Making The Cuts

I moved the piece of

Structoglas

and my tools down to the aft cabin of DREAM AWAY. I struggled to get

the piece of Structoglas

up into position. I got what spare pieces of wood I had on DREAM AWAY

to help hold up the piece of Structoglas,

but could not get it done! Very frustrating.

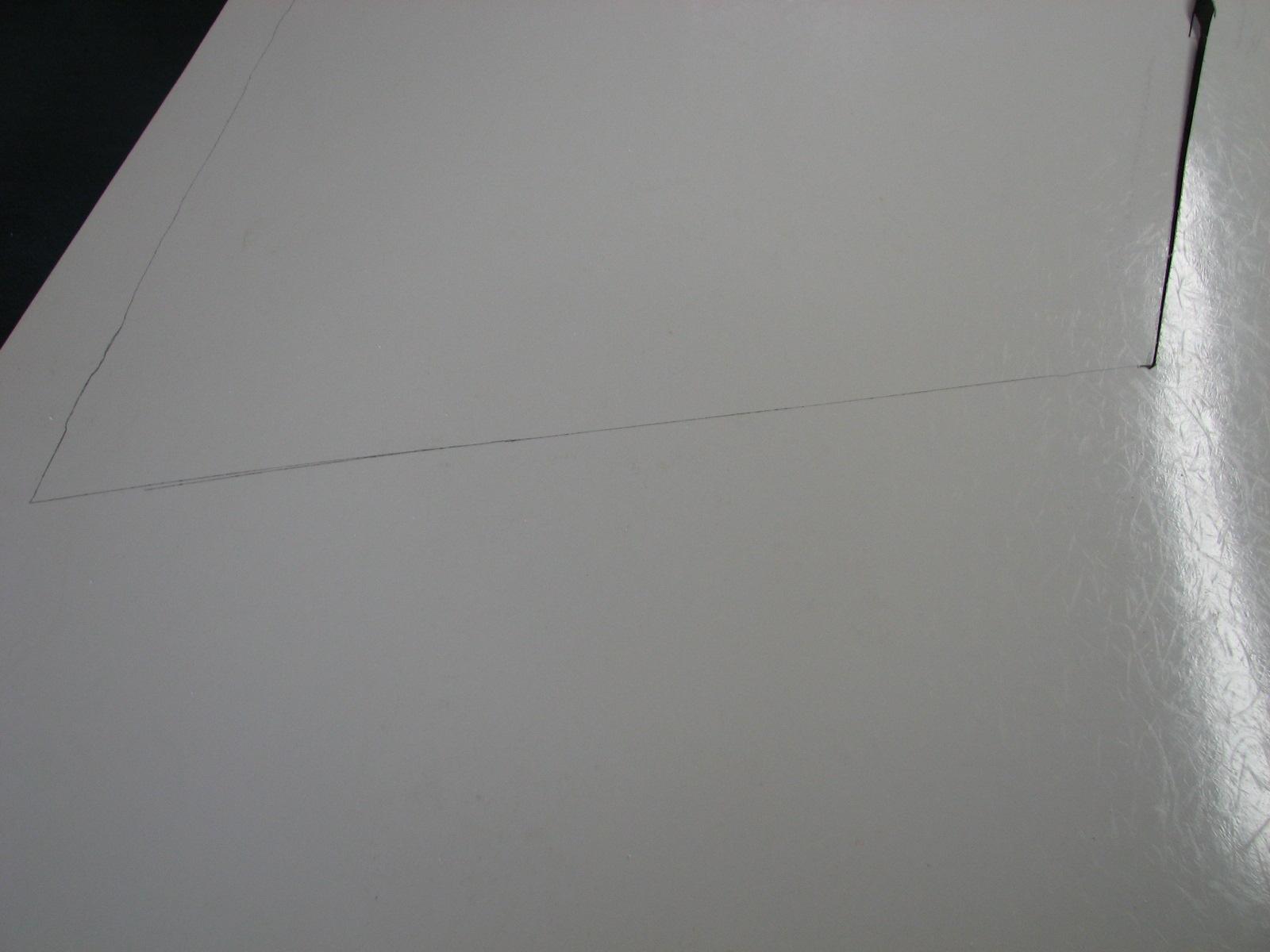

Piece Of Structoglas

In Aft Cabin Ready For Fit

I decided to wait and

work on this project another day. I went back to the Black Beast and

got out the pressure washer. I took it, and a hose and the fuel can

out on Pier “C” so that I could clean the dock of bird doo. We

had a cruising boat coming in later, and I needed to get the dock

presentable.

When finished, I took

the pressure washer back to the Port

of Delcambre’s storage

room. I also went by the shop

and picked up several pieces of medium length wood to help at my next

attempt of putting the Structoglas

back into place.

August 30, Friday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

I went over to the shop

first thing and picked up all of the cardboard I had for template

material and brought it back to DREAM AWAY. As it turned out, I spent

the whole day getting the template for the hide hole cover.

When I brought the

template material to DREAM AWAY, I got it in the aft cabin, and spent

what seemed like forever trying to get small individual pieces of

cardboard taped together.

There is not a lot of

room to start with. I am laying on my back trying to get work done,

and nothing is going very well. After an hour of not getting very

far, I decided to take a lot of measurements of the proposed

templates.

Before going back to

the shop

to build a template, I called Raymarine

about the wind instrument. While on hold for 20 minutes they

mentioned a web site to go to which is the Raymarine

technical forum. I did this

and found some entries about checking voltages on the instrument,

which I did. After I checked the voltages, and they seemed to be

correct, the instrument started working!

I had the instrument

connected to my spare cable and vane. I left it as it was, and went

to the shop.

While at the shop, I found a large piece of cardboard, so I used it

as the basis for my template. I built one template based on the

measurements I took earlier.

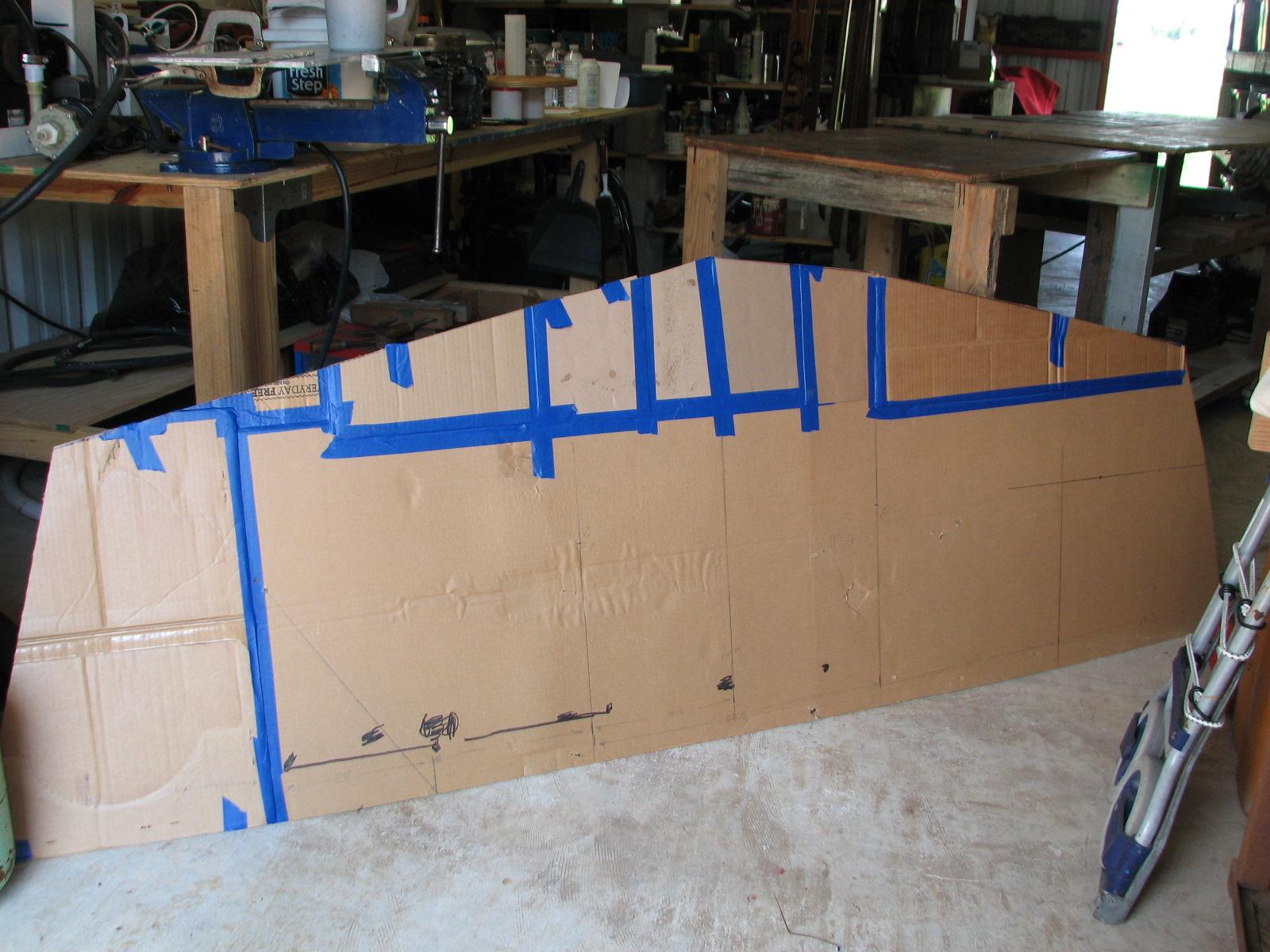

Template Built At The

Shop

I took the single

template back to DREAM AWAY, and installed it in the aft cabin.

Before I got very deep in the template project, I worked on the wind

instrument project.

The wind instrument was

still functioning properly on the spare vane and cable, so I powered

down the instruments. I disconnected the spare vane and cable from

the wind instrument, and connected the wind instrument to the

masthead vane and cable. I powered up the instruments and the wind

instrument functioned properly. Jumping to the future, it is 2030 and

the wind instrument is still functioning in the manner to which it

was designed!!

Now back to the hide

hole project. I put the template up in the aft cabin, and using push

pins I attached the template to the main cross piece and the battens.

As expected the template was not perfect. I added small pieces of

cardboard, and cut off some cardboard in places. Finally got the

template where I needed it. I took the template down and took it out

to the Black Beast.

Starboard Side Of

Template In Aft Cabin

Center Of Template In

Aft Cabin

Port Side Of Template

In Aft Cabin

August 29, Thursday,

2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Drove to New Iberia to

ship two routers back to Amazon, and the Bounce

Shoes to Stacy. We ordered

the two routers, unfortunately the item listed on the web page, the

one we want, is not the one they ship. Hopefully it will get

straightened out, and we will get the proper item. If not they are

available on eBay.

While in New Iberia,

purchased some groceries, and then stopped at Petsmart

to get some Kitty food. On

the way back to the marina

I stopped at the Port

of Delcambre’s storage

room and loaded the lawn mower and fuel into the Black Beast. Then it

was back to the marina.

Took all of the

groceries to DREAM AWAY, and changed into my work clothes. Went out

and did all of the trimming around the trees and gardens, and mowed

the grass. When that project was finished, I loaded up the mowing

gear and took it back to the Port

of Delcambre’s storage

room. Then back to DREAM AWAY, so I could get started on my projects.

Got to work on the aft

cabin. I had cut the necessary battens yesterday. Today when I put

the battens up on the overhead, two of them needed adjustment!

Starboard Side Before

Batten Installation

Port Side Before Batten

Installation

I measured the battens

that needed “adjustment”, and I also marked where to drill holes

for the screws to attach the battens to the overhead.

Working With The

Battens On The Workbench

When I had all of the

cuts made and the holes drilled, I got in the aft cabin and installed

the battens in the overhead.

Battens Installed On

Starboard Side

Battens Installed On

Port Side

Now all of the

framework is done, tomorrow I have to bring the template material to

DREAM AWAY, and make templates so I can cut the five pieces of

Structoglas that will cover the hole and backing plates. Hopefully

tomorrow or the next day I will get this project finished, and have a

nice looking overhead in the aft cabin.

I also inserted some if

the spray foam in the empty spaces in the overhead. This will help

with temperature control, but also cut down on condensation during

the winter.

Foam Insulation

Squeezing Out From The Overhead

August 28, Wednesday,

2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Slept in this morning

until 0620, so was running behind. I also had to spend some extra

time getting caught up with emails.

I went over to the

shop

and cut out the battens for the hide hole project in the aft cabin. I

have a table saw on a table that I take outside the shop to make my

cuts, so the saw dust does not get all over the shop.

Cutting Battens On

Table Saw

Cut Battens Ready To Go

Loaded up the battens

and other stuff into the Black Beast, and went to the Port

of Delcambre’s storage

room. I loaded up the paint and all of the painting accessories and

went to the

North

Pier Marina. I was going to

paint the lamp pole bases as per the director. While I was masking

off the pole bases, the dockmaster showed up. Since I was there he

decided to go and get the weed killer and show me how to mix it up.

T-Boy came back with

all of the weed killer and showed me how to do the mixing. Since

there was almost no wind I pumped about six gallons of the weed

killer around the marina

garden and fence lines.

I finished off the

masking of the light pole bases, and then I painted the four light

pole bases.

Masked Off Light Pole

Base

Painted Light Pole Base

When I finished the

painting, I cleaned up all of the roller, brushes and pans. I took

all of the painting supplies, and weed killer stuff back to the Port

of Delcambre’s storage

room.

When I got back to

DREAM AWAY, it was 1530, I was tired, so I decided to call it a day.

I took a shower, mixed rum wookies, and then got on the computer.

August 27, Tuesday,

2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

After breakfast and

completing the Maintenance Log for August 26th, I went into

Abbeville. I had to go to Stine’s to purchase two cans of the spray

foam that I will need for the hide hole project. I also asked in the

paint department about tinting paint brought in from the outside, and

they said no problem.

I also stopped at

Winn-Dixie

to do some grocery shopping. Finished the shopping, then went back to

DREAM AWAY. Changed into work clothes and went over to the shop.

I checked the long

piece of wood I am using in the hide hole project, and it had set up

nicely.

Repaired Long Piece

I sanded down the

repaired area of the long piece, and put the piece in the Black

Beast.

Long Piece Ready To Be

Used

I then mixed up a small

batch of the Smith’s

penetrating epoxy and

applied it to the “trash compactor”.

Smith’s Penetrating Epoxy Applied To The “Trash Compactor”

Loaded up needed parts

and tools into the Black Beast and went back to DREAM AWAY. Hauled

everything from the Black Beast to the boat. Removed the mattress

from the aft cabin bunk and got to work.

Will not go into huge

detail, but because of the crown on the overhead in the aft cabin, I

had to cut the long piece into four pieces. I drilled holes for the

screws, countersunk the holes, and installed the four pieces along

the overhead in the aft cabin.

Starboard Side

Installation

Port Side Installation

With the front piece

installed, I was able to measure the length of the battens I will

need to finish the installation of the Structoglas

to cover all of the holes. I will cut the battens tomorrow and get

them installed.

I also removed one last

piece of rotten plywood I had left behind yesterday.

Teak And Plywood I

Removed

I decided to install

our new idea for a hatch security device. This is an inexpensive but

strong way to keep someone from coming into the boat through our

hatches. I am using carbon fiber arrows, with a stainless steel

welding rods inside the arrows.

I drilled holes in the

base of the hatch inside the boat. I ran the arrows through the

holes, then ran the welding rods through the arrows, cut off the ends

of the welding rods, and then bent the rods so they could not be

pushed out. It went very well, and will be a great deterrent.

Hatch Base Before

Installation

Outside Of Hatch Base

Where Holes Are Drilled

Carbon Fiber Arrows And

Welding Rods Before Installation

Hatch Base After

Installation

Bent Welding Rod &

Empty Arrow

This system will work

great on all of our wooden based hatches, but not sure what to do for

the Lewmar

Hatches.

August 26, Monday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Went over to the shop

after breakfast. First thing was to finish sanding the “trash

compactor”. I got it about as round as it can be, and the top and

bottom surfaces very smooth. I drilled a hole in the center, and put

the lifting rope back into it. I put the “trash compactor” in the

Black Beast to take over to DREAM AWAY. I want to verify it fits into

the buckets before I apply the Smith’s

penetrating epoxy and the

top coat of paint.

Sanding Completed On

“Trash Compactor”

Next I started looking

closer at the spare outboard engine. I now have all of the parts to

put the engine back together. I have found a couple of bad places on

the engine, where there are cracks or an actual hole. I will be

cleaning these up and using J.B.

Weld to repair the bad

places.

Hole In Exhaust Output

Chamber

Crack On Exhaust Outlet

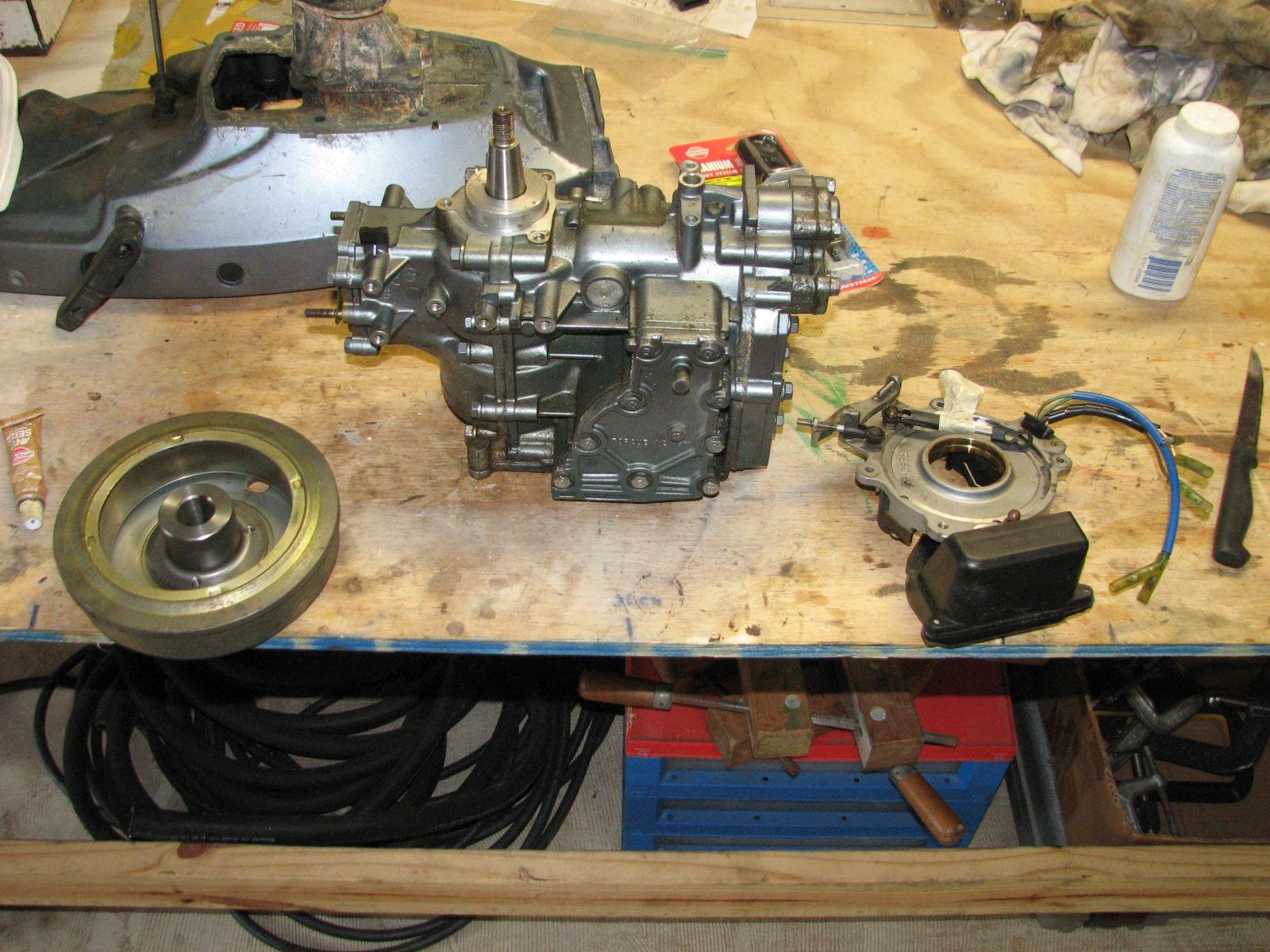

I got out all of the

parts required to put the flywheel back on the power head.

Flywheel, Power Head

And Magneto Ready For Assembly

I fixed up the piece of

aluminum I will be using for the main mast sail step, and filled in

the four holes on one side of the piece.

Aluminum Piece With

Four Holes Filled In

I loaded the cross

piece for the hide hole project, and all the parts I thought I would

need for the hide hole project into the Black Beast, and went over to

DREAM AWAY.

The first thing I

checked was the “trash compactor”. It fit into the barrel

perfectly, so now it is ready to be finished off.

I had measured the

amount of the 1” stainless pipe I had at the shop, and I have 32.5

feet. I measured the amount of pipe I will need to weld up the stern

ladder, and the amount I will need for the hard dodger project. I

have plenty for both projects, and may have enough to fabricate the

hand holds for the main cabin.

I started on the aft

cabin hide hole project. The first thing I had to do was to move the

mattress off of the bed. This was fun it that having the mattress off

of the bed made it difficult to get parts and tools in and out of the

aft cabin.

I measured the main

cross piece, and it was too long, so I cut it off to the proper

length. I also had to remove some trim wood to make room for the main

cross piece. Then came the fun of removing a lot of rotten plywood

from the overhead.

Plywood Removed From

Port Side

Rotten Wood On

Starboard Side

Rotten Wood Removed And

Cleaned Up On Starboard Side

Port Side All Cleaned

Up

I was ready to install

the main cross piece, when I discovered a real problem. The crown of

the deck! I had completely forgotten that issue. The was a crown of 1

½” to be taken into account.

I decided to go back to

the shop

and see if I could find more wood to make the crown in the main cross

piece. When I went back to the shop

I realized adding wood would not completely solve the problem, and in

fact would cause issues with the battens I have to install to hold up

the Structoglas

I am using as a ceiling panel.

I tried to bend the

main cross piece, but since it was a laminated piece, all I did was

crack the piece! I have decided to cut the main cross piece into two

or more pieces to make the crown. Hopefully this will work. I will

find out tomorrow!

Since I cracked the

main cross piece, I had to mix up some epoxy to repair the main cross

piece, which I did.

It started to rain, so

I worked on the spare outboard engine. I installed the magneto, and

then the flywheel. It all went on pretty well. The good news is I

have pictures of the disassembly of the power head so I can use them

to help with the reassembly. The rain stopped, so I called it a day.

August 25, Sunday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Up early and on the

road so Kitty could catch her flight from Lafayette to Atlanta via

Houston. She got off with no problems, and arrived safely in Atlanta.

On the way back from

the airport in Lafayette, I stopped at the Lowe’s in New Iberia. I

purchased four 2” X 3” X 8’ studs to be used for the hole

hiding project in the aft cabin. I stopped by the shop

and dropped off the four studs, then back to DREAM AWAY.

The hole hide project

actually got started back in April, so you can see the beginning the

work in the April

Maintenance Log.

I had planned to get

right into the hole hide project, but there were several small

projects I wanted to get out of the way before I got into this large

project.

It was

time to clean out all of the raw water strainers and manifold. I

cleaned out the main strainer for the manifold (Sea Chest), and the

manifold (Sea Chest). Also cleaned out the strainers for the ice

maker cooling pump, the refrigeration cooling pump and the forward

air conditioner cooling pumps. During this cleaning process, I also

cleaned out the hoses for all of the cooling pumps using high

pressure water from the dock. I also vacuumed off the air filter ojn

the intake of the forward air conditioner.

I repaired one of the

overhead lights in the garage. They use incandescent bulbs, and when

they are on for a long period of time the current they draw melts the

lead on the base contacts of the bulb. I pulled out the bulb, and

with a soldering gun, resoldered the base contacts.

A strap on one of the

cockpit sun shades needed to be repaired. I got out the parts needed

and repaired the sun shade.

Strap Removed From Sun

Shade

Repaired Sun Shade

The two doors under the

sink in the galley, have latches to hold them shut while underway.

The left hand, or aft latch was not working. I removed the latch and

repaired the spring mechanism, then put the latch back on the door.

Latches On Doors Under

The Galley Sink

To continue with the

hide hole project in the aft cabin, I had to move all of the books on

both the starboard and port side. Once the books were out of the way,

I had to move one of the fans mounted in the aft cabin on the port

side overhead. I had to move the fan forward to get it out of the way

of the cover I will be installing.

Fan In Original

Location

Fan In New Location

With Helper Observing

Following are a couple

of pictures of the holes and backing plates that will be covered up

with the hide hole project

Port Side Cleat Backing

Plate

Starboard Side Cleat

Backing Plate

Starboard Side Dinghy

Davit Backing Plate

Last item for the day

was working on the wind instrument. The wind instrument was still not

working connecting to the masthead transducers. I connected the spare

transducers and cable to the wind instrument in the instrument pod.

It worked for a few minutes, and then quit working. I am pretty sure

the problem is the instrument itself, so will have to send it off to

get it repaired.

Wind Instrument Back,

Removed From Instrument Pod

Spare Vane Connected

Directly To Wind Instrument

Wind Instrument

Working, But Briefly!

August 24, Saturday,

2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

The two cruising boats

that came into the marina on Thursday, departed early in the morning,

0900, to get on their way back to Houston.

No work done on DREAM

AWAY projects. Ran errands, spent day with Kitty, hanging out,

reading.

August 23, Friday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Went over to the shop

and inspected the “trash compactor”. The application of the

Smith’s

penetrating epoxy looked

good, but I noticed a couple of more places where the plywood was

delaminating. I decided to dispense with this old “trash

compactor”, and cut out a new one. I measured, and cut out the new

“trash compactor”. Tomorrow I will sand it down, and apply the

Smith’s

penetrating epoxy.

Old “Trash Compactor”

With The Smith’s

Penetrating Epoxy

Connected the battery

charger to the battery on the SeaScooter. Did not take long and the

battery was fully charged. Put the SeaScooter back together, and

tested the unit. Still sounds like a thrashing machine. Will have to

take the unit apart and see if I can find any issues.

Back over to DREAM

AWAY, and Kitty and I called our son Stacy and sang him happy

birthday.

We then drove into New

Iberia with the cruisers from the two boats that arrived into the

marina

yesterday. We made several stops for parts and groceries, and had

lunch in downtown New Iberia at Victor’s

Cafe, a tradition in New

Iberia!! If you have ever read any James

Lee Burke books you will

know Victor’s

Cafe.

Came home with barely

enough time to shower, then it was off to Shuck’s

in Abbeville for dinner.

August 22, Thursday,

2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Went to shop,

and applied a coat of the Smith’s

penetrating epoxy on the

“trash compactor”. Left the “trash compactor” to dry

overnight.

“Trash Compactor” With The Smith’s Penetrating Epoxy Applied

Installed the battery

that had arrived for the SeaScooter. I installed the battery and

verified that the battery actually ran the propeller on the unit. The

propeller turned, but it sounded like a thrashing machine, very

noisy. Did not have time, but will charge the battery completely, and

see if that night be the problem with the loud noises.

Battery In SeaScooter

Loaded up the pressure

washer from the Port

of Delcambre’s storage

room and took it to the North

Pier Marina. Took the power

washer out to pier “C” to finish off washing the bird doo off of

the end of Pier “C”.

On my way out to the

end of Pier “C”, I noticed a large amount of bird doo in the area

where we were expecting to cruisers to arrive later in the afternoon.

I cranked up the pressure washer and cleaned all of that area of Pier

“C”. When I finished that area, I went out to the end of to

finish there. What a surprise! The area I did yesterday was covered

again in bird doo. It looked like I had not even been there, and only

24 hours. I worked on the end of Pier “C” until the rain

threatened, cleaned up the pressure washer, and put away the hose.

I am going to have to

come up with some method to keep the seagulls off of the pier.

Cleaning up a bit of bird doo every couple of weeks will be OK, but

not this.

I went back out on Pier

“C” and cleaned up the pier by removing some ropes and old tires

from the pier. If I do a little of that every week, eventually I will

have all of Pier “C” looking really good.

Went back to DREAM

AWAY, and completed the installation of the speakers on the boom

gallows. One speaker did not work. Swapped the speakers from port to

starboard. One of the speakers if defunct, and the working speaker

worked on either side with different wiring.

August 21, Wednesday,

2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Went to shop

and worked on “trash compactor”. When I removed the two pieces of

Formica,

they pulled off some of the delamination! I decided to try to fix the

delamination with Liquid

Nails. I applied a small

amount of Liquid

Nails, and used the two

pieces of Formica

to clamp down on the “trash compactor”.

I loaded up my Skil

saw, long extension cord,

and spare plywood into the Black Beast. I also loaded the new

pressure washer out of the Port

of Delcambre’s storage

room and went over to the marina.

I loaded the Skil

saw, long extension cord,

and spare plywood onto the dock trolly, and went out on Pier “C”.

I cut the plywood and put it down on the places on Pier “C” where

the tar was really bad. Keeps from tracking the tar onto the

transient boats.

I cleaned up from that

project, and rant the pressure washer and hose out to the end of Pier

“C”. I started washing the dock down to remove all of the bird

doo that had accumulated. What fun! Rain threatened again, so put all

of the gear into the Black Beast, and returned it all to their

respective storerooms.

I then helped a fellow

boater on the dock with his battery and air conditioner problems. I

connected the battery so the generator and starboard engine would

start. We connected a pump to the air conditioner cooling lines, and

ran a descaler solution through the lines. When we finished, we

connected all of the cooling lines back to normal, but the air

conditioners still did not stay on. I suspect a refrigerant leak.

August 20, Tuesday,

2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Went over to the shop

and checked on my attempt to repair the car charger. It did not go

well, so the un-repaired car charger went into the trash can.

I sanded down both side

of the “trash compactor”, and the edges in preparation for the

application of the Smith’s

penetrating epoxy.

Starting The Sanding

process On The “Trash Compactor”

Sanding Process On The

“Trash Compactor” Complete

When the sanding was

complete, I was able to look into a couple of places where there was

plywood delamination. These needed to be fixed before I applied the

Smith’s

penetrating epoxy to the

“trash compactor”.

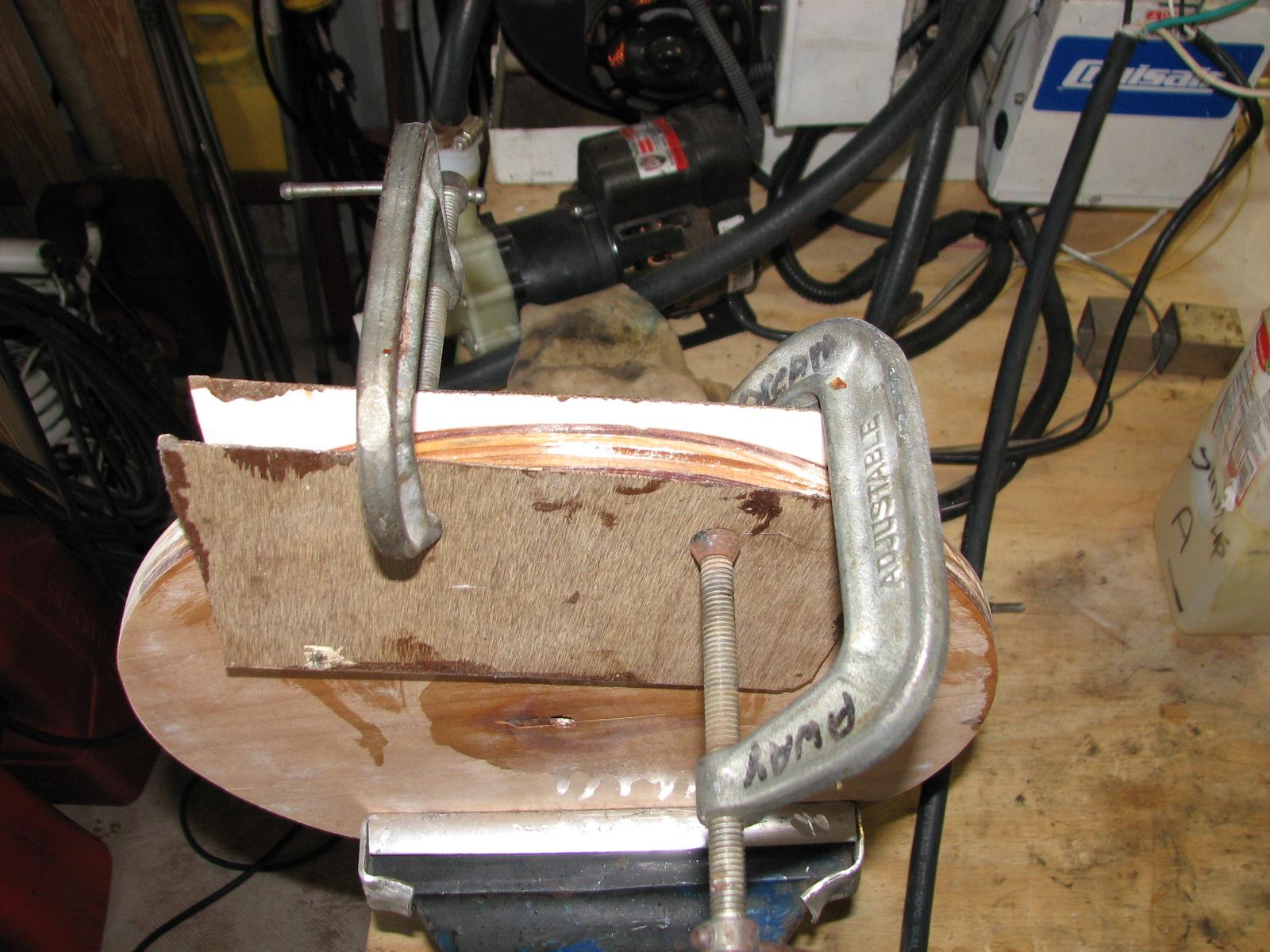

I got the two pieces of

Formica

I had used on the boom gallows to use on the “trash compactor”.

I mixed a very small batch of the

Smith’s

penetrating epoxy, and

applied it to the de-laminated portions of the “trash compactor”.

I put on the two pieces of Formica,

and clamped it all together.

Trash Compactor”

Clamped Up

I got all of the

instruments and the instrument pod front panel on the workbench.

Instruments Ready For

Insertion Into The Pod Front Panel

I then inserted the

instruments into the pod front panel.

Instruments Inserted,

Back Of Front Panel

Instruments Inserted,

Front Of Front Panel

I loaded up the

instrument pod, speakers, bell holder and all of the fasteners into

the Black Beast and went over to DREAM AWAY.

I attached the

instrument pod to the bottom of the boom gallows, and then ran the

wires for the instruments and speakers.

Instrument Pod On Boom

Gallows

Wires Running To

Instrument Pod

I connected all of the

wires to the instruments, and put the front panel on the instrument

pod, and powered the instruments up. Still having wind instrument

issues. Will be looking into that problem.

Instrument Pod

Installed With Functioning Instruments

Went out and trimmed

the grass around the trees and gardens. I then cut the inside and

outside grass in the marina.

When Kitty came back

from her errands, she told me the air conditioner had a high pressure

error on the digital control. I knew what that meant. I took out the

main input strainer, and the air conditioner strainer, and cleaned

them out. I also connected the high pressure water from the dock, to

the air conditioner hose. I turned on the water which cleaned out the

hose for the air conditioner from its connection at the manifold top

the overboard discharge. Put it all back together and the air

conditioner functioned normally.

August 19, Monday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Went over to the shop

for the first time in a couple of days. Did a clean up and a

straighten up. Ran the vacuum, and got it looking pretty good.

Brought over my “trash

compactor”. The plywood is starting to delaminate, so it needs work

so it will not go completely bad.

Trash Compactor On Work

Bench

As you can see the

“trash compactor” is pretty simple, and it really does work. I

have two big buckets on the stern of DREAM AWAY that I store trash in

on a passage. I drop the trash bag in the bucket, then put in my

“trash compactor”, and stand on the “trash compactor”. It

really does a good job of getting a lot of trash into a small area.

I then started in on

repairing the car charger for our iPhones and iPads. A little piece

had broken off on the inside. I used a bit of the BoatLIFE

LifeSeal to hopefully hold

the spring in place. We will see tomorrow!

Car Charger Being

Repaired

I then went back over

to the marina.

Kitty took the Black Beast to our mechanic in Delcambre to have the

evaporator on the air conditioner checked out.

I got the clippers out

of the Black Beast and trimmed grass around the fence lines and trees

in the marina.

Tomorrow, if it is not raining, I will mow the grass in the marina.

I also took down all of

the flags that were up for the Delcambre

Shrimp Festival. I got them

all folded and stored away.

Kitty came back from

the mechanics with great news. As I suspected the evaporator was

clogged up with dirt, mud and leaves. This was the cause of the water

dripping into the car, the air conditioner not putting out cold air,

and the air volume being so small. Cleaning out the area of the

evaporator made a huge difference.

We then had to make a

run to the Vet’s. I had allowed our cats out on deck while I was

taking down all of the flags. It turns out our male cat had captured

a bee and it had stung him in the left front paw. The vet found the

stinger in his paw, removed it and gave him two shots. All is better,

although he was feeling pretty low, and Jillian was also a bit upset.

I took a shower, and

did some more work on the June Maintenance Log. I am up to June 24th,

so I am getting to the end!

August 18, Sunday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Spent most of the

morning working on the computer and updating the June Maintenance

Log. Had a break and with errands and interruptions, never got back

to finishing up the log.

August 17, Saturday,

2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Spent most of the day

working on the computer and updating the Maintenance Logs. I did get

the July Maintenance Log finished. Now I need to get the June one

finished, then I can incorporate them into my web

page.

I did spend about ½

hour working on weeding the North

Pier Marina gardens. Later

in the afternoon we went to the Delcambre

Shrimp Festival to eat a

shrimp Po-Boy and listen to a band named Krossfrye.

We left the Delcambre

Shrimp Festival when

Krossfrye

finished playing. We then went to a friends “camp” across the

bayou from the marina

to visit and listen to more live music. Pretty much a great day!

August 16, Friday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee. Spent extra

time working on the computer and updating the Maintenance Logs.

Went into New Iberia to

pick up laundry and grocery shop. Came back to DREAM AWAY, put all of

the laundry and groceries away. Had a nice early dinner, and listened

to some music from the Shrimp festival.

August 15, Thursday,

2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee. Spent extra

time working on the computer and and updating the Maintenance Logs.

Had to drive into

Lafayette again today for a followup visit with Kitty’s

cardiologist. Nothing specific found, except a possible heart valve

problem. Doctor ordered more tests. With some confusion, we finally

got some more chest X-Rays, and a nuclear test performed on the lungs

looking for clots. We got out of the hospital well after 1900, and

drove home.

No work done on DREAM

AWAY projects.

August 14, Wednesday,

2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee. Spent extra

time working on the computer and fighting Internet access.

Had to drive to

Lafayette today for a dermatologist appointment. Good appointment,

only two biopsies! Came back from Lafayette, and the remainder of the

day was spent working on the Maintenance Logs, computer work, reading

and general stuff.

August 13, Tuesday,

2013

We left Connie and

Wayne’s house, and drove over to the Municipal

Marina in Freeport, Texas.

We met with dockmaster, Kevin, and the Marina Director, Tamara.

Tamara took us out to

the three

stall shower trailer, and

opened it up for us. We took many pictures, and inspected the unit as

closely as possible. The unit seems to be in great condition, and

would make a great addition to the North

Pier Marina until the

building gets built here.

Kitty and I then made a

report to our port director, Wendell, and I titled all of the

pictures. Kitty sent her report to Wendell, and I sent all of the

pictures to him. When we finished all of this we went to lunch with

Wayne, Connie, Tamara and ourselves.

When we came back from

lunch I backed the Black Beast up to the trailer to check out the

lights. It was a no-go, none of the lights worked. Wayne backed his

truck up to the trailer. and connected into the trailer lights, and

all of the lights worked. Talk about good news, bad news! All of the

lights on the three

stall shower trailer

worked, but the trailer hitch light connection on the Black Beast was

not working. Now I have another project, to get the trailer hitch

light connection working. I have never used that system since

purchasing the Black Beast, so I will have to start from scratch.

We then left Freeport,

heading back to Delcambre. We arrived at DREAM AWAY around 2100. We

unloaded the Black Beast, fed our Kitties, took showers, and headed

to bed!

August 12, Monday, 2013

Made a pot of coffee,

and checked the weather. Packed our stuff and were under way by 0800.

We were driving to Freeport, Texas, to check out a three

stall shower trailer. The

city of Freeport is going to auction off this unit, and it would be a

perfect temporary solution for the North

Pier Marina.

The Port Director asked

us to drive down and evaluate the unit, and if in good shape and a

viable solution for the the North

Pier Marina, for us to take

many pictures. We will be sending the pictures and a report to him

tomorrow after we do the inspection. He wants to have as much

information as possible to present at the board meeting of the Twin

Parish Port District board meeting tomorrow night.

On our way to Freeport,

we stopped in Clear Lake Shores to have lunch with our friends Jimmy

& Barbara, and friend Al. After lunch, we drove by Momentum

Metal Recycling in League

City, Texas, to see if they had any stainless steel square tubing or

pipe. We got lucky, they had on hand about 30 feet of 1” stainless

steel pipe, which I purchased!

This pipe will be used

for the ladder at the stern of DREAM AWAY, and the frame for the hard

dodger.

We then continued on

our trip to Rosharon, Texas. We spent the night with aour friends

Connie and Wayne. We had met them in Delcambre, when they stopped by

North

Pier Marina, on their way

to and from Florida. In fact they are the ones that told us about the

three

stall shower trailer

available in Freeport.

Tomorrow we will be

going to the Municipal

Marina, to actually check

out the unit.

August 11, Sunday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Stayed on DREAM AWAY,

caught up on email and still working on the Maintenance Logs for June

and July.

Went and got the lawn

mower and gasoline from the Port

of Delcambre’s storage

room and brought them back to the North

Pier Marina. Trimmed and

mowed all of the grass at the North

Pier Marina. Returned the

mower and the gasoline to the storage room, and back to DREAM AWAY.

Spent the remainder of the day working on the Maintenance Logs.

August 10, Saturday,

2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Stayed on DREAM AWAY

working on the Maintenance Logs. Had breakfast, and then went out and

weeded the marina

gardens.

Went over to the shop

and unpacked the water scooter that Stacy had shipped from China. It

was unpacked and seems to be a neat device. The only issue so far is

that there is no included battery, and no battery number.

Water Scooter Out Of

Box

Left the shop

and came back to the marina.

Continued with the garden weeding until it started to rain. Back to

DREAM AWAY, and continued working on the Maintenance Log. The

remainder of the day was working on the Maintenance Log, and some

reading.

August 09, Friday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

No work done on Al’s

boat today. Went to Cheryl’s office and attempted to get the

wireless printer working on XP, but to no avail. Very frustrating,

for of course it only took two minutes for me to print to the printer

from my MacBook Pro!!

Al took me to the

Amtrak station in Houston. The train was late arriving into Houston.

Had a tie-up in San Antonio, so we did not get underway until 1340. I

arrived in New Iberia around 1830.

August

08, Thursday, 2013

Got up in

the morning and had coffee and breakfast. Got on the Internet,

checked email and the weather.

Yesterday

I had not used permanente wiring when we tested the alternator on the

port engine. After we verified the alternator did work, I got some

connectors, and connected all of the proper wires to the alternator.

This

morning I realized we did not test the alternator operation after the

wiring was complete. So we started up the port engine and verified

the operation of the alternator.

Next, I

moved one of the old batteries back into place for the starboard

house battery. We decided not to use one of the new batteries for the

starboard house, while still having old batteries in place for the

port house battery.

I also

moved the source wiring for all of the DC accessories from the

starting batteries to the house batteries. I went through all of the

wiring, and verified tightness of connections, and dressed up as much

of the wiring as possible.

That

pretty much ended the day working on Al’s boat, so I took a shower

and had a late lunch. Later I went to Texas City to help a friend of

Al’s get her printer working in the office.

August

07, Wednesday, 2013

Got up in

the morning and had coffee and breakfast. We got right to work on the

alternator problem on the port engine. We verified the alternator was

not putting out any voltage when the engine was running.

Alan had

two spare alternators, but because the drive pulleys on them did not

match the engine drive belt configuration, they could not be

installed. We removed the alternator from the port engine, picked up

the two spare alternators and took all three to a local alternator

shop.

The tech

at the alternator shop tested all three and verified their operation.

The alternator we had on the engine, we actually had connected to the

wrong post on the alternator. The tech mentioned we should have a

good ground for the alternator to work properly. We then took all

three alternators back to the boat.

After

some interesting issues, Alan falling into the engine room with an

alternator landing on his knee, lunch and a dermatologist appointment

for Alan, we finally got back to installing the alternator back on

the engine. I connected the positive battery wire to the correct post

on the back of the alternator. Instead of assuming the ground to the

alternator was connected to the engine start battery, I moved the

alternator to the start battery ground. When we cranked up the

engine, the alternator started working. A six year project complete.

I also

connected the trickle charge output on the Freedom Marine 30

Inverter/charger to each start battery. There are two trickle charge

outputs, so now we have the Freedom Marine 30 Inverter/charger

charging each house bank, it is also charging each start battery.

Now we

have most of the electrical/battery problems sorted out. I still have

a couple of items to do, but the big item will be for Al to build the

two new battery boxes.

August

06, Tuesday, 2013

Got up in

the morning and had coffee and breakfast. Alan went off for Doctor’s

appointments, and was away for pretty much the whole day.

I stayed

on TORI, and worked with the electrical/battery problems. Will not go

into a lot of detail, but made quite a bit of progress finding and

identifying problems, and coming up with some solutions.

The

biggest change is that we are delaying the trip, mostly because of

the electrical problems, and a couple of engine oil leaks. Alan had

purchased a set of new batteries, because of some problems with the

current set.

The issue

with the new batteries is they will not fit in the existing battery

box. I gave Al a couple of options, but he decided that the way to go

would be to fabricate new battery boxes. This is the best way to go,

but that necessitated putting off the trip until the new boxes are

fabricated.

I will be

staying on until Friday so I can help Al with a couple of other

issues, and to get him pointed in the right direction to get most of

the outstanding issues settled.

August

05, Monday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Went out to the parking

lot and finished screwing down the blocks at the end of the parking

spaces which I had painted blue yesterday.

Blocks At End Of

Parking Spaces

Next

project was to get the main boom gallows Installed and the hard

bimini bolted back to the gallows. I had all of the hardware cleaned

up. I had also cut out some pieces of sheet plastic to insulate the

aluminum from the wood. Hopefully this would keep the different

metals from causing the wood in the boom gallows to deteriorate.

Boom

Gallows Support & Hard Bimini Support Before Gallows Installation

Boom

Gallows On Dock Before Installation

Boom

Gallows & Hard Bimini Installed Looking Forward

Boom

Gallows & Hard Bimini Installed Looking Aft, Starboard Side

Boom

Gallows & Hard Bimini Installed Looking Aft, Port Side

When I

completed that project, it was in to take a shower, and head to the

train station to make the trip to Houston. I am off to do a boat

delivery for my friend Alan.

Got into

Houston on the train about 30 minutes early, and Alan was waiting for

me. Made good time and got to his boat, and finally had dinner.

August

04, Sunday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Went over

to the Port

of Delcambre’s store room

and picked up all of the painting supplies, including the paint and

handicap stencil. Went back to North

Pier Marina and started in

with the painting project. I am converting two regular parking spaces

to one handicapped parking space, and one handicapped unloading area.

I masked

off all of the current yellow lines, and masked off some necessary

lines in the unloading area. When I got all of the masking done, I

opened the paint and painted all of the necessary. I did two coats

over the current yellow lines. When completed, I removed all of the

masking tape, put all of the supplies including the buckets used to

mark off the area into the Black Beast and took it all back to the

Port

of Delcambre’s store

room.

New Lines

Painted In Marina

Parking Lot

I then

went to the shop

and put together the SeaLand

pump with the new duck bill

valves. I loaded the pump, the boom gallows, and the teak pieces to

cover the davit holes in aft cabin, the teak piece to cover the winch

hole in the main cabin, and the teak electrical wire cover and went

back to DREAM AWAY.

After

breakfast, I installed the teak pieces that had been varnished. The

first piece was over the hole in the overhead of the main cabin. This

is where the bottom of the main sheet winch used to be.

Hole In

Main Cabin To Be Covered

Hole In

Main Cabin Covered

Next we

installed the teak electrical wire cover in the main cabin.

Exposed

Wires In Main Cabin

Exposed

Wires Covered In Main Cabin

Then we

moved back to the aft cabin to cover a couple of the holes that were

cut in the teak to enable installation of the dinghy

davits. After installation

of these two teak covers, there is more work to do. I am working on

that project, but it is on hold for the moment.

Starboard

Davit Hole To Be Covered

Starboard

Davit Hole Covered

Port

Davit Hole To Be Covered

Port

Davit Hole Covered

I then

worked on preparing for the installation of the main boom gallows. I

got most of the prep work done, but the afternoon thunderstorms

interrupted completion of the boom gallows.

Time to

shower and prepare a grilled chicken dinner!

August

03, Saturday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Went over

to the shop

and finished up the cleaning of the SeaLand

pump. Now it is ready to be

put back together and have it ready for service.

SeaLand

Pump Cleaned And Ready For

Assembly

Went to

the Port

of Delcambre’s dock and

waited in line to get some big shrimp just in from the gulf! Well

worth the wait!!

Notice

Size Of Shrimp In My Hand!

Did some

work for the Port

of Delcambre, in the

parking lot at North

Pier Marina. I marked off

two parking spaces, then swept and washed them in preparation to be

painted. I am making them into handicapped spaces.

August

02, Friday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

No work

done today on DREAM AWAY. We both had dental appointments first thing

in the morning, then I went with Kitty to her audiogram of her heart

in Lafayette, which was cancelled. Did some shopping, attempted to

find the necessary switch for the aft air conditioner, but was not

successful.

August

01, Thursday, 2013

Started off the morning

with my normal ritual of getting on the Internet, answering email,

and checking the weather, while making a pot of coffee.

Took Black Beast into

Chabill’s

Tire Service to have the

air conditioner checked. The air temperature coming out of the vents

is just not cold enough. They could find nothing, except there might

be an issue with the evaporator. They could not source an

evaporator, so it was left up to me to find one.

Mark was with me so we

were on a hunt for parts. We first went to Ralph’s

Electronics in New Iberia.

Here I purchased the switch for the aft air conditioner, that I had

to wire around a couple of days ago. We then went to an Ace

Hardware store named

Handyman Hardware. Here I was able to purchase a metric nut I needed

to re-install my Taco

LED spreader light. Last we

went to Hose

Speciality so Mark could

get some exhaust hose for his new engine installation.

Hose Speciality was an amazing place to visit. I am pretty sure anything having to do with hoses they could produce. It was very impressive.

Back to DREAM AWAY, and

I put the new Texas registration decals on the tender, then put the

tender back up on the davits, and the Yamaha outboard back on the

life rail.

I then went over to the

shop

and worked on the SeaLand

pump that I had removed

from the sanitation system last week. I have to remove all of the

built up calcium on all of the parts. To do this I soak the parts in

a toilet bowl cleaner that I also use to clean the stainless steel on

the exterior of DREAM AWAY.

I also did some clean

up and moving around of stuff in the shop.

I then applied the

fifth and last coat of varnish on teak pieces to cover the davit

holes in aft cabin, the teak piece to cover the winch hole in the

main cabin, and the teak electrical wire cover.