I then put the Sharp

Microwave back into it’s place in the galley,

and put all of the hold downs back in to keep the microwave from

shifting during a passage. As a final test, I heated a cup of coffee,

and it all went well.

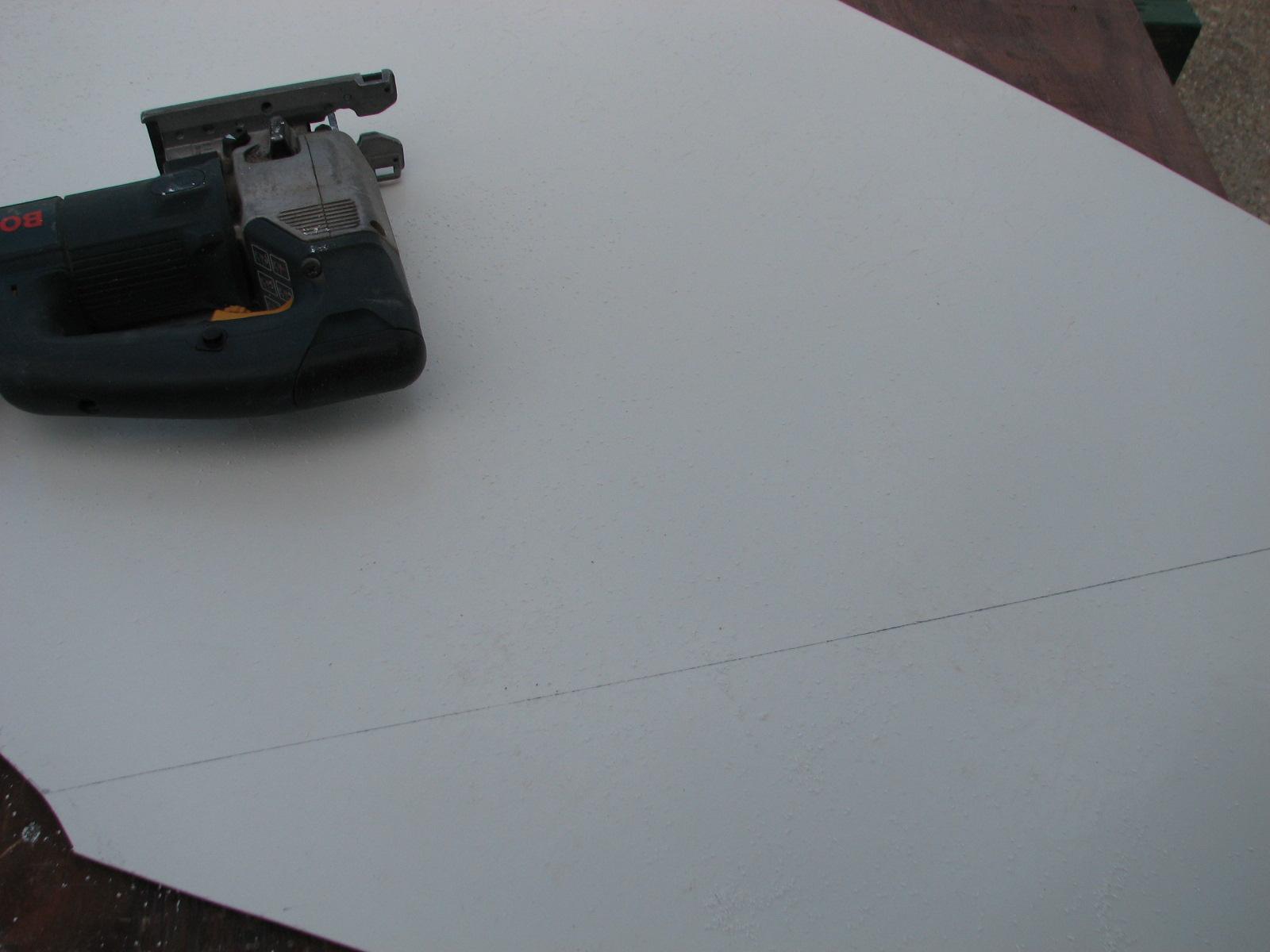

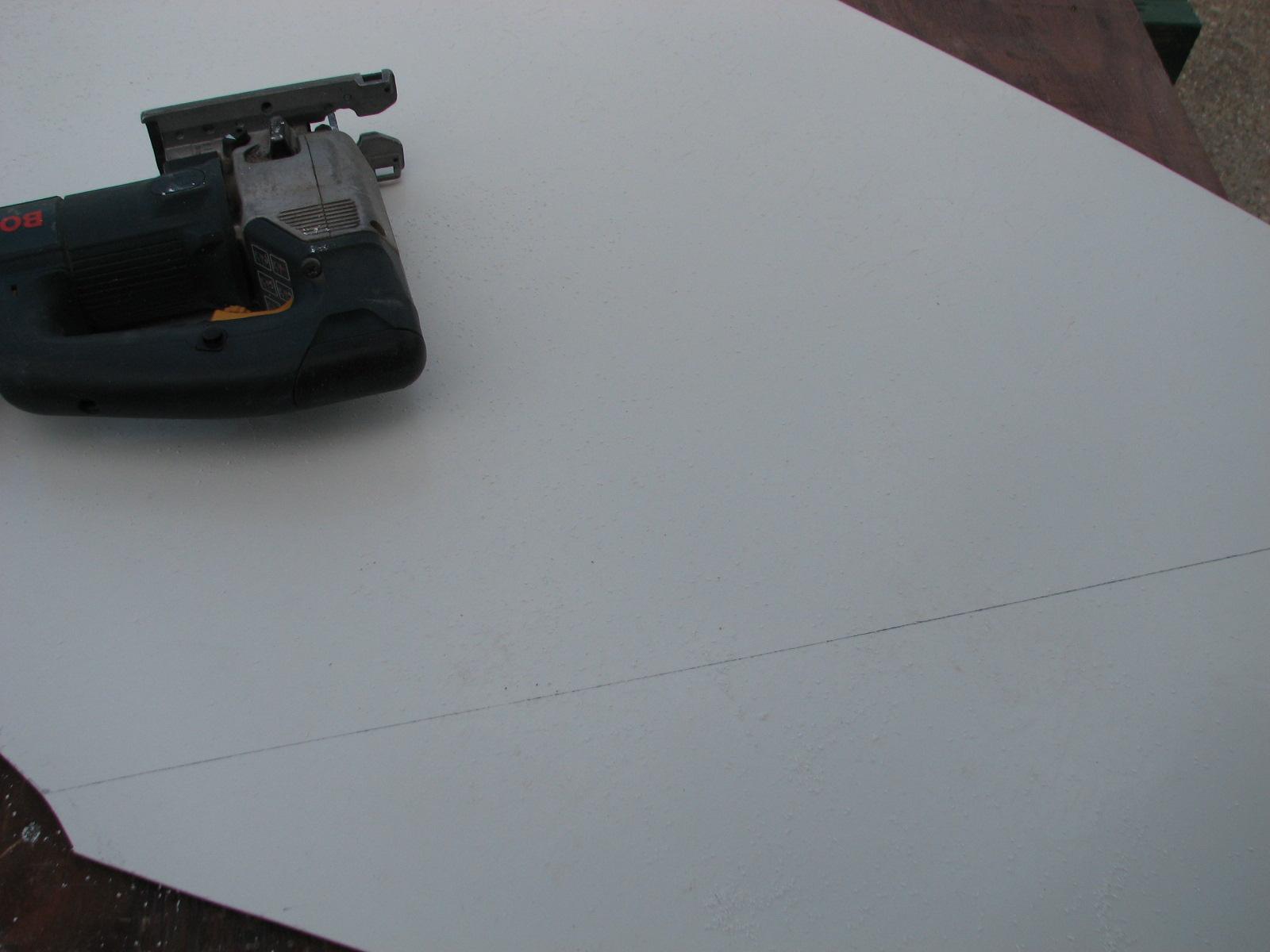

I then went over to the shop

to get to work on other projects. First on the list was to cut out

some pieces of fiberglass

to use to attach the battery box and the gratings in the tender.

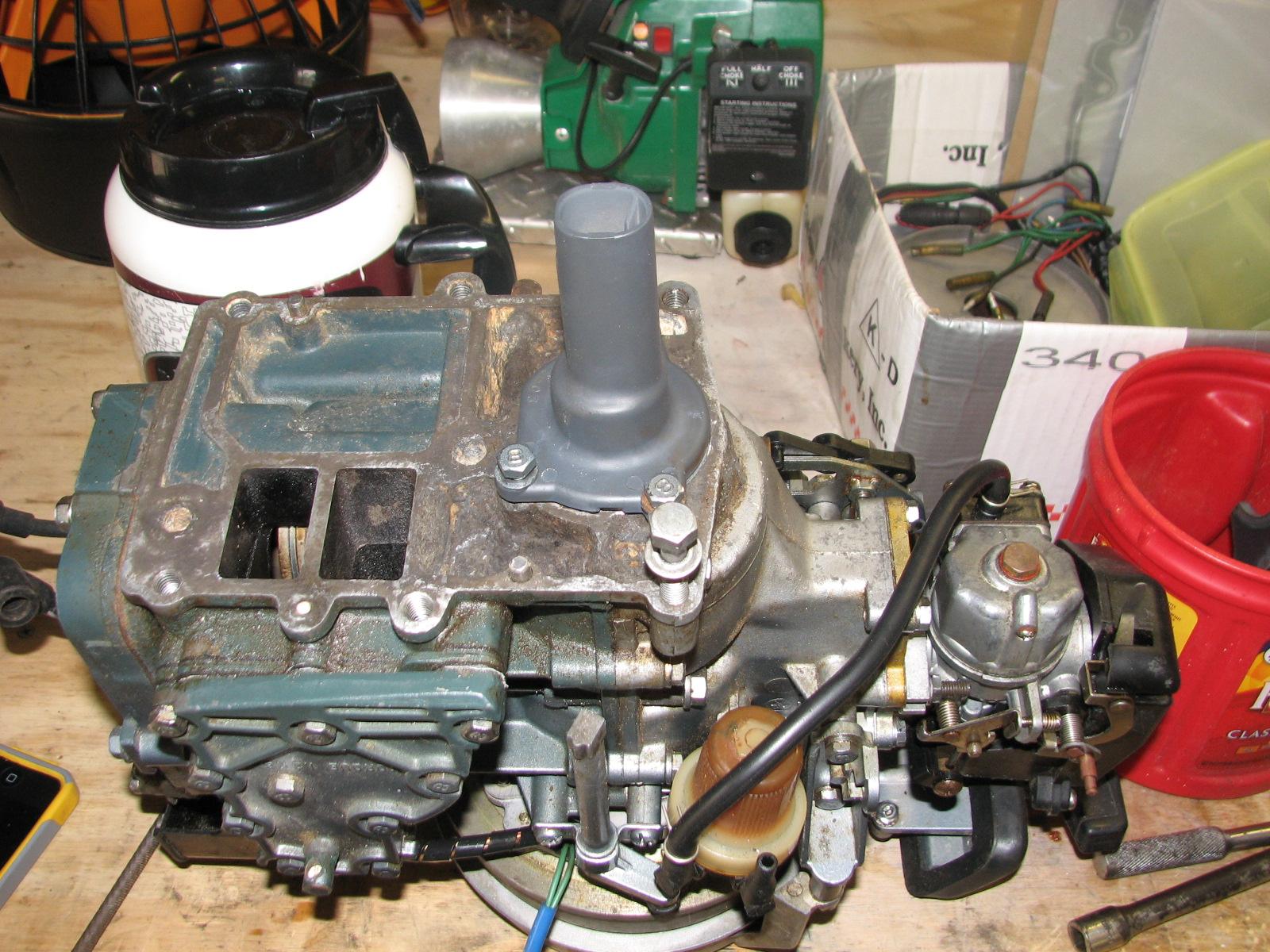

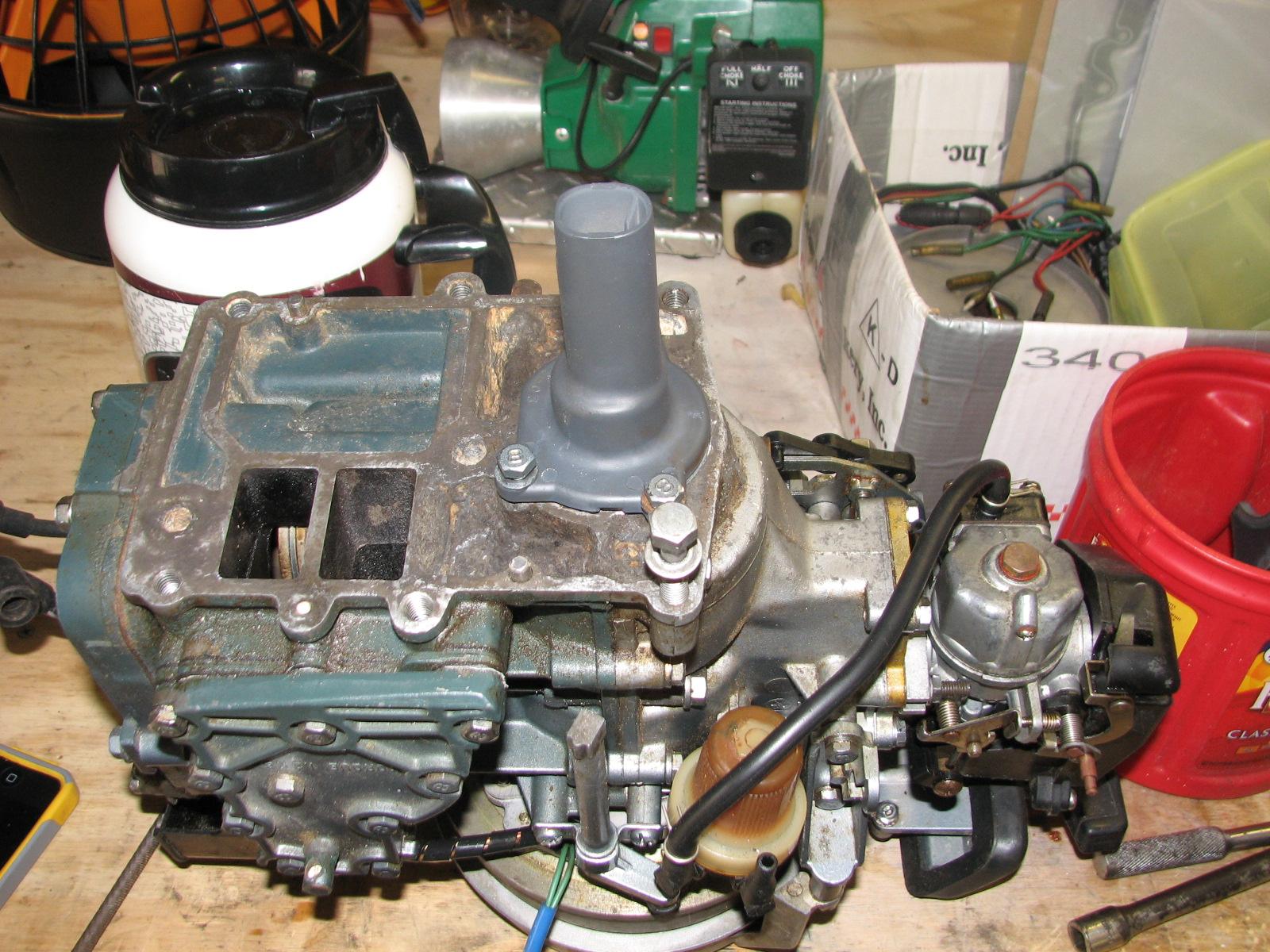

Now I put together the bracket

assembly. While putting all of these parts together, I

am putting a silicon

grease on all parts for protection, and using an

anti-seize compound so I will be able to take apart the engine again

without problems.

Spare Outboard Mostly Assembled

Spare Outboard Mostly Assembled

Hopefully all that remains is the lower

drive, and a couple of small items, and this motor

will be ready for a run and a test.

September 28, Saturday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Kitty got up early, and we drove over

to the Farmers Market in Erath.

Erath

is our sister city next to Delcambre.

It was a good turn out, and we purchased a few fresh vegetables and

fruit, some smoked meats, and a couple of sweet treats. We came home

and had a breakfast of fresh cantaloupe, smoked canadian bacon, and a

fresh baked muffin.

First thing on the list is to see if

the newly purchased prop for the Mercury

outboard will fit. I installed the new prop with no problem, so that

is an item off of the list.

Now I was determined to complete two

items on the list with Kitty’s help. I needed to go up the main

mast, and finally install the

Taco

spreader light. Second I wanted to drop the back stays

and masthead

fitting to the deck, so I could change out the hex

head bolt for a carriage bolt. The head of the hex head bolt was

wearing on the main halyard, and I needed to stop that. The bolt I

needed to change actually holds the back stays to the main mast

masthead

fitting.

It took about an hour to get everything

ready to do these two projects, but I was finally ready. Kitty helped

me get up the main mast to the level of the spreaders, and then she

hauled up the tool bucket to me. I bolted on the new Taco

spreader light, and then wired it into the electrical

system. Kitty went below and turned on the new light to verify

operation, and it worked great. Will have to check the operation

tonight when it is dark to see how well it lights up the foredeck.

Wires Sticking Out Of Starboard Main

Mast Spreader

I sent the tool bucket back down to the

deck, and then I went up to the top of the mast with some wasp spray!

There is a wasp nest at the top of the mast! Kitty changed the tools

necessary for this project, then hauled the tool bucket up to me. I

worked the pin holding the backstay

fitting loose, and sent the tool bucket back down to

the main deck. I kept a screw driver and hammer with me. Kitty

disconnected the tool bucket from the topping

lift and sent the topping

lift back up to me.

Went to the

shop

and unloaded the Black Beast, and got it back into shape. I then got

out my bench grinder with wire wheel and cleaned all of the parts of

the backstay

fitting. Now as soon as I can get the proper sized

carriage bolt and square out the hole in the backstay

fitting, I will be ready to put the backstays

back onto the mast.

Bench Grinder With Wire Wheel To Clean

Parts

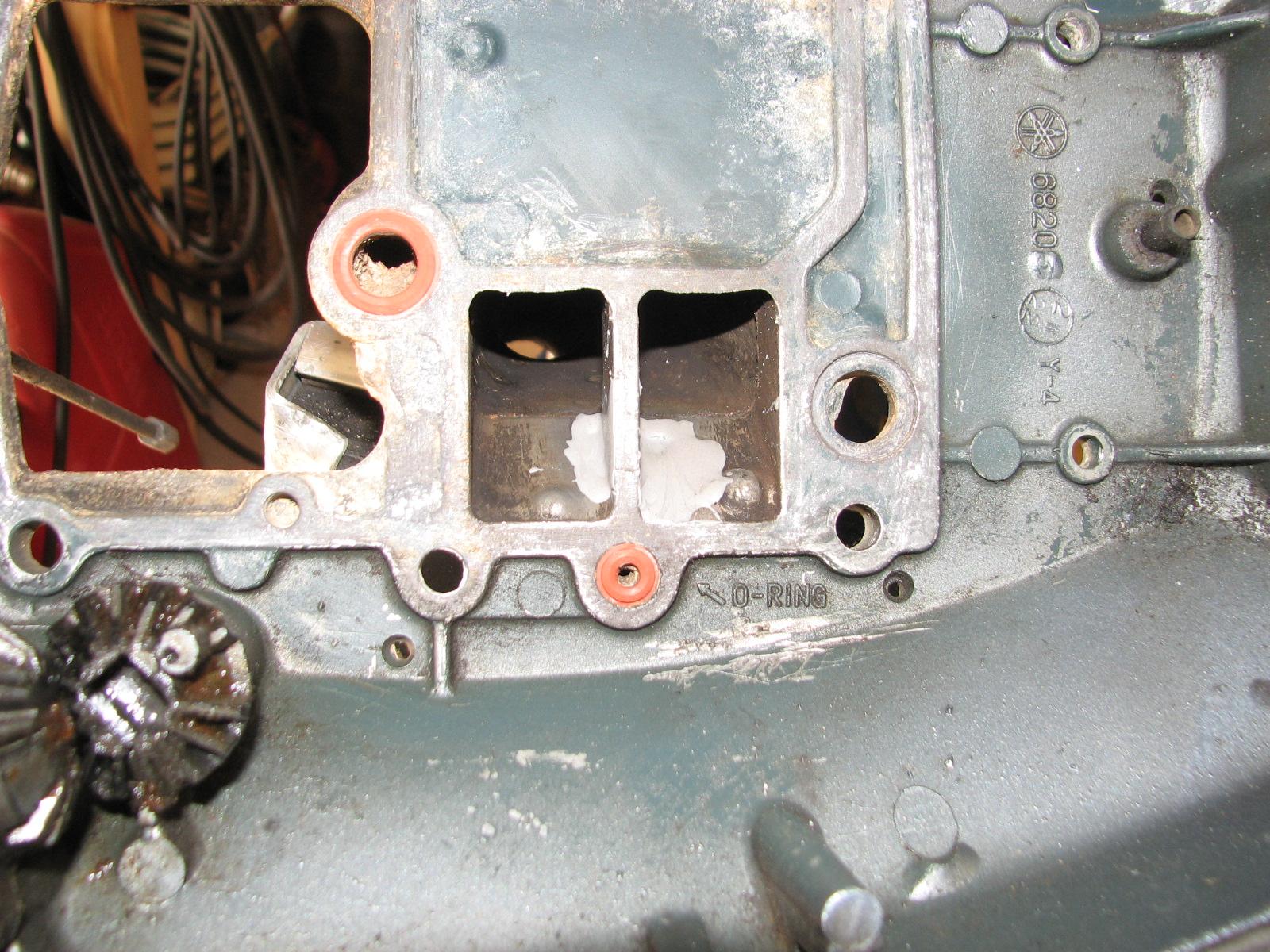

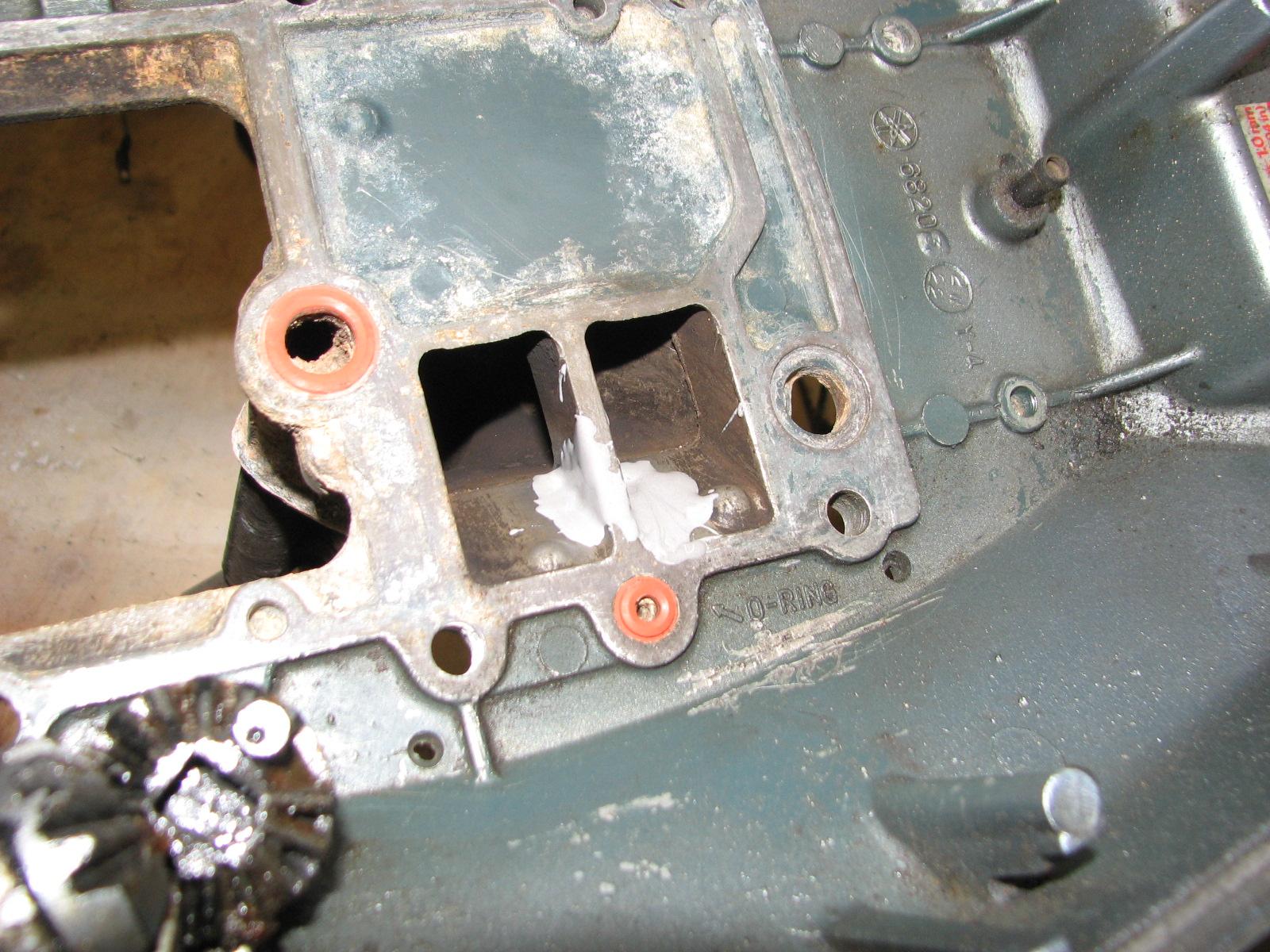

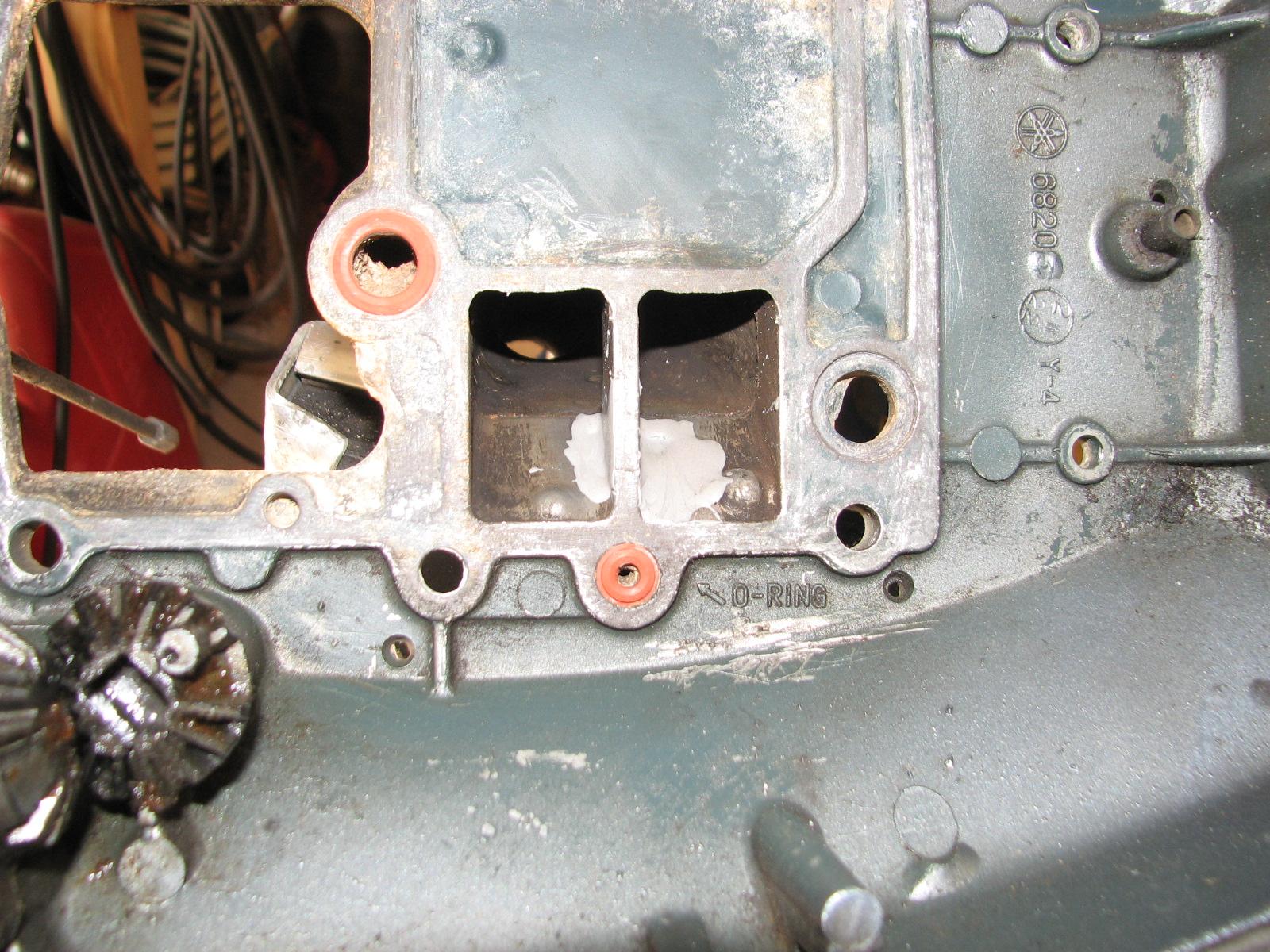

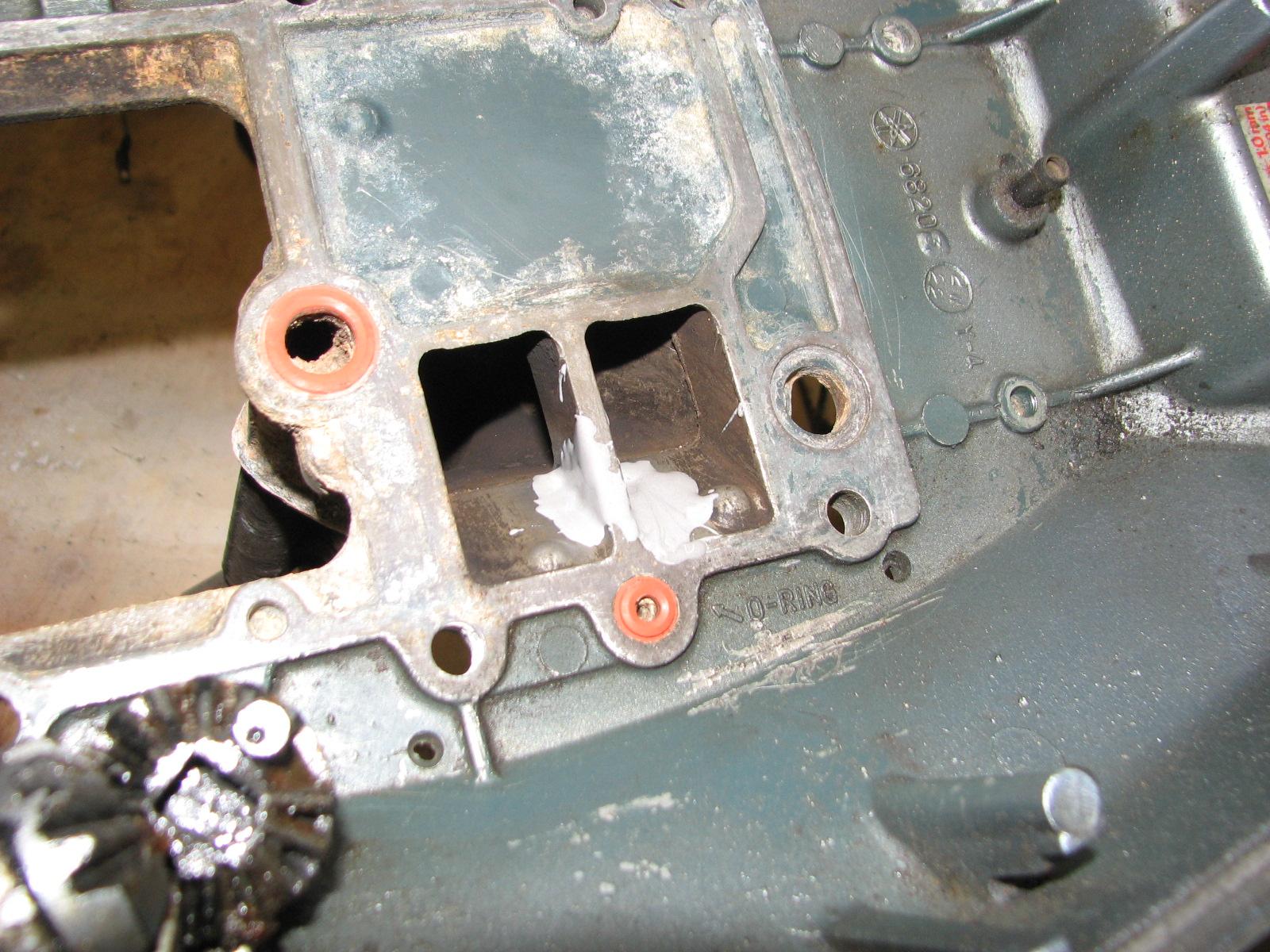

I then started to put back together the

spare Yamaha outboard motor, now that I had all of the parts. When I

started digging around looking for the specific parts, I realized I

had not cleaned all of the parts and fasteners. I kept the bench

grinder out and cleaned all of the parts and fasteners.

I then applied the second coat of

varnish to the nav

station chair and the third coat on the backing plate

cover for the head. I applied the seventh coat of Cetol

to the teak wheel on DREAM AWAY.

I left the shop

and went back to DREAM AWAY, where I was presented with good news and

bad news. The good news was Kitty had prepared me and adult beverage,

rum and pink lemonade. The bad news was the Sharp

Microwave had died.

Kitty and I removed the Sharp

Microwave from its place in the galley,

but could find no apparent problem. It would just not turn on, like

an internal fuse or circuit breaker had popped. It will have to wait

until tomorrow as I needed a shower and Kitty was preparing dinner.

The Sharp

Microwave was put into the garage

until tomorrow.

After dinner, when it got dark, we

checked the brightness of the Taco

spreader light. It is amazingly bright, and uses about

1/5th of the current of my present spreader lights. The Taco

spreader light uses about 6 watts, and the Hella

spreader light uses 55 watts! I will see how the new

light does after a storm, because of talk about leaking issues. If no

problems are found, I will be ordering four more. Three for the main

and mizzen spreader lights, and one for the davits on the stern.

September 27, Friday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went to the shop

and wiped down the nav

station chair and the backing plate cover for the head

with the tack

rag. I then applied the first coat of varnish to the

nav

station chair and the second coat on the backing plate

cover for the head. I applied the sixth coat of Cetol

to the teak wheel on DREAM AWAY.

Went back to DREAM AWAY, to take a

shower. We got ready and headed out to New Iberia, with Monica and

Warren, to have lunch at Victors

Cafe. After lunch we went to tour the Shadows

On The Teche house. We were going to stay and watch

the boat parade on Bayou

Teche presented by the Sugar

Cane Festival. We got information the boat parade was

not going to be much this year, and Monica and Warren were tired out,

so after the tour, we headed home.

September 26, Thursday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went to the shop

and the first item on the list was to check the PVC

cap I purchased at Shannon

Hardware in Morgan

City yesterday. I had purchased a piece of 6” PVC

pipe to use as my heat

exchanger cleaning device. The problem was I could not

find a cap to seal off one end.

As I was walking around Shannon

Hardware on our visit there yesterday, showing Monica

and Warren around, I came across the 6” PVC

cap. I purchased it immediately. The good news is the cap fits the

pipe, so now all I have to do is cut the pipe to the proper length,

and I will have a heat

exchanger cleaning device to use at any time!.

I took a look at the pump that was left

for me, and was able to separate the pump from the motor. It was

obvious there had been salt water allowed to get into the motor. I

was able to break loose the shaft in the motor and it was able to

spin, but sounds very rough.

I have spares for all of my pumps, and

this model, I do not use, so I will not waste any more time on the

project. I will put the pump outside the shop and someone will pick

it up for use or scrap.

Motor And Pump Separated

I then got back to work on the nav

station chair. The seat cover had dried, so I put the

cover back on the foam.

Dried Seat Cover

Seat Cover Back On Foam

I then got busy and completed the

sanding process on the nav

station chair. When I finished it was ready for the

first coat of varnish.

I loaded up the small varnished

hatch for the mid cabin in the Black Beast, and stopped at the Port

of Delcambre’s storage room to pick up the lawn

mower and fuel can. I went back to the marina,

and then went to DREAM AWAY for breakfast. I removed the temporary

hatch in the mid cabin, and installed the freshly varnished hatch.

Freshly Varnished Hatch In Mid Cabin

New Office Chair Being Tested In

Kitty’s Office

After breakfast, I trimmed the grass,

and pulled weeds around the marina

gardens, then mowed the grass.

I took a shower, Kitty and I had lunch,

then we drove to Lafayette,

for we both had doctor’s appointments.

September 25, Wednesday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Spent some extra time catching up on

the Maintenance log and emails, and then played tourist the remainder

of the day, We went with new cruisers Warren and Monica down to

Berwick and Morgan City. We looked at the dock facilities they had in

the area, and had lunch at Cafe

JoJo’s on Front Street in Morgan City. It was a

great lunch, and the ambience was wonderful.

We then drove back to Delcambre. It was

a very enjoyable and relaxing day.

September 24, Tuesday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went to the shop

and checked on the “trash compactor”. I applied the last

coat of paint yesterday, and the paint had dried perfectly. I

attached the carrying line to the “trash compactor” and it was

ready for prime time. When I go back to DREAM AWAY, i will take the

“trash compactor” with me.

Finished “Trash Compactor"

Messed about with the pump given to me

by Kittie and Mark. I was able to get three of the bolts out that

hold the motor to the pump, but I have three more remaining. I

sprayed more Aero

Kroil on the remaining bolts. Will keep at it and they

will all come loose, and then I will be able to see what the problem

is.

I took the cushion off of the nav

station chair, and washed it out in soap and water in

the sink

at the shop.

I then started the sanding process. It will take a bit to get the nav

station chair sanded with all of the curved and round

surfaces.

I loaded up some of the teak pieces

that were finished and came over to DREAM AWAY. The plan was to

finish the gelcoat

on the floor of the tender, but it started to rain, and that stopped

that plan.

In the meantime we got word another

boater is coming in tomorrow and will be on pier “C”. I drove

over to the Port

of Delcambre’s storage room to pick up the pressure

washer, and returned to the marina.

Kitty had a hair appointment, so I got to work pressure washing the

area of pier “C” where the new boat will be. I also washed all of

the power pedestals on pier “C”.

When I finished that project, I had a

shower, and Kitty returned, we then went into New Iberia to run

errands.

September 23, Monday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went to the shop

a bit late because I slept in until 0650 this morning! I did the

finish sanding on the teak piece for the backing plate in the head.

The dry fit went very well yesterday. All that remained after the

final sanding is to apply the dye, and then apply the Smith’s

penetrating epoxy. When the Smith’s

penetrating epoxy sets up, I will be able to apply the

varnish.

Teak Backing Plate Cover After Final

Sanding

Teak Backing Plate Cover With Dye

Applied

I had an old kitty litter bucket I used

in the tender to carry my sponge, bailing bucket and other

accessories. It was a little worse for wear because of the UV.

I decided to use a new kitty litter bucket, but I am painting it with

the Rustoleum

orange spray paint to see how it holds up to the UV.

Bucket With Rustoleum

Orange Spray Paint Applied

I sprayed a coat of Rustoleum

orange spray paint on the second side of the “trash compactor”.

It is pretty much ready for prime time.

Rustoleum

Orange Spray Paint On The Second Side

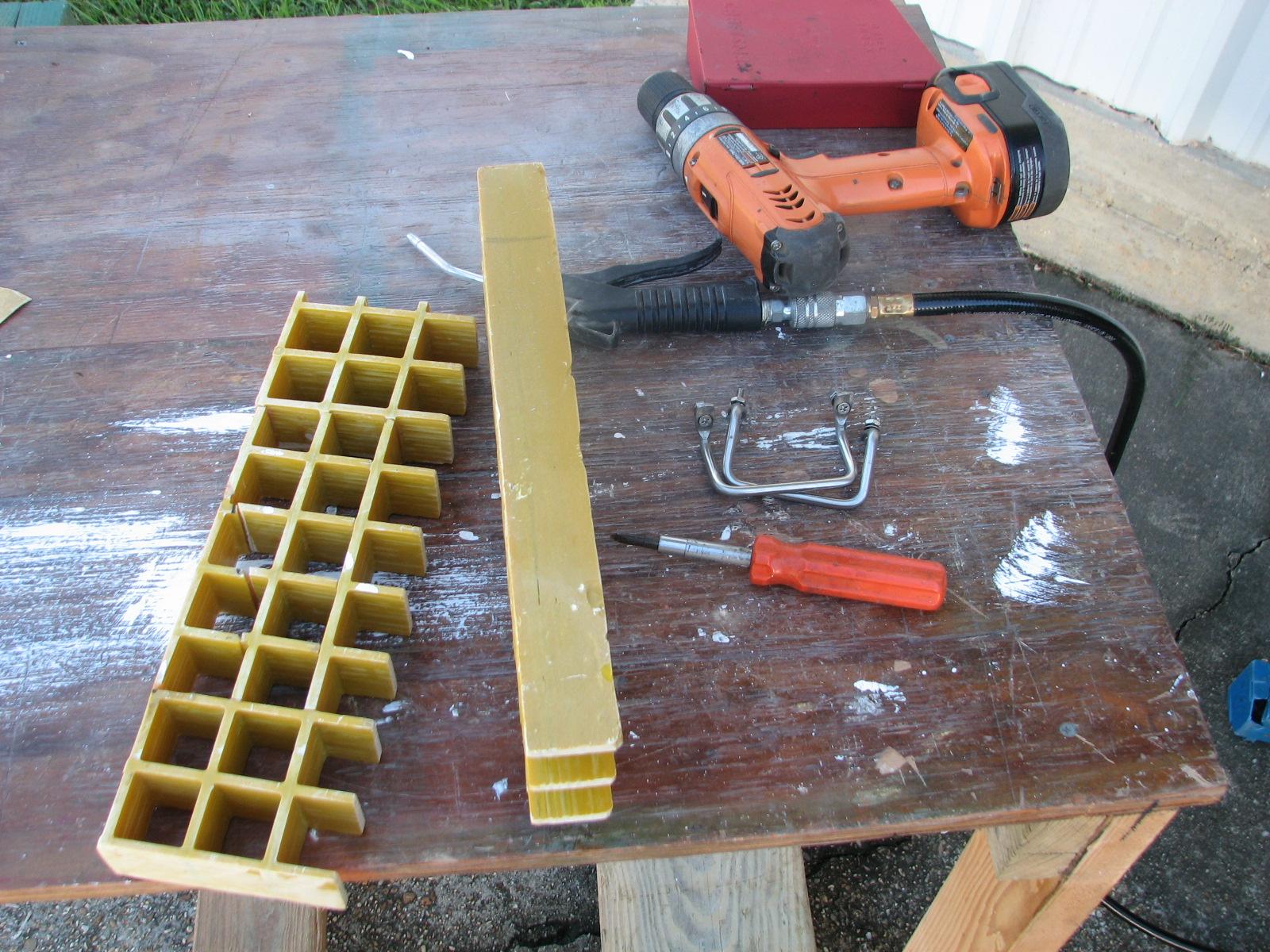

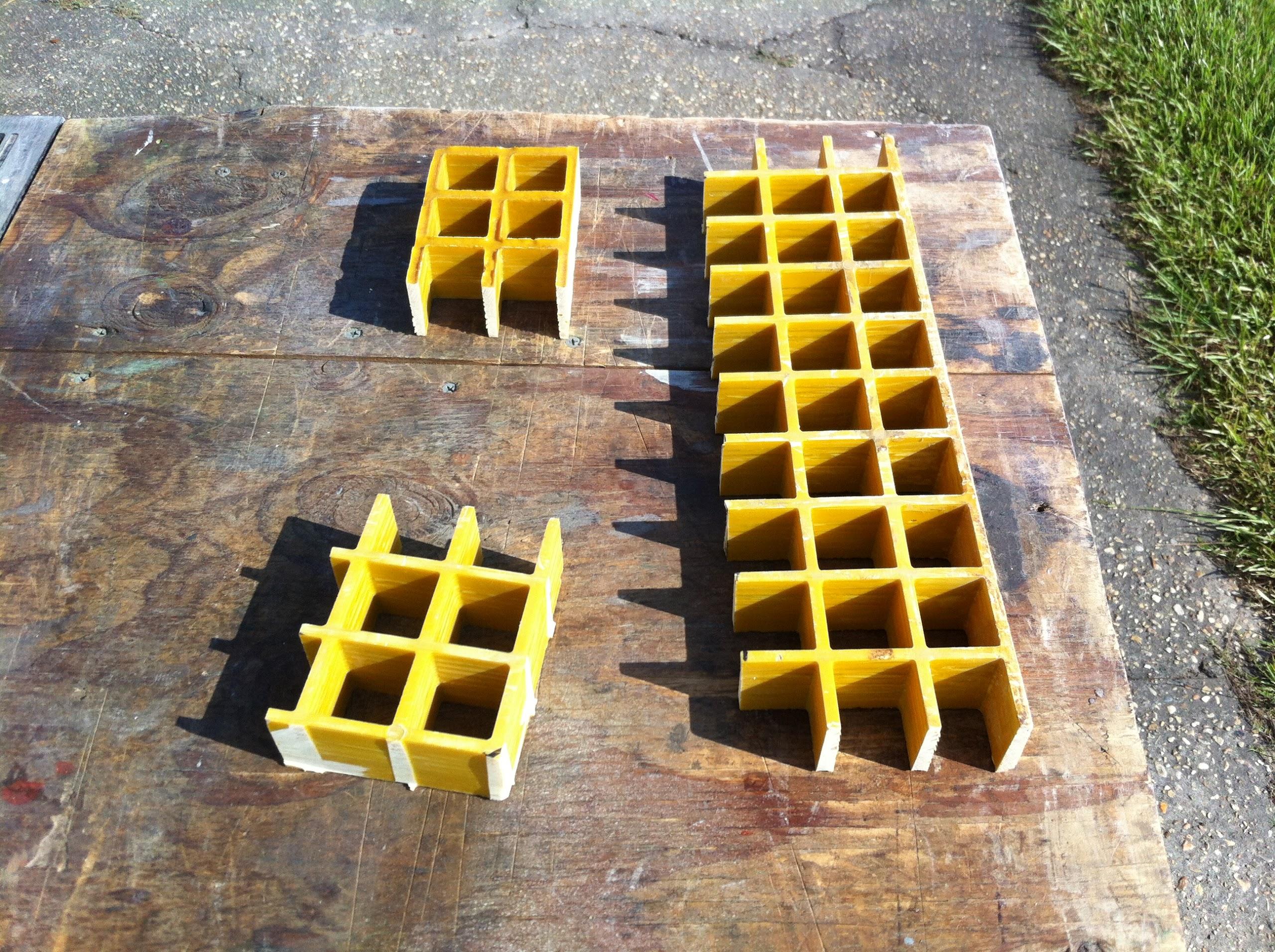

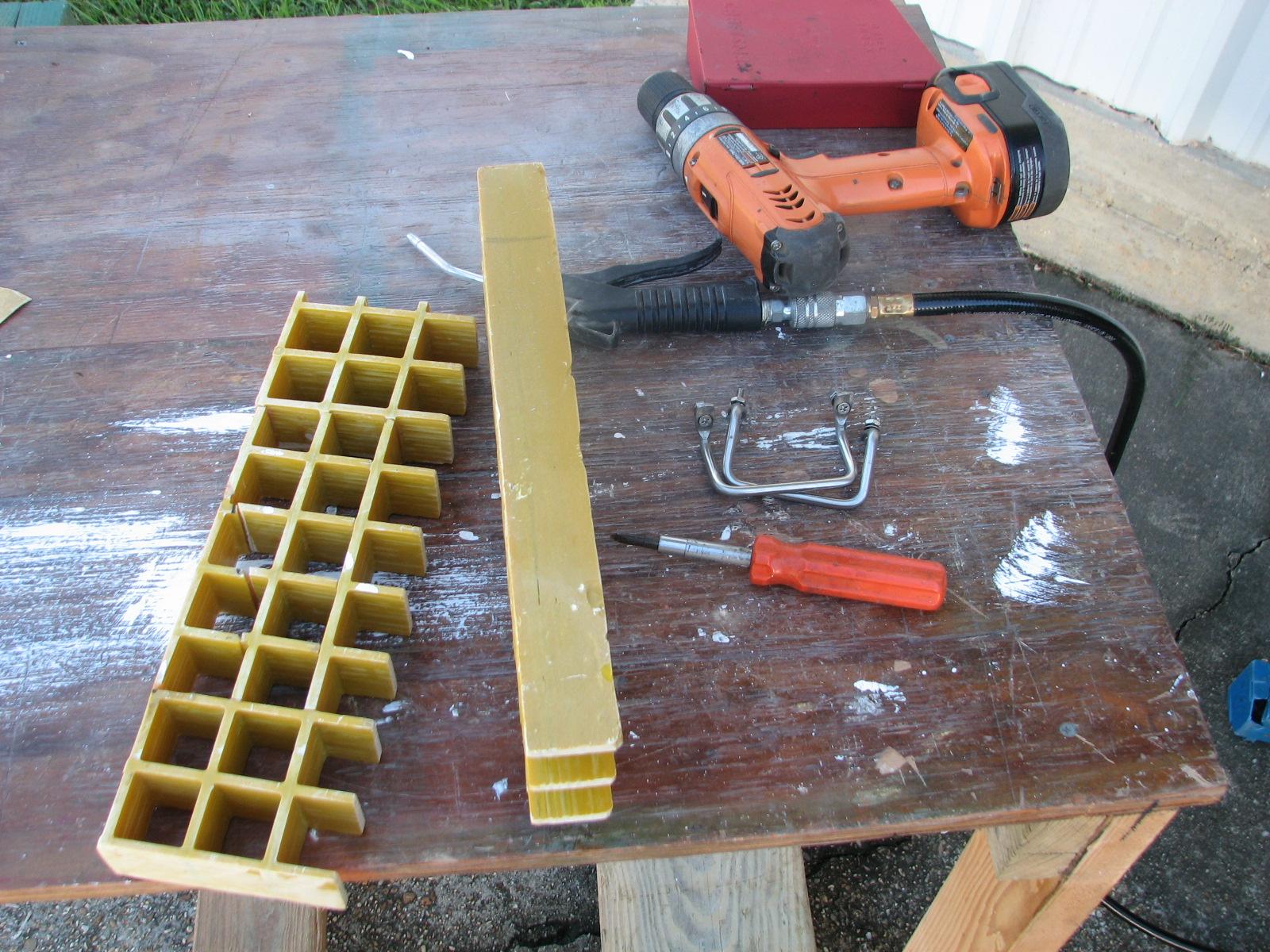

I worked on the grating I will be using

to keep the fuel tank in the tender. I attached some stainless steel

pieces to the gratings to hold the cable and locks to keep the fuel

tank in the tender, and to keep the fuel tank from being stolen out

of the tender.

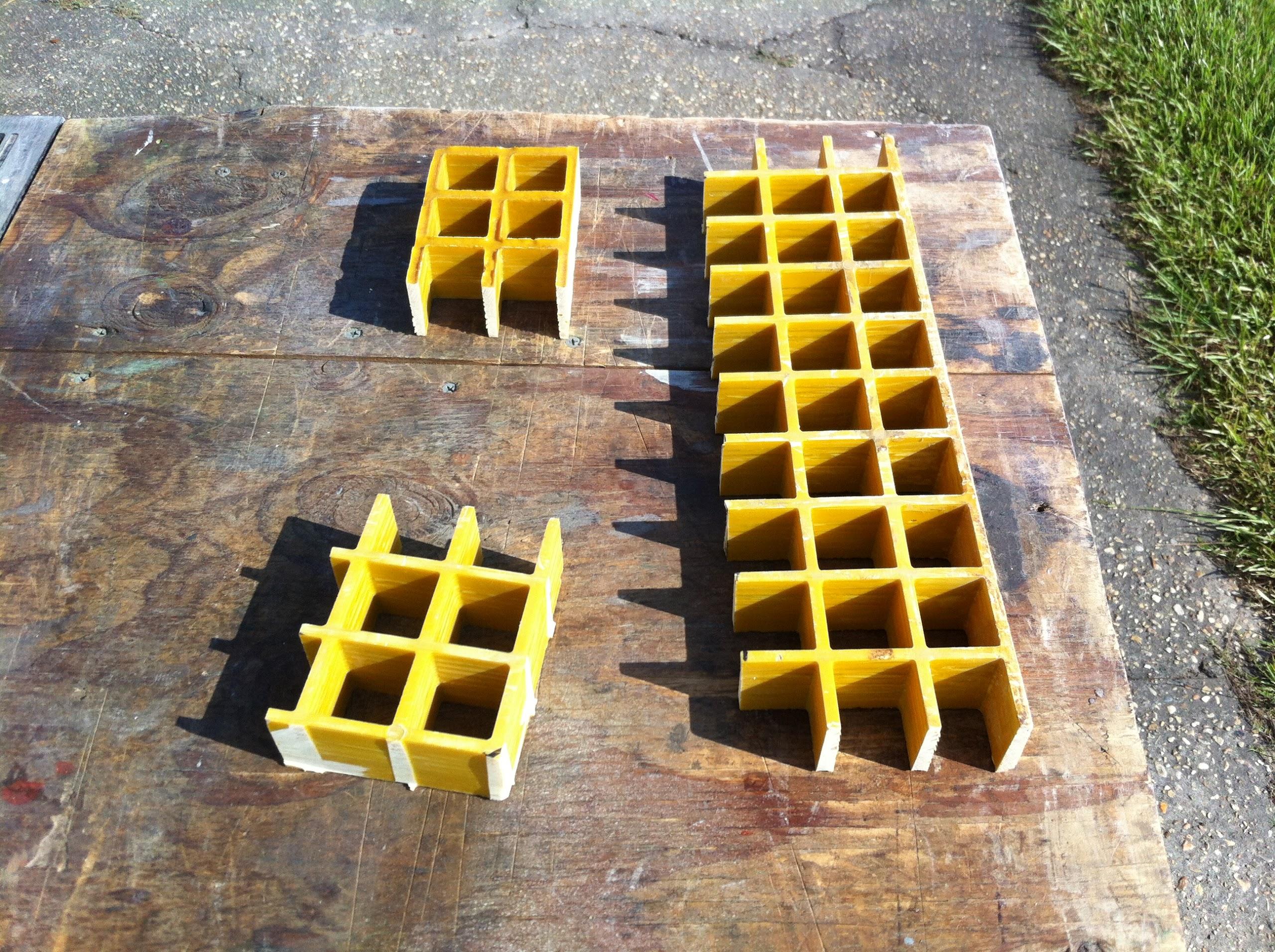

Gratings And Hardware

Gratings With Hardware Attached

When Mark and Kittie left, they left

me a pump that they said did not work. I verified the motor on the

pump would not turn. I put the pump in the vise and applied Aero

Kroil to all of the bolts seized up to separate the

pump from the motor.Pump In The Vise

Went over to DREAM AWAY, and prepared

to apply the gelcoat

to the tender decks. I found a couple of places that needed an

application of finishing putty, so I did that. After the putty kicked

off, I sanded it all down and the wiped down the whole area with

Acetone.

I then masked off the areas where the gelcoat

is to be applied. I mixed up a batch of gelcoat

and applied it to the tender transom, and to the port side deck. I

mixed a smaller second batch and started application to the starboard

deck, but the rain came and halted progress.

Decks Masked Off In Tender

Gelcoat

Applied To Port Deck, Incomplete Starboard Deck

When it got serious about the rain I

went back to the shop

and applied the fifth coat of varnish to the interior teak pieces,

the first coat of varnish to the backing plate cover, and the fifth

coat of

Cetol

to the teak wheel on DREAM AWAY.

September 22, Sunday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the

shop

and sanded on the teak piece to cover the backing plate in the head.

Got it all finished to take over to DREAM AWAY, and try a dry fit.

Teak Piece Just Out Of The Jury Rig

Clamps

Teak Piece Sanded And Ready For Dry Fit

Just had to put a photo of the pipe

clamps and the pipes in the Maintenance Log.

Newly Purchased Pipe

Clamps With Attached Galvanized Pipe

I had purchased a new can of Rustoleum

orange spray paint yesterday on one of the errands, and I sprayed a

coat of paint on one side of the “trash compactor”.

“Trash Compactor” With Coat Of

Spray Paint

Sanded the teak interior pieces and the

ships wheel in preparation of the varnish and Cetol

application. As it turned out, I did not make the application today.

I put the SeaScooter back together

after making another attempt to get to the motor and gearing in the

unit. It still sounds like a thrashing machine, so I will try the

water test again and run it until the battery runs down.

SeaScooter Back Together

Next item was to remove the pump on the

Blender

Blaster that had come apart. I need to get a new one

before I can use the Blender

Blaster again. Just a not here, it appears the Blender

Blaster company has ceased to exist, as the original URL does not

work.

Went back to DREAM AWAY and sanded down

the deck in the tender. I had applied the finishing putty day before

yesterday, and it needed sanded before I apply the gelcoat

to the deck.

Deck In Tender Before Sanding

Next on the list was an inside DREAM

AWAY project. It could be a long story, but lets just say, I need to

cut into the main cabin overhead and install different backing plates

for the boom gallows supports. While I was cutting into the overhead,

I also needed to apply the expandable Great

Stuff foam between the overhead and the fiberglass

liner. This will cut down on condensation problems in the future.

Bolts And New PVC

Backing Plates Installed

Since I was In the overhead of the main

cabin, I also sprayed the Great

Stuff foam around where the main sheet winch used to

be installed.

Hole Covered With Finished Teak Piece

Fitted new piece of teak to cover

backing plate in located in head. Used cardboard to plot location of

bolts to drill holes in the teak cover. Got the holes drilled, and

the teak piece dry fitted.

Teak Piece Dry Fitted Over Backing

Plate

September 21, Saturday,

2013

Up and at ‘em at 0430, and at the

Shrimp Festival Grounds at 0500, in the amazingly pouring rain. My

job was to help direct traffic for the Delcambre

Seafood and Farmers Market. It was not a good start,

but the rain finally stopped around 0800, and we had a surprisingly

good turn out for the market.

Kitty showed up at 0730, and we worked

at the market as volunteers until 1330. We went back to DREAM AWAY,

had a nap, and then finished out the day with computer work and catch

up. No DREAM AWAY projects today.

September 20, Friday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Before going over to the shop

this morning, I raked in the garden at the marina.

There are a couple of small hills of left over dirt that are not fun

trying to mow around, so I am slowly trying to get them smoothed out

and the weeds removed, so a nice green ground cover will grow.

I then went over to the shop

with a roll of wax paper. The first thing I did because of the threat

of rain was to roll my table saw out of the shop

to the driveway and cut the Structoglas

piece to be used in the after cabin.

Since I had no pipe

clamps, I came up with a jury rig to fabricate the

side to the teak piece I am using in the head to cover a turning

block backing plate.

Dry Fit Of The Teak Piece

When I was satisfied the clamping

system I was using would work, I mixed up a batch of epoxy

resin, and applied it to all of the pieces and clamped

it up. It made me determined to purchase a set of pipe

clamps.

I left the shop

and went back to DREAM AWAY. I applied a layer of finishing putty to

the fiberglass

I applied earlier to the deck of the tender. This will help smooth

out the deck in preparation of the application of gelcoat.

We then went to lunch at Shuck’s

in Abbeville with our newly arrived cruisers Warren and Monica. After

a fabulous lunch we ran a bunch of errands in Abbeville and New

Iberia. I purchased the pipe

clamps at an Ace Hardware (Handyman Hardware) store in

New Iberia.

September 19, Thursday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the

shop

and sanded down the teak piece for the head, the cutting board, and

the battery box top. All three pieces looked good. The cutting board

was ready to go back to DREAM AWAY, the teak piece for the head was

ready to finish the fabrication process, and the battery box top was

ready for the application of gelcoat.

Finished Teak Piece

Finished Cutting Board

Finished Battery Box Top

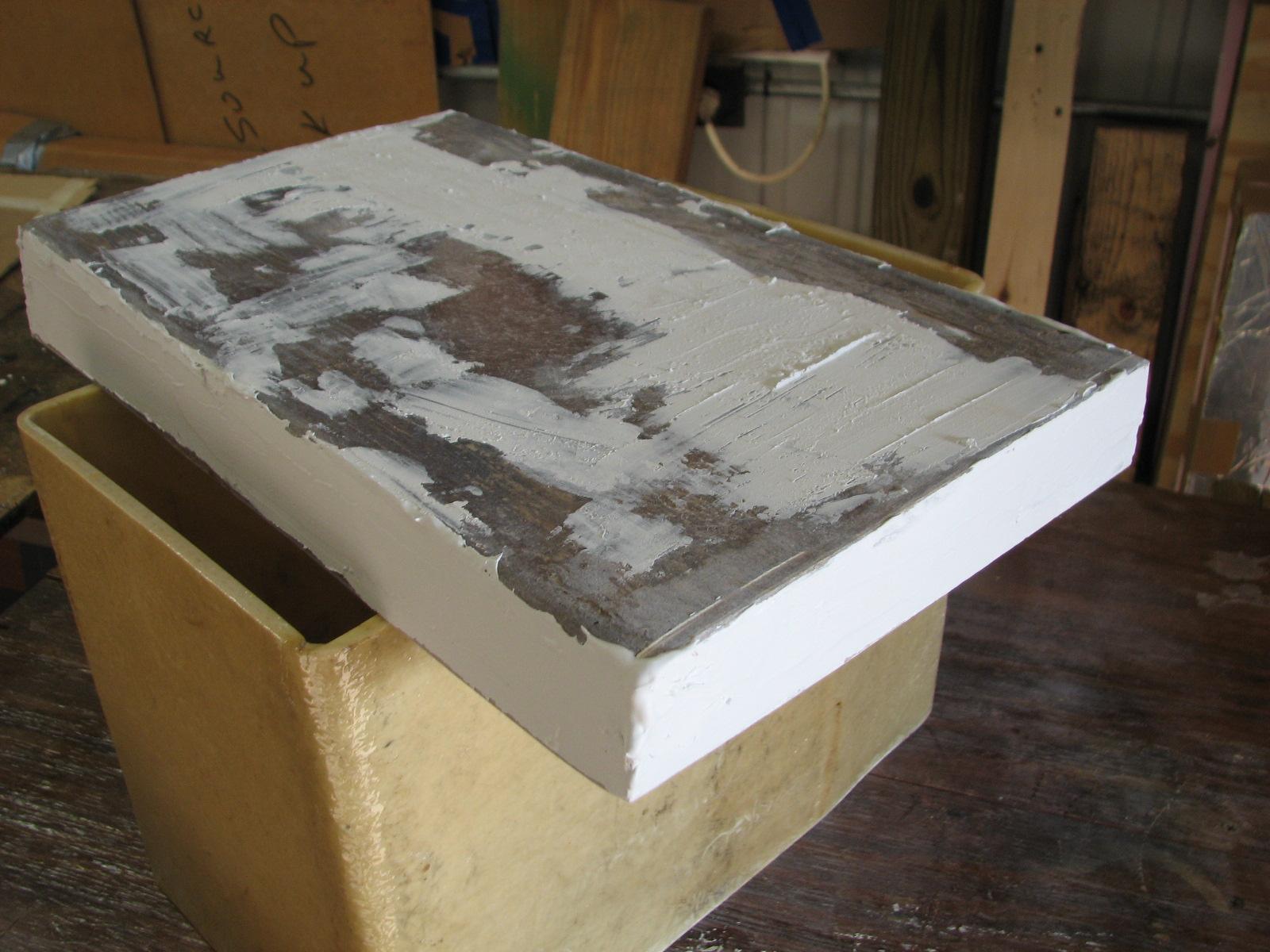

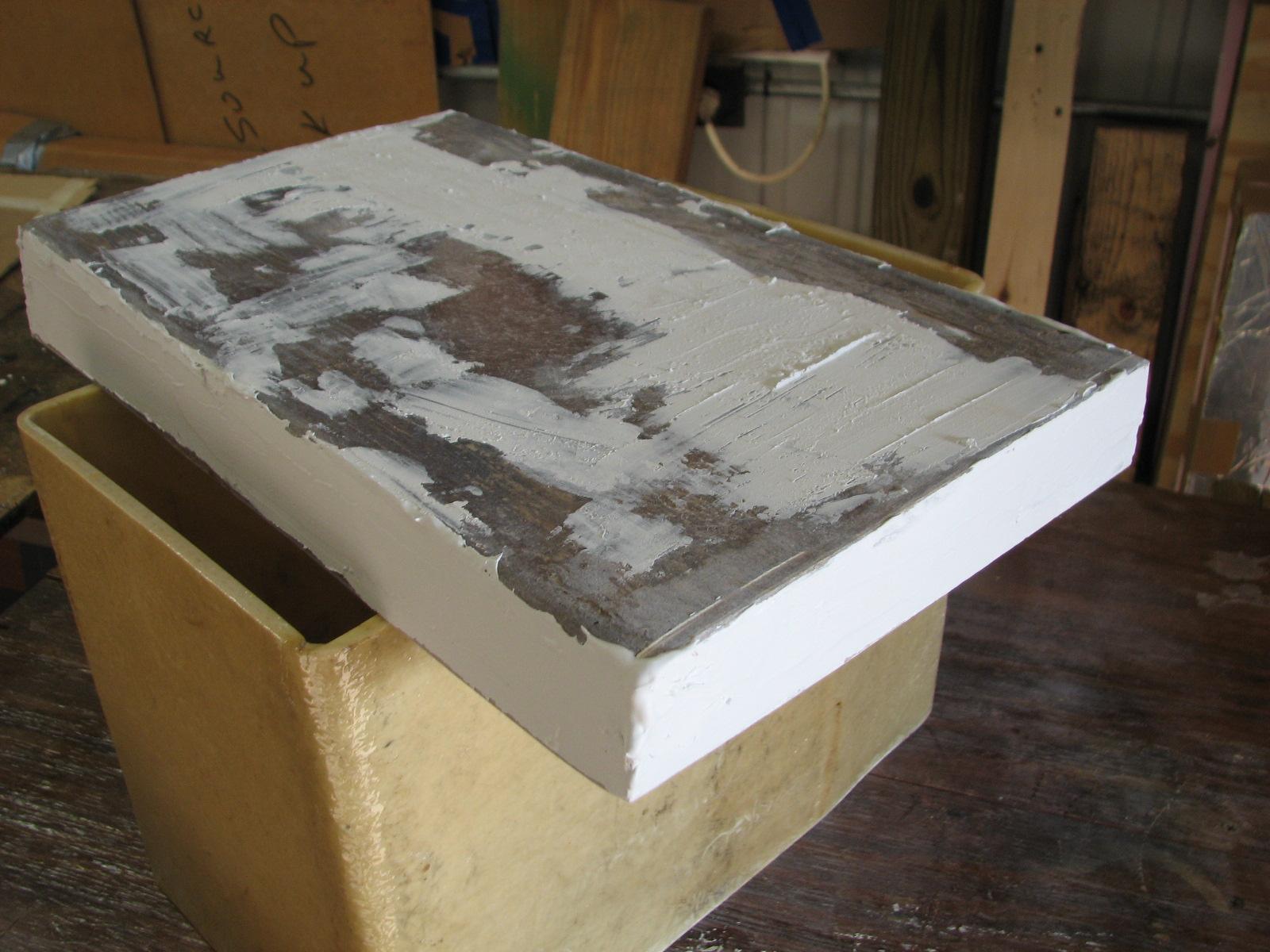

Now that the battery box top was

finished, the actual battery box was also finished it was time to

apply gelcoat

to both pieces. I had purchased a new supply of gelcoat,

but it did not have wax (Styrene)

in it. What this means is the gelcoat

will never cure, so the wax must be added to have the gelcoat

cure in air.

You must play the game of amounts! the

normal mixture with gelcoat,

and polyester

resin is a 2% mixture ratio of hardener (MEKP),

and the same with the wax. The fun you get to play with, is working

times and temperature. Anyway, I mixed up a gelcoat

batch with 2% of hardener, and about 3% of the wax and applied it to

the battery box and the battery box top.

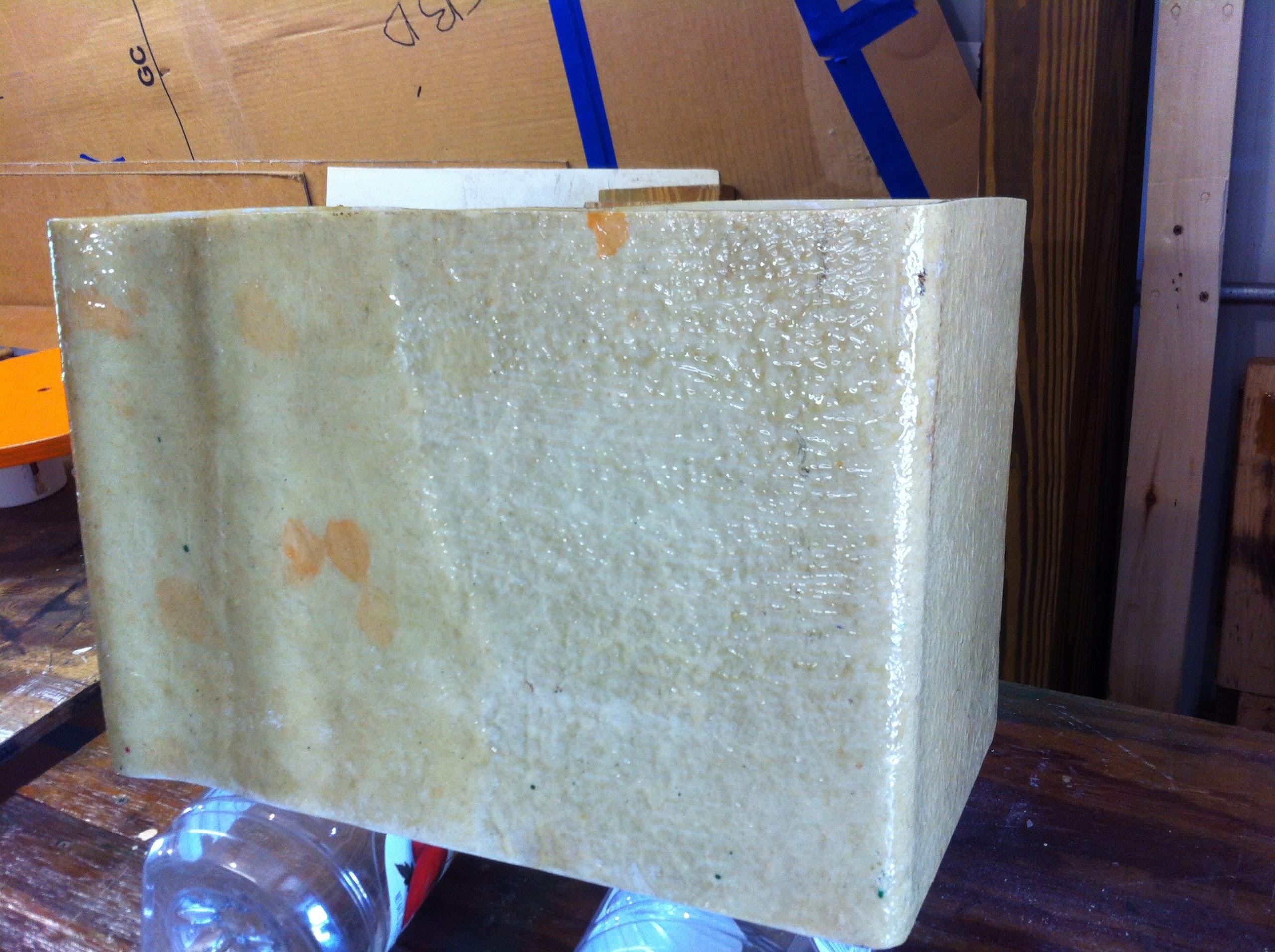

Battery Box And Top Before Gelcoat

Application

Battery Box And Top After Gelcoat

Application

I needed to cut some pieces of teak

wood to finish fabrication of the cover for the backing plate in the

head. I cut a couple of pieces using the table saw, and then did the

finish cutting with my new Evolution

Rage III compound miter saw.

Dry Fit Of Fabricated Teak Piece For Head

I applied the fourth coat of varnish to

the interior teak pieces, and the fourth coat of

Cetol

to the teak wheel on DREAM AWAY. I also applied the fourth coat of

orange paint to the “trash compactor”, and the third coat of

orange paint to the outboard cover.

I went back to the marina,

and did some raking of rocks with a borrowed garden rake. I then took

the pressure washer out to the end of Pier “C”, and cleaned the

end of Pier “C”. We have a 56’ Grand Harbor cruising yacht

coming in this afternoon, and wanted the dock as free of bird

deposits as possible.

We welcomed two cruisers, Warren and

Monica to the marina.

They are from New Zealand, have purchased a US flagged yacht, and are

on their way to do the Great

Loop. They had had a long day so we presented them

with the Welcome Basket, and left them to get settled. They will

probably stay with us for at least a week.

Monica & Warren With Welcome Basket

I went back over to the Port

of Delcambre’s storage room to return the pressure

washer and fuel, then I went to the

shop.

I wanted to epoxy the three newly cut boards to the piece of teak. I

discovered I did not have any wax paper at the shop. I use the wax

paper under the pieces I epoxy so the epoxy

resin will not adhere to the workbench. Had to put

that off until tomorrow.

September 18, Wednesday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the

shop

and got to work on one of the ABUS

locks that does not work properly. I am hoping I can free up the

inside mechanism. ABUS

does offer a repair service, but it costs more than a new

lock. I actually have two locks that are not working properly.

I got out the remaining piece of

Structoglas

I had in the shop,

and laid out the template made from yesterday, and marked up the

Structoglas.

I cut out the piece that will go on the overhead of the head.

I got out the battery box lid and

sanded it all down to be smooth as possible. I will be applying some

Marine-Tex

to the battery box top to finish out the top completely. I have some

Marine-Tex,

but it is old, and I do not know if it is any good. After I apply the

Marine-Tex,

and it sets up I will know if it is useable repairing some small

places on DREAM AWAY. When I finish with the battery box top, I will

apply gelcoat

to the battery box and the top.

Sanded Battery Box Top

Next project is to finish applying

epoxy

resin to a piece of teak I had fabricated to cut

covers for the main cabin, and aft cabin. I now need a piece of teak

to build a backing plate cover in the head, under the deck. I also

need to repair a cutting board from the galley sink, that is starting

to delaminate. Working on both at the same time, I only need to mix

one batch of epoxy

resin.

Cutting Board To Be Repaired

Teak Piece To Finish

I dry fitted the teak piece to make

sure I had all of the clamps and other pieces necessary. The fun is,

I need to apply the epoxy

resin, then make sure all of the individual pieces of

teak are flat, then squeezed together to make one piece of teak. So I

am working on two planes, and you do not want to squeeze the pieces

together too hard, and squeeze all of the epoxy

resin out. As you can see, it is an interesting

solution. I really need some pipe

clamps to do the job properly.

To repair the cutting board, I need to

drill into the two pieces and insert wooden dowels. For dowels, I use

chopsticks! I have used this method several times on wood repairs on

DREAM AWAY. I drilled the holes in the two pieces, then I had to do a

dry fit. That is putting all of the pieces together in the vise.

Here again I am working on two planes.

I also had to use two pieces of Formica

and backing plates for the Formica

to act as dams. I did not want epoxy

resin running all over the place.

I mixed up a batch of epoxy

resin and went to work on the teak piece, then did the

cutting board. It all went amazingly well.

Teak Piece Clamped On Two Planes

After breakfast Kitty and I made a

template for another piece of Structoglas

to be fitted in the aft cabin, just forward of the newly installed

Structoglas

covering the davit and cleat backing plates in the aft cabin.

We also made another template for a

Structoglas

piece for the head that will go around the backing plate cover I am

fabricating.

I then went out and weeded the marina

gardens, and trimmed around the grass yards. Then I cut the grass

inside the marina

and the two areas of grass just outside the marina fence. When that

was finished, I took the lawn mower and gasoline jug back to the the

Port

of Delcambre’s storage room, then I went to the

shop.

Did not have very much time in the

shop, but did notice the epoxy

resin had set up on the teak piece and the cutting

board, so the efforts there successful.

I then left and went to the Shrimp

Festival grounds to help set up and mark the booths

for this weekend’s Delcambre

Seafood and Farmers Market. We are all looking forward

to the market, but the prediction is lots of rain, so I think spirits

will be dampened!.

September 17, Tuesday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

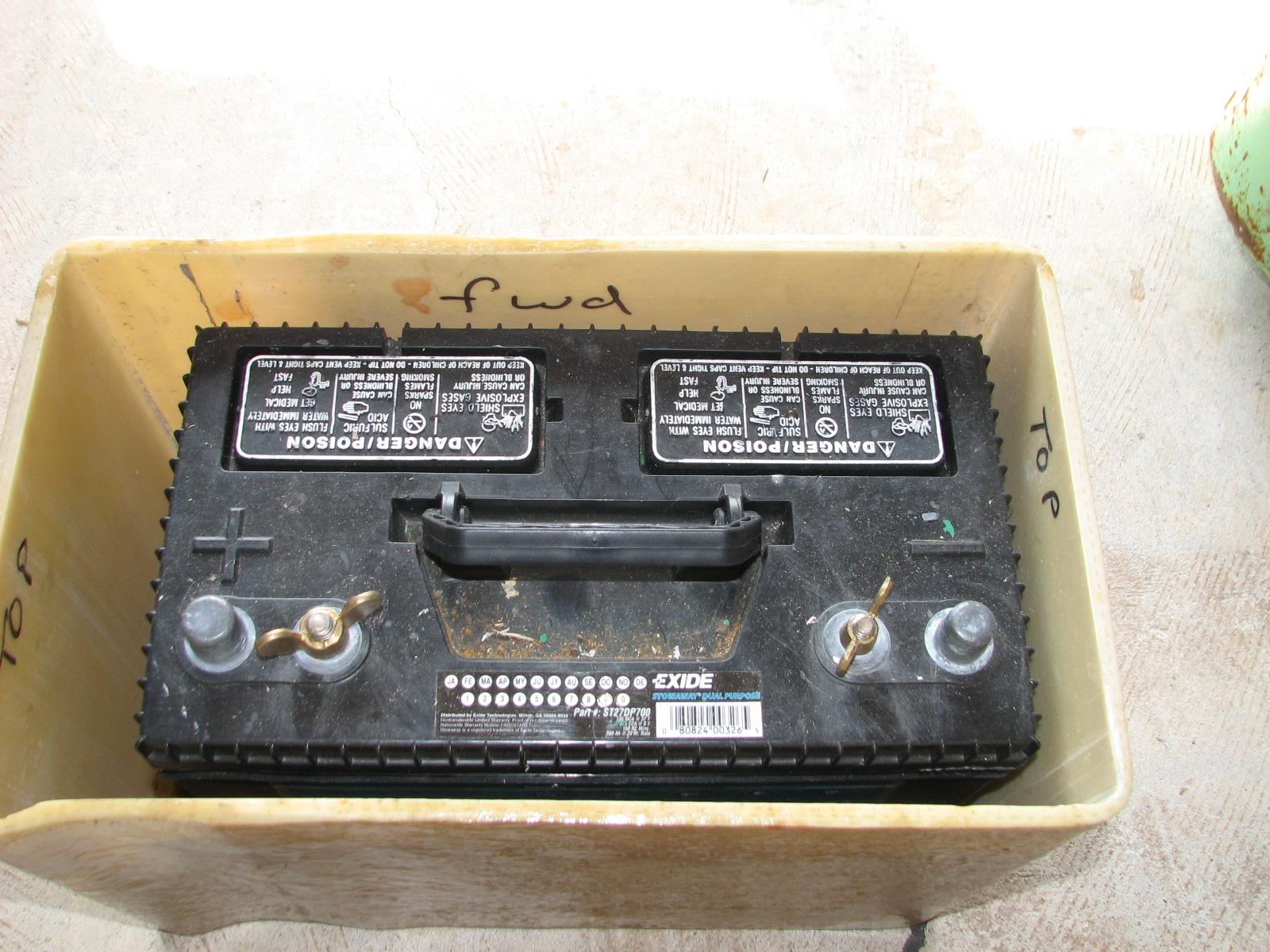

Went over to the

shop

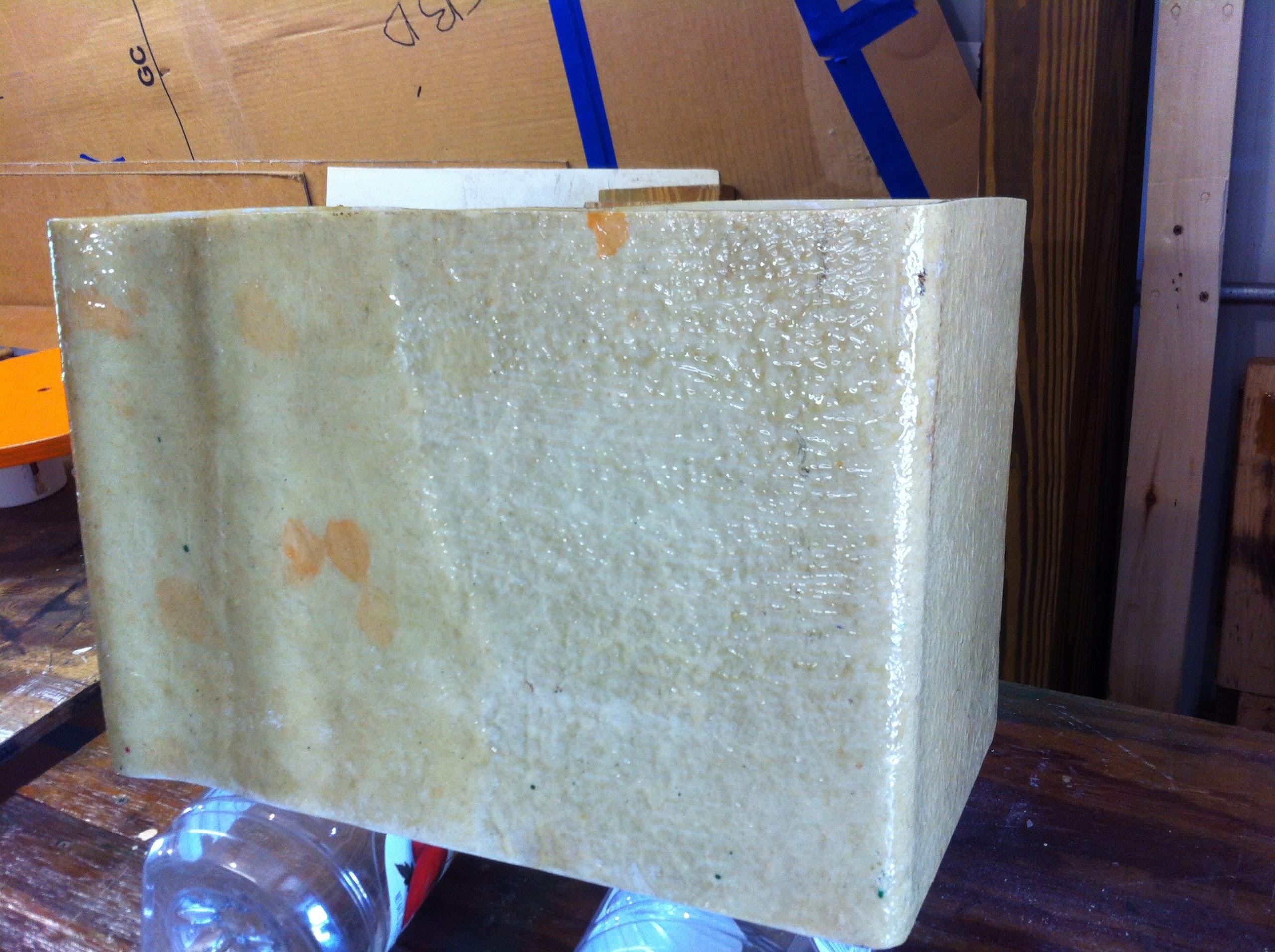

and got to work sanding on the battery box and the battery box top. I

got the top pretty smoothed out, and the box bottom sanded smooth. I

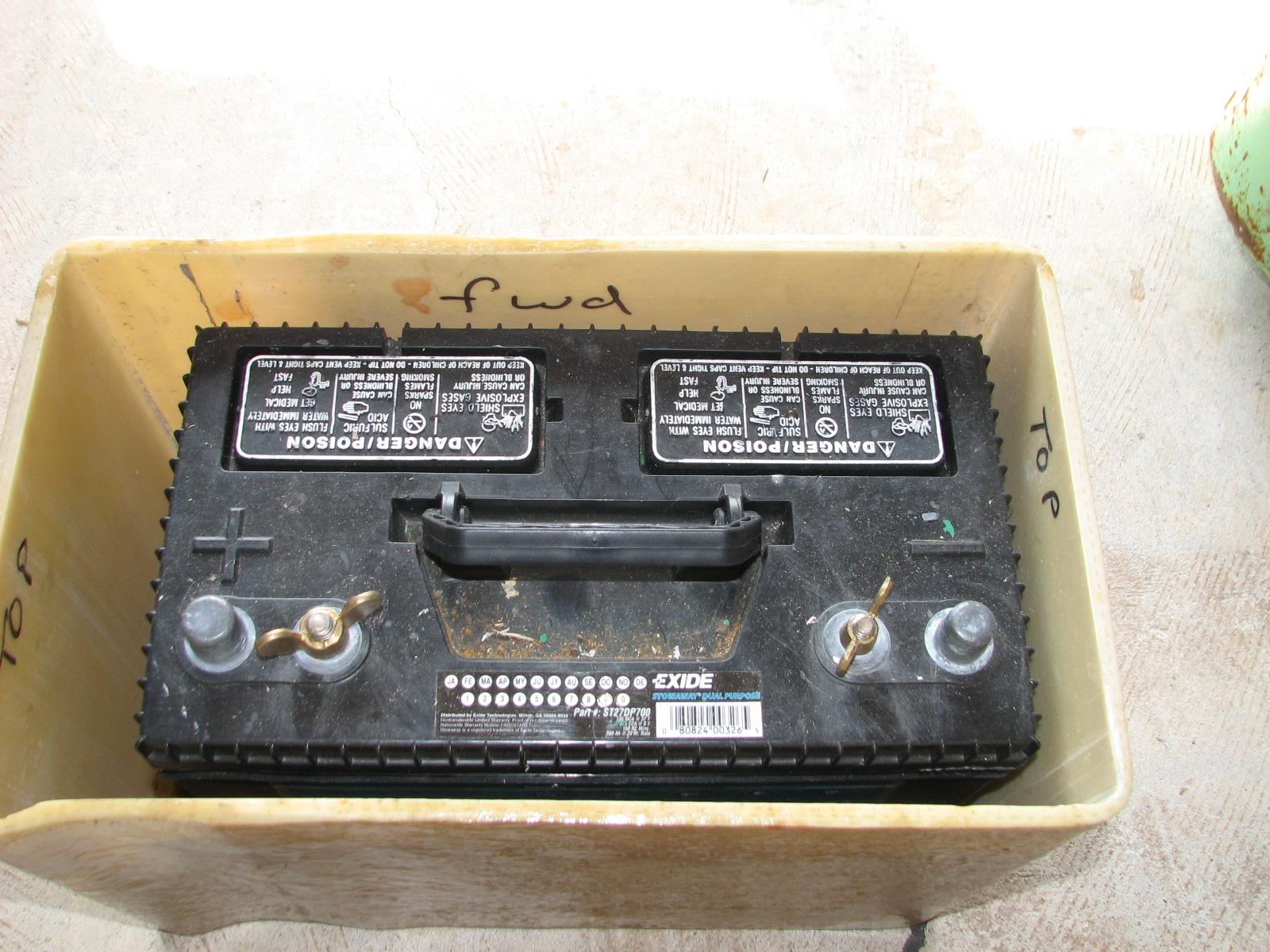

actually put the battery in the new box, and dropped on the lid, it

fit.

Battery Inside Battery Box

Battery Box With Top

I will have to drill a hole in the side

of the box for the cables, and I have to do at least one application

of finishing putty on the battery box top, and the box will be ready

for installation in the tender.

Back to DREAM AWAY, and did the

template for the overhead in the head. I want to cut a piece of

Structoglas

to put on the overhead and finish the head off nicely. Also measured

the size of the backing plate in the head that will need to be

covered with a finished piece of teak.

Backing Plate In Head To Be Covered

I also sanded down the fiberglass

I applied to the deck of the tender. This is in preparation of

applying some finishing putty to the deck to smooth out some rough

spots, then I will apply some gelcoat.

While on DREAM AWAY, I ordered the

parts necessary for the assembly of the spare Yamaha outboard motor.

I also ordered a new prop for my 6 HP mercury

outboard. For whatever reason, one of the blades on the prop broke

off, so it needed to be replaced.

I went back to the

shop

and got out the remaining piece of Structoglas,

and using the template, marked off the piece I will need for the

overhead in the head.

I mixed up a couple of batches of the

finishing putty, and applied the putty to the battery box top.

Battery Box Top With Finishing Putty

Applied

I got out the can of Rustoleum

orange spray paint and finished covering the one barrel and top to be

used on the aft deck. I used the last of the spray paint to put the

last coat on one of the outboard covers. I brought the painted barrel

back to DREAM AWAY, and put it on the aft deck. This will be the way

to test the paint with the elements.

Freshly Painted Barrel On Aft Deck

I applied the third coat of varnish to

the interior teak pieces, and the third coat of

Cetol

to the teak wheel on DREAM AWAY. I also applied the third coat of

orange paint to the “trash compactor”.

September 16, Monday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the

shop

and got to work sanding on the battery box and the battery box top. I

did some cutting and sanding on the top to get all of the sides and

edges looking square. The actual battery box looked very good after

yesterdays application of the polyester

resin. I had to do a little touch on the box, to get a

couple of rough edges smoothed out.

I then cut out a piece of spare

fiberglass to make the bottom of the battery box. I got the bottom

piece dry fitted to the battery box.

Battery Box Top Ready For Mash Mix

Application

Battery Box Bottom Ready For Mash Mix

Application

I then mixed up a batch of mash mix to

apply to the battery box top, and the inside of the battery box to

adhere the bottom piece of fiberglass to the battery box.

Mixing The Mash Mix

Mash Mix Applied To Battery Box Top

Mash Mix Applied To Battery Box Bottom

Next I started in on the SeaScooter. I

took the unit apart as much as I could without being destructive, but

could not get into the motor or gear housing. I got the unit mostly

back together, which was good. I did not want to get too heavy handed

with the SeaScooter, so I stopped working on it for the day.

Tomorrow I will put the unit completely

back together and verify the operation. I will then do the bucket of

water think again. If that all works, I will see if I can “cheat”

the on/off switches, and leave the unit running in the water until

the battery runs down. If I can do that a couple of times, and the

motor mechanism does not sound any worse, it could be the “thrashing

machine sound” is the way it is supposed to be.

Next I decided to get to work putting

together the spare outboard. I really wanted to get that project off

of the list.

I started to put the power

head onto the bottom

cowling, but I did not have the proper gasket! I was

really surprised, as I thought I had ordered all of the parts for the

assembly of the spare outboard. I will have to get the gasket ordered

ASAP.

I decided to put the bracket

assembly and the upper

casing together, so that would all be ready when the

needed gasket arrived. Foiled again! I was missing one of the upper

side damper mounts (58) in the bracket

assembly drawing.

Now I had to get two parts ordered to

get any of the spare motor back together.

I applied the second coat of varnish to

the interior teak pieces, and the second coat of

Cetol

to the teak wheel on DREAM AWAY. I also applied the second coat of

orange paint to the “trash compactor” and the two outboard

covers.

September 15, Sunday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop

and got to work on the spare air conditioner. I thought I had the

wires sorted out to get the digital control to work, but I could not.

It could be the control is bad, and will never work, The good news is

the spare air conditioner works, and I have a spare in case my new

unit dies. The spare is stored in the shop,

but on my next trip to Atlanta, I will take the unit there for

storage until needed.

Spare Air Conditioner In The Shop

I then started in on sanding the

battery box parts for the tender. I cut the bottom of the box so that

it was even, and sanded off the side of the box. There are some

fiberglass

fibers stick out on the side of the battery box, so I will apply a

layer of straight polyester

resin to the sides, to smooth out the sides.

I cut the pieces to the end of the top,

and will mix a pot of polyester

resin mash mix to “glue” the ends on the battery

box top.

I also cut pieces of the fiberglass

grating so I could fabricate a long piece of grating to support the

fuel tank in the tender.

When I got all of the pieces cut and

sanded, I dry fit all of the pieces I was going to put together, I

mixed a patch of polyester

resin, and applied it to the sides of the battery box.

When I finished applying the straight

resin, I then added the cabosil

to the polyester

resin to make the mash mix to complete this days work

on the battery box. I dry fit the ends to the battery box lid, then

applied the mash mix to complete the battery box lid.

Dry Fit Of Battery Box Top

Battery Box Lid With Mash Mix Applied

I then used the mash mix to put

together the pieces for the grating assembl.

Grating Together With Mash Mix

Next on my list was to get to work on

the SeaScooter Stacy had sent to me to test several weeks ago. I got

the unit out and ran it to be sure the battery in the unit was up. It

ran just fine, but still sounded like a thrashing machine.

SeaScooter On Work Bench

I decided to fill one of my barrels

with water, and submerge the SeaScooter in the barrel and see if it

worked partially underwater. When the barrel was 3/4’s filled with

water, I put the SeaScooter in the barrel and started it. It

definitely moved water! Once it splashed the excess water out of the

barrel, I was able to go to the high speed. I ran it for about 30

seconds.

When I took the unit out of the water

and ran the propeller, it still sounds like a thrashing machine. I

will let the unit dry off, and tomorrow I will see how to get to the

electric motor and the gear box if there is one. It sounds like there

is a lack of grease or lubricant in the propeller driving mechanism.

I will let you know how it goes with the testing.

Last projects for the morning was

painting. There is a new color scheme coming on DREAM AWAY, it will

be green and orange. Because of that, the “trash compactor” and

the two outboard covers are being painted orange, and I applied the

first coat of orange paint.

Orange Paint Applied To “Trash

Compactor” & Outboard Cover

I also applied the first coat of

varnish to the interior teak pieces, and the first coat of Cetol

to the teak wheel on DREAM AWAY.

Suspended Teak Wheel After Cetol

Application

I moved the tender from the dock and

put it back into the water in the slip next to DREAM AWAY. I then

started up the pressure washer, and completed the cleaning of “A”

dock and all of the power pedestals.

I then removed the “Hummer

Grill” from the davits, and took it up to the

parking lot. I used the pressure washer and thoroughly cleaned the

grill. It took well over an hour, because of the rain storms. When

the rain clouds would come over, I put the pressure washer away into

the Black Beast, then ran for DREAM AWAY. When the rain clouds

passed, I started over with the pressure washing project.

When the first rain cloud was coming, I

also pulled the tender out of the water and back onto the dock so I

can do the work with the fuel tank and battery box. I did not want

the tender to get filled with water, and make it difficult for me to

get the tender out of the water.

September 14, Saturday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

An off day today, no work done on DREAM

AWAY projects today. We went to the Lydia

Food Festival in Lydia, Louisiana. We enjoyed some of

the food, but we went with our friends Bonnie and Joel to see and

admire the older cars on display from the 50’s and 60’s. Great

fun.

We came back and watched the Texas

Aggies lose to the Alabama Crimson Tide. It was a good game, but

tough because we lost.

September 13, Friday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the

shop

and changed the blade on the table saw to the

fiberglass

cutting blade. I then rolled the table saw out of the shop onto the

driveway.

I cut the fiberglass

grating so I could use some of the parts as a stand for the fuel tank

in the tender. I also cut off a piece of the fiberglass

rectangular tube I have to be used for the battery box in the tender.

I then cut up a piece of fiberglass

so I can use some parts to make a top to the battery box.

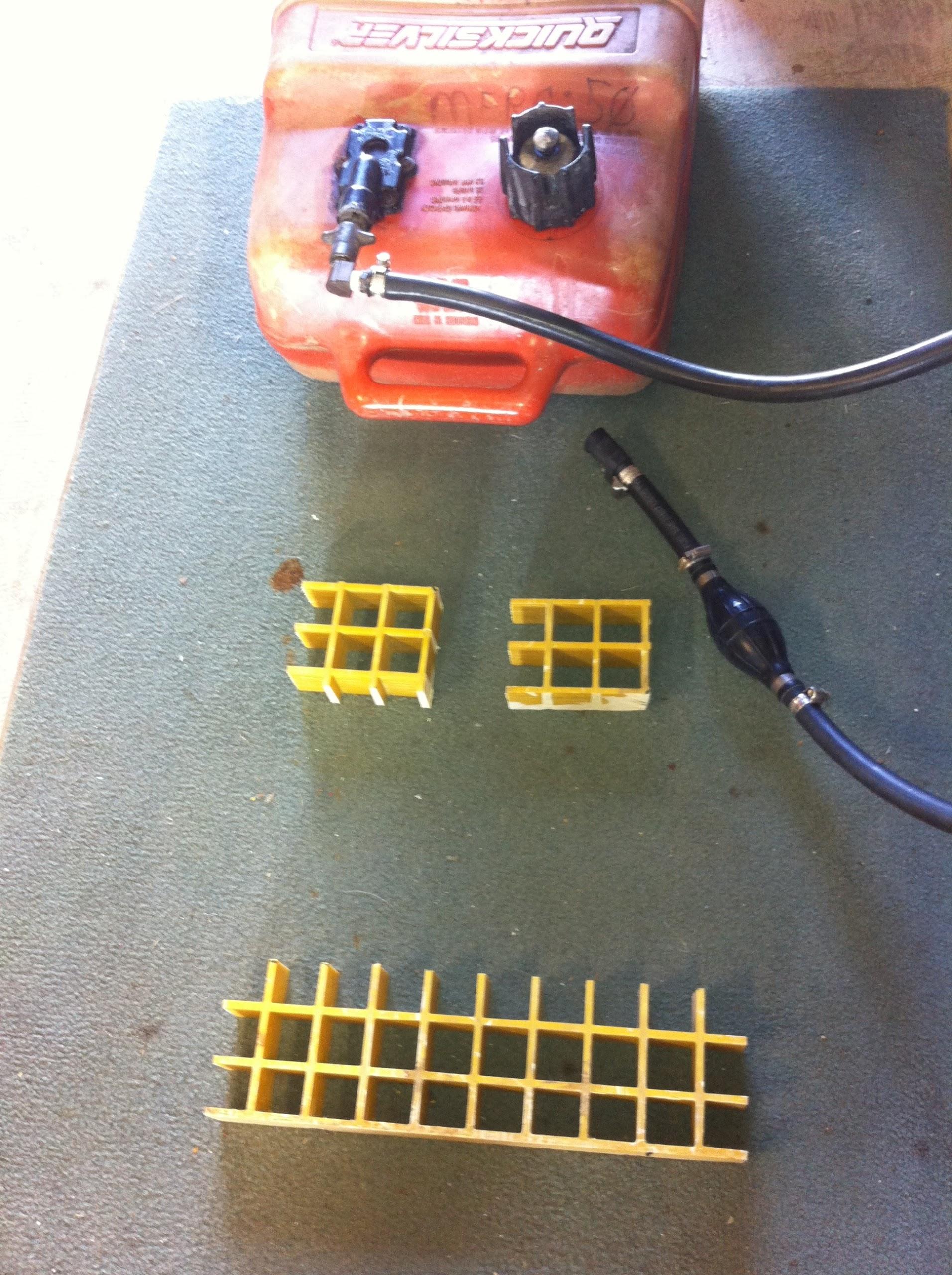

I am going through all of this effort

so I can lock the battery and the fuel tank to the tender. This will

serve as security and will keep all of the parts with the tender

should the tender turn over. This has happened twice, so there is no

reason it could not happen again.

Cut Grating

Cut Battery Box Parts

Cut Pieces For Battery Box Top

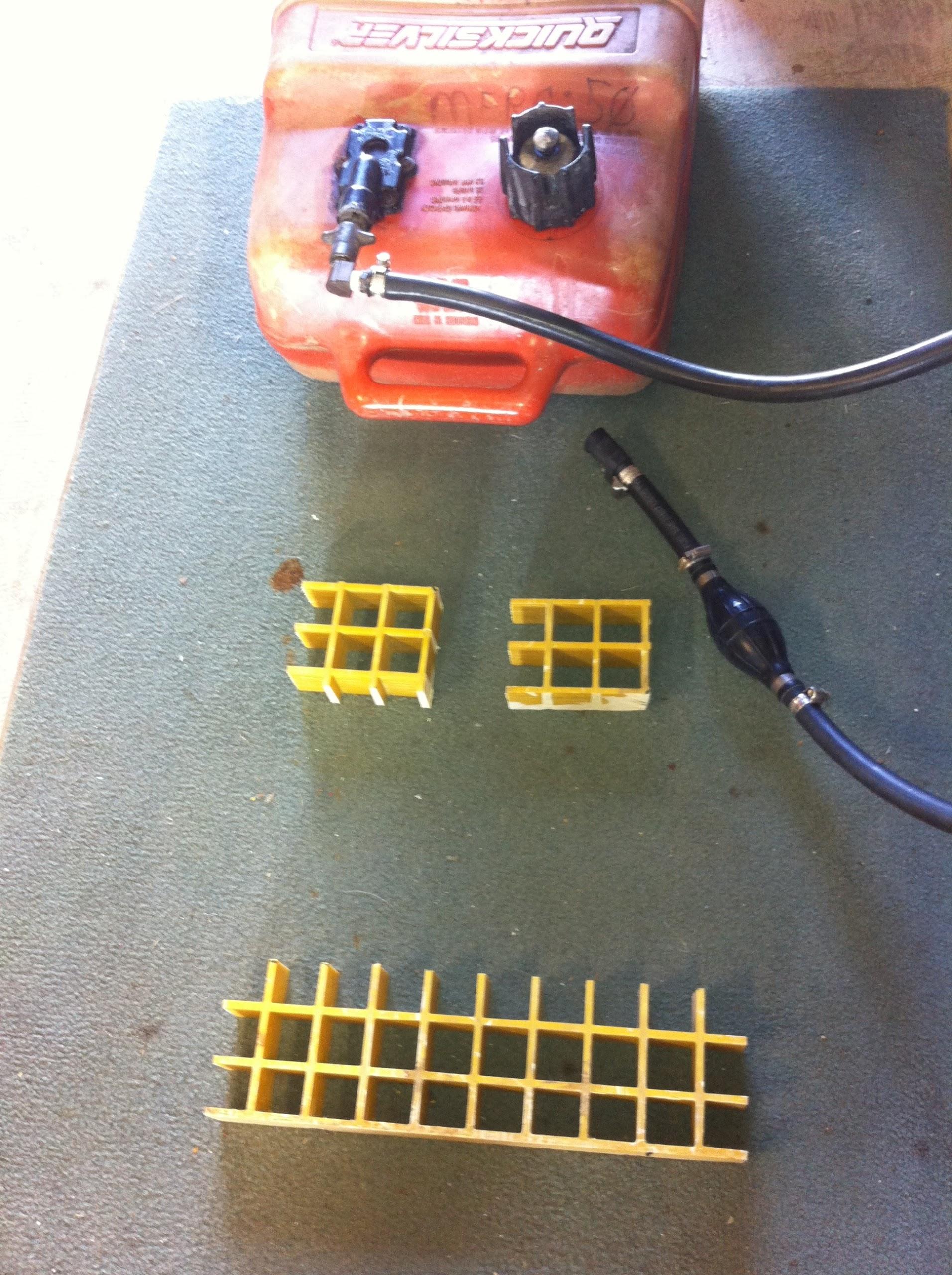

Checking Cut Grating Pieces To Fuel

Tank

I then fitted the two battery box top

halves together to make sure they would fit. I mixed up a batch of

polyester

resin mash mix, and used the mash mix to hold the two

pieces together. When the mash mix sets up, I will glass a layer of

mat to the inside of the battery box top.

Battery Box Top Pieces Fitted Together

Battery Box Top Pieces With Mash Mix

Applied

The Smith’s

penetrating epoxy I had applied to all of the teak

pieces and the “trash compactor” yesterday had dried. I sanded

all of the pieces down with 220 grit sandpaper, and got them set up

for the varnish application. I also got the wheel sanded and ready

for the application of the Cetol.

Teak Pieces Sanded And Ready For

Varnish Application

Mid Cabin Hatch Sanded And Ready For

Varnish Application

Wheel Sanded And Ready For Cetol

Applicatio.

Before leaving the shop I spent some

more time figuring out the wiring for the digital control on the

spare air conditioner. I think I might be getting close to a

resolution.

Spare AC Power Control.

Went back to DREAM AWAY to shower and

get cleaned up. We had a lunch date, and then ran some errands.

Arrived back at DREAM AWAY, and made a wonderful four banana

daiquiri.

September 12, Thursday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop

first thing. I put the countersink into the drill press and smoothed

out the holes I had drilled into the stainless steel plates

yesterday.

Plates With Countersunk Hole

I made sure all of the teak pieces were

dry and smooth, and then applied an a very thick coat of

Smith’s penetrating epoxy

to all of the teak pieces. I also

applied an ample second coat to the “trash compactor”.

Next project is to test a spray paint

from Rustoleum

that is supposed to work on plastic. I keep two 10 gallon plastic

buckets on the stern of DREAM AWAY for trash and other storage. The

sun with the UV takes a toll on the buckets. I am going to try this

paint on the buckets and some other plastic items. Specifically I am

going to try it on the manual bilge pump I keep in the tender.

Paint Test - First Pass

Went back to DREAM AWAY, and had

breakfast. We then took a drive to the new facility being built by

the Port

Of Delcambre. It will be wonderful when finished, and

I am going to try and go by at least once a week to keep a pictorial

history of the construction.

Dredging Out For Piers And Boat Launch

We drove back to DREAM AWAY, and I did

a fitting of the stainless steel plates that fit on the front of the

boom gallows. I will be welding 1” pipe onto the plates for the

fabrication of the hard dodger. I wanted to verify fit before I start

the welding.

Starboard Side Plate Fit

Now I started the repairs in the

tender. I cut out the fiberglass

to repair the cracks in the deck of the tender on both the port and

starboard side. I also removed some hardware from the transom so I

could brush on some polyester

resin. The fiberglass

fibers are exposed on some of the transom.

Hardware Removed From Transom

With that complete, I loaded up all of

the gear into the Black Beast, and went back to the shop.

The Smith’s

penetrating epoxy had nearly set up, so I know all of

the teak pieces will be ready for sanding and varnish tomorrow.

I also did some searching and measuring

for fiberglass

parts that I can use for the battery box and fuel tank in the tender.

The plan is to move the battery and fuel tank as far forward as

possible in the tender, and put security fittings for the fuel tank

and battery box so they can be locked and made secure.

I also check the paint application on

the plastic parts I had painted in the morning. The application went

very well, so I cleaned all of the unpainted parts of the bucket and

lid with acetone. Tomorrow I will complete the painting of the

buckets for the aft deck.

September 11, Wednesday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

A moment of silence for all the folks

who lost their lives in the 9-11 tragedy.

Caught up on emails, scanning in

documents, and financial stuff.

Kitty had to go to

Lafayette to see a doctor about a sleep study. I stayed on DREAM AWAY

as it was time to clean out all of the raw water strainers and

manifold. I cleaned out the main strainer for the manifold (Sea

Chest), and the manifold (Sea Chest). Also cleaned out the strainers

for the ice maker cooling pump, the refrigeration cooling pump and

the forward air conditioner cooling pumps. During this cleaning

process, I also cleaned out the hoses for all of the cooling pumps

using high pressure water from the dock.

When I finished that

project, I pulled the tender out of the water and onto the dock, so I

could do some repairs on it. I will let it dry out, and then start

the repairs tomorrow.

Tender On Dock Next To DREAM AWAY

Deck Inside Tender Where Repairs Are

Needed

Transom On Tender That Needs Repair

I then went over to my shop

to make some progress on some of my projects. I finished sanding all

of the pieces of teak I had removed from the main cabin overhead, the

aft cabin overhead, the head overhead, and the small hatch from the

deck in the mid cabin. I blew all of the pieces off with air, then

wiped them all down with acetone.

I then wiped down all of the pieces with the “agent orange” dye.

Teak Pieces Ready For Dye Application

Applying Dye To Mid Cabin Hatch

Dye Applied To All Teak Pieces

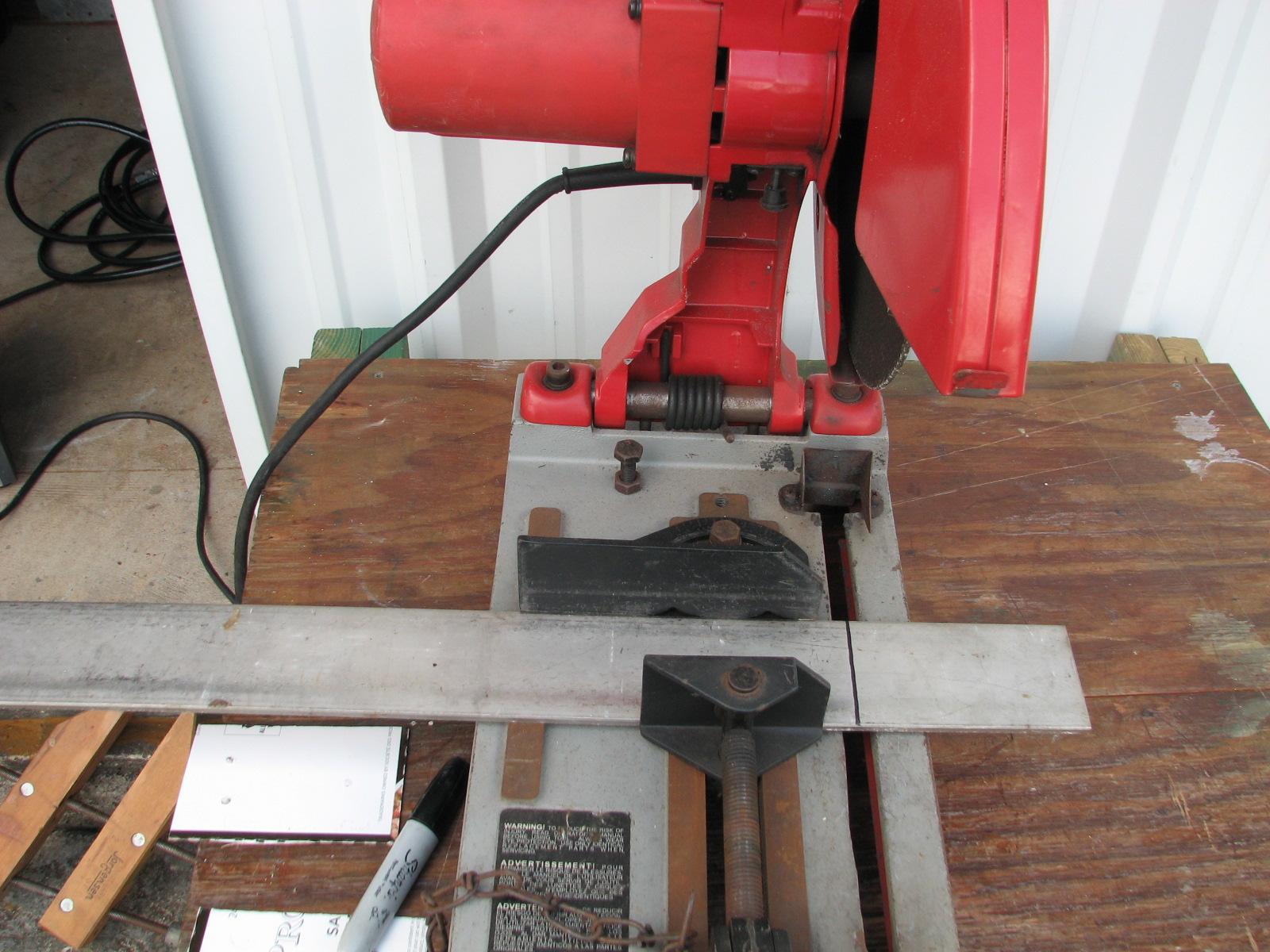

I had done two templates for the plates

I need as the base plates for the frame of the hard dodger on the

boom gallows. I got out the chop saw, and cut the two pieces, from

some 3” stainless steel ¼” flat bar. After the pieces were cut,

I used the drill press and drilled the required holes.

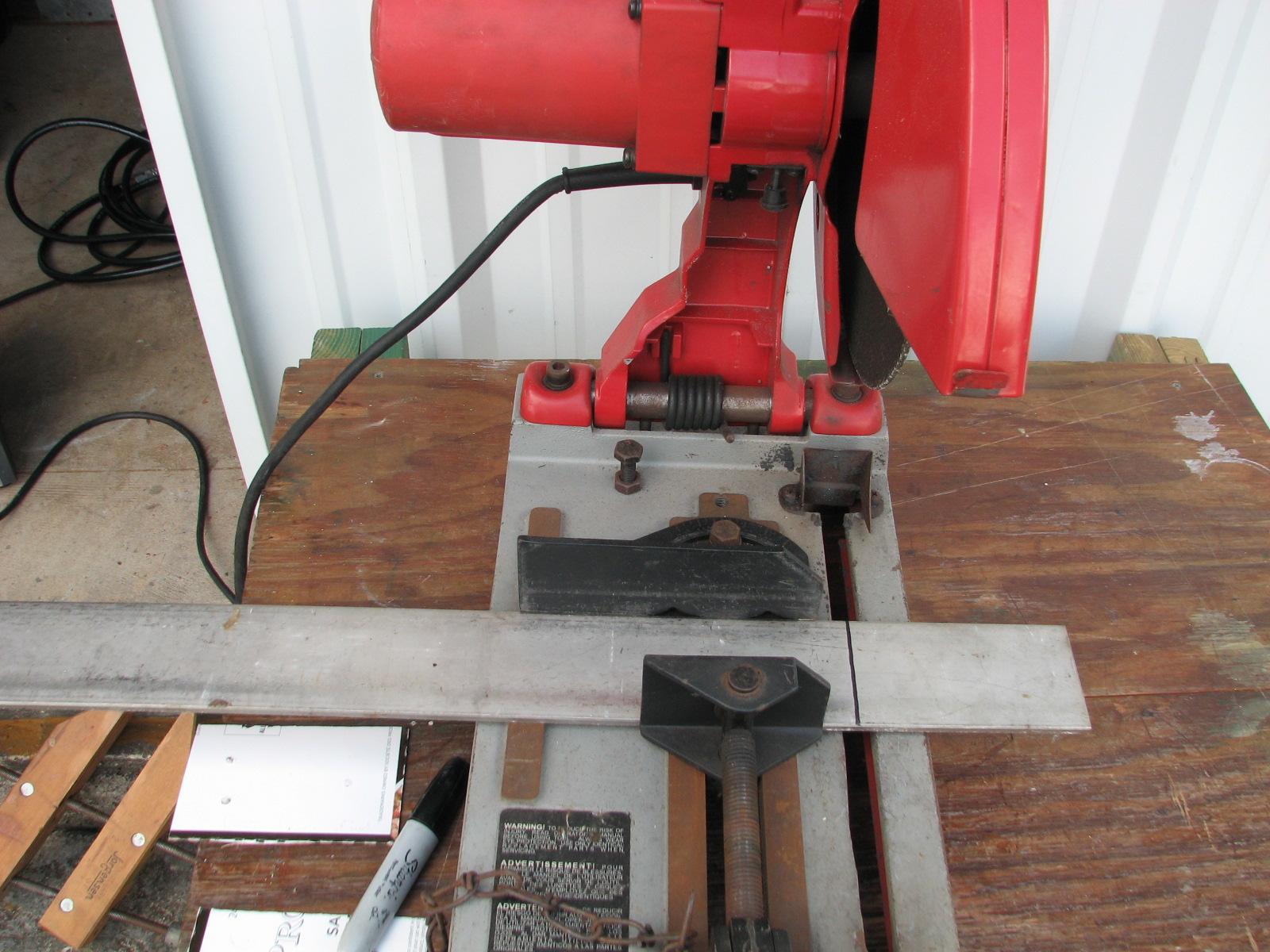

Setting Up Cut In The Chop Saw

Set Up In Drill Press

I closed up the shop

and went back to DREAM AWAY. I checked the fit of the two plates, and

it looks like it will be a nice fit. Now I am ready for further

progress on the hard dodger project.

Time for a shower and an adult

beverage.

September 10, Tuesday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

I accompanied Kitty to her kidney

doctor in Lafayette. On the way back home I stopped at

Aluminum & Stainless

in Broussard to pick up some 90

degree ells for the hard dodger and aft latter project.

When we returned to DREAM AWAY, we had

lunch, and I changed into work clothes. I put the tender into the

water and moved it into an empty slip next to DREAM AWAY. I removed

everything from the inside of the tender. I have some repairs to

accomplish on the tender, and I must glass in a battery box and some

tie downs for the fuel tank.

I then helped our friend Hollis with a

problem he was having with one of his main engines. I discovered the

source of the leaking fuel problem, but did not know enough about the

engine to repair the problem. Hollis is going to call Chad of C

& J diesel to repair the problem.

I then went over to the shop and

serviced all of the ABUS

locks. I cleaned them off, and then lubricated them thoroughly. I

found two that were not working properly, and will have to be sent

off for repair.

September 09, Monday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

First thing in the morning, I caught up

with emails and other computer related items. Kitty and I then drove

into New Iberia so Kitty could have her Renal Ultrasound and

bloodwork. We then ate lunch in New Iberia and returned to DREAM

AWAY.

On the way back to DREAM AWAY we

stopped by Port

of Delcambre’s storage room and loaded the lawn

mower and fuel. Spent the remainder of the day mowing the grass,

trimming grass and weeding the gardens at the

marina.

I took all of the ABUS

locks, except for one new one, off of DREAM AWAY, and took them to

the shop when I returned the mower to the Port

of Delcambre’s storage room. I put all of the lock

in a tub of gasoline to clean all of the locks. They are very good

locks, but need to be cleaned and lubricated periodically.

September 08, Sunday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

I stayed on the boat today as a catch

up day. Had to catch up on financial issues, had a lot of documents

to scan into the computer, and even took some time reading.

We did some rearranging of Kittys

office, by moving her big chair to the main cabin, and putting a

folding chair in the mid-cabin for her office. We are experimenting

with this to see how the comfort level is for her. If she stays with

the folding chair, we will get a cushion, to add to the comfort. The

big chair will go on the block, and the original nav

station chair will come back. Time will tell.

Kitty’s New Office Chair

Big Chair Moved To Nav Station

Around 1700, I took off with my

neighbor on his boat, the LORAINE D. He needed to get his boat to the

De Hart in Abbeville, and needed some help with the trip, so I

volunteered. It poured rain as we were about to leave, so we waited

for the rain to pass. It was a nice trip down the

Delcambre Canal

to the GIWW,

then west to the Vermillion

River, then up the river to Abbeville.

Waving Goodbye To Kitty

September 07, Saturday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop,

and started in sanding all of the teak pieces removed from from DREAM

AWAY yesterday. I finished sanding several of the pieces, but I will

have to repair one of them.

Teak Pieces Being Sanded

Had breakfast, then spent an hour and a

half pressure washing Pier “A”. I cleaned the aluminum dock and

the power pedestals until the pressure washer ran out of gas.

I took a measurement for the bolt

pattern on the front of the boom gallows, for the base piece of the

hard dodger.

Kitty had to run an errand so she

dropped me off at the shop

with the pressure washer, which I took back to the Port

of Delcambre’s storage room.

I mixed up a pot of epoxy

resin and repaired the small teak hatch that was

coming apart. This teak hatch is in the floor of the mid cabin. I put

the epoxy

resin on and in the hatch, then clamped it up until

the epoxy

resin sets up.

Since completing the hose project on

DREAM AWAY yesterday, I had a short piece of ¾” hose to attach to

my spare air conditioner, which I did. I got a bucket of water,

dumped the inlet and outlet hoses into the bucket, primed the pump,

and turned the unit on. It worked wonderfully. I still have a problem

with mismatched controls, but I am going to give that problem one

more shot.

Spare Air Conditioner Working On Bench

When Kitty finished her errand, she

picked me up at the shop

and we went back to DREAM AWAY.

I had one thing with which I wanted to

experiment. We have several of the ABUS

locks onboard DREAM AWAY. One lock got the combination screwed up,

and I could not open the lock. A friend had lost one of the locks, so

we needed a couple of new ones.

A deal came up at a very good price,

with an additional 10% off, so we purchased three of the locks, and

they arrived this week.

One thing I have always wanted to do is

see how hard it would be to cut one of these locks open. I got out my

36” bolt cutters, and gave it a go. It was not easy. Just grabbing

the bolt cutters, and squeezing the jaws shut would not do it. I had

to put one handle on the floor and press down on the other handle to

be able to cut through the hasp on the lock. I am pleased that these

lock will keep most petty thieves away from our stuff.

Bolt Cutters With Good Lock

Bolt Cutters Cutting Into The Lock

Bolt Cutters With Cut Lock

September 06, Friday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

After breakfast, went out on deck and

finished the hose project by getting both anchors and all of the

chain, washed off, and into the anchor locker. A slow go, as it took

two hours this morning.

When I finished this project, we went

out to run errands, including stops at Stine’s

and Winn-Dixie.

When we came back, I went over to the

shop,

and unloaded all of the teak wood pieces I put in the Black Beast

yesterday. I will start the sanding process tomorrow.

Teak Wood Pieces Set Out And Ready To

Sand

There is the small teak hatch from the

mid cabin that needs to be repaired, and it will be started tomorrow.

I checked out the application of the JB

Weld to the exhaust manifold of the spare outboard. It

looked pretty good, but had sunk a small bit in the large holes. I

mixed up another small batch of JB

Weld, and applied it to the exhaust manifold. I will

check on it tomorrow.

JB

Weld Applied To The Exhaust Manifold

While at Stine’s

today, I purchased paint to apply to the two outboard motor covers,

and the “trash compactor”.

Two Outboard Motor Covers

September 05, Thursday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

This morning I went over to the

shop,

and started in on the spare outboard motor. I mixed up a batch

of JB Weld.

I applied some to the outboard motor cover that had several holes in

it. I also applied some to the broken spots I had found on the

exhaust manifold.

JB

Weld Applied To Exhaust Manifold

I worked on some boxes of office

supplies that I had brought from Atlanta. I will be keeping some of

the supplies, but giving most of them away.

I left the shop

and went back to DREAM AWAY. The project for the day was to run a

hose for the raw water washdown system. While waiting to get Kitty’s

help, I removed various teak covers in the main cabin, head and aft

cabin. I will be taking these to the shop,

stripping them all down, applying Smith’s

penetrating epoxy, then the agent orange dye, and

finally applying varnish. I want to get all of the interior trim

approximately the same color and look.

The raw water washdown hose had to be

run through the chain

locker, and I could not do it with the anchor chain in

the locker. I had to remove all of the chain!! So I ran all the chain

out for both anchors, off of the front of the boat into the Delcambre

Canal mud.

To run the new hose, I first

disconnected the short piece of hose from the old hose, the taped the

remaining old hose to the new hose to have a ‘messenger’. Of

course I used duct tape! (Shades of Red Green!) WIth Kitty’s help,

I was able to pull the new hose through the middle cabin, the forward

cabin, and into the chain

locker.

I connected one end of the new hose to

the deck outlet, and the other to the pump. I started the pump, and

all worked as designed. There were no leaks.

New Hose Attached To Underside Of Deck

Fitting In Chain

Locker

The last item to complete the project

is to put the chain back into the chain locker. This is a good news /

bad news situation. I good news is that I have my fine Lighthouse

1501 windlass to bring the chain up. The bad news is

that all the chain (400 feet on the primary, and 350 feet on the

secondary) is now caked with mud.

I started working on the primary chain,

bringing it up ever so slowly, and washing it off with dock water

from a hose as it came up. I did not finish the primary chain,

because a storm came up with bunches of rain, and ran me down below.

It was already 1730, so I called it a night, and took a shower. I

will finish the anchor chains tomorrow.

September 04, Wednesday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I have been doing another

thing to add to the morning ritual. I spend between 15 to 20 minutes

playing with and brushing our two cats,

Jillian

and Jordan.

This morning I went over to the shop

after breakfast. I unloaded the Black Beast of all of the pieces of

wood I had over on DREAM AWAY, so I could work on the hide hole

project in the aft cabin.

I then worked on putting all of the

parts I had stripped off of the spare outboard powerhead. Even after

so much time away from that project, I was able to get all of the

parts back on the powerhead. I did not have to search for the

required bolts because I had taped the bolts to each part when I took

it off the power head.

Assembling The Power Head

Power Head Complete Right Side

Power Head Complete Left Side

Straightened up the shop and then drove

over to DREAM AWAY. I had the forward hatch to finish with

installation of the hatch security devices. I got out all of the

required tools, and parts. Did the measurements on the hatch base,

and then drilled the holes.

I measured the carbon fiber arrows, and

the welding rods, and installed them in the hatch base. This idea

will certainly keep the average intruder out of DREAM AWAY. If we are

at anchor, and someone tries to enter the boat, we will have enough

time to take corrective action.

Hatch Security Devices Installed On

Forward Hatch

That project is finished, but will have

to look into adding the same devices to the Lewmar hatches in the

main

salon and aft cabin.

I cleaned up the tool and parts from

the project, and took all of the excess out to the Black Beast. Kitty

is coming home tonight, so did the vacuum the boat thing, fresh

sheets on the aft cabin bunk, and general spruce up.

Will go into Abbeville

tonight for the Marine Corps League monthly meeting, and then drive

into Lafayette to pick up Kitty.

September 03, Tuesday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee.

Did not go to the shop

this morning, but stayed on DREAM AWAY. I went up to the Black Beast

and brought down all of the small pieces of wood I had in the shop

and loaded into the Black Beast yesterday.

I had rolled up the cut piece of

Structoglas

and stored it in the forward cabin, so after removing the mattress

from the aft cabin bunk, I brought the piece of Structoglas

to the aft cabin and unrolled it. I placed the piece of Structoglas

up to the overhead in the aft cabin. With all of the wood pieces I

had, and I had to “adjust” a couple of pieces, I was able to

support the piece of Structoglas.

Starboard Side Supported

Port Side Supported

Now that I had the piece of Structoglas

supported, I could make sure it was fitted to the main cross piece

and all of the battens I had installed. The piece was a bit large so

I made the markings to cut the piece of Structoglas.

Now more fun! I had to take the piece of Structoglas

down from the overhead of the aft cabin, out of the aft cabin, and

then outside DREAM AWAY so I could make the cuts. So much fun moving

a piece over eight feet long and three feet wide at its widest point.

Before I made the cut on the piece of

Structoglas,

I drilled some holes in the overhead of the aft cabin. I did this so

I could use Great

Stuff spray insulation foam and fill the voids between

the fiberglass deck and the interior paneling. When I finished

spraying in the Great

Stuff foam, I went out on the dock and made the cuts

on the Structoglas.

Holes Drilled In Overhead Panel

I brought the piece of Structoglas

back into DREAM AWAY, then into the aft cabin, and up against the

overhead. I got the piece of Structoglas

all blocked up again. The cuts were just right, so now I had to screw

the piece of Structoglas

to the main cross piece of wood and the battens. I did the measuring

and marking for the location of the screws, and did the deed.

Now all that remained was to “iron”

on the teak tape on the front of the main cross piece. The teak tape

was ironed on, so now it will need to be dyed, and varnished.

Main Cross Piece Before Teak Tape

Installation

Main Cross Piece After Teak Tape

Installation

Shot Of The Finished Product

Of course, this project took up the

whole day, by the time I finished cleaning up, vacuuming, making up

the bed, and putting all of the tools and parts away.

I took a shower and went to the ground

breaking ceremony for the South

Pier Dock and Pavillion. Construction and dredging

will be starting tomorrow.

Officials Doing The Actual Ground

Breaking

September 02, Monday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee.

Worked on the Maintenance Logs, and the

DREAM AWAY update, and finally got the update out with links to the

June, July, and August Maintenance Logs. A lot of effort and a

milestone.

I wanted to get the mid cabin deck

hatches fixed before Kitty returned, and set up her office in the mid

cabin. The smaller hatch had a problem where some of the wood on

which the hatch rested had loosened and fallen out. That made the

hatch wobbly, and it needed to be repaired.

I founds some very small pieces of wood

at the shop, and was able to fit them into place. They made the hatch

very stable.

I had a similar problem with the larger

hatch in the mid cabin deck. The unevenness of the hatch base had

been there since I installed the hatch during the

main mast compression post repair. Here again, I had

to find a very small piece of wood to put into place that would cause

the hatch to sit evenly in the hatch base.

I also had some small pieces of teak

wood that had come loose from around the storage area under the

microwave/convection oven. These needed to be epoxied in place.

I mixed up a pot of epoxy

resin, and epoxied the three small pieces of wood from

around the storage area. I then epoxied the small pieces of wood

around the small hatch and the large hatch in the mid cabin.

Helpers Standing By

Small Hatch With Wood Fitted

Large Hatch With Wood Fitted

Pieces Of Wood Missing From Storage

Area.

Pieces Epoxied In Place Around Storage

Area

Next I got working on finishing the

“security bars” in the hatches in the main cabin and the mid

cabin. For a more complete explanation look at the August

Maintenance Log. Check the end of the August 27,

Tuesday, 2013, entry.

Main Cabin Hatch Security Bars

Installed

Mid Cabin Hatch Before Installation Of

Security Bars

Mid Cabin Hatch After Security Bar

Installation

September 01, Sunday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee.

Spent the remainder of the day working

on getting the Maintenance Logs for June, July, and August completed.

When they were completed, I downloaded them and got them ready for a

DREAM AWAY update.

I also did some cooking while working

on the computer.