Maintenance Log July 2013

July 31,

Wednesday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Spent

extra time getting information for Kitty printed, and trying to get

some air conditioner information. Also working on the Maintenance Log

for June and July.

The

technician from Tim’s

air conditioning called and

said he was on a call, but would come to DREAM AWAY as soon as he

finished. He came, and to make a long story short, I had fixed the

problem but did not know it. Yesterday when I cleaned out all of the

strainers, and blew out the hoses with the pressurized dock water,

there must have been a minor blockage in the AC cooling hose. After

cleaning out the hose yesterday, I did not attempt re-starting the

air conditioner, because I was afraid of damaging the unit.

When the

technician ran the unit, it did not cool properly, because i did not

bleed the air out of the cooling lines yesterday. Today after we bled

the air out of the AC cooling lines the system ran with no problem,

and has been the remainder of the day.

Next on

the agenda, I went out to pier C in our tender, and cleaned all of

the plants that were growing on the dock. Not a big item, but it did

not give a good professional appearance. When that was completed, I

mowed the grass at the marina,

and did a lot of grass trimming, and garden weeding. That pretty much

ended the day.

I still

have to find the switch numbers to properly repair the aft air

conditioner.

July 30,

Tuesday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Also

spent some time working on the Internet getting in touch with the

folks from whom we purchased the new Dometic

ECD16K-HV air conditioner

last January.

The

bottom line after spending a lot of time on the Internet and the

phone, is I am screwed and did not get a kiss! The Dometic

support person said it sounds like the problem is either water flow

or the high pressure switch. I know it is not the water flow, so it

must be the high pressure switch. The support person said those

switches rarely fail that new, the usually fail in the five year

range.

I also

found out the warranty for this unit is one year if purchased and

installed by a Dometic

certified technician. If purchased from anyone else and self

installed the warranty is six months from date of manufacture! To put

more salt in the wounds, I can not find the manuals that came with

the unit. So I am trying to find an electronic copy of the manuals.

The aft

air conditioner works, but the off/on switch is not working. I

removed the air conditioner controls from the panel, and used butt

connectors to wire out the switch. I verified the aft air conditioner

worked, then shut it off.

Aft Air

Conditioner Control Panel

To insure

there were no water flow problems with either air conditioner, I

cleaned out the main strainer for the manifold (Sea Chest), and the

manifold (Sea Chest). Also cleaned out the strainers for the ice

maker cooling pump, the refrigeration cooling pump and the forward

and aft air conditioner cooling pumps. During this cleaning process,

I also cleaned out the hoses for all of the cooling pumps using high

pressure water from the dock.

When I

finished and cleaned up from this process, I started the aft air

conditioner. Kitty was out doing laundry, and I wanted the aft cabin

cool when she returned. A problem presented itself with the aft air

conditioner. When it had run for about 10-15 minutes, the breaker on

the control panel would pop. Not a good thing. I would wait about 3

minutes, reset the breaker, and it would run again for about 10-15

minutes.

So now I

have an additional problem with the aft air conditioner. I suspect it

is a problem with another switch on the control panel. The input wire

(black), is has been very hot and is corroded, and the connector on

the switch is not very nice either. I will try and get the numbers

off of the switch and see if I can find a new one.

I also

contacted Tim’s

air conditioning in

Broussard, Louisiana, to see if they could come out and repair the

high pressure switch on the forward air conditioner. The Dometic

support person recommended Tim’s

air conditioning as the

closest Dometic

approved repair vendor. The technician was gone for the day, but the

secretary said the technician would call first thing tomorrow

morning.

I then

went over to the shop

and got the awnings for DREAM AWAY. They are not in the best of

shape, but will probably help keep the inside temperature down until

they fail. I put up the aft awning and the midships awnings. They are

in the best shape, but they need to be replaced. That project has

moved up the list a lot. The forward awning is in such bad shape, I

did not put it up. I will probably put it up tomorrow, and leave it

up until it blows out completely.

July 29,

Monday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

The MacBook

Pro is still up and

running, with no apparent problems, so I will continue to catch up on

my email, and trying to get the June and July Maintenance Logs

updated.

Drove into Lafayette

for doctors appointment for Kitty. Doctor was delayed by two hours,

so we did not get back until 1830. When we arrived on DREAM AWAY, the

forward air conditioner was down.

We were getting a HPF

error indication which is a high pressure shutdown. This error

usually indicates a cooling water flow problem. It did not appear to

be the problem, but I cleaned out the main input strainer, and the

specific air conditioner strainer. I also vacuumed the air filter on

the evaporator. Nothing helped the problem.

We went to bed without

air conditioning. It was not bad at all, the temperature was in the

mid 70’s, and we have plenty of fans.

July 28,

Sunday, 2013

Started off the morning

with my normal ritual of getting on the Internet and checking the

weather, while making a pot of coffee. Having computer problems, so

no checking of email.

I had left a

permissions fix program running on the MacBook

Pro all night long, and it

did not finish. I then decided to do a backup from my Time Machine

backup hard drive on the MacBook

Pro. Somehow I completely

screwed that up! It was a bust!

As of this point in

time I am backing up from my last clone which is two months old! I do

have a backup of all my data files from yesterday morning, and email,

so I will be able to restore those files if the backup is successful.

I have been successful,

and I am now back up and running on the MacBook

Pro. I have been able to

download email, so the remainder of today will be getting caught up

on email, and working on the maintenance logs for both June and July.

An unusual occurrence

on the Delcambre Canal this afternoon. After my shower I was enjoying

an adult beverage in the cockpit, and a spud barge and towboat came

by, and went up into the lake.

Towboat

With Spud Barge

Towboat

Pushing Spud Barge

July 27,

Saturday, 2013

Started off the morning

with my normal ritual of getting on the Internet and checking the

weather, while making a pot of coffee. Having computer problems, so

no checking of email.

Went over

to the shop,

and did some cleanup because Mark has moved some of his stuff out of

the shop.

He still has a bunch of engine parts in the shop,

but they will be going on his newly installed engine on PERELANDRA.

I

unpacked the new Evolution

Rage III compound miter

saw, and put it together and tested it. Looks like it will be a

dandy. I was able to cut my stainless steel square tubing at a 20

degree angle. This saw will be most helpful with future projects.

Evolution

Rage III Compound Miter Saw

In Box

Evolution

Rage III Compound Miter Saw

Ready For Use

Evolution

Rage III Compound Miter Saw

After Cutting Stainless Steel Square Tubing

I then

applied the fourth coat of varnish on teak pieces to cover the davit

holes in aft cabin, the teak piece to cover the winch hole in the

main cabin, and the teak electrical wire cover.

Left the

shop

and then back to DREAM AWAY to try and get out of the hole with my

computer problems. The MacBook

Pro I am using is dying a

slow death. I did all of the backups, and have moved all of my data

to my backup Gateway PC. In fact I am doing this entry from the

Gateway. I have to try and get the MacBook

Pro back up and running

from the backups I have been doing.

I got the

power washer out to see if I could make any progress on the rust

stains on the outside of the hull. No effect whatsoever. I will have

to remove the stains the old fashioned way, with elbow grease, and

stainless steel cleaner. A good toilet bowl cleaner works wonders on

stainless steel and stained fiberglass.

July 26,

Friday, 2013

Started off the morning

with my normal ritual of getting on the Internet, and checking the

weather, while making a pot of coffee. No email because I am having

some computer problems.

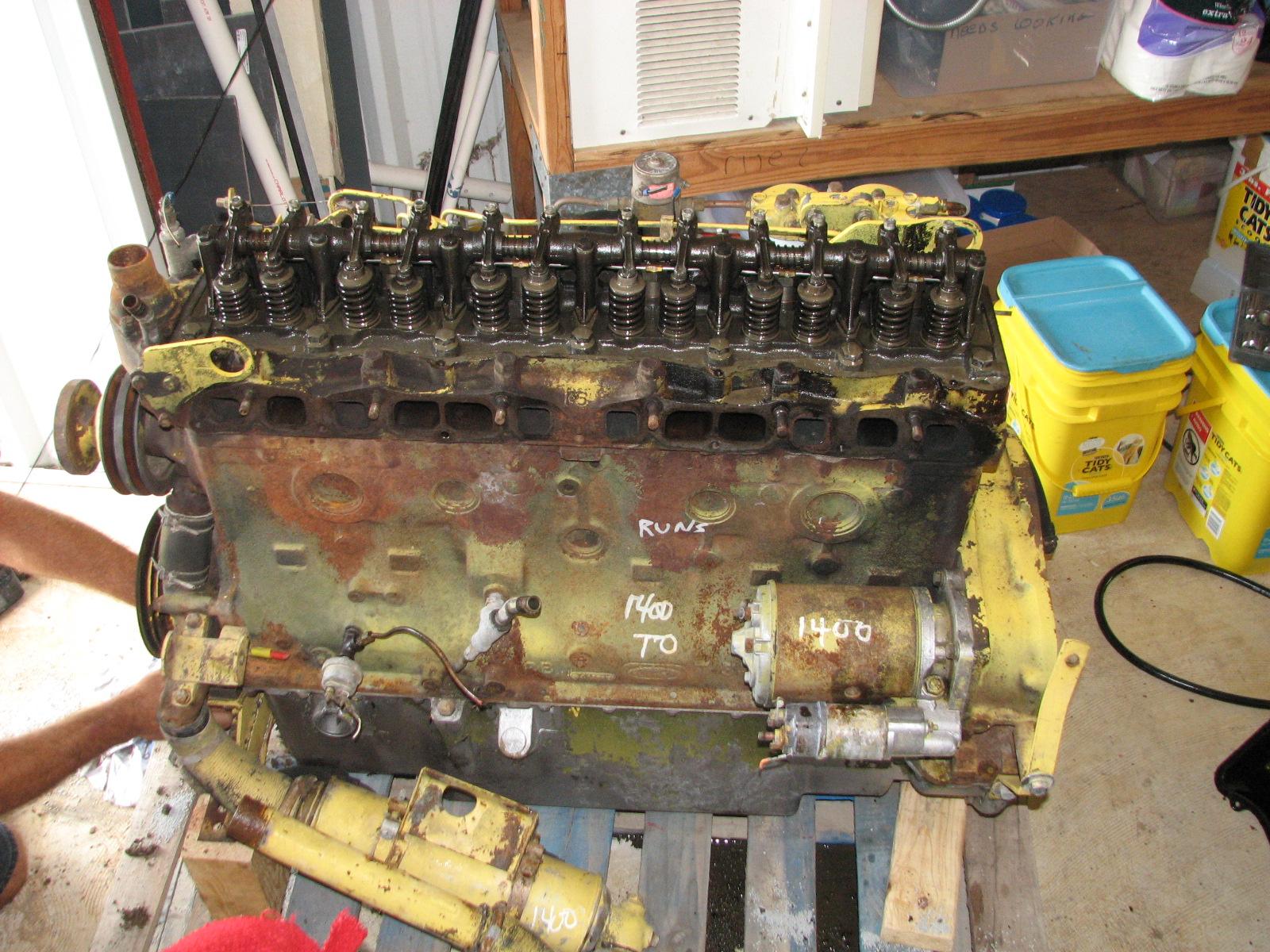

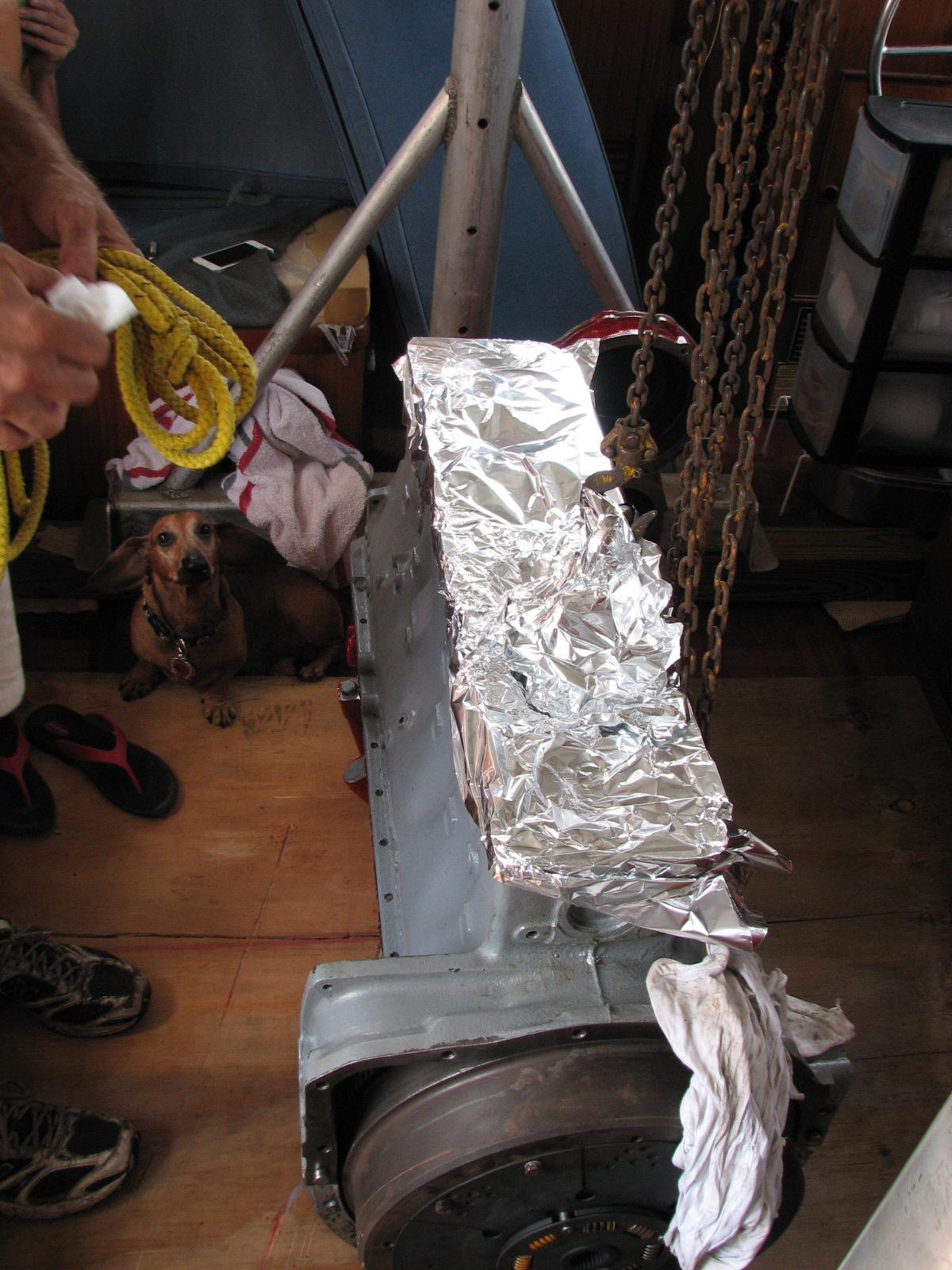

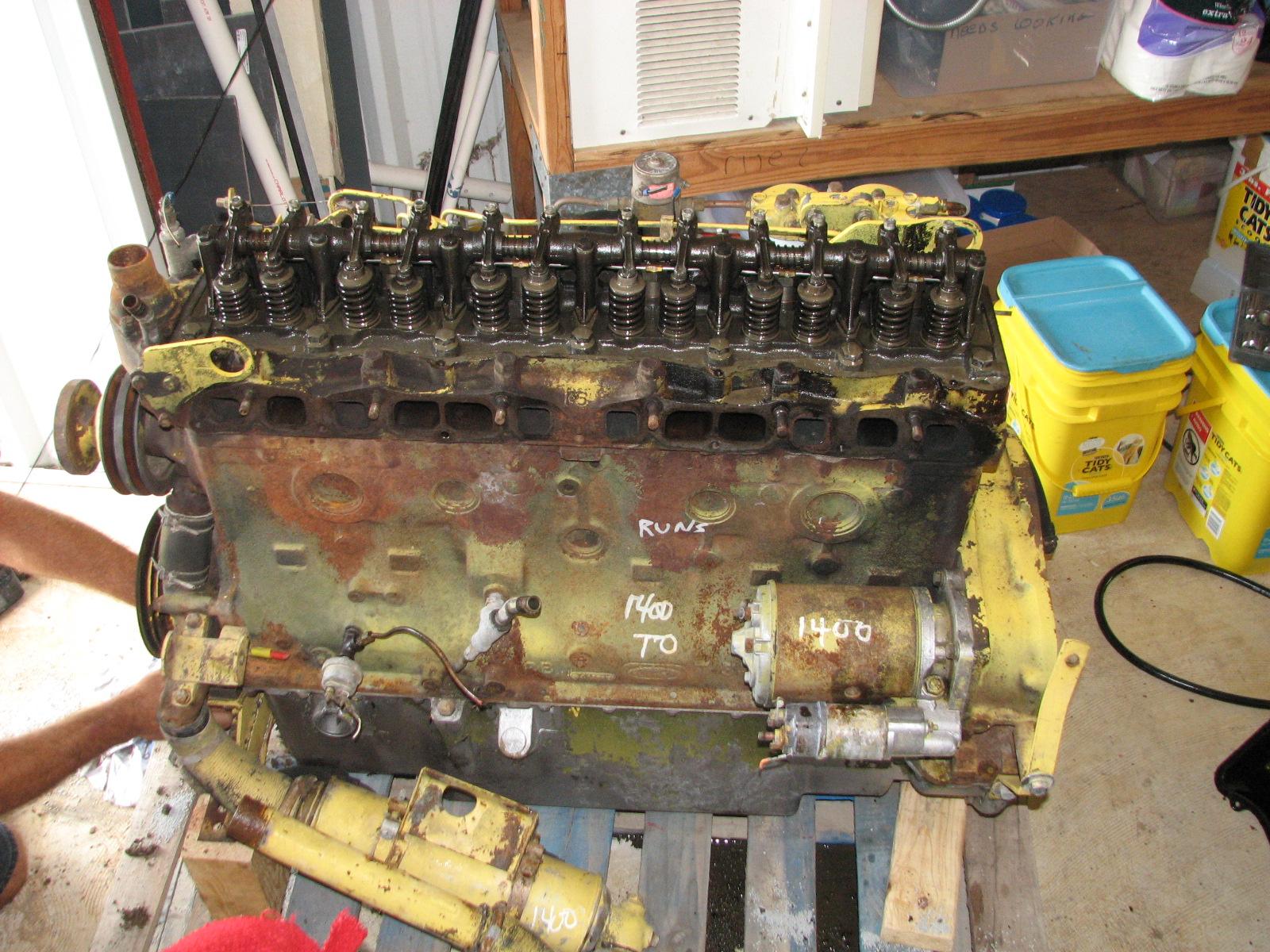

Today was the big day

for Mark and PERELANDRA. Will not go into a huge amount of detail,

but Mark had been working for the past week on rebuilding the diesel

engine for his trawler. Today was the day we put the rebuilt short

block back into the boat.

Lots of work and

effort, but we got PERELANDRA moved, the engine inserted in the main

cabin, and PERELANDRA moved back to her dock. Because of several

issues, we did not get the engine mated up to the transmission. To be

continued tomorrow.

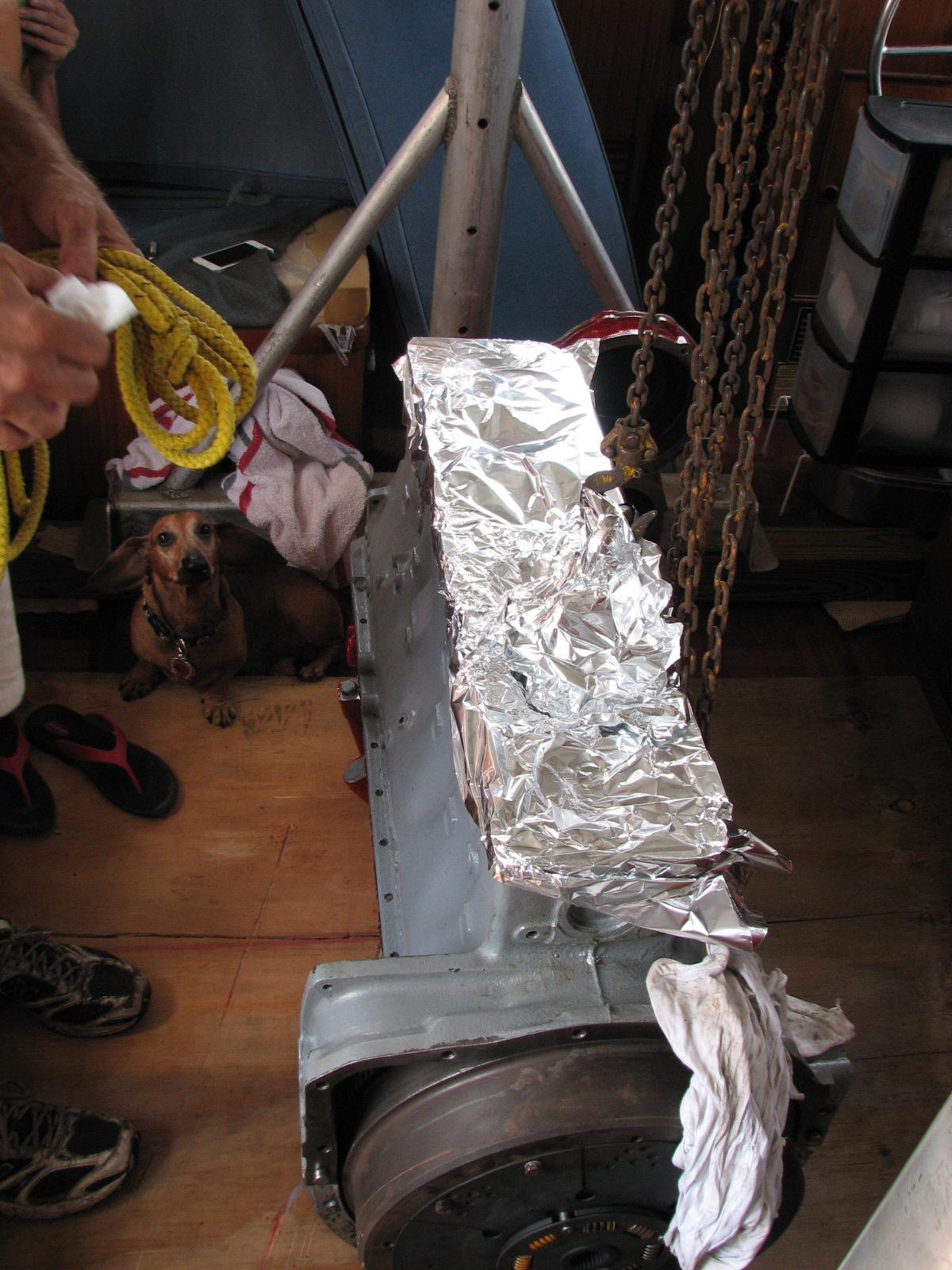

Engine Lifting Device

In PERELANDRA’s Main Cabin

Short Block Sitting In

PERELANDRA’s Main Salon

I did borrow Mark’s

pressure washer, and brought it over to DREAM AWAY. I washed down the

topsides and it really got rid of a lot of dirt. Very pleased.

July 25,

Thursday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Spent extra time

working on email, scanning and updating the maintenance log

I then applied the

third coat of varnish on teak pieces to cover the davit holes in aft

cabin, the teak piece to cover the winch hole in the main cabin, and

the teak electrical wire cover. I also applied the second coat of

Watco

teak oil finish to the boom

gallows, and the second coat to the instrument cluster housing, and

the bell holder.

July 24,

Wednesday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Spent a couple of extra

hours working on getting caught up on email, and the maintenance log.

Went over to the Port’s

storeroom and picked up the lawn mower, trimming shears and the wasp

spray. Came back to the marina,

and cut all of the grass, and trimmed around the trees, and along the

edges of the grass. I then weeded all of the gardens.

I then took apart the

Nicro

day/night vent that had not

been working. The vent is located in the overhead of the head. I

removed the battery, and the solar vent started working. I checked

the battery and it was as dead as a rock! Now the vent works during

the day. As soon as I can get a rechargeable “C” NiMH

battery, I will have the

day/night vent back.

Loaded the lawn

equipment into the Black Beast, and took it back to the Port

of Delcambre’s storage

room. Then it was off to the shop,

which is actually at the other end of the storage room building!

I then applied the

second coat of varnish on teak pieces to cover the davit holes in aft

cabin, the teak piece to cover the winch hole in the main cabin, and

the teak electrical wire cover. I also applied the first coat of

Watco

teak oil finish to the boom

gallows, and the second coat to the instrument cluster housing, and

the bell holder.

July 23,

Tuesday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Drove into New Iberia

to get my new TWIC

card. That was fun! Could not schedule an appointment because the

scheduling system had been down for seven days! Had to go in on a

first come first serve basis. I was fourth in line, and it took 2.5

hours. The Internet connection kept going up and down, but I was

finally successful. I now have the TWIC

card for three more years.

Did some shopping, and

then back to DREAM AWAY to catch up on email, scanning and the

maintenance logs!

Since I wanted to keep

the one Taco

LED spreader light, I

needed to replace the butt connectors with shrink wrap butt

connectors. I also had to put a nut on a bolt to adjust the light. I

did not have the correct metric nut the first time up the mast. I had

purchased what I thought was the correct nut. When I got up the mast

to the Taco

LED spreader light, I then

discovered I had the wrong nut, and broke one of the shrink wrap butt

connectors, and I only had two! So the effort was pretty much wasted.

I completely disconnected the Taco

LED spreader light and

brought it down with me when I came down the mast.

This way I can insure I

have the proper nut, and the shrink wrap butt connectors will already

be on.

July 22,

Monday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went over

to shop

and did final sanding on boom gallows. All of the voids had been

filled, so we were ready with the next step.

Sanded

Boom Gallows

I hung up

the boom gallows from the overhead. This was so I would have access

to all four (six) sides of the boom gallows. I then mixed a batch of

Smith’s

penetrating epoxy, and

applied it to the boom gallows.

Smith’s

penetrating epoxy Applied

To Boom Gallows

Took

apart

Sealand

pump and removed the

duck

bill valves from the valve

housings, and the pump itself. I then put all of the parts in a

bucket of water to soak to try and get the build up of calcium

removed. This will be a long dirty process!

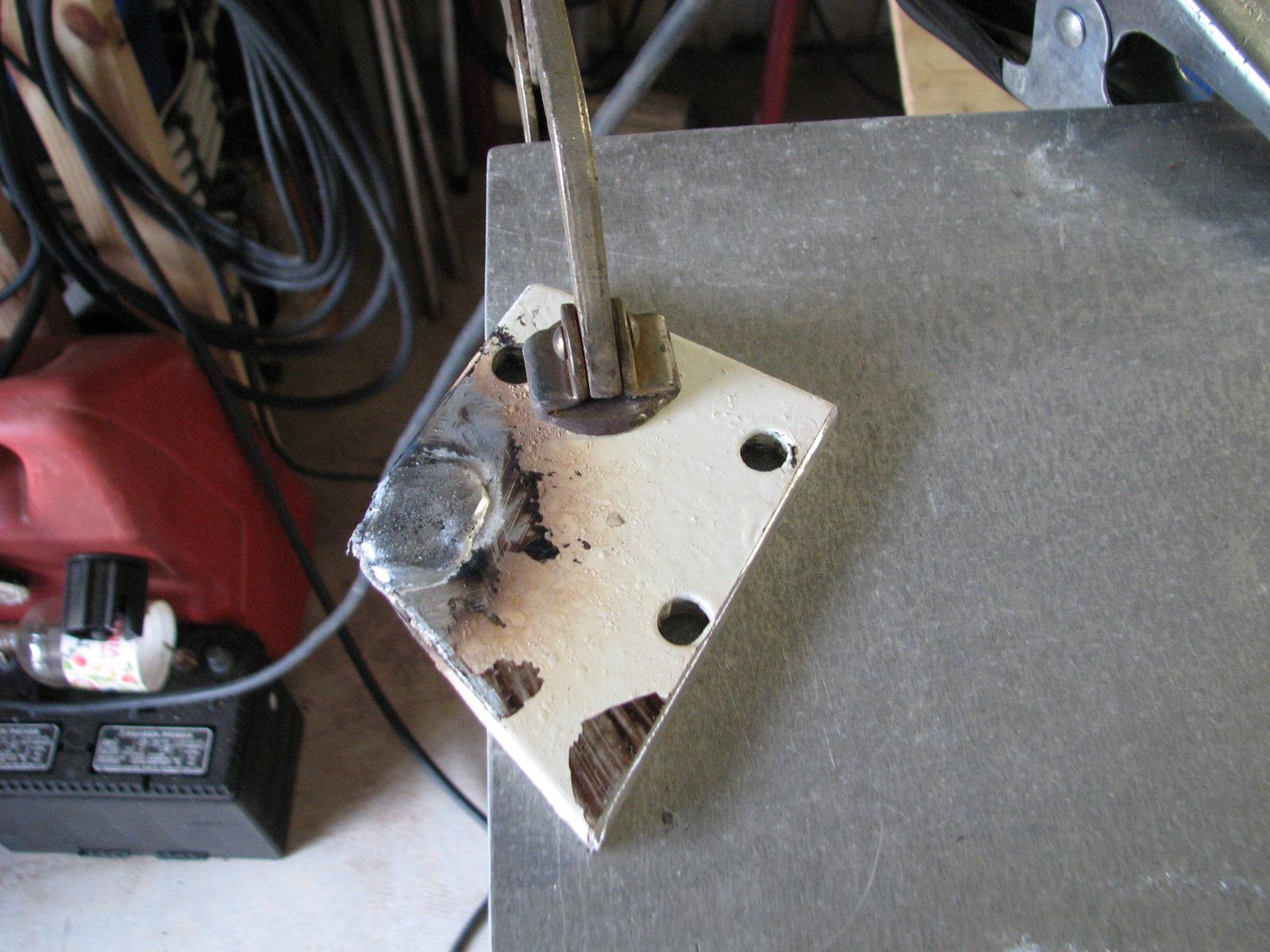

Hopefully

I will be getting into working on the main mast sail deck, which will

require welding of aluminum. To help with the preparation, I decided

to practice filling a hole in a piece of scrap aluminum. The effort

worked out very well.

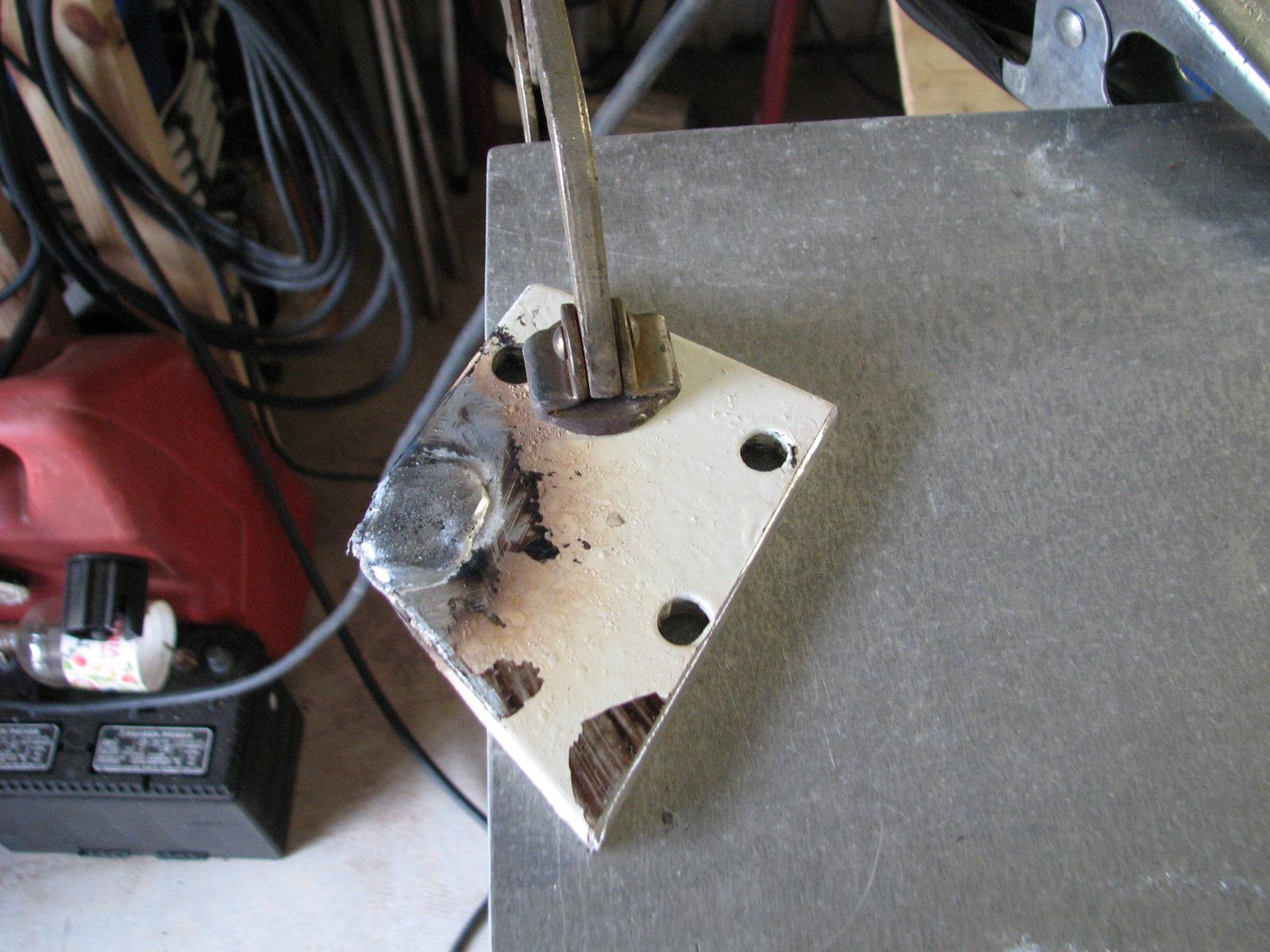

Practice

Weld On Scrap Aluminum

I then

went back to

marina.

The project for today was to clean all of the power pedestals on “C”

dock. I had purchased a long handled brush for just this purpose. It

would clean away spider nests and wasp nests, and my hands would not

be very close to the activity! I got all of the pedestals cleaned,

and there was no wasp nests!

I went

back to the shop

and applied the first coat of varnish on teak pieces to cover the

davit holes in aft cabin, the teak piece to cover the winch hole in

the main cabin, and the teak electrical wire cover.

Varnish

Applied To Teak Pieces

After the

varnish application, I applied the first coat of

Watco

teak oil finish to the

instrument cluster housing, the bell holder, and a third coat on all

of Troy’s wood.

Watco

Teak Oil Finish Applied To

Hanging Instrument Cluster

Watco

Teak Oil Finish Applied To

Troy’s Wood & Bell Holder

July 21,

Sunday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went over

to the shop.

The epoxy I had left yesterday had set up nicely. I was able to sand

down the boom gallows again. I discovered I had five new hole to fill

with teak bungs, and still had a few voids to fill where I had filled

the slots in the boom gallows

I mixed a

pot of epoxy, and used it to put in the teak bungs. I then mixed a

small amount of teak dust with the epoxy, and filled in the voids.

Bungs And

Voids Filled With Epoxy

While the

epoxy was sitting up, I sanded smooth the teak pieces to cover the

aft cabin davit holes, the piece to cover the main cabin hole in the

overhead, and the teak wire cover for the main cabin. I wiped them

all down with a tack

rag to remove excess dust.

I then applied the “agent orange dye” to all four pieces of teak

wood.

Agent

Orange Dye applied to the Teak Wood Pieces

I then

went to DREAM AWAY and participated in a port meeting concerning the

Safe Harbor Initiative with one of the shrimpers.

Then I

had to fix the toilet. It would not pump out into the holding tank. I

was pretty sure I knew what the problem was, and as it turned out I

was correct! The duck

bill valves were covered in

calcium deposits, and would not allow the pump to work as designed. I

had a new pump ready to go with all of the valves and housings.

Because of the location it still took about three hours to get the

job completely done.

Now I

have to take the removed pump apart and clean it out thoroughly,

install new duck

bill valves, and it will be

ready to go again.

July 20,

Saturday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went over

to the shop,

and removed the Formica

from the first filled slot on the boom gallows. Overall, not too bad

of a job. Will require some sanding, and some voids that will need a

fill in of epoxy0.

First

Slot In Boom Gallows, Formica

And Clamps Just Removed

Went

through the same drill as yesterday for the second and third slot in

the boom gallows. Used the Formica

and the clamps with lots of epoxy to fill the second slot. When it

was filled, I put the boom gallows outside in the sun to get the

epoxy kicked off.

Second

Slot In Boom Gallows Filled

When the

epoxy in the second slot had kicked off, I filled the third slot. Had

to use some extra weight to keep everything in place.

Third

Slot In Boom Gallows Filled

Went back

to DREAM AWAY for lunch. When I came back I mixed up a batch of

Smith’s

penetrating epoxy. I

applied it to the Instrument pod, the two teak covers for the aft

davit holes, the teak cover for the main cabin hole and the teak wire

cover for the main cabin.

The epoxy

had kicked off on the third slot in the boom gallows, so I was able

to sand down all three filled slots in the boom gallows. As

suspected, there were some voids that would need filling with an

additional application of the epoxy mash mix.

Voids In

Slots Of Boom Gallows

Slots one

and two were pretty easy to fill in. I used masking tape to build

dams, and the just poured in the mixed epoxy. The mixed epoxy was a

mild mash mix. By that I mean I mixed in a small amount of teak

sanding dust. This thickens the mixture, but also gets closer to the

real color of the teak wood.

Slot

three turned out to be a bit short, so I had to add some teak wood to

it. The good news was I had to cut off a high piece on one of the

other slots, so it fit in perfect.

Masking

Tape Dam On Slot Two Of Boom Gallows

Showing

Extra Weight On Third Slot With Added Teak Wood

While

working on the boom gallows, I found two more holes that needed to be

filled with teak bungs. This will be done tomorrow, after the epoxy

has set up over night.

July 19,

Friday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went to

the shop

to work on the Black Beast ignition problem. I will relate here the

entries I put into the Chevy Truck Forum trying to get help with the

problem.

I have

a 1996 Suburban diesel that will not start. When I turn the key to

the run position, all is well, when I turn the key to the start

position, nothing happens. I have done a bunch of troubleshooting,

and have narrowed down the problem to the gear mechanism between the

cylinder and keys and the ignition switch.

If I

remove the ignition switch from the steering column, and turn the

ignition switch with a flat blade screw driver, it goes to the run

position, then the start position, and the engine starts normally.

When I turn the key in the cylinder, the gear that operates the

ignition switch turns, and does not seem to have a problem. When I

put the ignition switch into the gear mechanism, and turn the key,

the engine will not start.

Has

any one seen this problem and have a fix for it? What is the gear

mechanism that connects the ignition switch to the cylinder and keys

called? I can not find the part name on any parts list.

Not

sure of the how or why, but the problem has been repaired. Hopefully

the fix is long lasting, but I am not sure. I swapped in a new

ignition switch and I got the same symptoms as I described in the

original problem. Put back in the original ignition switch, and the

same problem was there, so it seemed like the problem was not the

ignition switch assembly.

We

took the original ignition out of the vehicle, as I wanted to ohm out

some of the connections. I took the wrong side of the switch apart,

and six little springs went flying! I recovered four of the springs,

but could not find the other two. I took two ball point pens apart,

and used the springs out of the pens in the ignition switch, and put

the switch back together.

We put

the ignition switch back in the vehicle, and it worked! Tried

starting the vehicle several times, and it always worked. We put the

steering column and all of the sundry parts back together, and it

still works.

That

was yesterday, and I am still not having a problem. Not sure why the

new ignition switch would not work, and not really sure why messing

with the springs in the original ignition switch fixed the problem.

Hope this information helps someone else!

That

finishes the entries I put in the Chevy Truck Forum. Just a note

here, I am actually writing this in the middle of August, and still

no problem with the igintion switch!!

I cut the

pieces of teak wood I am going to use as the fill-in for the

rectangular cut-outs in the boom gallows. These pieces of wood are

left over from the teak deck that was removed many years ago. I

clamped pieces of waxed Formica

on either side of the cut in the boom gallows. I also did a dry fit

of the teak wood pieces in the cut out. I labeled each piece at to

position and top and or bottom.

Formica

And Clamps On Boom Gallows

I mixed

up a pot of epoxy and started putting the pieces of teak wood into

the cutout in the boom gallows.

Cut

Pieces Of teak And Pot Of Mixed Epoxy

Initially

I poured some of the mixed epoxy into the cutout in the boom gallows.

I wanted to make sure I had plenty of epoxy on all sides of the

pieces of teak.

Epoxy In

Boom Gallows Cutout & First Piece Of Cut Teak Wood

Then it

was just a process of putting epoxy all over each piece of cut teak

wood, and inserting the piece into the cutout in the boom gallows.

When all of the cut pieces of teak wood had been inserted, I put

another clamp on the outside of the Formica

to make sure it was a good tight fit.

Insertion

Complete, Waiting For Epoxy To Kick Off

While the

epoxy was kicking off, I cut out the second slot in the boom gallows,

and also cut the pieces of teak wood to be used as the filler.

Boom

Gallows Marked For Rectangular Cutout

Cut Made

On Boom Gallows

Cut Teak

Wood Pieces In Rectangular Cutout

Long day

finished, went back to DREAM AWAY for a shower and supper.

July 18,

Thursday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went over

to the shop

and continued work on the boom gallows. As I figured, I found my jar

of screw starters and bung cutters where I had put them last! I did

not have enough ⅜” teak bungs, so I had to cut about 50 of them.

Having a drill press and some scrap teak really helped this process.

Cutting

Teak Bungs

Mixed up

a pot of epoxy, and epoxied all of the bungs needed on one side of

the boom gallows. I set the boom gallows out in the sun. When the

epoxy had kicked off, I brought the boom gallows back into the shop,

mixed another pot of epoxy, and epoxied the bungs into the other side

of the boom gallows. The boom gallows went back out to the sun to

kick off the epoxy.

While

that batch of epoxy was kicking off, I sanded and scraped off all of

the old Cetol

on the instrument cluster. Had to be down to bare wood.

Went back

over to the North

Pier Marina, as it was that

time of the week to cut the grass and do some additional weeding of

the gardens. I cut grass until the rains came. Will finish that

project tomorrow.

Went back

over to the shop

to continue work on the boom gallows. Right after I had installed the

hard bimini, I realized I would have to fill in the slots for the

boom on the boom gallows.

Slots For

The Boom On The Boom Gallows

I had cut

out some pieces to fill in the slots, I have just never had the time

to shape the pieces and fill in the slots in the boom gallows. The

time had come! I started in on shaping the pieces to fill the slots.

Teak

Piece For Slot In Boom Gallows

I worked

at the teak pieces, and it was going to be a chore to try and get the

pieces to fit the curved, angled slot in the boom gallows. I decided

to go at it another way. I did not have any teak as thick as the boom

gallows, but I could cut out four or five pieces to a better shape

and epoxy them into the slots. I worked on that for some time.

Pieces

Cut To Fill Slots In Boom Gallows

Pretty

soon I came to realize that I am a fair carpenter, but I was never

going to get the pieces shaped properly. I came up with plan “C”.

This plan is to cut rectangular slots in the boom gallows, completely

removing the curved, angled slots. With a rectangular hole to fill, I

would be able to cut the necessary pieces, epoxy them into place, and

the boom gallows would look very good.

This new

plan would be started on the morrow!

July 17,

Wednesday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went over

to the shop

and cut out the teak piece for the main cabin overhead, and the two

pieces for the aft cabin davit holes.

One Of

The Aft Cabin Davit Holes

Went back

to DREAM AWAY, and completed removal of the boom gallows. Loaded the

boom gallows into the Black Beast.

Boom

Gallows Removed

We then

went off to New Iberia to attend a Port

of Delcambre luncheon about

safe harbor in Vermillion and Iberia Parish.

Came back

to Delcambre, got Mark and we headed off to the Dugas Engine Services

shop

in New Iberia to pick up Mark’s engine block, crankshaft, and my

power head (yea).

Came back

to Delcambre, unloaded the crankshaft, the engine block, and my power

head.

I got

back into work on the boom gallows. I drilled out all of the “extra”

holes in the boom gallows where screws used to be, but were no

longer. I drilled them out for teak bungs to be inserted. I still

have not been able to locate my jar of screw starters and bung

cutters

Had to

leave early, to prepare for and attend a pot luck supper for and by

the Delcambre

Seafood and Farmers Market.

It was put together by all of the vendors, just to have a social.

July 16,

Tuesday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Had

breakfast and then started striping the boom gallows. The boom

gallows needed some work in preparation for installing the hard

dodger. There were also three indentations in the boom gallows in

which the main boom could drop. These were not needed anymore because

the hard bimini interfered with the indentations. I wanted to fill in

these indentations so the boom would not fall into them and damage

the solar panels I plan to install on top of the hard bimini, in the

future.

I removed

the external speakers, the instrument cluster, and all of the

associated wiring. I removed the track and supports for the soft

dodger. I also removed the bolts attaching the hard bimini to the

boom gallows. Without the boom gallows in place the hard bimini would

just lean against the boom gallows supports.

Boom

Gallows Before Removal

When I

had all of the removed parts from the boom gallows, I put all of the

pieces in the Black Beast. Kitty then drove me over to the shop,

I unloaded all the boom gallows parts and started in to work on them.

The plan

is to sand down all of the parts, including the boom gallows, soak

them with Smith’s

penetrating epoxy, then

apply at least three coats of Watco

teak oil finish. The first

pieces to work on was the instrument cluster. This had to be scraped

and sanded to bare wood.

Working

On The Instrument Cluster

Went to

lunch, and then back to the shop.

Started in on the instrument cluster, and Kitty called and said there

was a problem with the Black Beast. The ignition switch would not

start the engine!

Was able

to get the Black Beast started, then drove it over to the shop.

Spent the remainder of the day working on that problem. At the end of

the day, 1800, we (Mark and I, mostly Mark) had the ignition switch

off of the steering column, and with a flat blade screw driver, were

able to start the Black Beast at any time.

July 15,

Monday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Had

breakfast, and went over to the shop

and started in on the teak pieces I had epoxied yesterday. I already

had templates made for the pieces I needed to cut out, so I marked

off the templates on the teak. These two pieces are going to be used

to cover the holes cut in the aft cabin bulkhead to install the

backing plates for the dinghy davits.

Templates

On Fabricated Teak Piece

Cut Marks

On Fabricated Teak Piece

I

realized I had enough wood remaining in my fabricated teak piece, I

could cut out another piece to cover a hole in the overhead of the

main cabin, which I did.

Hole In

Main Cabin Overhead

I am

working on fabricating a deck from the main mast to the cabin top as

an area to work on the main sail. I will be referring to this project

as the main mast sail deck. I have some aluminum pieces at the shop

I am going to use as the primary support at the main mast. These

pieces had to be cut and modified. I used my chop saw to cut the

piece, and then sanded it down smooth. In the future I will weld up

the present holes in the piece.

Piece

After Cut In Chop Saw

Piece

Sanded Smooth

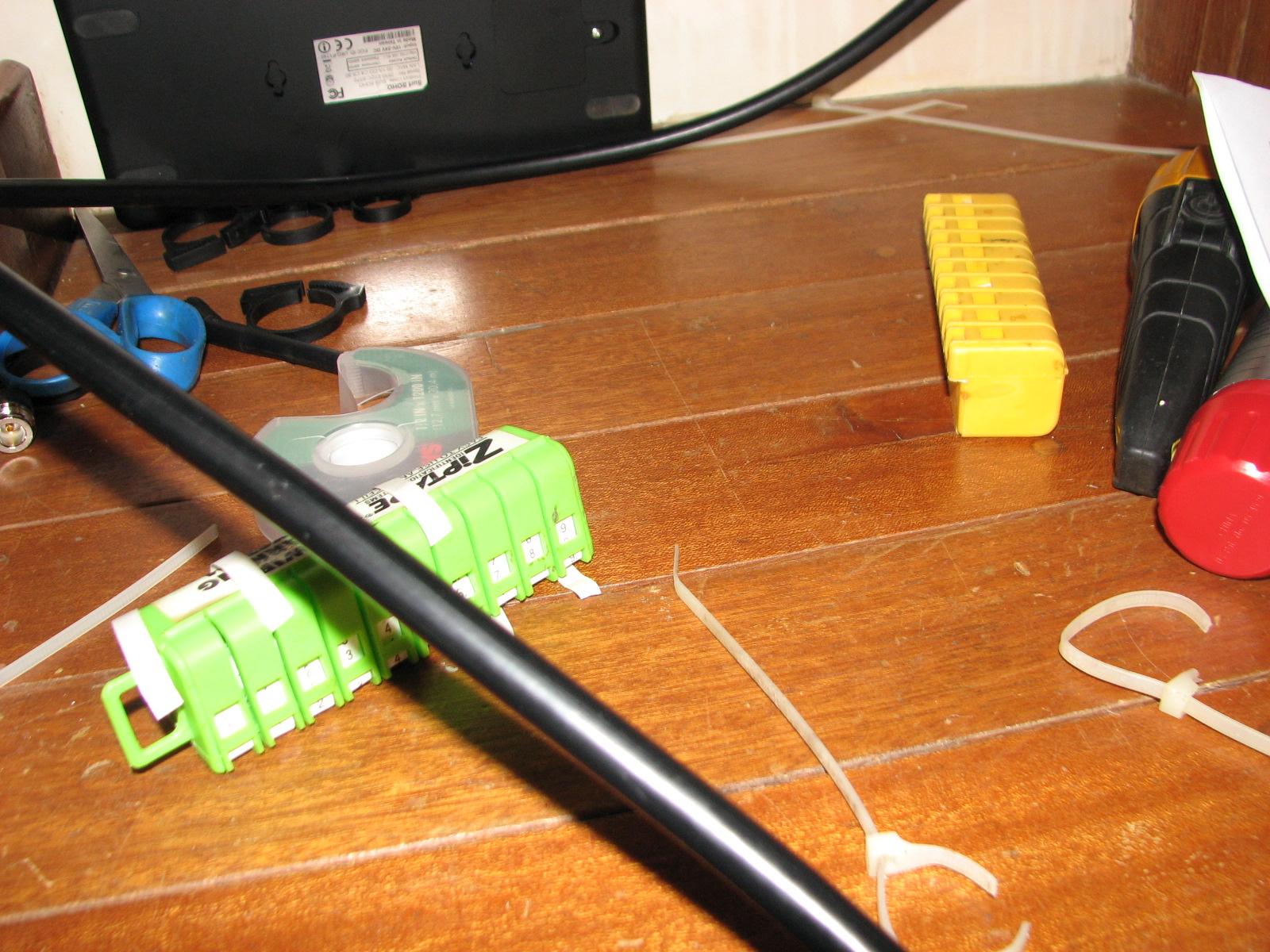

Running

Cable In Garage

July 14,

Sunday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went over

to shop

and removed the compressor from the air conditioner tray. When that

was removed I finished cleaning all the junk and rust out of the

tray. The tray is ready to send off to Stacy.

Finally

got the epoxy pumps for my epoxy, so I was able to finally mix some

up! I did mix a batch and epoxied a piece of teak to the piece I had

made to cover the holes I had to cut for the davit backing plates. I

had made the teak piece some time ago, but it was not wide enough.

Epoxying

Teak Piece’s Together

I also

added a couple of small pieces of teak to a teak wire cover I am

using to cover electrical wires in the main cabin.

Teak

Electrical Cover Being Added To

I used my

chop saw and started doing some experiments with putting a curve in

the stainless steel tubing. I am pretty sure it will work, so I might

use it for the fabrication of the stern ladder. The theory is to cut

out a portion of the metal at a thirty degree angle, then gently bend

it back together, and weld it.

Experimental

Cut Square Tubing

I had

finally received the gun cleaning kit I ordered. I have not cleaned

the line

launcher since our trip to

Atlanta at the first of just, so it was due. I got the line

launcher cleaned, oiled

down, and all put back into it’s case.

Line

Launcher With Cleaning Gear

Went back

to DREAM AWAY, and had breakfast, then up the main mast.

The wind

instrument had quit working. I have a spare piece of cable and wind

vane, so I had connected them directly to the wind instrument, and it

worked great. I then disconnected the cable that came down from the

top of the main mast at the junction box and connected the spare wind

vane cable at the junction box. The wind instrument worked just fine.

Now it

was time to take the wind vane up the main mast and install it. I

took it up to the top of the mast and removed the old vane and

installed the spare. When we tried the wind instrument, it worked

great. So now I had to get the wind vane repaired.

Captain

Jim At The Top Of The Main Mast

I did a

quick installation, and then back down to the deck. I waited until

the night, and was pleasantly surprised with the amount of light put

out by the Taco

LED spreader light. Now I

will have to purchase three more of the Taco

LED spreader lights.

I just

might use one of the Hella

Marine Halogen Deck Floodlights

back on the dinghy davits to light the area when getting into and out

of the tender at night, and also as a security device.

July 13,

Saturday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

took off

tender hold down lines and started wash process; removed soft dodger;

measures bracket for main mast base grating; helped Joel with air

conditioner.

Went to

the shop

first this in the morning and started cleaning up the parts on the

spare Yamaha Outboard. Hopefully I will be getting back the repaired

power head and will be able to reassemble the spare engine.

Upper

Casing Getting Cleaned Up

I

continued working on the tray for the failed air conditioner. My son,

Stacy, has a friend who can fabricate the tray out of stainless

steel, and he offered to get it done for my spare Cruisair

Air Conditioner. What I

need to do is strip all of the parts out of the tray so it can be

sent off to Stacy’s friend. Once all of the parts are out of the

tray, then the tray itself will have to be cleaned out.

Evaporator

Removed From Tray

Air

Conditioner Tray With Compressor

Went back

over to DREAM AWAY for breakfast, and afterwards, I installed the

washed and clean sheet nets in the cockpit.

Aft

Cockpit Without The Nets

Aft

Cockpit With The Nets

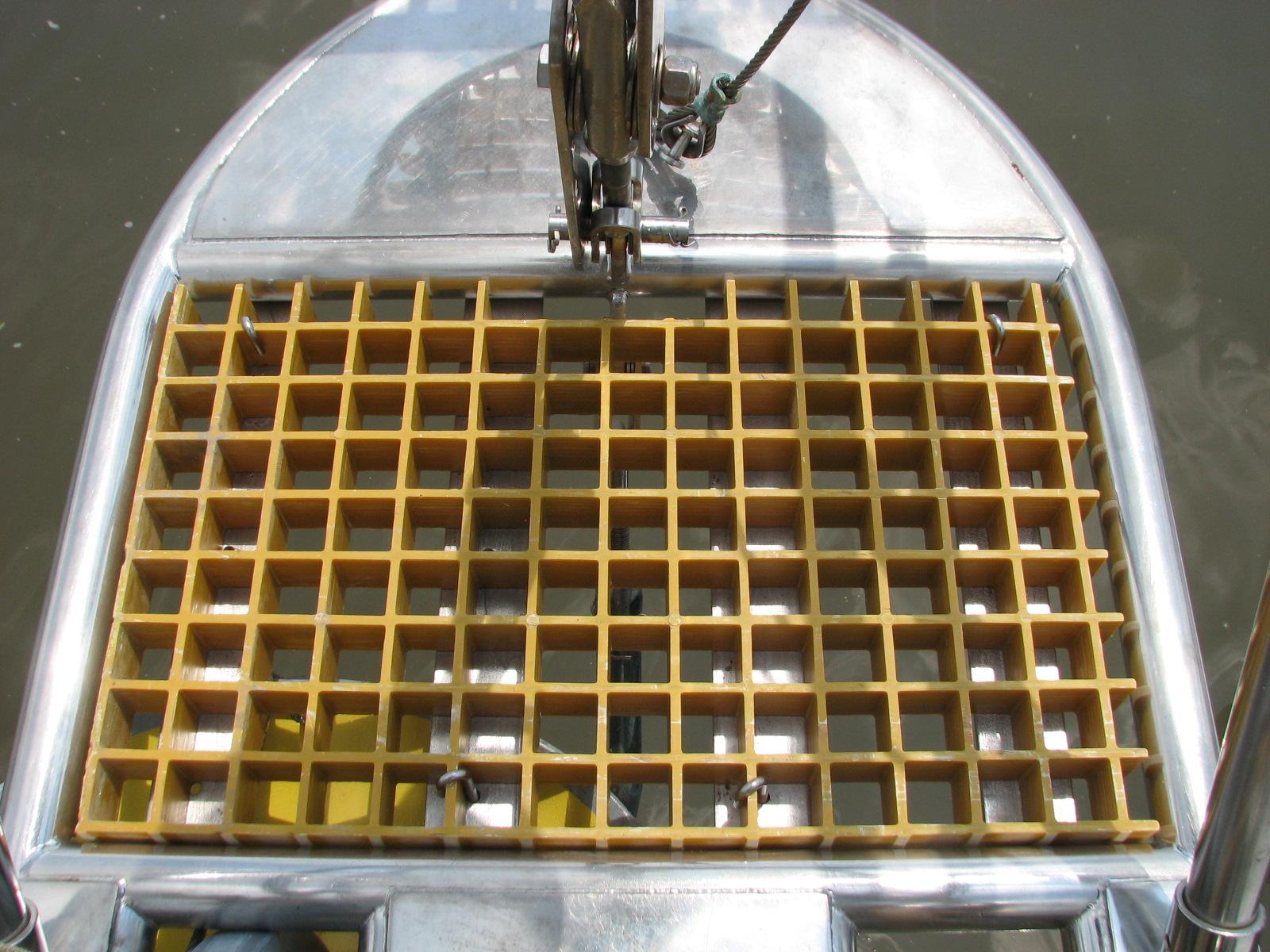

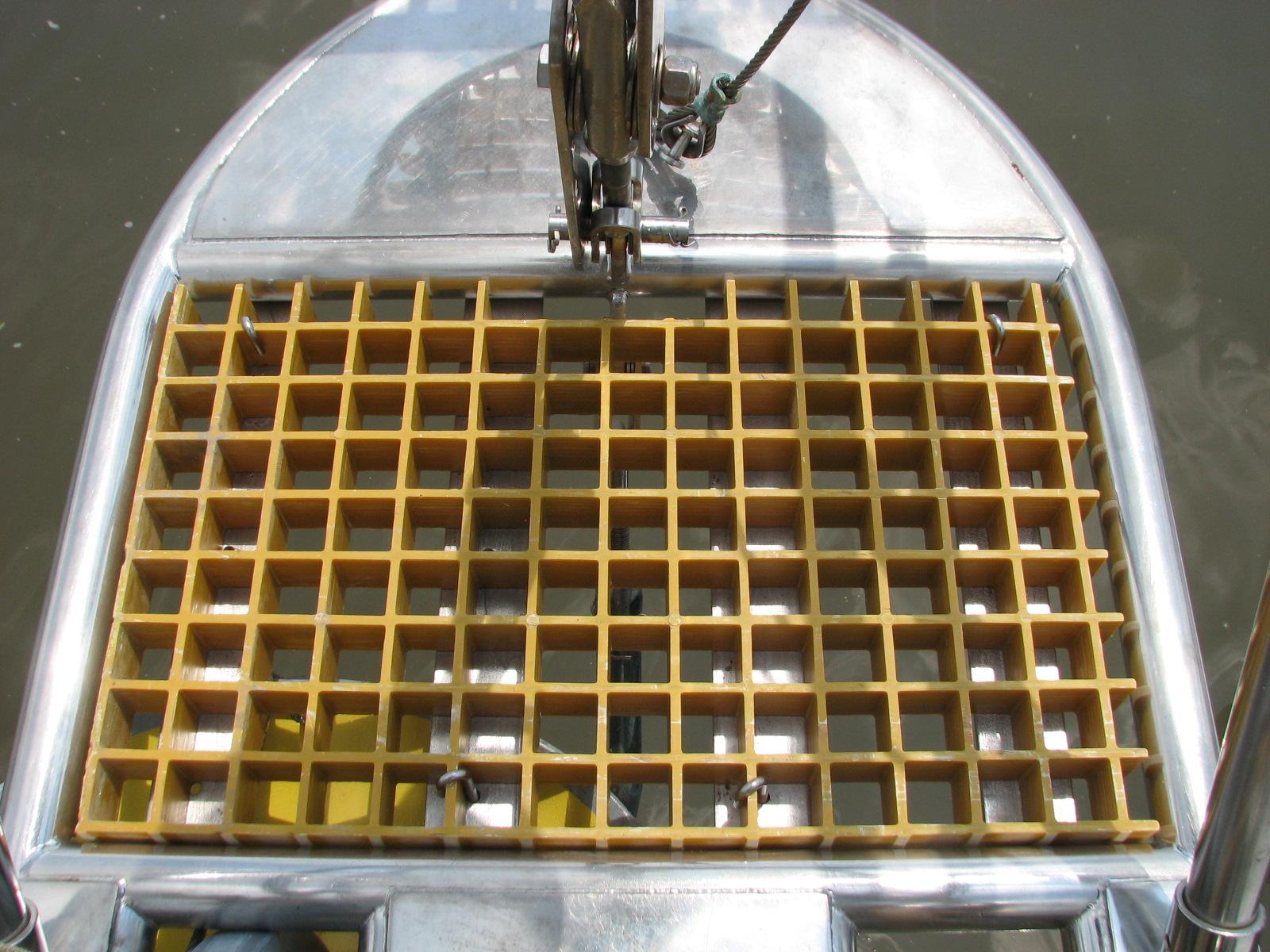

The new

J-Bolts I had ordered came in so I am able to bolt down the

fiberglass gratings I had cut for the bow pulpit. First I had to

clean the bow pulpit deck and seat area in the bow pulpit before I

installed the gratings.

Bow

Pulpit Deck Before Cleaning

Bow

Pulpit Seat Before Cleaning

Bow

Pulpit Deck After Cleaning

Bow

Pulpit Seat After Cleaning

Grating

Installed On Bow Pulpit Deck

Grating

Installed On Bow Pulpit Seat

J-Bolt

And Grating Detail

I took

off the tender hold down lines off of the davits to clean them up.

They had been unused for some time, and were getting green. It was

time to start washing lines on DREAM AWAY, and these were it. The

plan was to soak them in a bucket with a mild bleach and soap

solution, for a couple of days.

Lines

Getting Ready For The Bucket

Last item

for today is to remove the soft dodger. As you can see from the

pictures, it needs replaced, and we are going to replace it with a

hard dodger. The boom gallows needs work, so the soft dodger has to

be removed for that project also.

Soft

Dodger Before Removal

Soft

Dodger Removed

I then

helped our neighbor Joel with his air conditioner. We were able to

remove the AC unit from his boat, and really get a good look at the

burnt capacitor. We were able to get the capacitor removed, so he

could use it to go get another one at an electric supply store in New

Iberia this coming Monday.

July 12,

Friday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Started

off the day by cleaning out the main strainer for the manifold (Sea

Chest), and the manifold (Sea Chest). Also cleaned out the strainers

for the ice maker cooling pump, the refrigeration cooling pump and

the forward air conditioner cooling pump. During this cleaning

process, I also cleaned out the hoses for all of the cooling pumps. I

clean out each hose by sending water through each hose with water

from the dock!

Went out

to pier C and checked the electrical issues on the 29/30 pedestal.

Finished

up work on Hollis’s boat. Was able to finally get the diesel leak

on the generator repaired. I also changed the oil and the oil filter

and fuel filter on his generator. Hollis was a happy camper.

Helped

Joel with his air conditioner problem. Could not resolve problem, we

need to remove the unit to get a better view of the electrical parts

at the back of the unit.

July 11,

Thursday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Did not

go over to the shop

first thing, stayed on DREAM AWAY and worked on getting caught up on

email, financial issues, and updating the Maintenance Log and web

page.

Went to a

safe harbor meeting for the Port

of Delcambre in New Iberia.

Well worth the effort!

Came back

from the meeting and purchased docking lines at Touchard’s.

Returned to Marina

and installed the lines on the designated boat. Cleaned all of the

power pedestals on pier B, and weeded the south garden at North

Pier Marina.

I then

went over to the shop

and worked on cleaning up the parts for the spare Yamaha outboard

engine. I also worked on smoothing out the rough places on the new

grate in the seat on the bow pulpit.

Grate To

Replace Seat On Bow Pulpit

July 10,

Wednesday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Did not

go over to the shop

first thing, stayed on DREAM AWAY and worked on getting caught up on

email, financial issues, and updating the Maintenance Log and web

page.

Helped

Mark with his engine. We loaded the stripped block and the crankshaft

into the Black Beast. We also put in my spare Yamaha powerhead, and

drove into New Iberia to the machine shop. We dropped off both parts.

They are going to drill out my powerhead and put helicoils

in it, and bore out Mark’s block.

When we

returned, I got the lawn mower and cut all of the grass at the

Marina.

Next I helped Hollis with his boat, but when we went to the Onan

dealer, they did not have the correct part, so we ordered what we

hope will be the correct part.

July 9,

Tuesday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Did not

go over to the shop

first thing, stayed on DREAM AWAY and worked on getting caught up on

email, financial issues, and updating the Maintenance Log and web

page.

Helped

Mark work on his engine, helped Hollis work on his boat, and worked

on the Marina

gardens! No work done on DREAM AWAY.

July 8,

Monday, 2013

About

mid-morning, Jimmy and Barbara left to go back home in Houston. Kitty

and Connie, off of IMPETUOUS, drove over to Orange, Texas, so Kitty

could get her driving license.

I stayed

in Delcambre and worked on Hollis‘s boat at North

Pier Marina with the owner

for the remainder of the day. He had some engine issues, leak issues

and air conditioning that he needed some help with.

We got

the main engine issue solved, still working on the diesel leak on the

generator.

Kitty did

get her driving license, and was back in Delcambre by 1900. Long wait

for the license!

July 6

and July 7, Friday & Saturday, 2013

Did not

do any work on DREAM AWAY during this time. We just kicked back and

enjoyed our friends while they were here. I had a couple of small

projects planned with Jimmy’s help, but the weather was most

uncooperative, so did not get them done.

July 5,

Friday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Got

called out to help Mark unload the new engine he had purchased to

replace the blown one in his trawler. We moved the old block out of

my shop

and then put the new engine in the shop

on a pallet. Now between the new combine engine and the blown marine

engine, he will be able to build a pretty good running marine engine.

New

Engine In Shop

New

Engine In Shop

We then

got a call to come over to the marina

to help another boat back into the marina.

This boat had gone out for a couple of days, but had lost an engine.

Once we got the boat in its slip and settled, a dive under the boat

found a crab trap line wrapped around the shaft.

Since

Wayne, off of IMPETUOUS, was already in his SCUBA gear, I asked him

to check the prop on DREAM AWAY. Not good, he confirmed my

suspicions. The prop is nothing but a ball of barnacles. The prop and

shaft will have to be scrapped before we go out sailing. Another

project to add to the list!!

Went back

to the shop

and cut out the grating for the seat in the bow pulpit. I had the old

teak seat to use as a pattern, so I probably got the new grating

pretty close.

Grating

Cutout & Old Teak Seat On Workbench

Late in

the afternoon, our good friends from Houston, Jimmy and Barbara drove

in from Houston, so we kicked back and enjoyed their visit.

July 4,

Thursday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Did not

go over to the shop

this morning. Stayed on the computer and worked on updating the June

Maintenance Log. Did some work for the port moving a boat, and then

using my lines to moor it in it’s slip.

Worked

most of the day getting ready for our Independence day cookout. Had a

great cook out with Kittie and Mark from the marina,

and new friends Wayne and Connie off of a transient boat staying in

the marina

for a few days, and Miss Glo. We all ate more than we should, but we

cleaned up, and then drove over to Otto Herbert Lumber. We set up our

folding chairs and watched the fireworks display put on by the town

of Erath. It was a great day, and we were all happy to lay heads on

pillows.

July 3,

Wednesday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Went over

to the shop

and picked up the finished Panduit

wire duct covers. Then I

went to the Port

of Delcambre’s storage

room and pick up the lawn mower, after topping off the gas tank. I

came back to the marina

and mowed all of the grass. It was a much easier job than last week

because the grass was not near as high. Only took about 1.5 hours!

When I finished the grass, I loaded the mower back into the Black

Beast and took the mower back to the storage room.

When I

got back to the marina

I took the two Panduit

wire duct covers to the

boat. After breakfast I installed the two pieces in the aft cabin.

Not an easy task as all of the books on the starboard and port side

had to be removed before the Panduit

wire duct cover could be

installed. I also had a little help from Jordan.

Panduit

Wire Duct Cover Before

Installation

Panduit

Race Track With Wires

Exposed And Helper

Wires

Exposed

Panduit

Wire Duct Cover After

Installation

DREAM

AWAY Burgee

DREAM

AWAY Dressed

Ship

When I

finished with the flags, I walked over to the shop

and picked up the shelf I had been working on to install in the

storage area under the galley stove. I also picked up the necessary

tools for the installation, and walked back to DREAM AWAY.

The

installation of the shelf was not a big issue, the problem is the

space to work in! Too large a person working in too small a space.

After much slippin’ and perhaps a four letter word or two, the

shelf was installed. Now when we remove a pan or anything from the

front of the storage area, all the items in the back will not slide

forward.

The bad

news is, because the shelf has new white paint on it, it is plain to

see how much the other white paint in the storage area has faded.

Another project for the future!

Front Of

Storage Area Under Propane Stove

Shelf Not

Installed

Shelf

Installed

Storage

Area With all Items Back In Area, New Shelf With Pans

Last item

for the day was to remove the seat that is on the bow pulpit of DREAM

AWAY. I am going to use the same fiberglass grating

on the seat that I installed in the anchor area of the bow pulpit.

As you

can see from the picture, the teak wood is in desperate need of

maintenance, so I am working to get rid of maintenance issues.

Replacing the teak with fiberglass

grating will accomplish

that task nicely.

Fiberglass

Grating On Anchor Area Of

Bow Pulpit

Teak Seat

That Was Removed From Bow Pulpit

July 2,

Tuesday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee. Spending extra

time working on the June Maintenance Log to put up on the web page.

Went into New Iberia

and had the new air conditioning compressor installed on the Black

Beast. When that was finished, I came back to DREAM AWAY and had

lunch.

After lunch I set up to

test my freshwater pumps. One had quit working, and the was an easy

fix. The micro switch that allows the pump to turn on was dirty. I

sprayed some corrosion block on the switch and actuated it several

times and that cleared the problem.

Now I got out two

pieces of ½” hose and attached to the pump. I then got a bucket

and filled it with water and brought it down into the garage. I

connected my jumper cables to the battery and verified pump

operation. The pump leaked, so I took it apart and cleaned up all of

the mating surfaces. I put the pump back together and used

never-seize on the bolts.

Freshwater Pump Being

Tested In The Garage

The pump worked

perfectly this time! I connected the hoses to the second pump and

verified it’s operation. Both pumps worked as advertised, and I put

them back into the spares locker.

I also helped a fellow

boater solve his air conditioning problem. He had cleaned the

strainer for the air conditioner, and now he was not getting water

through the system. I initially thought the problem was the pump

needed primed, but it turned out to be simple. He had forgot to open

up his seacock after cleaning the strainer! We open the seacock, and

the air conditioner worked just fine.

We then

welcomed back another transient into the marina.

They were very happy to be back with us.

July 1,

Monday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

checking the weather, while making a pot of coffee.

Day started off with me

accompanying Kitty to the Iberia Medical Center for a CAT scan, that

did not work out as planned. On the way home I noticed the air

conditioning compressor on the Black Beast was not coming on.

I knew this was a

problem that would come up because the noise the compressor was

making when I had to change the harmonic dampener earlier in the

year. So off I go to Chabill’s

Tire Service to get the

compressor replaced. Chabill’s

Tire Service is where I

originally had all of the air conditioning work done. I had a two

year warranty on the compressor, and one year on the labor.

Lots of back and forth,

that I will not go into, but the new compressor is on order, and I

have to go back tomorrow at 1000 to have the work done! Then I went

back to DREAM AWAY, and finally had breakfast and lunch, 1400!

Went over to the shop

and sanded down the shelf I am building for the area under the

propane stove in the galley. I also sanded the white area of the

V-berth insert, and the Panduit

wire duct covers.

Shelf Sanded And Ready

For Paint

V-Berth Insert Sanded

And Ready For Paint

I then mixed up a batch

of the two part paint I have left over from Guatemala, and painted

the top of the galley shelf, the shelf supports and the top of the

V-Berth insert.

Painted Shelf And

Supports

Painted V-Berth Insert

I left the shop

and went back to the marina,

and performed my daily gardening activity. This means I pulled weeds

out of the marina

landscaping for about 30 minutes. This is an ongoing part of my part

time job as the Marina

Maintenance man!