Maintenance Log December 2010

December 31, 2010, Friday.

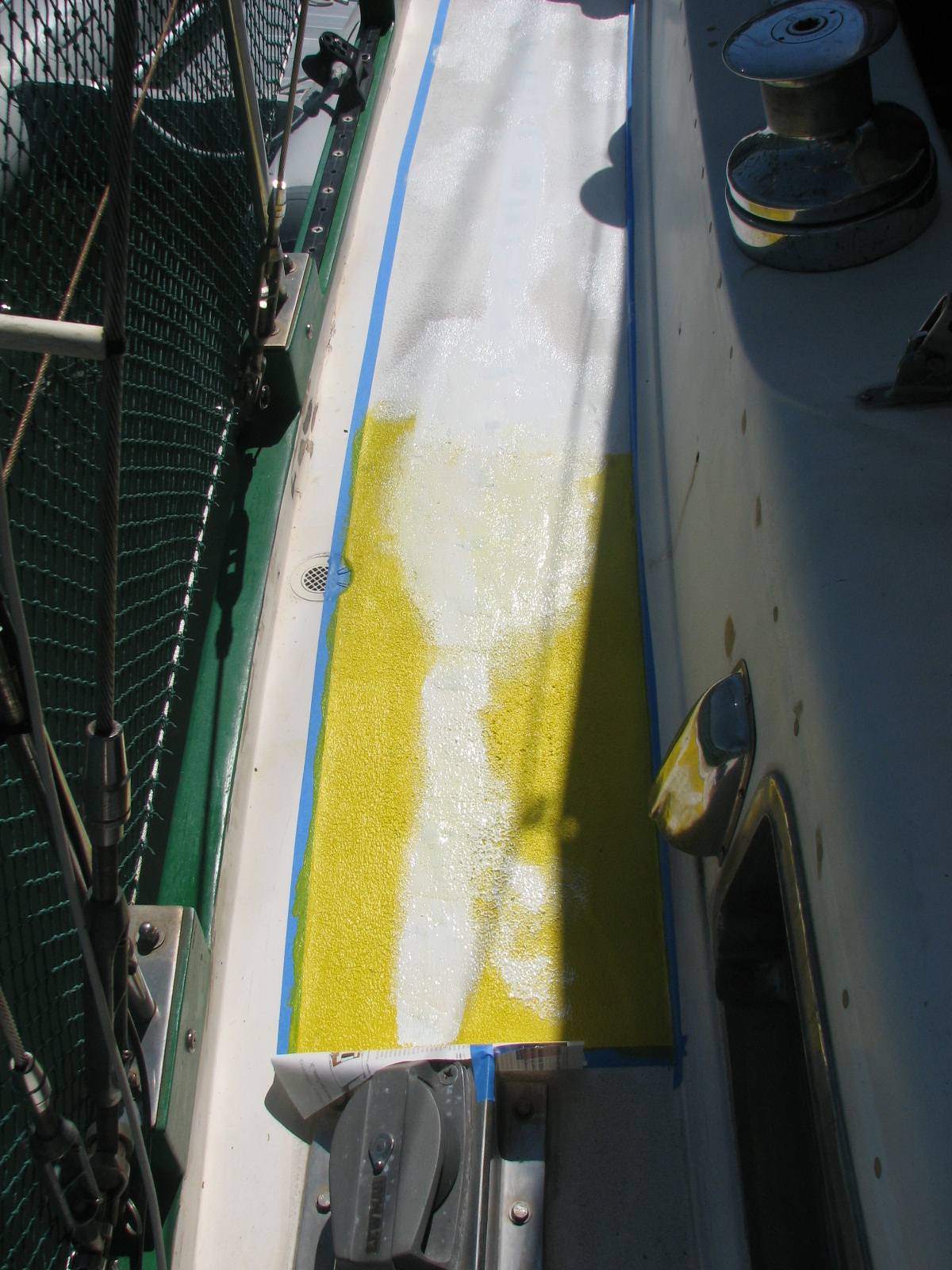

Went to

the shop and brought the three pots of mixed gelcoat back to Dream

Away. Mixed the catalyst into the first pot, and started rolling the yellow gelcoat on the deck. At once

I discovered a problem. The yellow gelcoat did not cover the darker

colored spots on the deck. I used the remainder of the first pot with

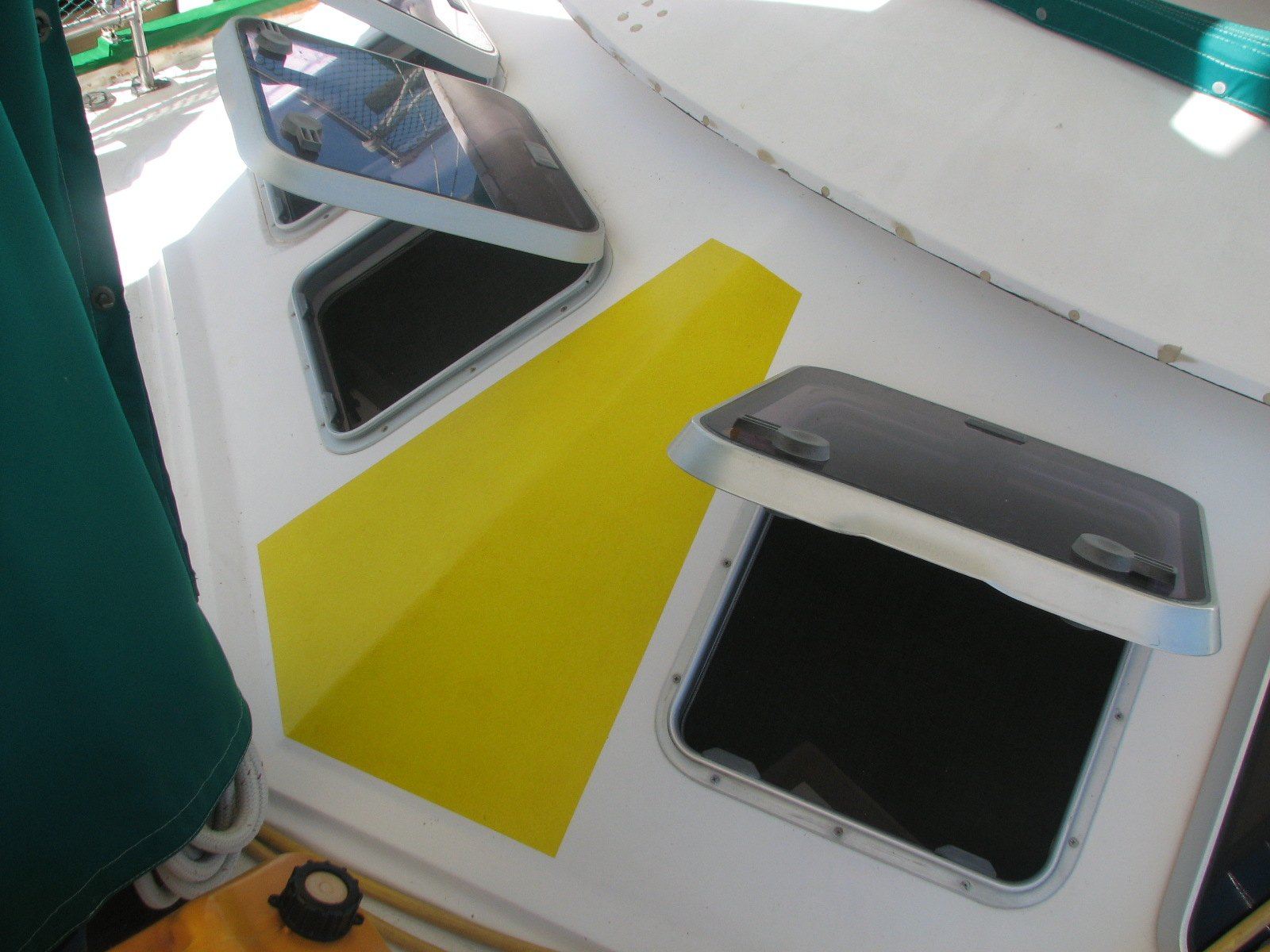

catalyst already mixed on the front part of the main cabin dog house. I

have always wanted non-skid in those areas because it is so slippery,

and could cause a real problem. I also rolled on the

remaining mixed yellow gelcoat on the after deck box lid. I did not do

good coverage for this lid and had prepared the lid in case I had too

much yellow gelcoat with catalyst already mixed in. Now the after deck

box lid is really safe to walk on.

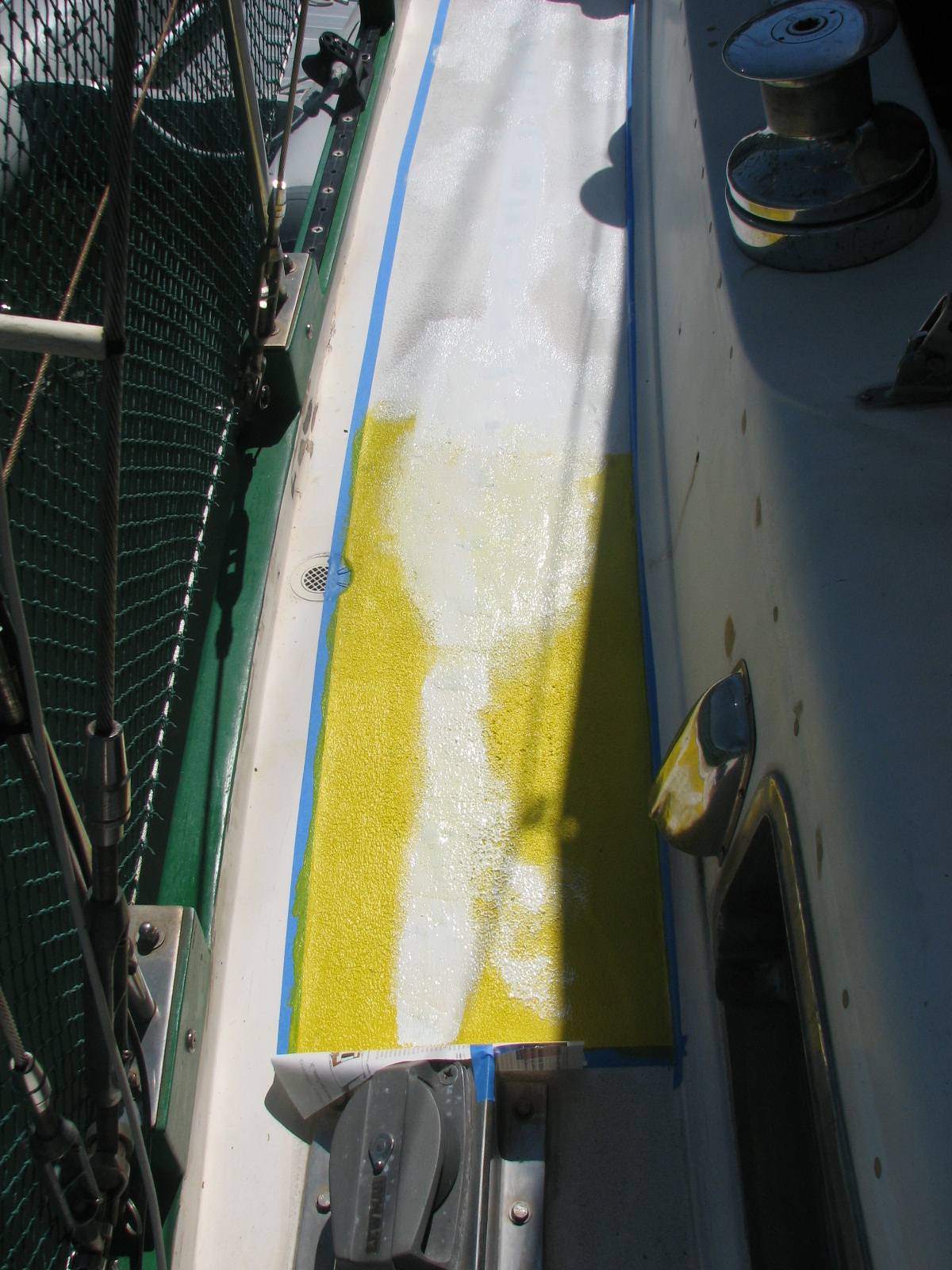

I immediately went to plan B. I

went back to the shop and mixed up a pot of white gelcoat, mixed in the

catalyst, and painted the white gelcoat over the patches and

discolorations. The white gelcoat did a great job of covering the

patches and discolored areas. It took about an hour for the white

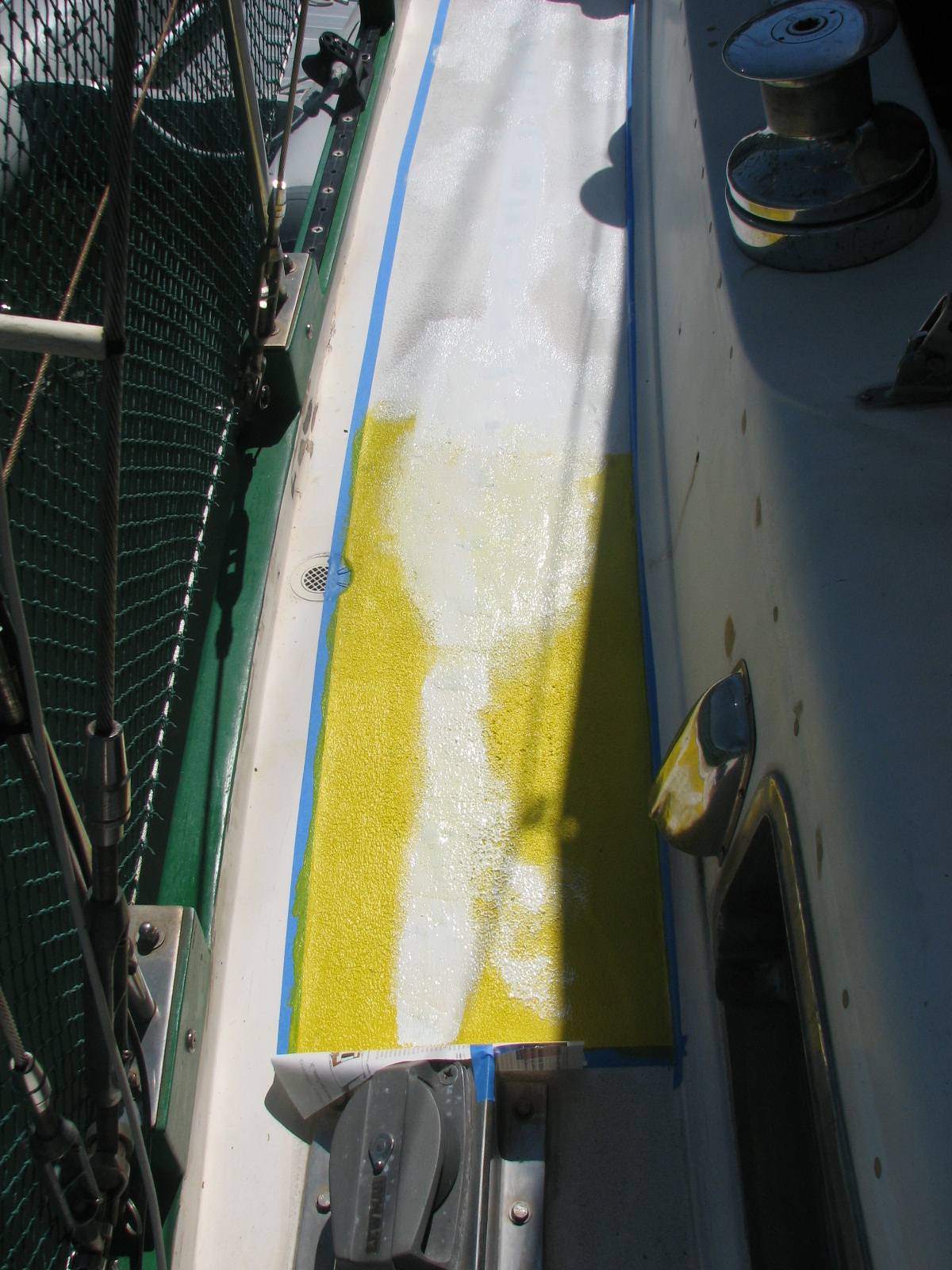

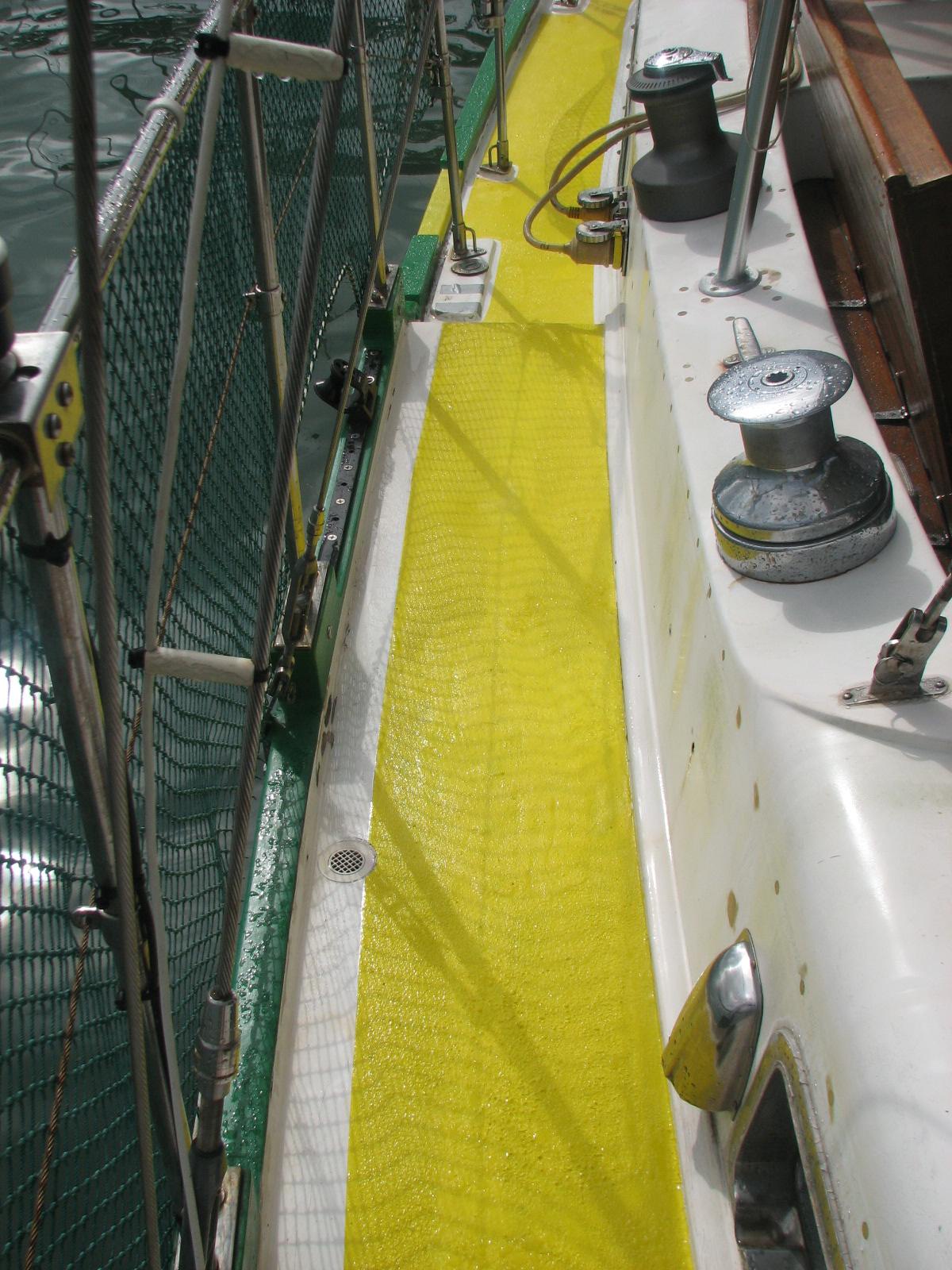

gelcoat to set up. I then went back to mixing the catalyst with each

pot of yellow gelcoat, and rolling the yellow gelcoat onto the deck.

Yellow Non-Skid Gelcoat Covering White Gelcoat

Masked-off Deck Area With White Gelcoat Applied

Yellow Gelcoat Rolled On Port Side Of Deck Area

Outer Portside Main Cabin Dog House With New Non-Skid Applied

Center Main Cabin Dog House With New Non-Skid Applied

After Aft Deck Box Lid With New

Non-Skid Applied

I applied the third coat of paint on

dinghy oar. It now needs to dry completely, and I can put it

back into the dinghy and start refinishing the second oar.

We had decided to replace

the material on the main cabin settee cushions. We had contracted with

a local person to do the work, and the price was very reasonable. The

person, Luis, had come by several days ago and picked up the old

cushions. We had previously selected the material. Kitty was very

pleased with the selection, but I had concerns. Luis showed up with the

new covered cushios, and two extra pillows we had requested, in "my"

color. It turned out to be an outstanding choice.

Forward Main Cabin Settee With New Cushions And Orange Pillow

Aft Main Cabin Settee With New Cushions And Orange Pillow

Kitty pointed out to me that I

had to put the yellow gelcoat non-skid on the top of the SCUBA

compressor cover. I agreed it had to be done as a safety issue, and the

box had to be patched and cleaned up so it was not such an eyesore. I

took the cover up to the shop to start work on the repairs. I covered

the compressor with a tarp while I am doing the work in the shop.

First repairs done to the box was

to put more fiberglass on the corners to help with overall

reinforcement.

December 30, 2010, Thursday.

Had to

go into Fronteras today to do some shopping and drop off and pick up

laundry from the Backpackers Hotel.

When we got back to Dream Away, I

got all prepped to paint the shear stripe on the bad areas I am trying

to fix. I got the areas painted, and it appears I will have just enough

paint to get a second coat on the damaged areas. For sure the next time

I leave the US, I will bring enough Easypoxy Kelly Green

paint, and Nyalic

protectorant to put at least three coats of Easypoxy Kelly Green

paint and three coats of Nyalic

protectorant on the complete cap rail and shear stripe.

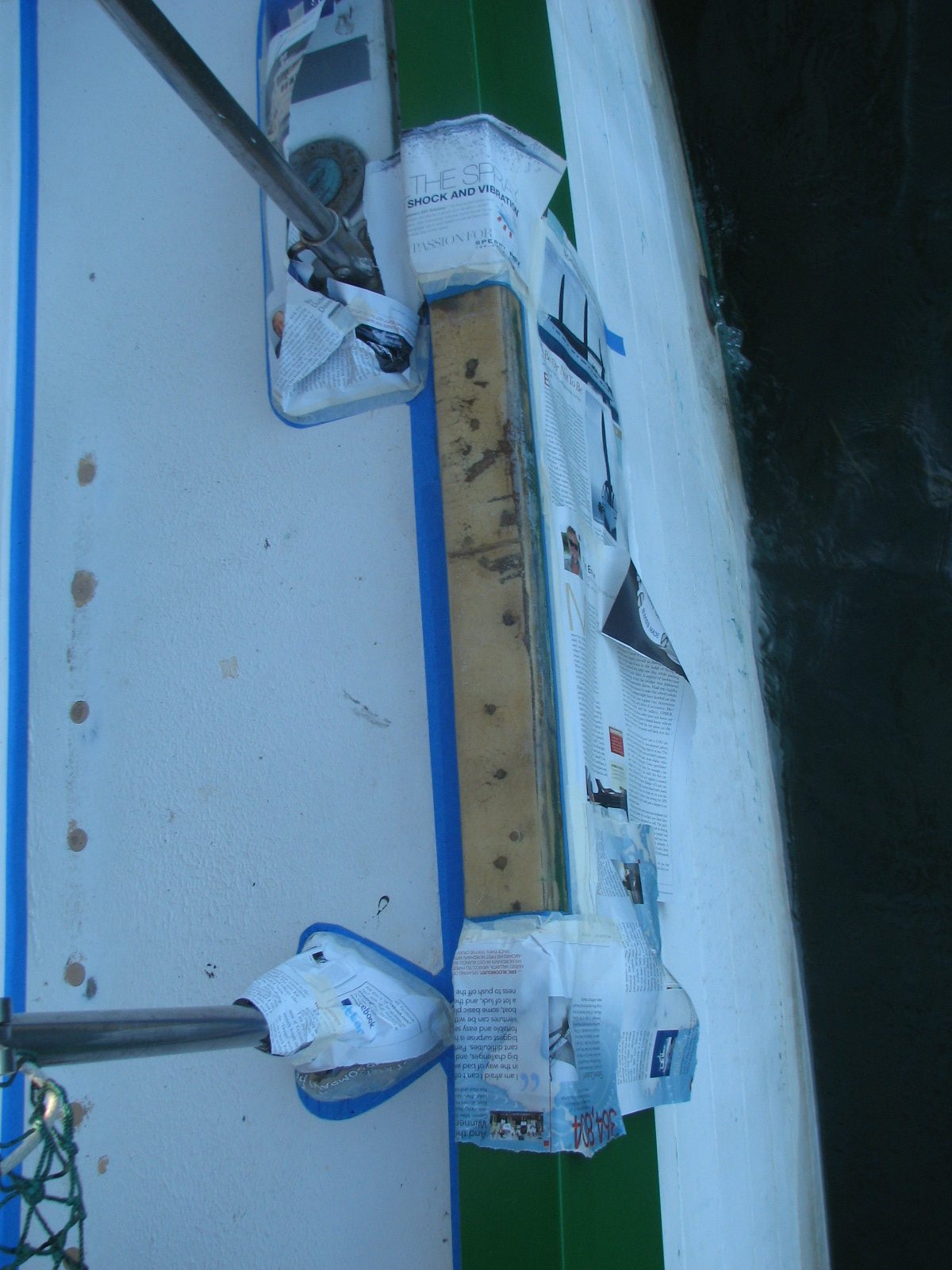

I finished the masking of the

area I am going to roll on gelcoat non-skid on the port side and part

of the front of the main cabin dog house. I also went ot the shop and

mixed up three pots of gelcoat to roll on tomorrow. The pots are made

up of 5 oz of gelcoat, 1 1/4 oz of wax (styrene), 1 1/2 oz of cabosil

and 1/2 oz of talc. It is all ready to go on tomorrow.

Port Side Dog House And Deck Masked-off For Gelcoat Application

Port Side Gate Area Masked-off

Port Aft Deck Area Masked-off

December 29, 2010, Wednesday.

I

applied masking tape to the shear stripe

in preparation of paint application when we have a great sunny day,

hopefully tomorrow. I also started masking the deck for the gelcoat

non-skid application.

I put an application of putty on

the repaired deck box area. I then finished applying fiberglass in the

hole behind the anchor windlass. Another application or two, and these

areas will be ready for gelcoat non-skid application.

December 28, 2010, Tuesday.

I

applied the second coat of paint on dinghy oar.

Will wait a day or two for good drying time, and then decide about a

third coat. Will probably apply the third coat, just so I have good

protection for at least a year of cruising.

Scrubbed the port side deck

around the dog house with a soap and bleach solution in preparation of

rolling on gelcoat

Recovered from outboard

experiment. Had to remove the Suzuki

outboard from my dinghy and install it back n Paul's dinghy. We

then had to remove the aft awning so I could lift the mizzen boom to

use as a motor crane. We then lifted my Yamaha motor off of the aft rail

of Dream Away and installed it on our Livingston tender. We then put the

aft awning back into place and all is now well. The problem now will be

to find a long shaft that will fit my motor.

Next, and last for the day was to

cut out the pieces of material for the outboard cover and the fuel tank

cover in the dinghy. I use a hot knife, so I do not have to run an

additional group of hems on the pieces.

December 27, 2010, Monday.

Started day working on the

computer getting pictures ready

for the web page, and ended the day that way also!

Sanded down the bad areas of the

shear stripe with 220 grit sandpaper in preparation for painting. I f

we have a sunny day tomorrow will mask the shear stripe, and put on the

Easypoxy Kelly Green

paint.

Worked on the FoodSaver

vacuum packer. It will not work properly. The folks at FoodSaver

are sending me a new unit, but of course it will not be available until

I return ot the states. Was able to figure out the problem is the

vacuum chamber will not seal unless I put hand pressure on the center

of the unit. At least now I can get bags vacuumed packed until I get

the new unit.

Last project for the day was an

experiment with the Livingston hard dinghy and a long shaft

outboard motor. Our dinghy with a 15 HP Yamaha 2 stroke engine is a great unit

for us as a tender, and we love it. The problem we have is when I get

three people or a lot of gear in the dinghy. I can not get the boat up

on a plane because the prop cavitates. I have always thought the

problem was because of the three hulls the Livingston dinghy has.

Today I was able to get with my

friend Paul who has a Suzuki outboard with a long shaft. We off loaded my

Yamaha and put his Suzuki

on the Livingston. With three of us in the Livingston we were able to get

up on a plane, and go through some large wakes with no cavitation. This

is both good and bad news. I have an 1989 Yamaha 2 stroke engine, with a ton

of spares, and just had it completely rebuilt, so I do not want to get

rid of that engine. Now I have to find a long shaft assembly that will

fit my Yamaha.

Put a coat of yellow paint on one

of the dinghy oars.

December 24, 2010, Friday.

I

removed the tape from the port side cap rail and the shear stripe. I

wanted to get that done, as it had been on for over a week. It says it

is 14 day tape, but you never know. I then scrapped and sanded

the crinkled paint areas on the port side shear stripe. It will be a

fairly easy repair, just takes time I wanted to spend on other

projects, and I really hope I have enough product to finish the job.

December 23, 2010, Thursday.

Another

rainy day. Took all of the Sunbrella

material up to the Rancho where I had plenty of room to lay out the

material and measure for the pieces I needed. I was able to get all of

the material measured for the OB cover and fuel tank cover. The good

news is I was able to find big pieces of material, so I will not have

to do a lot of sewing once I get the pieces cut out.

Rain stopped so we went shopping.

December 22, 2010, Wednesday.

Not a

lot accomplished today. Was able to dig out more green Sunbrella

to be used for the outboard cover and dinghy fuel tank cover.

Worked on printing pictures for

an album the boaters are putting together for the guardian family here

at Monkey Bay Marina. What an experience that was.

Great pictures but using Hewlett Packard printer was very

frustrating. I am using a Hewlett

Packard printer, with Hewlett Packard software, and Hewlett Packard picture paper, and

still get a bunch of confusing errors, that just wasts paper and ink.

There is no way I am ever going to purchase another

Hewlett

Packard printer again.

December 21, 2010, Tuesday.

What a

day of highs and lows, and I do mean both.

Started off the day by finishing

off the installation of the ice head in the ice maker. Just a matter of

putting new connectors on the end of some of the wires coming from the

ice head. Finished that up, and turned the ice maker on. Great news,

the motor in the ice head turned the system to the zero spot. The motor

was working. About 1.5 hours later, I heard the first ice cubes drop!!

The system was working!! I waited for the first five drops of ice

cubes, and threw them away. I wanted to make sure the system was making

clean ice!!

Somehow water had gotten into all

of the electrical connections, and corroded them. I think the solution

is to get all of the water out of the ice tray in the ice head before

making a passage. My bet is the last time I stopped the ice maker

before a passage there was water in the ice tray, and it sloshed out

during the passage. A couple of those events, and I have generated a

problem. Having the ice maker working was a big high.

Captain With First New Ice Cubes

Next

was to get a coat of Nyalic

protectorant on the port side cap rail and shear stripe. I wiped

down the cap rail and shear stripe with a clean rag and clean water,

and then dried the cap rail with a clean dry rag. I got all set up for

the application, and had just started to apply the Nyalic

protectorant, and it started to rain! So the application was

shut down. When it finally quit raining, I got another dry rag out and

dried down the cap rail and shear stripe. I waited another 30 minutes,

and started the application of the Nyalic

protectorant. First the Nyalic

protectorant was applied on the cap rail, and it went on very

well. I then got in the dinghy and started the Nyalic

protectorant application on the shear stripe on the front of the

boat. I had worked my way down about half way applying the Nyalic protectorant, and looked back

to check my work, and was horrified!! The green paint on the shear

stripe had started lifting off the surface with a really pretty crackle

pattern.

I

immediately stopped the Nyalic

protectorant application. I looked at the application that I had

done on the cap rail, and had no problems showing up there. The shear

stripe was in a bad way. Not sure what the problem was, but I am in a

fix. I am very short of the Easypoxy Kelly Green

paint. Not sure I will have enough paint to cover the repairs.

Tomorrow I will get an email off to the Nyalic

folks and see if they can tell me what I did wrong. My only thoughts

are that the surface on which I applied the Nyalic

protectorant was still damp. This was a major low!!

Cap Rail Showing No Effects Of Nyalic

Protectorant Application

Damage To Shear Stripe After Nyalic

Protectorant Application

Damage To Shear Stripe After Nyalic Protectorant Application

In between bouts of the rain and

applying the Nyalic

protectorant, I got out the sewing machine and worked on two projects I

needed to finish up. First thing I did was to finish the straps I made

for Paul's sewing machine. I had decided to finish the straps for Paul

as a Christmas present. I also decided to make two straps for each boat

in Monkey Bay Marina as a Christmas

present. The straps are five foot long pieces of black webbing, with

the proper sized buckles on them. Very appropriate for the Sailrite

sewing machine case, or any other hold down use. This

was another high for the day.

When I finished the straps, I

next worked on the mizzen sail cover. At the last day of bad weather, I

had sewn the skirts on the mizzen sail cover, but had not sewn on the

hook & loop material to keep the skirts in place. I was able to

complete the attachment of the hook & loop material,

so now that was finished. I finished the day by repairing a wrap that

Kitty uses to go to the shower. The hook & loop

material on it needed to be relocated. This was another high for

the day.

Mizzen Sail Cover With Skirts In Place To Cover Sheets And Halyards

December 20, 2010, Monday.

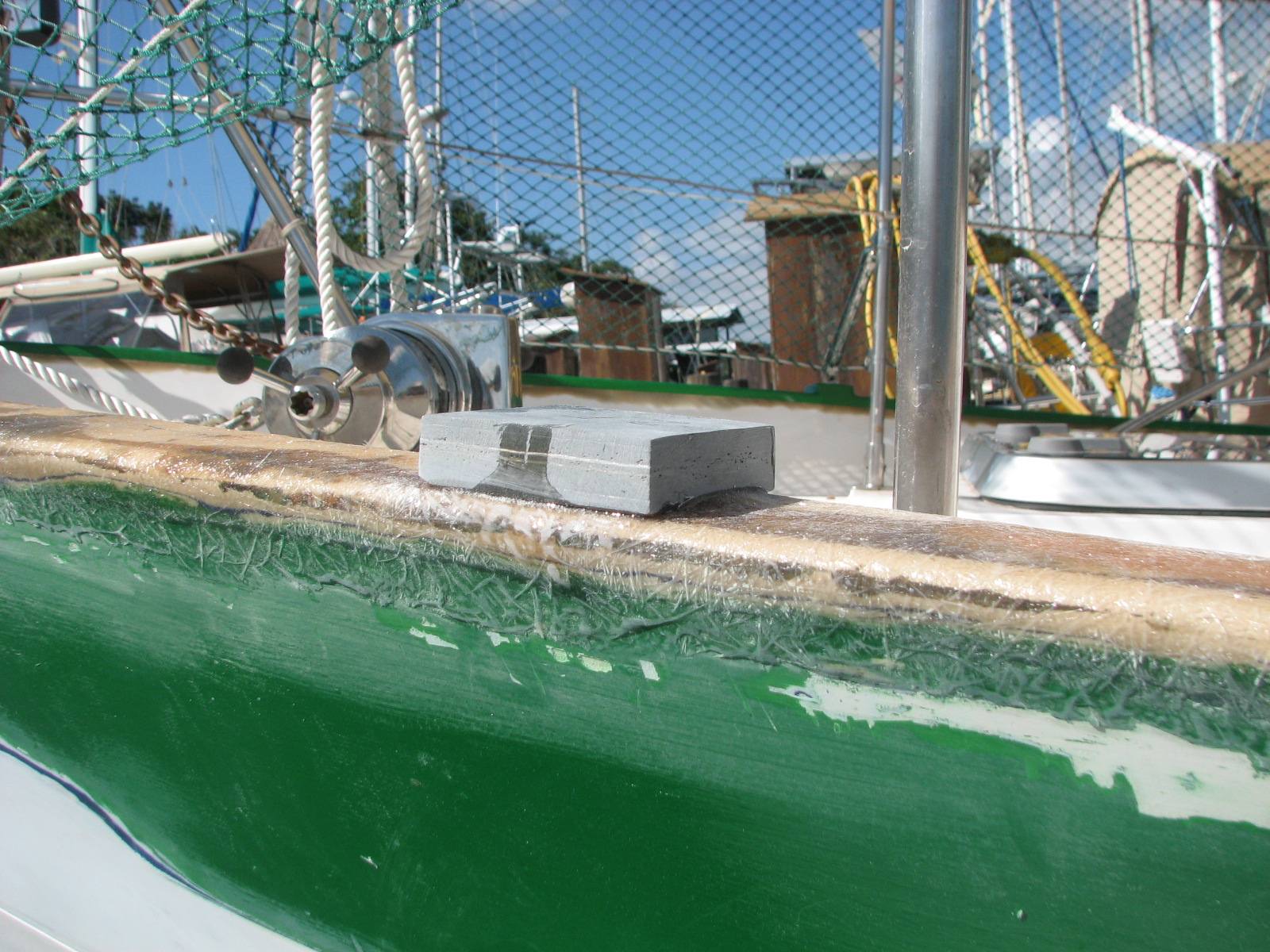

Did a

few small items today. Went up to the shop and drilled out all of the

chocks for the port side. They used to be screwed down to the cap

rail with large wood screws. I added the extra 3/4" fiberglass pads to

the cap rail/hull to deck joint, so I can use 5/16" bolts. I will drill

and tap the fiberglass. Because I am using larger fasteners, I had to

drill out the chocks and counter sink them for the flat head brass

machine bolts.

Next I mixed up a pot of

polyester resin, and put down the fiberglass to repair the port side of

the forward deck box, and to start filling in the hole behind the

anchor windlass. I got the deck box area done, but did not cut enough

fiberglass for the hole repair. Will finish that up tomorrow.

Just because, I decided to take

the ice head apart that I removed from the ice maker, to see if there

was anything obvious. Yes there was something obvious, I hope. The

electrical connections were all very much corroded. I took the

ice head up to the shop and took it all apart. I cleaned all of the

pieces, and did a really good job on all of the electrical connections.

I put the ice head back together, and installed the ice head back into

the ice maker. I did not get the ice head completely installed before I

ran out of time. I will complete the installation tomorrow.

I am hopeful the ice head will

operate properly, but the damage could have already been done. The

initial problem was the heater on the ice head would not come on and

release the ice cubes. Because of that the ice cube scoop could not

push the ice out of the tray. I am concerned, because the motor that

drives the ice cube scoop could be

defective. If that is the case, I will have to replace the ice head. I

am hopeful the problem was just electrical connections. Film at 11!

December 19, 2010, Sunday.

Day

off, Christmas stuff!!

December 18, 2010, Saturday.

Today is another beautiful day, so will have to wait until the port

side cap rail is in the shade.

In

the meantime, I worked on cleaning up the work bench and garage area on

Dream Away. It was a mess, and piled pretty high with the big power

tools. Hope fully will not need them for a while, so put the big eight

inch grinder and reciprocating saw away. Got the

garage area looking much better, and much more usable.

Cap rail

finally got in the shade, so went to the shop and got the paint and

brushes prepared, and went back to Dream Away. Wiped down the cap rail

and shear stripe with the tack rag, and applied the second coat of Easypoxy Kelly Green

paint. The application went very well, and I had enough paint. I even

have enough to do some touch up if necessary. I will wait a couple of

days and then apply the two coats of Nyalic

protectorant. Then I must install all of the hardware back on

the cap rail.

Two Coats of Epoxy Applied Near The Port Side Gate

Two Coats of Epoxy Applied To The Port Side Chain Plate

Area Shear Stripe & Cap Rail

Next, I

applied some putty to the place on the side of the forward deck box and

the hole in the deck just behind the anchor windlass.

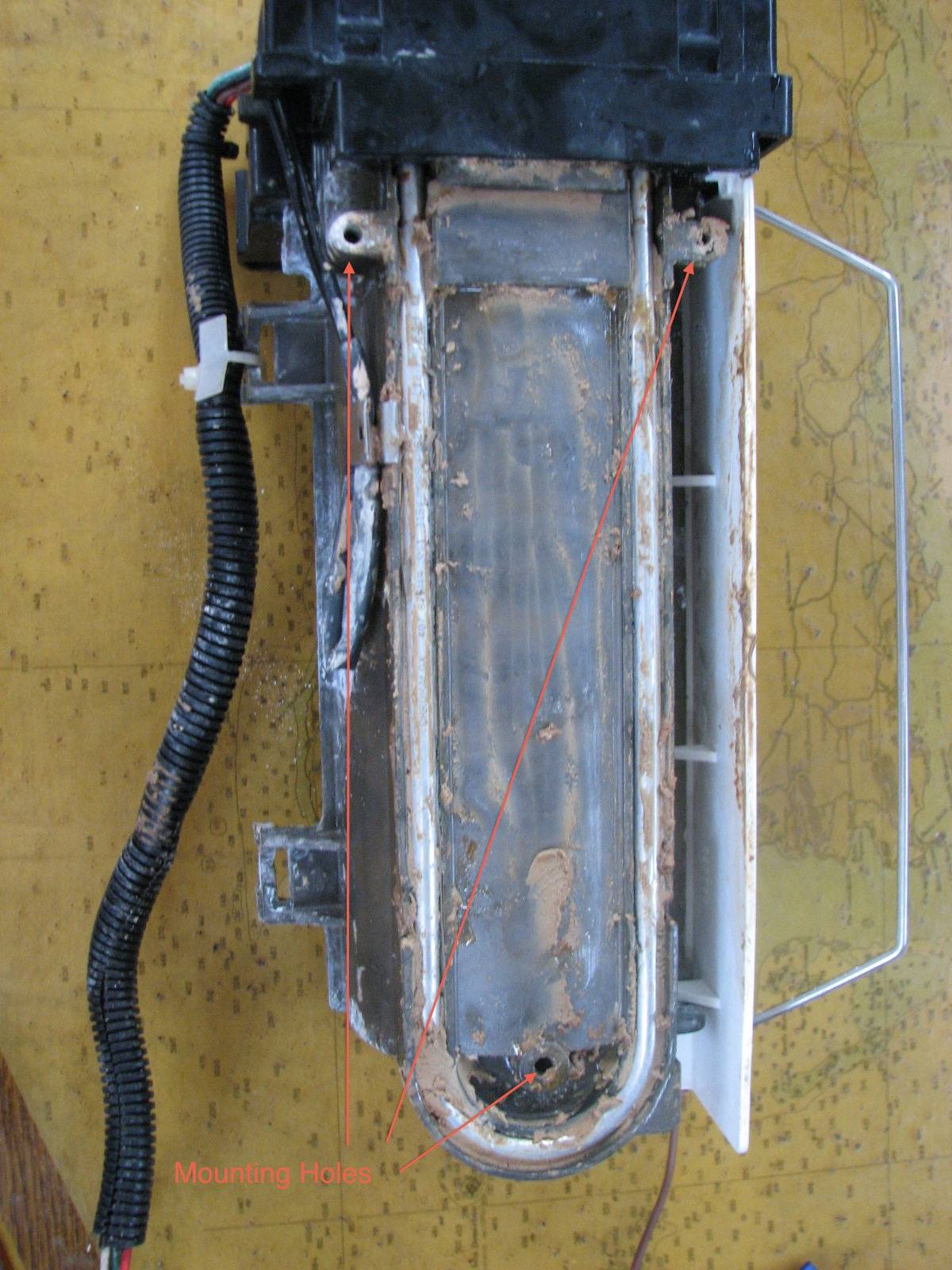

Last item for

the day was to remove the ice head from the ice maker. Good friend Jim,

had done some research on the Internet for a replacement. It seems that

a new drive motor for the ice head is more expensive than a complete

new ice head, so I will probably just replace the entire ice head. From

what I have seen, all of the ice heads look the same, so the new one

should just fit into place.

Removed Ice Head Showing Two Side Mounting Tabs

Ice Head Bottom Showing The Three

Mounting Tabs Used In My Ice Maker

December 17, 2010, Friday.

Today

is a bright sunny day, so looked good for masking the

port cap rail, and getting the first coat of Easypoxy Kelly Green

paint on the cap rail and shear stripe.

Fortunately when I was shopping

yesterday, I had purchased another couple of rolls of Scotch Blue Masking Tape.

This tape can stay on a surface for up to 14 days without leaving an

adhesive residue. As I was masking the port side cap rail I ran out of

masking tape and had to use the new tape.

Port Cap Rail And Shear Strip Masked Off Near Port Side Gate

Port Side Chain Plate Area Of Cap Rail And Shear Strip Masked Off

When the taping was completed, I

cleaned off the whole area with Acetone. I then went to the shop, and

got the paint prepared, and a final wash of the brush with acetone.

Back on Dream Away, I wiped down the cap rail and shear stripe with a

tack rag. I then started on the first coat of Easypoxy Kelly Green

paint on the cap rail and shear stripe. It is going to be close

to see if I have enough paint to complete two coats. The sun was really

out, so I had to wait until the port side was in the shade before I

could start the painting. I was able to finish the first coat of paint

with no large issues. I got all of the equipment cleaned up, and felt

pretty good.

December 16, 2010, Thursday.

Was

able to get some major grinding done on a couple of repair spots on the

forward deck. One place is on the port side of the forward deck box

that needs repair. The other spot is just behind the anchor windlass.

There is a foot operated deck switch for the anchor windlass that is

not used any more. The switch is in the way, and the hole could be a

major leak problem. I decided to remove the switch, and grind out the

area, and fiberglass and fill the hole.

Ground Down Area On Side Of Forward Deck Box

Hole Behind Anchor Windlass With Switch Beside Hole

The remainder of the day was

spent shopping and preparing food.

December 15, 2010, Wednesday.

No

work on Dream Away today. Went on an edible tour to a farm near the Rio

Dulce, named Frutas Del Mundo.

December 14, 2010, Tuesday.

Sorry

about no pictures for the last few days, but once you have seen a

sanded cap rail, it becomes uninteresting very quickly!

Today was a great day to work, no

rain, but overcast and downright cool. I was able to sand the entire

port cap rail with 120 grit sandpaper. I also sanded smooth a couple of

places where I will be putty down new gelcoat non-skid. I cleaned, and

hosed down the cap rail. While sanding I noticed a couple of places

that needed more putty, so I mixed up a bit of surfacing putty, and

filled the few places. There are actually many more pin holes and

slight imperfections, that could be tended to, but the cap rail is what

I call 3-foot perfect. Stand back 3 feet, if it looks perfect, it is!

When the surfacing putty had

dried, I again sanded down the entire cap rail with 220 grit sandpaper.

I washed down the cap rail and cleaned up the area. The cap rail is now

ready for masking, and the first coat of Easypoxy Kelly Green

Paint.

December 13, 2010, Monday.

Beautiful

sunny day with the wind blowing, but not from the perfect direction.

Was able to get the port cap rail all sanded down using

80 grit sandpaper and the area cleaned up. I still had a few

places that needed another application of putty. After a short rain, I

mixed up a 2.5 ounce pot of finishing putty, and applied it to the cap

rail.

December 12, 2010, Sunday.

Went

into town today to do some grocery shopping and

to drop off mail. Finished off the sanding of

the port cap rail using 80 grit sandpaper. I checked all three sections of the cap rail, looking for

places that could use another application of putty. Went to the shop

and mixed two five ounce pots of putty. Back to Dream Away, and applied

the two pots of putty on all three sections of the cap rail .

If weather holds, will be back sanding tomorrow on the port cap rail.

December 11, 2010, Saturday.

Many

interruptions today, plus I had to go to town to get more polyester

resin and MEK. I did get most of the port cap rail sanded down using 80

grit sandpaper. Still have more to go.

December 10, 2010, Friday.

Started

out by cleaning up the third section of the cap

rail preparing it for the putty application. I also checked the first

and second sections, looking for places that could use another

application of putty. Went to the shop and mixed two pots of putty, and

one two ounce pot of plain resin. Back to Dream Away, and applied the

two pots of putty, mostly on the third section, but some additional on

the first and second sections. I then applied the plain resin on the

top of the cap rail to fill in the imperfections of the mat fiberglass.

Tomorrow will be a day of sanding!

Fiberglass Plate On Cap Rail With No Putty Applied

Fiberglass Plate On Cap Rail With Putty Applied

I installed the newly finished

handle to the forward deck box.

Newly Finished Handle On Forward Deck Box

December 9, 2010, Thursday.

Different

day, same stuff! I removed the masking tape dams from the second

section of cap rail, and cleaned up the area. I then put on the masking

tape dams for the third and last section of cap rail. Following is

pretty much what happened in the entry for December 7, 2010.

When I

finished applying the fiberglass and the resin on the third section of

cap rail, I finished cleaning up the first section of cap rail and

prepared it and the second section of cap rail. I then mixed up two

pots of filler putty, and applied them to the first and second section

of cap rail. The weather is holding so I am moving along very well.

When the putty was applied to the

first and second sections of the cap rail, the resin on the fiberglass

of the third section had kicked off. I removed the masking tape dams on

the third section of the cap rail, which is the last section.

I

wiped down the handle for the forward deck box, and applied the second

coat of Nyalic protectorant. When that

dries, I will re-install the handle on the forward deck box.

December 8, 2010, Wednesday.

Removed

the masking tape on the first section of fiber glassed cap rail. This

is necessary because the masking tape used is only a one day tape if in

the sun. If the tape is left on more than one day, adhesive is left on

the boat, and then it has to be removed.

Next I started in building the

dams out of masking tape for the second section of cap rail. The

process is exactly like the first section, so please read about that

under the entry for December 7, 2010.

I wiped down the handle for the

forward deck box, and applied the first coat of Nyalic

protectorant.

December 7, 2010, Tuesday.

Started

in on the cap rail. First thing to do is measure the section of the cap

rail I am going to fiberglass. When this is done I build dams out of

masking tape on both sides of the cap rail. These tape dams are to

prevent the resin from running down the side of the boat. The first

time I did this on the aft cap rail, I did not build the dams, and

spent most of the time wiping up resin. When I get the dams built, I

wipe down the cap rail to be fiber glassed with acetone. I then

cut the actual fiberglass mat that I am going to use. I cut two layers

of the 1 ounce mat. I then make sure the pieces of fiberglass plate I

am also glassing to the cap rail are handy and I also do a dry fit.

The fiberglass plate is something

added to the cap rail for extra strength in areas where I am putting

stanchion supports, chocks and Genoa T-Track on the cap rail.

I then went up to the shop and

mix four pots of five ounces of resin, and bring them back to Dream

Away. I verify everything is prepared, and then add the catalyst to the

resin. From now on, timing is important. To much catalyst or to much

time, and the resin kicks off before you are finished, to little

catalyst, and it takes to much time for the resin to kick off. Once the

catalyst is added, I wet out the cap rail, then add one layer of the

fiberglass mat. Make sure the first layer of mat is completely wetted

out, then apply the second layer of mat, and completely wet it out.

When you add a piece of fiberglass plate, add more resin to the area on

the cap rail, and apply some resin to the bottom of the fiberglass

plate, then put the fiberglass plate into place. You must keep an eye

on the plate as it could slide off position when you initially put the

fiberglass plate on the cap rail. As you are doing all of this resin

application, of course when you run out of resin in one pot, you must

add catalyst to the next pot of resin, mix thoroughly, then apply. It

is like a race, get all the mat down, the fiberglass plates down, get

all the mat wetted out, be careful and do not make a mess!

Building Masking Tape Dams For Cap Rail

Masking Tape Dams Built And Ready For Fiberglass And Resin Application

Captain Appling Resin and Fiberglass To Cap Rail

Fiberglass Plate For Chock On Port Cap Rail

Fiberglass Plate For Genoa T-Track On Port Cap Rail

Fiberglass Plate For Stanchion Support On Port Cap Rail

Finished Fiberglass Plate For Stanchion Support On The Starboard Cap

Rail

I finished up, took all of the

stuff back to the shop and cleaned up all the mixers, pots, and

brushes. When I went back to Dream Away, I checked the resin, and it

was kicking off very nicely.

I

wiped down the forward deck box lifting handle and applied the seventh

coat of Cetol on the handle.

I cleaned out the overhead in the

galley dish locker. This is where the backing plate for the aft

mid-ships cleat goes, and the cleat is presently removed. I was

tracking down a leak there, so removed the cleat and backing plate. I

am keeping the cleat off the boat until the cap rail on the port side

is finished. It makes it so much easier to sand and paint the area.

December 6, 2010, Monday.

First thing

in the morning went to town to shop and have lunch, then came back to

Dream Away.

Overcast day but it seemed it

would not rain, so got out the tools and such to work on the port cap

rail. Was able to sand down the entire port cap rail, and get it rinsed

off. I then applied one more application of filler putty to the cap

rail in all of the places I missed on the last application. I put all

of the tools away and the dinghy, plus a wash down of the dinghy.

I went back to the shop at Monkey Bay, and cut out the fiberglass I

will be needing to cover the hull to deck joint. Naturally, I did not

have enough to finish the job, so the next trip into town I will have

to purchase more fiberglass.

I

sanded, then wiped down the forward deck box lifting handle and applied

the sixth coat of Cetol on the handle.

December 5, 2010, Sunday.

Day

started off cloudy and overcast, so got out all of the tools and

sanders to sand the cap rail on the port side. Got about eight feet of

the cap rail sanded and it started to spit rain. Put all of the tools,

electrical stuff and the inflatable dinghy away.

Made a few phone calls, had

lunch, and decided to try the sanding project again. Got out all of the

tools and sanders and it started to spit rain, and looked like more was

coming. I put everything back again. I was spending more time getting

tools and equipment out and putting it back than I was on actual

sanding.

It

was time to get the sewing machine out and continue with the "skirts"

on the mizzen sail cover, which I did. I got the "skirts sewn on the

sail cover but did not get the hook & loop material sewn on to

close the skirts. Depending on the weather tomorrow, I might get the

skirts finished, or more sanding done on the cap rail.

December 4, 2010, Saturday.

Dawned

a beautiful sunshiny day! Started off getting the remainder of the 5200 residue off of the cap rail.

Then got all of the cap rail prepared to put on the filler putty in

places where it was required. I mixed up a pot of filler putty and

applied it to the cap rail. A boat two down from me is applying varnish

today, so did not do any sanding.

Forward Section Of Port Cap Rail With All Residue Removed

Putty Applied To Port Cap Rail

I wiped down the

forward deck box lifting handle and applied the fifth coat of Cetol on the handle.

December 3, 2010, Friday.

Another

rainy day, so no progress made on the cap rail, but we did find the

source of a leak in a cabinet in the galley. When the weather improves,

and I can get back to work on the cap rail, I will get the leak fixed.

The problem is some damage from Wilma that I did not notice before, but

verified yesterday with a hose.

The Sailrite sewing machine I had been

using was a borrowed machine. The owner came by today and took his

machine back, so I was without a sewing machine. My good friend, Paul,

has a Sailrite sewing machine, but

back in September when we tried to use it, the machine was seriously

out of time, and would not sew. We borrowed the other Sailrite from friend Pete and

had been using it ever since.

Note:

As of right now those maintenance log

entries, from September, are in my written maintenance log and not in

this electronic log. I hope to get the electronic maintenance log up to

date in the future.

I went to Paul's boat and

picked up his Sailrite sewing machine, and

brought it back to Dream Away. When I borrowed Pete's Sailrite, I also borrowed his

maintenance CD's for the machine, and copied them to my computer, and

returned the CD's to Pete. Having the maintenance manual available

electronically was nice. When I was using Pete's machine, I had to

adjust the tension because the stitches were not correct. Having the

electronic manual available made the adjustments very easy. While

looking through the electronic maintenance manual, I had noticed there

were timing adjustments.

When Alan was here he said he

thought the problem with Paul's machine was a timing adjustment, but we

did not have a maintenance manual at that time. When I got Paul's Sailrite to Dream Away, I

started with the needle bar adjustment, which was way out. Next I

checked the gib hook and needle timing, and this seemed to be right on.

The problem seemed to be in the rotational timing as the gib hook did

not catch the thread loop from the needle. It took some time to figure

out how to do the rotational timing adjustment, because of not knowing

all of the term and words used in the timing adjustment. With a little

study of the drawings and the procedure, I was able to get the

rotational timing properly adjusted. Paul's Sailrite is now working

wonderfully!

I had to make a thread stand from

scrap Starboard, as one is necessary to use the

large commercial spools of thread.

Starboard Thread Stand (Crude But It

Works)

I had fabricated carrying

strap's for Pete's Sailrite, because I was worried

about the case coming apart, and the machine falling into the river

during a dock to boat transfer. I made one strap for Paul's Sailrite as I did not have

enough webbing out for two. I will dig out some more webbing in the

near future and make Paul a second strap.

Sailrite Case With Webbing Strap

I then went to work on

fabrication the skirts to sew on the mizzen sail cover. It took a while

to find enough cloth to make the skirts, but I got the parts cut out

and sewn together. The day was pretty much over by this time, so I will

sew the skirts onto the mizzen sail cover tomorrow, or the next rainy

day. The sun is supposed to come out tomorrow.

One Of The Fabricated Skirts On Main Salon Table

December 2, 2010, Thursday.

As

predicted, the rains are still with us, so spent the whole day on the

mizzen sail cover. There was a lot of work to do on the cover. I had to

do a large amount of re-stitching. This necessitated taking out all of

the old stitching, and then sewing in all the new stitching.

I decided the best way to fix the

problem of having the sail cover fit around the mast steps was to

splint the sail cover on each side of the mast, and add a piece of

material on each side. The piece I added on each side was three inches

wide at the top, and five inches wide at the top. I also had to add

three patches to the sail cover. I also wanted to add "skirts" to the

bottom of the sail cover that would cover the sheets, protecting them

from the sun, while the sail cover is on.

I spent most of the day working

on the sail cover, and got everything done to the sail cover except the

"skirts". If it is a rainy day tomorrow, I should get the "skirts"

added to the sail cover.

Captain Removing Old Stitching

Front Of Mizzen Sail Cover

Around Mast, And Patch (The Sail Cover Would Not

Go Around Mast Until The Repairs Were Made )

Sail Cover With New Insert to Accommodate the

Mast Steps

December 1, 2010, Wednesday.

Day started out raining, because of a cold

front that moved in. Waited for a break, then headed into Fronteras to

do shopping. We were very lucky. We were able to get all of the

shopping done without getting rained on.

Got back to Dream Away, and

because of the rainy weather, started on the current sewing project

which is to repair the mizzen sail cover. It needs a major

re-stitching, some holes patched, and refitted. The cover was never

modified after adding mast steps to the mizzen mast, so the sail

cover never fit correctly. I will repair that problem. It is supposed

to rain all day tomorrow, so hope to get the sail cover finished then.

Will have pictures tomorrow.