Maintenance Log 07/2009 - 10/2009

October 29, Thursday.

It has been a very long day, and it is not over yet!!

Went over to the shop first thing and met up with Al. We loaded the truck with all of the remaining items that Al wanted and took them over to his shop. I then went back to my shop and loaded all of the items that should have gone to Atlanta, but did not make it. I took them over to Al's shop and put them all on the top shelf of the shelves I put in Al's shop.

I then went back over to my shop and loaded up all of the items to take to the boaters resale shop. I got all of the items over to the Boaters Resale shop and did all of the paper work for the goodies. Hopefully they will all sell at my asking price and I will have lots of money to go into the cruising kitty.

From the resale shop, I went back to the

shop and moved all of the cardboard boxes off of the second floor and

the overhead shelf. I broke down the boxes, and loaded more wood into

the truck and some other items that were trash. I left the shop,

stopped by the dumpster and put all of the trash items into it, then

off loaded the wood and other items that might be useful to the pier

four pavilion.

I went to Dream Away and decided to pack

away the new inflatable dinghy into the forward deck box. Naturally the

new 9'2" dinghy is bigger than the old 10' 2" dinghy. It took me

awhile, but I got it all packed away in the forward deck box. Then I

started on the raw water manifold. I cleaned the strainer, the

manifold, the ice maker strainer, the reefer strainer and the A/C

strainer. That also included flushing out the hoses with fresh water. I

then replaced †he lift pump for the raw water washdown/ watermaker. I

got that system working, and started the watermaker running into the

port water tank. I have a kit to rebuild the old raw water pump, as it

was making a lot of noise, and I believe there is a problem with it.

Next I replaced the freshwater pump. I wanted to get one of the spares into the system to make sure we were good for the passage. The new freshwater pump checked out great.

Then I went to dinghy and worked on getting it all ready for the passage. When I attached the blocks to the tabs I welded onto the davits, the line was not long enough. I will have to get more line from West marine tomorrow so I can secure the dinghy to the davits.

We went to dinner to Oscar and Elizabeth's boat, and had a great gumbo. After dinner we went over to the shop and loaded up the truck with a full load of trash which we took to the WYC dumpsters.

Went back to Dream Away with the new 80 cu ft bottle of Argon and packed it away under the bunks in the front cabin, along with a lot of teak for projects. I then started the watermaker. I was able to top off the port tank and started on the stbd tank.

October 28, Wednesday.

Yesterday was a long we. I finally finished packing spares, tools and sundry other items at 0030.

First thing this morning I went to Al's

boat, had coffee, then we went over to the shop. We dismantled some

large shelves I was giving to Al so we could move the shelves to his

shop, and put them back together. A friend of Al's come over to help,

which was a great help. We moved all of the big tools and tables

including the vise over to Al's shop. We also moved two truckloads of

stuff that Al wanted over to his shop.

The big set of shelves we moved to Al's shop, the top shelf is reserved for me. I am putting some items on there that I can move to Atlanta later, or I can use when I get back to Texas.

When we got all of the stuff moved over to Al's shop, I went back to my shop and started to do more cleaning. I worked on separating out the ferrous and non-ferrous metals for recycling. I also loaded all of the non teak wood into the truck to take to our pavilion for our winter fires. I also loaded a bunch of trash to take to the dumpster. Friend Troy came over to the shop and hauled away my big work bench. Now even more space. I still have a fair amount of items to take care of but I am getting closer.

I left the shop and went over to Dream

Away. I loaded a bunch of tools and consumables into a cart and took

them to the boat. I got them all loaded onto the boat with Kitty's

help. After lunch friend Oscar showed up with the two raw water pumps

rebuilt. That was great timing. I unloaded the truck so Kitty could run

some errands. I was going back to the shop, but I decided to stay on

Dream Away and check out the raw water pump on the main engine. I

installed the pump on the engine, connected all of the hoses, opened

the sea-cock, and hoped for the best. I started the engine and ran it

for about ten minutes. No sign of a leak. Oscar is a hero!!

When I finished that project, I removed one of the propane tanks from it's locker to take to the propane store. I took a shower, loaded the propane tank and headed out with Kitty. We stopped by Gordon's boat and picked up his propane tank. We then stopped by the shop and loaded the 120 cu. ft. argon tank. down the road to the propane store. We got my tank and Gordon's tank filled.

We then went down to Texas city to the Argon store. We had purchased a 120 cu. ft argon tank to use while I built the davits. It became obvious the 40 cu. ft. tank I had purchased with the welder was not big enough to do some serious welding. The purchase of the big tank was a sliding scale thing. Your purchase the tank, and in the first month you return the tank you get back 90 percent of the price. The second month you get back 70 percent, and so on until the fourth month you own it. When we went to the Argon store I wanted to trade the 120 tank I had for an 80 cu. ft. with no charge except the Argon. The reason being is I have room for the 80 but not the 120. Anyway, they agreed to the swap, but did not have any filled 80 tanks. They will fill one tomorrow morning, and Kitty will pick it up.

We left the Argon store and went to the Reef for dinner. After dinner we stopped by Walmart and filled all of the diesel jerry jugs with diesel, and one jerry jug with gasoline. We got back to Dream Away, and we brought all of the jerry jugs to the boat and got them loaded onto the boat.

Next I put away all of the tools and

consumables I brought down to the boat before lunch. An early night, it

is only 2300.

October 27, Tuesday.

Jim picked up Gordon and went to the shop to bend some tubing for him, and to pack the truck with chemicals, tools, and spare parts to bring to the boat. From the shop Jim went to Walmart to fill the diesel jerry jugs. He bought 35 gallons. Then he went back to the shop, picked up Gordon and took him home, and then he went to West Marine where he checked out the new dinghy (it was the right one this time), filled out the registration for the dinghy, and picked up other parts, including a new lift pump for the watermaker.

Jim came back to the boat, unloaded the oxy-propane torch, and bent the newly welded cleats. Then he brought down two cart loads of items from the truck that had to be stowed on the boat. While the carts were being loaded, the dinghy was delivered from West Marine, so that, along with the jerry jugs of diesel, were also brought down to the boat.

After lunch, Alan came over and he and Jim put the new exhaust elbow on the generator. Then they ran generator, and it checked out great. No problems encountered. Next they started the engine to check out the installation of the newly cleaned heat exchanger. Unfortunately, the heat exchanger could not be checked out thoroughly as the engine had to be turned off quickly because the raw water pump was leaking. This was bad news because our backup raw water pump had a known leak that had not yet been repaired.

We decided to work on the pumps tonight, and use the daylight to get the fuel in the boat, and to set up the dinghy. Twenty-seven gallons topped off the starboard fuel tank. Then we got the dinghy out of the box, took the wrappers off all the pieces, and set them out in the grass in front of the boat.

Being already behind on projects and packing due to yesterday’s storm, Jim was very concerned about having the time to properly repair the raw water pumps. When Oscar kindly volunteered to help in any way he could, Jim took him at his word, and asked if he would repair the two raw water pumps for us. Oscar graciously agreed to do so, at a cost of $2,000, which was magically the very same amount that Jim was charging Oscar to borrow our big grinder :-). Oscar now has the pumps and repair kits in hand, and said he would make the repairs and return the pumps tomorrow.

While Oscar and Jim removed the raw water pump from the engine, and discussed the repair procedures, Kitty and friends put the floorboards into the new dinghy, and inflated it. It looks great. It has been tethered to a tree in front of the boat for the night to see if it holds air correctly. Then we left for a lovely steak dinner with Pam and Steve.

After dinner, we hauled two more cart loads of stuff from the car, and loaded them on the boat. Jim is stowing chemicals and parts, and Kitty is assisting as possible, and writing this update with the Captain’s input.

It has been a long and productive day. Still more to come.

October 26, Monday.

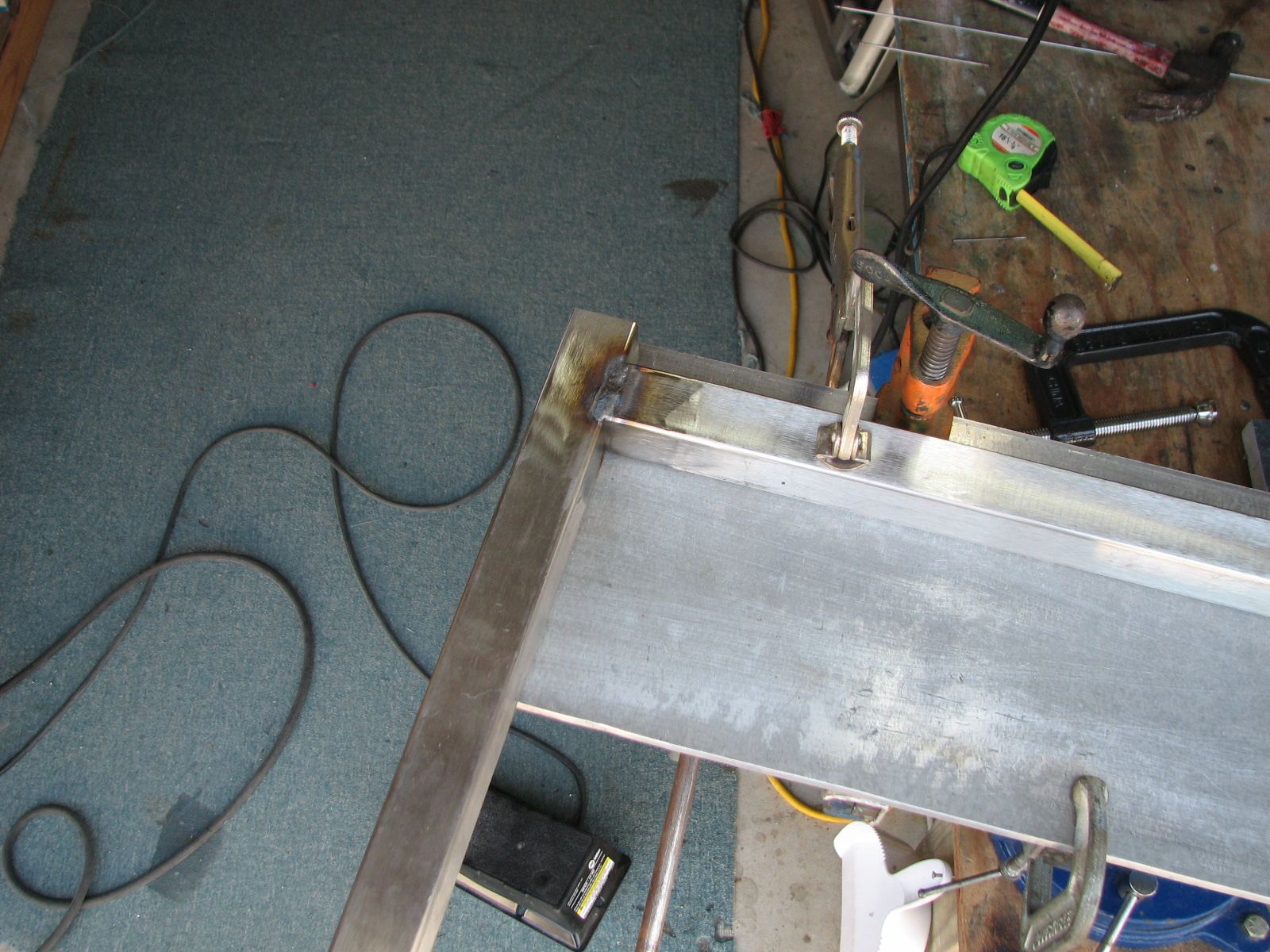

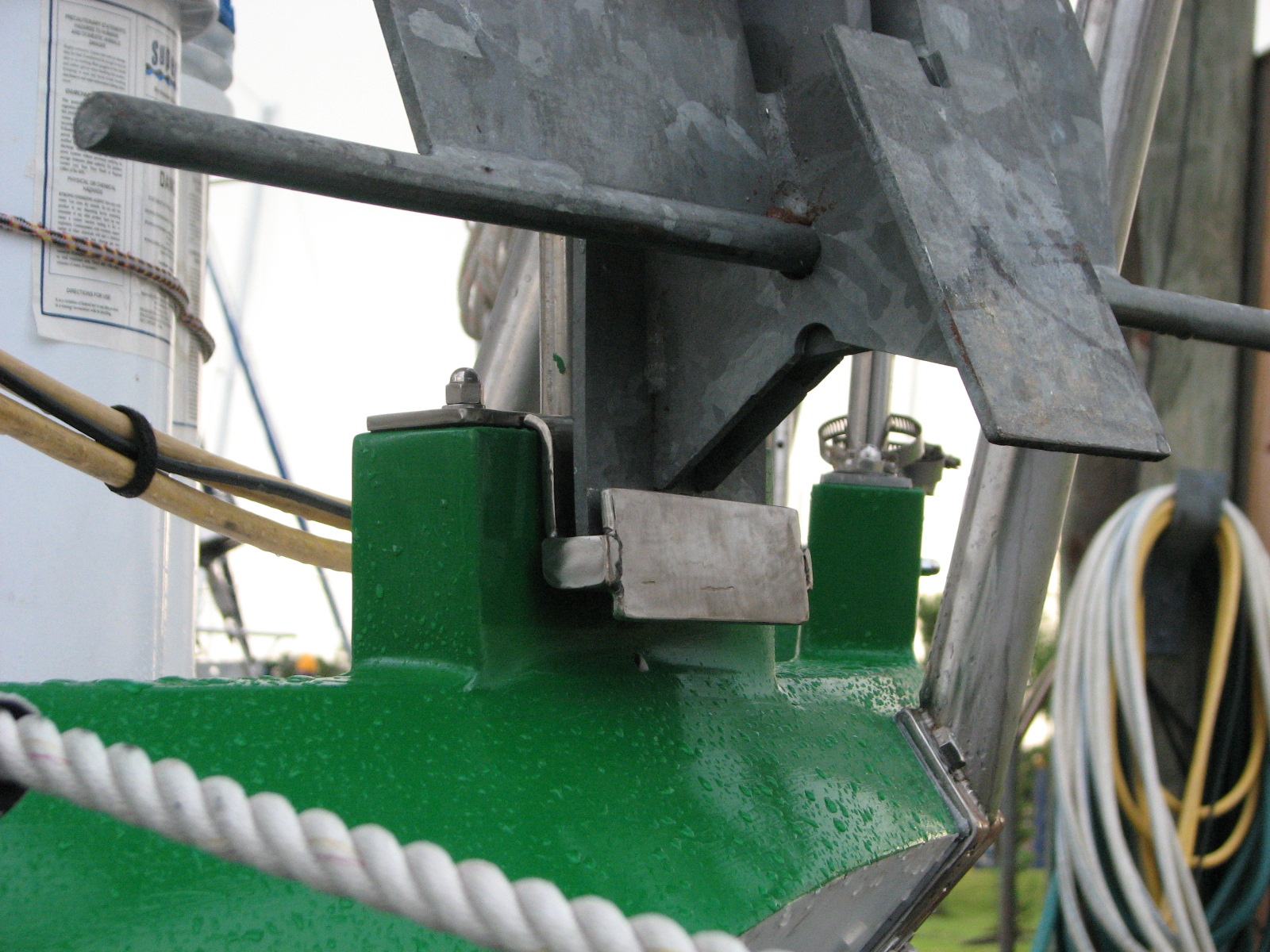

Started off the day welding tabs onto the dinghy davits. These will serve as hold-down blocks to keep the dinghy from moving laterally. These, in addition to the PVC pipes that have been installed, should help keep the dinghy stable while we are underway, and minimize its banging into the stern of the ship. I also welded two cleats onto the davits.

In an effort to beat the weather front headed this way, the torch parts were brought down from the truck and set up on the dock very early in the morning. However, the front came in with a vengeance so no torch work could be accomplished. The torch parts were set on the aft deck while the day’s appointments were undertaken, and then put back in the truck later in the evening.

The boat had been moved close to the dock to accommodate the torch work, but the front was so severe that the boat had to be moved away from the dock to keep the davits from being damaged. This was no small feat as the winds were in excess of 25 knots. It rained all day, soaking all the cockpit cushions, and everything else that was outside. The good news is that the heavy rain was a good wash-down for the boat.

From noon until late in the evening, we were involved in a doctor’s appointment, going to CostCo for some provisioning, stopping by Johnson’s Paint and Supply for a quart of resin, and getting some tools from Tommy’s Tools with which to replace the elbow on the generator. We then had dinner with Iris and Terry, and heard about their travels and travails aboard their barge in the canals outside of Paris. We look forward to visiting them some day and taking a lazy trip through France’s famed wine country.

When we got home, Jim

packed away the welder and the associate equipment. Then the late night

found him at his computer, as usual, attending to family business and

emails.

October 25, Sunday.

A long day and the eyes have it!! More later.

I checked on Blue Water Ships Store web

site, and they listed the wet exhaust elbow and the gasket I need on

line.

Went over to the shop first thing. On the way to the shop I stopped at Blue Water Ships Store. Their computer said they had the parts in stock, but they could not find them on the shelf. I left a note to get the parts ordered first thing tomorrow morning. I will call tomorrow to make sure the parts are on order, and the shipment is expedited. When I got to the shop, I worked on cleaning up the new parts I am going to weld on the davits for more dinghy support.

October 24, Saturday.

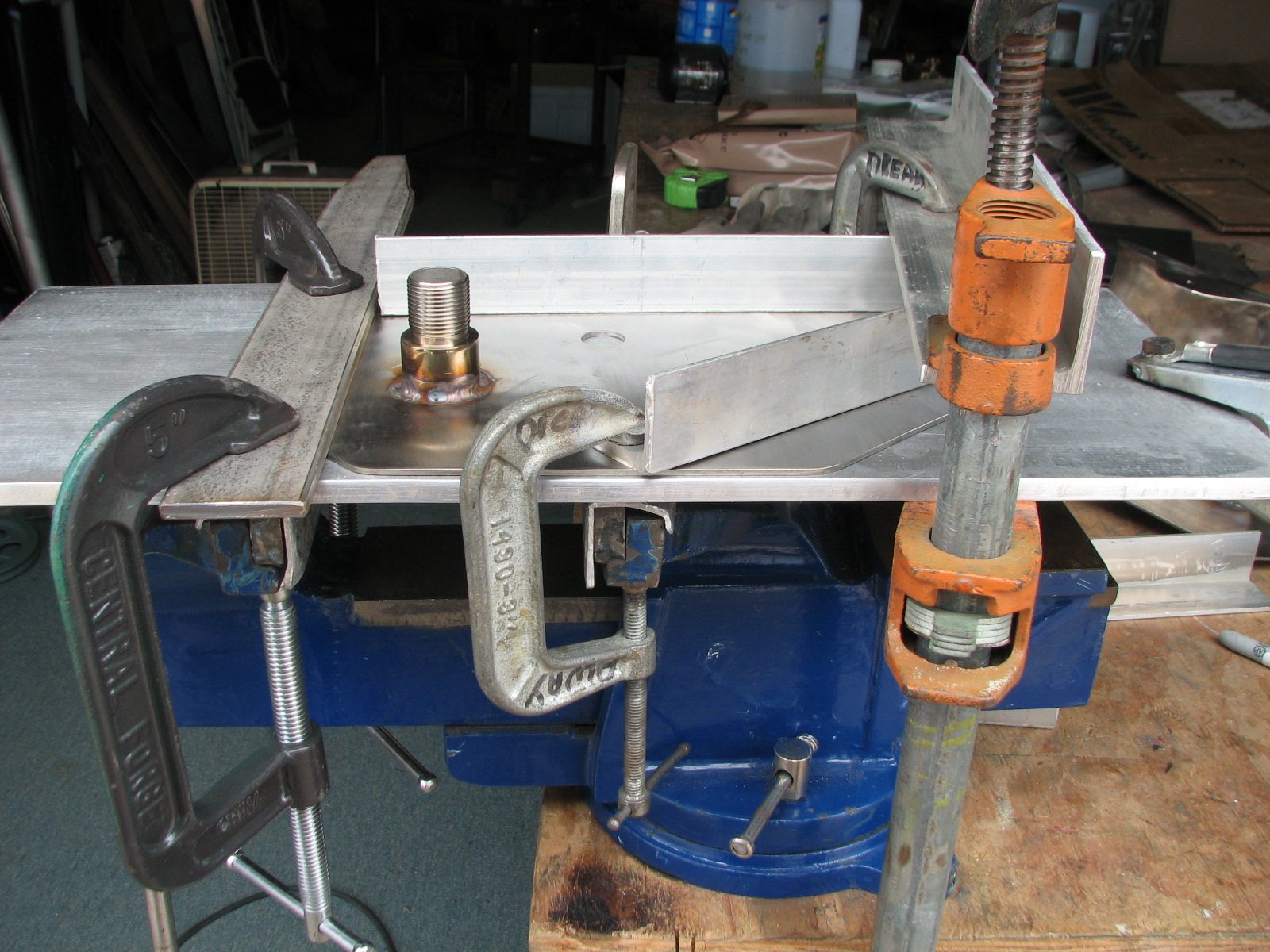

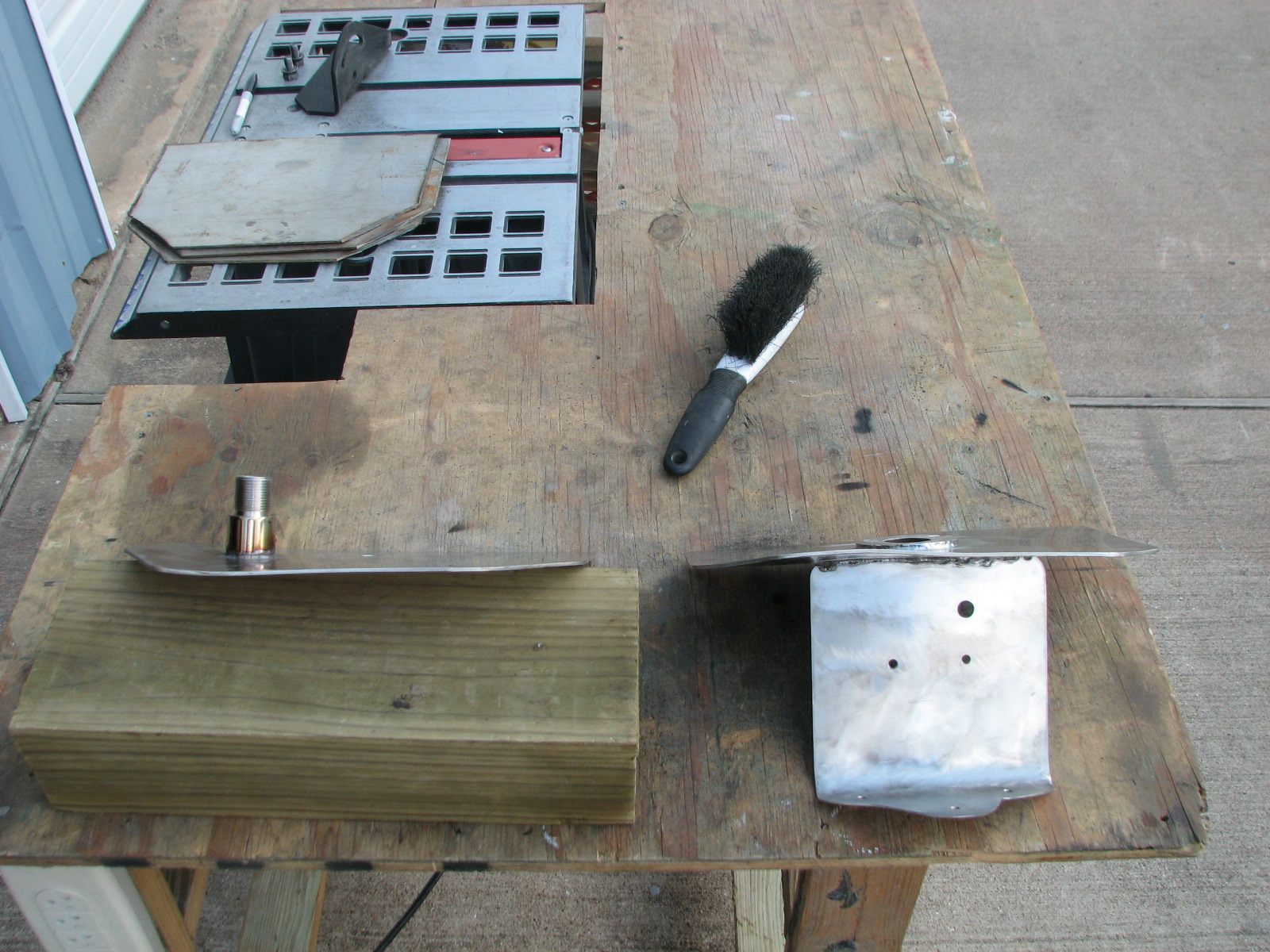

Went over to the shop first thing. Fabricated the parts I will need to weld onto the dinghy davits for the extra tie-downs of the dinghy. Friend Al showed up, and he helped me drill out all of the pieces of metal I will be using to support shelves, and to hold up Pelican cases.

I also went through all of the teak wood I have and separated out what I want to put on the boat for projects. I also cut a piece of PVC sheet to put on the boat for backing plates. I separated out some sheet fiberglass pieces i want to take in the boat. All of the separated out pieces I loaded into the truck to take to Dream Away. I also loaded the spare heat exchanger for the main engine.

Went back over to Dream Away. I took all of the doors off of the engine room, and did a good look around. I had to find the source of the salt build up in certain areas. I ran the generator for about ten minutes, but did not see any leaks.

Friend Al showed up to help me so we started on replacing the main engine heat exchanger. We took the old one off, put a zinc in the freshly cleaned one, and installed the clean heat exchanger. While we were doing the worked on the main engine, Al noticed a small crack in the generator wet exhaust elbow. We looked at it closely, and this seems to be the source of the problem. Water would leak out of the elbow into the generator pan. When there was enough water in the pan, raw water, the cooling fan of the generator would sling the water in the pan out right into the area where I was seeing the dried salt. So the source of the salt problem was solved.

We finished off the installation of the heat exchanger. We had a look at the old heat exchanger, and sure enough several of the cooling tubes were clogged. I had cleaning this heat exchanger on the list, so it will get done tomorrow.

Al and I started in on removing the old wet exhaust elbow. Of course the socket I needed, I did not have. I have a complete set of 1/4" drive sockets in metric, but somehow I have misplaced the 10 mm socket. So AL and I went over to his shop and retrieved a deep-well 1/4" drive socket from his tool box. We then went back over to Dream Away, and we were able to get the exhaust elbow off of the generator engine. When we got the elbow off, it was cracked on the back side also.

I am going to get a new elbow as soon as I can, and also see if I can get the old one welded up. The old elbow is cast iron, and I have no experience with welding cast iron, so I will have to take it out to get welded.

By the time all of this was done, it was

time to go see Steve at SeaTech systems. We went over to his

home/office, and he checked out my navigation computer, which is a

virtual XP machine running on my Mac. We did some tuning ox XP, and he

loaded a lot of new government publications, and the latest copies of

the government charts for the US.

October 23, Friday.

I got up the morning and started in on the email, and cleaning up the computer files. The wind was still blowing. It was a beautiful day, but cold, the overnight low was 53 degrees.

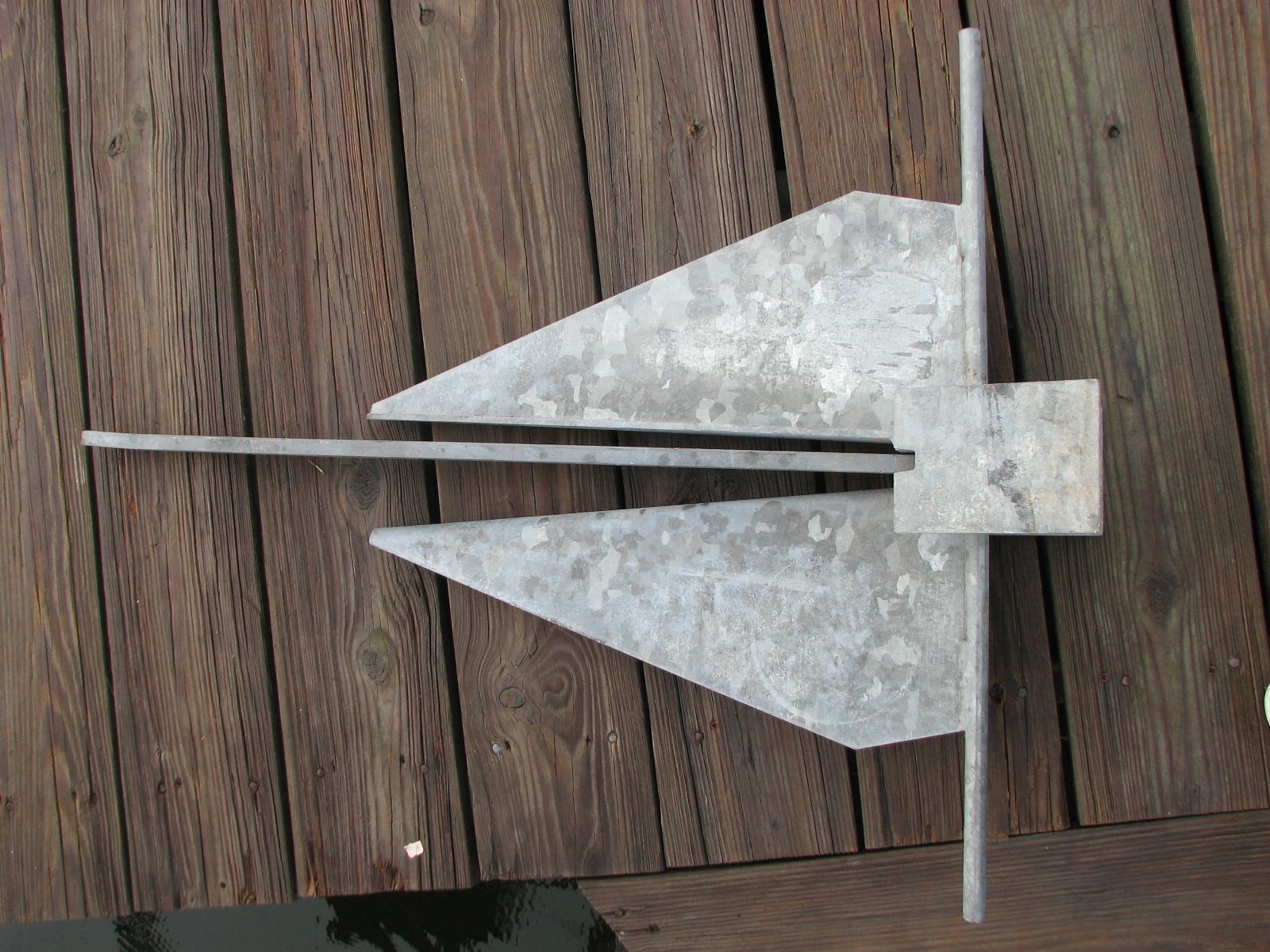

Kitty got up, we had breakfast, and then got ready for the anchor dance. I knew, as usually happens in Offatt's Bayou, once I get the anchor set, it really digs in. Having the wind blow all night from 20 to 30 knots really buried the CQR plow. I also knew it was going to be a hard slog home up the Houston Ship Channel (HSC), with an outgoing tide and a 20 knot wind on or nose.

It was a struggle getting the anchor up.

The chain was very muddy, so took a long time to get it in as I had to

hose the chain off as it came onto the boat. Finally got the anchor in

and stowed, and on our way. As predicted, when we got the HSC, it was

slow going. We averaged about 4 knots. Because of the crud on the prop

I could not speed up the engine any more as it would cause the engine

to overheat. We finally got into our slip at Watergate around

1730. I am having a friend come over on Monday and he is going to clean

the prop, and clean all of the thru-hulls.

One problem was discovered on our trip up the HSC. Kitty noticed some water on the floor in the garage. She opened the door to the engine room and could not see a problem. I went down and could find nothing wrong with the main engine, but did find residue of salt that appeared to be coming from the generator, but I could not find the exact source of the problem. That will be something I will have to look into tomorrow.

Kitty and I generated a project list that must be finished before we leave a week from Saturday. The list probably has 15 items on it, so this week will be a very busy one.

While backing Dream Away into the slip,

I had to rev up the engine a bit, and it overheated just as I got into

the slip. It appears the heat exchanger project has moved up on the

list. Got Dream Away secured into the slip. electricity and water

connected, and we were good to go.

October 22, Thursday.

I started off the day by getting on the

computer. Really not much else to do as it was raining and the wind was

really blowing. Continued with emails, and more back and forth emails

and phone calls to get the insurance squared away for the boat.

I decided to look into the issue with the watermaker. I decided that

the pump may still be part of the problem, but the first 30 micron

filter in the water input could be clogged, so I was going to change

it.

While I was getting all of the goodies out to work on that project, both of the anchor alarms went off on the two GPSs I keep running while at anchor. The weather had cleared up, and the norther had come through, so we were swinging on the anchor. The weather report said the front would come through later in the afternoon, but here it was 1100. So we dropped everything, got the engine running and went to the anchor drill.

We got the anchor up without any problems, and headed over to the north side of the Bayou to re-anchor. As expected it took over two and a half hours to get the anchor set. I do not know what the issue is with Offatt's bayou, but I have the devil of a time getting the anchor to set. Anyway after eight attempts we got the anchor set, and the snubber set. Just in time as the wind was really starting to pick up, 15 to 25 knots.

I went back to the water maker project.

I go the first filter changed, and bled. I started the generator, then

started the water maker. I set the unit to 600 PSI, and was making

about 20 gallons per hour. The unit ran for about two hours, so I think

the real problem was the filter, but the pump makes a lot of noise, and

it was very hot after the two hour run. While the generator was on I

also charged the batteries, and had the hot water heater on.

Felt pretty good about all systems on

the boat, so to finish off the day went back to the computer to scan

documents and answer emails.

October 21, Wednesday.

Another day started out with

electronics. I used the Single Side Band (SSB) radio to download

weatherfax. It went pretty well, but had some problems. I went through

the help file with the WeatherFax2000 software and set up the

software. I made several changes, so I will have to see. The USCG

broadcasts the weather faxes every six hours, so if I can remember to

tune in I will check out the new setting in the program.

We also spent time getting new insurance for the boat. We have to change policies to go to Mexico and Guatemala, so we were getting all of that organized.

Next was the dinghy and motor checkout. I was very pleased with the way the dinghy handled the trip. The tie down system I have seems to really work. I will have to weld on a couple of tabs and two more sets of cleats. It should work out very well. The PVC pieces will have to be adjusted some, but the basic down will work.and

We got the dinghy all untied and into the water. We dropped the Yamaha on the dinghy and got it all connected and set up. The engine started right up. We let the engine idle for a bit, and then put the peddle to the metal. Everything worked just fine. We went to the other side of the Bayou and stopped at the convenience store to get a couple of items. The dinghy really performs well with the Yamaha 15HP. It gets up on a plane quickly, and is a very dry boat. Both Kitty and I love it.

When we got back, we secured the dinghy and the motor. The checkout was very successful. Kitty turned too on contacting various people and Doctors in preparation of our departure. I wanted to get the WiFi system finished off. We got in the 12VDC to 24 VDC converter last Saturday. The converter had to be installed to power the EnGenius bridge. I finally got the converter installed, along with fixing a cabinet door in the mid-cabin. Got that all completed and everything put back the way it was. The WiFi system now runs completely off of 12 VDC. It also works very well. We are using a WiFi network here in Offatt's Bayou that is not secure, and is much faster then the Verizon Broadband. The only problem with the connection is we can not send email. To send email we switch to the Verizon Broadband connection. I will probably look for another free WiFi network that will work completely.

While I was working on finishing the

WiFi system. I started the genset so I could run the watermaker. Got

everything all set up and working, and was making water in about 10

minutes. After about an hour and ten minutes, I noticed the watermaker

was making some sounds that told me it was not getting enough water. I

shut the system down, and checked the overboard discharge from the lift

pump. There seemed to be enough water flowing, but when I reached down

and checked the pump motor, it was extremely hot. That means it was

working way to hard. It was then I realized I do not have a spare pump,

nor the parts to repair the pump. This will have to be fixed tonight. I

will order the repair parts, and a spare pump.

I remember I was going to solve the

problem with my one pump solution, but that did not pan out, and I

forgot to get the spares for the lift pump.

October 20, Tuesday.

Got up in the morning, had breakfast and got Dream Away ready to get underway. The windlass and wash down system worked great, and we had the anchor up and stowed in about 20 minutes.

We jumped into the Houston Ship Channel (HSC), and headed down to Galveston and Offatt's Bayou. With the wind direction, we were not able to sail, so we motored down the HSC, switched over to the Gulf Inter-Coastal Waterway (GIWW), and went into Offatt's Bayou. We were concerned about the wind instrument, so when we got into the clear and calm waters of the Bayou, we calibrated the wind instrument. It seems to be operating normally.

We then started the anchor dance. I do not know why, but Offatt's Bayou has it in for me when anchoring. I have never had really good luck getting the anchor down and set. Today it took six times, but I finally got the anchor set. Of the five times the anchor did not set, I let out 125" of chain. The windlass performed outstanding, so I could say all of the anchoring attempts were just to check out the windlass!! I know when we try to up the anchor, it will really be buried in the mud and will take a real effort to get it out. That will be an issue tomorrow. There is supposed to be a front come through tomorrow afternoon. The wind is now coming out of the south-southeast. When the front comes through the wind will blow out of the northwest, then the north. We will have to move to the north side of the bayou, and set the anchor.

I got out the Iridium phone and all of

the accessories to have a look and see how much effort it will be to

get the phone system installed. I was hoping I could install the phone

without removing the Globalstar phone, but that will not happen. Just

do not have the physical space. So I will have to remove the Globalstar

phone and all of its accessories. I am going to leave the antenna and

the antenna wire installed. At least that way I can re-install the

Globalstar with out too much trouble.

October 19, Monday.

Today started off with us getting ready to take Dream Away out and around Galveston Bay to check out the boat, the systems, and the captain and crew.

We left the dock about 1030 and headed out to the bay. When we got past marker #2 we raised the mizzen sail, and rolled out the Genoa. Everything looked good. We then raised the main sail and shut off the engine. We sailed across the ship channel into Trinity Bay, and just sailed around changing tacks when necessary. Everything checked out very well. We were able to tack with almost no problem, since I moved the stay sail stay back to the port main fife rail. This seems to be a good solution, and cheap!! I also checked the rigging on both a port and starboard tack. It needed very little adjustment. When I get back from this week's checkout, I will put cotter keys in all the turnbuckles on the main and mizzen standing rigging.

We were going to anchor at Red Fish Island. I wanted to anchor here for several reasons. First was because if we had a problem with the windlass, it would not be very far to get back to our marina. The windlass performed perfectly and we had no oil leaks! We also got the anchor down on the first try. The other reasons I want to anchor at Red Fish Island is because it is right beside the Houston Ship Channel (HSC). That means lots of traffic. I wanted to check out the radar and the new AIS systems. It is easier to be able to check out the radar if I am stationary, and can watch the targets go by. This worked perfectly, and the radar is working great. The new AIS system worked great also. The targets all came up on the CAPN software, and I could identify all of the ships and tows moving up and down the HSC. Both these systems were important, because I took the mizzen mast down and back up on Saturday, and both the antenna for the radar and the AIS are on the mizzen mast.

The wind generators on top of the mizzen

mast are performing wonderfully.

We then checked out the Hummer Grille by

grilling out steaks, potatoes and peppers. The grille worked perfectly.

The meal was washed down with wine and rum!

October 18, Sunday.

Went over to the shop first thing, and

went to work drilling the stainless steel shelf parts. The bad

news is I broke a drill bit, so could not continue with that project!!

I did get the teak covers all sanded down and drilled out to fit over

the fasteners for the SCUBA compressor rack.

Disappointed again with the fiberglass resin application. The resin kicks off great when I put the resin on the fiberglass, but the resin that was not applied to the fiberglass mat, did not kick off. I am at a loss. I am going to a company called Johnson glass and purchase some of their resin.

Loaded more stuff into the truck, and went back to Dream Away.

Hauled the stuff from the truck to the boat, and got most of it stowed away.

Got to work on the SCUBA compressor

rack. Put more roof mastic on the base pads, and bolted the rack down

to the after deck. Used longer bolts than before so I could put the

teak pieces over the bolts, and then put an acorn nut on the bolt to

hole the teak piece in place. Looks pretty good.

Next was getting the mizzen mast back together. I had to splice some wire onto the wires for the wind generators because I used about a foot of wire in the "S" fold in the wind generator mount. I got the splice made, then ran the wires back down through the hole in the deck. I then connected all of the wire back up. Wouldn't you know, when I got all of the wiring done the wind dropped so the wind generators would not turn. I hope the wind comes up so I can check out the operation of the units.

Got all of the wiring done. Climbed back up the mizzen mast to disconnect the line I used to attach the main topping lift to. I got the mizzen boom back on the mast and the sail folded properly. Put on the sail cover and dressed all of the lines, sheets and halyards. I put the Hummer Grill back into its place of honor. I then put new polypropylene line on the Horseshoe Buoy overboard system. The line is great because it floats, and is perfect in this application, but the polypropylene line really does not like UV. The line has to be changed yearly, in cruising conditions.

Got everything back together on the

mizzen mast, so we are ready to go on our check out cruise this coming

week. I then turned to on my work bench in the garage. I got most

everything squared away for an offshore trip.

October 17, Saturday.

Alan came over first thing in the morning to help with the mizzen mast project. We had coffee, and a nice breakfast prepared by Kitty. I had added the SCUBA compressor rack to the area just behind the mizzen mast. We had to remove the rack to be able to safely drop the mast. Alan and I got the rack removed, then we loosened all the rigging in preparation for the event. I secured a safety line around the base of the mizzen mast so if the mast kicked off of the mast step, it would not go flying.

Finally all hands showed up, we had nine folks helping with the project. We got under way and had the mast down in about 20 minutes. We moved the mast to a convenient area so I could fix the wind generator wiring problem. We got the wind generators removed, but my original plan for the fix would not work. The #8 AWG has a jacket on it, and the clamp I made was to go over the jacket. I had removed the jacket on the wires inside the wind generator mount. I came up with another plan. What I ended up doing was lashing a line to the wires, folding the wires over in an "S" shape, then shoving the wires down into the pipe mount. The line holding the wires was clamped down to the pipe using the clamp that is used to mount the wind generator.

We tested the installation by putting on the wind generator, then removing the wind generator, and pulling out the wires using the line. It all worked very well. It was great with the mast on the ground. It will not be easy removing a wind generator while the mast is up. We got both wind generators wiring repaired, now we were ready to put the mast back up.

I got the crew all back into place and

we got the mast back up in about 20 minutes. I got all of the rigging

secured, and we were done. I released the crew, and we went to the

pavilion and had pizza and beer. Kitty and I felt it was least we could

do for the crew helping with the mast project. Certainly it would have

cost a bunch more than the cost of four pizzas and a case of beer if I

had to do it at the yard.

After our pizza lunch with good friends John and Lee, I went back to the boat to get the rigging all tightened down and make sure the mast is aligned. Got that finished up, and it was the end of the day.

Picked up the new Iridium phone and all

of the accessories from SeaTech systems. Now I have another project.

October 16, Friday.

Went over to the shop and started

working on stainless steel shelf parts that I will be taking with me.

The parts are 2" stainless steel flat bar that I have used the torch to

bend at 90 degree angles to be used to support shelves or Pelican cases

or anything. I am using the drill press to drill holes in the stainless

steel. The drill press is much easier than trying to use a hand drill.

Now I will already have the holes in the pieces to mount them.

I also started cutting out pieces of teak with a hole saw that I will use to cover the holes in the overhead in the aft cabin where the bolts for the SCUBA compressor rack come through.

Loaded some more goodies into the truck

to be stored on the boat, and went over to Dream Away.

Hauled all of the stuff to Dream Away,

and got most of my stuff stored away in its proper place.

Got busy on getting the mizzen mast

ready to drop tomorrow to fix the slack cable issue for the wind

generators. To get a better idea of the problem, please see the April

25 entry in the maintenance log on the web page. http://www.dreamaway.net/maintenance_log_04-2009_06-2009.html

Took off the mizzen sail and the boom. Then took both out into the grass behind the boat and replaced the mono filament line on the sail that is used for the DutchMan system. Finished the installation of the mono filament line and folded the sail back onto the boom, and took the boom and sail over to the boat.

Went up the mizzen mast and tied off a line so the mizzen mast can be lowered to the ground using the main mast topping lift. Also removed the Hummer Grill, the boat hook, and the Horseshoe buoy overboard system. I verified the mizzen topping lift and mizzen halyard were long enough to act as staying lines as the mast dropped. I then disconnected all of the electrical lines that go to the mizzen mast. When I was sure I got everything done I could for the mizzen mast dropping project, I went back to the shop.

Kitty had purchased the two new belts

for the drill press, so I installed them. Those belts made quite a

difference. I finished cutting out the pieces of teak using the drill

press and a hole saw. I also sorted out more stuff to get rid of in the

shop, and loaded more stuff into the truck.

I then mixed up some more resin, and put

some fiberglass onto the SCUBA compressor cover. This cover would be

completely finished if I did not have so many problems with the resin

not kicking off properly. Any way we will see if any progress has been

made.

October 15, Thursday.

Went over to the shop first thing in the morning. Did not stop by the auto parts store to get the new belts. I decided to let Kitty do that errand, and also to stop by Triad and check on the pricing of a new inflatable dinghy. I worked on the SCUBA compressor cover. I completely washed out he inside of the box with acetone. I also worked on the clamps for the mizzen mast wiring. Loaded some more stuff into the truck to take to Dream Away. Left the shop, and went over to Dream Away.

Only took one cart full of goodies down to Dream Away. I stored away some spare rigging wire in case of an emergency in the forward cabin port side under the berth. I also stored away some fiberglass parts I will be using on the forward cap rail under the port forward berth. I also put some teak doors there that I will be using to make some changes in the mid cabin to take advantage of storage space not being used. Stored away a few other items.

Went to work on a problem we have with the staysail stay. When we tack the big genoa I have, the tack always gets hung up on the staysail stay. The solution is to move the staysail stay out of the way, but it is not as easy as it sounds. Any way I believe I have come up with a solution. That is all I'll say now. After we go out sailing next week and the solution is successful, I will take pictures and explain.

Next project is to try and get the dinghy in the davits from moving around while under way. Here again, I believe I have come up with a solution. I had two block systems left over from the previous davits. I have installed them in such a way I can keep the dinghy from moving horizontally back and forth in the davits. The arrangement I have now works, but is temporary. If the system holds up next week, I will weld a couple of rings to attach the blocks directly to the davits. Right now the blocks are attached to the davits with line. I will also weld on another set of cleats to tie off the line. If I do this, I will have to get new line, as the old line I have is not long enough.

Dinghy With Crossing Blocks and Tackles

to Secure Back And Forth Motion.

To solve the vertical motion of the dinghy while under way, I decided to use 3" PVC pipe. I cut the pipe to the proper length, and then notched each end to fit around the dinghy, and the other end to fit around the dinghy davits. I then tied a line on the dinghy, ran the line through the PVC pipe, then tied the line off on the davits. This PVC pipe, in conjunction with the blocks and tackles keep the dinghy very secure. Again this will be checked out next week.

PVC Pipe Between Dinghy And Davit On

Port Side.

PVC Pipe Between Dinghy And Davit On

Starboard Side.

The last thing for the day was a high

and a low. I am getting way to many of these. With Stacy's help we

purchased a new inflatable dinghy at West Marine today. It is a really

good boat with a lot of the features I want in an inflatable. It has

aluminum floor boards, it is made out of Hypalon rather than PVC. It

also has three chambers, and an inflatable keel. It also comes with a

pump, repair kit, oars, seat and a carrying case. The folks at West

Marine delivered the boat to me late this afternoon. When I finished

with securing the hard dinghy to the davits, I wanted to get the new

inflatable out, pump it up and make sure it holds air over night. Now

comes the bad news/good news. The boat we ordered was not in the box.

The boat that was in the box is a much better boat. It is a sport cat

by AMI. It is a great boat, a bunch of features, but two items that

made me decide not to keep it. First and foremost, it is much bigger,

so to store it in my forward deck box means I will have to remove some

stuff, and I have no place to put it. The second item is the boat is

made of PVC, which has really poor UV characteristics. It is a bummer,

because the boat I have in my possession is a $2800.00 boat, and the

one I purchased is a $1500.00 boat. I will return the boat tomorrow,

and hope they can find another boat of the one I ordered. I will try

and get some money off, because I am saving West Marine about $1300.00.

I will see if they will throw in a cover for free. Oh well more fun

October 14, Wednesday.

Went over to the shop first thing after stopping at Alan's boat for coffee.

Took a good look at the SCUBA compressor cover, and I am still having problems getting the resin to kick off all over. Just as I was shaking my head, John came by the shop. I had him come over and look at the cover. He seems to think there is some kind of contamination on the outside, and inside of the box. He recommended I was the box down with a lot of acetone, then sand the whole surface of the box both inside and out, then another generous washdown with acetone. I started that phase of the project. I washed down the outside of the box with acetone, and started sanding. I do not have many 80 grit disks left, but I have a bunch of disks for my big grinder, which was on Dream Away.

I loaded a bunch of stuff into the truck

and went back to Dream Away. It took two cart loads to get all of the

stuff down to the boat. One item was the ditch bag which I put into

it's place. I also brought over the remaining sails and packed them all

onto the storeroom. I also put the boarding ladder in it's proper

place, and filled the fuel tank for the Yamaha. Also packed away

several other items. I replaced the shock cord around the aft trash

containers. The shock cord was in bad shape due to UV, and I came

across my stash of shock cord while stowing away the sails. It was a

good time to get it done.

I/We decided not to go out and test the boat this week. Too many things were cropping up, so we have decided to go out Monday for the entire week next week.

After lunch Kitty had some errands to

run, so she took me to the shop to work, while she ran the errands.

I am taking down the mizzen mast on Saturday. The one thing I need to fix is the wire for the wind generators. The wire drops down into the mast, and the wire is so heavy, I can not lift up the wind generator to remove it. Alan and I came up with a fix for the problem. Build a cable clamp to put on the wire, and drop it down into the wind generator support. So while at the shop this afternoon I cut out the two clamps I need out of the 3/4" fiberglass I have left over from the stern stanchion project. I got one clamp fabricated, and will make the other tomorrow. I am planning to drill two holes in the wind generator support pipes, and put a rivet in each one. This will prevent the wire clamps from dropping down any further. When that is all done, I should be able to remove the wind generators from the support pipes.

Also while at the shop I sanded down the outside of the compressor cover. I will wash it down with acetone tomorrow and then put some resin and fiberglass onto the box.

I also started cutting out the four teak

pieces I need to cover the holes I put in the aft cabin overhead to

secure the SCUBA compressor rack. I ran into a problem as one of the

belts on the drill press broke. So tomorrow I will have to go get new

belts to be able to use the drill press.

Kitty arrived at the shop around 1730, so we both headed back to Dream Away for a welcome shower.

I started to use the new WiFi setup I

finished installing yesterday, but was very disappointed. With the MAC

I cannot access the wireless network. If I take the MAC into the same

room as the wireless router, I can access it. BTW, the router is only 8

feet away from the MAC. I used the Gateway PC, and was able to access

the wireless router from the main saloon. When I moved to the aft cabin

with the PC, I dropped the connection. Very disappointing!! I looked up

the EnGenius router specs, and it says the transmit power is 6db. The

transmit power for the Kyocera we normally use is 15dBm of power. This

tells me there is not enough power from the EnGenius router. This of

course will necessitate a few calls to get to the bottom of the problem.

October 13, Tuesday.

Never left Dream Away today, and it was a day of highs and lows. First the low. Triad called us in the morning to tell us about our inflatable dinghy. It has a lot of very small leaks, a seam coming apart, along with the bad valve which I knew about. They said it would cost around $800.00 to get the dinghy fixed. A new Achilles from Triad would be around $1600.00. For me there is not much of a choice. I can not see spending half the cost of a new dinghy on the old one, and I still end up with a 20 year old dinghy. I also cannot see spending the money for a new dinghy right now, so we shall see what plan we can come up with.

Started in on the continuing wiring project. First off was the WiFi amplifier wiring. Naturally I had to take half of the mid cabin apart to get the wiring completed. I finally got it all done. I had to wire the antenna from the antenna to the EnGenius EOC160 bridge. From the bridge I had to run a CAT5 Ethernet cable to the EnGenius ESR1221 router. I also had to run power to both units. I got the power cable ran to both EnGenius units, and the WiFi amplifier. Last was actually connecting the power cable to the correct breaker in the breaker panel. I then powered up the complete system and verified operation, and it does work.

Next on the list was installing the new EPIRB in the old EPIRB box. This was done, so we are ready to go with the new EPIRB. With the EPIRB and the Spot, everyone should know where we are under all normal and emergency situations.

Now we move onto the AIS receiver. Got the power ran to the AIS receiver. Naturally the power connector is unique for the receiver, so had to cut and splice to get the power working. I got the power cable wired into its proper breaker in the breaker panel. I was able to get a PL59 to BNC adapter from SeaTech systems. This item saved a bunch of hassle. I got the antenna connected to the receiver. When I powered it on, the lights blinked. I still had to connect the receiver to the computer via a new Serial to USB converter, install the drivers, and then make sure the CAPN software would see the new AIS signals.

Before I could do the AIS checkout, I had to put the navigation station back together. I got all of the pieces put back into their proper places, and checked out. I brought up my Mac, then the virtual XP machine. I loaded the new drivers on XP, then brought up the CAPN. Bingo, I was able to see vessels going up and down the ship channel so that system checks out good.

When I got the boat put back together,

and all of the tools and other things I had scattered about, Kitty and

I had a tot of Zaya to celebrate the tasks accomplished for the day.

October 12, Monday.

Went over to the shop first thing and worked on the SCUBA compressor cover. The wax added to the resin seemed to help, but could not say for sure. Mixed up some more resin with some wax in it, and glassed some of the outside corners of the cover. Film tomorrow morning.

Went back over to Dream Away, and started back into the wiring project. I installed the new black box for the Globalstar satellite phone. That went good, and was able to charge the battery on the phone. If they ever get the satellite constellation back up to par, will be be able to communicate with the Globalstar phone.

Next on the list is the AIS receiver. Naturally a bunch of problems there. The antenna coming down from the top of the mizzen mast needs to be plugged into a piece of antenna wire running to the navigation station where the AIS receiver is located. I have PL59 connectors at the end of each wire, but did not have a PL59 union. At the end of the antenna wire for the AIS receiver is a PL59 connector, but the AIS receiver takes a BNC connector. Now I will have to get two parts to get the AIS receiver working!!

Started in again on the power wire for

the WiFI amplifier, and Sirius antenna. Got both wire run up through

the navigation station. Ran the power wire through the navigation

station and into the electrical panel area. Ran the Sirius antenna up

through the navigation station up next to the radar display. This is

where we decided to put the Sirius radio. I ran the power connector and

the audio wire for the Sirius radio. Was able to get the Sirius radio

working with the aft external antenna, so now we will have music, news

and games all the way across the Gulf of Mexico.

Went into a small locker on the

starboard side of the main salon and installed a terminal board for the

WiFi power cables. The power is run from the main breaker panel to a

terminal board in the locker. From the terminal board, power is run aft

to power the WiFi amplifier. Power is run forward for the EnGenius

bridge and router. I started on installation of the EnGenius bridge,

but did not get very far. Hopefully the 12 VDC to 24VDC converter I

ordered will be in so I can complete the WiFi amplifier installation.

October 9 - October 11.

Went to San Antonio Texas for a reunion

of the employees of Bendix Field Engineering Corporation. This was the

company I worked for when I was working on the Apollo Manned Space

Flight Network.

October 8, Thursday.

Went over to the shop first thing and worked on the SCUBA compressor cover. Applied some more finishing putty in areas on the edges. Talked to one of the guys in another shop about the problems i am having with the polyester resin not setting up, or kicking off properly. He suggested I am using a lamination resin, and I need to add wax to the resin so the surface of the resin will kick off. I mixed up a batch of resin, added the hardener, then a small amount of wax solution. We will see.

Went back over to Dream Away and got

back into running wires. Ran the Sirius antenna wire, plus the 50'

extension cable from the aft starboard side to the main salon, then

under the floor to the port side in the navigation station. While

running the antenna cable I also ran the power cable for the WiFi

amplifier system. I installed the WiFi amplifier on the bulkhead

between the head and garage on the starboard side.

I did not even get the power cable for the WiFi system, and the Sirius antenna wire ran all the way to the ultimate destination. Both wire stopped just under the navigation station. The WiFi antenna did get to the mid cabin.

That is all I was able to finish. It is

very difficult moving everything out of the way to run the wires, then

put it all back in place. I should have taken a photo of the mess in

the main cabin.

October 7, Wednesday.

Alan came over first thing and he helped me get the repaired anchor windlass on deck. It really helps to have a second person, because my arms are just not long enough. We got the basic windlass with the new gasket installed. Alan had to go, so he went off. I decided to finish the windlass installation later. Kitty was going off to shop.

With Kitty gone, I was able to turn off the air conditioner and open the boat. I disconnected the AC electricity coming into the boat, and got to work on the wiring. I got all of the AC wiring from the input breakers to the output breakers with new 8 GA wire. I added in a new double pull, double throw breaker for the SCUBA compressor/welder outlet at the stern of the boat, and got the breaker all wired up with the new 8 GA wire.

I installed two new DC breakers, and moved the main salon light to a different breaker. I then ran a wire for the AIS receiver power. I still have to run the power wire for the WiFi amplifier. Hopefully tomorrow.

I finished the installation of the

anchor windlass. I attached the anchor chain to the anchors, so now we

are ready to go.

October 6, Tuesday.

Kitty and I had a meeting to get all of our plans together for the next two weeks to make sure we have everything on the list to get done.

I went over to the shop, but forgot the key, so had to come back to Dream Away and get the key. Back over to the shop to work on the SCUBA compressor cover. I sanded down a couple of areas, then put some putty on a couple of seams. When the putty had kicked off, I cut out some pieces of fiberglass, and glassed then to a couple of seams. I left the shop while the resin kicked off.

Got back to Dream Away, and put the

"Whales Tail" on the Yamaha outboard motor. This device helps keep the

prop of the motor down in the water, and also allows more power of the

prop to actually push the dinghy along. I then used one of the new

locks to lock the two outboards to the rail. I also used one of the new

locks to lock the dinghy to the new davits using a stainless steel wire

for that exact purpose.

I then went to the Hummer Grill on the

davits, and rotated the arm the Hummer sits on 90 degrees towards the

back of the boat. I fabricated the arm to be able to rotate the grill

out of the way of the mizzen boom. Great idea, but I have not tried it.

The good news is after I rotated the grill, the mizzen boom cleared the

grille. This rotation will be used for passages.

Next was a fun part. I ran the new wire,

8 GA tri-plex wire, from the back of the aft cabin to the circuit

breaker panel. This job took about 1.5 hours, but I did get it done.

Hopefully tomorrow I will get the time to get it all wired up in the

circuit breaker panel.

I then replace the two Hella 12 VDC fans in the aft cabin with the two new fans I purchased last week. These new fans are much quieter, they move more air, and hopefully parts will not fall of while in use. One of the fans removed from the aft cabin went to replace a bad fan in the forward cabin. The second fan will become a spare. It the tropics, it is very important to have air moving. Hopefully i will be able to afford new fans to replace all of the old Hella fans remaining in the boat.

I then put the second bronze padeye on the outside of the boat on the starboard side right at the gate. This padeye along with the first padeye i put on a couple of weeks ago will support the boarding ladder. That finishes a small project, but I can now deploy the teak boarding ladder on the port or starboard side of the boat.

Last item for the day. I went back to

the shop and loaded the anchor windlass. I have made arrangements for

Friend Alan to come over in the morning to help me install the

windlass, hopefully for the last time this year or next!!

October 1 - October 5.

Participated in the annual Harvest Moon Race. Dream Away did not participate because we did not get the anchor windlass back in time. The Harvest Moon Race is an annual race from Galveston, Texas, to Port Aransas, Texas. It is usually a fun time, especially because of the social events in Port Aransas and the Bacardi sponsored parties.

The morning of the start of the race, October 1, Rick had pancakes for breakfast at 0600. We enjoyed the breakfast, than started out around 0700 to get to the start by 1420 in our case. It takes about five hours to go from Watergate Yachting Center to the start of the race off of the Flagship hotel on the beach at Galveston.

We had a good start, but the wind was on our nose. We tacked back and forth for many hours, but did not make much headway. Finally a cold front blew through. It was very exciting for a while, but after the front came through, we had good steady wind from the north, and Vista Cruiser really started to go. We finally finished the race around 0140 on Saturday morning, with barely any wind blowing at the finish.

We got settled into our area, got the boat tied up, had a margarita, then a shower, then sleep. I slept in to 0930 Saturday morning. Had a great day visiting with a who;e bunch of friends.

At the awards ceremony Saturday night we got first place in our division. There were only two boats that finished in our division, and we beat the other boat!

Next day after breakfast, we departed Port Aransas to sail back home. Had a great sail all day, as the winds were out of the south and we were heading north. The winds finally gave out to such a point we were only making three knots, so we started the engine to get our speed back up. Jacob, one of our crewman, had purchased fishing tackle in Port Aransas. During the trip back he caught two fish, a Kingfish and a Bonita. Both were cleaned and put into the refrigerator.

We got back to Watergate around 1700 on

the 5th of October. Vista Cruiser was pretty well cleaned up when we

arrived. We all took showers, then grilled the fish in our

pavilion. With all of the fixins' we had some great fish tacos. I

was in bed by 2100, and slept through till 0600. It was a great race

and sail, and I am really happy I decided to do it.

September 30, Wednesday.

Went over to the shop first thing in the morning with Gordon. I worked on welding two support pieces for Gordon's dinghy davit's. While Gordon worked on fabricating pieces for me to weld, I worked on the other storage room. I moved all items out of the storage room, and moved them into the shop. Most of the items were to move onto Dream Away, but just did not have time to clean up areas on the boat, and get the stuff moved. I did get the other storage room emptied and swept out.

I finished Gordon's welding. We loaded the two pieces into the truck and went back to Watergate. We took the two pieces out to Gordon's boat. I then went back to Dream Away.

I spent the afternoon getting my

equipment ready for the Harvest Moon Race. I also helped friend Rick do

some last minute items on his boat to prepare for the race. I got all

of my gear packed and loaded on Rick's boat, Vista Cruiser. By the way,

Vista Cruiser is a Hardin Voyager 44'. It is almost exactly the

same as Dream Away. Also went by the Watergate office and picked up the

anchor windlass. I opened up the box to verify that there were no

leaking seals. I also verified a gasket was included.

September 29, Tuesday.

Went by friend Oscar's boat and picked him up. We then went over to the shop and loaded the welder and the Argon bottle. We then went back to Oscar's boat. He had asked be if I could weld one of his aluminum stanchions that had broken on his boat. This seemed like a small job, so I agreed. He needed it done by the first of October as Oscar and his boat are participating in the Harvest Moon Race. The good news is the job went very fast, and the welding was done in about 15 minutes. Earned another bottle of rum!!

I then took all of the welding gear back to the shop and unloaded it. I loaded the truck with three SCUBA tanks, the oxygen tank, and all of the dive gear I could locate. Because we were installing the SCUBA compressor rack over the aft cabin, I had Kitty break down our bed in the aft cabin. Because the bed was broken down, it left the whole area under the bed exposed, and that is were we store the three SCUBA tanks, the oxygen tank, and all of the dive gear. Two birds with one stone.

Got the SCUBA compressor on the boat, and got it aligned on the pads I had glassed onto the deck over the aft cabin. I drilled the four holes for the through bolts, through the deck. With the four holes in the overhead of the aft cabin, I was able to use a four inch hole saw to cut four holes in the overhead liner. This was to make room for the three inch backing plates. I cleaned out the area exposed with the holes in the overhead liner. We did a dry fit of the rack, but I did not have the correct size bolts. I had four inch, and three inch bolts, but needed three and a half inch bolts. Off to Kemah hardware. We purchased the bolts, and the PVC pipe and fittings to store the spare water maker membrane.

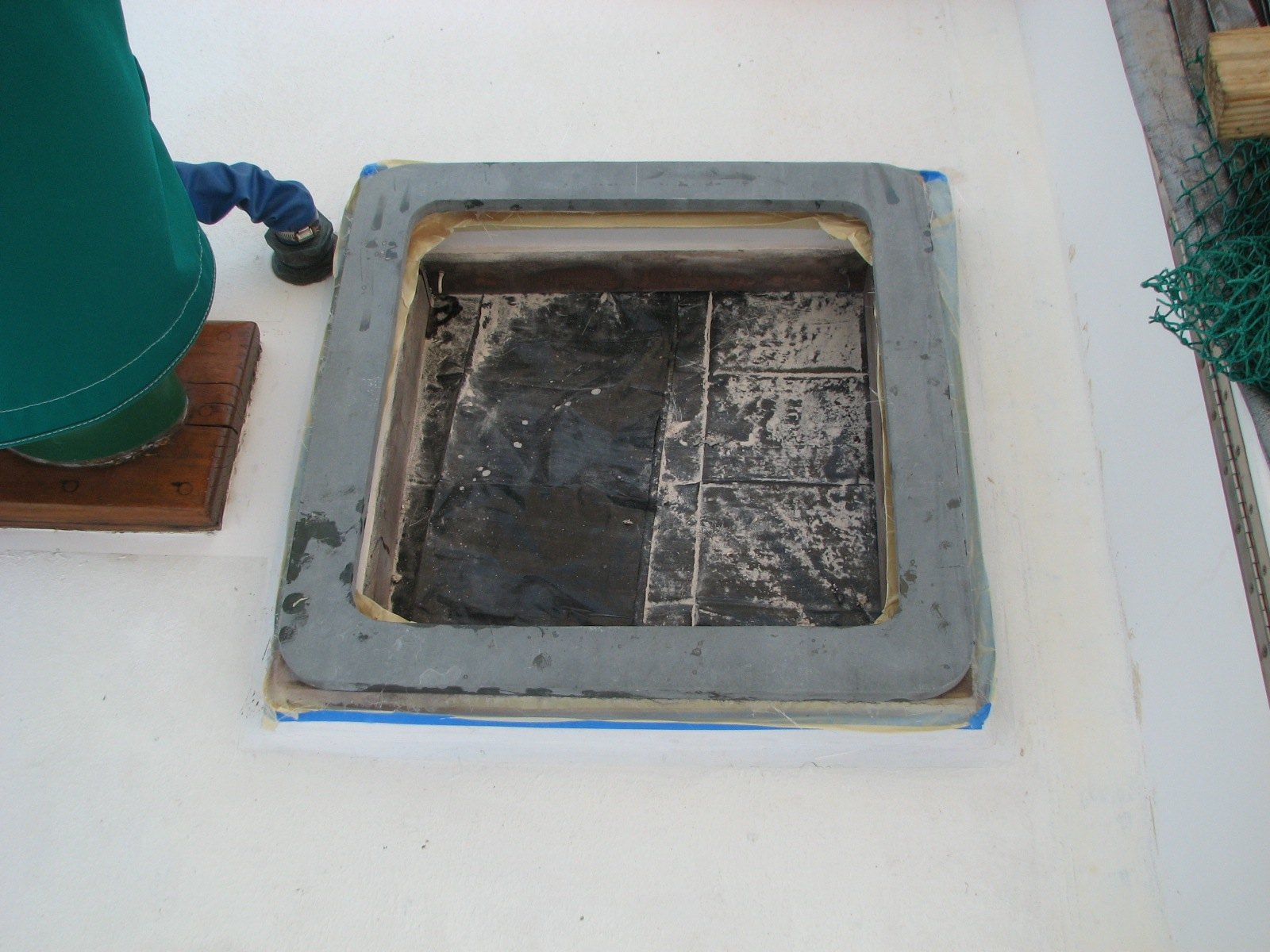

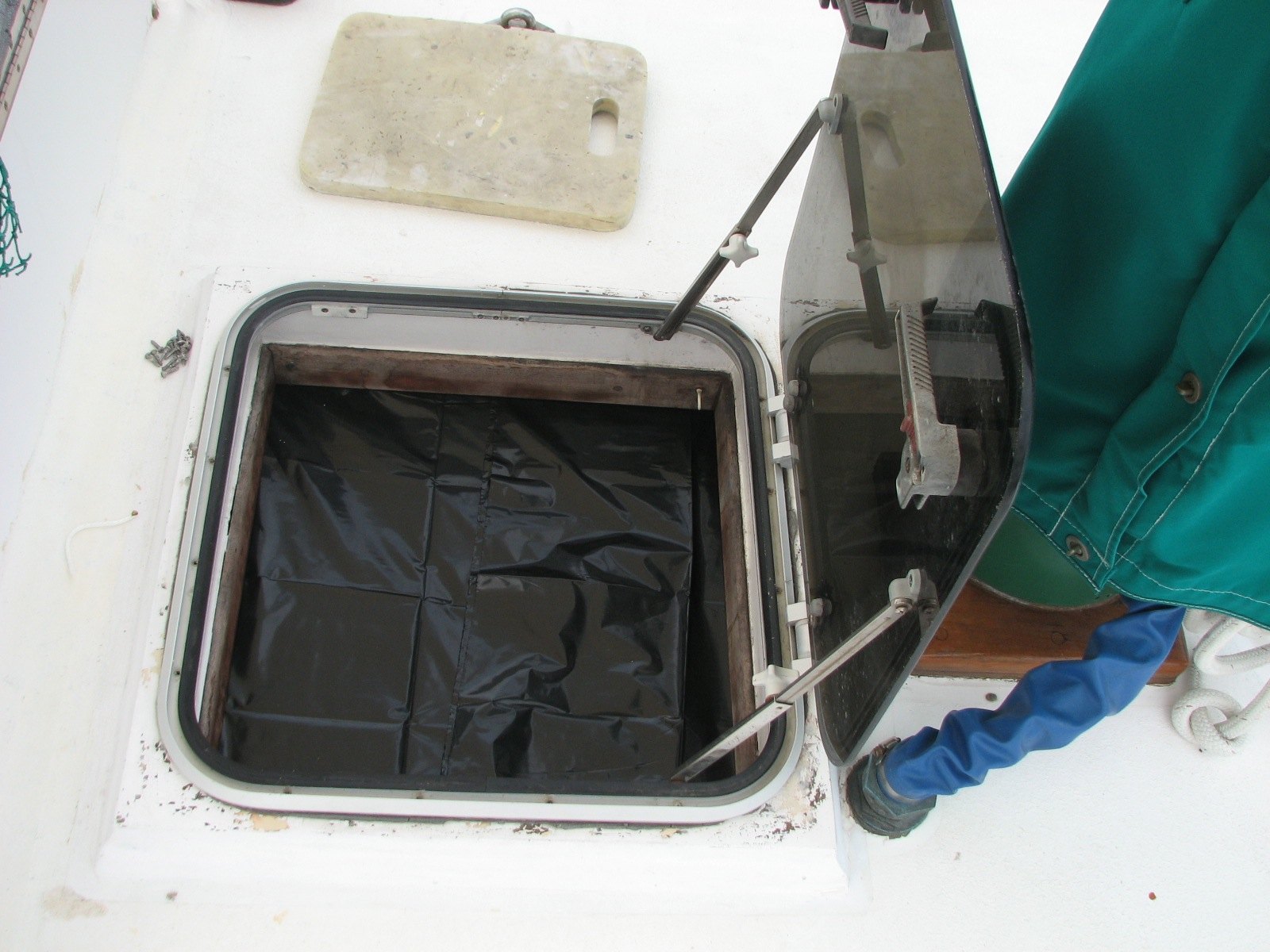

We came back to the boat, Kitty dropped me off, and she went to Best Buy to get her computer repaired. I went back to work on the aft cabin hatch. I marked all of the holes that required drilling with a screw starter. I then drilled the holes out with the screw starter. I did another dry fit of the hatch, and all of the holes were right on. I then applied plenty of roof mastic to the hatch, and installed the hatch onto the base.

Kitty returned, and we were able to get

the SCUBA compressor rack installed. I needed a second person because

my arms were not long enough to hold the head of the bolt and twist the

nut. The installed rack looks really good.

I then carried the three SCUBA tanks, the oxygen tank and all of the dive gear to the aft cabin. I got all of the tanks put into their places. Kitty tightened down the tank hold downs, and put all of the SCUBA gear and dive gear away.

Meantime, I was working on the mid-cabin hatch. I marked all of the holes that required drilling with a screw starter. I then drilled the holes out with the screw starter. I did another dry fit of the hatch, and all of the holes were right on. I then applied plenty of roof mastic to the hatch, and installed the hatch onto the base.

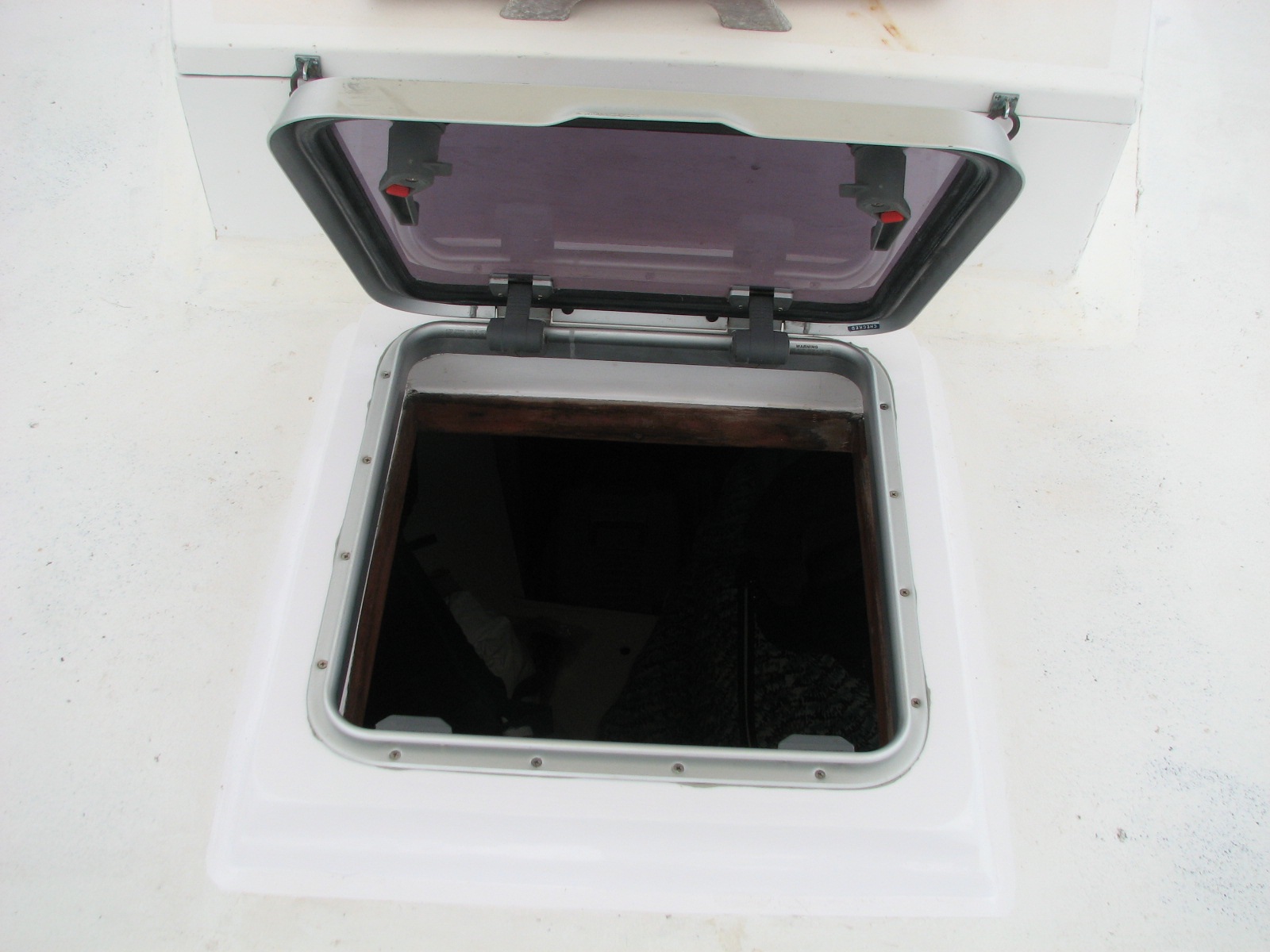

That is another milestone on our way cruising. The hatches and the compressor rack is the last of the major projects. What remains are several small projects that I will probably get done before we leave in November, but we could leave now. A toast was drunk in honor of the finished project.

Mid-cabin Hatch Base With Gucci Hatch In

Place. New Lewmar Hatch on Top Of Gucci Hatch.

Aft Cabin Hatch Base With Gucci Hatch In

Place.

September 28, Monday.

Kitty and I went over to the shop first

thing in the morning. We loaded all of the stuff in the staging

storeroom that was give away into the truck. Kitty drove the truck over

to Goodwill and dropped it all off. I moved all of the remaining items

I want to try and sell, back to the main shop. All that remains in the

staging storeroom are items that need to be loaded onto the boat.

I also worked on the SCUBA compressor cover until Kitty returned. I then loaded both outboard motors into the truck along with their fuel tanks, then we went back to Dream Away. I unloaded the motors and tanks and took them to the boat. Got some help from friend Harold, and was able to get the 15 HP Yamaha onto the outboard bracket. I then loaded the 5 HP Mercury onto the bracket. This was the first time both motors have been on the new outboard bracket, and they both fit perfectly.

Kitty went out to the Doctor's and to run some errands, so I was able to shut down all of the AC power to the boat. AS I said in an update a couple of months ago, I am running a AC wire to the aft deck box so I can plug in the SCUBA compressor and the welder. The wire is an 8 AWG wire, so I have to change all of the wires on the input breaker panel and the main AC Switch to 8 AWG wire. I started this process, but did not get it finished. I still have a fair amount of wiring to do. Hopefully when I return from the Harvest Moon Race, the weather will be cool enough that Kitty will be able to have the air conditioner off.

When Kitty returned to the boat, I put all of the wiring stuff I had out back into its proper places, got AC power back to the boat, and started the air conditioner. I then went over to the shop and worked some more on the SCUBA compressor cover. I am making very good progress with the cover.

September 27, Sunday.

Went over to the "staging" storeroom with Jimmy and Barbara. They looked over all of the stuff we are selling and giving away, and took some of it. They left and Kitty and I remained behind. We went through all of the stuff I had saved to go onto the boat. A few things were added to the give away pile, but most remained to go to the boat.

Went back to Dream Away. I prepared the hatch bases of the two hatches. I hit the bases with 220 grit sandpaper. Got both of the bases smooth, then wiped them down with acetone. I then went over the bases with a tack rag, and then put on the second coat of the Interlux Brightside single part epoxy paint. The bases really look good. I will now wait 48 hours before I install the hatches and the SCUBA compressor rack.

I then went below and worked on the

battery wiring. I had noticed a couple of problems with the wiring

yesterday while charging the batteries with the main engine. There is

still a weird reading I have no explanation for. I measure the battery

voltage at the batter with my DVM. The LINK 2000-R also measures the

voltage at the battery, but my meter consistently measures at least a

tenth of a volt higher. More checking will have to be done on that

issue.

I took the remainder of the day off. I

showered and read!

September 26, Saturday.

Went to the shop first thing, and started on the library store room. I loaded the remaining two sets of shelves into the truck, and took them over to Alan's shop. Back to my shop and the library store room. Loaded all of the trash into the truck.

I then spent some time working on the SCUBA compressor cover. Since I am making this cover out of several pieces of fiberglass, I have to put the cover together in pieces. I put two or three pieces together with finishing putty. I also use the finishing putty in the corners so I have a nice radius for the fiberglass. When the finishing putty dries, I then put one or two layers of mat plus resin, to build up the strength. I need to do this because I am sure the cover will be stepped on.

Went back to Dream Away, unloading the trash into a dumpster at the marina. Went over the two hatch bases looking for problems. Found a few, and hit them with 220 grit sandpaper. Got both of the bases smooth, then wiped them down with acetone. I then went over the bases with a tack rag, and then put on the first coat of the Interlux Brightside single part epoxy paint. The bases really look good.

I then attached the brackets that hold on the man overboard light and horseshoe ring. I then installed the light and horseshoe ring onto the brackets to finish that project.

I washed the third awning, and got it dried. I folded it up into a nice compact package, then had to re-fold the other two awnings so the foot print was the same for all three. There is limited space for the folded awnings, so I have to be careful.

I ran a complete battery cycle on just

three of the gel cells in the house battery using the engine

alternator. It took about five hours to go through the bulk charge,

accept, and then float. That time is more like what I would like to

see, but the real problem is, the measured voltage at the LINK 2000-R

never for above 13.95 volts. The bulk charge cycle, and the accept

cycle should have been at 14.4 volts. I generated an email and sent all

of the information concerning the charge to Xantrax. I have a technical

support call open with them concerning this problem. I opened the

support call on 9-22-09, and have not heard anything more from them.

September 25, Friday.

Started off the day by removing the covers from the hatch bases. Got out a soft cloth and wiped down the area around the hatch bases so they area would dry and continue applying the primer.

While waiting for the drying to occur, I installed the blocks Robert took off the stanchions for the roller furling back in place. I also removed the forward awning and put it off on the dock.

Next I got a new soft cloth, and with acetone, wiped down the mid-cabin hatch base and the aft cabin hatch base and compressor blocks. I then used a tack rag on both areas and applied the second coat of primer.

We went to South Carolina with Stacy, for the weekend to see good friends Dale and Karen. Had a great time. Came back to Atlanta and spent more time with the kids. Left Atlanta on the 23rd and had an eventful trip back to Houston.

Went over to the shop first thing, and spent the day loading the Dino onto the trailer, and then loading the truck with all of the Atlanta stuff. Had lots of help from many friends, so it all went very smooth.

Tomorrow it will be up very early, and

then under way to Atlanta with a truck full of stuff, and the Fiat Dino

on the trailer.

Went over to the shop first thing, and brought all of Gordon's Davits back to his boat. Helped him get his davits installed on the boat.

No Dream Away Projects today. Was employed with the Buffalo Bayou Partnership pontoon boat for the day.

Went over to the shop first thing in the morning. It was off and on raining, but I was able to get the generator working long enough to weld the chain on the SCUBA compressor rack, and the two aft gate wire.

Chain Welded to SCUBA Compressor Rack.

The remainder of the day was spent working on getting stuff packed and ready to move to Atlanta.

A small historical note, we had a Ike

survivors party party, and it was well attended. It was a year ago

today we all evacuated for the storm. Much of the area is back to

normal, but there are still many areas that have not been rebuilt, and

even still living in tents. It is all up to the media where the

suffering is. Even with Katrina, all anyone remember is New Orleans,

but the Mississippi Gulf Coat suffered much more damage than New

Orleans. They just rebuilt and moved on. Pretty much the same with Ike,

you are still hearing about Katrina in New Orleans, but nothing about

Ike, we are rebuilding and moving on.

It was raining like cats and dogs, so

did not do the walk with Puss-N-Boots. Stayed inside and worked on

getting the EnGenius bridge working. Another hour and a half wasted, no

progress.

Went over to the shop to do some welding. I wanted to weld the stainless steel chain to the SCUBA compressor rack, and to fix the two gate connections for the stern. Would you believe, as soon as I got the generator started, and the welder set up, it started to rain - a lot. Had to stop the generator and put it away.

No welding, but for the next two or three hours worked on getting the storerooms cleared out and organized. Kitty and I made good progress.

Went back to Dream Away for lunch. After lunch got back on the EnGenius Product. Called their support line and found out I have to use the router that was purchased with the system. Spent the next hour and a half working on getting the bridge and router working. Did not get it working. I will be calling the support line again tomorrow to see if I can get the system up and running. It is really interesting, in that the on line manuals are horrible, and do not match the software installed on either device. They could really use a technical writer.

Back outside and started in on the hatches. Worked on trimming and cleaning up the mid cabin hatch. Got the first application of the filler putty on the base.

Went to the aft cabin hatch, and finished off getting all of the gelcoat cleaned off of the hatch base, and the pads for the SCUBA compressor. Did not finish, but the filler putty on the mid-cabin hatch base had kicked off, so went back to that hatch.

Cleaned off and sanded the hatch base on

the mid-cabin hatch. Got it looking pretty good. Applied the first coat

of the finishing putty on the mid-cabin hatch base.

Back to the aft cabin hatch base. Got

all of the gelcoat cleaned off of the area, and all sanded down. Of

course there were a few bad spots, so had to put on another application

of the finishing putty. This will be the last application of finishing

putty on the aft cabin hatch base and compressor pads. Tomorrow,

weather permitting, I will sand the area down and get the first coat of

primer on the area.

Went back to the mid-cabin hatch, and

sanded down the hatch base. it was looking really great except for a

few minor issues. Applied the last coat of the finishing putty. Like

the aft cabin hatch, when I sand down this last application of

finishing putty, and clean up the hatch base it will be ready for the

first coat of primer.

The weather tomorrow is not looking good

for painting, but we will see.

Started off the day on Dream Away wanting to continue work on the hatches, but Mrs Nature had other thoughts. I made the attempt several times during the day, but each time it was raining. So it was other things that needed attention.

The last project for

the day actually happened while work on the WiFi network was

progressing. The air conditioner had stopped, and I heard water

dripping. This was not a good sign. I investigated, and discovered the

condensate from the air conditioner evaporator, was not draining

properly, and running out of its pan. I also discovered the sump for

this overflow was not working. I got the sump cleaned and working

properly, they was able to blow out the hose for the condensate pan,

and get it flowing properly. Just the routing maintenance of living on

a boat.

Went over to the shop first thing, and finished up the major welding on Gordon's Davits. Finally!!

Went back to the boat, and went down hill from there. There had been a major rainfall at the marina, but barely rained over at the shop. When I walked up to the boat, I noticed Robert's canoe, which he left behind our boat, had about 3 inches of water in it. He also left a lot of his work tools in the bottom of the canoe. I jumped down into the canoe and started to bail out the canoe. Next thing I know the canoe had capsized, with me in it. My iPhone got soaked. Major Bummer. I got all of Roberts things out of the canoe onto the dock, and hosed everything off with fresh water. We then put it all out on the dock to dry. I also finished the canoe bailing, and was successful this time.

Kitty and I went to the dentist for a six month cleaning, so that shot the remainder of the day.

Went over to the shop first thing and

spent the day welding on Gordon's davits. Finished at the shop around

1430.

Went to Gordon's boat first thing and helped him get his backing plates in for the Davits I am constructing. I know, please leave it at that!!

Went back to Dream Away to get ready to put the second coat of gelcoat on the after hatch base and SCUBA compressor pads. Not a good thing. For some reason, not all of the gelcoat had kicked off!! Some had done a fine job, and some of it was a bit tacky. I was pretty upset about it. I fumed about it for a few minutes, and decided to blow off the gelcoat. I could futz around with it for a couple of days, but the bottom line is I do not want to solve some kind of chemical problem. I want the hatch base to look nice.

I decided to remove the wet and dry gelcoat, and paint the area. Of course it is not as easy as 1-2-3. I started off with a scraper, and Acetone and paper towels. I got about half of it done before I had to got to the shop.

Went back to the shop and welded on

Gordon's davit project.

Went over to the shop first thing and worked for 2.5 hours on getting stuff ready to ship to Atlanta. I also put another layer of finishing putty onto the new piece added to the aft hatch cover. Went back to Dream Away.

Once at Dream Away, I got the mid-cabin hatch ready to glass. I got all of the fiberglass pieces out and made sure they fit onto the hatch base correctly. When I finished the sizing, I mixed up the resin. I went out and put both layers of fiberglass down on the hatch base which had been wetted-out with ample resin. Then I applied the hatch insert to the wetted-out resin, and made sure the insert was in the proper place.

Next, I started on the aft cabin hatch and the pads for the SCUBA compressor. I wiped down the whole area with Acetone and got the gel-coat ready for application. I was going to roll and tip the gel-coat. I thinned the gel-coat with Styrene, then added hardener. Then I applied the gel-coat to the aft hatch base and to the compressor pads. It looked pretty good, although I will have to add a second coat. I did not want to put it on super thick at first and have it look bad.

Aft Cabin Hatch With First Coat Of

Gelcoat Applied.

I went over to friends Alan's boat and

helped him with some electrical connections. From Alan's boat I went

over to the shop. I welded tabs on Gordon's davits. Went back to Dream

Away around 1830.

First thing in the morning, I masked off

the water line on the dinghy. I stirred up the anti-fouling paint and

applied two coats to the bottom of the dinghy. When I finished the

painting, I pulled off the masking tape.

Dinghy Bottom Painted With Masking Tape

Removed.

Went over to the shop first thing to work on the spreader bars for the dinghy davits. I cut some fiberglass pieces that just fit into the square tubing of the spreader bars. These fiberglass pieces will prevent crushing of the square tubing when the bolts and nuts on the eyes are tightened down. I inserted the fiberglass pieces into the square tubing, and drilled the holes for the eye bolts. I had marked the location of the eye bolts yesterday. I cleaned up the spreader bars, and went back to Dream Away.

On the way back to Dream Away, I stopped by West Marine and purchased four carabiners for the spreader bars. They only had three in stock, but I would get the fourth later in the afternoon.

When I got back to Dream Away, I got all of the hardware needed and constructed the spreader bars and put them on the dinghy. I then pulled the dingy over to the stern of Dream Away, Hooked up the block and tackle from each davit, and lifted the dinghy off of the dock so it was supported by the davits. Everything worked great and the project is mostly finished. I put the dinghy back onto the dock, and pulled it over to the grass. I turned the dinghy over and masked it off for a coat of anti-fouling paint. I will put the paint on tomorrow.

Dinghy With Aft Spreader Bar, Eyes and

Carabiner Attached.

Dinghy Hanging From Davits From The

Stern. Spreader Bar With Eyes to Davit Block and Dinghy Attachment

Point.

Dinghy Hanging From Davits With Spreader

Bars.

While I was working on the davits, Kitty had called Lighthouse Manufacturing, and talked to Jordan. He was very surprised the gasket was not included and upset about the oil leak. He issued us a FedEx Label to send the windlass back to him. Before the day was out, I had the windlass packed back up and in the truck. Tomorrow I will take the windlass over to the Watergate office to be picked up by FedEx.

Kitty found the missing Sirius radio outdoor antenna last night. I installed the antenna on the starboard antenna mount on the dinghy davits. I will run the cable next week when I have the "Day of the Wiring".

I started the installation of the pad eyes on the starboard side of the boat for the boarding ladder. I got one pad eye installed before I had to leave to run the flu shot errand.

After getting our flu shots, we went

back to the marina, where we picked up Gordon. We then went to the

shop. Kitty dropped Gordon and I off at the shop, and Kitty left to run

more errands. I helped Gordon with cutting and drilling pipes for his

dinghy davits. I cut out fiberglass pieces that I can use to complete

my cover for the SCUBA compressor. I have all of the pieces cut out,

now all I have to do put them all together into one piece and finish it

off so it looks good.

Started off today with friend Alan coming over to help me re-install the anchor windlass. The windlass had been sent back to Lighthouse Manufacturing because the seals on the shafts were leaking. I wanted to get the windlass installed, but it was very difficult to do by myself, so Alan came over to lend a hand.

I had not even opened the box with the windlass in it, because I first wanted to finish the forward hatch before installing the windlass. When I opened the box, which had been shipped upside down, I was shocked and depressed to see grease leaking out of the seal on one of the shafts. I also realized the gasket between the windlass and the deck, had not been returned with the windlass, so even if there was no leak the windlass could not be installed. I was so mad and upset, I dared not call the company. I just sent them an email with pictures asking what they are going to do, and where was my gasket.