Maintenance Log October 2013

October 31, Thursday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian and Jordan.

A

cold front with lots of rain was coming today, so I did not work on

DREAM AWAY projects. Spent the whole day working on the computer,

email, scanning, and generally catching up.

I actually did do a bit of work on DREAM AWAY today. During

the heavy rains, we looked at the leak in the head, and it was just as bad as

before. Not very happy about that. We removed the backing plate for the turning block,

and discovered there is water leaking in, and it appears to be coming from the

turning block.

As soon as the weather dries out, I will pry the turning block

from the deck and see if I can find the source of the problem. We also have another

leak in the aft cabin on the starboard side near the clothes closet, and another leak

aft on the port side. I will be looking into them also.

October 30, Wednesday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop

and started sanding all of the parts I had worked on yesterday in the

shop.

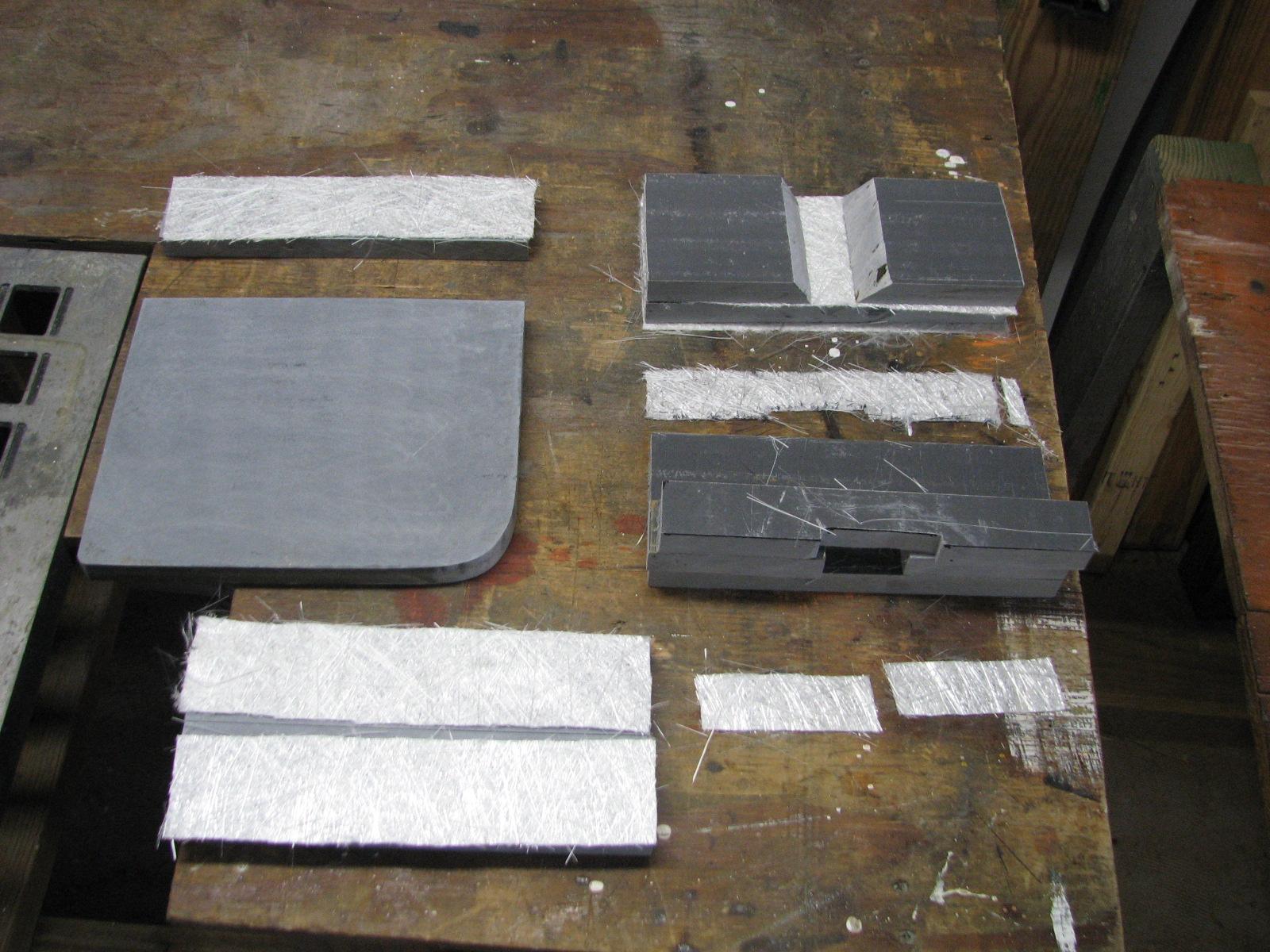

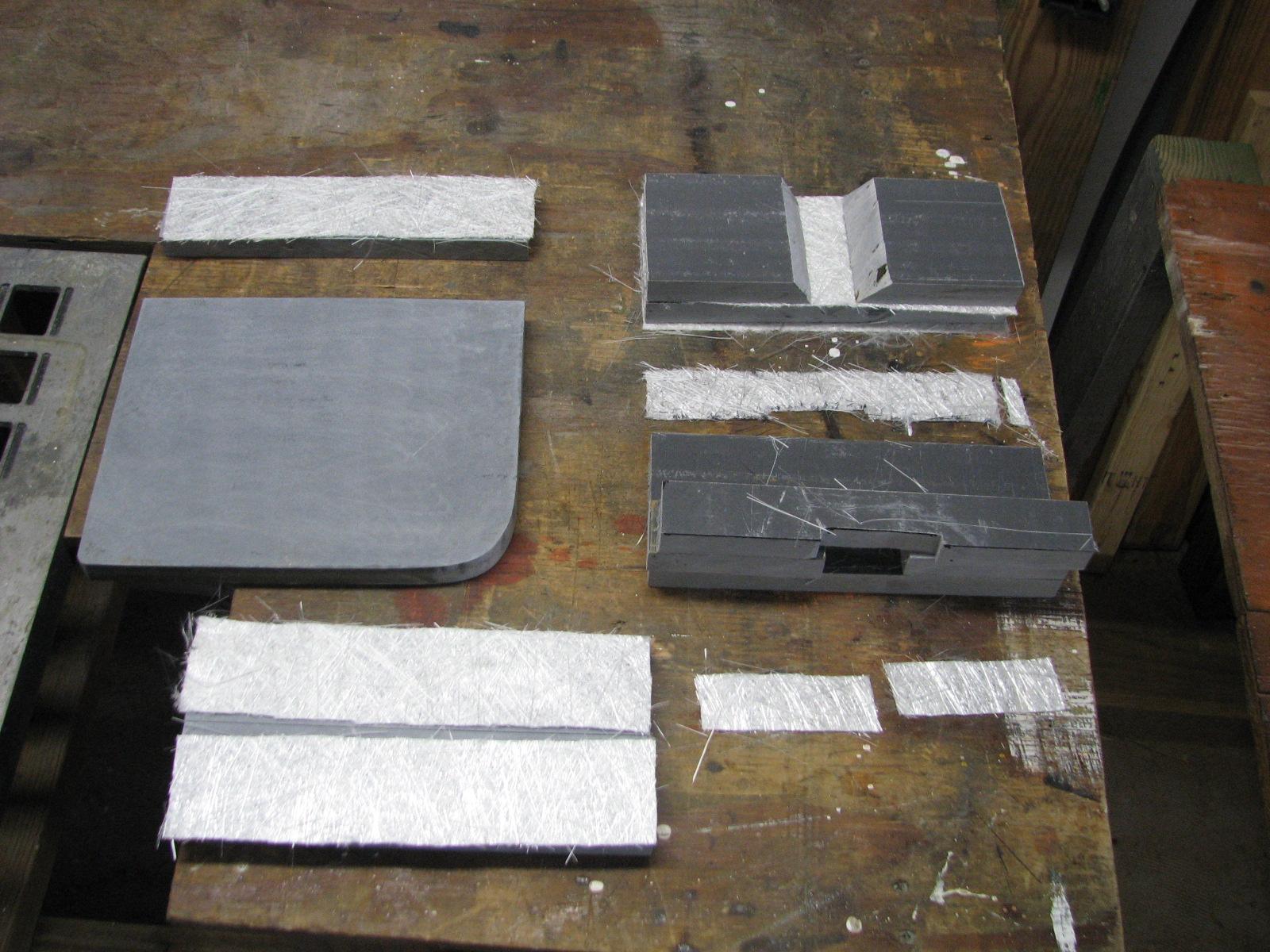

The anchor support parts were sanded first. The belt sander does a

great job on sanding the Strongwell

Extren plate. I will still have to use some finishing

putty in the parts for the final finish, but we are making great

progress.

Anchor Support Parts Before Sanding

Anchor Support Parts Before Sanding

Anchor Support Parts After Sanding

Anchor Support Parts After Sanding

When I finished the anchor support

parts, I sanded down the hard dodger angled base support pieces I had

fabricated.

Hard Dodger Angled Base Support Pieces

Before Sanding

Hard Dodger Angled Base Support Pieces

After Sanding

Hard Dodger Angled Base Support Pieces

After Sanding

When the sanding was completed, I

cleaned up the tools and the area. I loaded up the“Box

O’ Resins”, sander, fiberglass

mat, and other items in the Black Beast. Went back to DREAM AWAY and

had breakfast..

After breakfast, I started in on

putting the hard dodger angled base support pieces on the doghouse

with the front pieces of the hard dodger base. I did a dry fit of the

starboard angled piece, and decided not to put the piece down with

fiberglass

mat, because of the inconsistencies in the surface of the angled

piece mating with the top of the doghouse.

I decided to use my own fabricated

putty, made with polyester

resin, cabosil,

and cotton flock. After the dry fit I mixed up a batch of my putty. I

started with 200 ml of polyester

resin, and kept adding the cabosil,

and cotton flock until the consistency was similar to peanut butter.

When I was all ready except for adding

the hardener, I got Kitty out to help me. We did the dry fit, and

then I explained what I wanted to do, and how she could help.

I added in the hardener, and mixed it

thoroughly into the putty. I applied the putty to the bottom of the

angled piece, then we put the piece in place. Using a pipe

clamp, we were able to fit the angled piece up to the

front piece of the hard dodger base. I also had to use a quart can to

adjust the distance of the piece from the boom gallows upright.

Once that was done, I used the

remainder of the putty to fill in any spaces left, and also as a

filler around the base pieces to get a nice radius rather than the

hard angle.

Dry Fit Of Starboard Angled Piece

Starboard Angled Piece In Place With

Putty

Front View Of Starboard Piece Clamped

To Front Piece

Inside Of Starboard Piece To Front

Piece

The port side was pretty much the same

as the starboard side. I mixed up a batch of putty, and did the dry

fit with Kitty as the helper. I applied the putty to the angled

piece, and then applied the piece to the front piece with the pipe

clamp. I used the remainder of the putty to fill in

any spaces left, and also as a filler around the base pieces to get a

nice radius rather than the hard angle.

Dry Fit Of Port Angled Piece

Dry Fit Of Port Angled Piece

Port Angled Piece In Place With Putty

Port Angled Piece In Place With Putty

Captain Applying Putty

Front Piece Showing Putty Applied As Radius Filler

I cleaned up all of the tools and

various items used in the application of the angled pieces. I got

cleaned up a took a shower.

We then drove into New

Iberia, to pick up laundry, and to take the tour of

the Konrico

Rice Mill. The visit to the Konrico

Rice Mill was well worth the time. Kitty, as the

Cruisers Market Manager for the North

Pier Marina, made some good contacts, and got some

goodies for the cruisers welcome baskets. We also saw a film as part

of the mill tour, which we thoroughly enjoyed. It was a brief history

of the Acadians from the expulsion

to more or less present day. Kitty and I decided this was the first

place we should take cruisers new to the area, so then can get a

taste of the history of Acadiana.

We had a wonderful time seeing all of

the children dressed in some very interesting costumes.

October 29, Tuesday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop and did a dry fit of the remaining parts I have to glass to

the anchor support. The dry fit went well. I also taped up the second

anchor support piece to act as dams. I have to run some resin in a

gap between two pieces I glassed together.

Dry Fit Of Anchor Support Piece

Anchor Piece With Dams Attached

Anchor Support Glassed Together

Another Angle Of The Anchor Support Glassed Together

Next I decided to use the Evercoat

Formula 27 finishing filler to fill the gaps on the

angled piece of plate I fabricated for the sides of the hard dodger

base.

Hard Dodger Plates Needed To Be Filled

I got some of the filler out of the can

and onto my mixing slab. I added the cream

hardener and mixed the two together. I then applied

the mix to the angled piece of plate for the hard dodger.

Filler Applied To Angled Piece

Now I wait until it all sets up, and

then there is more sanding to be accomplished. The hard dodger parts

will need to be sanded. The anchor support pieces have to be sanded,

and the some holes drilled into them before they can be finished and

gelcoat

applied.

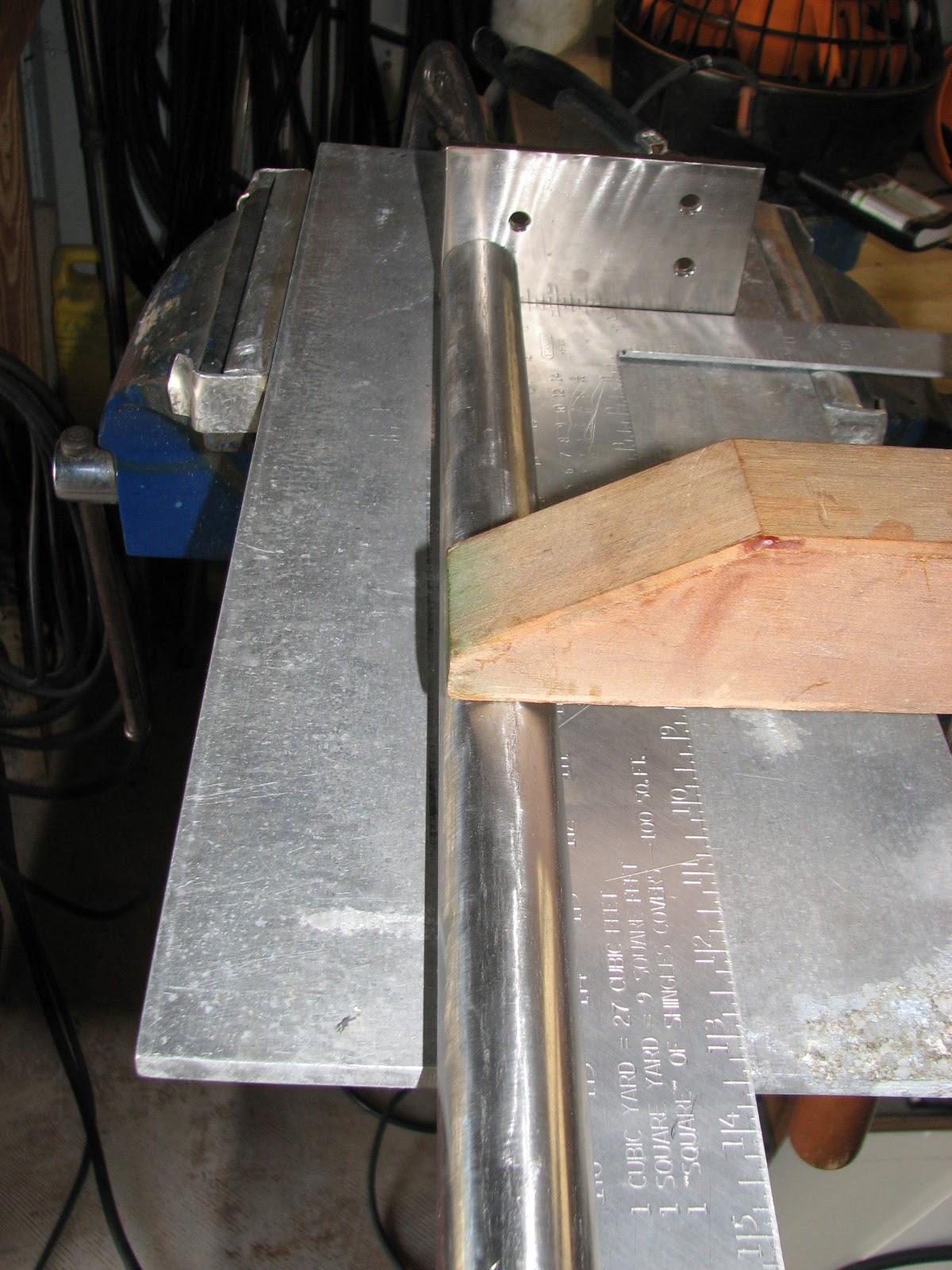

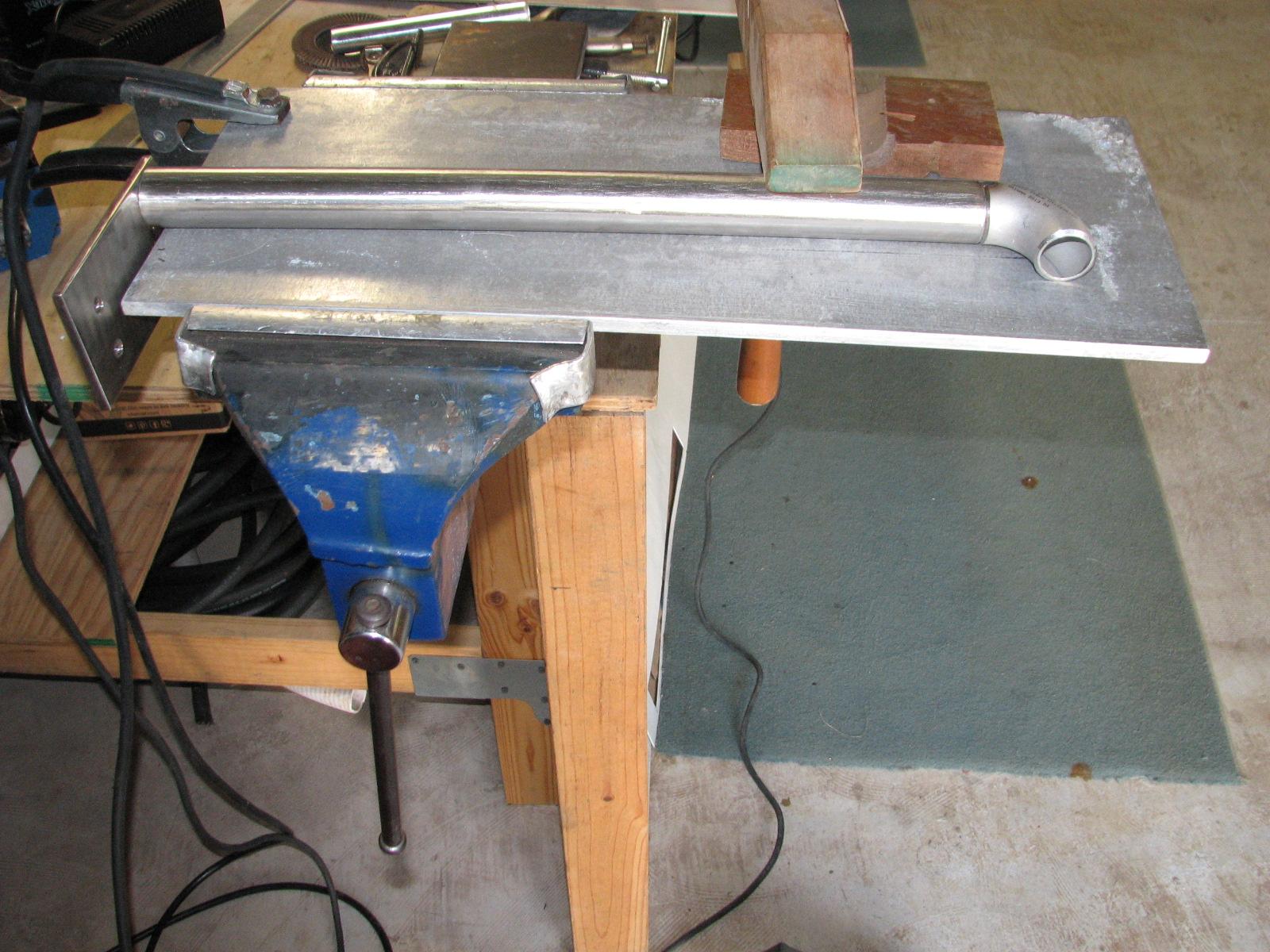

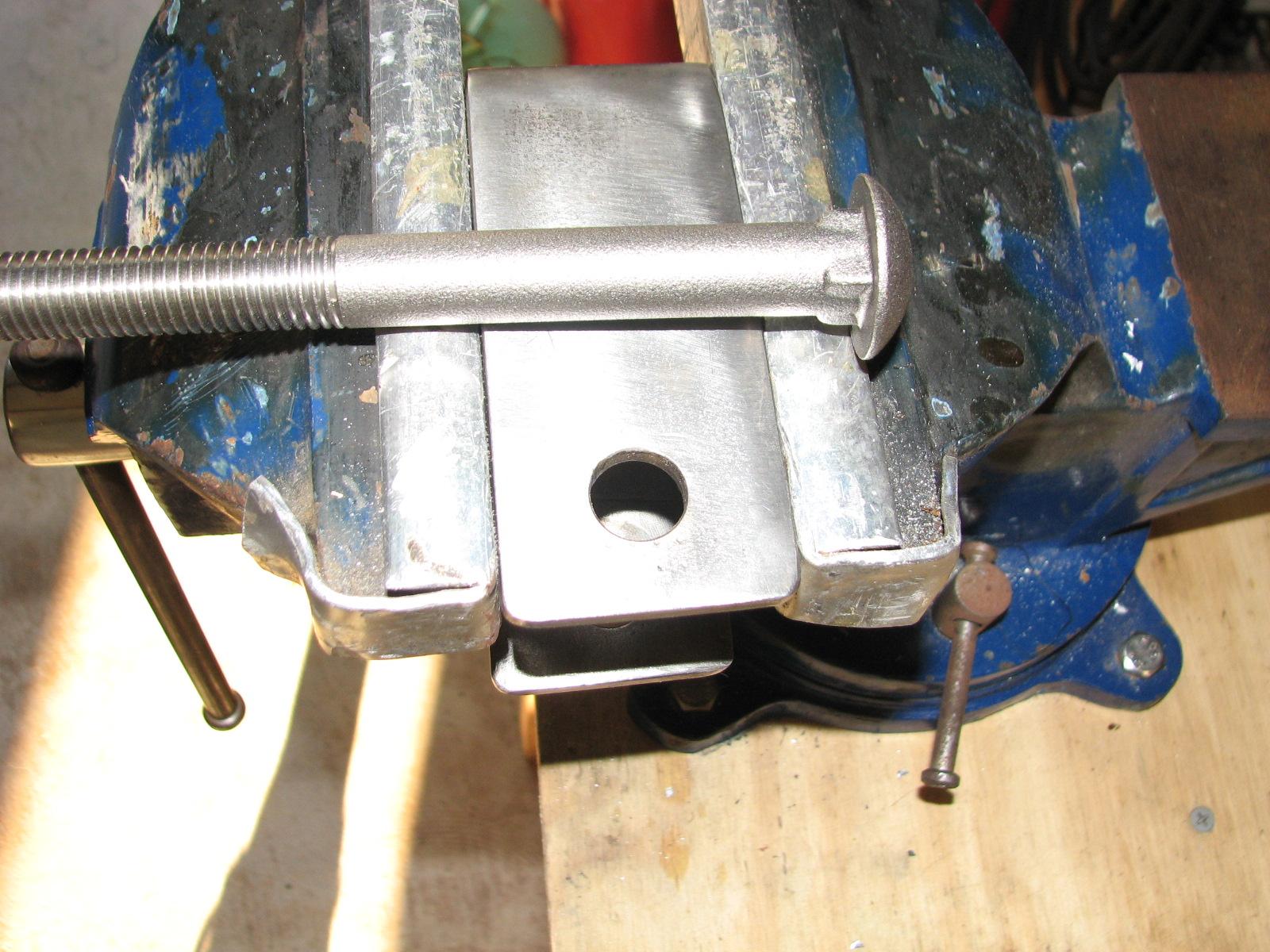

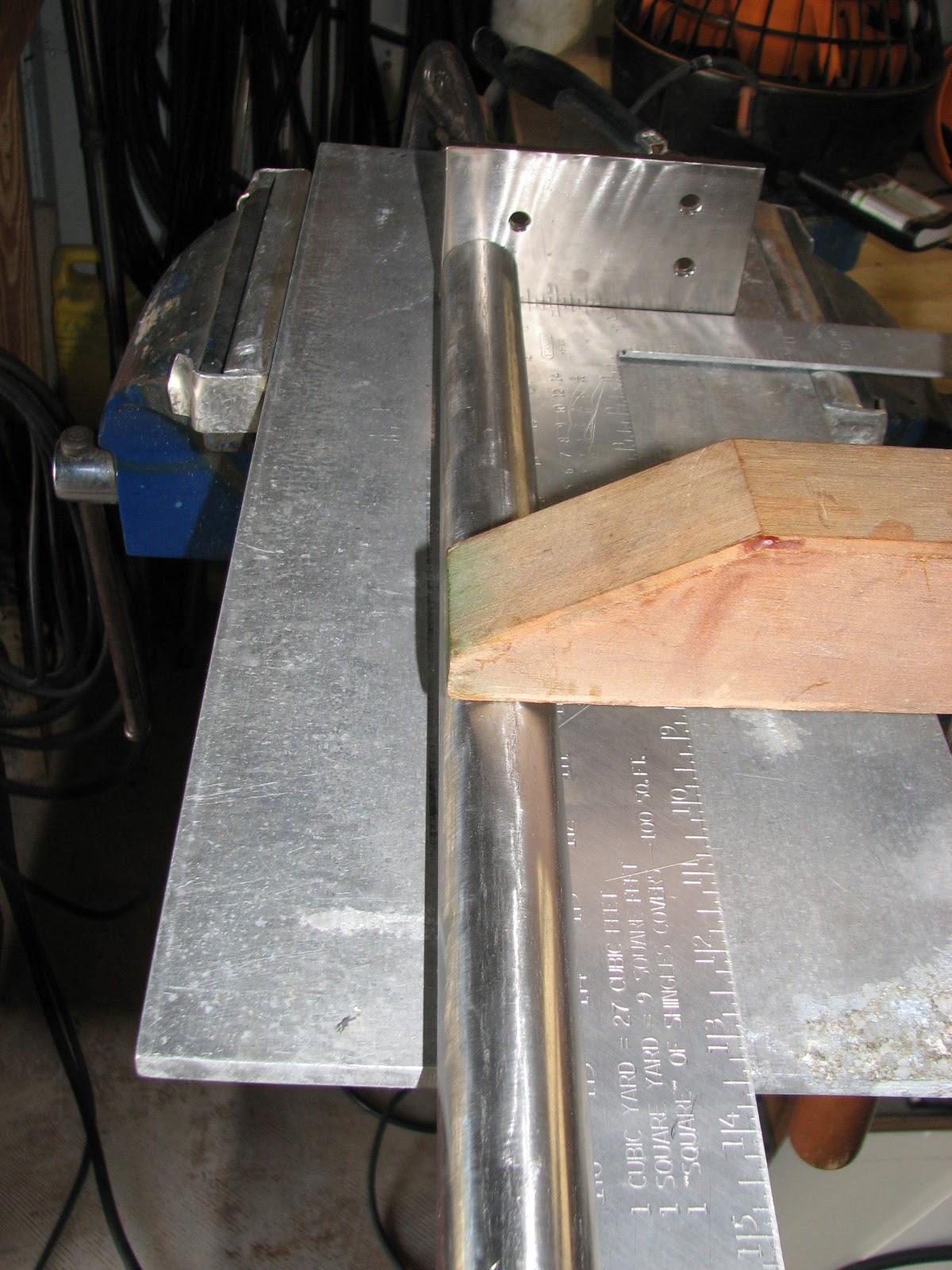

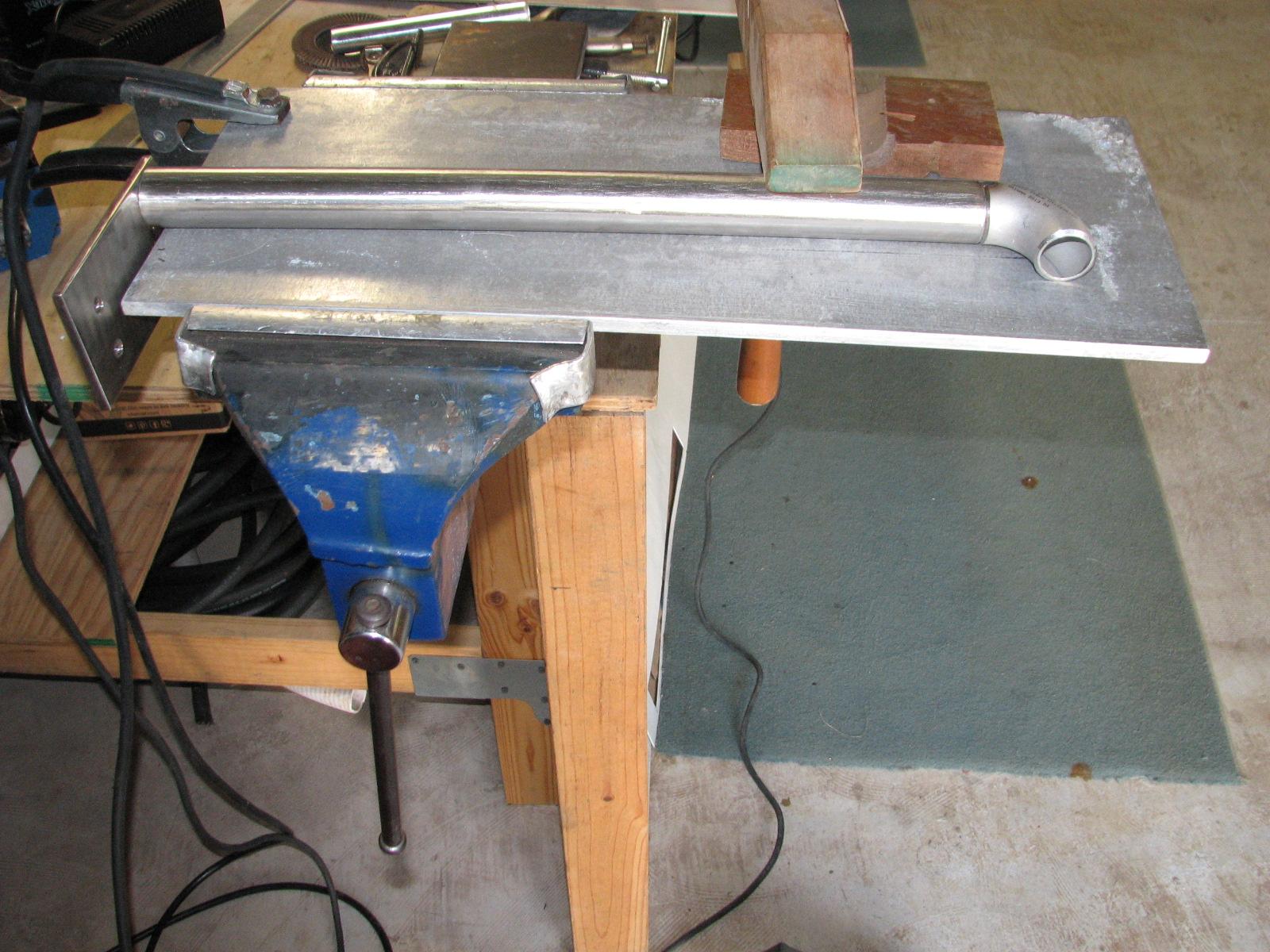

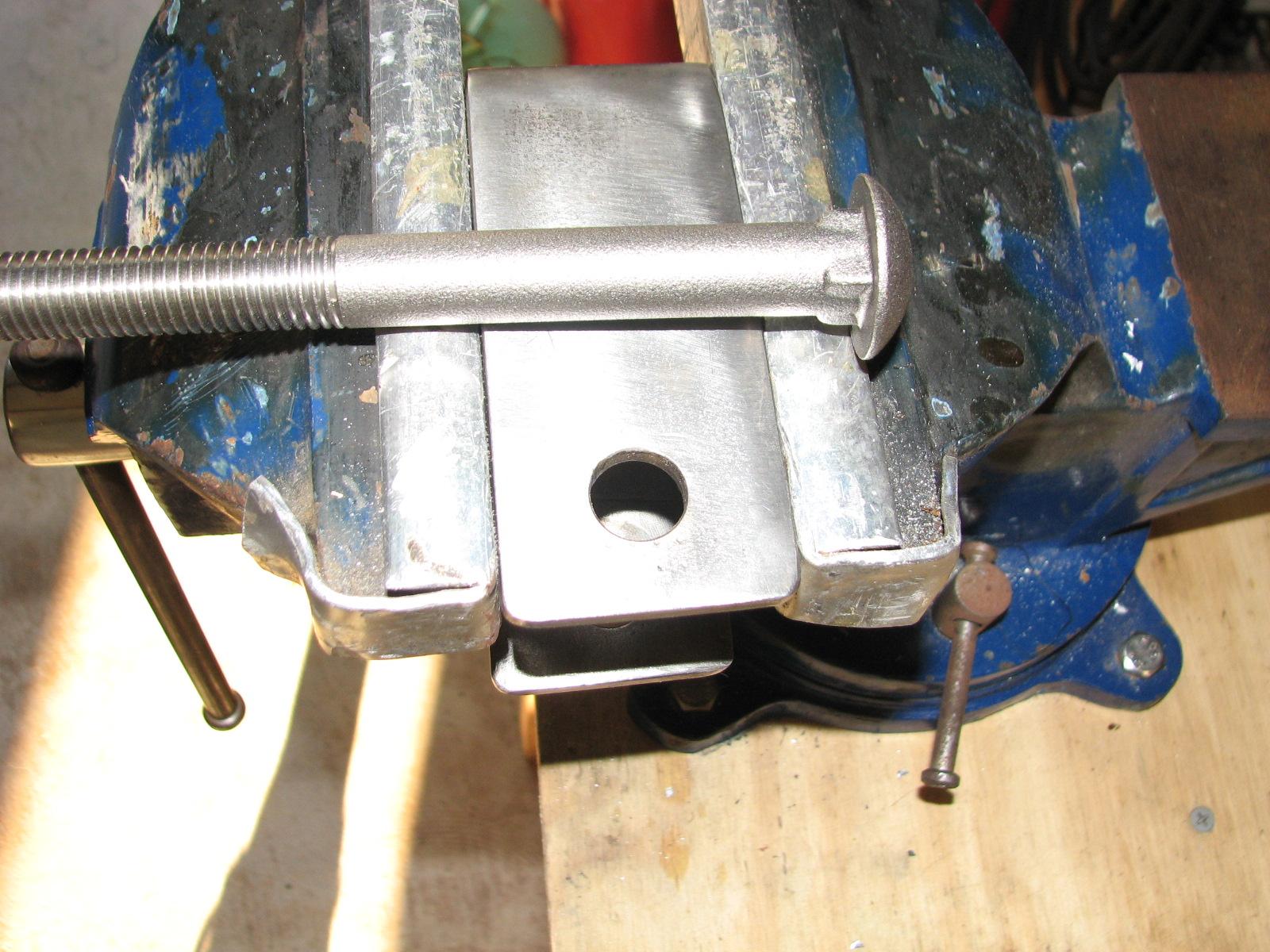

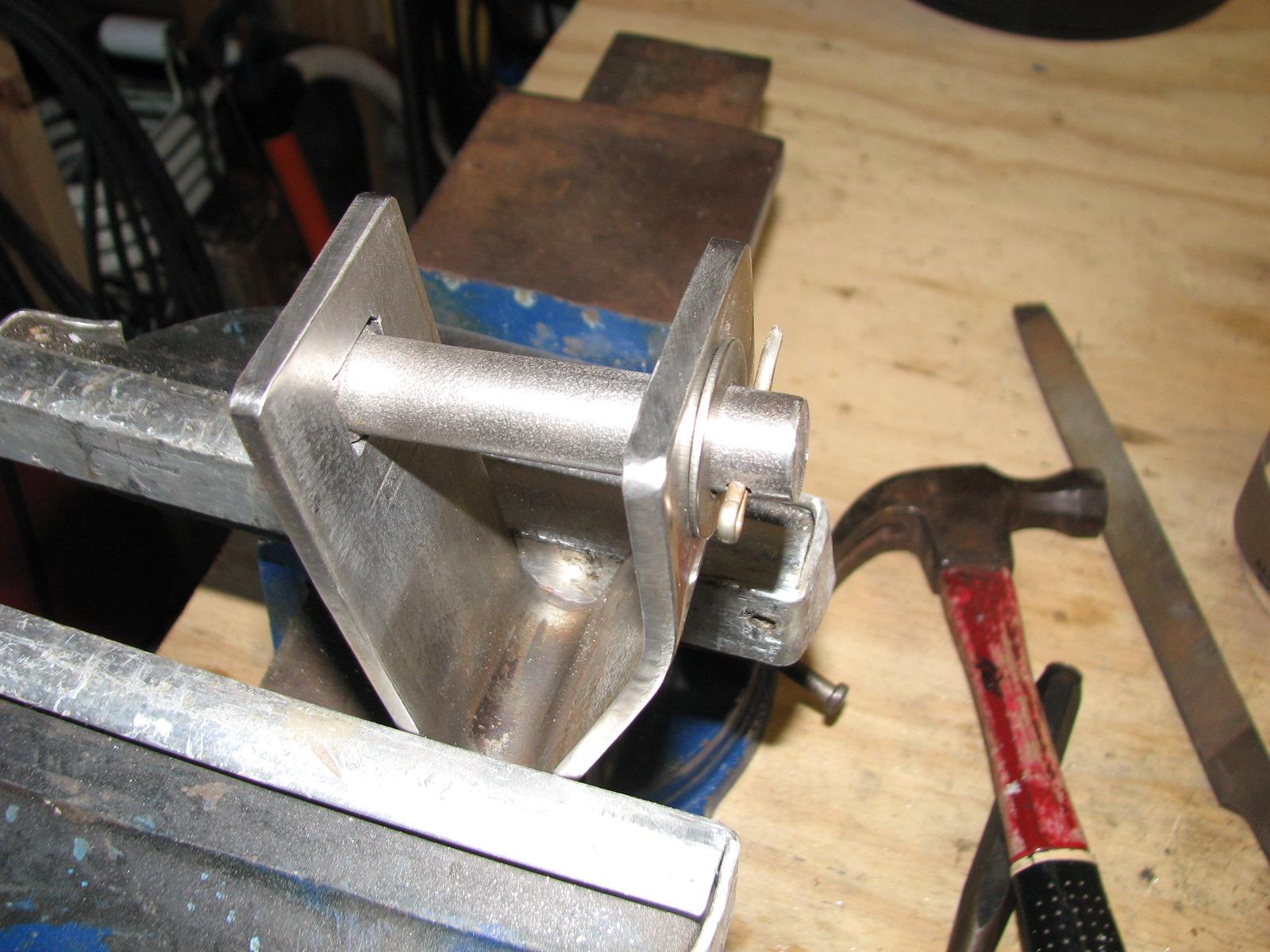

Next I decided to cut and sand a second

piece of aluminum plate I will be using as part of the base on the

main mast sail deck. This is in preparation of welding the unit

together.

Cut Made

Sanding Complete

Went back over to DREAM AWAY and had

breakfast.

Kitty had some errands to

run in New Iberia, so she left on that project. I stayed on DREAM

AWAY as It was time to clean out all of the raw water strainers and

manifold. I cleaned out the main strainer for the manifold (Sea

Chest), and the manifold (Sea Chest). Also cleaned out the strainers

for the ice maker cooling pump, the refrigeration cooling pump and

the forward air conditioner cooling pumps. During this cleaning

process, I also cleaned out the hoses for all of the cooling pumps

using high pressure water from the dock.

I closed up the boat and

did the sanding in the area where I want to glass down the two angled

pieces as part of the hard dodger base. The wind was really blowing,

so dust was everywhere. I had to hose down the boat to get it all

cleaned up. I dried the seats in the cockpit, and took a reading

break before I hit the shower.

October 28, Monday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop

and started sanding on the parts which I had glassed yesterday. They

all came out pretty well. One of the anchor support parts had a small

problem. The 1” stainless steel tubing of the liferail would not

fit exactly, so I had to do some sanding to get the tubing to fit

into the proper slot.

Stainless Steel Tubing Fitting In

Anchor Support

I then sanded and trimmed the other

anchor support. It will need some extra resin to be put between two

pieces, but not a big deal.

Anchor Support Piece Before Trimming

Anchor Support Piece After Trimming

The last pieces that needed a lot of

trimming and sanding, were the angled pieces I fabricated for the

hard dodger base. Both pieces worked out pretty well. I will have to

take the pieces over to DREAM AWAY and do a dry fit to know for sure.

Sanded Hard Dodger Piece

Hard Dodger Piece Showing Fabricated

Angle

I loaded the hard dodger pieces into

the Black Beast, and went back to DREAM AWAY. After breakfast I dry

fit the pieces on the top of the doghouse, and it looks like the

fabricated pieces will be a good fit. I will take the two pieces back

to the shop,

and use some finishing putty to fill in all of the spaces.

The remainder of the day, I worked on

the shower trailer purchased by the Port

of Delcambre. I checked out all the systems, and only

found one problem. The on demand hot water system does not work. It

will take more research to get to the source of the problem.

October 27, Sunday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the

shop and finished

sanding all of the pieces of the

Strongwell

Extren plate I am using to build these parts. I sand

down all of these parts to rough them up so the fiberglass

and polyester

resin will stick together to form a single piece.

Sanding The Small Piece

When the sanding was complete it was

time to cut out the fiberglass

mat pieces I will need to glass the pieces together.

Dry Fit The Hard Dodger Piece

Dry Fit The Anchor Support Piece

Hard Dodger Pieces Glassed Together

Anchor Support Pieces Glassed Together

The anchor support piece for the

liferail had so many pieces, I could not glass them all together at

one time. I glassed four of the pieces together now, and will add the

other three pieces tomorrow.

Three Pieces Not Glassed Today

I then went back to DREAM AWAY and we

had breakfast. After breakfast we drove to Intracoastal

City to support one of the fishermen in the Delcambre

Direct Program. They are Cheryl and Big Al Granger off

of the shrimp boat MISS BRITTANY G.

This morning they had Kimberly

Schlapman from the Kimberly’s

Simply Southern cooking show on board. Kimberly is a

founding member of the Little

Big Town Band which was doing a show in Lafayette.

Kimberly wanted to go out on a real shrimp boat and see how real

Cajun shrimp gumbo was made.

Cheryl, T-Al( Cheryl & Big Al’s

Son) , Kimberly, Big Al

October 26, Saturday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop

and I remembered the tool to repair the screen. Our male cat, Jordan,

again laid on a screen and fell through, so it needed repair. I laid

the screen out and did the number on it, and had it back together and

looking good.

Repaired Screen With Screen Tool

The trimmed upright I had dry fit

yesterday was not exactly cut properly, so this morning, I cut an

extra ¼” off of the bottom. It will take it back to DREAM AWAY and

check the fit again.

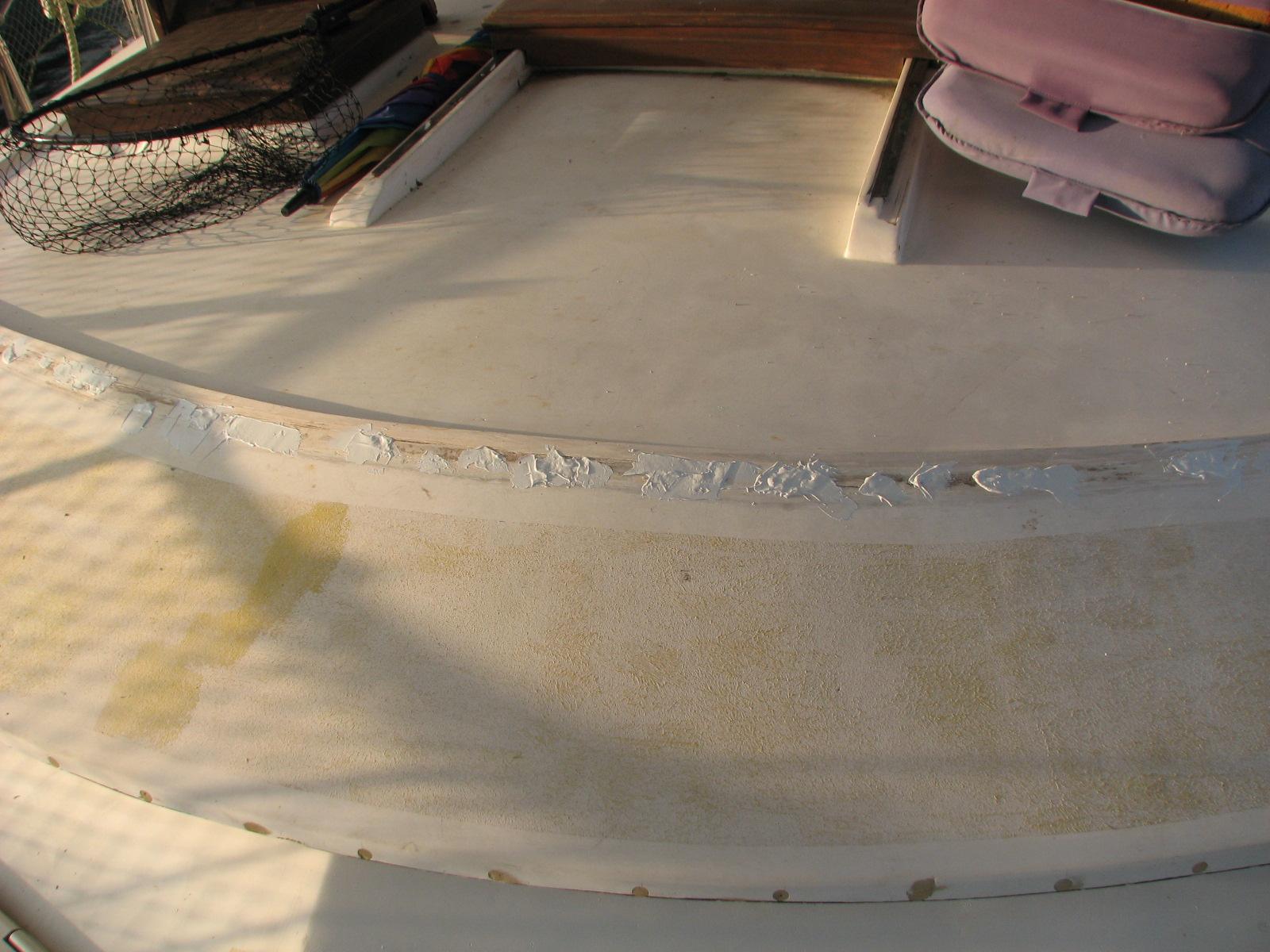

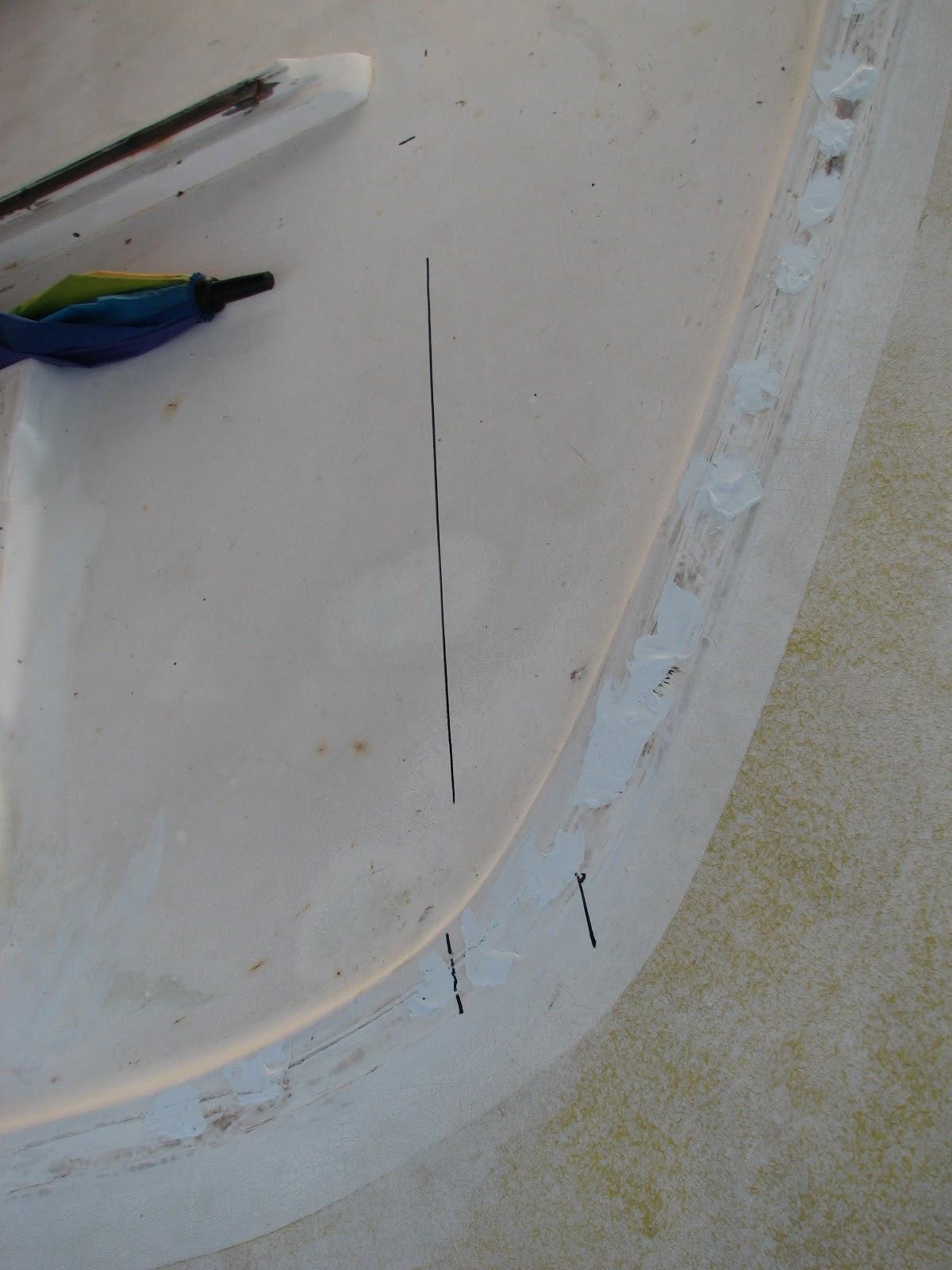

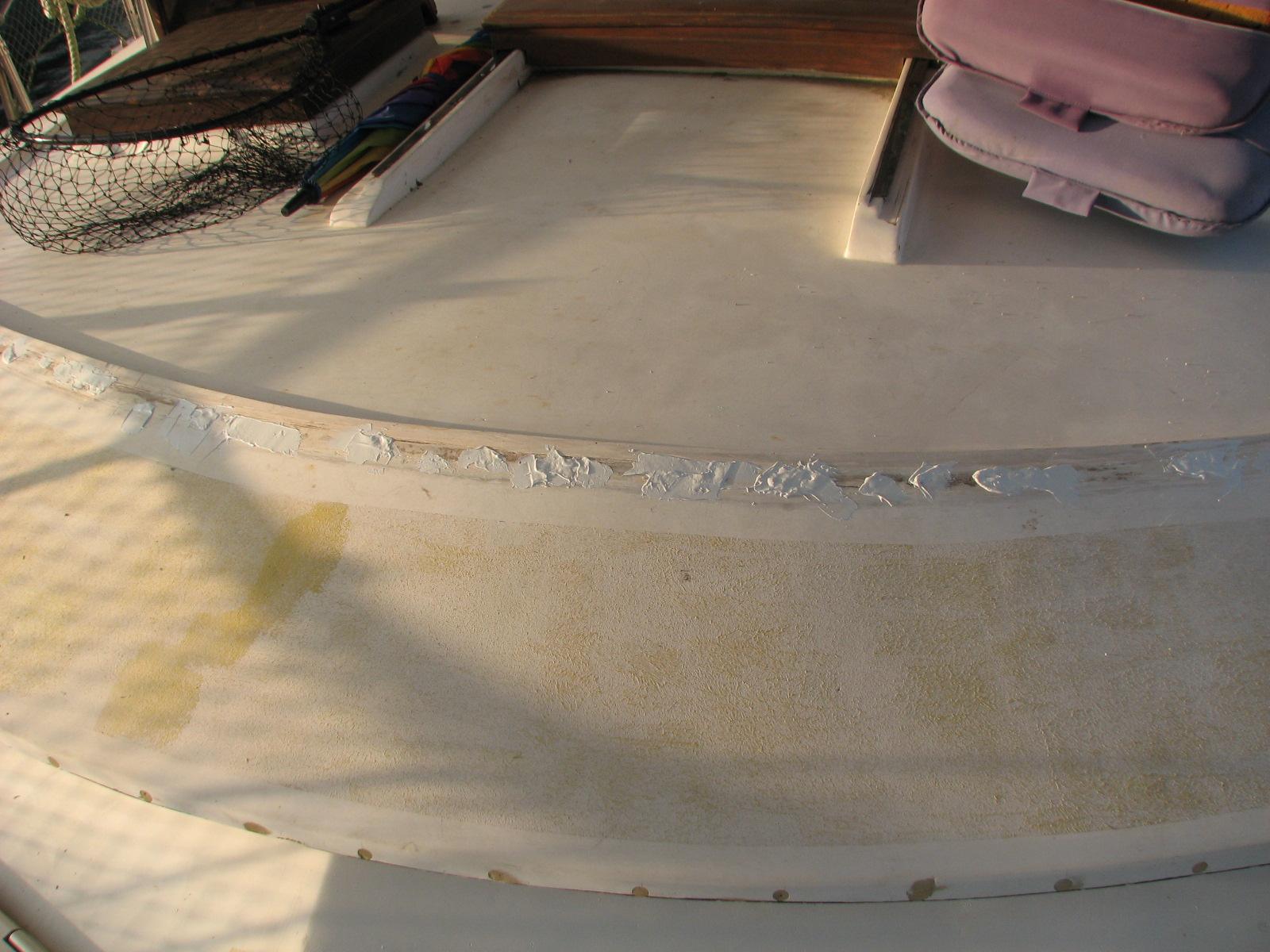

After breakfast, I started in on

repairing the broken gelcoat

that was discovered yesterday while rebedding the starboard turning

block on the aft deck. I sanded the area, and also the seam between

the deck and the side of the doghouse. I also sanded a couple of

other little broken areas of gelcoat

on the deck.

I vacuumed up all the dust in the area,

and then wiped it down with acetone.

I mixed up a batch of Marine-Tex,

and applied it to all of the area and hole I had cleaned out. Now all

we have to do is wait for the next rain to see if any progress was

made.

Next item on the list was to finish

rebedding the stanchion bases. I had one base remaining, but that

base also had the supports for the 100 LB storm anchor. Obviously to

rebed the stanchion, the anchor had to be moved. So this is one of

those cases where it takes 30 minutes to get to the project, 5

minutes for the project, then 30 minutes to put everything back.

I hooked the anchor up to the mizzen

boom, and lifted it off of the supports.

Mizzen Sheet And Boom Connected To The

Anchor

I moved the stainless steel plate out

of the way. I cleaned up the area, applied the Ace

Rope Caulk Weatherstrip, and put the stainless steel

plate back on the stanchion.

Stainless Steel Plate Moved To Enable

Rebedding

I have a wooden block attached to the

anchor support that the anchor actually sits on, and another wooden

block used to tie the anchor to the liferail. Kitty suggested I

replace these two wooden blocks with fiberglass

pieces. I heartily agreed, because once they were made, no more

maintenance. The down side is that I do not have the blocks of

fiberglass,

I will have to build them. I have the spare Strongwell

Extren plate, so all I will have to do is cut the

pieces of plate, and sandwich the pieces of plate together using

fiberglass

mat and polyester

resin.

I took the two pieces of wood off of

the support and life rail to take over to the shop.

Wooden Block On Stainless Steel Support

Wooden Block On Liferail

Wooden Blocks Ready To Take To Shop

Anchor Back On Supports Without Wooden

Blocks

Now all of the stanchion support block

have all been rebedded, and again we wait for a rain storm to see if

any progress has been made on the leaks.

I started in on attempting to put on

the side base pieces for the hard dodger, but decided I will

construct a piece of the Strongwell

Extren plate that is flat on the top for the hard

dodger, and angled on the bottom to fit the contour of the dog house.

I loaded the upright, all of the

weights, fiberglass

mat, sander, “Box

O’ Resins”, and wooden blocks into the Black

Beast, and went back to the shop.

I got out a couple of pieces of my

Strongwell

Extren plate, and using the wooden blocks as a

template I was able to get the pieces of plate necessary. I also was

able to template out a couple of pieces to build my angled piece of

plate.

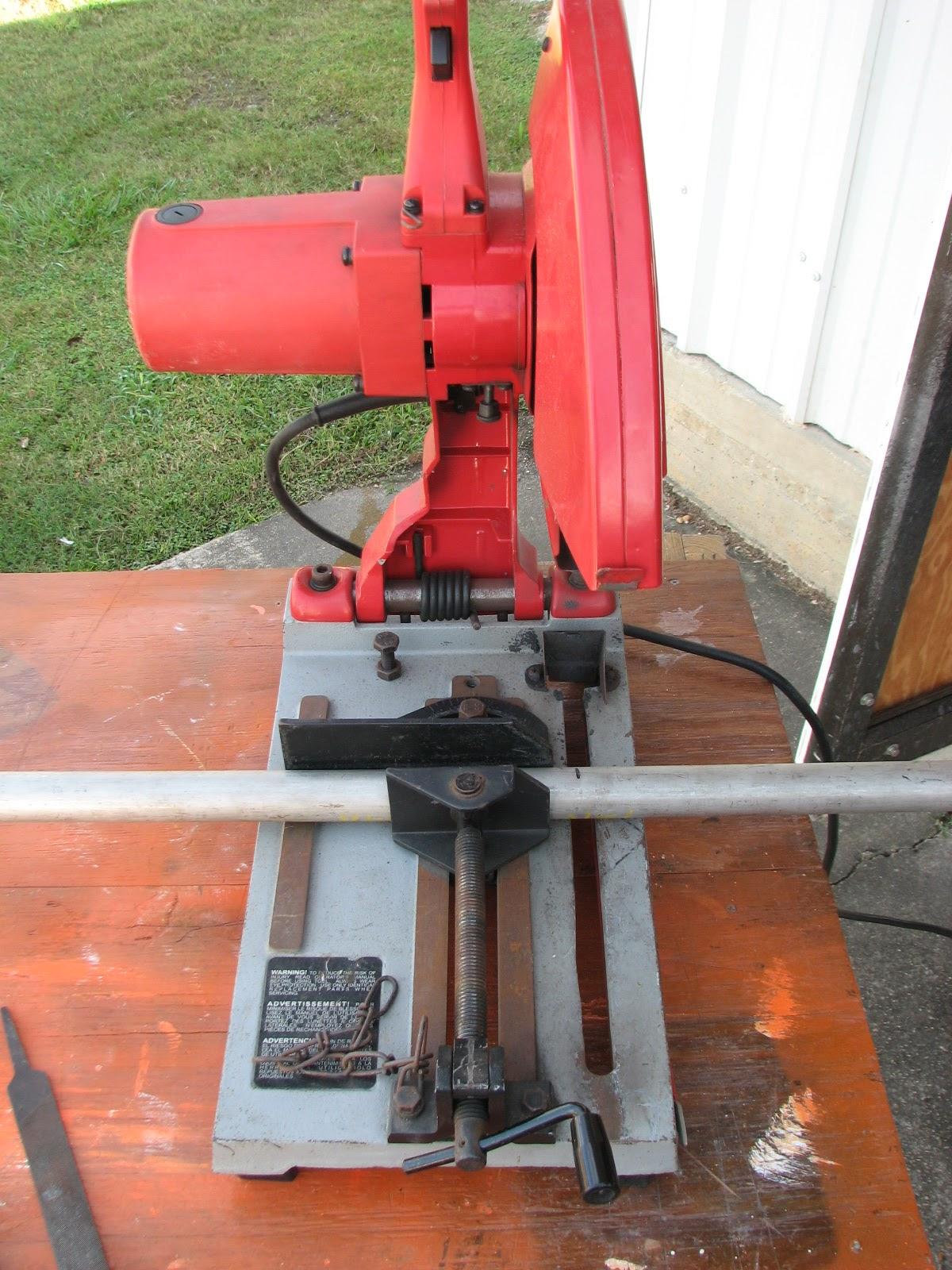

Of course this meant I needed to roll

the table saw outside the shop

and bring out my new Evolution

Rage III compound miter saw. I set a good sized

squirrel cage fan in the door of the shop,

so most of the dust is kept outside during the cutting process. I cut

all of the pieces I needed. I then cleaned up all of the pieces and

cleaned up the table saw and Evolution

Rage III compound miter saw with air from the

compressor.

Some Of The Pieces Cut On Table Saw

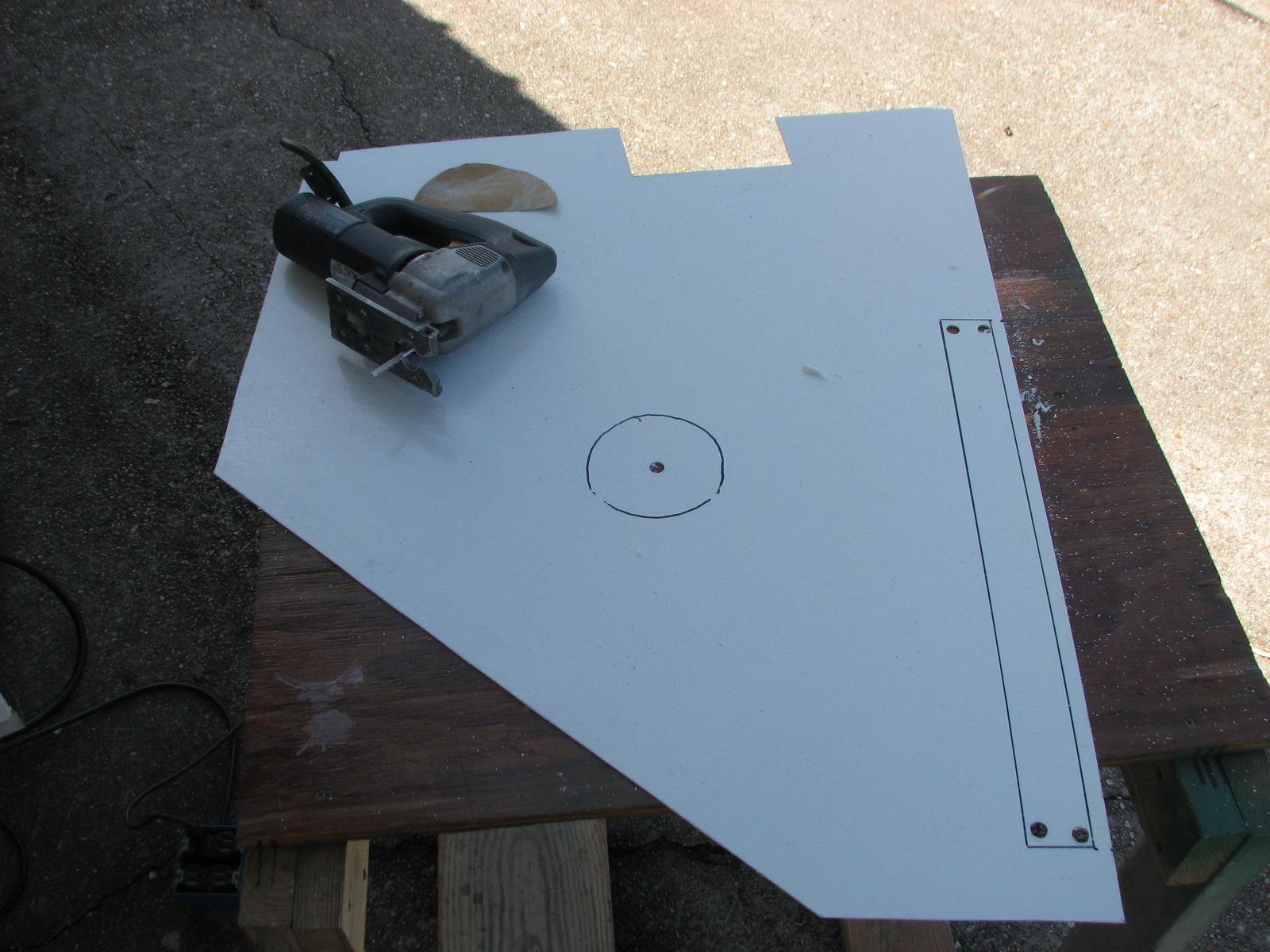

Using Jig Saw With Fiberglass Cutting

Blade

Cut Pieces On Bench With Wooden Pieces

As Templates

Next I worked on getting together the

scrap pieces of the Strongwell

Extren plate, and some small left over pieces from the

grating I put on the bowsprit. With these pieces and the original

piece I had cut for the hard dodger, I am going to build the angled

piece for the sides of the hard dodger base.

Scrap Pieces With Original Base Piece

I started in sanding all of the pieces

of the Strongwell

Extren plate I am using to build all of these parts. I

sand down all of these parts to rough them up so the fiberglass

and polyester

resin will stick together to form a single piece.

Kitty came back from her excursion to

Lafayette,

so I did not finish the sanding. It was well after 1700. Will finish

the sanding and do the glassing tomorrow.

October 25, Friday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop

and straightened up the shop. When I finished the welding yesterday,

I went off and left everything out. Not very me, if you know what I

mean!

I dusted the welder off, and put away

all of the cables and accessories. I then swept and vacuumed the

shop,

so now it looks like I work there.

Next I had to do some more cutting of

the Strongwell

Extren plate. I had to notch one of the upright pieces

of plate that will span the center and starboard sections of the hard

dodger. I also had to cut some small filler pieces to fill in under

where I am going to glass in the side pieces of plate for the hard

dodger. This will become clearer, as I actually do it.

Do do the cutting, I had to use the

table saw. I rolled the tables saw out of the shop,

made the cuts, then cleaned up the saw and the rolling table. I then

put the table saw back into the shop,

and I was finally done. As with a lot of projects, the prep and

cleanup took a lot longer than the actual cutting.

Cut Fill Pieces And Notched Upright

Notched Hard Dodger Upright

Went back to DREAM AWAY and had

breakfast. Today I was not going to work on the hard dodger, but try

and locate, the fix a couple of leaks on DREAM AWAY. I “had” all

of the leaks fixed on DREAM AWAY. The last rain we had was

substantial, so it showed a couple of leaks, and of course the source

was not obvious.

First thing to try was run the hose in

the suspected area of the leaks, get frustrated because it never

finds a leak, and then check the obvious.

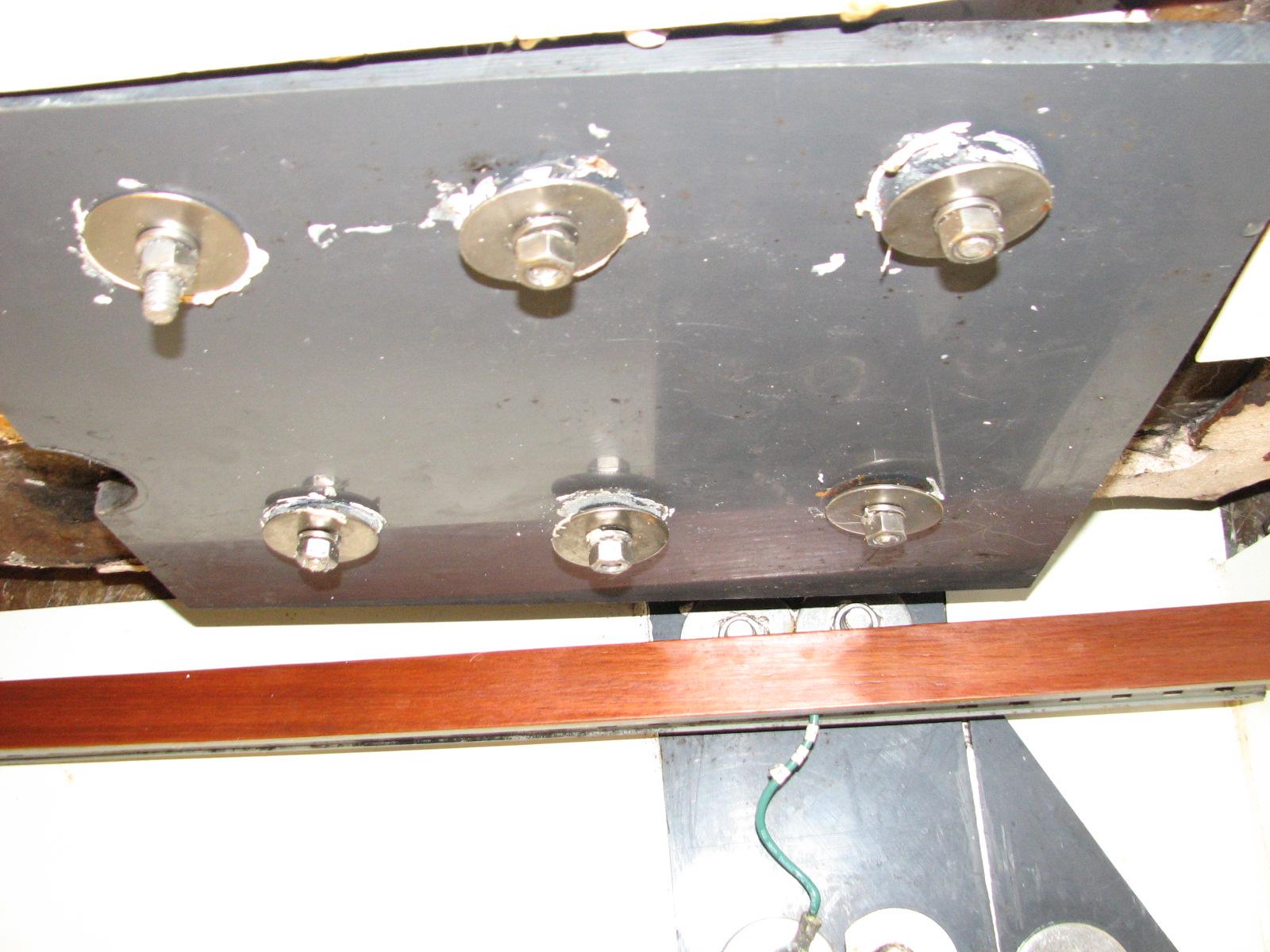

The first leak to attempt to repair was

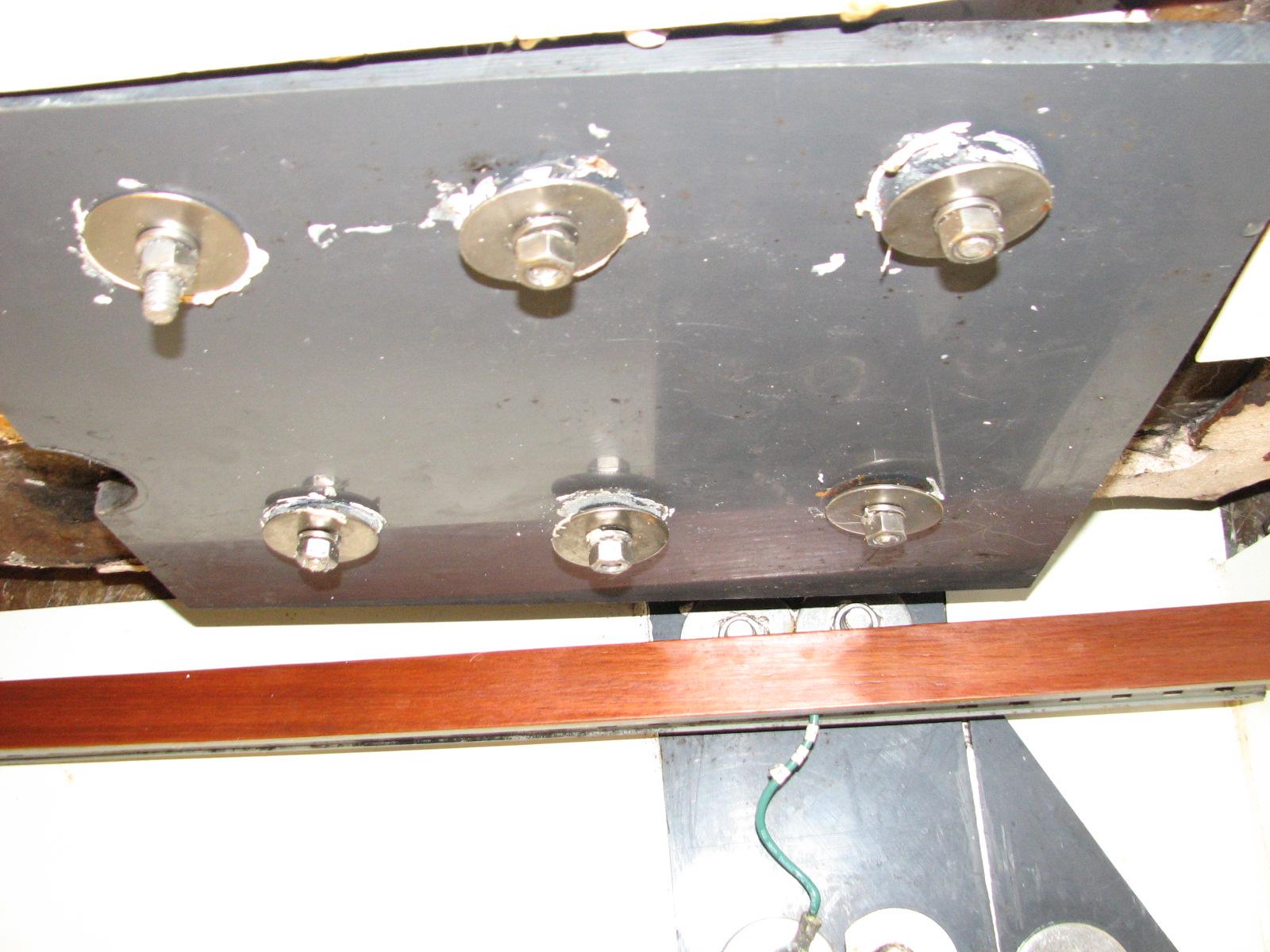

the turning block on the port side, and the backing plate for the

turning block which is located in the head. We removed the backing

plate and found a couple of damp areas, not wet, but suspicious.

Backing Plate For Turning Block

Because of the dampness, I decided to

remove the bolts holding the backing plate, and also rebed the

backing plate. When I removed the six bolts holding the backing plate

to the deck, I did not see any dampness on the bolts. In fact the Ace

Rope Caulk Weatherstrip I used around the bolts still

looked in good shape. I also cound not budge the turning block from

the deck. I surmised, because of that, it was not leaking.

Turning Block On Deck

I cleaned up the bolts, applied more

Ace

Rope Caulk Weatherstrip to the bolts, and put the

bolts through the deck and into the backing plate. I tightened all of

the nuts on the bolts, and was pretty satisfied the turning block was

not the source of the leak.

While I was on deck working on the

turning block, I noticed a piece of the gelcoat

broken out, and I could see raw fiberglass

in the hole. This might be a source of the leak, so I will repair

that possibility tomorrow.

The next suspect on the list is a cleat

that is on top of the cabin, with it’s backing plate in the head.

We removed the bolts from the cleat, and lifted the cleat off of the

deck. I rebedded the cleat and it’s bolts using the Ace

Rope Caulk Weatherstrip, and then tightened it all

back together.

Another suspect in the find the leak

project are all of the new stanchion bases I fabricated and installed

on the aft portion of DREAM AWAY. The fabrication and construction is

all covered on my web

page. I suspected that water may be leaking under the

stainless steel plates, and then down through the threaded rod, and

into the boat.

I decided to pull up the stainless

steel plates on all 14 of the stanchion bases, and apply the Ace

Rope Caulk Weatherstrip, then bolt the plates back

down to the stanchion bases.

Stanchion Base, Stainless Steel Plate

Removed

Stainless Steel Plate Back On Stanchion

Base

I was able to do 13 of the stanchion

bases. One of the port side stanchion bases also supported the stern

anchor. The anchor systems on DREAM AWAY are covered in the Ground

Tackle section of the About

DREAM AWAY page. This one was a bit of a pain.

Stainless Steel Plate And Holder For

Stern Anchor

Stern Anchor On Aft Deck Box

The 14th and last one did not get done

today! That stanchion base also hold the 100 LB storm anchor. I have

to use the mizzen boom to raise the anchor off of the stanchion base.

It will be done tomorrow, running out of time today.

Stanchion Base With Storm Anchor

October 24, Thursday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop

and worked on cleaning up the welds on the pipe for the hard dodger.

Some of the welds were not pretty, but they clean up with a grinder,

sandpaper, and a stainless steel wire wheel.

Welds Before Cleanup

Welds After Cleanurp

Pipe Clamped Up Getting Cleaned Up

When I had finished all of the cleanup,

and some of the polishing, I loaded the pipe into the Black Beast. I

will have to do more welding to the pipe. I will have to add supports

for the fiberglass

pieces that will be holding the plexiglass

pieces of the hard dodger. I also may fill in some of the dips in the

welds to make them look even better.

The real question is how much did the

pipe flex or twist during the welding process. I clamped down the

sections as I was welding, but from previous experience all side of

the work need to be clamped as well as possible. We will see when we

get over to DREAM AWAY.

Went back to DREAM AWAY and had

breakfast. Kitty then helped me get the pipe piece bolted to the boom

gallows. The piece had not twisted very much, and it fit right onto

the boom gallows. We were both very happy about that.

Pipe Piece On Boom Gallows

Pipe Piece Port To Starboard

I had brought over with me one of the

Strongwell

Extren plate pieces cut to be one of the hard dodger

uprights. The uprights will be the frame that holds the plexiglass

in the hard dodger. The uprights will have a groove cut into them for

the plexiglass

to slide into. So far the plan for the hard dodger is working out.

Upright Sitting On Base And Leaning On

Upper Support Pipe

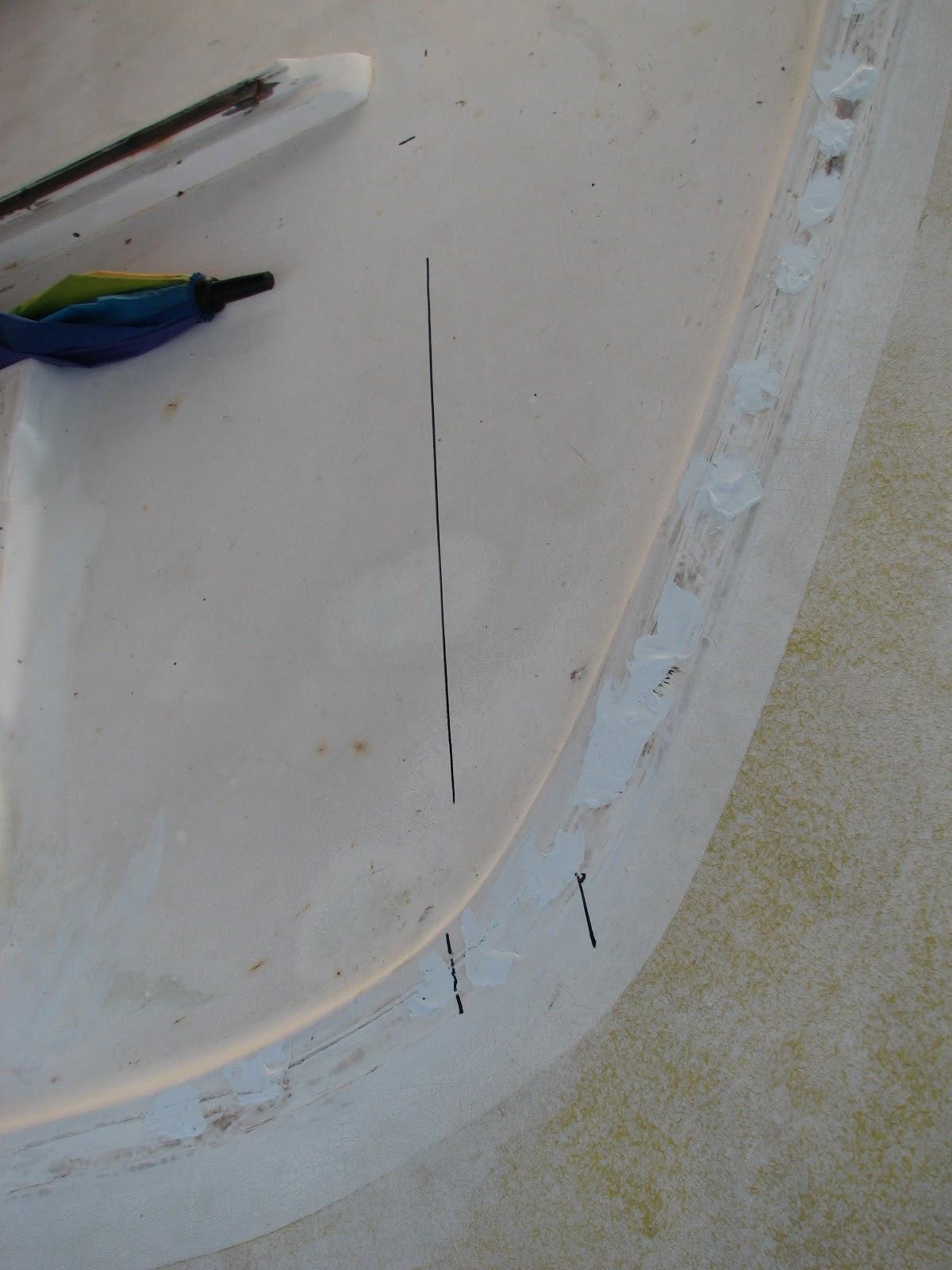

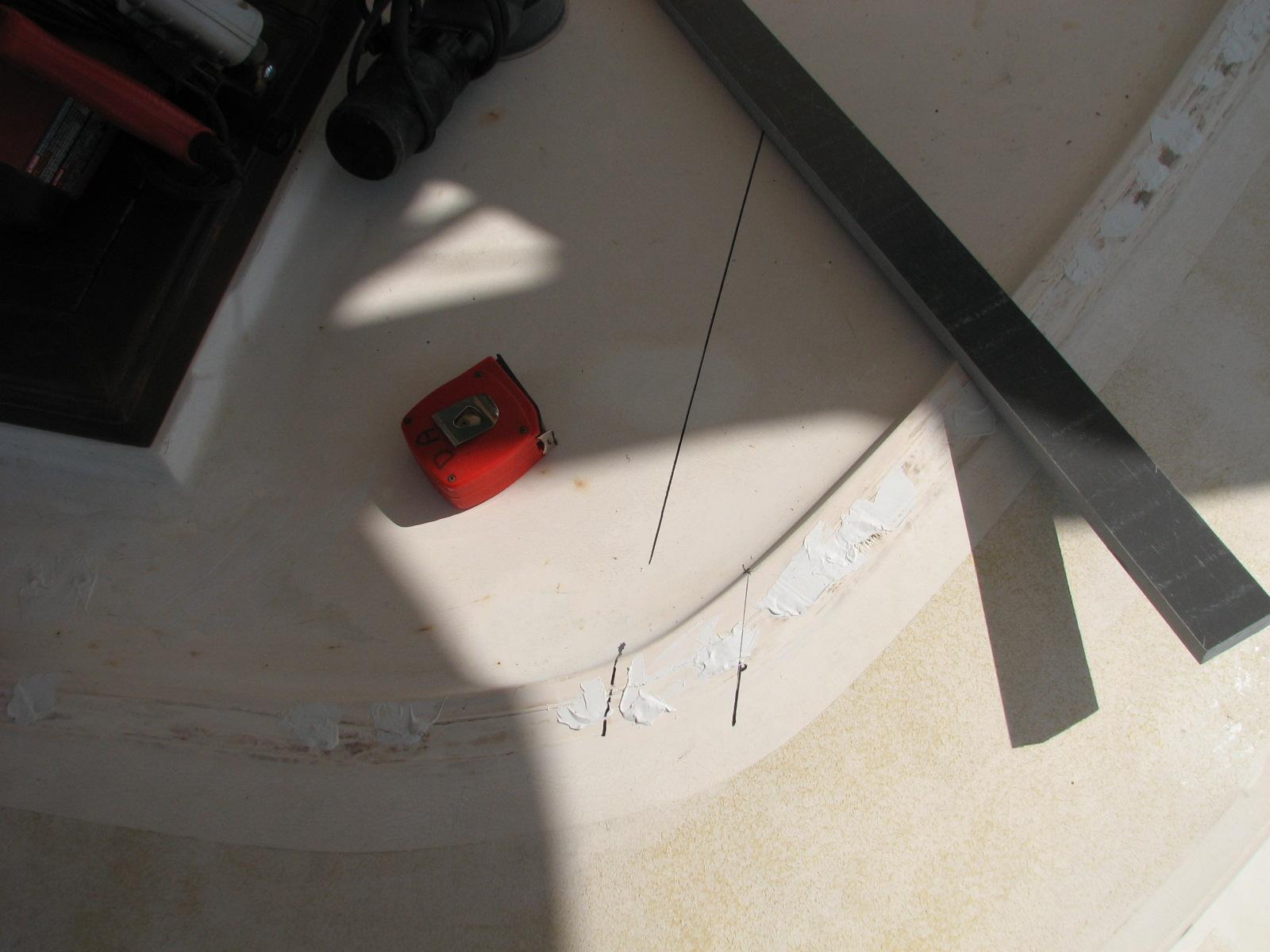

Now it was time to get to work on

getting the piece of Strongwell

Extren plate that has to be glassed to the dog house

on the port side. Just like the starboard side, I had to make cuts in

the top of the dog house for the cut piece of plate. I measured the

area and then cut out the fiberglass.

Measured Area To Be Cut Out Of Top Of

Doghouse

Area Cut Out Of Doghouse Top

The bad news about the cut was a bad

measurement! I had cut the channel for water to escape on the wrong

side of the plate. I remeasured, cut again and moved on. It will not

be a big problem, and I even found a piece of scrap Strongwell

Extren plate that pretty well fits the area.

I cleaned up the area that was cut in

the doghouse top, and sanded and prepared the area for the

application of the fiberglass

and the polyester

resin. I cut the needed pieces of fiberglass

mat, and dry fit the them along with the piece of plate. I also got

the weights handy that will be needed on the piece of plate. There is

a slight crown to the doghouse top, and the weights are needed to

“bend” the piece of plate.

All was prepared, so I mixed up a batch

of the polyester

resin. I wetted out the area with the resin, then put

down the fiberglass

mat, and made sure it was wetted out. I then put the piece of plate

on top of the wetted out mat, and then put on the weights. The resin

kicked off pretty quick, so I did not have to hold it long.

Weights On Outer End Of Plate

Weight On Inner End Of Plate

Plate With Weights At Both Ends

One more item to check. I wanted to

make sure the new piece of pipe for the pipe

clamps would accomplish the task I have in mind. I

have to glass an additional piece of the Strongwell

Extren plate to the sides of the doghouse for the side

windows in the hard dodger. One I glass and clamp the plate down, I

have to fill in the area under the plate. I clamped the piece of

plate to the starboard side front base of the hard dodger, and I am

sure it will work the way I have it in my mind.

Plate Clamped To Starboard Base

All that remained was to clean up. I

loaded up the “Box

O’ Resins”, the Skil

saw with the fiberglass cutting blade, sander,

weights, and other items in the Black Beast. Then I had to hose down

DREAM AWAY, as there was a lot of residue and dust on the boat.

When I finally get all of the pieces of

plate I am using for the hard dodger base glassed down, there will be

a lot of cleanup and sanding, application of filler and finishing

putty, and finally a couple of coats of gelcoat

for the finishing touch.

Now it was off to the shower, and a break in the cockpit. No adult beverage

as today is a fast day on our diet.

October 23, Wednesday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop

and set up for cutting the long bar on the hard dodger stainless

steel upper support. The old adage of measure twice, cut once really

came into play here, except I measured many times. I measured and

verified that the center was the center, and I cut equal distance

from the center, but the total length was the same aa we measured

yesterday.

I finally made the cuts on the pipe,

and trimmed up the ends. Then I did the set up to actually tack weld

the long pipe to each end.

Long Pipe Tack Welded To Starboard End

Long Pipe Tack Welded To Port End

Long Pipe Tack Welded Showing Both Ends

We were meeting the port director at

the marina

so he could look over the new shower

trailer and discuss location and hookup. We made those

decisions, and decided I would attempt to get an extension cord and

hoses to get to the shower

trailer in its present location, and test the

functionality of the onboard systems.

Kitty then called a locksmith in New

Iberia to get a key for the maintenance room door on

the shower

trailer. It was an ordeal, but we finally got the

project accomplished, after driving around New

Iberia to find the locksmith, and now the maintenance

room door is locked.

When we came back to the marina,

we met Cheryl and Johnal who are cruisers that are considering coming

to the marina

next month for a couple of months. We all went to Jac’s

Po'boy

shop here in Delcambre and had lunch.

After lunch, we came back to the

marina,

and I got to work on the hard dodger frame. Kitty helped me, but we

did finally get the top frame up and on the boom gallows. That is the

whole point in the tack welds. The frame was “adjusted” some to

make the fit, but was happy to see it went well.

Frame On Port Side Of Boom Gallows

Frame On Boom Gallows Showing Starboard

Side

We took the frame off of the boom

gallows, and I took it to the Black Beast

and went back over to the

shop.

I did the set up and the clamping of the pipe down to a flat surface,

and completed all of the welds. I will bring the pipe/mount over to

DREAM AWAY tomorrow to verify it still fits.

Set Up With Clamps For Welding

October 22, Tuesday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop

and decided I had to move the Structoglas

from where we left it yesterday in front of the storage shelves. If

left there it would surely be damaged. I moved the table saw out of

the way, the Jim

Rabby Painting I have, and all of the cardboard

templates I had behind the table saw also.

I then moved all five sheets of the

Structoglas

up against the wall, and then moved everything back into place. It

will be a fair amount of effort to move stuff to get to the sheets of

Structoglas,

but the Structoglas

will not get damaged in it’s present location.

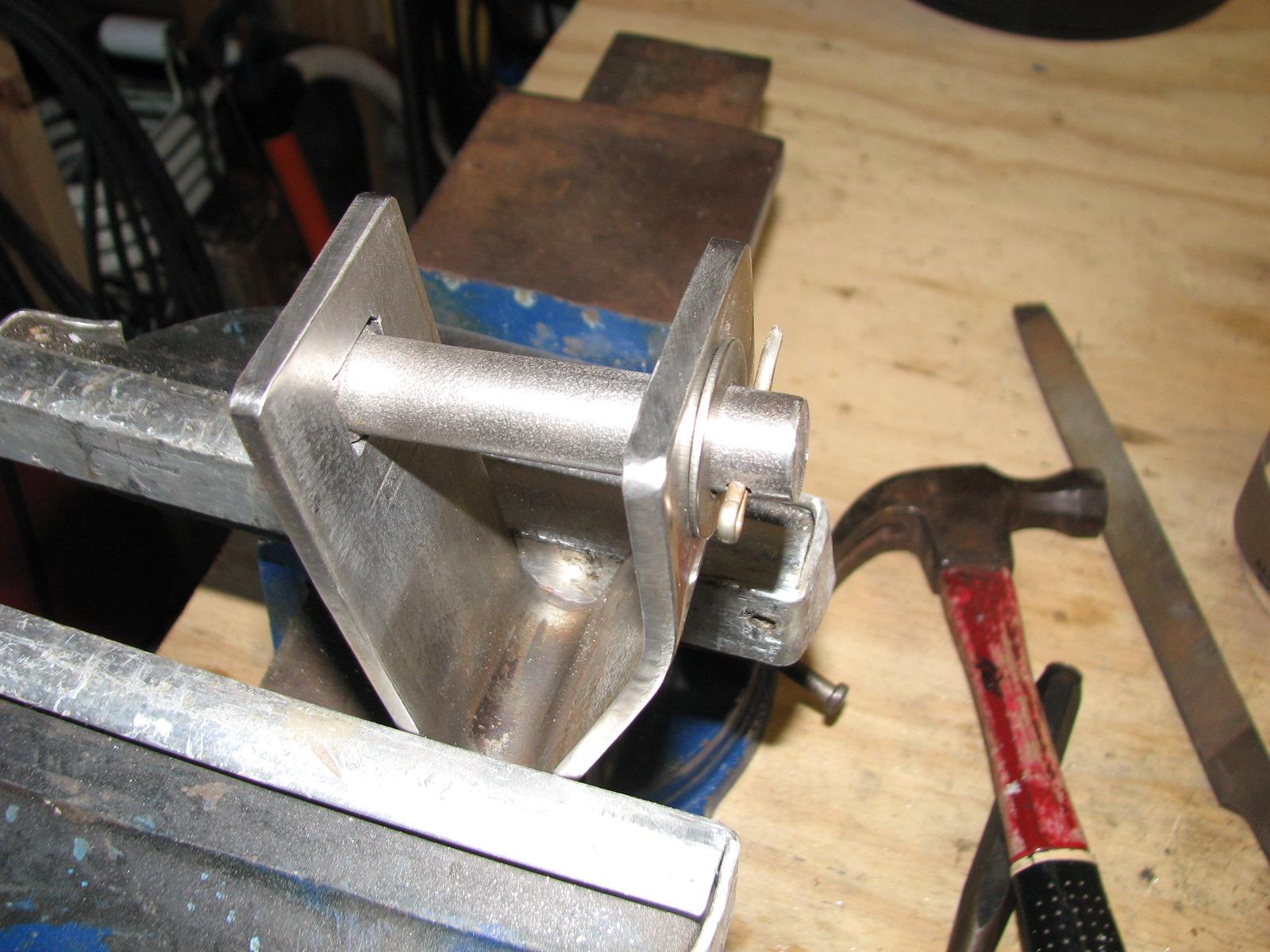

Since I had the welder all set up, I

finished welding on the base piece for the main mast sail deck. There

is still some sanding and grinding required to finish off the piece

to make sure it is ready for installatio.

Finished Main Mast Sail Deck Piece

I then set up the welder to weld

stainless steel. I wanted to tack up one of the base pieces for the

top of the hard dodger. With the piece just tacked up, if there are

any changes to be made it can be done easily. The base piece

consisted of the base, the 18” pipe, and the short weld ell. I did

the set up, and then did the small welds.

Base And Pipe Setup

Weld Ell Setup

Tack Welds On Weld Ell

I left the shop

and went over to DREAM AWAY with the tacked up piece for the hard

dodger.

Kitty and I had breakfast, and then got

busy with domestic shores. Our good friends Iris and Terry were

coming over in the early afternoon, and were staying for dinner.

When Iris and Terry arrived, Kitty and

Iris went off shopping and visiting, and Terry and I walked over to

the shop.

I wanted to show Terry the shop, but also wanted to tack up the other

base piece for the top frame of the hard dodger.

I did the set up on the pieces, and

tacked them up. Terry and I then went back to DREAM AWAY with the two

tacked up pieces, and the long piece of pipe that is to be welded

between the two base pieces.

When we got back to DREAM AWAY, we

bolted the two base pieces to the boom gallows, and then hung the big

piece of pipe between the two base pieces, and marked where the cuts

will be made. With the big piece of pipe marked, I will be able to

cut off the ends of the pipe, and tack it to the base pieces. That

will be tomorrow mornings project.

October 21, Monday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop

and continued sanding the stainless steel pipe for the hard dodger. I

also sanded smooth the stainless steel base for the starboard side of

the top of the hard dodger frame.

Starboard Base Of Hard Dodger Frame

Before Sanding

Starboard Base Of Hard Dodger Frame

After Sanding

I decided to set up the welder

and tack the pipe and base together. When I checked the welder

it was still set up to weld aluminum. I was last welding on a base

piece for the main mast sail deck, and had not finished.

I decided to continue with the aluminum

welding and finish the base piece for the main mast sail deck. Just

when I was ready to start welding, Kitty called to say she was up,

and to come home for breakfast.

Set Up To Weld Main Mast Sail Deck Base

I went back to DREAM AWAY and had

breakfast. After breakfast we went to the Lowe’s

in New

Iberia to pick up the five sheets of Structoglas

I had ordered for DREAM AWAY projects.

We drove directly to the shop

and unloaded the Structoglas,

then back to DREAM AWAY. We had lunch, then drove over to Abbeville

to meet our friends Iris and Terry who were driving their new motor

coach from Florida back to Texas. We had a great visit, and dinner at

Shuck’s

in Abbeville.

October 20, Sunday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop

and started in on repairing a screen for the forward facing hatches

in the main cabin. Our cat Jordan,

when he is outside roaming the decks likes to lie down on the screens

we have in all of the hatches. When he does lie down in the screen,

he falls through, and the screen has to be repaired. He did this

yesterday, that is why the repair is necessary.

Screen On Bench Ready For Repair

I repaired the screen, then I washed

the screen, and set it out to dry.

Repaired Screen Drying In The Sunshine

I had finally applied eight coats of

varnish to the nav

station chair, so I was ready to take it back to DREAM

AWAY. I first had to put the cushion back on and the rubber ends on

the legs, and it was ready to go.

Next I worked on the upper frame for

the hard dodger. I got out a piece of the 1” stainless steel pipe,

and cut off two 18” pieces with the chop

saw.

The two pieces then had their ends

trimmed, and filed smooth. I then got sand paper and polished the

pipe. It will not be perfect, but look better than coming straight

from the mill. I also polished the base piece the pipe will be welded

to.

Pipe Undergoing Sanding

One Piece Complete, One To Go

I then did a dry fit of the polished

pipe, the base plate, and the weld ell. I will tack these pieces

together, and then check the fit on the boom gallows. I will have to

get the starboard side and the port side tacked together, so I can

measure the exact length of the pipe for the middle.

Dry Fit Of Pipe, Base, And Weld Ell

“Box O’ Resins"

After breakfast on DREAM AWAY, I

prepared the deck in the center of the dog house where I was going to

put the hard dodger center piece of fiberglass.

I did the measuring, then I built dams out of duct tape to keep the

resin from running all over the place.

I then cut all of the necessary

fiberglass

mat I would need to fill in the crown under the center piece. When

that was all prepared, and I did a dry fit, I was ready. I mixed a

pot of polyester

resin, not too hot, and applied the polyester

resin to the mat and the center piece. The dams worked

perfectly, and the application went off wonderfully.

Hard Dodger Center Piece Fiberglassed

In Place

Hard Dodger Center Piece Fiberglassed

In Place

October 19, Saturday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Spent extra time on the computer

catching up. Did not get any DREAM AWAY projects done today. Ran some

errands, and then watched the Texas Aggie football game.

Unfortunately the Aggies lost to Auburn.

October 18, Friday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the Port

of Delcambre’s storage room and unloaded the steps

and railings that came with the shower

trailer. Until the port director decides where the

trailer is going to be situated, there is no use attaching the steps

and handrails to the shower trailer.

I also got under the Black Beast to

check the rear brakes. A couple of months ago, I tried adjusting the

rear brakes on the Black Beast. The passenger side would adjust, but

the driver’s side would not. I checked again this morning, and the

same situation prevailed. I decided to apply some Aero

Kroil to the adjuster. I will do this application for

a couple of weeks, and see if the adjuster can be loosened.

I then got to sanding the center base

piece for the hard dodger. This is the piece that is actually three

pieces of Strongwell

Extren plate I had glassed together.

Sanding Center Hard Dodger Base Piece

Went over to DREAM AWAY to have

breakfast, and then returned to the shop.

I finished sanding the center piece of fiberglass for the hard

dodger. I used the Evolution

Rage III compound miter saw to trim the ends of the

sanded center piece to the measured length.

I knew I was going to use one of the

pieces of the 1” stainless steel pipe for the top frame of the hard

dodger, so I decided to get started on that phase of the project. I

cut off the threaded ends of one piece of pipe that was at least 100”

long, actually 114” long after the trimming.

I also wanted to put a crown in the

pipe to match the crown in the hard

bimini. I measured the pipe to find the center, and

marked that location. I then put two pieces of 4” X 4” on the

floor of the shop,

and then stood in the middle of the pipe. This action got a pretty

good crown in the pipe, but I did not want to overdo it.

I loaded the pipe and blocks of wood

and the center piece of fiberglass

into the Black Beast, and went over to DREAM AWAY.

I fitted the center piece of fiberglass

to the top of the dog house, and the fit was very close. I have come

up with a plan to glass the center piece to the dog house, but did

not have enough time today, and also rain was on the way.

I then checked the fit of the crown on

the stainless steel pipe. It needed some adjustment, so I used the

two pieces of 4” X 4” blocks and stood in the center of the pipe.

After a couple of adjustments, I was able to get the crown very close

to the crown of the hard

bimini.

Now I can set up a jig to tack the

stainless steel pieces together, and then check the actual fit on

DREAM AWAY.

October 17, Thursday, 2013

October 16, Wednesday, 2013

We got up this morning, had a cup of

coffee, loaded the Black Beast with our luggage, and

the big chair,

and drove to Clear

Lake Shores, Texas.

We met our friends Pam and Steve for

lunch, then we took Alan and the big chair to Alan’s boat. On our

way to Rosharon,

Texas, we stopped at the Momentum

Metal Recycling in League City, Texas. I wanted to

purchase some more 1” stainless steel pipe for the main cabin grab

rails. I was lucky, and they one piece 10’ long, which I purchased.

We then drove on to Rosharon,

Texas, to spend the night with friends.

These friends, Connie and Wayne, are

the ones who got the port looking at and finally purchasing the

shower trailer.

October 15, Tuesday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop

and started in on the submerged running of the SeaScooter. I had

charged the battery for the SeaScooter over night, so I know the

battery was topped off.

We went through the same drill we did

yesterday with the SeaScooter. We used masking tape to secure the on

button down, then tied the unit into the bucket of water. The

SeaScooter ran full blast for about 30 minutes, and it ran slower,

but still capable of moving a diver around.

After 1.5 hours, the SeaScooter was

still running. When we removed the SeaScooter from the water, it

still made the thrashing machine sound. The sounds have not gotten

any better or worse. I am going to charge the battery again, and run

the unit on the bench a couple of more times to see if there is any

change in the sound.

I think the SeaScooter could be a

useful and functional unit. It’s runtime, if you run it from the

time the diver is in the water, until the diver is out of the water,

it will outlast a normal divers tank of air.

SeaScooter Running In A Bucket Of Water

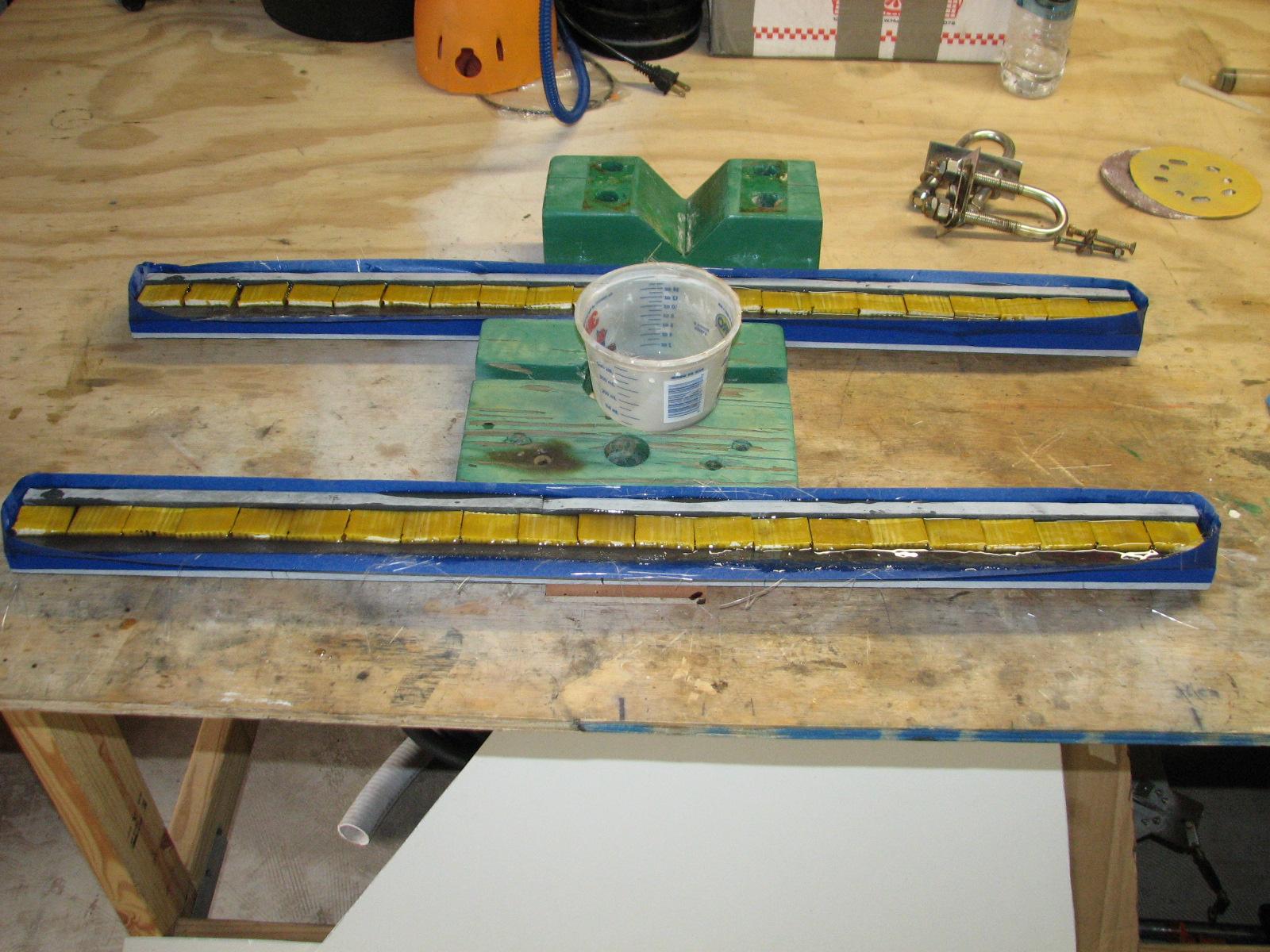

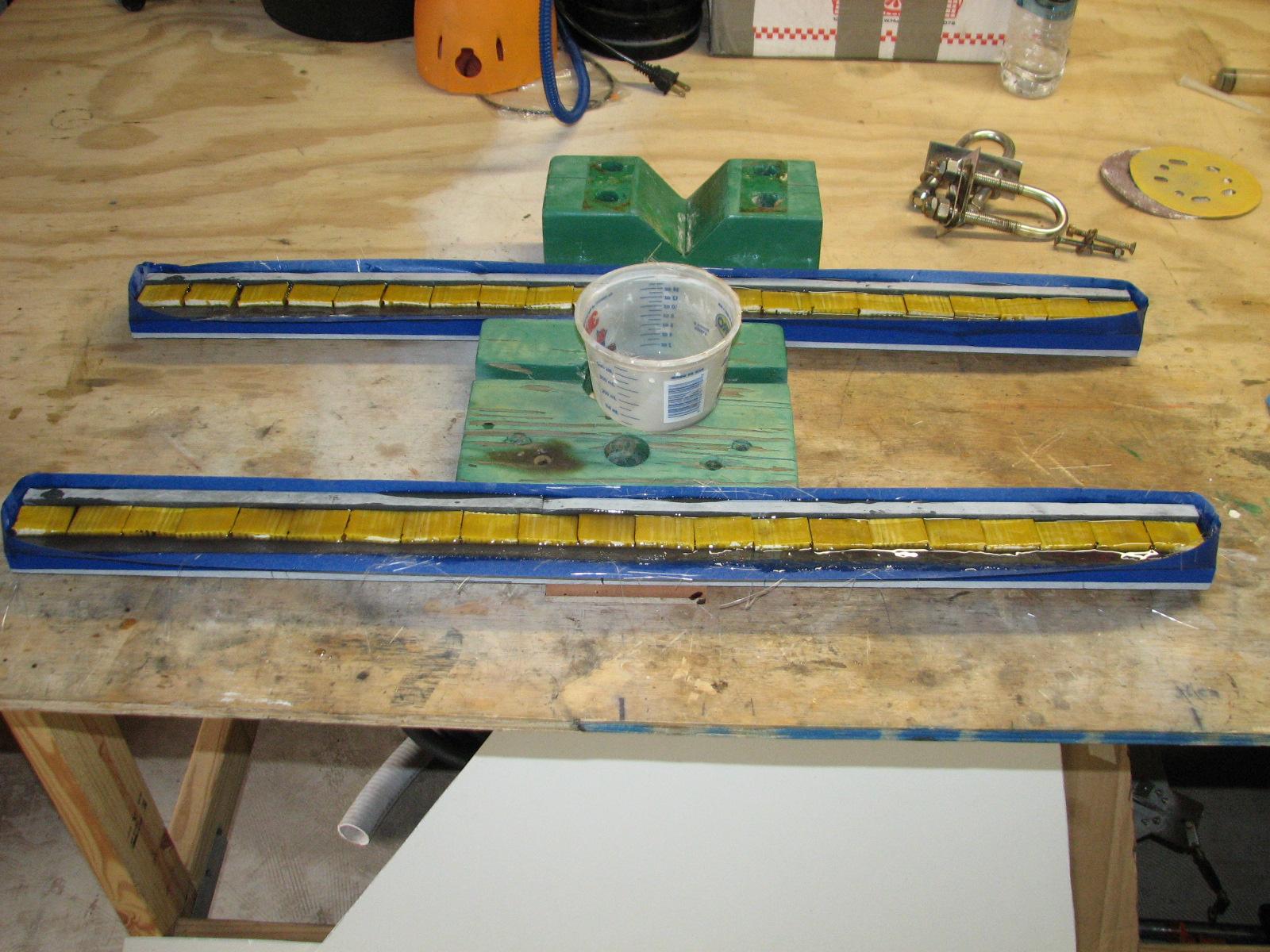

Next on the list was to put together

the center base piece for the hard dodger base. The piece of

plexiglass

in the center of the hard dodger will have to clear the companionway

hatch, so the base needs to be higher off of the deck than the other

base pieces.

To accomplish this I decided to

fiberglass together three ¾” pieces of the Strongwell

Extren plate we had cut yesterday. I measured and cut

two pieces of fiberglass

to put between the three pieces of Strongwell

Extren plate. We sanded the surfaces of the Strongwell

Extren plate, so the resin would adhere to the plate.

I also got out clamps, and did a dry fit.

I laid out a piece of wax paper on the

bench, and then mixed up a batch of polyester

resin. We then put down the first piece of plate, and

wetted out the surface, then laid in the piece of fiberglass,

and wetted it out with the polyester

resin. We continued this process until we had all

three pieces of plate glassed together. We applied the clamps to the

piece, and applied just enough pressure to keep the pieces together,

but not so much as to squeeze out the resin.

Completed Piece On Work Bench

When we finished that, we loaded up the

“Box

O’ Resins”, the Skil

saw with the fiberglass cutting blade, sander,

weights, and other items and went back to DREAM AWAY.

We had a great Kitty prepared

breakfast, then we got to work on the hard dodger base on the

starboard side.

I have decided that the hard dodger was

going to be at 90 degree angles, not a wrap-around or curved dodger.

There will be three pieces of plexiglass

in the forward facing part of the dodger. These three pieces will

slope back to the stainless steel top of the hard dodger. On each

side of the hard dodger will be one rectangular piece of plexiglass

that will go straight to the stainless steel top of the hard dodger.

Also on each side will be a triangular piece of plexiglass

that will be the fill between the forward facing pieces and the side

pieces.

Of course there are a couple of issues

that will have to be addressed before I can realize the hard dodger

as I have it designed. Because of the way the Hardin had the “dog

house” with the eyebrow designed, I have to make some

modifications. There is also a crown in the top of the “dog house”

to be accommodated.

I know this seems complicated, but I

hope the pictures will help to explain what I am talking about.

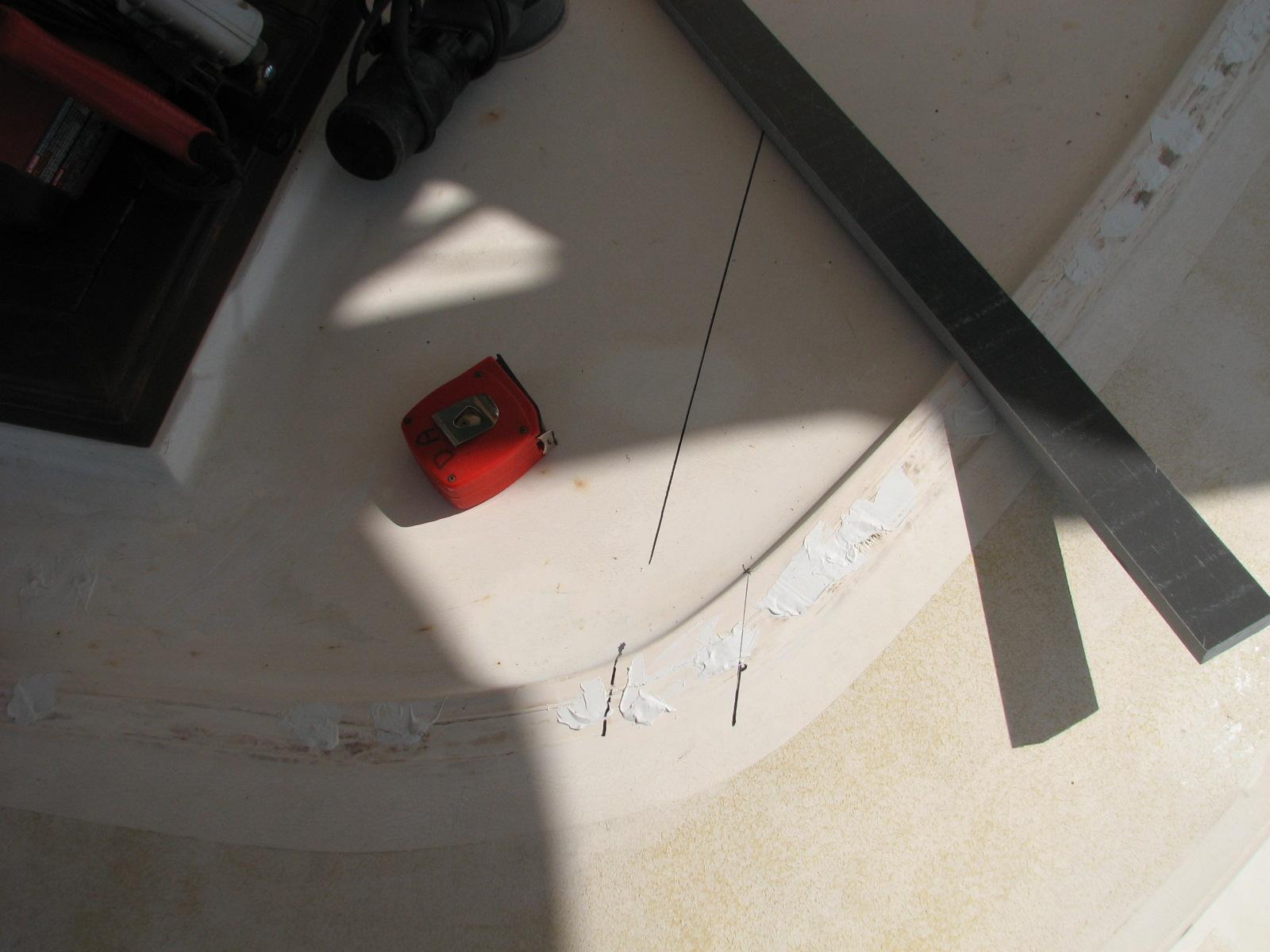

We had to cut out the eyebrow on the

starboard side to fit in the starboard forward base for the hard

dodger. I also had to cut out a channel in front of the hard dodger

base so water would not accumulate after the hard dodger base is

glassed in.

Alan and I measured and set up the cuts

with the Skil

saw with the fiberglass cutting blade. We made the

cuts in the eyebrow, and then used a chisel and file to get the area

smooth enough that we could set the base piece of Strongwell

Extren plate to lay flat.

When we were satisfied with the fit, I

cut the necessary pieces of fiberglass

mat we would use to glass the Strongwell

Extren plate to the top of the doghouse. I then mixed

up a batch of polyester

resin. I wetted out the measured area on the deck,

then wetted out the two cut pieces of fiberglass

mat, then we applied the Strongwell

Extren plate. There was a slight crown to the deck

surface, so we had to use weights to force the Strongwell

Extren plate to follow the crown. I also put down some

fiberglass

mat in the channel in front of the hard dodger base piece.

Measured Area Top Of Doghouse And Hard

Dodger Base Piece

Cuts Made In Eyebrow

The resin I mixed up was pretty hot, so

it kicked off pretty quick. Alan and I loaded all of the tools,

parts, weights, and “Box

O’ Resins” into the Black Beast, and took it all

back to the shop

and unloaded it. We got the Black Beast ready for the trip to Clear

Lake Shores.

October 14, Monday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop

and started in on the submerged running of the SeaScooter. It was fun

trying to get the SeaScooter tied into the bucket of water after

taping down the start switch. I am not sure I could have done it

myself. The Sea Scooter moves an impressive amount of water.

The Sea Scooter ran full blast for

about 30 minutes, and then slowed down considerably. After 50

minutes, and it was still running, I stopped the SeaScooter and

removed the battery. I was not sure the battery was fully charged, so

I will take the battery and charger over to DREAM AWAY and make sure

the battery is fully charged.

SeaScooter Running In Bucket Of Water

SeaScooter Running In Bucket Of Water

Alan got busy painting the second

bucket for the after deck on DREAM AWAY, while I sanded on the nav

station chair.

Alan Painting After Deck Bucket

First Coat After Deck Bucket

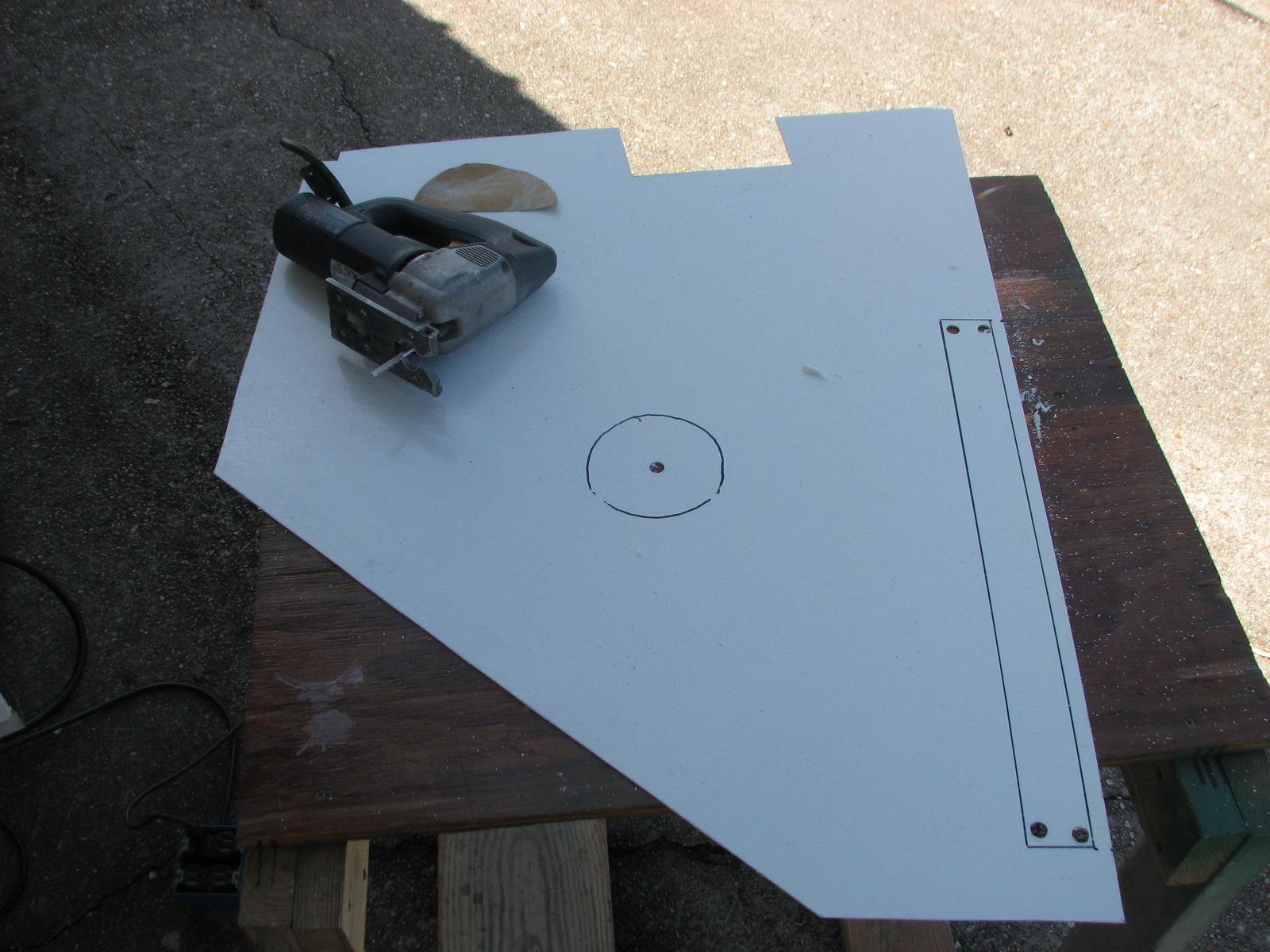

I got out my drawings for the hard

dodger. Alan and I looked over the stash of

fiberglass

I had accumulated for the project, and decided to cut a couple of

pieces of fiberglass

to take over to DREAM AWAY and work on the exact measurements we

needed for the hard dodger. I wanted to make sure the plan in my mind

would actually work on the boat. Then I wanted to verify we had all

of the necessary fiberglass.

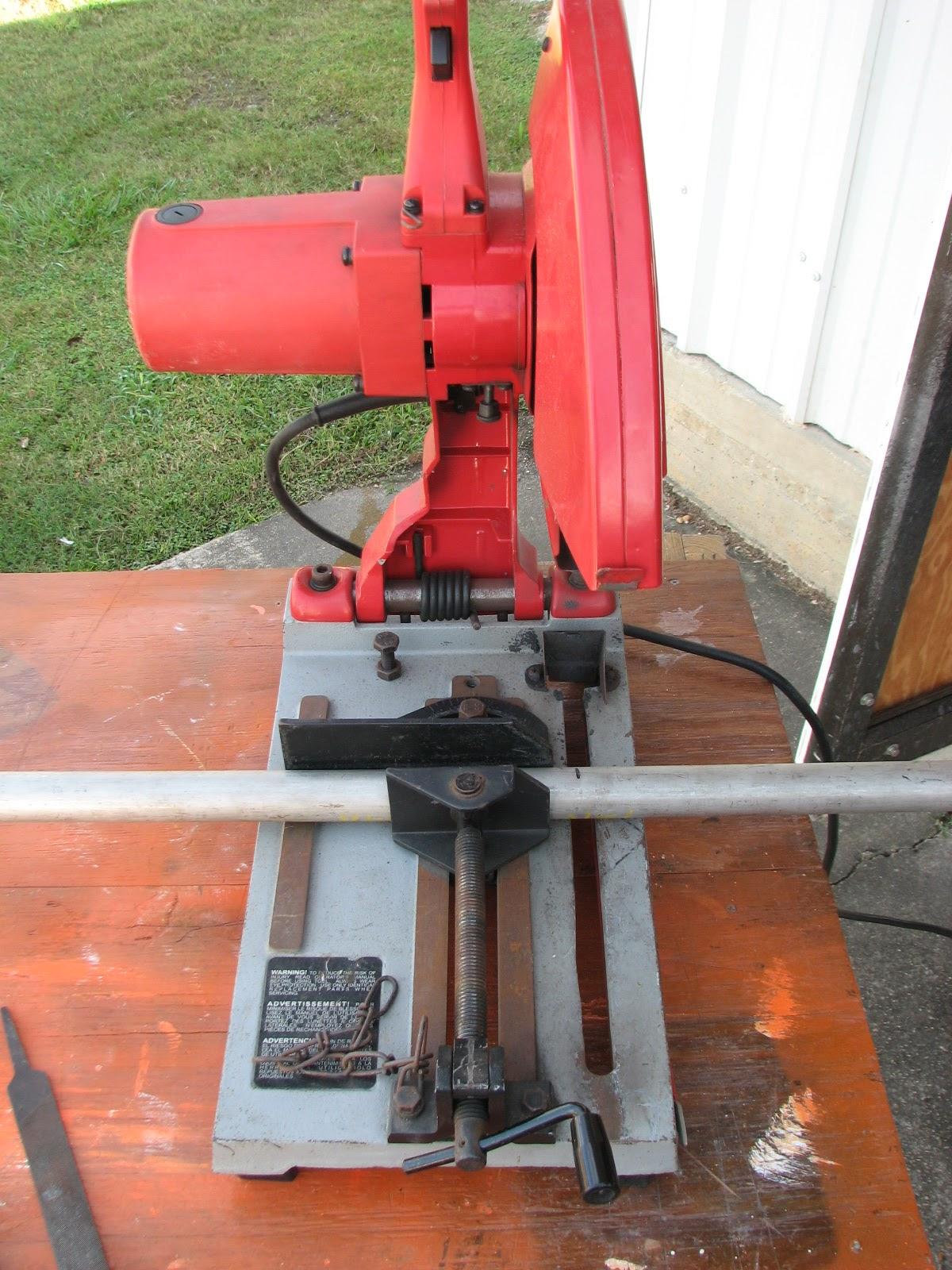

We rolled the table saw out of the shop

and onto the driveway where I cut four pieces of

fiberglass

2” wide and about 35” long. I used the new

Evolution

Rage III compound miter saw to trim the ends of the

cut fiberglass.

We loaded up the cut pieces of

fiberglass,

and the SeaScooter battery and went over to DREAM AWAY to have

breakfast. When we arrived on DREAM AWAY, I plugged the SeaScooter

battery into it’s charger.

After breakfast, Alan and I went out on

the eyebrow of DREAM AWAY and did the measurements and marking for

the base of the hard dodger. Sounds easy, but took a fair amount of

time to get in position and get the measurements made properly.

Starboard Side Measurement

Center And Port Side Measurement

With measurements in hand we went back

to the shop.

We rolled the table saw out of the shop

and onto the driveway. We did the measurements, set up the fence on

the table saw, and cut all of the fiberglass

pieces necessary for the hard dodger. There will be a couple of

additional fiberglass

pieces that will need to be cut, but I can not get accurate

measurements until the hard dodger is mostly together.

When all of the fiberglass

pieces were cut we cleaned up the saw, and all of the cut pieces. We

put the saw back into the shop and headed to DREAM AWAY for a shower

and an adult beverage.

Cutting The Pieces On The Table Saw

Cutting The Pieces On The Table Saw

October 13, Sunday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

This was another no DREAM AWAY project

day. Spent the morning working on the computer, and catching up on

financial stuff and scanning in paperwork.

Around noon Alan, Kitty and I went into

New

Iberia, and attended the Red,

White and Roux Gumbo cookoff. We had a great time and

ate a lot of good gumbo. Had an unusual gumbo from the team from

Saint Louis, a ham and pork gumbo. We headed back to DREAM AWAY, and

I got back on the computer.

October 12, Saturday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

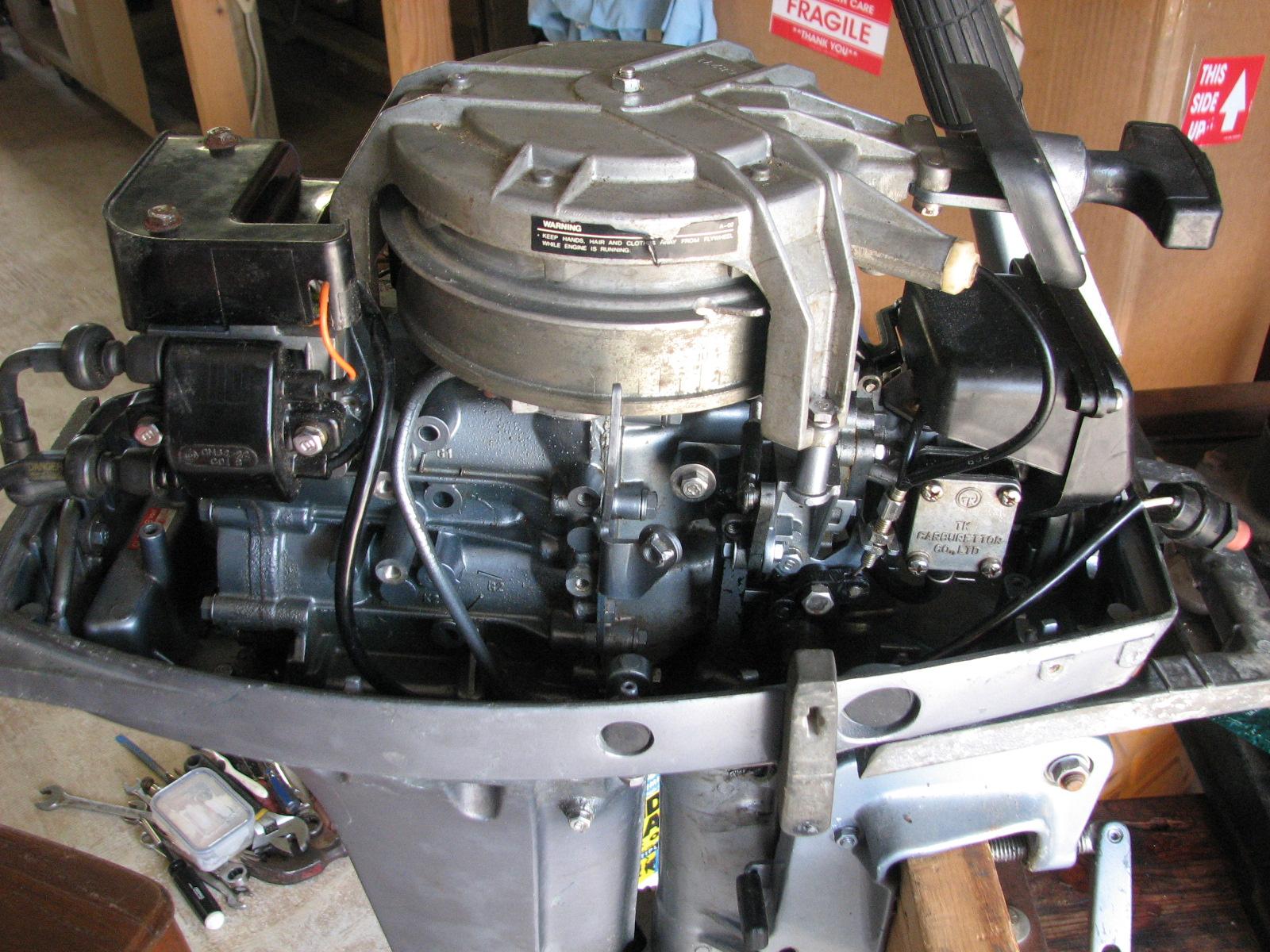

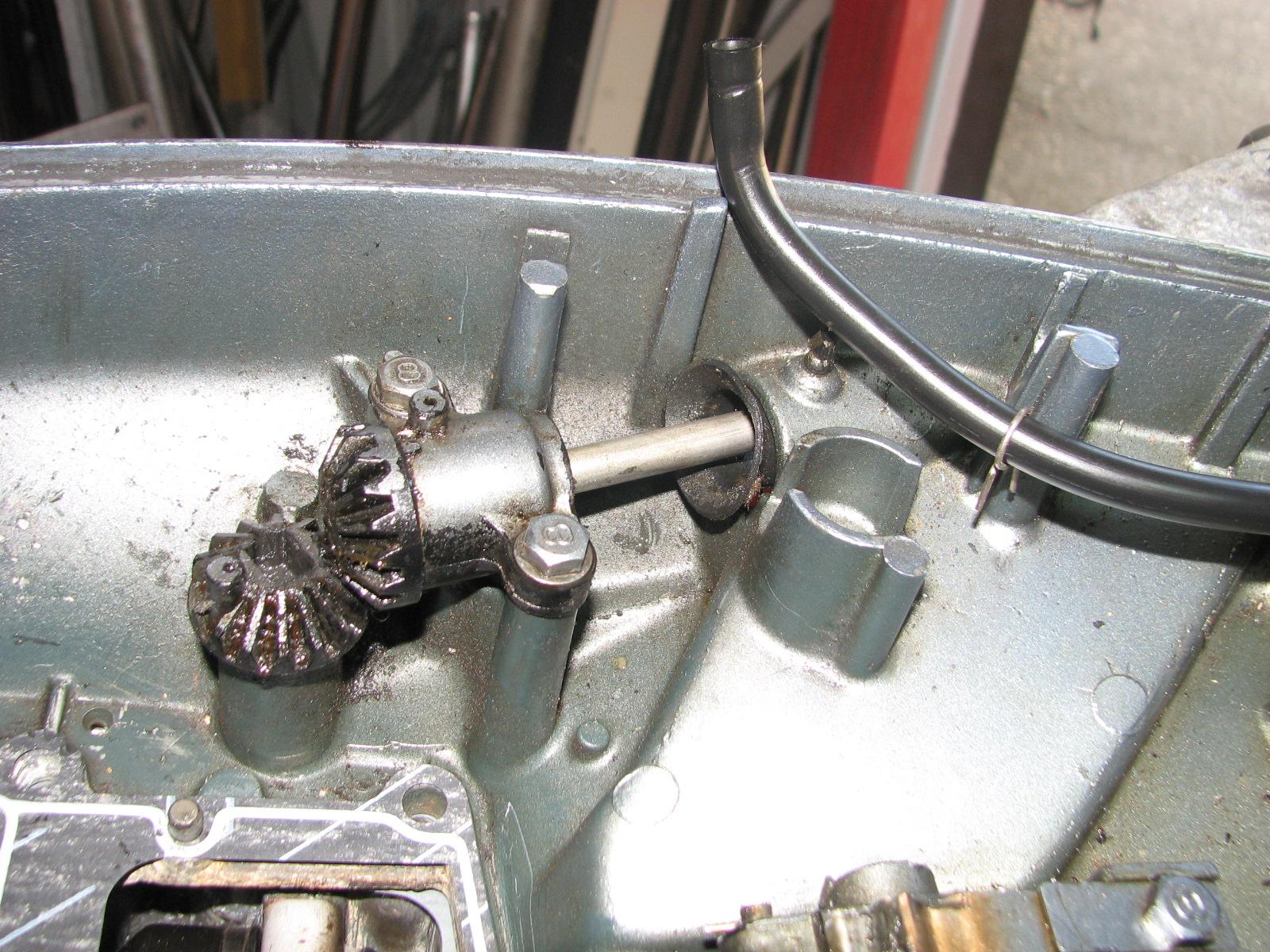

Went over to the shop

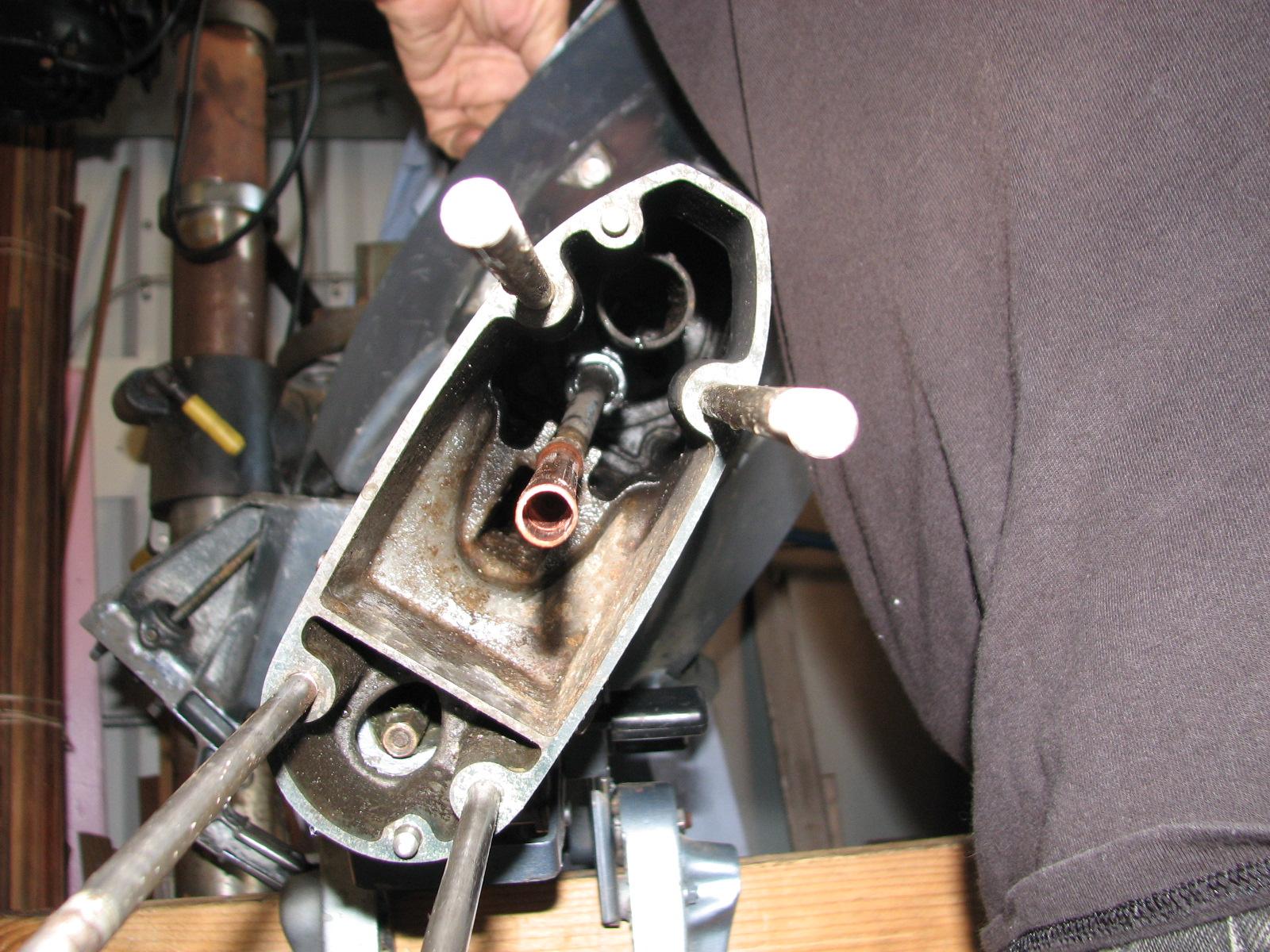

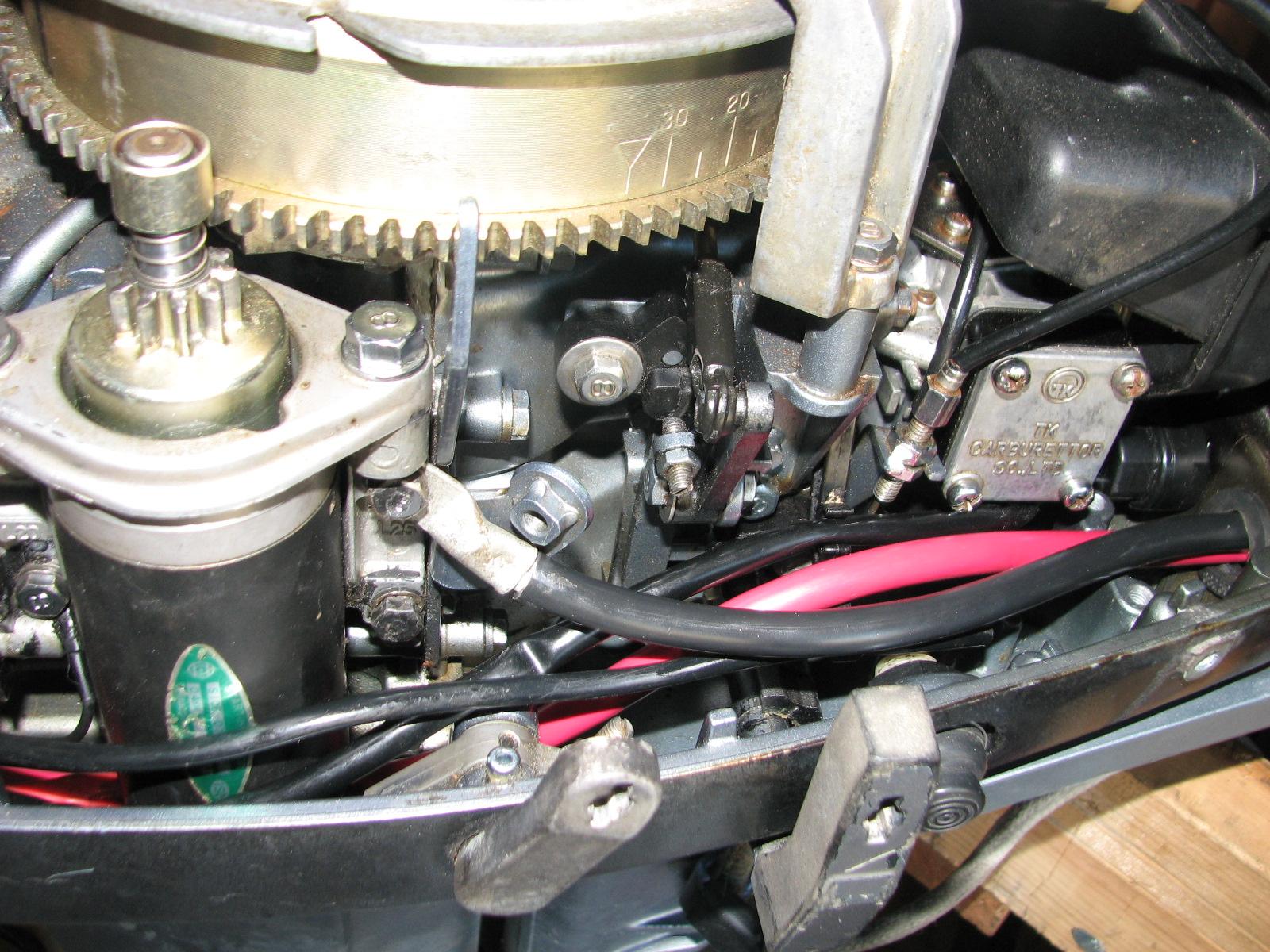

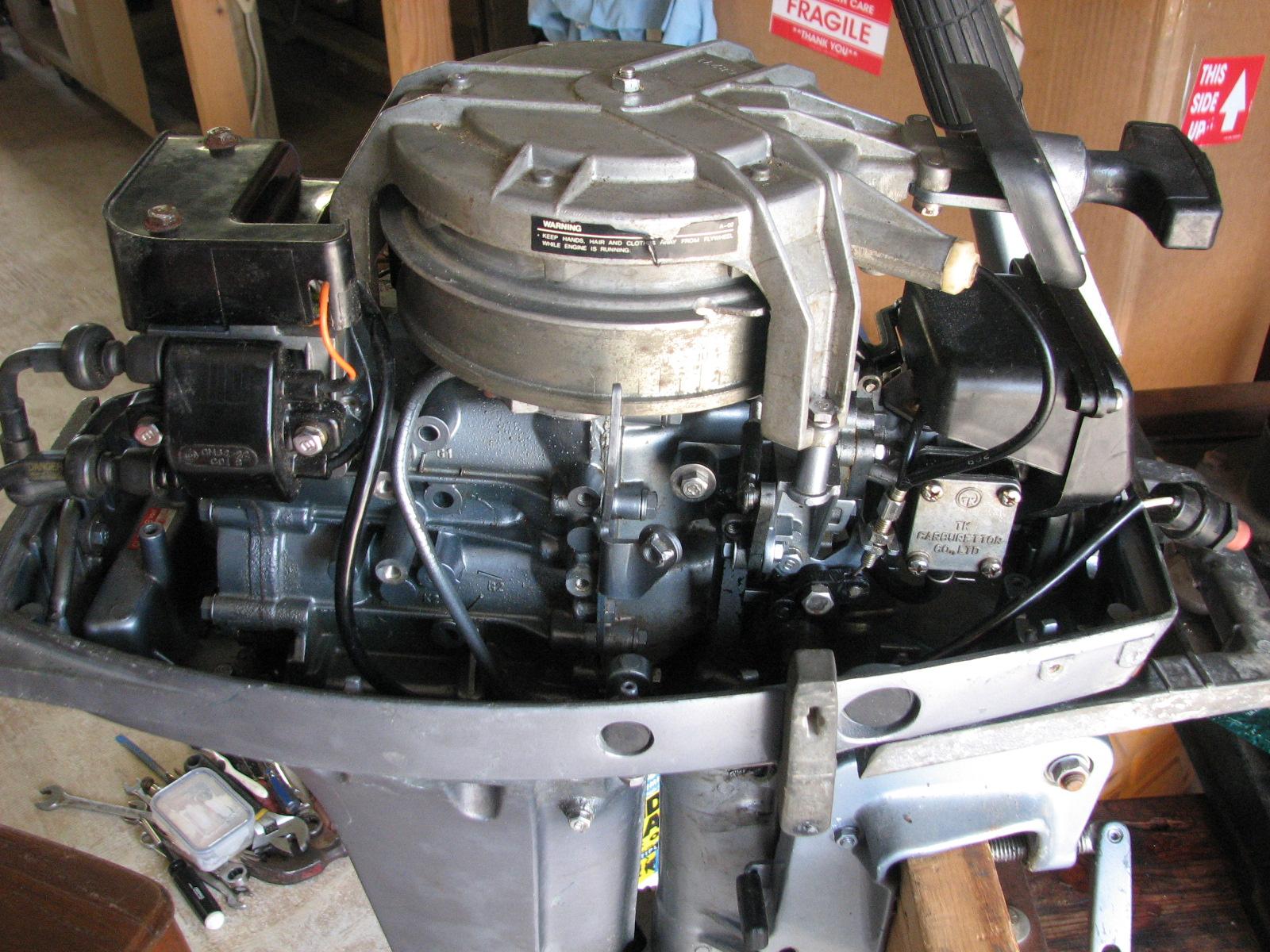

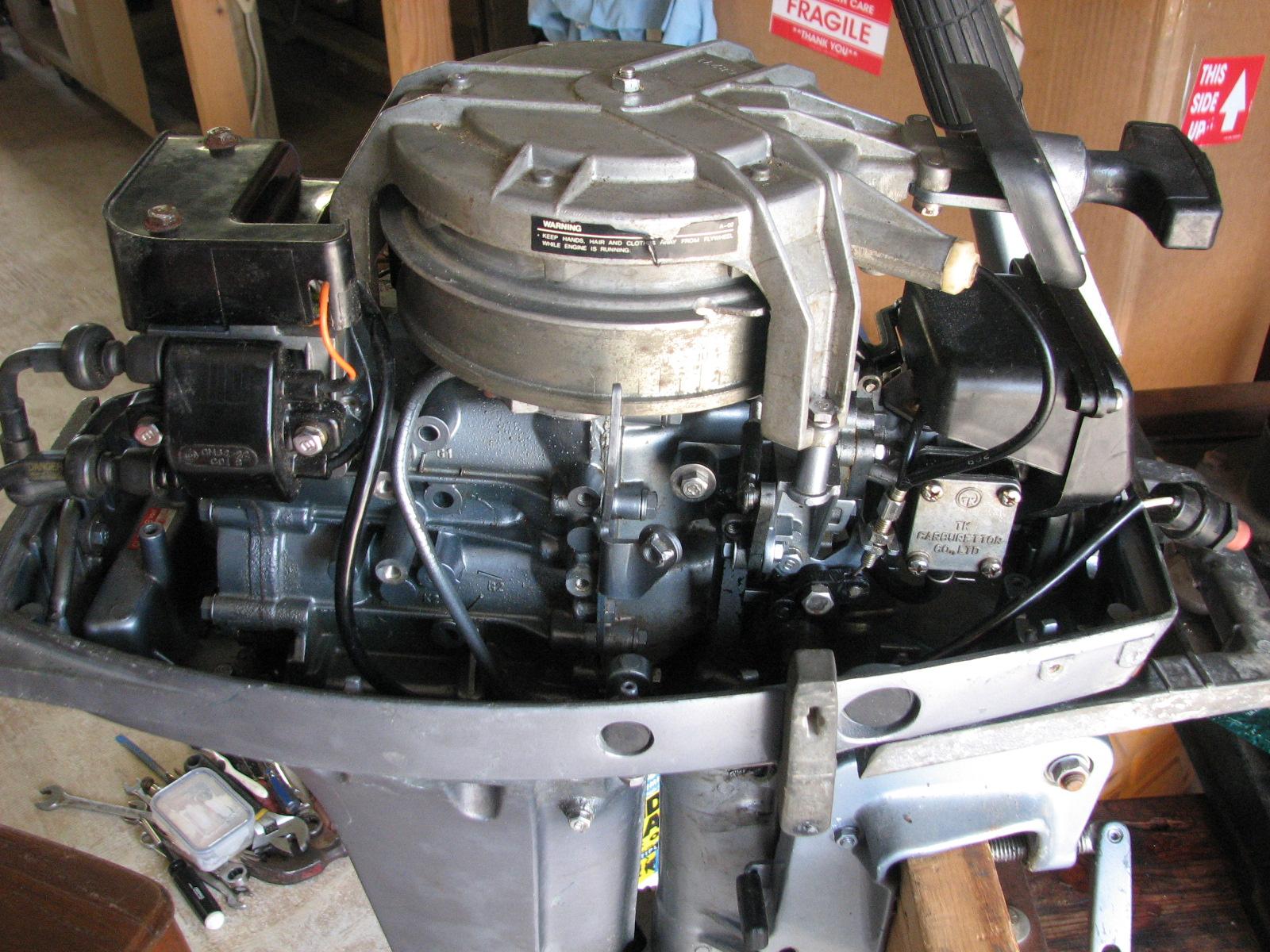

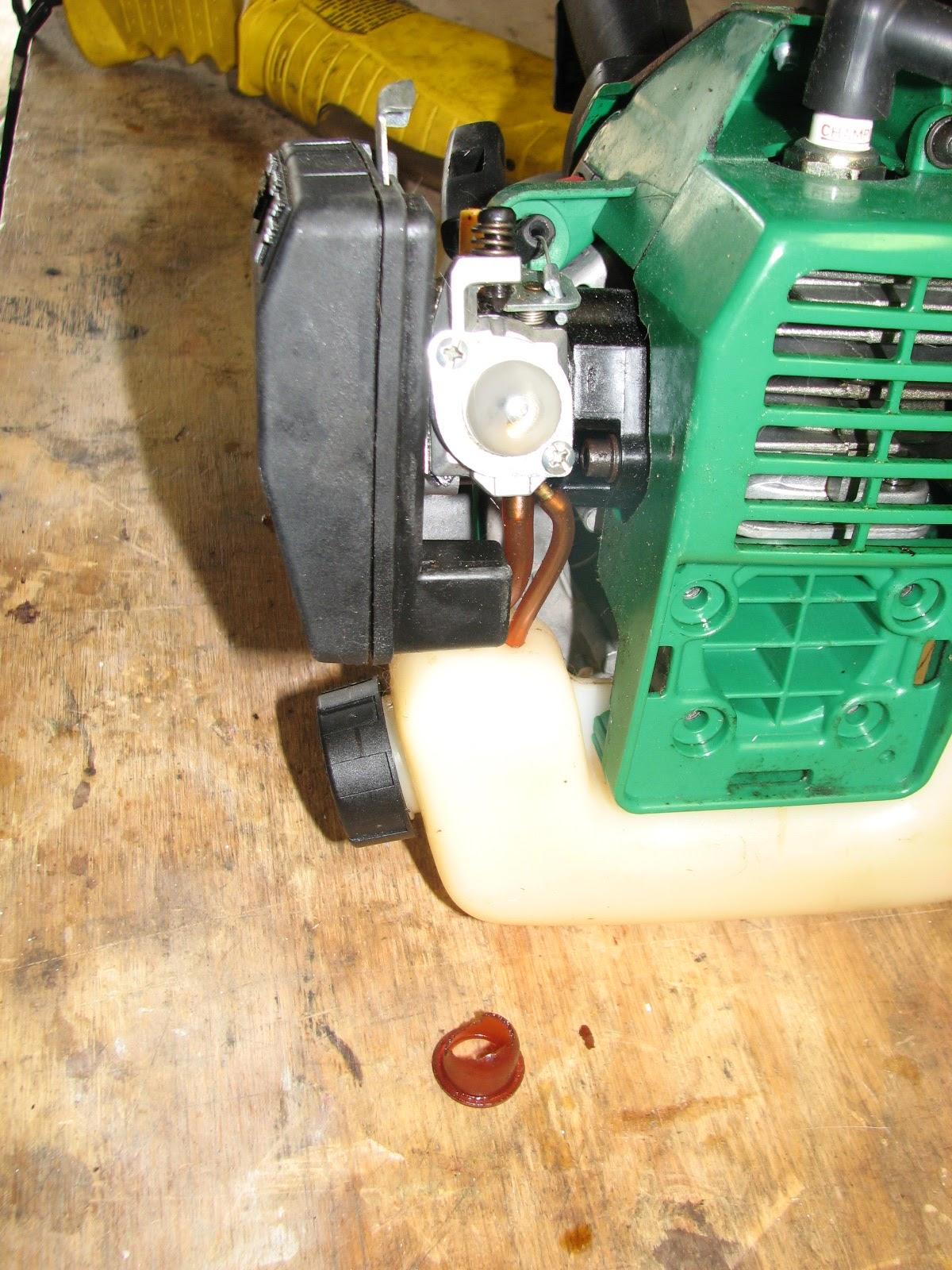

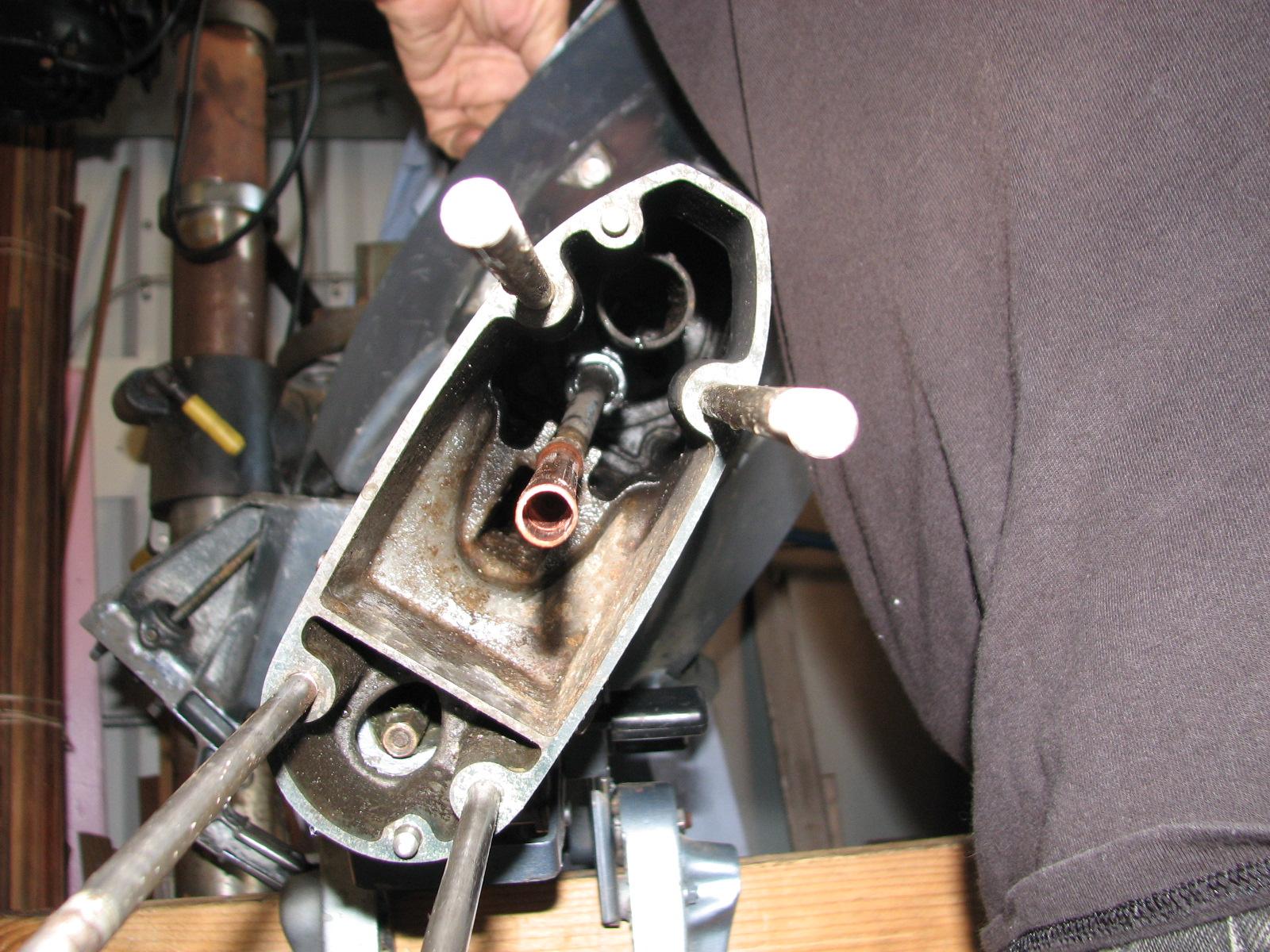

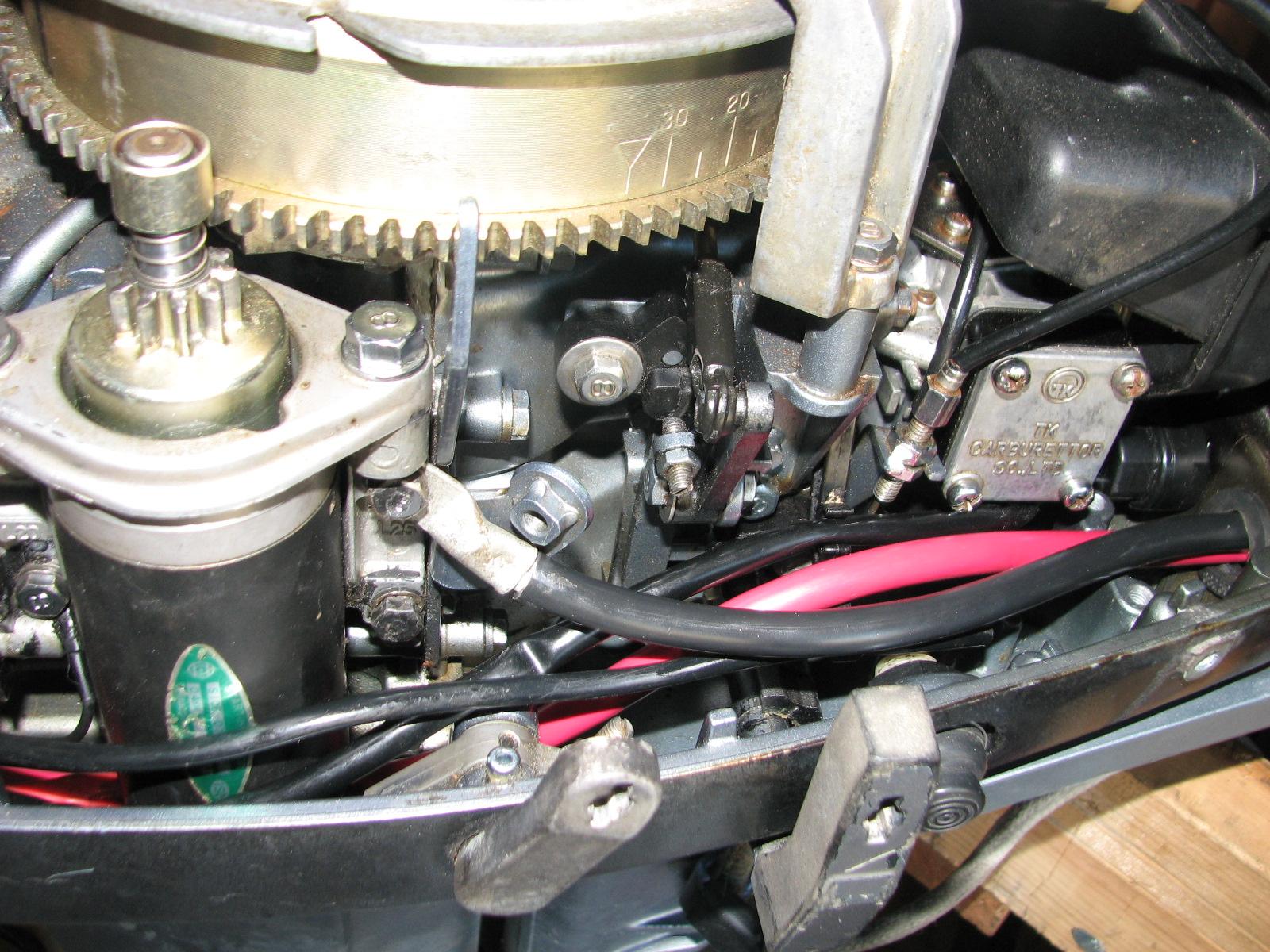

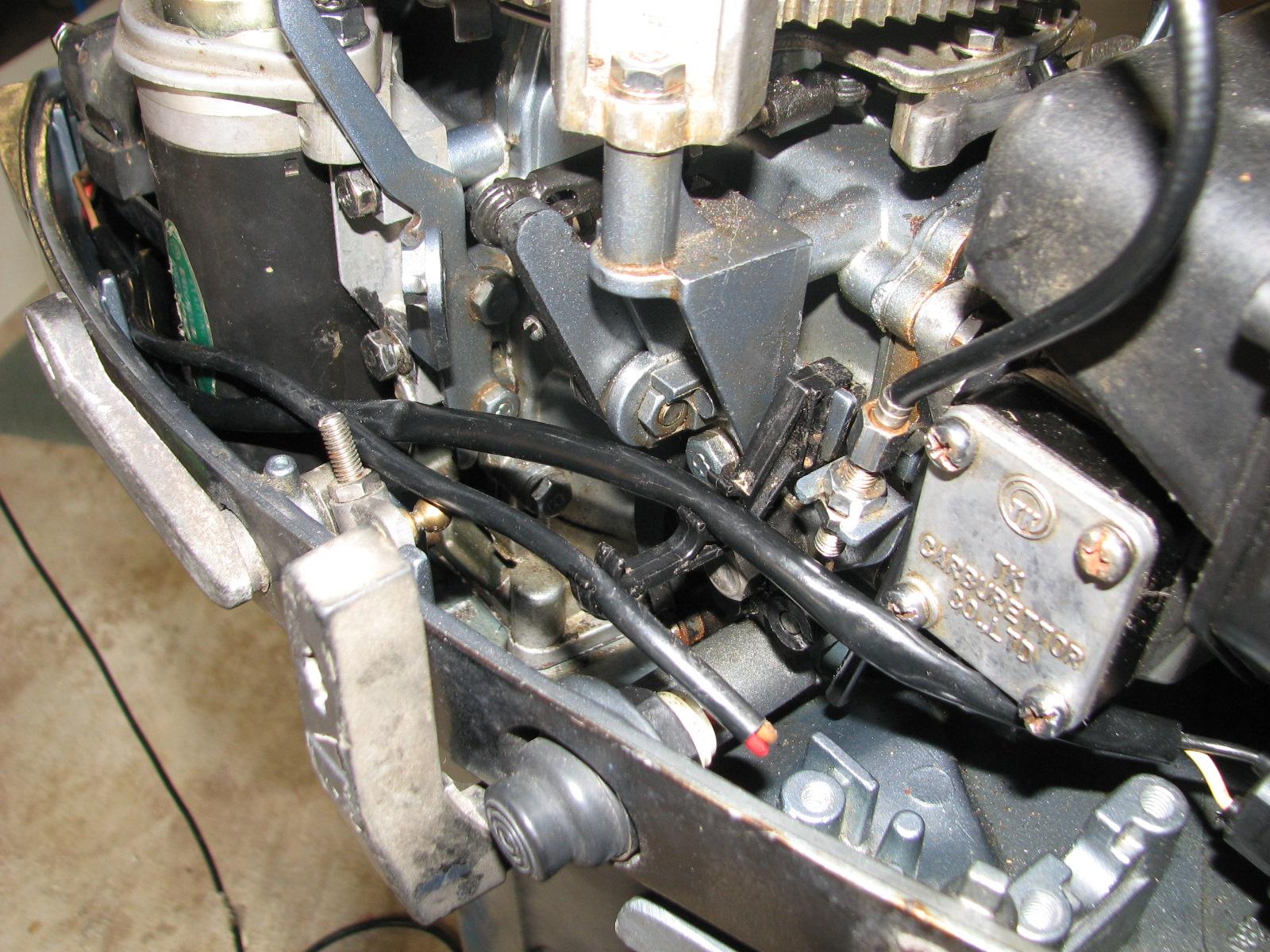

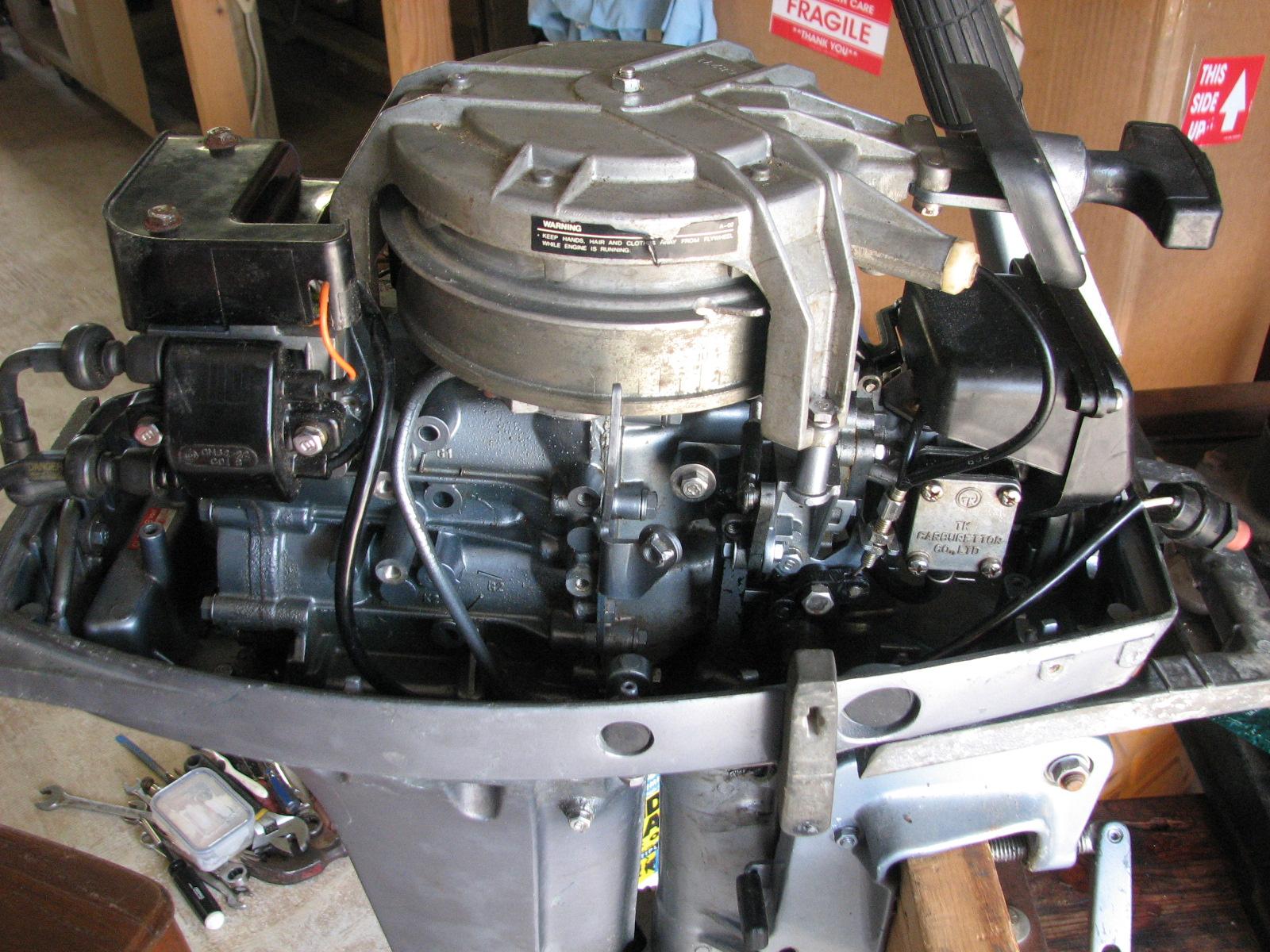

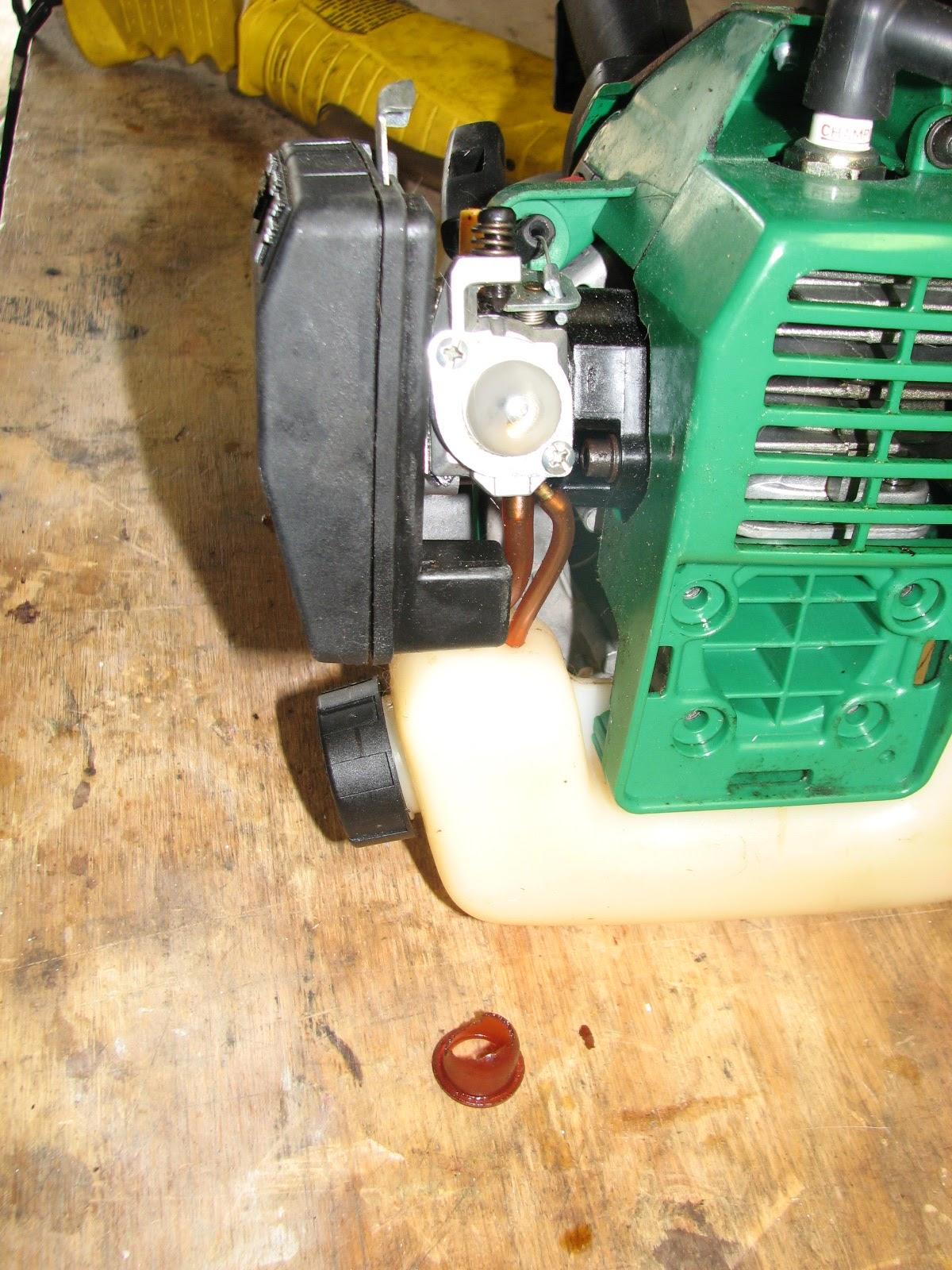

and started in on the spare outboard. We separated the lower

drive from the upper

casing to see if we could discover the problem. We

looked into the water tube and found the problem. The good news was I

had put together the two pieces with the water tube correctly, the

bad news was the water tube was clogged up with debris.

My plan was to fill one of the big

buckets i have in the shop

with water, and run the SeaScooter in the bucket to see how long it

would run. This plan was put on hold.

SeaScooter Ready For Water Test

Before I lugged the spare outboard back

to the marina,

we decided to use the bucket full of water to test the outboard. We

cleaned out the water tube, and put the lower

drive and the upper

casing back together. We started the engine on the

stand, and initially it pumped water, but then stopped again.

We took the cover off of the motor, and

disconnected the “P” tube. I used my air compressor, and blew out

the “P” tube. It was clean. We then blew back into the “P”

tube, through the engine. Bubbles appeared in our bucket of water,

then they quit! Now it was back to taking the

lower

drive and the

upper

casing back apart again. The water tube was clogged

with debris again.

Taking Spare Outboard Apart Again

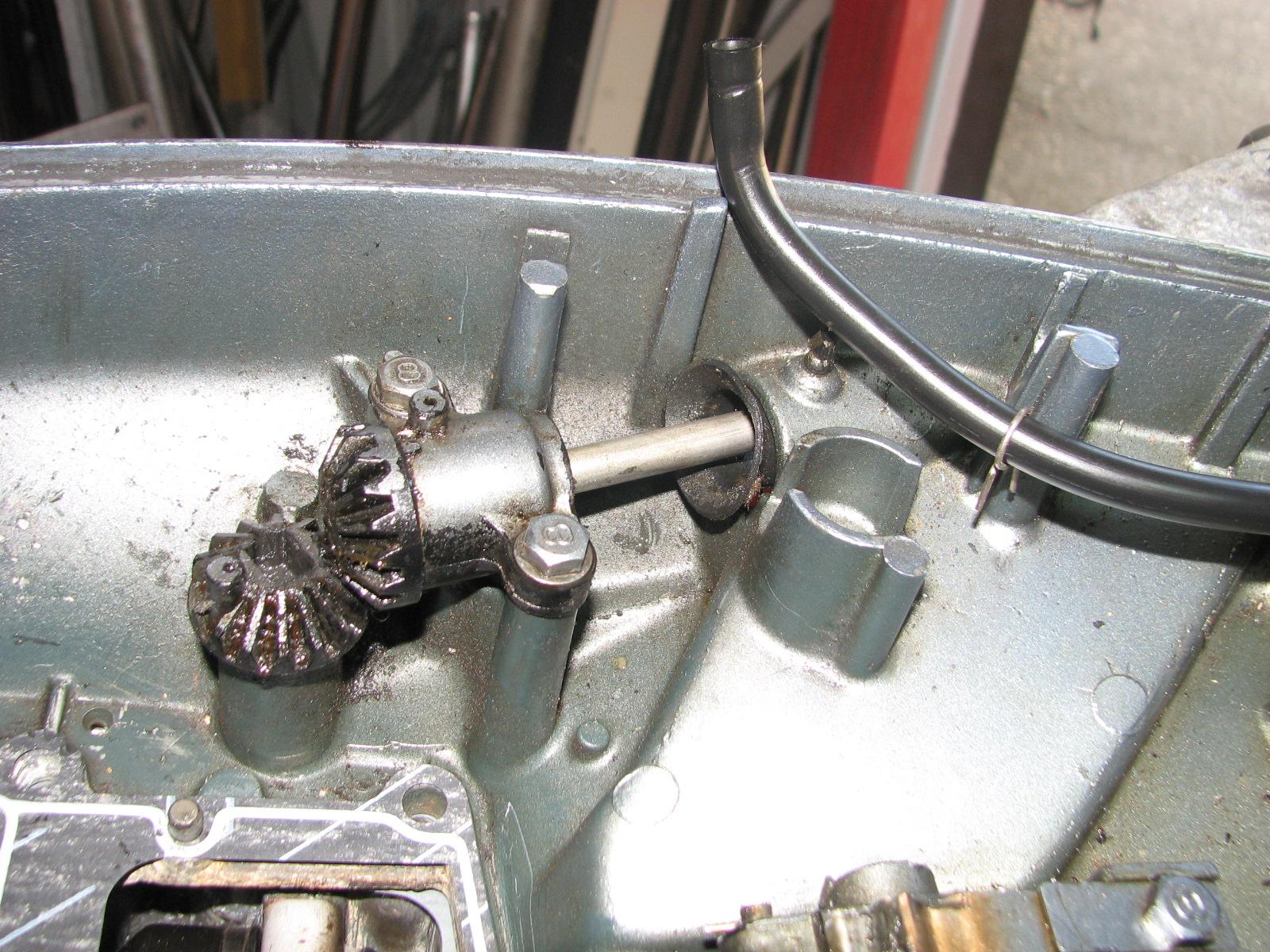

We took the water pump apart from the

lower

drive, and cleaned out all the surfaces and pathways.

We then put the pump back together, and reassembled the lower

drive. I also used the air from the air compressor to

blow out the water tube and up into the engine, and it was clear.

Checking All Water Passages

Looking Up Water Tube

We again put the lower

drive and the upper

casing back together. We started the engine and the

water pump was working this time. We ran the engine for about five

minutes, and it just kept pumping.

Now it was time to put the spare

outboard and the fuel tank into the Black Beast, and go back to the

marina.

We took the spare outboard down to the tender. We removed the main

engine, and put the spare engine on the tender. It started right up

after putting on the dead man key.

Outboard Exchange On Dock Next to

Tender

We drove down the bayou, and then got

it up on a plane. It was still pumping lots of fresh water, and was

running pretty good. It was not running perfect, but the spare engine

was running, that was the important news. I will have to take a look

at the plugs and the carburetor. We went back to the marina,

and changed out outboard engine again! The spare outboard off and

into the Black Beast, the main outboard back on the tender and all

locked on.

We took the spare outboard to

the shop.

I then applied the fifth coat of varnish to the

nav

station chair. We then went back to DREAM AWAY.

Alan and I got to work on the remainder

of the teak wood on the eyebrow. We removed the wood, then scraped

off all of the remaining putty and adhesive under the removed teak.

We then drilled out all of the screw holes with the counter sink, and

cleaned up the whole area with the vacuum.

I mixed up a batch of Marine-Tex,

and applied it to all of the area and hole we had cleaned out.

October 11, Friday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop

and realized I had pretty much finished up all of the projects I was

working on in the shop.

I still have to do some more testing of the SeaScooter, and I want to

do one more check on the spare air conditioner. I am going to have to

get a couple of projects going in the shop.

I did do some preventative maintenance

on the Black Beast. I checked all of the fluids, and applied a coat

of Rain-X

on all of the windows.

I loaded up the electric start outboard

motor, battery, and the backing plate cover for the head, and went

back to DREAM AWAY.

Kitty had breakfast ready, so we had a

nice breakfast, and then I installed the backing plate cover for the

head. Now we are waiting for the Structoglas

to come in so we can finish off the head.

Backing Plate Cover Installed In the

Head

The tender was pretty much finished, so

I slid it into the water, and tied it off to the dock. I installed

the battery into the new battery box, and then I put the outboard

motor on the tender. I connected the new battery cables from the

motor to the battery.

I wanted to check to see if the

rectifier

I had installed on the motor was working. I checked the voltage on

the battery with my DVM.

I primed the carburetor with fuel, and just for grins, I tried one

pull on the manual starter, and it started right up! It’s great to

have a Yamaha.

I checked the battery again with the

DVM,

and the voltage was higher than the first check. I increased the

RPM’s of the engine, and the voltage climbed, so the

rectifier

is working. Now I know the battery will be charged when the engine is

running. I shut the engine down, and then started it with the

electric start, and it started right up, again. This was sweet.

Tender Ready With Outboard And Battery

Installed

I got Kitty into the tender, and

explained how to start the engine, since it was her electric start,

and she started the engine. She backed us out of the

marina,

and we went down the Delcambre

Canal. Kitty loved driving the tender using “her”

outboard.

Kitty At The Helm

I took over at the helm, and we went

further down the Delcambre

Canal. I opened up the engine, and got the tender on a

plane with us both in the tender. I turned around, and went back to

the marina.

Now that the main outboard engine and

electrical systems were running with the tender, it was time to test

the finished spare outboard engine.

I went over to the shop

and loaded up the spare outboard, manual bilge pump, and the oars in

the Black Beast. Back to the marina,

and brought all of the stuff down to the tender. I removed the main

outboard and installed the spare outboard on the tender. I also

installed the oars and the manual bilge pump. I was ready for the

next trip.

The spare Yamaha

outboard started after two pulls, so that was good. The problem was

there was no water coming out of the Pee tube. This means I did not

put the

upper

casing and lower

drive together properly. I probably did not mate the

water pump tube correctly, although I made a big effort to do so.

I pulled the spare outboard off of the

tender, and put the main outboard back on the tender. I loaded the

spare outboard back into the Black Beast, and took it over to the

shop.

I came back to DREAM AWAY, took a

shower, and then we headed to New

Iberia. We had some grocery shopping to do, then we

went to the train station to pick up our friend Alan, coming for a

visit from Houston.

After getting Alan, we stopped at a Chinese buffet in New

Iberia, and hurt ourselves, but it was very good

eating. Then it was back home to DREAM AWAY.

October 10, Thursday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Did not go over to the shop

this morning, but stayed on DREAM AWAY, and did computer work. I go a

DREAM AWAY update out that included the September Maintenance Log. I

also worked on emails.

We had to drive into

Lafayette

as I had an appointment with my cardiologist for a stress test. I

completed the test, and then we drove back to Delcambre.

When we returned, I got back onto my computer, and started in on

emails. before I quit for the evening, I was down to 30 emails.

October 09, Wednesday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

Went over to the shop

this morning and started in on the carriage bolt I received that had

to be modified for my use on the backstay

fitting. There were not enough threads on the bolt for

me to use, so my modifications will make the bolt into a pin.

The first item on the list was to make

a square hole out of a round hole for the carriage bolt head to fit

into. For this task I used metal files and the stainless steel saw

blade for my Sabre

Saw. The saw did the major work, and I finished up

with the files.

I then cut the bolt, making it a pin to

the proper length using my chop

saw. When I verified the length and fit of the pin, I

drilled a hole through the pin, using my drill

press, for the cotter

pin to hold the pin into the backstay

fitting. When all was finished, I polished the head of

the pin so it would not rub on the main sail halyard.

Left the shop,

and went to the marina.

I unloaded the outboard engine, and the “Box

O’ Resins”, and took them down to the tender on

the dock beside DREAM AWAY.

I needed to finish the battery cables

from the outboard engine to the new battery box. I put the outboard

engine on the tender, and ran the wires. I measured the wires, cut to

the proper length, and put on the terminal ends. I put shrink tubing

on the cable ends in the battery box. I removed the negative cable

from its location on the outboard motor, and installed a piece of

shrink tubing on it, and then reinstalled the negative cable. The

positive cable on the outboard motor, already had a protective cover.

That finished the battery cable project on the outboard motor.

Battery Cables Running From Outboard To

Battery Box

Cables Running To Outboard Moto.

I sanded the hole I cut in the battery

box, and the areas where I fiberglassed

the battery box and fuel tank gratings to the deck of the tender.

After sanding the areas, I cleaned the areas and made them ready for

the gelcoat

application. I wanted to make the installation of the battery box and

fuel take gratings look finished.

I then mixed up a small batch of

gelcoat,

and applied it to the battery box hole and areas attaching the box to

the deck, and the same with the fuel tank gratings. Now we wait for

the gelcoat

to set up, and we are done with that project.

Fuel Tank Gratings Before Gelcoat

Application

Fuel Tank Gratings After Gelcoat

Application

Battery Box Gratings After Gelcoat

Application

Last item for the day, and one of my

favorites, going up the main mast. I was not comfortable have the

backstays

down for over a week. I know there was no way the mast could fall

over, it still made me uncomfortable.

Kitty was to stay on deck, as my

helper, and I went up the mast. No trouble going up, just watching

for wasps, and spraying them as I climbed up the mast. At the top

there was quite a few of them, but they were encouraged to depart.

Now it was back down the mast, and get

everything put back as it was. I attached both backstays

to their respective chain

plates. I put all of the lifts and halyards

back in place, the awnings back in place and the boson’s

chair away.

I took the Black Beast over to the

shop,

and unloaded all of the tools, the “Box

O’ Resins”, clothes and books. Came back to DREAM

AWAY, took a shower and got ready to go to the New Iberia Public

Library for a class on Tapas,

and accompanying wines. Kitty and I really enjoyed the class.

October 08, Tuesday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the Shrimp

Festival Pavillion and packed up all of the Delcambre

Seafood and Farmers Market tents, tables, and chairs.

We had left the items at the Pavillion to dry out on Saturday.

Everything was dry, so Tammy and I loaded all of the stuff into our

vehicles, and took it all over to the Port

of Delcambre’s storage room. We unloaded both

vehicles, and I loaded the lawn mower and fuel can into the Black

Beast.

I then went over to the marina.

I finished trimming the grass around the gardens and lawn, and then

cut the grass. When finished we had lunch, and then I took the lawn

mower back to the Port

of Delcambre’s storage room, then I went to the

shop.

The seven inch carriage bolt I had

ordered had arrived. I checked it out against the hex bolt it is

replacing, and I will need to do several adjustments to make the

carriage bolt work on the backstay

fitting.

I had the terminals necessary to

fabricate the battery wires for the outboard engine. In the positive

terminal, I had to add two wires in addition to the battery wire. One

wire to power the start switch, and one wire from the rectifier.

This was done successfully, and I also fabricated the negative

terminal. When the terminals were fabricated I installed them onto

the outboard motor.

Positive Battery Cable Bolted to

Started

Negative Battery Cable Bolted To Engin.

I then applied the fourth coat of

varnish to the

nav

station chair and the fifth coat on the backing plate

cover for the head.

I loaded up my “Box

O’ Resins”, and the outboard engine into the Black

Beast, and went back to the

marina.

I was going to put the outboard motor

on the tender, and cut the new battery cables to size, and also apply

a coat of gelcoat

to the hole I cut in the battery box, and to cover the fiberglass

I used to attach the battery box and fuel can gratings to the tender

deck.

When I got on DREAM AWAY, I was so

tired, I could do one thing more. I took a shower, had dinner and was

in bed very early. I realized the problem was the drugs I took to

combat my fall allergies.

October 07, Monday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Spent some extra time catching up on

emails, but had an emergency come up at the

marina.

The oldest boat we have at the marina

had sunk! This boat is a wooden boat built in 1915 as a Maine lobster

boat.

The owner of the boat arrived and asked

me to watch over the process of raising the boat and see that it got

to the GEO

Shipyard in the Port

of Iberia. The owner had hired LeBlanc

Marine to raise the boat, and they would then tow the

boat to the Port of Iberia.

By 1530, the boat had been raised, and

was on it’s way. I do hope all works out with the boat, and we will

see it again at the marina

in a couple of months.

Boat Underwater

Boat Mostly Raised And Floating

I then got started on a project on pier

“C”, to try and keep the seagulls off of the pier. Who knows if

it will work, but it is worth a try. Right now it is some streamers

hanging from a cross of scrap aluminum I had in the shop. If the

streamers do not work, I will try old CD’s and DVD’s.

Streamers From Aluminum Cross And Pier

“C"

The remainder of the day was spent

cleaning out the gardens and trimming grass in preparation of cutting

the grass tomorrow. I did not finish the trimming, so will have more

to do tomorrow.

October 06, Sunday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Today was an electronics catch up day.

I have to catch up the October Maintenance Log. I also have to catch

up on web page update, email and paper work scanning. Did not make

it!.

I got the October Maintenance log

caught up, but at 2013 in the evening I am just starting on the email

of which there are 131 messages! Before stopping for the night, I got

the emails down to 99. Will do more catch up tomorrow.

October 05, Saturday, 2013

Up and at ‘em at 0430. While making

my pot of coffee, I checked the weather on the Internet. When the

coffee was finished, I filled my big “Aggie” cup and walked over

to the Shrimp

Festival Grounds at 0515. My job was to help direct

traffic for the Delcambre

Seafood and Farmers Market. It was forecast for a 60%

chance of rain, and the morning set up and start of the market was

beautiful. The first spattering of rain did not show until 103

Kitty showed up at 0730, and worked the

registration booth at the market as a volunteer until 1000. She had

to leave because she was overheated. I worked the market in the

registration booth after Kitty left, and then at the end of the

market at 1300, I helped shutdown, and put away tents, tables and

chairs. I went back to DREAM AWAY, around 1430 where Kitty had a

great lunch prepared. We then had a nap, and I finished out the day

with computer work and catch up. No DREAM AWAY projects today.

October 04, Friday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Kitty was up early, so we had

breakfast, and I got to work removing the teak trim wood on the

starboard side to prepare the deck for the hard dodger frame.

Once I got several screws removed, I

was able to lift off the teak wood. Then the area where the teak wood

was had to be cleaned up and sanded smooth. I then counter sunk each

of the screw holes, and then vacuumed the area. Next I mixed up a

batch of white Marine-Tex,

and then applied it to the deck to fill in all of the counter sunk

holes.

Removing Teak Trim On Eyebrorw.

Counter Sunk Holes On Eyebrow

Did some weeding in the marina

gardens, and trimming around the gardens.

When I got there, I realized I did not

bring the proper connectors for the battery cables, so could not

finish the wires.

I did realize I had the tender spreader

bars in the shop

and would be needing them soon, so I cleaned them up and got them

ready for use.

Cleaned Spreader Bar On Work Bench

I did work on some other electrical

issues on the outboard motor. I moved some wires around to a loom so

the start switch wire and the kill switch wire were out of the way of

things.

Wires And Loom On Outboard

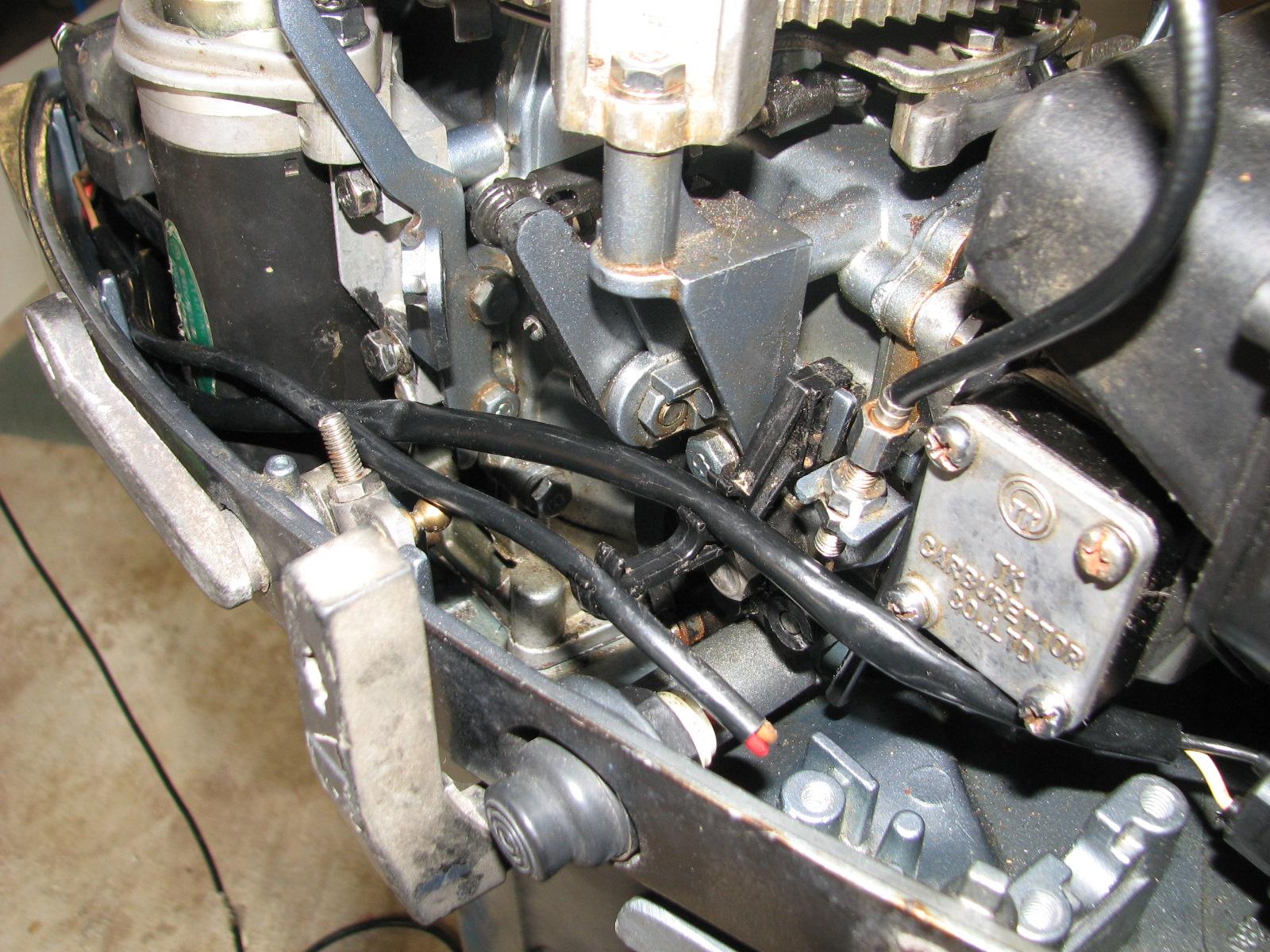

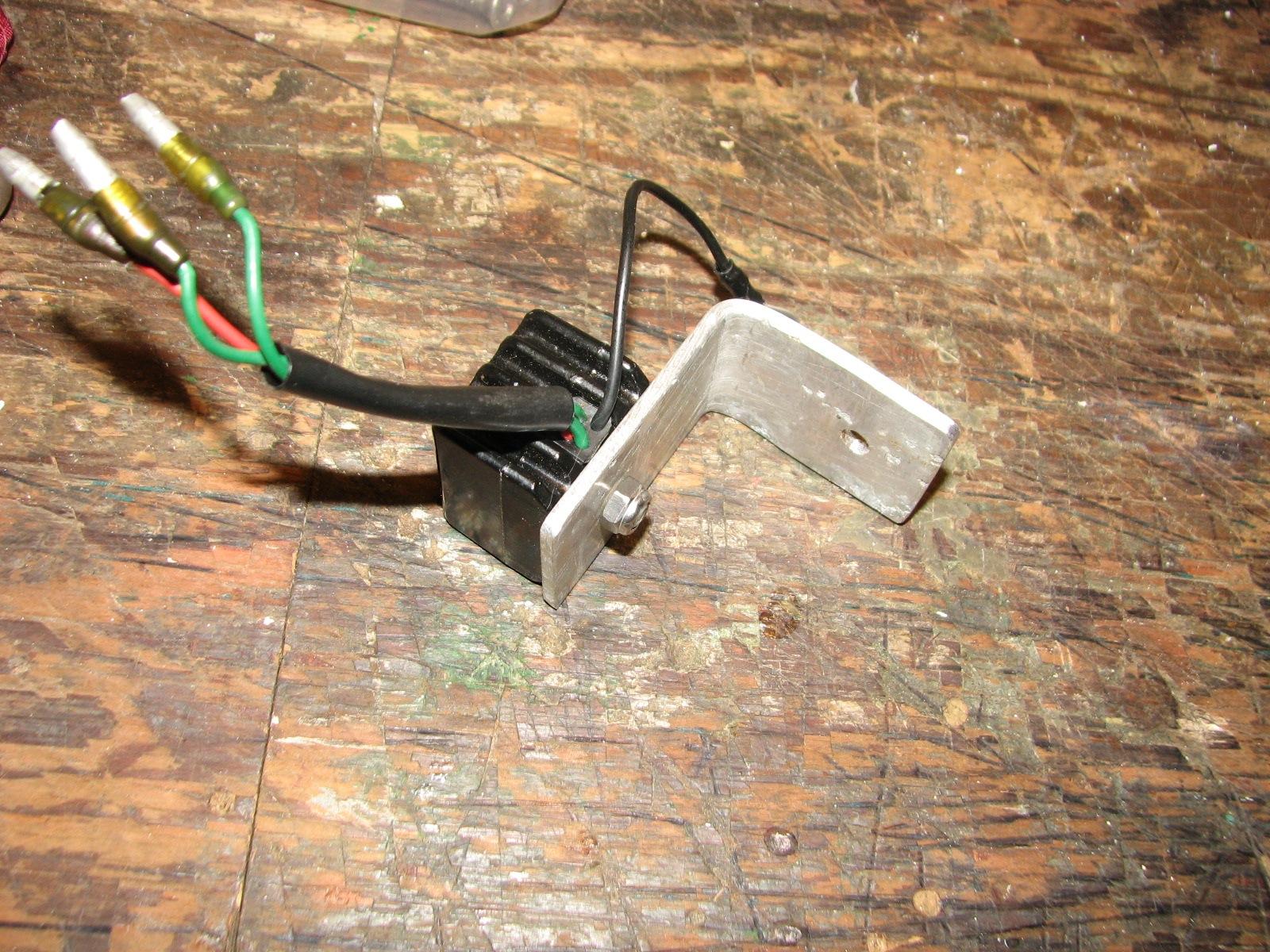

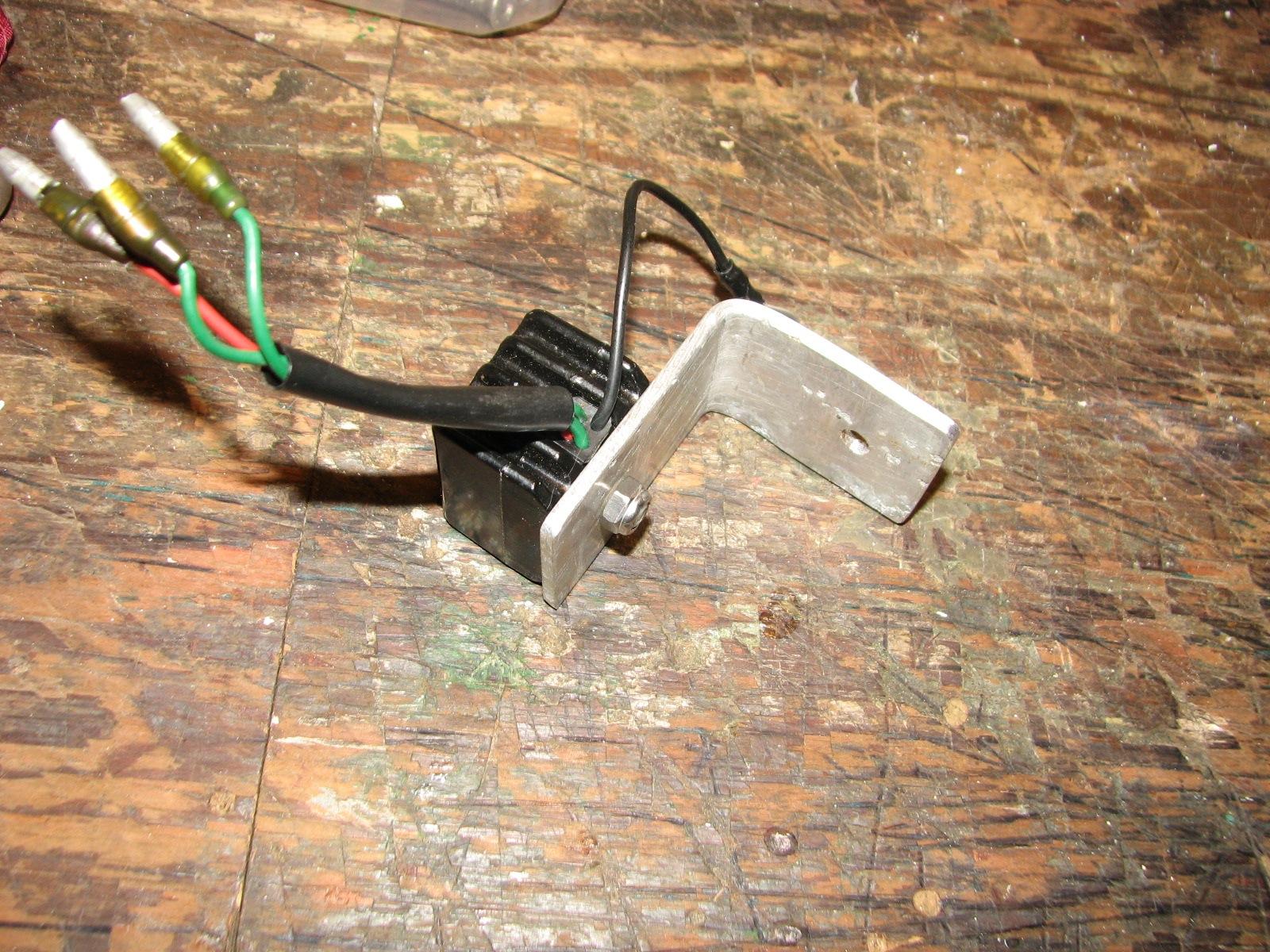

I came across a wiring diagram for the

rectifier

in my Yamaha

after market shop manual. According to the diagram, I would be able

to connect the rectifier

into the electrical system without the big wiring harness provided

with the electric start option I purchased.

The only problem was how to attach the

rectifier

to the motor. I finally figured a way, so I fabricated a small piece

of aluminum to attach the rectifier

to, and then attach the aluminum piece to the terminal

cover.

It should all work, once I get the

battery cables made up with an extra wire on the positive connection

to power the rectifier.

I brought the rectifier

and the aluminum piece over to DREAM AWAY to get the proper bolt and

nut to attach the rectifier

to the aluminum piece. I got the fasteners, so when I go back to the

shop

with the rectifier,

and the proper battery connectors, I should be able to get it all

connected up.

October 03, Thursday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop

and worked on the Black Beast. There were several items that needed

attending to, that had been put off.

I repaired the covering on the console.

It was pretty easy to do, as all it needed was a coating of contact

cement, and wait approximately 10 minutes, and then put the piece

back on the center console.

While I waited for the contact cement

to set, I took the the right side rear door apart. There was

something loose in the door, and needed to be investigated.

Everything on the door worked, so did not know what to expect. When I

got into the door, I found a one inch square of metal, but had no

idea where it came from. Removed the piece of metal, and put the door

back together.

When that was done the contact cement

had set up, so I applied the piece of material to the console. Now I

had two Black Beast projects complete.

Now to the right side back door.

Sometimes the door would not open from the inside, and there was

something loose inside that door. I took that door apart and

discovered a piece of the locking mechanism that is riveted to the

door was loose. One of the rivets was broken, and the second rivey

was very loose. I did not have my rivet gun nor my rivets at the

shop,

so I would have to wait until I got those two items off of DREAM

AWAY.

Last item for the morning was to

completely clean out the rubber channels around all of the doors. I

have mentioned before that I had some serious leaks around the front

two door, and also the two barn doors in the back. I finally figured

out what the problem was.

Apparently this truck had been parked

under some very dirty trees by the previous owner. The rubber

channels were blocked with dirt. I cleaned out the channels, but not

a great job. The leaks had been stopped, but I knew if I did not

completely clean out the channels, the problem might return. So the

channels were cleaned out around all six doors.

I then went back to DREAM AWAY and had

breakfast. I then drilled a hole in the tender battery box for the

electric wires to exit. I also found in my wire stash on board two #4

AWG black and red wires to use for the new battery cables for the

electric start outboard motor.

Got the rivet gun, rivets, electric

battery cables, and the outboard safety wire and went back to the

shop.

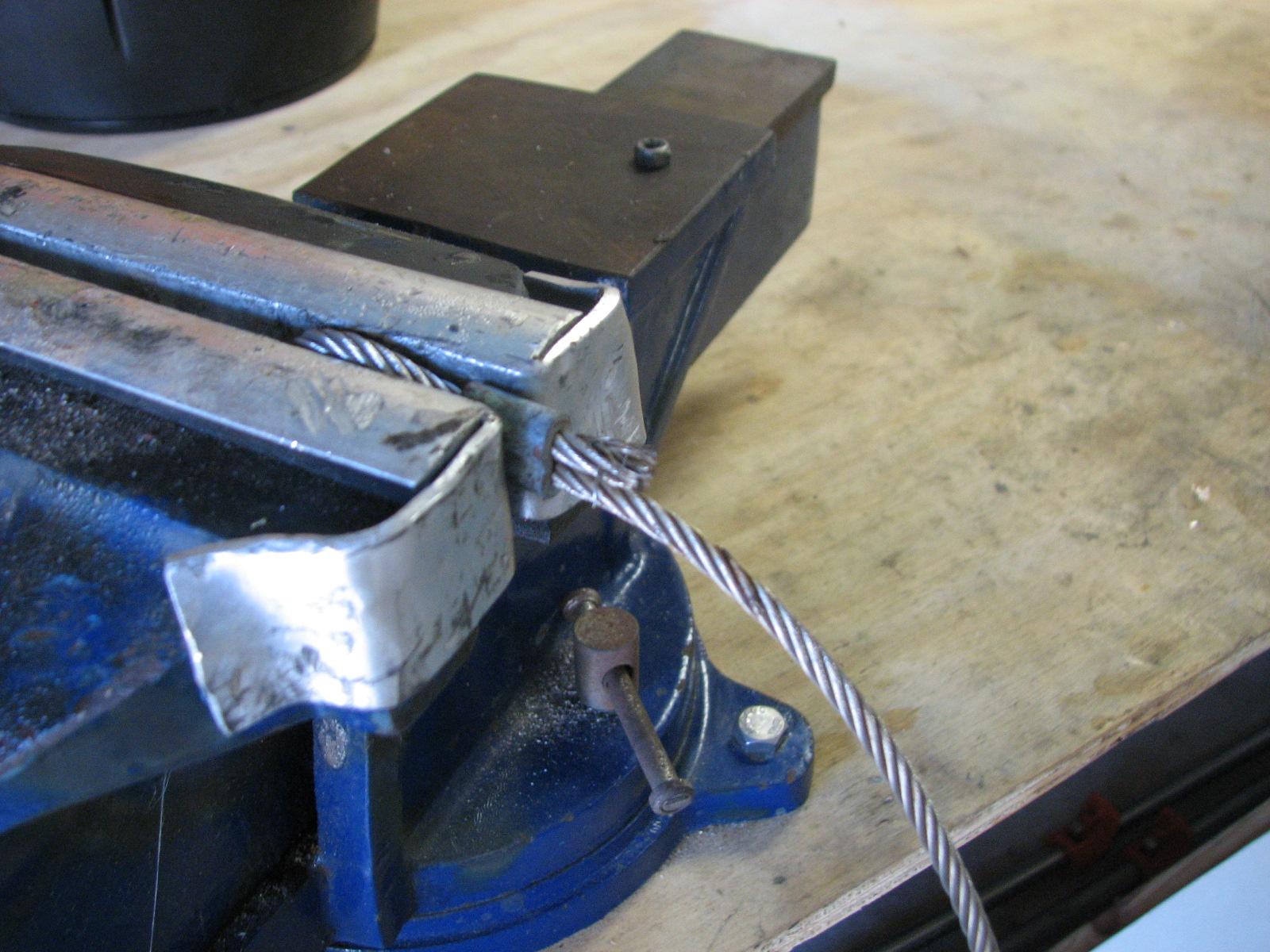

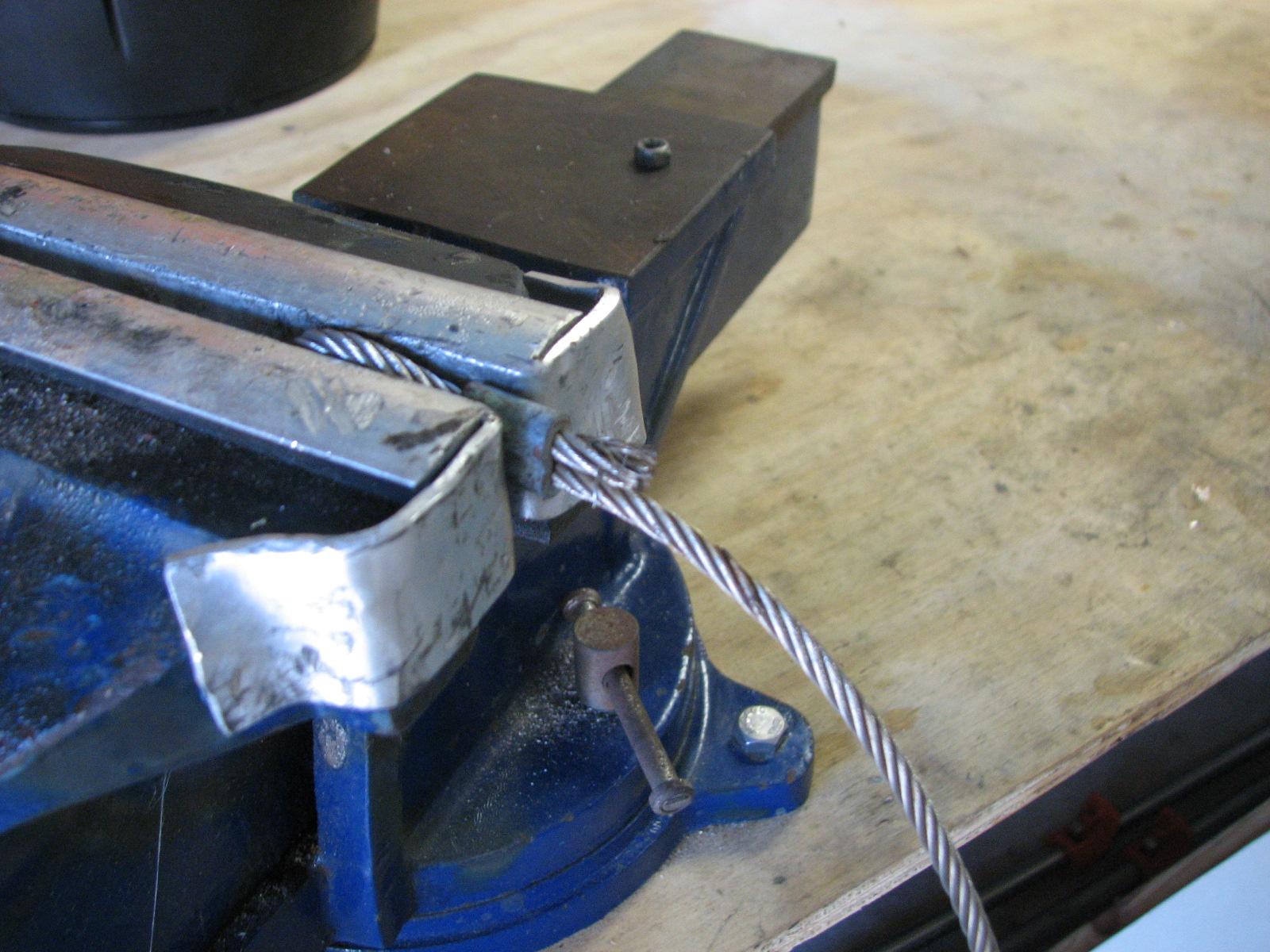

First thing to was to repair the

outboard safety wire. this wire is used to lock the outboards to the

lifeline when not on the tender ot dinghy. The problem with the wire

was left over wire from the Nicopress

sleeve. Those remaining wires have always been a problem, but I never

fixed the problem, so now was the time. I cut off the wires even with

the sleeve.

Wires Sticking Out Of Sleeve

Wires Removed

I then went to work on the right side

passenger door. I drilled out the broken rivet, and put in a new

rivet. I then drilled out the loose rivet and replaced it. Now the

door worked properly from inside the truck. I put the door back

together, and that was finished.

The remaining Black Beast project for

the day was repairing the two reading lights for the back seat. It

turned out both bulbs were defective, so off to V&V Auto Parts in

Delcambre to purchase new light bulbs, and that problem was fixed.

I went back to DREAM AWAY, and started

removing the teak trim on the eyebrow to make way for the frame of

the new hard dodger. This means the teak bungs had to be drilled out,

then the heads of the Phillips head screws had to be cleaned out.

When this was done, hopefully the screw would back out, and then move

on to the next screw. Had pretty good luck today, except for the

first screw, the head was broken off. Will continue with the teak

removal over the next couple of days.

Removing Teak And Screws On The Port

Side

October 02, Wednesday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Started off the morning by weeding the

marina

gardens, and trimming grass around the trees and parking lot.

Warren And Monica Leaving On UNTID.

I then went over to the

shop

and started in cleaning all of the left over parts from the boom

gallows project. We had changed out several of the bolts for shorter

bolts. The remaining bolts needed clean up before I could put them

back in my stash of fasteners.

Bench Grinder With Parts Being Cleaned

I got back into the SeaScooter testing.

I was busy with a couple of other items, but I wanted to see if the

“thrashing machine” sound would go away or get worse by running

the SeaScooter. The SeaScooter was on the bench, so I taped the start

control on, and let it run. It ran for 2.5 hours before the battery

started to slow down.

Depending on your mood, it was good

news! The “thrashing machine” sound did not change during the

run. My thought is, if there is a problem with the motor/gearing, it