Maintenance Log November 2010

November 30, 2010, Tuesday.

Got right to work

on the cap rail. Filled in the Wilma damage, and several other places

that needed filled in. After the putty set up, got into removing the

cap rail. Got all of the cap rail on the port side removed. Removed all

but four feet of the residue 5200 on the cap rail. Will finish

up the residue removal tomorrow, weather permitting.

Teak Cap Rail Lifted Off Of Hull To Deck Joint

Captain Removing Teak Cap Rail

Teak Cap Rail Completely Removed, 5200 Residue Remaining

November 29, 2010, Monday.

I wiped down the forward deck

box lifting handle and applied the fourth coat of Cetol on the handle.

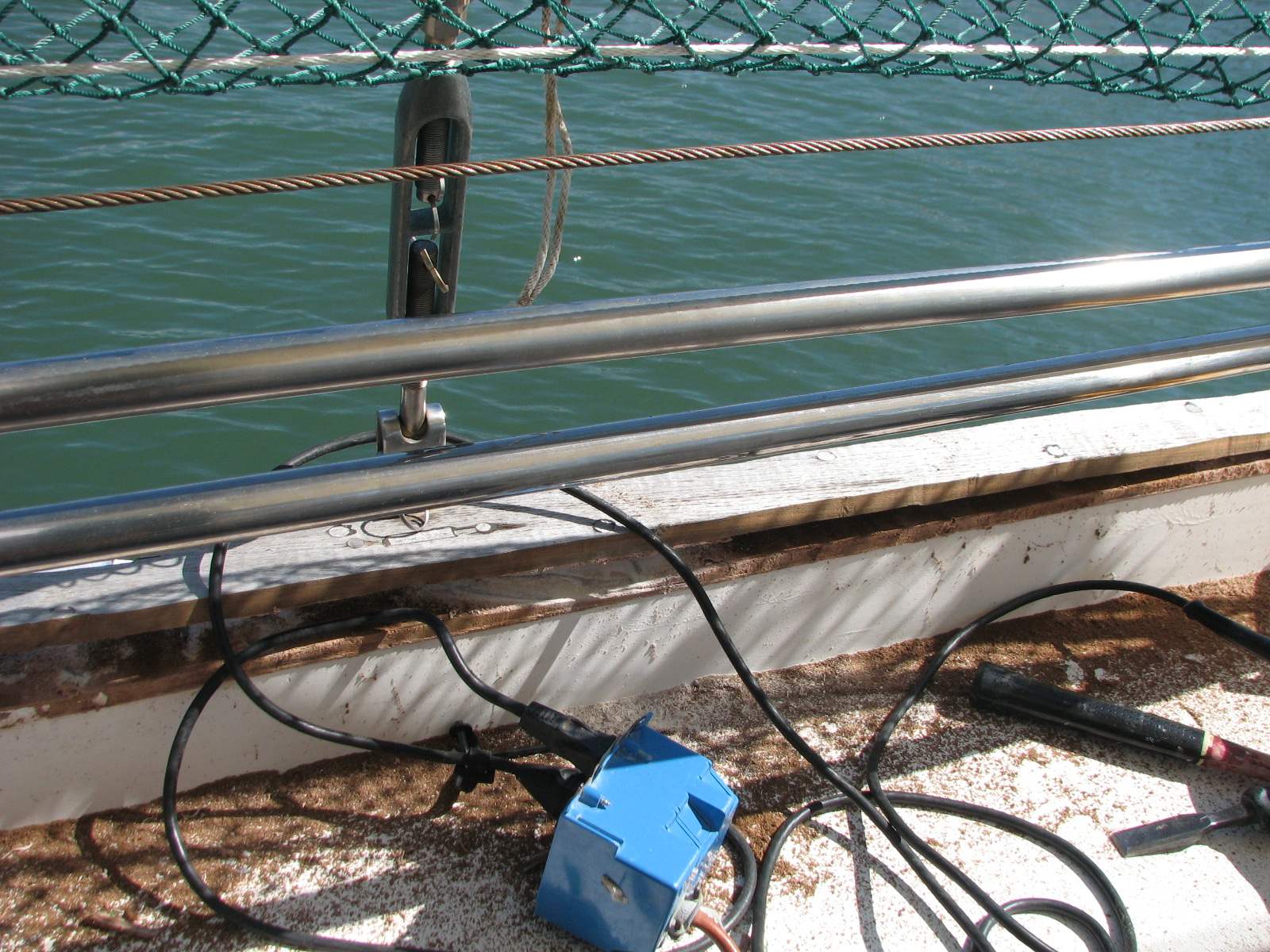

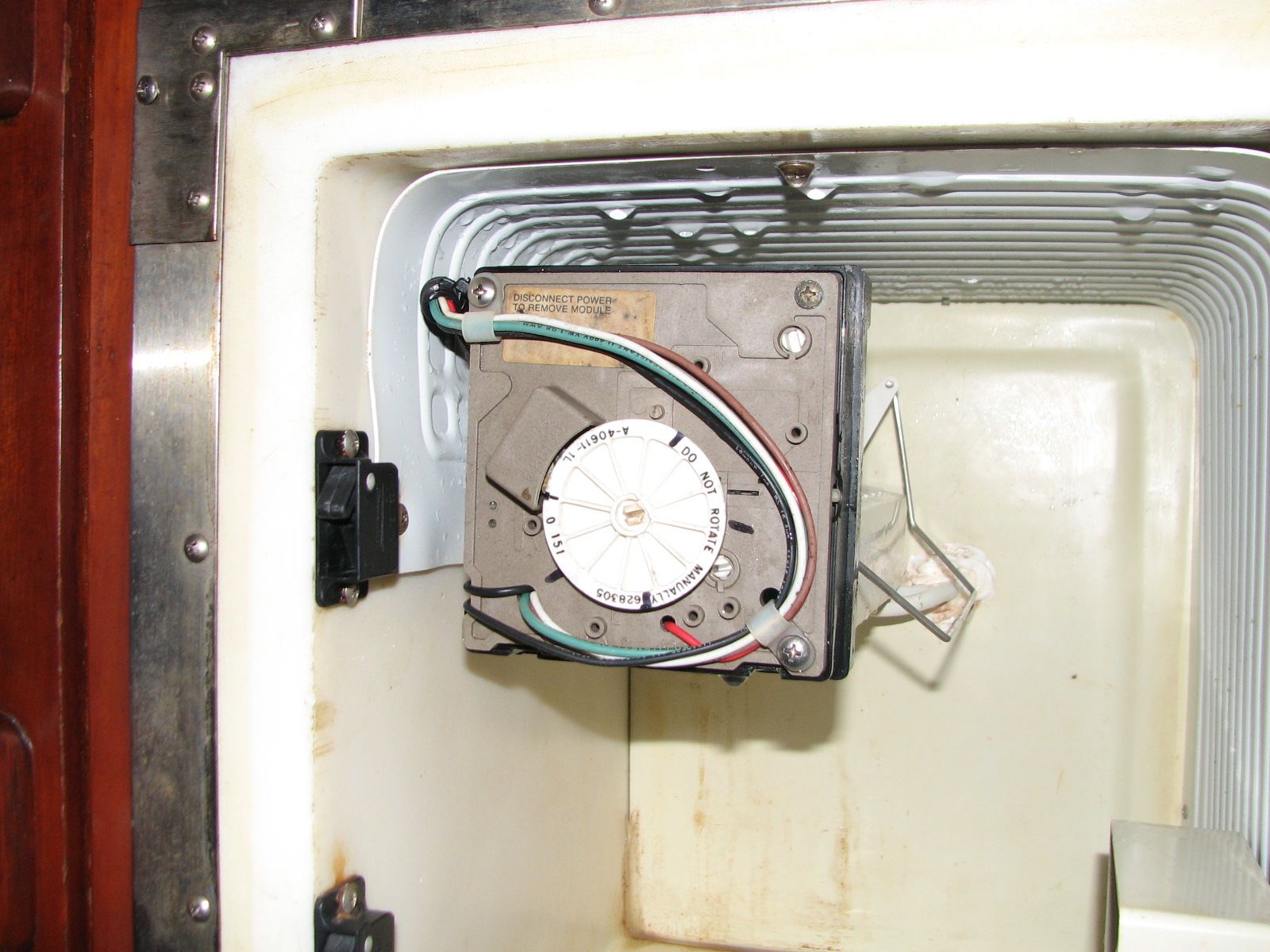

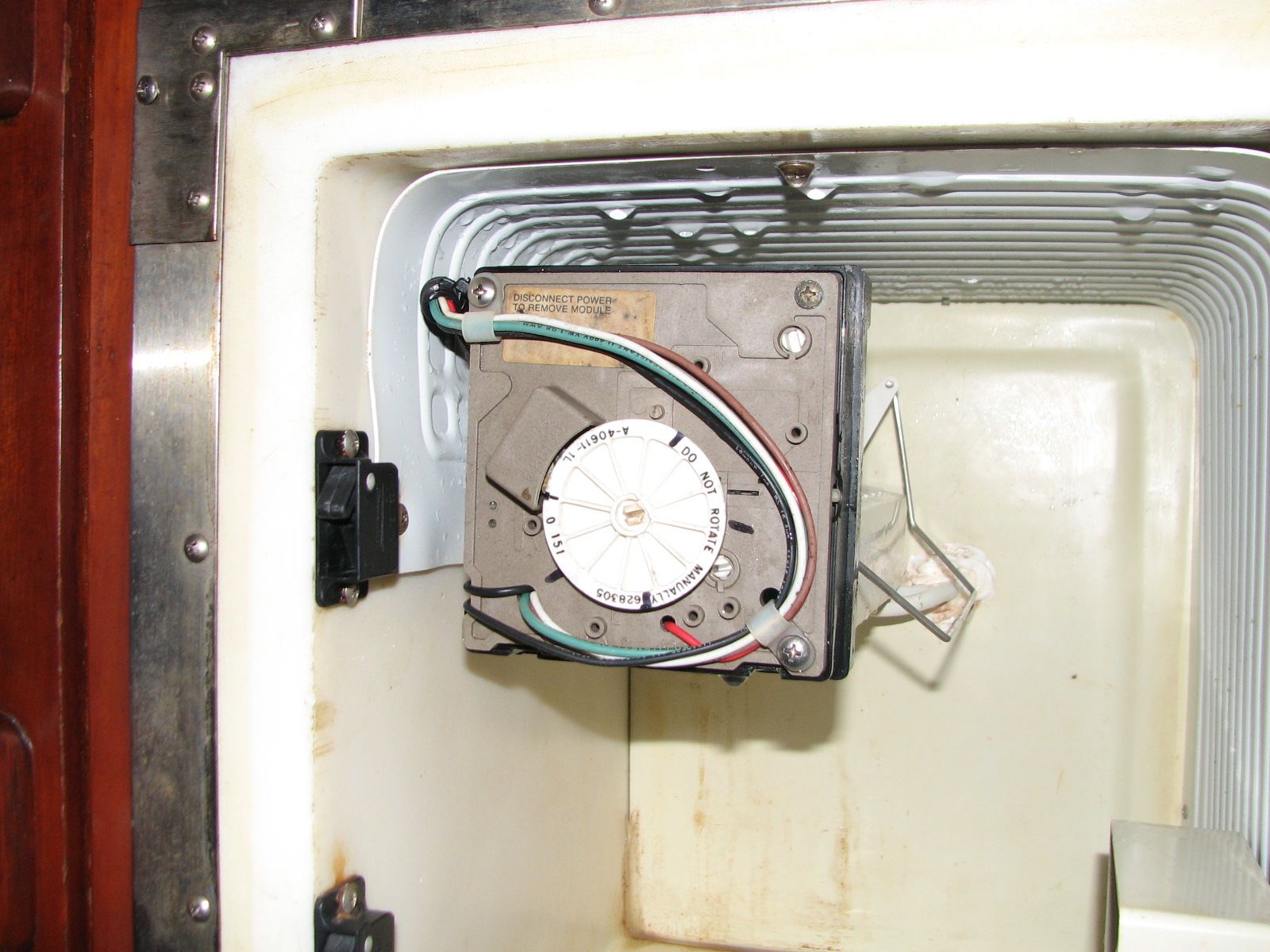

Finally got a few minutes to test the ice maker. Brought the testing

procedure up on my computer and checked out the different points in the

test procedure. It appears the motor that runs the process of

extracting the ice is bad. I will have to take the unit apart and see

if the motor is available separate from the ice making mechanism. If

possible, I might be able to get the motor locally. If not I will wait

until I can get one from the states.

Ice Maker Head Showing Test Points

Started back into working on the cap rail. Not sure what happened, but

the putty I applied to the cap rail yesterday did not set up. I scraped

and cleaned off all of the bad putty, preparing it for new putty. I

mixed up new putty and mixed in a little more hardener, and

applied new putty to the area of the hull to deck joint from which I

removed the cap rail yesterday.

I then removed another six feet of cap rail from the port side. I got

up to the area that was damaged during hurricane Wilma in 2005. I am

sure this is where my major leaks are on the port side. The good news

is, the area can be repaired and made ready to be covered with

fiberglass.

Captain Removing Sides Of Cap Rail

Captain Cutting Off Bottom

Of "U" Cap Rail With Reciprocating Saw

Wilma Damage To Cap Rail, All Cleaned Out

Ready For Putty

November 28, 2010, Sunday.

Was

able to get a good start on the port side cap rail removal project. I

got the safety netting and all of the stanchion supports moved out of

the way. I am starting on the cap rail amidships, and then moving

forward. I got several pieces of hardware removed from the cap rail,

and then started the cutting process. The actual cap rail is a "U"

shaped piece of teak that covers the hull to deck joint. With the jig

saw, I cut off the sides of the "U", and then use a Sawzall®

Reciprocating Saw to cut through the 5200 to separate the teak, which is the

bottom of the "U", from the hull to deck joint. Next I have to remove

the wood and 5200 residue. Tomorrow I will use a heat

gun to see if I can remove the residue 5200 from the hull to deck joint. I will

also try and get some pictures of the actual removal of the cap rail

teak.

Captain Cutting Into Cap Rail With Reciprocating Saw

Captain Removing 5200 Residue, Getting Ready To

Cut More Cap Rail Off

November 27, 2010, Saturday.

Ready

to turn Dream Away around, but had to wait for the rain to pass. Rain

stopped and was able to get Dream Away turned around and settled in her

new position. Got the lines all set up for the new orientation, and

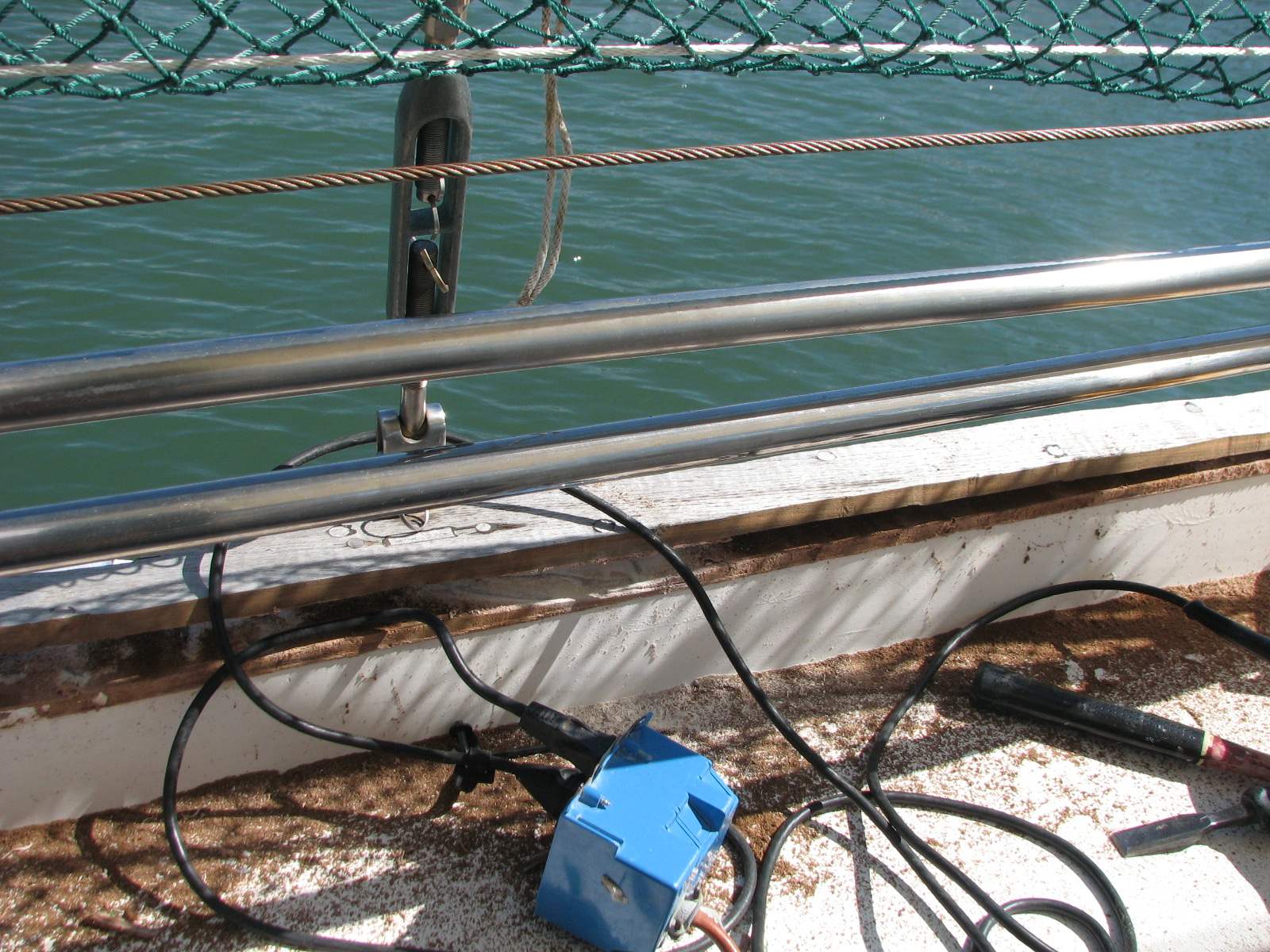

went to install the electrical cords, and one of the

connector/receptacle connections was burned up. This happened to be the

connection for the air conditioner.

As usual, I had the spare receptacle and connector for the repair. I

was able to get the new parts installed, and the electrical connections

to Dream Away are back in working order. I also took apart all of the

other electrical connections on the wiring from the dock to Dream Away.

I cleaned the connections, and sprayed everything down with Corrosion Block to keep back any

problems of that type.

Connector From Wire To Dream Away

Receptacle On Dream Away

It started to rain again, so spent the remainder of the day cooking and

making dip!! Hopefully tomorrow I will get started on the port side cap

rail project!!

November 26, 2010, Friday.

Was

able to find some scrap pieces of Starboard that

I used to cut out sacrificial

pieces for under the starboard side chocks. I got the pieces cut out

and got them installed under the three chocks on the starboard side.

The difficult part was drilling the holes in the Starboard pieces. The holes in the hull

to deck joint were already drilled and tapped, so had to measure the

placement of the holes, and then drill the holes in the sacrificial

pieces. Was very successful, with the placement of the holes. Got all

three pieces installed. I also was able to get the netting tied down to

the lifeline stanchion supports. We are now ready to turn Dream Away

around and start on the port side cap rail.

Captain Attaching Netting To Lifeline Stanchion Supports

Starboard Mid-ship Chock

With Sacrificial Starboard Between Chock And Cap Rail

Most Forward Starboard

Chock With Sacrificial Starboard Between Chock And Cap Rail

November 25, 2010, Thursday.

Thanksgiving

Day, no work on Dream Away today.

November 24, 2010, Wednesday.

Went

into town to do some shopping and to get time on the telephone. The

cellular company was offering triple day to day, so took advantage of

that.

Sanded down the

lifting handle for the front deck box. I wiped down the handle and

applied the third coat of Cetol on the handle.

Finally got most of the hardware

back on the starboard side cap rail. I only need to install the Genoa

track, but it is not required to get the boat turned around to start on

the port side cap rail. I did realize one problem as I was installing

the chocks. When a line runs through any of the chocks, it is going to

wear on the new paint and fiberglass. I am going to have to put a small

piece of wood or Starboard under each chock as a sacrificial

piece for the lines.

Tomorrow will be a day off,

cooking Thanksgiving day turkeys. Friday I will get the sacrificial

pieces made, and hopefully by Saturday morning, I will get the boat

turned around and started on the port side cap rail.

November 23, 2010, Tuesday.

A

good productive work day, and also our daughter, Judy's,

birthday!

The sun was out, so started in

again on the installation of the starboard side cap rail hardware.

While I was there, I also tightened up the two starboard main mast

lowers. They were just a tad bit loose, so fixed that issue before it

became a problem. As I was drilling and tapping holes for the hardware,

it started to rain! Mad scramble to get all of the tools, and

electrical cord down below. Also had to rush to get the hatches closed.

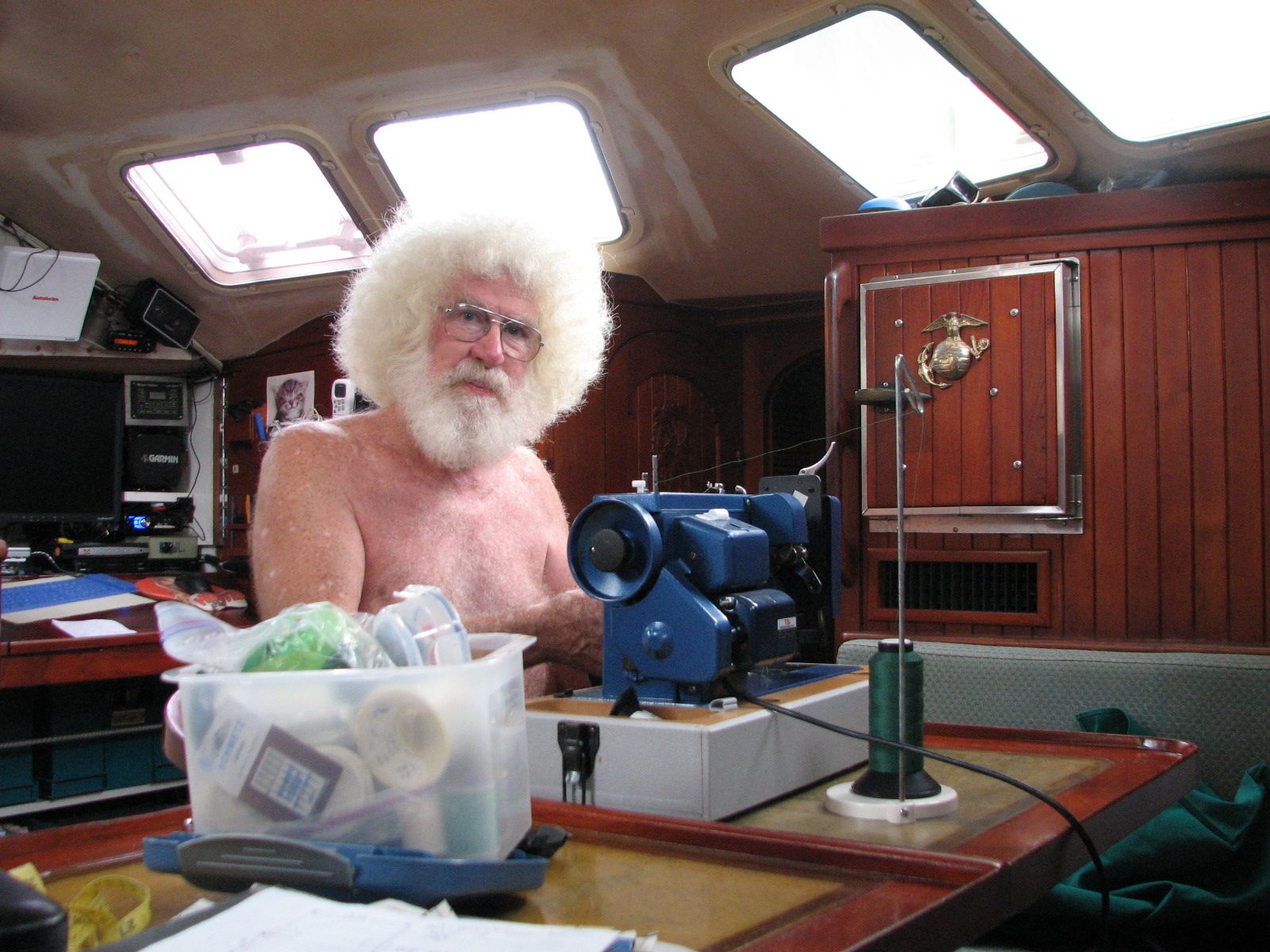

Back to the sewing projects. I

was able to get some pieces to use for the chain exit of the windlass

cover, so got the windlass cover completed and installed.

Back Of Windlass Cover

Front Of Cover With Hook

& Loop Covers And Chain Exit Holes

Captain (Tailor) With The Completed Anchor Windlass Cover

November 22, 2010, Monday.

Went

into town to grocery shop and get a standard household receptacle for

the Sharp Microwave. The weather was beautiful, so was

looking forward to a good day putting the starboard side deck hardware

back on Dream Away.

It was not to be, by the time we

returned to Dream Away, It had just started to rain. First on the list

was to remove the receptacle on loan from the marina

Back to the sewing projects. I finished the second oar pocket/holder on

the starboard side of the dinghy, so that project is complete.

Next is the cover for the Lighthouse 1501 anchor windlass. I got the

pieces measured and cut out. Since I am using various scraps for all of

these covers, it is a challenge to maximize the use of the material to

get the correct sized pieces. The good news is sewing together a couple

of pieces to make one big piece is easy, because they are all straight

seams. I got the basic windlass cover cut out and sewn together. Now

the challenge will be to make holes in the material to allow the anchor

chain passage through the cover, and to make tie downs of some sort so

the cover will not blow away. I will probably use hook & loop for

the tie downs. Not sure when I will get back to this project, as I am

hoping for good weather tomorrow to get the hardware put back on Dream

Away.

November 21, 2010, Sunday.

Another rainy day in paradise, so it was back

to the sewing projects. I got the pieces cut out for the boarding

ladder cover, and got it sewn together. It looks pretty good, and will

keep the sun off of the ladder when on deck.

Starboard Side View Of Boarding Ladder Cover

Port Side View Of Boarding Ladder Cover

I also started on another sewing

project. In the dinghy there are holders or pockets that hold the end

of the oars off of the bottom of the dinghy. The actual pockets were

deteriorating because of UV, so needed to be replaced. I had some spare

sun shade material, so decided to use it to replace the pockets/holders

for the dinghy oars. I got one made and on the dinghy before happy hour.

Dinghy Oar Cover/Holder

A problem reared its ugly head

with our Sharp Microwave. We had to take

apart the shelf above the microwave to get to the GFCI

receptacle, because the circuit breaker was tripping. We discovered

that every time we opened the door to the microwave the GFCI

circuit breaker would trip, very annoying! I was able to borrow a

standard receptacle from the marina, so we were able to get through the

day. I modified the shelf just above the microwave to make it easier to

get to the GFCI receptacle.

Kitty made some, from scratch,

Parker House rolls as a practice run for our Thanksgiving meal this

coming Thursday. She presented them hot at our happy hour for all to

test, and it was unanimous, very good! In fact we encouraged Kitty to

make another batch each day until Thursday, to make sure she was doing

it right. Not sure if we made any progress with our request, as it took

her about four hours to make the rolls. The rolls went fast, and I did

not have my camera, so I have no photos!!

November 20, 2010, Saturday.

As

predicted, it was another rainy day, with a couple of spots of

sunshine. I got out the sewing machine, and finally finished the last

Jerry Jug cover. Could not find a problem with the sewing machine.

Looked up the video for lubricating the sewing machine, and did a

complete lubrication on the unit, and also cleaned the machine. I then

took the measurements for the boarding ladder cover and the windlass

cover. I was able to find a couple pieces of material to use for the

boarding ladder cover. I got that all measured out and ready to cut.

Completed Diesel Jerry Jug Cover

Completed Jerry Jug Cover Showing Hook & Loop Hold Downs

I then sewed up a couple of hold

down straps for the HP printer in the computer

electronics area. When we made the passage earlier this year to Roatan,

the printer fell off of it's shelf, and broke the paper tray, but

otherwise the printer worked just fine. I decided to prevent this from

happening again by using the hold down straps.

Hold Down Strap On HP Printer On Printer Shelf

Printer Shelf On Top Of Other Computer Electronics

November 19, 2010, Friday.

A

front came down from the States, so it rained all day. Sewing gear back

out and working again on the Jerry Jug covers. Finally got to the last

Jerry Jug cover, but had a problem with the machine. It was dark and

the light was not good so put all of the gear away. I will probably

finish the last Jerry Jug cover tomorrow, because it is supposed to be

very wet and rainy tomorrow. If I ever finish the Jerry Jug covers, I

can start in on the windlass cover, outboard covers, and the boarding

ladder cover.

November 18, 2010, Thursday.

Went

into Fronteras to grocery, vegetable, and paint shop. By the time we

got back to Dream Away it was starting to rain. Got out all of the

sewing gear, and started in on the Jerry Jug covers.

November 17, 2010, Wednesday.

Took the day off.

Kitty and I went to Morales with the Monkey

Bay marina manager. Had a great time!!

November 16, 2010, Tuesday.

Started the day by cutting all of the 5/16" bolts I will be using to

attach the Genoa T-Track to the starboard side cap rail. Also gathered

up all of the hardware to be put back on the starboard side cap rail.

This is all of the chocks, the fittings for the stanchion supports, and

the fasteners to attach all of the parts.

I

attached one of the chocks and three of the stanchion support fittings.

I am using bolts rather than screws, so each hole had to be drilled

out, then tapped. Because the drilled holes do not go all of the way

through the hull to deck joint, I could use the tap for five to seven

turns, then back the tap out, vacuum out the hole, then back with the

tap for five to seven more turns. Took a lot more time to get the

hardware on than I expected, but the job is being done right, and so

far it looks good.

November 15, 2010, Monday.

Went

up to he shop here at Monkey Bay and sanded down

the oar I had put the thinned epoxy on, and sanded down the lifting

handle for the front deck box. I wiped down the handle and applied the

second coat of Cetol on the handle.

Applied one coat of Nyalic

on the starboard cap rail and shear stripe. Do not have a lot of Nyalic

left, so only applied one coat. When I finish the port side cap rail

and shear stripe, and apply two coats to it, hopefully I will have

enough Nyalic to apply

a second coat to the starboard cap rail and shear stripe.

When the coat of Nyalic

dried, I removed all of the masking tape and paper on the starboard

side. Bearing in mind my 36" rule, the starboard cap rail and shear

stripe look pretty good.

I added 5 gallons of diesel fuel

to the port fuel tank. I poured my 1 gallon of "Good Diesel" into the

port tank, and put fresh diesel into the "Good Diesel"

jug. I keep a gallon of known good diesel just in case of some

emergency. I also use it when I change filters, and have to top off the

filter housing. I also poured about two pints of used vegetable oil

into the port fuel tank.

November 13, 2010, Saturday.

Day

started off raining, so got out the sewing gear and continued with the

Jerry Jug covers. I am getting them done, but it seems slow!!

Captain Hard At The Sewing Machine

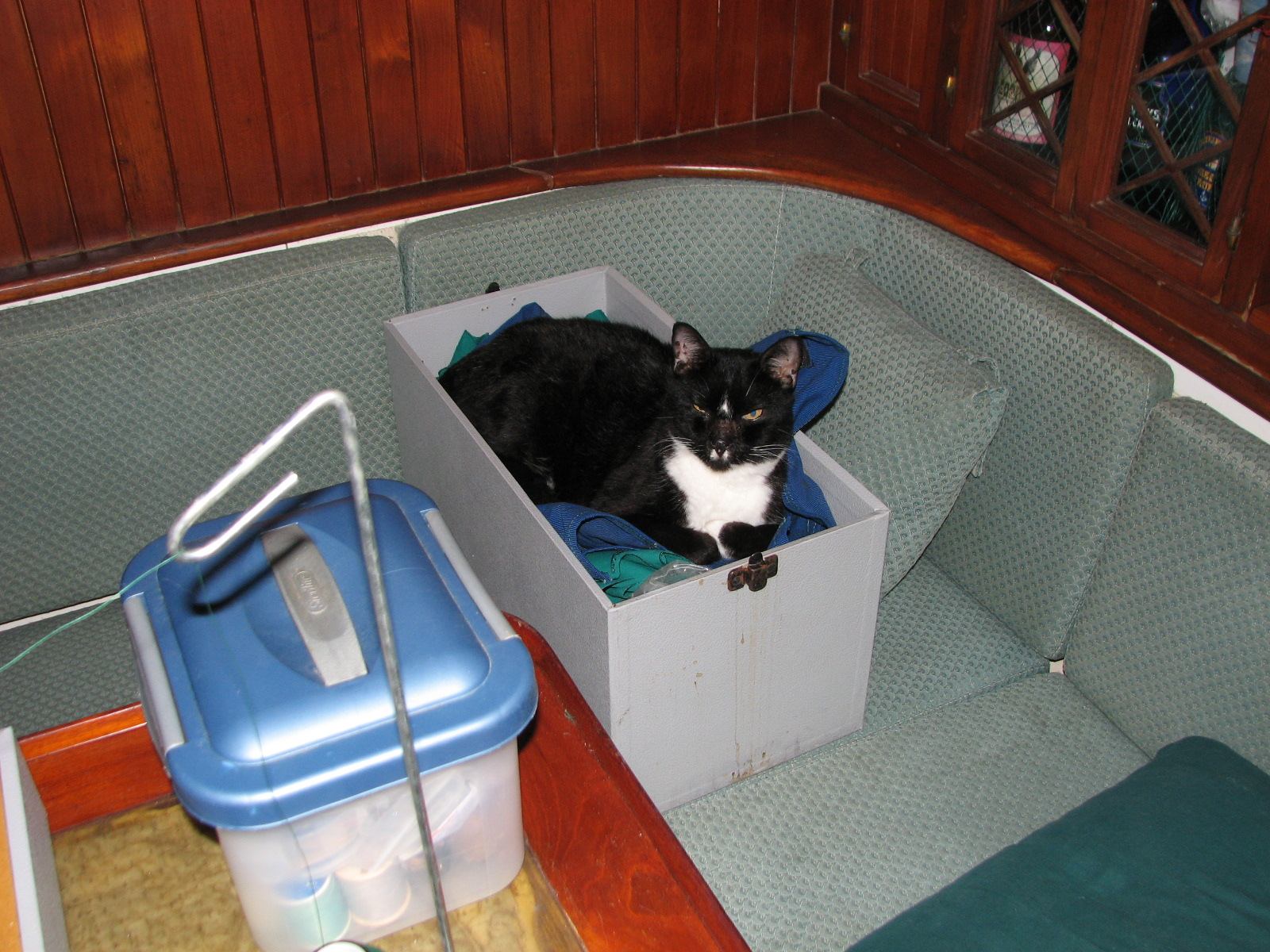

Sewing Helper Hard At It!!

Jerry Jug Cover Showing Hook And Loop Tabs

Finished Product On A Jerry Jug

By noon, the day was looking

good, and the sun was out. Got everything together, and applied the

second coat of Easypoxy Kelly Green to the

cap rail and shear stripe. The plan is now to let the paint dry for 48

hours, and then apply the two coats of Nyalic. When that dries, remove the

masking tape, and install the hardware.

November 12, 2010, Friday.

Another

rainy day, so did not get the second coat of paint on the cap rail,

shear stripe.

Masked off the area on the

forward deck box to roll on the non-skid gelcoat. Mixed up two 5 ounce

pots of the thickened, waxed gelcoat, and rolled it on the forward deck

box. waited about four hours, and brushed on the PVA wax. about an hour later it rained.

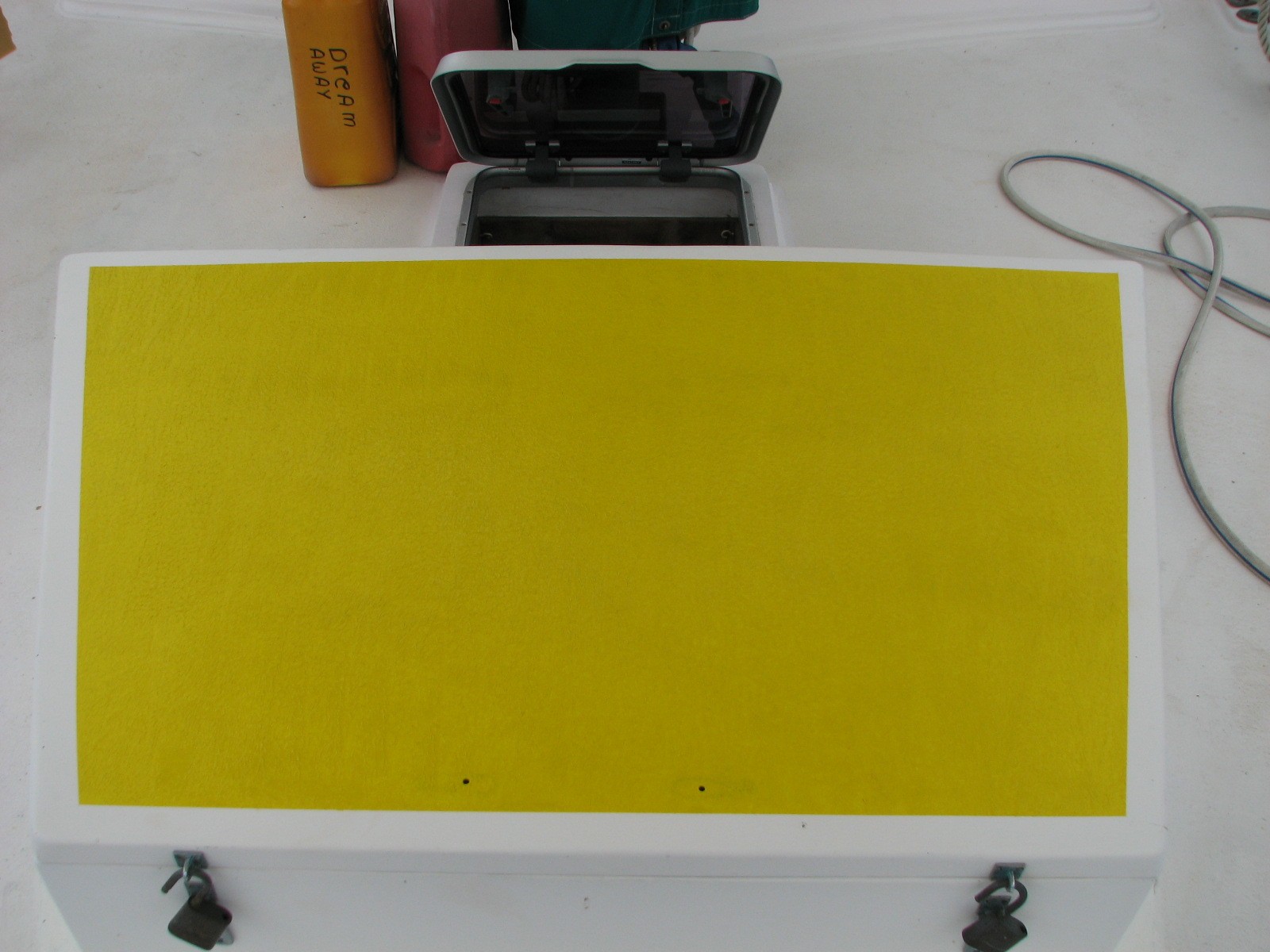

Forward Deck Box Lid Before Masking And Gelcoating

Forward Deck Box After Application Of Non-Skid Gelcoat

Forward Deck Box After Application Of Non-Skid Gelcoat

Mixed up some

epoxy, thinned it out with acetone and painted it on the second

side of the oar. Also put the first coat of Cetol on the forward deck box

handle. Must purchase some good exterior paint for the dinghy oar.

Got out the sewing machine and

continued sewing on the Jerry Jug Covers. Sewing is my usual rainy day

project. The Jerry jug covers are a lot of work because there are so

many small parts to be sewn together. It is much easier to sew large

items with long seams.

November 11, 2010, Thursday.

A wet rainy day, so no second

coat today on the cap rail. Ran the generator for three hours, and ran

a full cycle on the battery charger.

Took one of the oars out of the

dinghy, and stripped all of the paint off, and sanded down to bare

wood. Mixed up some epoxy, thinned it out with acetone and

painted it on the oar. Also, stripped down the handle for the forward

deck box, getting it ready for Cetol.

November 10, 2010, Wednesday.

Going

to try and keep this up for all to see. Was able

to put all of the hardware back on the aft deck box lids. I put on some

weather stripping to keep water out of the aft deck boxes. Did not have

enough weatherstripping, so had to cut the weatherstripping I had in

half to make it stretch. I then installed the aft deck box lids with

the yellow non-skid on them. Finally figured out the gelcoat issue with

the non-skid. Looks good, will get some pictures on later today.

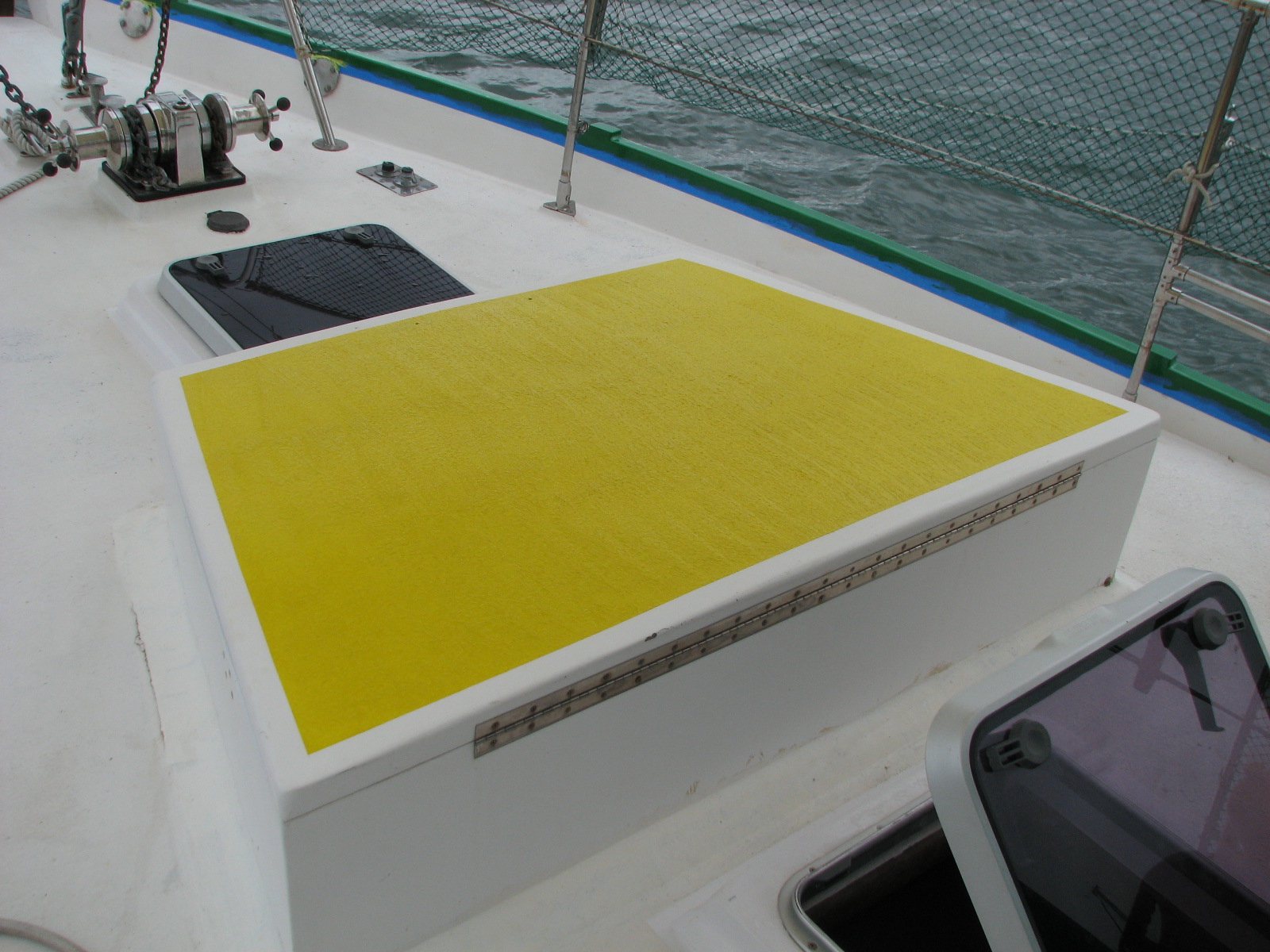

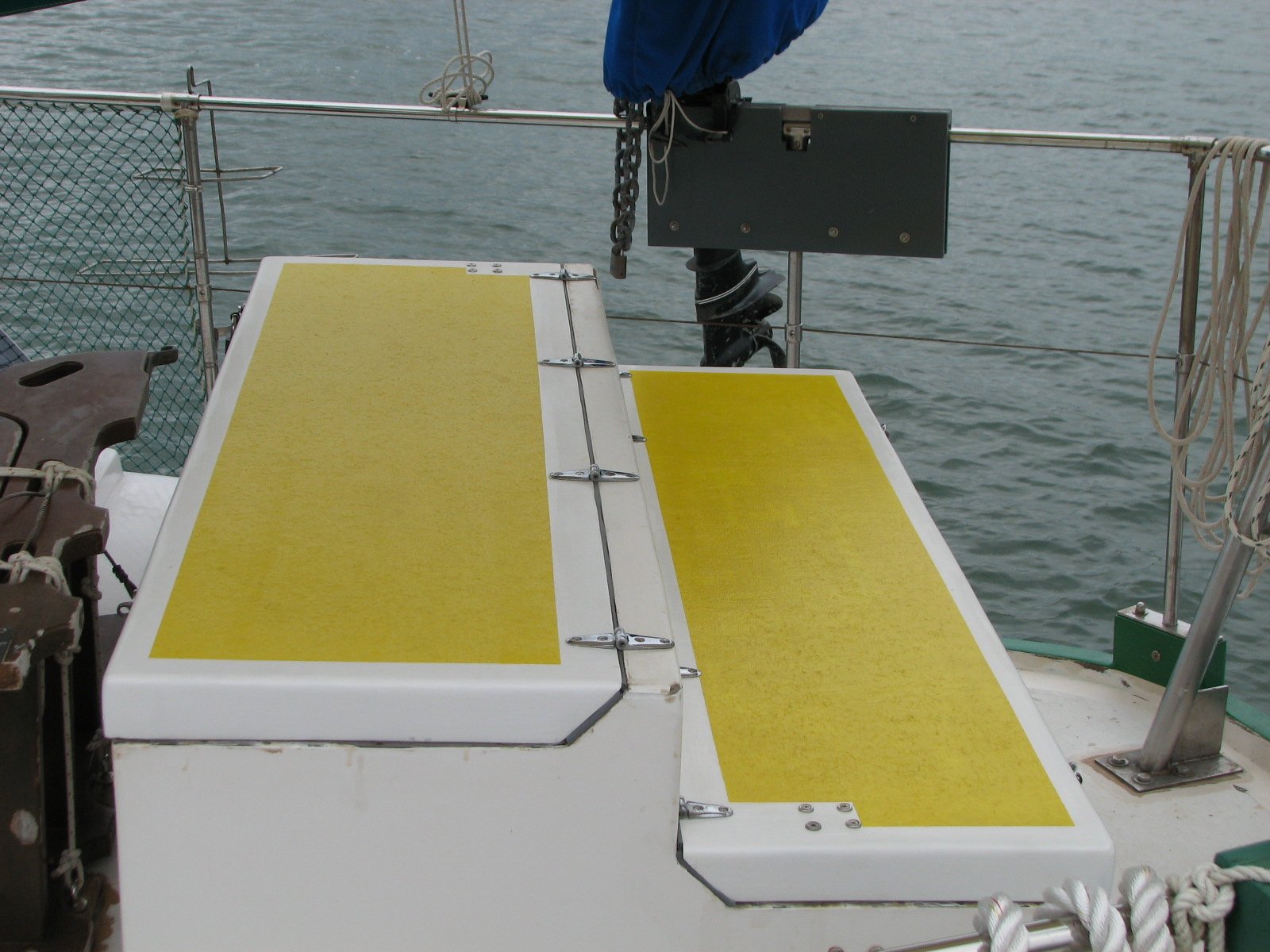

Side View Of Newly Installed Aft Deck Box Lids

Aft View Of Newly Installed Aft Deck Box Lids

Put the first coat of single part

epoxy paint on the starboard cap-rail and shear stripe. Was able to use

a roll and tip to get the paint on. Started with a foam brush, but the

foam brush came apart and had to finish with a standard bristle brush.

Will have to clean up the mess made with the foam brush tomorrow, and

apply the second coat. Other than the problem with the foam brush, the

first coat went on very well.

Jim Applying Single

Part Epoxy Paint To Starboard Forward Cap Rail

Bow Cap Rail After Paint Application

Cap Rail On Starboard Side

November 9, 2010, Tuesday.

Did

final sanding on cap rail and shear stripe on starboard side. Masked

off the cap rail and the shear stripe. Getting ready to apply first

coat of paint.

November 8, 2010, Monday.

Did

final sanding of port and starboard name board area. Will call the area

done. The gelcoat does not cover the area completely, but there are no

leaks from the name boards! When I get a chance to spray gelcoat on the

hull, the area will be perfect.

November 7, 2010, Sunday.

The lid that was sticky seems to

have finally kick off. I washed the wax off of the lid with yesterdays

gelcoat on it and it seems to have kicked off. Good news!!

November 6, 2010, Saturday.

Mixed

up a pot of yellow gelcoat for the second lid. I mixed wax (a Styrene

substitute) into the gelcoat, and added more cabosil into the gelcoat

mixture. rolled the gelcoat onto the lid. I waited until thegelcoat

started to kick off, the brushed on a caot of normal floor wax. I also

put the sticky lid out into the sun again.

November 5, 2010, Friday.

Mixed up a pot of

white gelcoat . This time I thickened the gelcoat with talc,

and applied the gelcoat to the forward name board area with a 2" wide

putty knife.

November 4, 2010, Thursday.

Sanded gelcoat off

of forward name board area. Put the sticky lid out into the sun to see

if it will kick off.

November 3, 2010, Wednesday.

First

project of the day was to get the repaired Inverter/Charger installed

back into the electrical system on Dream Away. This took most of the

day, as I had to clear off the work bench in the garage. I also had to

move one of the tool boxes so I could get to the area where the

Inverter/Charger had to be installed. Got the unit installed, and it

functioned as I had hoped. The charger and the Inverter work as planned.

November 2, 2010, Tuesday.

Finally

got the word late last week that our Charger/Inverter was repaired.

Today was the day I decided to go pick it up. I took the 0300 bus from

Rio Dulce to Guatemala City. Arrived intothe bus station around 0830.

Our Guatemala City taxi driver, Juan, was waiting for me at the bus

station. we took off to the Xantrax repair facility. I picked up the

repaired unit, paid for the repairs, and headed back to the bus

station. I then caught the 1130 bus from Guatemala City to Rio Dulce,

arriving in Rio Dulce around 1600. I finally got back to Dream Away

with the repaired Inverter around 1700. A very long Day

November 1, 2010, Monday.

Sanded gelcoat off of forward

name board area. Mixed up a pot of white gelcoat and applied it to the

port and starboard name board area. Washed wax off of problem top, but

the top is still sticky. Back to the chemical drawing board!!