Maintenance Log November 2013

November 30, Saturday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian and Jordan

Went over to the

shop and unloaded the

Black Beast. We had a lot of

stuff in the

Black Beast that I brought from

the store room in Atlanta.

Most of it is to give away, and some of it I will sell on

Ebay.

The big item was on the

Black

Beast. When we were on the way up to Atlanta, we

stopped at the Georgia welcome center. When I got out of the truck,

the door handle broke off! I put off working on the problem while in

Atlanta. It was fun though, having to roll down the window every time

I wanted out. The weather in Atlanta was not great. Lots of cold,

rain, and snow.

I started on the problem this morning.

I verified the problem was in fact a broken door handle, and not a

handle that just fell off. I put the door back together, and when I

went back to DREAM AWAY, I ordered a new door handle on

Ebay.

I will replace the handle when the new one comes in, and service the

lock and opening mechanism.

The remainder of the day was spent

watching football and catching up!

November 22 thru November

29, 2013

Went on a driving trip from Delcambre,

to Atlanta

and back to visit with our children over the Thanksgiving holiday.

November 21, Thursday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

Did not get any DREAM AWAY projects

done today. I saw our cruisers, Tammy

and Bruce off. They were meeting family in New Orleans

for Thanksgiving, so needed to get on the way. We had a great time

meeting and visiting with them.

The remainder of the day was spent

packing and getting ready for our trip to Atlanta.

I checked all of the fluids in the Black

Beast, and vacuumed it out. By evening the truck was

packed and ready to go.

November 20, Wednesday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

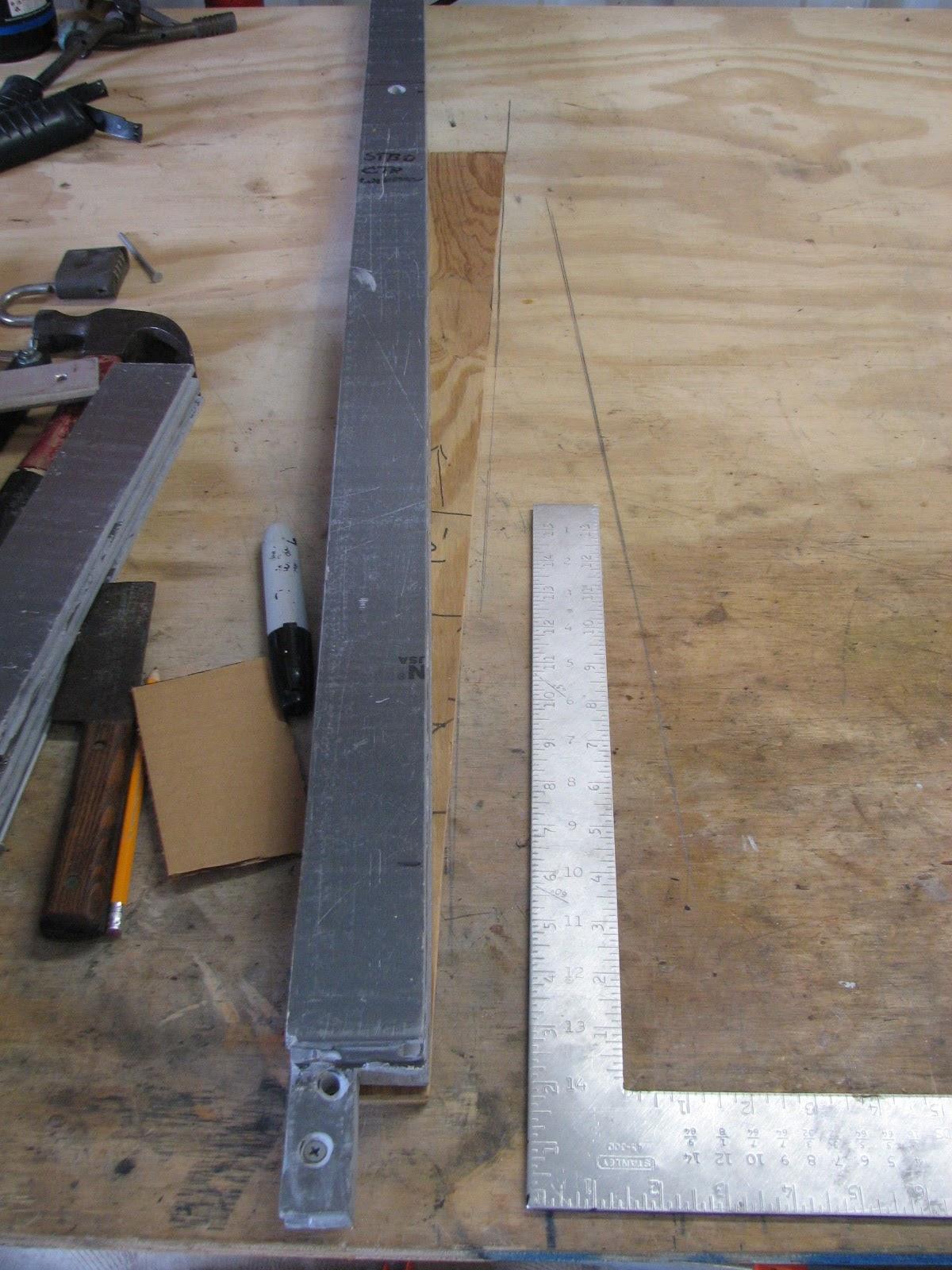

Went over to the shop

and rolled the table saw out of the shop,

and prepared it to cut the Strongwell

Extren plate for the hard dodger uprights. I also set

up my squirrel

cage fan to blow the dust away from me while cutting

the plate.

I cut the plate and matched the new

pieces with the original hard dodger uprights. They looked good, but

did not want to do any more cutting until I did a dry fit of the new

pieces on DREAM AWAY.

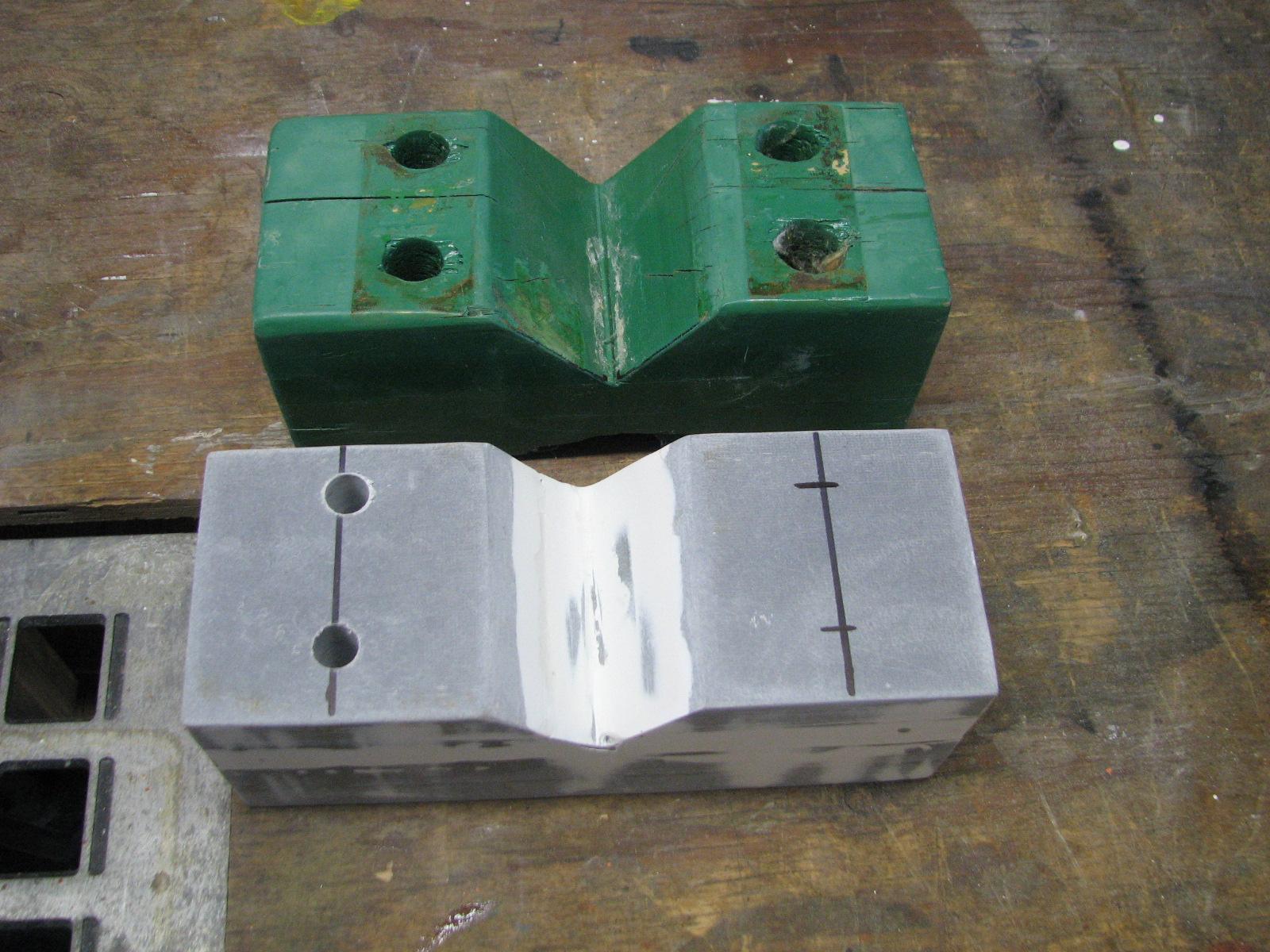

New Pieces Matched Up With Original

Uprights

New Pieces Matched Up With Original

Uprights

When I got to the marina,

I replaced the last two toilet seats in the shower

trailer. So now it is ready for prime time. The

digital controller is ordered for the on demand hot water heater.

When it arrives and is installed, hopefully that will fix the last

remaining problem with the shower

trailer.

Our cruisers, Tammy

and Bruce, left the marina

around 1000 this morning. They went to Leblanc Fuel dock to top off

their fuel tanks, and then they will be on their way east.

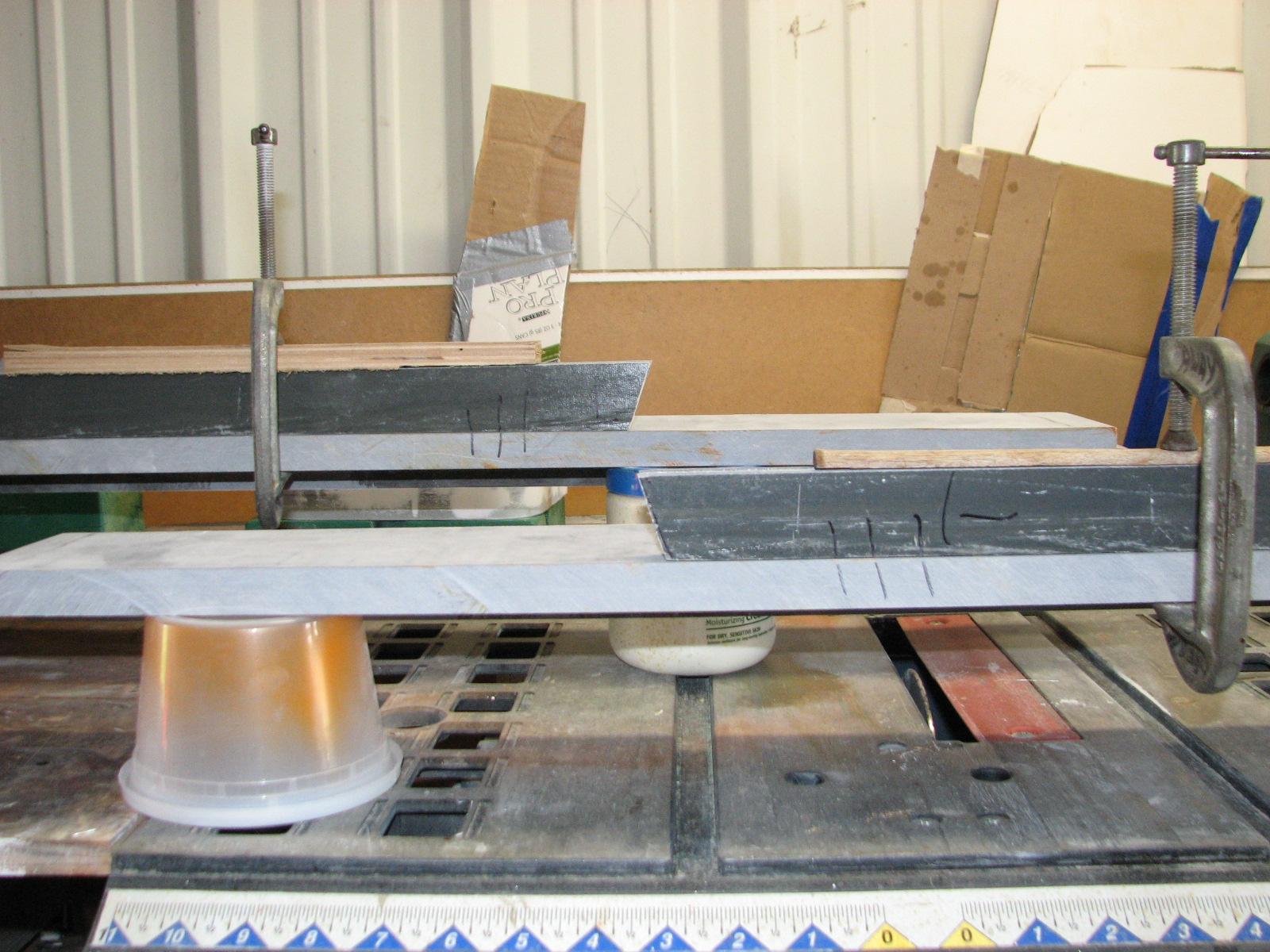

I brought down to DREAM AWAY, the box

of clamps and the new and original hard dodger uprights. Kitty and I

bolted and clamped on the original uprights, and then clamped on the

two new uprights that will repair the sliding window problem. With

the two new uprights clamped on the measurements are rights on.

Now “all” I have to do is cut off

the piece on the original upright that was there for the sliding

window, and glass on the the new piece.

Tammy

and Bruce on DOS LIBRAS are back at the marina!

While getting fuel, they inadvertently put diesel fuel into one of

their water tanks. It was only about three gallons, but quite a

problem.

I helped Bruce pump out the water tank

and start the cleaning process on the water tank. Tammy and Kitty

went off to the Tabasco

Factory on Avery Island.

I finally got to mix up and pour the

Smith’s

penetrating epoxy into the holes in the cockpit seat,

so I could bolt down the hatch in the cockpit. I had a bit of rot in

one of the screw holes. I saturated all of the screw holes with the

Smith’s

penetrating epoxy just to be sure I got everything.

Next I will put filler into the old rotten area, and then will be

able to screw down the cockpit hatch.

Rotten Area In Cockpit Next To Hatch

When that was complete, I put three

medium sized blobs of the

finishing

putty on the mixing board. I do this so I do not add

the cream

hardener to a large amount of putty, and have it go

off too soon. I am using the

finishing

putty as a filler to level out flat surfaces, and as

filler to make smooth radiuses in corners of the hard dodger base on

the dog house.

Hopefully I will not have to make many

applications of the finishing

putty. You never get it perfect the first time. After

the first application, you sand down the area, you find a few places

that were not filled properly with the finishing

putty. Then another application, then sanding. It

seems like this could go on forever, but I use the "36” rule.

The 36” rule is, if it is perfect

from 36 inches away, then it is perfect. When I do finally get all of

the area looking good, I will then apply the gelcoat.

Kitty and Tammy returned from their

outing, so I had a shower, and we went to Tammy

and Bruce’s

boat for a wonderful dinner. They are heading out to the east

tomorrow, so it was nice to get together.

November 19, Tuesday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

Went over to the shop

and started replacing the weather stripping on one of the companion

way inserts. The old weather stripping was failing and needed to be

replaced. It was a simple matter of completely removing the old

weather stripping, and applying the new weather stripping.

Old Weather Stripping On Companionway

Insert

New Weatherstripping Applied To

Companionway Insert

Now it was back to the problem uprights

on the hard dodger. Yesterday I had taken angles and measurements

while the uprights were clamped to the lower and upper base of the

hard dodger. Based on those angles and measurements, I cut out two

templates for the new pieces of Strongwell

Extren plate. One template was of thin plywood, and

the other was of cardboard.

It seemed no matter how I laid them out

on the bench I could not get the proper accurate measurement. Instead

of frustrating myself further, I decided I would take the uprights

and templates back to DREAM AWAY, and make the measurements on the

hard dodger uprights.

Starboard Upright And Template On

Workbench

Port Upright And Template On Workbench

In the meantime, while waiting for

Kitty to awake, I finally got back to painting one of the barrels

that act as a trash container, and goes on the stern of DREAM AWAY.

Paint Applied To Barrel

While they were gone I went to work on

the hard dodger uprights. First on the list was to attach the two

center uprights to the lower base, and clamp them to the upper base.

When this was done I verified the measurements on the outside

uprights to the center uprights.

When I was comfortable with these

measurements, checking more than twice, I clamped the templates on

the two center uprights. I then moved and measured the templates

until the measurements between the two templates was the same at the

top and the bottom. This will allow the plexiglas

panel to slide up and down in the center of the hard dodger.

I made sure the clamps holding the

templates were very tight. I then loaded the tools, clamps and

uprights into the dock cart and walked over to the shop.

Measured And Clamped Uprights With

Templates

Measured And Clamped Uprights With

Templates

When I got to the shop,

I measured out the two uprights with the templates, onto the

remaining piece of tall Strongwell

Extren plate. I checked these measurements several

times.

Tomorrow I will cut out the two pieces

of plate, and also cut the channels in them.

Kitty had arrived home by now, so I

walked back to DREAM AWAY, and had a welcomed shower.

November 18, Monday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

Went out to the hard dodger and

accurately measured and marked up the two cent forward uprights for

the hard dodger. When I had completed the measuring, I removed the

two uprights from the base, loaded them into the Black

Beast, and drove over to the shop.

I laid out the two uprights on the

workbench, as I wanted to see if the remaining piece of Strongwell

Extren plate will work for the fix. I also wanted to

get a piece of wood or cardboard to use as template material to make

sure if the size of plate I will need.

It appears I have enough of the plate,

and I did find one piece of plywood I can use as a template. That is

the good news.

The bad news is I realized I did not

measure the angle of each upright from the hard dodger base on DREAM

AWAY. I have the distance between the uprights at the bottom and the

top, but not the angle.

I will have to bring the uprights back

to DREAM AWAY, bolts the bottoms to the base and clamp the tops to

the stainless steel base, and then measure the angles. That will have

to be tomorrow’s project.

Upright Laid out On Workbench

Upright On Workbench With Template

Material

I went back to DREAM AWAY to get ready

for the day’s outing. We took our new cruisers, Tammy

and Bruce, out to some them some of the sights in New

Iberia. We left Delcambre,

and drove to the Konrico

Rice Mill. We all watched the video, then Tammy

and Bruce took the tour of the mill. When the tour was

complete Tammy

and Bruce did some shopping in the company store,

purchasing some of the goodies available.

We then drove to downtown New

Iberia and had lunch at

Victors

Cafe. It was a very tasty meal, and we all had left

over to take home!

We then went to Shadows

On The Teche house. Kitty and I watched the video

about the house with Tammy

and Bruce, and then they took the tour while Kitty and

I read our books. When the tour was complete, we headed back to

Delcambre,

completing three errands on the way.

We had about an hours break, then it

was off to Abbeville

to have dinner at Shuck’s.

Another great meal, then back to the marina

for a well deserved bit of relaxation.

November 17, Sunday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

I took the hoses, and the pressure

washer out on

Pier

“C” to where I had washed off the dock yesterday.

The dock was very clean, even though I saw birds at the end of

Pier

“C” where I had not washed and put up the

monofilament line. So far the monofilament line seems to be working.

I finished pressure washing Pier

“C”, and put up more of the monofilament line.

As you can see from the before and

after shots, the birds made quite a mess of the dock. I am VERY

hopeful the monofilament line will keep the birds away, and the dock

will remain clean!

The main reason Pier

“C” was being cleaned up is because we have a

cruising boat coming into the marina,

and the end of Pier

“C” is the easiest dock to tie up to and get away

from.

Bruce, T-Boy And Tammy WIth Welcome

Basket

Kitty and I worked on our problem with

the forward uprights on the hard dodger. We are going to modify the

two center forward uprights so the sliding window will actually work.

I hope to start on that project tomorrow.

November 16, Saturday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

I went out on deck to measure the sizes

of the plexiglas

panels I will be needing. I am planning to purchase template material

today as we are driving into New

Iberia.

Had a major problem come up with the

forward facing uprights. The two center uprights are straight, but

the port and starboard outer uprights are not straight. What this

means is the planned sliding windows will not slide down, because the

distance between the uprights get smaller as it gets closer to the

bottom!

I have Come up with a not too major of

a solution. The two outer uprights are four inches wide, so I will

cut them such that when they are installed, they inside edges will be

straight. I will have to cut off a piece of the Strongwell

Extren plate I glassed on for the window track, and

glass it back on once the upright is cut. So the progress on the hard

dodger has been slowed down a bit!

We got back to dream away around 1630.

We enjoyed an adult beverage while relaxing in the cockpit, reading

and entertaining our cats.

November 15, Friday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

I took the hoses, and the pressure

washer out on Pier

“C” to where I had washed off the dock yesterday.

The dock was very clean, even though I saw birds at the end of Pier

“C” where I had not washed and put up the

monofilament line. So far the monofilament line seems to be working.

I continued pressure washing the dock

on Pier

“C”, picking up where I had left off yesterday. I

washed off about half of the remaining “soiled” area, and the

strung the monofilament line over the freshly cleaned area. I ran out

of the monofilament line, so will have to pick up some more when we

pick up the two remaining toilet seats for the shower

trailer.

It was lunchtime, so Kitty and I had

lunch, then started in on the hard dodger uprights. My goal for the

day was to finish off all of the hard dodger uprights.

We did have a major disaster today.

Today was the monthly running of the generator. I try to run the

generator and main engine once a month for several hours. After the

generator had ran for about 15 minutes, it started making a horrible

noise and sounded like it was coming apart.

I checked the temperature and oil

pressure guages, and they looked normal, and immediately shut the generator down. I

then checked the oil and water again, but they were both good. I had

checked both before I even started the generator.

I cranked the generator, and it turned

over with no problem, but would not start. It is a diesel, so you

need good air and good fuel for the unit to run. I will check the air

supply, and verify it is good, but I suspect a fuel injector or the

injector pump. Fortunately I have a spare injector pump, and

injectors. Another project has risen very high on the list!

I decided to wait on the generator, as

it was not a pressing matter. The day is beautiful, so I wanted to

get the outside work done on the hard dodger.

We got the remaining hard dodger

upright installed. It went much easier today, as I learned a little

secret. This Strongwell

Extren plate I am using for the uprights, is extremely

hard and dull my drill bits. If I sharpen my bits before each hole in

the fiberglass

and the stainless steel, the drilling goes much easier.

We got all of the uprights attached to

the lower fiberglass

base, and to the upper stainless steel base. This is a major

milestone. I still have a lot remaining. I have to cut off the tops

of the uprights so the King

Starboard top will fit snugly. I have to do all of the

finishing work on the fiberglass

base and the uprights, and then apply gelcoat.

I also have to measure the plexiglas

windows so I can make templates, and then purchase the plexiglas.

And last I have to weld on some supports to the stainless steel top

base to support the King

Starboard top.

Top Bolt Details

Bottom Bolt Details

Corner Bolt Details

All Uprights From Starboard Side

Starboard Side Uprights

Port Side Uprights

Hard Dodger Uprights Center From

Cockpit

This last picture will give you some

idea of how the finished product will look. All of the grey

fiberglass base and uprights will be white.

I took all of the tools and the “Box

O’ Resins” up to the Black

Beast, came back to DREAM AWAY, and cleaned up the

area. It was time for a shower and an adult beverage.

November 14, Thursday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

Went over to the shop

and went through a box of Cat

Pump parts I had purchased very cheap on Ebay.

It seems that none of the parts will fit my water

maker Cat

Pump. I may have to sell all of the parts on Ebay.

The wind had died down, and the day was

getting warmer, so I had to get out and pressure wash Pier

“C”. We have two cruising boats coming in, and

one of them will be on the end of Pier

“C”.

The amount of bird droppings on the end

of Pier

“C” is amazing! I got a fair amount of the end of

Pier

“C” cleaned off, when the water pressure dropped.

I discovered a break in the water line on Pier

“C”.

I called Kitty, and she got the plumber

organized. While waiting for the plumber to show up, I ran some

monofilament line between the pilings on Pier

“C”. Rumor has it this will keep the birds from

landing on the dock. Time will tell. When I go out to finish Pier

“C” tomorrow we will see if there are any fresh

droppings on the pressure washed area.

While still waiting for the plumber, I

did a pressure washing job on Pier

“B”. It needed cleaning as there was a lot of bird

dropping on it also.

The plumber came and did the repair,

and got the water back on Pier

“C”. I loaded the pressure washer and fuel can

into the Black

Beast, and dropped them off at the Port

of Delcambre’s storage room.

I brought the tools down to DREAM AWAY,

and kitty and I worked on installing more of the hard dodger

uprights. It is slow, hard work, but we are making good progress. By

the time we finished at 1700, we had half of the uprights installed.

I still have to cut off the top of each

upright, but I did not want to do that until I have all of the

uprights installed, and there are no hidden issues.

Starboard Side And Front Uprights

Connection Point At Side And Front

Upper Stainless Steel Base

Starboard Side Uprights, Kitty In

Cockpit

Starboard Side From Forward

Starboard Side, Side View

Captain At Work On Uprights, Looking

Forward

We are making good progress. I did get

a call from Piedmont

Plastics with a quote for two sheets of King

Starboard. The price was very good, but the shipping

charge from their warehouse in Harahan, Louisiana is $130.00.

I may pick up the King

Starboard on the way to or from Atlanta, as that trip is

scheduled for next week.

My plan is to replace the King

Starboard on the hard Bimini with anti-skid King

Starboard product, and to use the King

Starboard I remove from the hard Bimini to use as the

top on the hard dodger. I will have a lot of King

Starboard left over that I hope to make cup holders

and such to replace the teak ones I have in the cockpit. This will

cut down maintenance!

November 13, Wednesday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

Did not go to the shop

today or work on any DREAM AWAY projects. Spent the day on the

computer working on the web page, catching up on email and scanning

in documentation.

It was way too cold and windy to be

outside working or even at the shop.

The shop

is not temperature controlled, so it would have been very cold

working there.

November 12, Tuesday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

I went over to the

shop,

and worked on “adjusting” the bolts needed to install the

uprights for the hard dodger. By “adjusting” (cutting off the

ends) the bolts I got all of the bolts to their proper size.

Bolts That Need “Adjusting”

“Adjusting” A Bolt

I went back to DREAM AWAY and Kitty and

I had breakfast. After which we drove into New

Iberia to run some errands. When we returned, the

weather had dropped in temperature, and the wind was blowing a steady

15 knots, and gusting higher. We decided not to work on the hard

dodger today.

I did some work on the Port

of Delcambre’s shower

trailer. The hinge assemblies had broken on all three

toilets in the shower

trailer with the hard use of this past weekend. We had

stopped and purchased a toilet seat at Lowe’s

in New

Iberia. The new seat fit perfectly, and was less than

half the price of the manufacturers toilet seat. We are sure the port

director will approve the purchase of two additional toilet seats.

The remainder of the day was spent on

the computer, and then we went to the Port

of Delcambre’s public meeting. We go to the meeting

to catch up on what is happening with the Port

of Delcambre’s

activities, and to get our monthly pay check!

November 11, Monday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

After breakfast I went over to the

shop,

and sanded down the two hard dodger uprights I had applied the

finishing

putty to yesterday.

Sanded Hard Dodger Uprights

Sanded Hard Dodger Uprights

I hauled all of these items down to

DREAM AWAY, to start installing the uprights onto the base of the

hard dodger. We got one upright installed. It is very time consuming,

and I broke two drill bits drilling through the stainless steel pipe

of the top base. But we got our start!

Stainless Steel Tab Installed On Hard

Dodger Base

Top Of Installed Upright

Bottom Of Installed Upright

I decided to stop the installation

after the first upright was installed. It was time consuming, and I

needed time to get all of the tools and material back to the Black

Beast.

There was a nice service at the war

memorial, and all of the service flags were changed. I assisted with

the changing of the Marine Corps flag.

After the service we had complimentary

refreshments at the Magdalen

Place. Kitty and I then went to Chili’s

for dinner as they were offering complimentary meals for all

veterans.

November 10, Sunday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

After breakfast I went over to the

shop,

and sanded down the two hard dodger uprights I had glassed

together this past Friday.

Sanding On The Uprights

Sanding On The Uprights

I put two medium sized blobs of the

finishing

putty on the mixing board. I do this so I do not add

the cream

hardener to a large amount of putty, and have it go

off too soon.

I then added the cream

hardener to one blob of the finishing

putty, and mixed well. I then applied the finishing

putty to the two uprights. In some areas I use the

finishing

putty as a filler to level out flat surfaces, and as

filler to make smooth radiuses in corners. Both uses make the

finished product look close to professional.

When the application of the finishing

putty was finished, I cleaned up the area, and went

back to DREAM AWAY. I was taking the remainder of the day off to try

and catch up on email, and to relax a bit.

Today is the 238th birthday of the

United States Marine Corps, so it was time to celebrate Marines past

and present, and those who had made the supreme sacrifice for this

nation.

November 09, Saturday,

2013

Up and at em’ at 0445, and at the

Delcambre

Shrimp Festival grounds at 0515. I put the steps down

and put on the railings of the shower

trailer. I connected the electricity to the shower

trailer, and verified lights and operation. I also

double checked we had plenty of toilet paper and paper towels in each

rest room.

Then I became a traffic monitor at one

of the entrance gates to help the vendors get into the grounds, and

find their correct spot to set up for the market. I finished that at

0750.

I picked Kitty up at the marina

parking lot, and we drove to the American

Legion in Abbeville.

The American

Legion was putting on a “typical military”

breakfast for veterans and their spouses. The breakfast consisted of

scrambled eggs, SOS,

bacon, biscuits and coffee. Can’t get much more military!

It was a great breakfast, and brought

back some good and bad memories. The mayor and one city councilman

from the city of Abbeville

was there and each gave a short speech. There were two World War II

veterans there.

We also did some a lot of our Christmas

shopping while at the market. We purchased some of the local sauces,

jellies and pickled vegetables that we thought is typical of

Acadiana.

The market was over at 1300, so now it

was time to help with the breakdown and loading of all of the tents,

tables and chairs owned by the Port

of Delcambre. We did have some help from some of the

local kids, so they took care of loading all of the stuff on the

trailer and transporting the tents, tables and chairs back to the

Port

of Delcambre’s storage room.

Kitty and I did a small bit of cleanup

on the shower

trailer. I drained the remaining water out of the

fresh water tank, and disconnected the electricity. I then removed

the hand rails, and put the steps up in travel mode. We got the

shower

trailer hooked up to the Black

Beast, and drove back to the

marina.

We disconnected the shower

trailer, and Kitty drove into New

Iberia to run an errand.

I stayed at the marina,

and dropped the stairs down to gain access to the restrooms. I then

cleaned out the two restrooms in the shower

trailer that were used during the market. I emptied

the trash cans, and then mopped the floors in each of the two

restrooms.

It was a hard day for the shower

trailer. The reason we only used two of the three

restroom was because the toilet seat hinges were broken on the third

restroom. At the end of the market, the toilet seat hinges were

broken on the other two toilets. Another project!

Kitty got back to the marina

at the same time I finished up, so we unloaded the Black

Beast, and relaxed in the cockpit for a bit.

We were tired and were in bed by 2030!

November 08, Friday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

Went over to the shop,

and started sanding all of the uprights that I had glassed

together yesterday. It is important to get as smooth as possible.

These double uprights will be the uprights on the front of the hard

dodger and will have the sliding, opening windows in them. Going

through the sanding process, I could see I may have to recut some of

the channels in the hard dodger uprights.

Sanding The Uprights Glassed Together

Sanding The Uprights Glassed Together

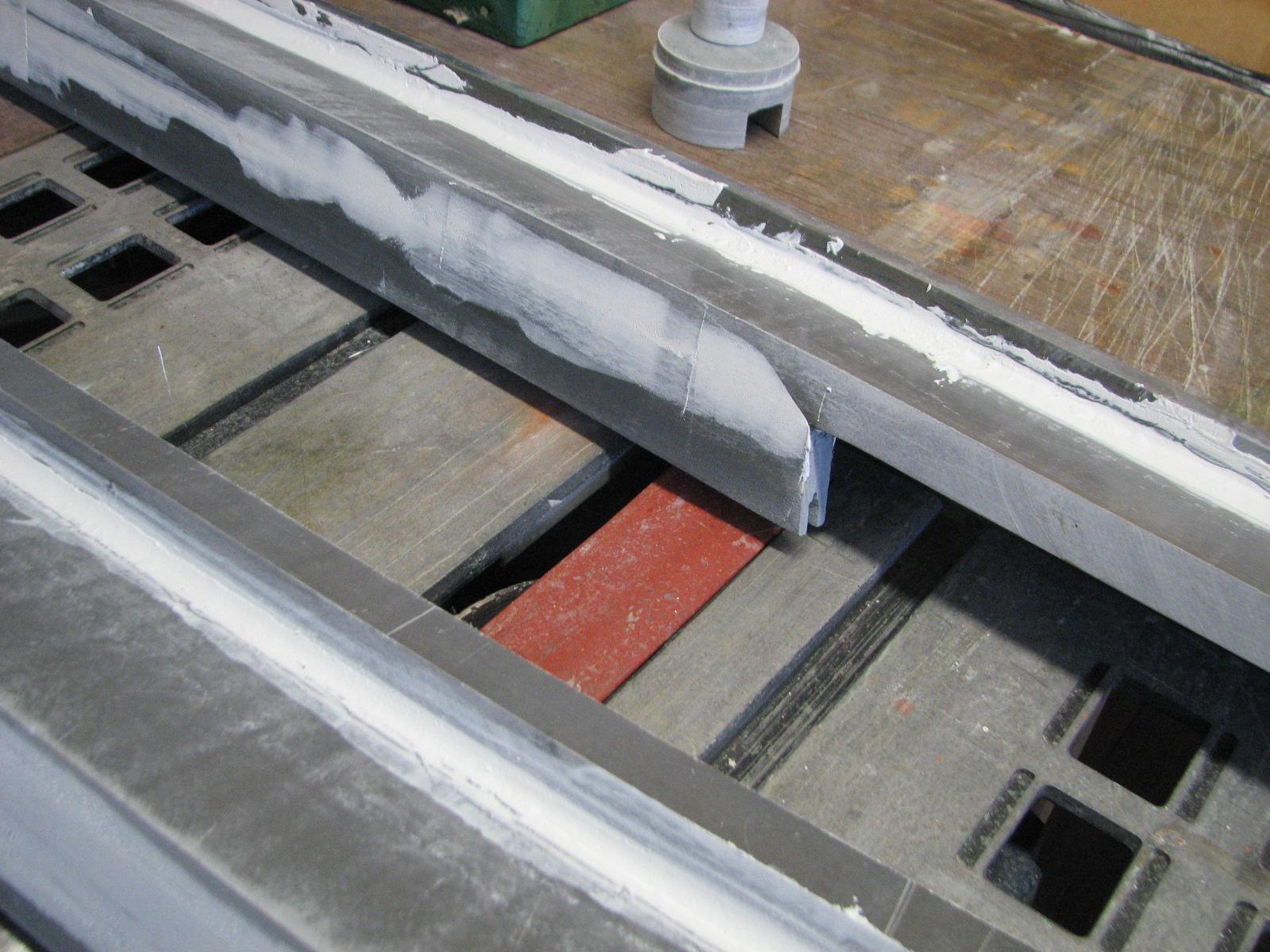

When all of the sanding was complete, I

did a dry fit of two uprights that had to have another piece of the

Strongwell

Extren plate glassed to it. The two uprights on the

front outside edge had to have a piece of plate glassed to it for the

sliding opening windows. It also had to have a piece of plate glassed

to it for the stationary side window.

After the dry fit of the parts, I cut

the fiberglass

mat that I use to glass the two pieces together. I then do a dry fit

of the fiberglass

mat.

I then mix up a batch of the polyester

resin, wet out the fiberglass

mat, and then clamp the two pieces together. As usual we wait for the

chemical process to happen, and we magically have one pice of plate

instead of two!

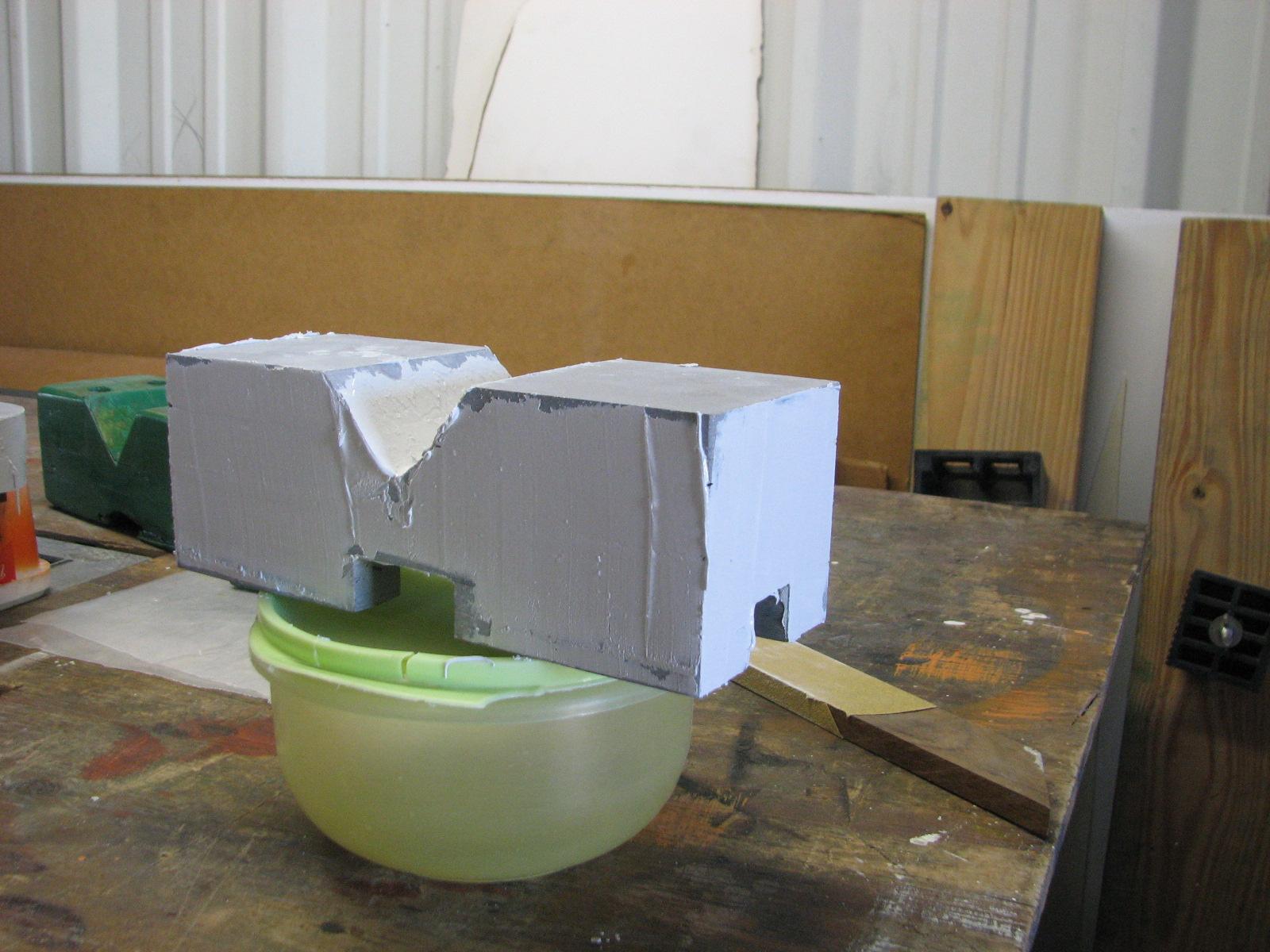

Two Pieces Of Plate Glassed And Clamped

Together

Two Pieces Of Plate Glassed And Clamped

Together

We hooked the shower

trailer to the Black

Beast, and went over to the Delcambre

Shrimp Festival grounds, maybe a third of a mile! When

we got there the Port director pointed out the location, and we moved

the shower

trailer to that location and unhooked it from the

Black

Beast. We dropped down the steps on the shower

trailer, and made sure all was ready in two of the

restrooms. I put water in the fresh water tank to about half full. We

verified we had electricity for the trailer, then put the steps back

up into the travel position. This was for security.

Kitty and I then traversed the

Delcambre

Shrimp Festival grounds looking for fire ant nests.

When we found a nest I applied ant poison. I ran out of the poison,

so had to go to the Port

of Delcambre’s storage room to get some more. I came

back, and we finished the ant eradication project.

We went back to DREAM AWAY, had an

adult beverage, a shower, and a great dinner of pork ribs!

November 07, Thursday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

Went over to the shop,

and started sanding all of the uprights that I had cut

channels into yesterday. I had to get edges smooth, and also to rough

up the places where two pieces of the uprights had to be glassed

together for the opening windows in the hard dodger.

Channelled Uprights Ready For Sanding

Channelled Uprights Ready For Sanding,

Look Close For Channels

Sanding The Uprights

Two Sanded Uprights Ready For Glassing

I also connected the electricity and

water to the shower

trailer, because we had a service coming by later this

afternoon to clean the shower trailer.

Kitty and I then had lunch, we had a

late breakfast, and I went back to the. I finished sanding all of the

uprights for the hard dodger, and had the specific uprights sanded to

be glassed together.

Sanding The Uprights

I then did a dry fit of all the

uprights that were to be glassed together, to make sure they all fit

together , and to make sure I had the required number of clamps. I

needed to clamp the two pieces together after applying the fiberglass

and polyester

resin.

Dry Fit Of Uprights

Dry Fit Of Uprights

I then got out my stash of fiberglass

mat and cut all of the required pieces, and verified the fit. When I

was satisfied with everything, I mixed up a pot of polyester

resin and applied it to the uprights. Even though it

was chilly out I did not make the mix too hot. I wanted to make sure

I had plenty of working time to wet out the mat, put the two pieces

together, then put on the clamps, and finally clean up any drips.

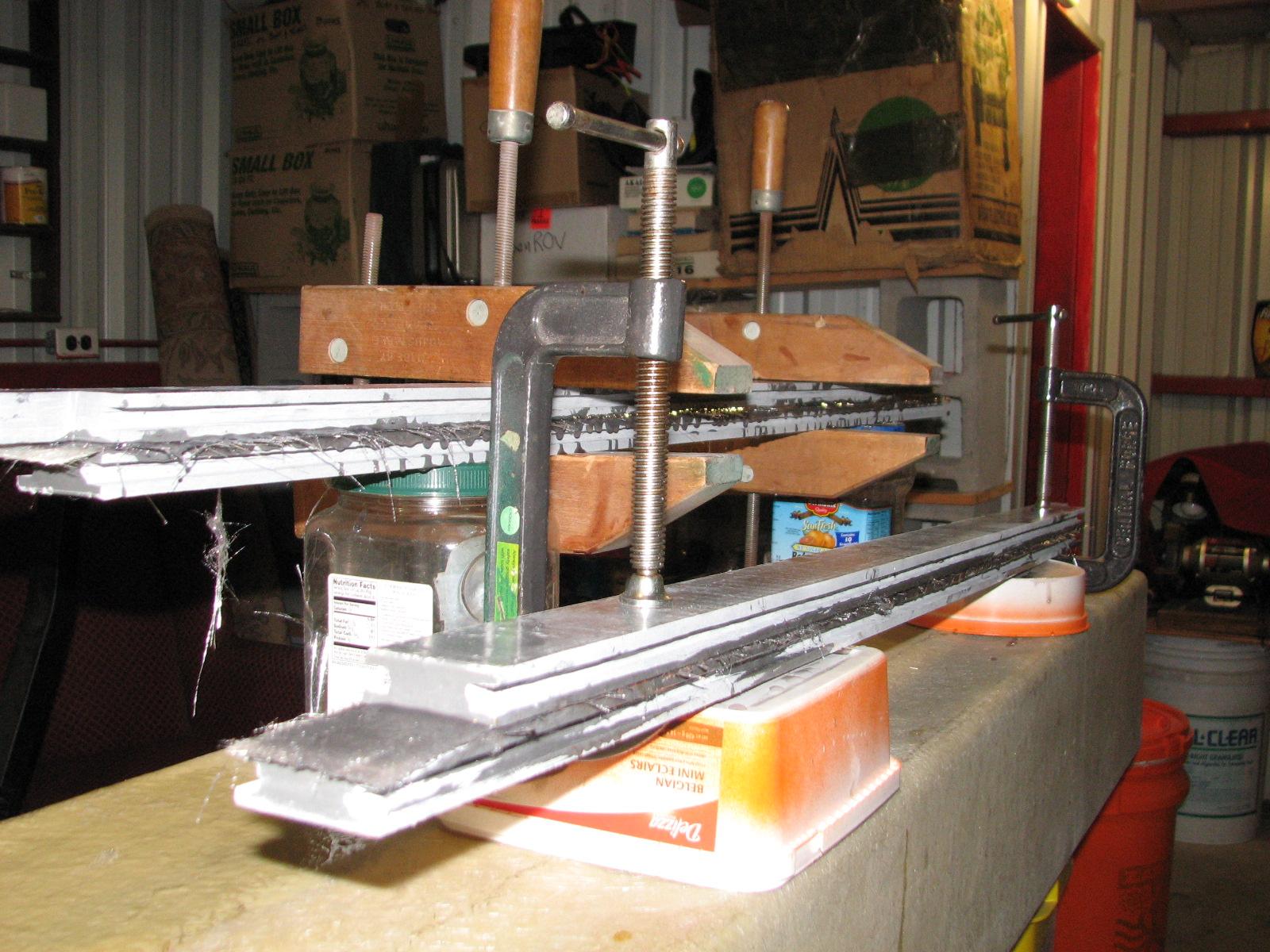

I did this with all four sets of

uprights I glassed together.

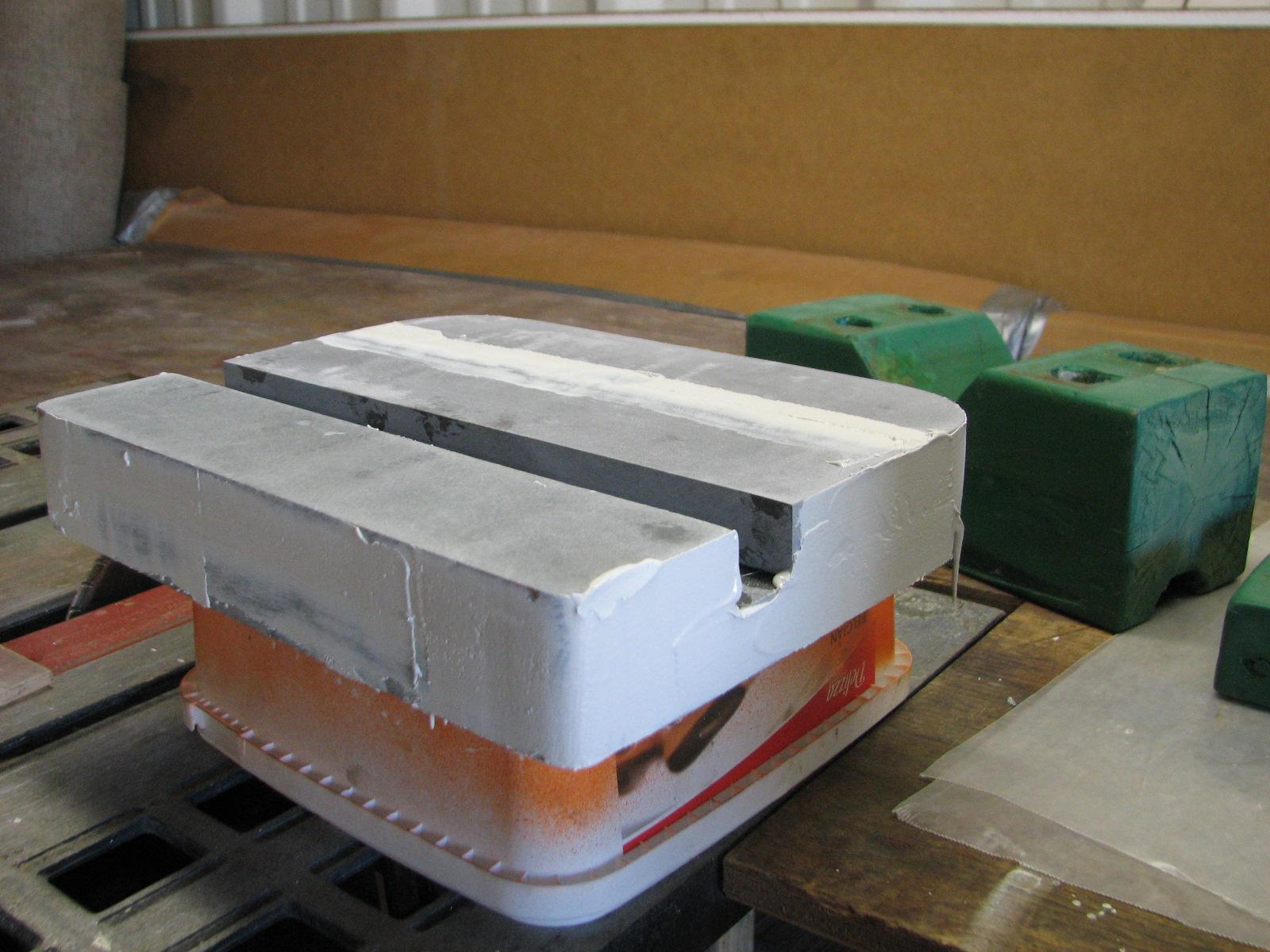

Uprights Glassed Together And Clamped

Uprights Glassed Together And Clamped

Uprights Glassed Together And Clamped

Uprights Glassed Together And Clamped

Uprights Glassed Together And Clamped

Uprights Glassed Together And Clamped

When I finished all the glassing of the

uprights, I cleaned up the uprights as best as I could. If you do too

much, you end causing more problems with resin everywhere, than when

you started. Besides thats why they made big grinders!

I then cleaned up the area, and my

self, and went back to DREAM AWAY and a hot shower.

Later that night we watched a two hour

special on PBS about Jimi Hendrix.

November 06, Wednesday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

I had breakfast and walked over to the

shop,

and continued cutting the channels in the hard dodger

uprights.

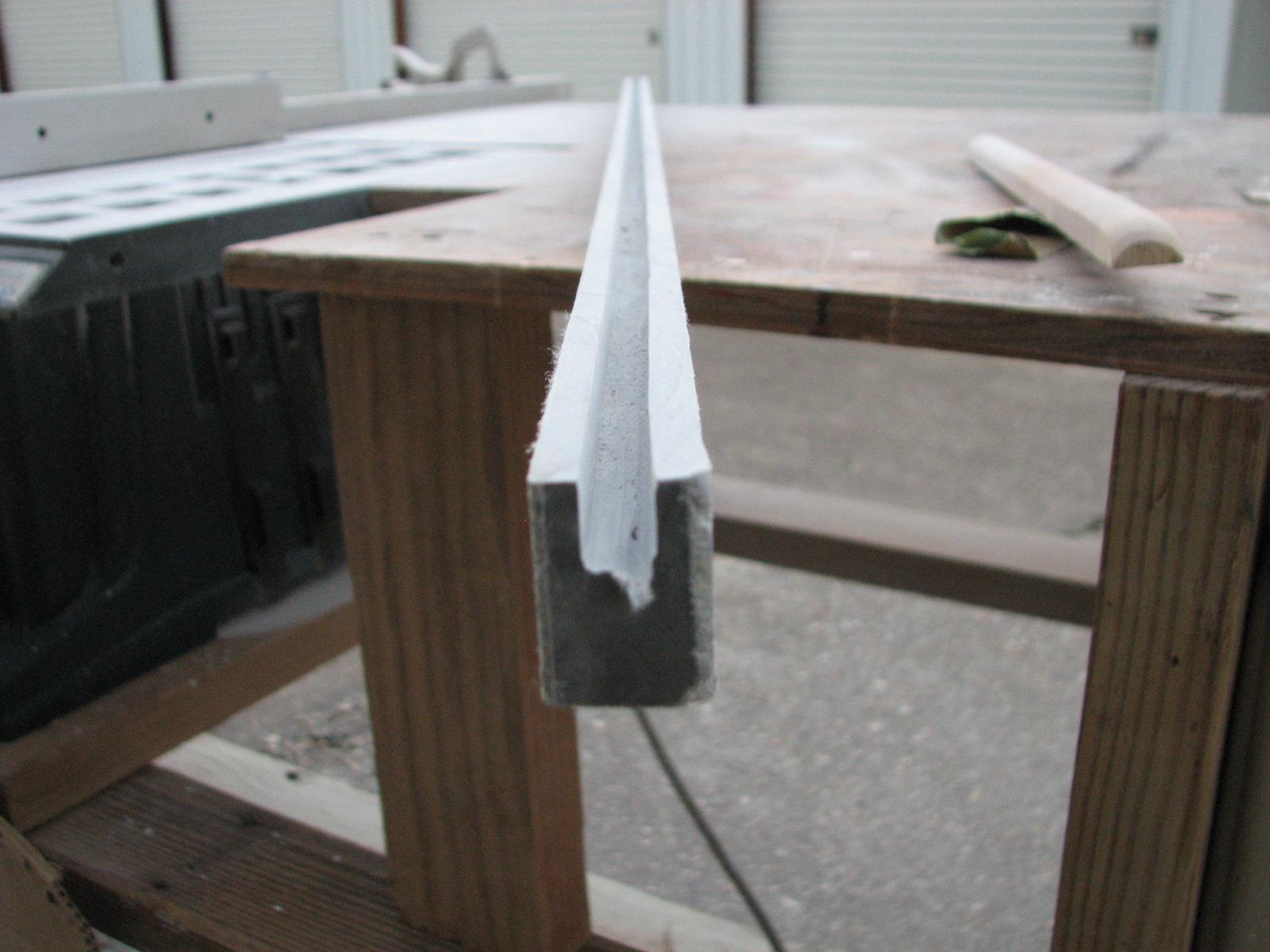

As I mentioned yesterday I had cut at

least one channel in each hard dodger upright for the

plexiglas

panels to be inserted into. The channels are ½” deep by ¼”

wide, and the length of the uprights are at least 38” long and

there are 12 uprights with a toyal of 20 cuts! As you can tell, this

is a lot of cutting.

I managed to get two fences set up on

the table saw so that I cannot cut wrong. We will see how that goes

in reality!

Fences Set Up On Table Saw

Fences Set Up On Table Saw

All Of The Uprights That Need Cutting

While I was doing the cutting on the

hard dodger uprights, I taped down the start control on the

SeaScooter. I ran the SeaScooter until the battery was almost out.

Since I can not run the SeaScooter under a load, I decided to run in

“on the bench” several time to check out the reliability of the

SeaScooter and the battery. Testing continues.

SeaScooter Running On Workbench

When I finished all of the cuts in the

hard dodger uprights, the morning was gone, and I needed a shower. I

cleaned up the table saw and it’s table, then walked back to DREAM

AWAY.

I took a shower and spent the remainder

of the day working on the computer in catch up mode as usual.

November 05, Tuesday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

I went over to the shop,

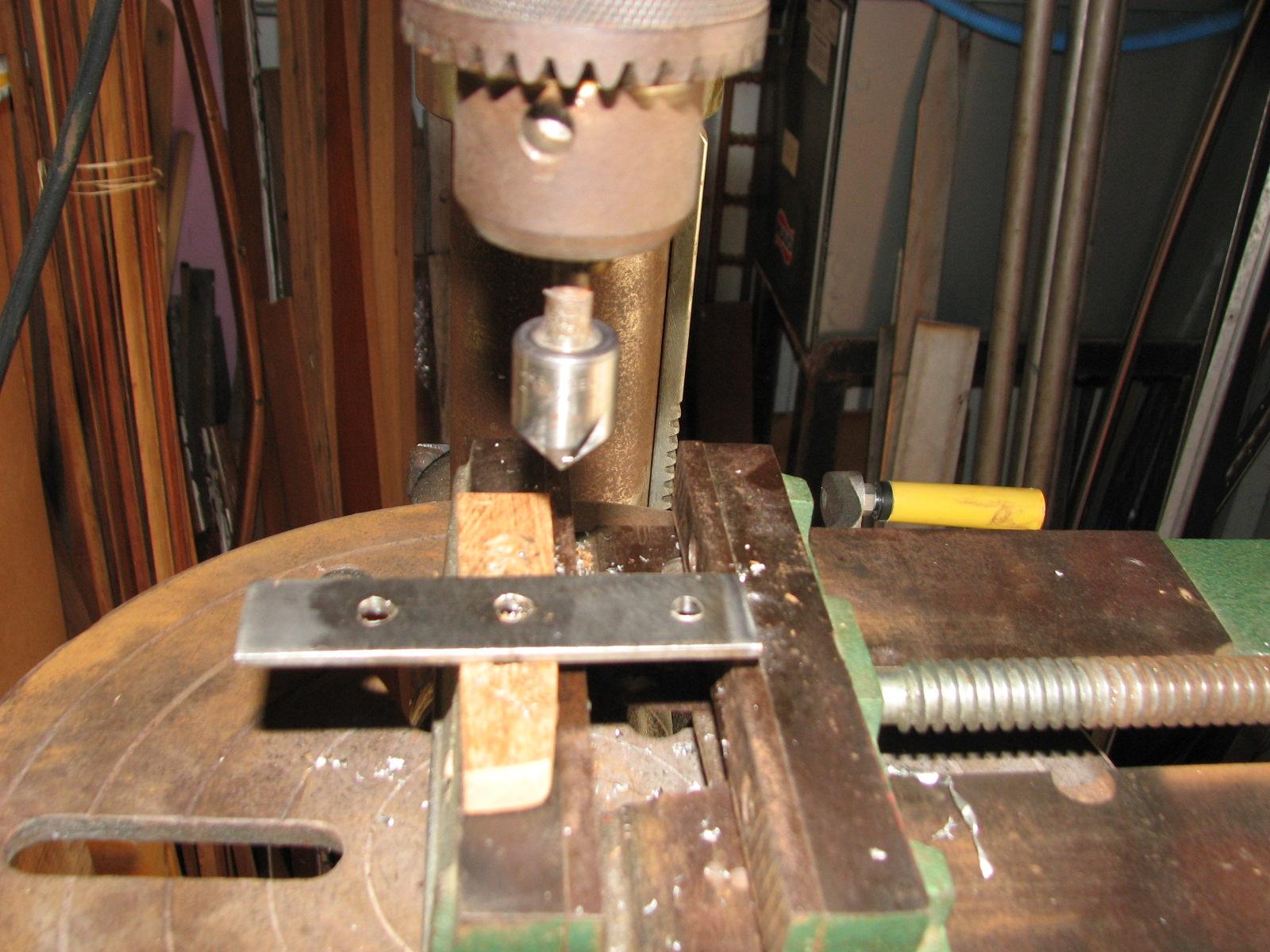

and got to work on the stainless steel tabs for the hard

dodger. I used the countersink

to clean out all of the drilled holes in the tabs.

I then got out my high speed grinder

and put on a 120 grit flap disk. With this disk, I cleaned up the

surfaces and the edges of all of the tabs. The tabs were now ready

for bending to meet the angle of the hard dodger uprights.

Kitty and I had our small breakfast.

Kitty and I are on a diet, the 5-2

diet. Good or bad, it seems to be working, and it is

not that difficult to stay on. I have lost 16 pounds in the two

months we have been on the diet.

Kitty and I removed the piece of

Structoglas

that I had put up in the back of the aft cabin. We have a leak that

is showing itself by water running off the piece of Structoglas.

It is supposed to rain tomorrow, so I am hoping I can find the source

of the leak?

I really hope the source of the leak is

not the davit bases. That will be a real struggle to fix, but one way

or the other it will have to be done.

Kittu and I took the piece of

Structoglas

off of DREAM AWAY and loaded it into the Black

Beast. I decided it was safer to store it in the shop.

I got the lawn mower, fuel can, grass

trimmers and gloves out of the Black

Beast. I went to work on weeding the gardens, trimming

the grass around the trees and sidewalks, and mowing the grass. I

also had to spread poison on several fire ant nests.

Kitty needed the Black

Beast to run some errands, so I walked over to the

Port

of Delcambre’s storage room with the lawn mower and

the fuel can. I locked the storage room and then walked down to my

shop

and went to work.

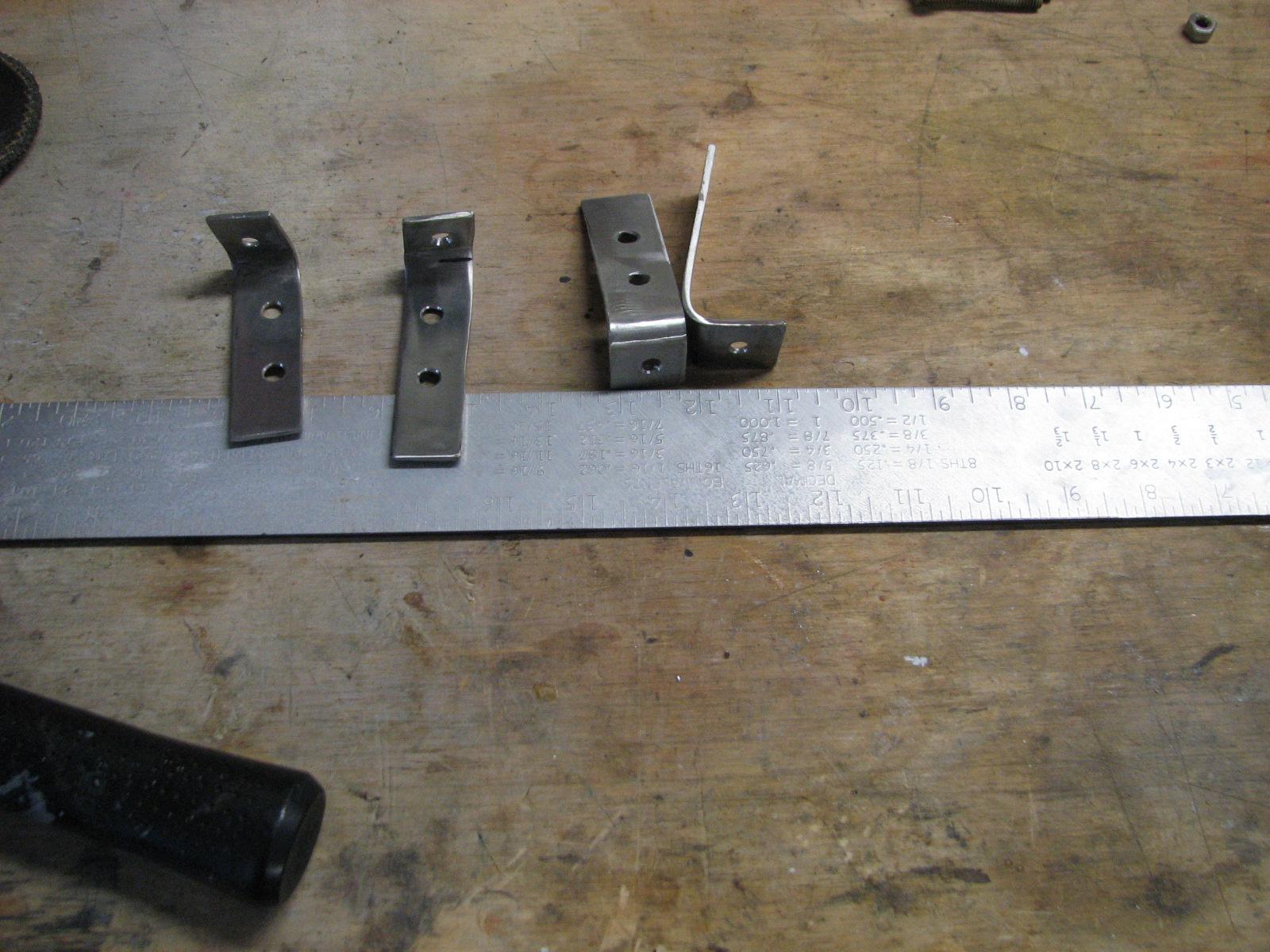

First item on the list are the

stainless steel tabs for the hard dodger uprights. I had to bend all

of the uprights to at least 100 degrees. I did this by putting the

tab in the vice, and then getting a piece of aluminum plate to put up

against the tab, then hitting the aluminum with the hammer. This

method works wonderfully, and does not mark the tabs.

One Tab In the Vice Partially Bent

Bent Tabs On Workbench

The next job is going to be a dirty

dusty one. I have to cut a lot of the Strongwell

Extren plate that I am using for the hard dodger

uprights. I rolled the table saw out of the

shop

onto the driveway. I set up the fence on the saw, and placed my big

squirrel cage fan to blow as much dust as possible away from me.

First off I cut a 2” piece of plate

into two 1” pieces for the uprights. These pieces will be glassed

to another upright, so I will be able to have windows in the hard

dodger facing forward that will be able to open and close. The plans

is to have a fixed piece of plexiglas

panel in one upright, and the upright glassed to it will have a

plexiglas

panel that will slide to open position or closed!

The next phase of the cutting is to cut

at least one channel in each hard dodger upright for the plexiglas

panels to be inserted into. The channels are ½” deep by ¼”

wide, and the length of the uprights are at least 38” long and

there are 12 of them! As you can tell, this is a lot of cutting.

I managed to get two fences set up on

the table saw so that I cannot cut wrong. We will see how that goes

in reality!

Channel Cut In One Upright

Channel Cut The Full Length Of The

Upright

I worked on the cutting the channels

until it was too dark to see. I cleaned off me and the table saw of

all of the fiberglass

dust, and put the table saw back into the shop.

I gather up my sack and water glass and

walked back to DREAM AWAY. I was really looking forward to getting a

shower and getting the fiberglass

dust off of me.

November 04, Monday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

I had my breakfast and went over to the

shop,

and set up to finish drilling the holes into the anchor support

pieces. The first piece needed just two 5/16” holes for the bolts

to hold it to the adapter I have on the stanchion base. I used the

original anchor support piece as the pattern to drill the holes in

the new fiberglass

piece.

Drilling Holes In First Anchor Support

Piece

I brought over my ¾” drill bit to

drill the necessary holes in the second anchor support piece.

Piece To Be Drilled And Original Anchor

Support Piece

Drilling The Holes In The Anchor

Support Piece

Now that I have all of the holes

drilled and cuts made in the anchor support pieces, they are ready

for final sanding and the the application of gelcoat.

I hope to applying gelcoat

to all of the uprights for the hard dodger very soon, so I will wait

and do all of the pieces at the same time.

Next project is the Shop-Vac

vacuum cleaner. As I mentioned yesterday, it had given up the ghost,

so I was hopeful I could somehow repair the problem. Yesterday as

part of the fix the vacuum cleaner, I had cleaned the filter used

inside the tank, but that was not the problem. I will have to get a

new cartridge filter.

I took the Shop-Vac

vacuum cleaner apart, and found two problems. The first major problem

was a nut and washer had come off of the shaft of the motor. I put

the nut and washer back on the shaft, and tightened as much as

possible. That fixed the main problem.

The next issue was shaft noise, like a

bearing going bad. It turned out to be the other end of the shaft in

a bushing, was not lubricated. I started the vacuum,and forced grease

into the bushing and that solved the second problem. I put the unit

back together, and it is working fine.

Shop-Vac

Vacuum Cleaner Apart On Work Bench

I again loaded the “Box

O’ Resins”, sanders, saws, a box with all of the

clamps in it, and all of the hard dodger uprights into the Black

Beast, and went to the marina.

I brought pretty much everything down

to DREAM AWAY except for the “Box

O’ Resins”. The main project on the hard dodger

today was to get all of the uprights cut to line up on the hard

dodger base.

My first measurement, I could not do,

because I needed a small short piece of the Strongwell

Extren plate. I walked over to the

shop

and brought back two pieces.

Needless to say after a couple of hours

of work, and cutting, Kitty and I got all of the bottoms of the hard

dodger up rights cut. The difficult part of the project was the

bottoms all had compound angles because of the crown of the doghouse,

and the angles the uprights leaned back to meet the top stainless

steel base for the uprights.

Two Saws On Dock Used For Cutting The

Uprights

Captain Making A Cut

Checking Uprights On Port Side

Port Center Upright With Additional

Piece For Sliding Window

Now that all of the bottoms are cut, I

need to cut and drill out the stainless steel tabs that are required

to attach the bottoms of the uprights to the hard dodger base.

I also have to cut grooves in the sides

of all of the uprights so the plexiglas

panels will slide into the uprights.

I then loaded everything I had brought

down to DREAM AWAY, back into the Black

Beast, and then back to the

shop,

and unloaded it all.

I changed blades in the Bosch

jig saw from the fiberglass

blade to the stainless steel blade. I clamped down a “fence” on

the stainless steel plate I was cutting, and cut the 1” piece of

stainless steel to be used for the tabs. I used cutting fluid to help

the process along. When the piece was cut, I cut it into 4” tabs.

Stainless Steel Plate Ready To Cut

I then measured all of the tabs and

marked where to drill the holes in the tabs. I smacked each

measurement for a hole with a center punch, then set up the drill

press. I drilled out all of the holes, but forgot my countersink on

DREAM AWAY.

Tomorrow I will bring the countersink

with me to the shop,

and finish off all of the tabs. I will also set up the table saw to

cut the grooves in the hard dodger upright.

A long day, I went back to DREAM AWAY,

ready for a shower and an adult beverage, not necessarily in that

order! It was not to be. When I got on DREAM AWAY, Kitty told me the

toilet was not flushing! This sounded like a lot of fun.

I took a few minutes to have a sip of

my adult beverage while we watched the cat play on deck. A couple of

birds were diving into the canal getting fish, and Jilly and Jordie

were fascinated.

Jillie Watching Me

Jordie Watching The Bird

Now it was time to face the toilet

issues. Because of recent events, I assumed the line or the pump was

clogged. I had to remove all of the toilet and pump spare parts to

gain access to the hoses.

When I finally gained access to the

hoses, they were disconnected and the pump removed. Lets just say it

was clogged. I took the pump outside on the dock and cleaned it all

out. The pump was put back, the hoses connected, and the toilet now

worked. All of the spare parts were returned to their original

location and the job was finished.

Pump Back In The System

Finally at 1900 I was able to take my

shower!

November 03, Sunday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

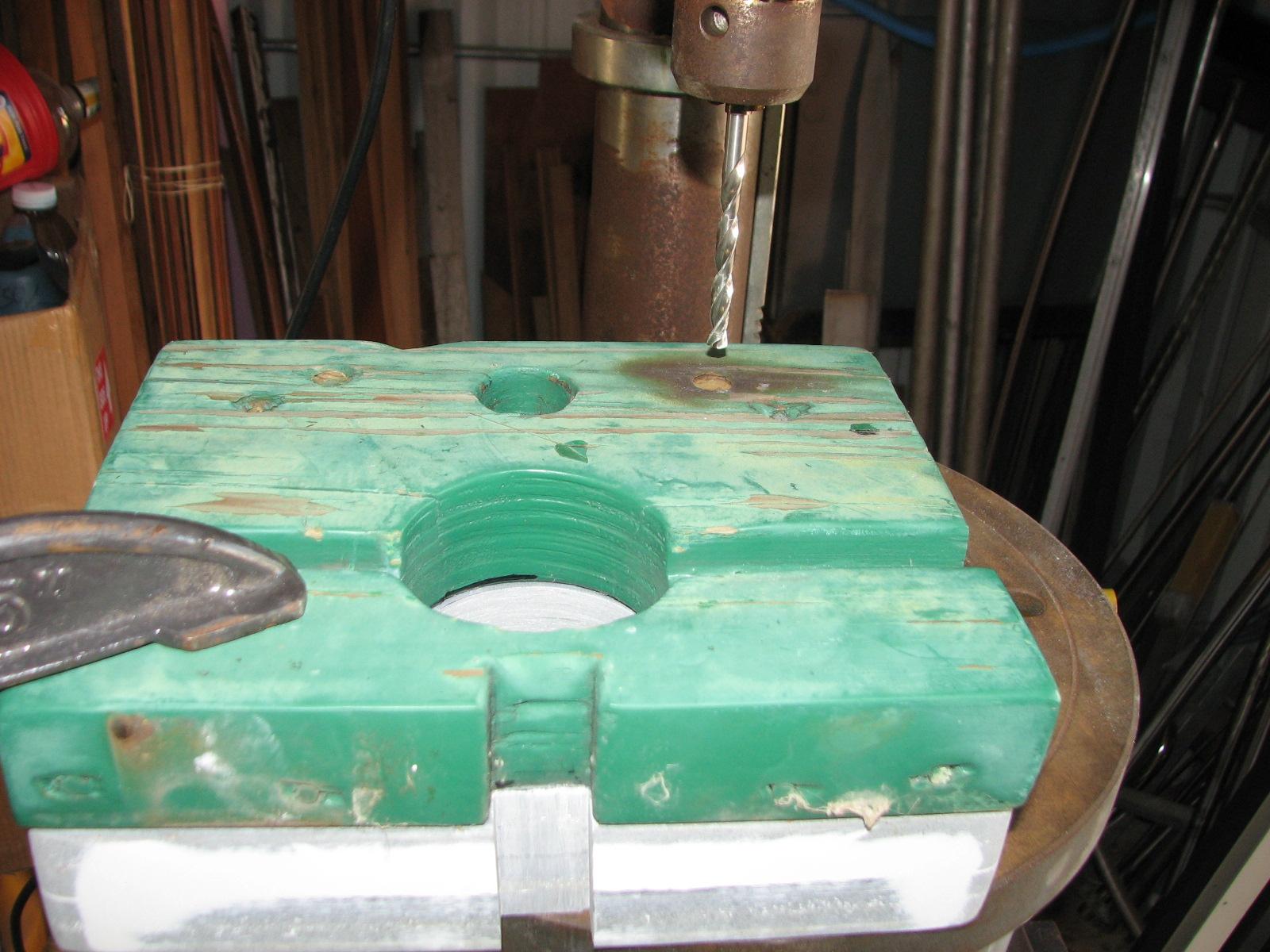

Went over to the shop,

and started in on drilling out the two anchor support bases. One of

the pieces I drilled out, but I needed a bigger bit. I will have to

bring over my larger bits tomorrow and drill out the holes again.

Drilling Holes In First Anchor Support

Piece

The second anchor support piece needed

to be drilled out with hole saws.

Marked Up Anchor Support Piece

First Hole Being Drilled

Second Hole Drilled

Holes Drilled With Plugs And Original

Piece

While making the cuts in the anchor

support pieces, I was using my wet dry vac, and the motor made a

funny noise, and quit. I will look into that tomorrow, but I may have

to put a new wet dry vac on the shopping list.

I got out the the

Evolution

Rage III compound miter saw, and made the angled cuts

in the two outside forward facing uprights for the hard dodger. I

cleaned up the area and the saw. I put the the

Evolution

Rage III compound miter saw into the Black

Beast along with two sanders, the jig saw, and all of

the uprights for the hard dodger.

I went over to DREAM AWAY, and brought

down a couple of the uprights to see how the cuts went. The cuts were

not exactly on, but that will be fixed later. I realized I will have

to bring a few of my clamps to DREAM AWAY from the shop.

It will make working with the uprights easier and safer.

As it turned out we did not get any

further work done on the hard dodger. We had a social commitment in

the afternoon. We went over to our friend Bonnie’s house and

watched the Saints game. She had made a wonderful lunch, which we

thoroughly enjoyed, but the game’s outcome was not good for Bonnie.

She is an avid Saints fan!

We came back to DREAM AWAY, and I

worked on the web page update, and attempts to upload files to the

web server. Very frustrating, as the program I use to upload the

file, Transmit, is not working in a very unusual way. More fun with

computers!!

November 02, Saturday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

Went over to the

shop

and rolled my sanding table outside, and sanded down the two anchor

support pieces. These are the two pieces on which I had applied

finishing

putty yesterday. I just have to drill some holes in

each piece, do some final sanding with 220 grit sandpaper, and they

will be ready for gelcoat

application.

Anchor Support Pieces Before Sanding

Anchor Support Pieces After Sanding

Next was the fun part, as I had to cut

the two 4” pieces of Strongwell

Extren plate. I rolled the table saw out of the

shop

onto the driveway. I set up the fence on the saw, and placed my big

squirrel cage fan to blow as much dust as possible away from me. I

then made the two cuts.

I cleaned up the table saw, the cut

pieces, and put the table saw back into the shop.

I loaded up several of the hard dodger uprights, the two new cut

pieces, and the “Box

O’ Resins” into the Black

Beast.

I cut two more of the 1” X 4” tabs

needed for the hard dodger uprights, and put them into the Black

Beast, and went over to DREAM AWAY.

I spent about an hour trimming grass

and weeding the gardens around the marina.

As I mentioned on the past Friday, the

leak in the head was still a problem. As with most leaks, I am not

sure of the source, so today I decided to remove the turning block

from the deck, and reseal it.

When I removed the turning block and

it’s base from the deck, it did not look like it was leaking. It

also did not look like the sealant had completely covered the bottom

of the base. I cleaned up the deck, and the bottom of the base of the

turning block. I then applied the Ace

Rope Caulk Weatherstrip to the base, and bolted it

back to the deck.

Turning Block Base Removed From The

deck

Deck With Turning Block Base Removed

Back Back On Deck, Caulk Squeezing Out

Under The Bolted Down Turning Block

Base

After we got the base all bolted down,

the next item is familiar to every boat owner looking for a source of

a leak. I got out the hose and ran water all over the area. Anything

that looked like it might be a source of the leak that is upstream

from the area of the deck where the turning block is bolted down to

the deck. I ran the hose for three hours, and of course not a drop

below decks! We have some rain predicted this coming Wednesday, so

maybe that will show success or not!

If by some chance this fixes the leak,

I will rebed the turning block on the port side. The turning blocks

were installed at the same time, so there could be a problem with the

port side block in the very near future. So far, no problem on the

port side.

Water Running From Hose Over Suspected

Area

While I left the hose running over the

turning block area, I turned to on the hard dodger base. I needed to

sand down the base and all of the putty that had been applied. I got

the area as smooth as seemed necessary. It is now ready for the

application of the finishing

putty.

Kitty and I did some more measuring of

the uprights for the hard dodger. We marked the uprights, and I

loaded them all back into the Black

Beast. I will take them over to the

shop,

and make the cuts in the morning. I think the next time we do the

measuring of the uprights, I will bring all of the saaws over to

DREAM AWAY, and we can do the cuts and measuring right away. This

will make quicker and easier progress.

Since I had done the sanding on the

hard dodger base, I had to wash down DREAM AWAY. There was a fine

film of fiberglass

dust all over the front of the boat and the cockpit.

Now it was time for a shower and an

adult beverage. Kitty had made a roast for supper. We were going to

have that, and then go to Joel’s boat and watch two football games.

We watched the Florida

State vs Miami game and then the Texas A&M vs UTEP

game.

I was 1 for 1. Very sorry Miami lost so

bad to Florida State, but happy about the A&M game!

November 01, Friday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats,

Jillian

and Jordan.

Went over to the

shop

and started sorting through the metal I have stashed. I was lucky,

and found a piece of ⅛” plate that I can use as the anchors for

the fiberglass

uprights on the hard dodger. I thought I was going to have to use

some of my ¼” plate as the anchors. I knew the ¼” would be very

hard to work with.

I calculated I would need 10 anchors,

or tabs, 1” X 3”, and 10 tabs 1” X 4”. I measured the

dimensions on the plate and started cutting. For the long cuts, I

used my Bosch

jig saw, and the shortcuts I used my

Milwaukee chop saw.

I only cut two of the 1” X 3” tabs and two of the 1” X 4” tabs.

I wanted to take the tabs over to DREAM

AWAY and do a check and dry fit to make sure the idea will work

before I take the time and effort to cut them all out.

Plate And Cut Tabs

Chop Saw Ready To Make A Cut

When I got the four tabs cut, I cleaned

them up and removed all the sharp corners. I loaded the tabs and two

of the fiberglass

uprights for the hard dodger into the Black Beast.

I then checked the two anchor support

blocks, and I had to make an adjustment on one of the supports. I was

able to use my Rockwell

Sonicrafter tool to make the adjustments. When I

cleaned up the two supports, after the adjustment, I was ready to

apply some finishing

putty.

Anchor Support Piece After Adjustments

I got out my putty mixing plate and

applied two separate blobs of the finishing

putty on the plate. I added the cream

hardener, and mixed it in quite well. I then applied

the putty to the first anchor support piece.

I then added the cream

hardener to the second blob, mixed it up well, and

applied the putty to the second anchor support piece.

Putty On First Anchor Support Piece

Putty On Second Anchor Support Piece

I got a couple of tools , and went back

to the shower

trailer. My project for the day on the shower

trailer is to make sure the steps and railing can be

installed, and to get one of the shower rooms presentable.

I got two hoses connected up, and one

end of the second hose into the shower. We ran the water, and of

course the shower would not drain. I went under the shower

trailer and loosened the drain connection and cleared

the debris.

Kitty and I got the steps installed,

the first shower room presentable, and verified the steps would fold

up to the sides of the trailer, and that the shower

trailer could be moved with the steps folded up.

Steps and Railings Installed

Steps Folded Up On Trailer

Because of all of the time spent on the

steps for the shower

trailer, I did not have time to do any sanding on the

hard dodger for DREAM AWAY. I did verify that the tabs I have cut

will work on the bottom of the hard dodger uprights.

Kitty and I decided not to use the tabs

on the top of the uprights. We will be able to cut the upright at the

proper length and angle, then through bolt the upright to the

stainless steel pipe that is the top support for the hard dodger. We

are still working on the “how to” in the forward corners of the

hard dodger, but we will come up with a solution.

Hard Dodger Upright With Stainless

Steel Tab At Base

Upright Leaning Against Top Support

We also decided we needed to change the

width of the outboard formars uprights of the hard dodger. To make

the forward uprights and the side uprights meet properly, the

outboard formars uprights need to be 4” wide. I still have some

left over Strongwell

Extren plate, so I will be able to cut two pieces 4”

wide. I then took all of the uprights back to the

Black Beast.