Together

Pipe And Stanchion Base Welded Together

Pipe And Stanchion Base With Welds

Cleaned Up

Pipe And Stanchion Base With Welds

Cleaned Up

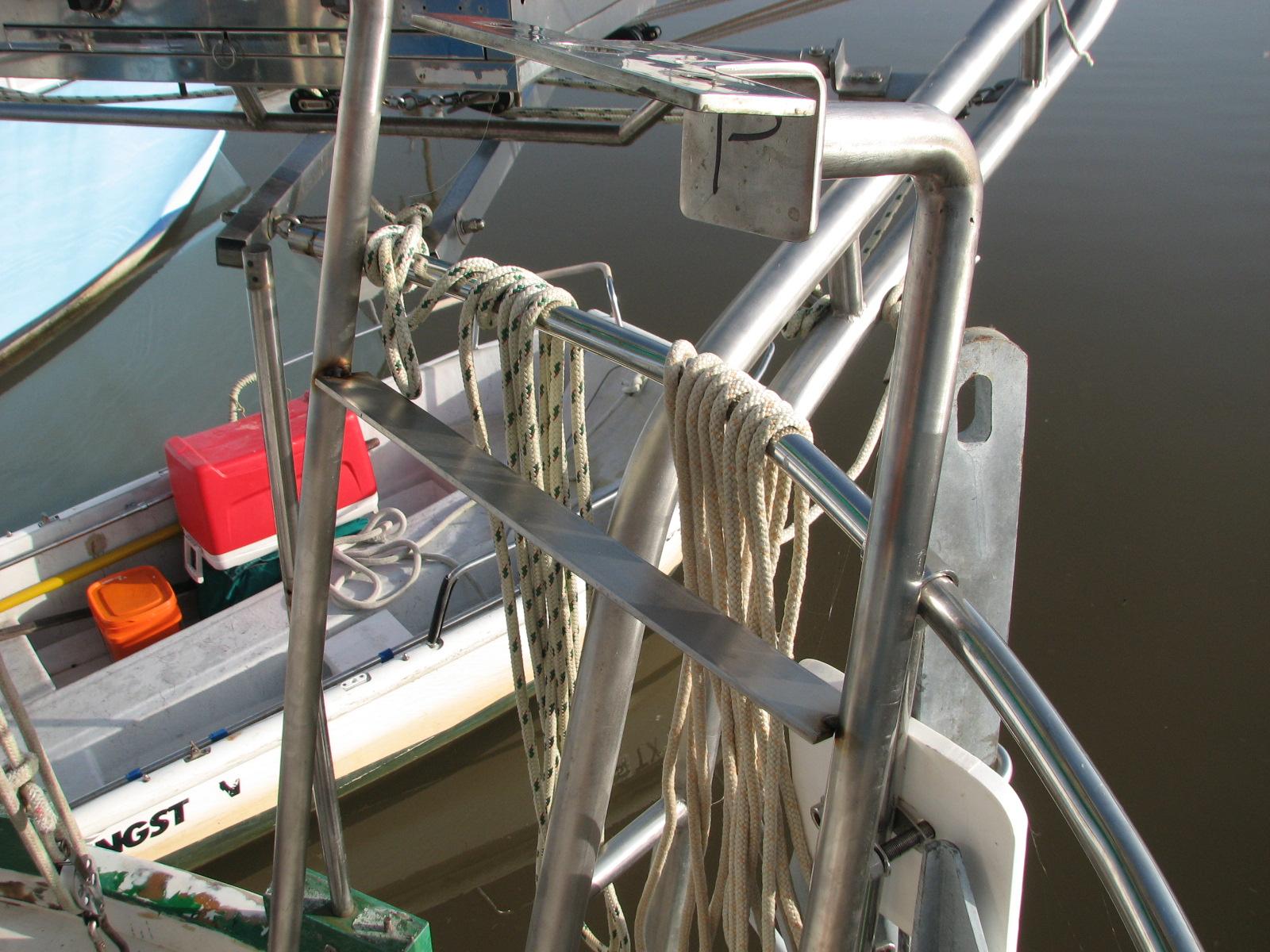

Now that the two stern ladder stanchion

bases were ready for fitting on DREAM AWAY, I started in on cleaning

all of the hardware that was used to bolt the Starboard

to the hard Bimini

frame. I am planning to use it again so all of the little bolts and

screws must be cleaned up.

Dish Of Hardware To Be Cleaned

Kitty called and said she was up, so I

went over to DREAM AWAY to have breakfast. After breakfast, Kitty and

our good friend Bonnie, went on a field trip to Washington,

Louisiana.

I stayed on DREAM AWAY to do the stern

ladder fitting, and some sanding at the stern.

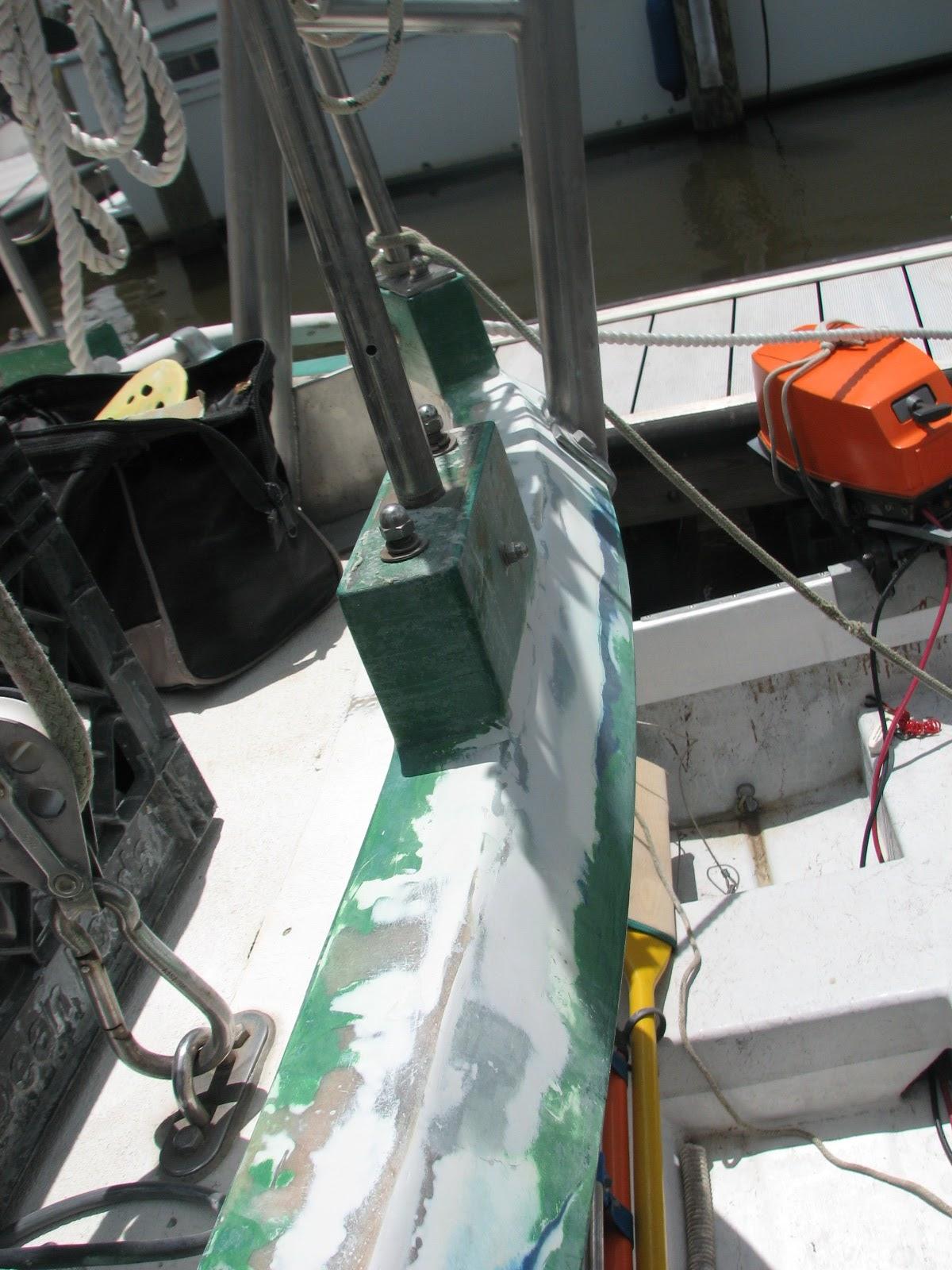

First off was the fitting of the stern

ladder stanchion supports. Once I got the stanchion supports bolted

down I could see there was an alignment issue. I had the tender

in the water so it was easy to straighten up the pipes leading down

to the water.

Initial Fit Of Stern Ladder Stanchion

Supports

Closer View Of Stern Ladder Stanchion

Supports

Starboard Stern Ladder Stanchion

Support

Port Stern Ladder Stanchion Support

Jordan Watching Me Fitting The Stern

Ladder

With the initial fit done, I measured

the distance from the bottom of the stern ladder pipe back to the

transom. I measured both sides several times to get a very good

average. Remember I am in a boat trying to fend off DREAM AWAY, and

using a tape measure to measure the distance, and trying to not hit

the pipes!

I also did a measurement of where the

first step would be placed on the stern ladder pipes and how wide it

will be. I got those measurements done, and was happy with them. The

real fun will be tack welding that first step. It will have to be

done on DREAM AWAY on a day with no wind. I can feel the fun already!

Lining Up The Pipes Of The Stern Ladder

Now it was time to do the final fitting

of the hard dodger Starboard

top. There were a couple of places where the supports needed to be

sanded down to be even with the top of the stainless steel frame.

When that was done, I needed to use the

Dremel

Tool to hollow out a couple of places in the Starboard

to make room for the bolts sticking above the stainless steel frame.

I completed all of that, and now the Starboard

top of the hard dodger is ready to be bolted down.

Hard Dodger Supports That Needed

Sanding

Hard Dodger Support Sanded Down

Next on the list was to scrape off the

hardened sealant that I initially used to try and seal the two pieces

Starboard

on the hard

Bimini

frame. As predicted, the sealant did not stick to the

Starboard.

I had much better luck with the

rope caulk

sticking to the

Starboard.

Before installing the new Starboard

onto the hard Bimini

frame, the old caulk needed to be removed.

Old Sealant On Hard Bimini

Frame

Old Sealant Removed From Hard Bimini

Frame

The last project for the day was to

sand down and prepare for painting the stern hull to deck joint. This

is the area I had patched to stop a couple of leaks in the aft cabin.

Still have some work to do, but wanted to get the area sanded down

while I had the time and the tender in the water.

Stern Hull To Deck Joint Being Sanded

Stern Hull To Deck Joint Being Sanded

Stern Hull To Deck Joint Being Sanded

Stern Hull To Deck Joint Being Sanded

Now I just had to clean up, put all of

the tools away, and then clean up myself! Time for an adult beverage!

June 07, Saturday, 2014

Because of the upcoming National Marina

Day celebration, they decided to have a marina

booth set up at the

Delcambre

Seafood And Farmers Market to show off the marina,

and invite one and all to the National Marina Day celebration on June

14th. Kitty and I worked the marina

booth until the market closed at 1300.

They also had a Father’s day tent set

up with free food and drink for father’s, so I took advantage of

that.

After the market shut down, I got the

shower

trailer ready for transportation. This means draining

the fresh water tank, removing the railings for the steps, and then

folding the steps up to transport mode. I moved the

shower

trailer back to the marina, and got it set up there.

I got the water turned on, the

electricity connected, and then changed out the trash bins in each

room. I cleaned up each room, and then I mopped out each room.

I then drove over to the

Port

of Delcambre’s store room and unloaded the trash

bins we used and some other stuff.

It was back to the

marina

and down to DREAM AWAY. I went and took a shower, then got to work on

the computer. My plan was to get the CAPN

software on the virtual machine I have running on my Linux

Mint PC.

I booted up the XP OS using VMware

Player. I noticed that the three USB to Serial converters were not

attached to the virtual machine. When I attempted to attach them to

the XP machine, using the Player software, I got an error. The error

pretty much said nothing, except to contact VMware and investigate

there, so I did.

It was very difficult to find any

support for Player on the VMware page. I get the idea that VMware

does not really put much effort into Player, and they want you to

purchase Player Plus. Bottom line after about 40 minutes of poking

around, I decided to reboot the machine.

Of course please keep in mind while I

am doing this research on the Internet, the WiFi is dropping out all

of the time.

With hindsight, I had made a mistake.

When I rebooted the Linux machine I had forgot I had VMware Player up

running the XP machine. When Linux came back up, and I booted the XP

virtual machine, it took 54 minutes to come up. Once XP was up, it

was very slow to respond to commands. I decided to reboot XP, and

this time it only took eight minutes to reboot!

When XP was up and running, I was able

to get the USB to Serial converters away from the host and attached

to XP. When this was complete, I rebooted the machine again, and

again it took about eight minutes to boot up. When XP was up and

running I checked the USB to Serial ports and they were all attached,

and I recorded the COM ports to which they were attached.

I then decided to run a defrag of the

"C" drive on the XP machine. It was a mess, and took a long

time to run. When it was finally finished, three hours had gone by

and it was time to eat dinner! The CAPN DVD was still sitting by my

keyboard unused!

June 06, Friday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the

shop

and did the set up to make the cut on the port piece of Starboard.

I made the cut, so we will have to see how the fit goes later today

on DREAM AWAY.

I had left the piece of stainless steel

pipe with the aft stanchion support in the vice, so I did the welding

necessary, and then did the grinding and cleanup to make the piece

look good again.

Pipe And Stanchion Support Ready For

Welding

Welding Complete Unit Cleaned up And

Ready For Test Fit

Welding Complete Unit Cleaned up And

Ready For Test Fit

Kitty called, so I went over to DREAM

AWAY, and had breakfast. After breakfast we did a check of the fit of

the ACR

EPIRB

and the solar charge controller under the companionway steps. If I

take an inch off of the acrylic moisture cover for the solar charge

controller it looks like it will fit.

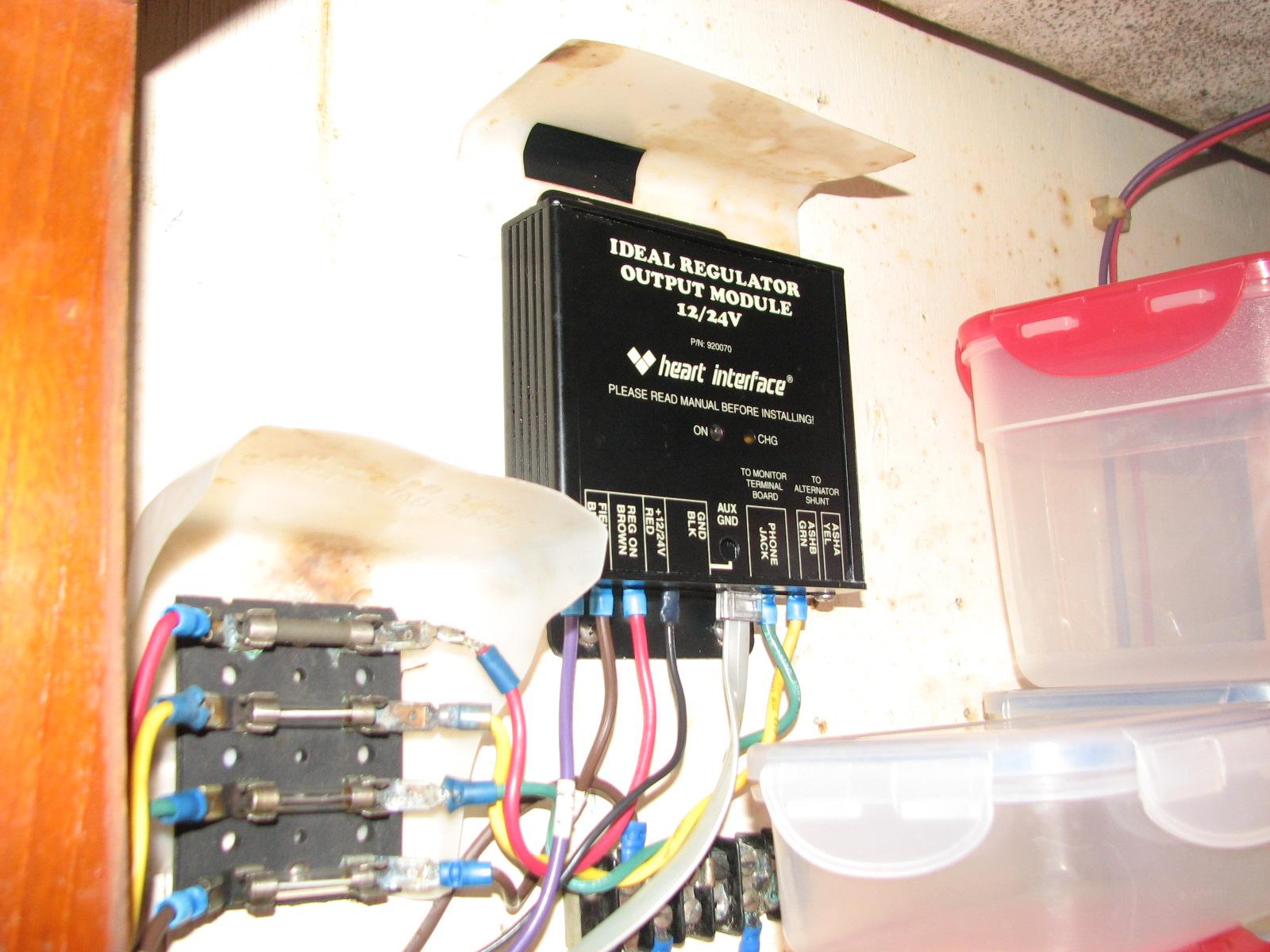

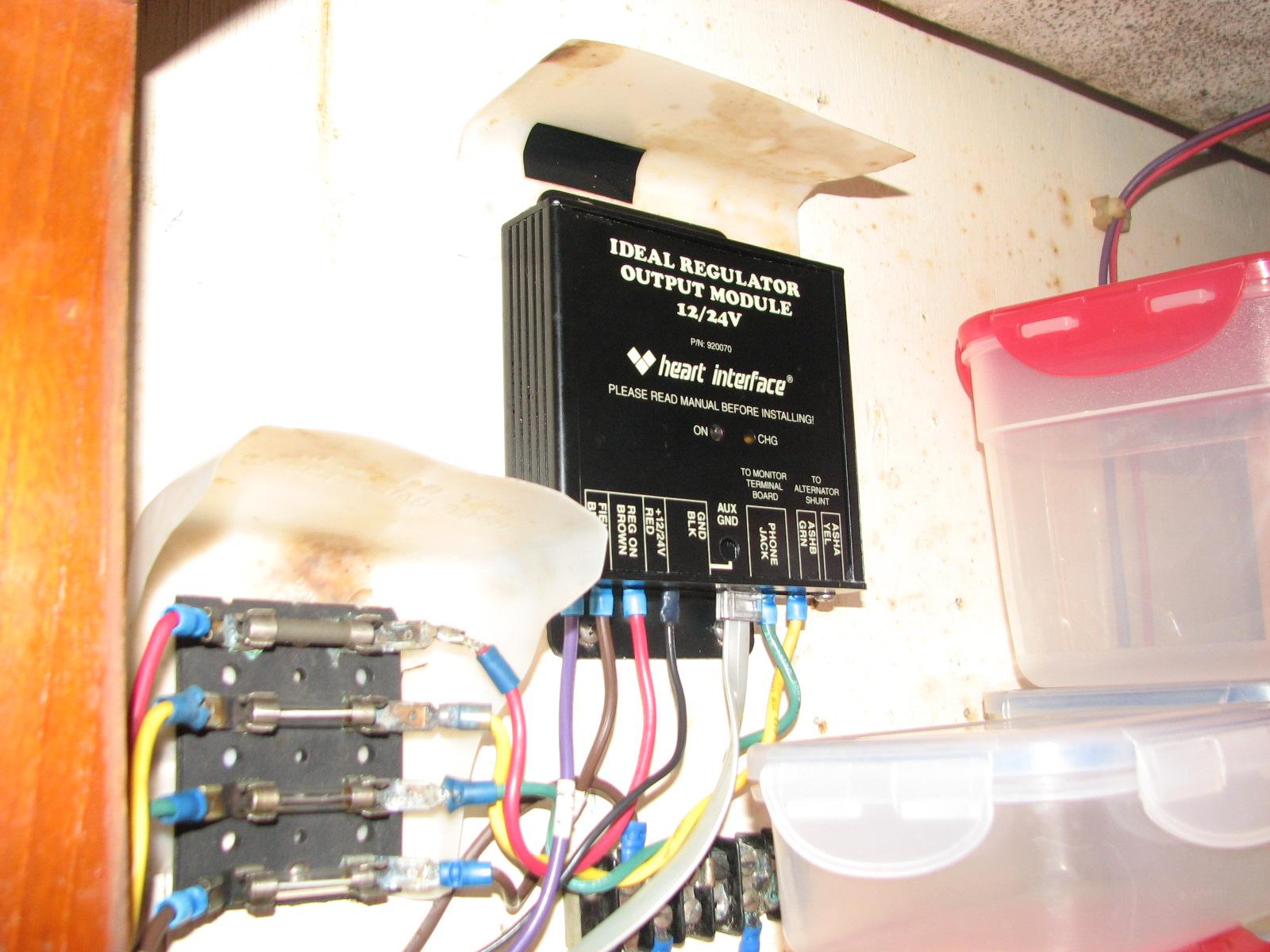

We had a leak in the cockpit and the

water was coming into our container storage area. This is also where

I keep the fuse panel for the Link

2000R regulator and the Link

2000R regulator. I have moisture protectors on these

units, but because I had such good luck with the moisture protector

for the solar panel charge controller, I am going to make moisture

protectors out of the Optix

acrylic sheet for them.

Present Moisture Protectors

T-Boy and I emptied the holding tank in

the shower

trailer, and then put the shower

trailer into transport mode. This means we have to

remove the railings on all three of the toilet/shower units, and then

put up the steps. We then moved the shower

trailer to the Delcambre

Shrimp Festival grounds, in preparation of the

Delcambre

Seafood & Farmers Market tomorrow morning.

We left the shower

trailer in transport mode, as we will not put the

steps down and the railing up until tomorrow morning. We did fill the

onboard water tank with water.

I then perused the Delcambre

Shrimp Festival grounds looking for fire ant hills.

When I did find one, I dumped the ant poison on it hoping the ants

would be gone by tomorrow morning.

The part for Ruby’s

transmission arrived at Norman’s Diesel Auto & Repair, so I

hope he can get the transmission put into Ruby

early next week.

June 05, Thursday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go over to the

shop

in the morning. Stayed on DREAM AWAY, and put the tender into

the water, and put the outboard on the tender. We are using the

tender to continue with the cleat project.

T-Boy and I started on the cleat

project for Pier “C”, but I had forgotten the long extension cord

from the shop.

I went over and retrieved the extension cord, and we worked on the

cleat project until noon.

We finished installing all of the

cleats on the portion of the dock that had the 8 X 8’s. We are

waiting on the longer bolts for the portion of the dock that had the

12 X 12’s.

Jim & T-Boy Working On The Cleat

Project

Jim & T-Boy Working On The Cleat

Project

When we finished the cleat project and

cleaned up, I had lunch on DREAM AWAY, and then went over to the

shop.

I had done a quick inventory of all of

the parts that came in from our solar panel order. I ordered the

system from Renogy

through eBay.

All of the items in the order looked to be in good shape, except they

forgot to send one package of the Mounting Z-Brackets. I am working

that out through eBay.

40 Amp MPPT Solar Charge Controller

MT-5 Tracer Meter For MPPT Charge

Controller

40’ Solar Cable & MC4 Branch Y

Connectors

Now we will take a look at the solar

panels. The came very well packaged, and they were physically in

great shape. I can hardly wait to get them installed.

Box Of Two Solar Panels

Panels Out Of The Box

Panels Out Of The Box

I was planning on removing some plant

growth from Pier “C” at the marina,

so I mixed up a batch of weed killer. My plan is to cut down the

weeds growing on the pier, and then spray the roots with the weed

killer.

Mixed Weed Killer Ready To Go

I had accomplished this task a couple

of days ago, but wanted to get visual proof in the Maintenance Log.

Miami Dolphins Cheerleader Calendar

Changed To June

LeBlanc Fuel Construction Babes

Calendar Changed to June

The next project is an experiment. We

have a problem with the placement of the 40 Amp MPPT charge

controller for the solar panels. It should be placed where it has

good air circulation, and “in-line” between the panels and the

battery.

So far the only practical place for the

controller is under the companionway steps, next to the ACR

EPIRB.

Since this could be a pretty wet location, I decided to fabricate a

piece of plastic to serve as a shield to keep the controller dry.

I had lots of pieces of Optix

acrylic sheet left over from cutting out the windows

for the hard dodger. I used one of these pieces to fabricate my

moisture shield for the solar panel charge controller.

I clamped the piece of Optix

acrylic sheet to the work surface, and then used a

heat gun to heat up the acrylic, and bend it at a 90° angle. When

this was completed, I clamped the piece again and went through the

same procedure to get a 45° bend. I then cut the piece of acrylic

piece to make a very passable moisture shield for the solar panel

charge controller.

When the bending was complete, I used

my Bosch

jig saw, and files to clean up and round the corners

of the piece of acrylic.

First Bend Made On Acrylic

Second Bend Made On Acrylic

Controller Sitting On Finished Piece Of

Acrylic

Now all I have to do is fit the

controller and the ACR

EPIRB

under the companionway steps and see if it will work as planned.

When we did the fitting of the

Starboard

for the top of the hard dodger, I discovered I need to cut a notch it

the Starboard

to make room for the stainless steel frame of the hard dodger.

I got out my Dremel

Tool and inserted a bit I thought would do the job.

Sure enough, the tool made the cut out just right. Of course we will

not know until I take the Starboard

back to DREAM AWAY and do the fit.

I cleaned up from that project and got

started on the next project in line! This is the stern ladder. I had

cut the stainless steel pipe earlier in the week, now all I had to do

was polish the two pieces of pipe before welding them onto the the

two aft stanchion supports.

I polished the first pipe with 80 grit

sandpaper, and then used 120 grit sandpaper with the palm sander I

have. The pipe looked pretty good, but the second piece of pipe I did

differently.

For this piece of pipe, I again started

out with 80 grit sandpaper, but did the sanding by hand. I then used

120 grit sandpaper, then 220 grit sandpaper, and then finished off

with 320 grit sandpaper. When the two pieces of pipe are side by side

it is easy to tell which is the better polished. In the photo the

best polished pipe is on the left. I am not sure you can tell from

the photos.

First Polished Pipe On Right, Non

Polished Pipe On Left

First Polished Pipe On Right, Non

Polished Pipe On Left

Well Polished Pipe On Left

Well Polished Pipe On Left

When the polishing project was

finished, I went over to the marina.

I loaded the weed killer into the tender,

and went out to Pier “C” and removed all of the plant growth and

sprayed the source of the plants growing from the Pier. This should

keep the plant growth under control for a while!

I brought the tender

back to DREAM AWAY, and then Kitty and I did the top for the hard

dodger fitting. The notch I cut in the Starboard

worked and the fit of the piece was great.

When we put the port and starboard

pieces together, it became clear that I needed to make one more cut

on the port piece. The cut was barely the width of the saw blade, so

I would have to be careful setting up the cut.

June 04, Wednesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go over to the

shop

in the morning but drove into

New Iberia,

to Norman’s Auto & Diesel Repair. I had to

take care of the problem with the transmission for Ruby.

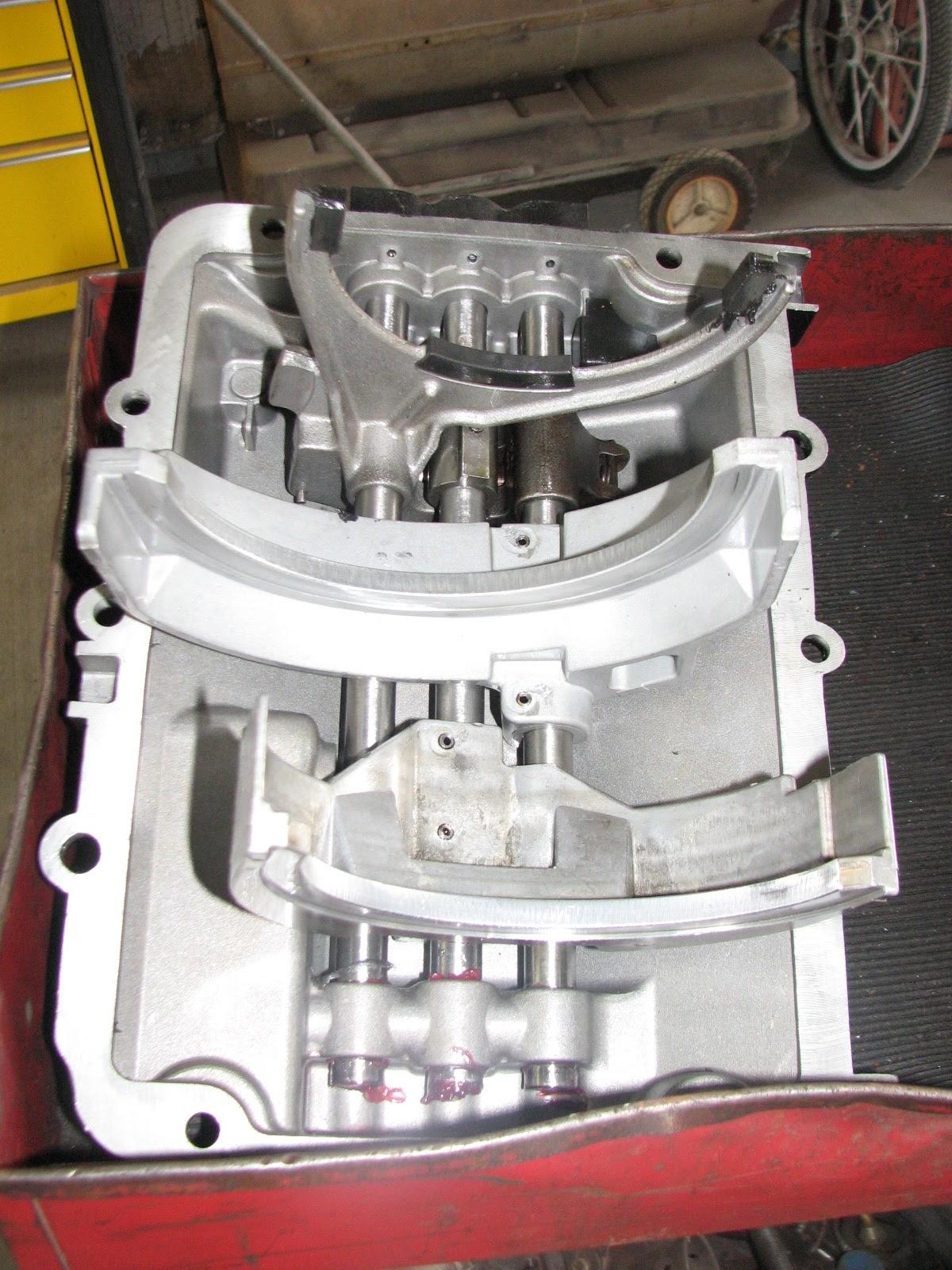

It turns out the transmission can have

a square top for the shifter or a round top. The transmission in

Ruby

had a square top and the replacement transmission has a round top. I

called Smart

Parts Automotive, from whom I purchased the

transmission, and got the problem worked out. They will be sending me

a new square top for the new transmission.

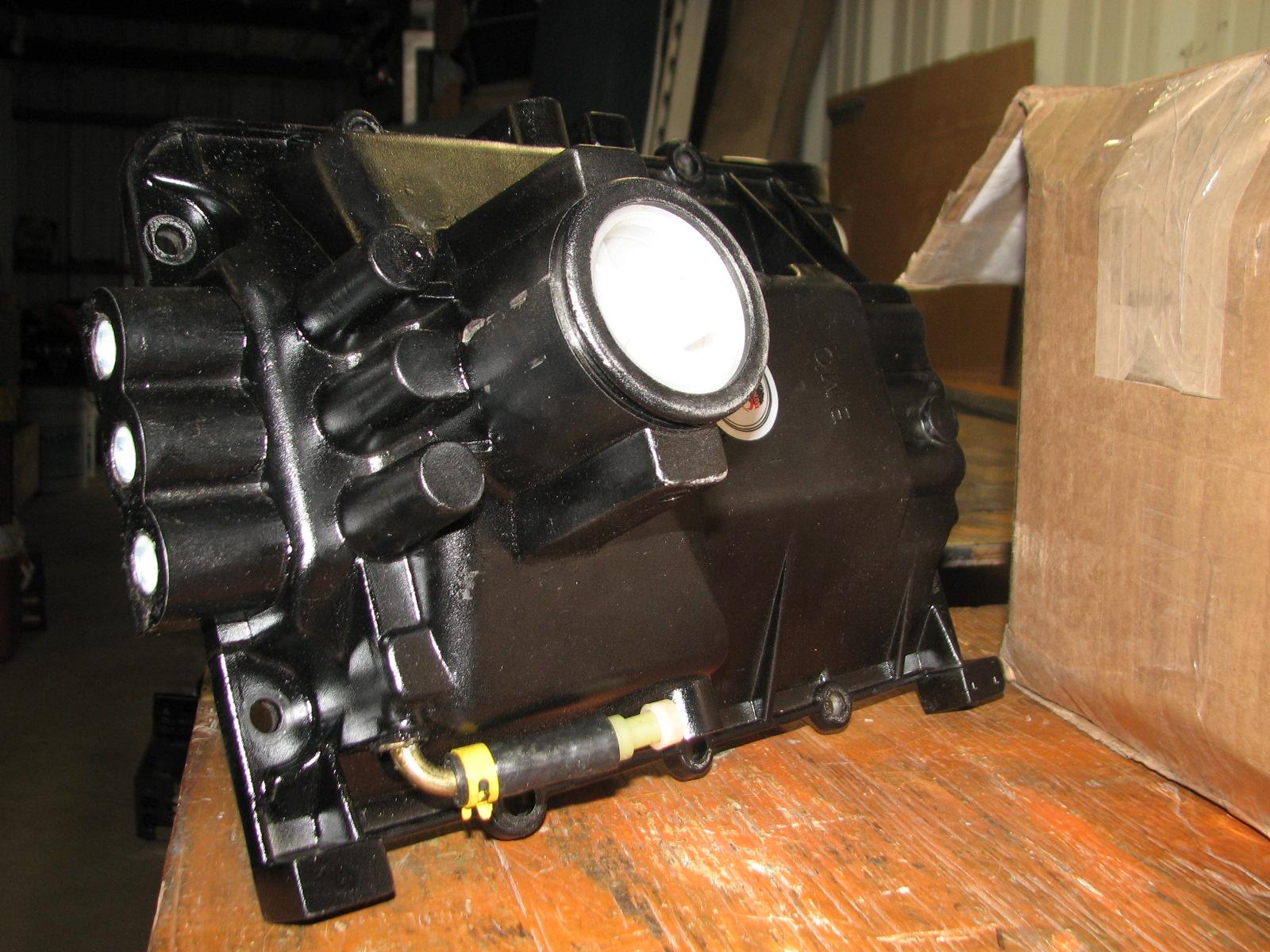

My Old Transmission With Square Top

New Transmission With Round Top

When we drove back to DREAM AWAY, it

was raining, so we canceled the Pier “C” cleat project until

tomorrow. The weather should be much better.

I spent the remainder of the day

getting all of my paperwork ready for my USCG

master’s license renewal and the VA

health system.

Now I have to get a date that I can get

over to New Orleans and submit the paperwork to the Coast Guard.

Hopefully with a clean bill of health, negative drug screen, and no

felonies to investigate, the process should go very smooth.

I got all of the VA

paperwork together so on my next trip to Lafayette,

I can submit it to the VA

office there. As it turns out, I was in the system, but you have to

update the system annually, and I had not done that. I am trying to

get an appointment for the Agent Orange test, and to get into the

health care system in case I ever need it.

I checked on the eBay

site and discovered that all of the solar panels had been delivered

to LeBlanc Oil. We drove over to LeBlanc Oil and picked up the four

boxes, and took them over to the shop.

Kitty and I unpacked all of the boxes

to verify contents and to verify physical condition. Everything had

arrived in great shape, but they did not send all of the Z

brackets. When we got back to DREAM AWAY, I logged

into my eBay

account and notified the seller. The remaining products will be on

their way soon!

Late in the evening, Kitty and I drove

to Hai

Nam Restaurant in

Abbeville

for the Marine

Corps League Meeting.

June 03, Tuesday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the

shop

and got to work on the console for Ruby.

I had finally completed all of the varnishing for the console, so now

it was time to put it all back together. There is a slight problem

with one of the tops not being in alignment, but that is what they

make sanders for!

Screwing Hinge To One Of The Tops

Top & Cup Holder Screwed Onto

Console Base

Console Completely Back Together

Console Completely Back Together

This is great, I have a project

finished. Now if I can just get

Ruby

back from the mechanic with the new transmission in it, I would have

a truck to put the finished console in!

I got a piece of the 1” stainless

steel pipe out and measured it. I need two 48” pieces to weld onto

the stern ladder stanchion bases. Before measuring, I had to use the

chop saw

to cut off the bad ends of the pipe.

When that was done, I measured out the

two 48” inch pieces and cut them on the

chop saw.

I cleaned up the area, and put the

chop saw away.

I then put a piece of the pipe in the

vice and started the polishing process. This will take some time, but

it is better to do most of the polishing before the welding process

starts.

Stainless Steel Pipe In The Vice

Kitty called and said she was awake, so

I went over to DREAM AWAY for breakfast. It is a light breakfast, as

this is a diet day, 600 calories max!

We went into Lafayette,

via the laundry in New

Iberia, for my appointment with the dermatologist.

Only two biopsies, so I felt pretty good about it.

Did a couple of errands on the way

home. Kitty called Norman’s Auto & Diesel Repair, and they said they

would be starting on the truck today or tomorrow!

We got home, and I started in on the

paperwork to renew my USCG

master’s license, and the VA

paperwork to get me into the healthcare system.

Around 1700, Tasha called from Norman’s Auto & Diesel Repair,

and said the transmission that I had ordered was

the incorrect transmission. Great another project and more expense.

June 02, Monday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went back to DREAM AWAY, worked on

computer and scanning the remainder of the day

Went over to the

shop

to finish cutting the Starboard

for the hard dodger tops. Before I got into that project, I had to

repair a couple of screens. It seems when our two favorite cats are

outside wondering the deck of DREAM AWAY, they step on the screen in

a hatch and push it through. So the screens must be repaired.

One Screen Waiting For Repair

Repaired Screen

I really needed to get the Starboard

cutting finished. I had cut one piece in the shop, and left the mess

on the floor. I wanted to get the second piece cut so I could get the

mess cleaned up.

I put the sheet of Starboard

on the saw table and placed the template in the best spot to keep the

holes in the hard dodger roof to a minimum. I used the template and

the first cut piece of Starboard

to get the exact measurements for the second piece of Starboard.

Getting Measurements With Template &

Starboard

Making Final Measurements With Template

With the measurements made, it was time

to get the fence set up on the sheet to make the actual cut with the

Skil

saw. Once the fence was measured and clamped down, the

cut takes about 10 seconds!

Fence Set Up & Ready For Cut

The Mess After The Cut

I got the second piece for the roof of

the hard dodger cut out, now it was time to get the shop

cleaned up.

Mess On The Floor Of The Shop

Finished cleaning up the

shop without

aid of a vacuum cleaner. I then started in on the stanchion plates

for the aft ladder I am fabricating. I am rounding out the hole in

the center for the 1” stainless steel tubing to go through.

Stanchion Plate In Vice

Kitty called, so I went to the

Port

of Delcambre’s storage room and picked up the lawn

mower and fuel tank, then went over to DREAM AWAY for breakfast.

After breakfast, I finished trimming

the gardens, and then mowed the lawns at the

marina

, finishing up in a light rain. One of

the wheels on the lawn mower had rusted away from the lawn mower

chassis, so finishing up was a challenge.

I loaded up the lawn mower and fuel

tank, and took them back to the

Port of Delcambre’s storage

room. When I came back to the

marina

, I took a shower.

I spent the remainder of the day

working on the computer, catching up on emails, working on the

Maintenance

Logs, and scanning in paperwork.

June 01, Sunday, 2014

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats,

Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go over to the

shop

at all today. I spent the whole day working on computers. I did

backups on the Linux

Mint PC and backups on my Mac. At this time, I still

do not have a navigation computer. As best I can tell, there is no

way to import the tracks and waypoints I have in my CAPN

software to the OpenCPN

software running on Linux

Mint.

I have not made the final decision

about the direction I am heading, but I am leaning back to the Mac. I

think I will install OSX

Snow Leopard back on my Mac and see how it runs. I

know all of my navigation products run on Mac’s XP virtual machine.

I do like some of the features of the

PC running Linux

Mint, but it seems like I am taking more time finding

out how certain applications run, than actually making progress. This

week will be my decision week.