Maintenance Log December 2013

December 31, Tuesday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Checked Kitty’s computer and still no

successful restore of the data from the iPhone 4S to the iPhone 5. I

tried several things, but still could not get a successful restore.

Kitty got up early, and we drove back

to the AT&T store in New

Iberia. Before Kitty could use the new iPhone 5, we

had to get the contacts off of the iPhone 4S. We got to the store and

were helped by a nice young lady who eventually got the iPhone 5

updated to Kitty’s satisfaction.

When we got back to DREAM AWAY, I got

to work fixing this iPhone issue. I will not go into any details, but

I am making progress.

Spent the rest of the day working on

the iPhone issue, preparing cat food for the next week, and making

sure we have blackeye peas for New Years Day.

December 30, Monday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the shop

and started looking through all of the items I want to put on eBay.

Several things need to be tested and batteries charged or purchased

to see if they still work.

I started off with an old Sony video

camera system. I even have an underwater housing for the camera. I

got out the battery charger, and the batteries, and plugged them in.

Time will tell!

Sony Video Camera On Workbench

Next I started in on fabricating the

standoffs I am going to use for the main cabin grab rail. Kitty and I

have decided not to use metal grab rails in the main cabin, but

stainless steel pipe standoffs that will have rope threaded through

them to be used as hand holds.

The plan right now is to keep the

standoffs permanently mounted, and remove the rings and rope when in

port. We will see how the fabrication process goes.

Stainless Steel Pipe and Plate For Main

Cabin Standoffs

I then went back to DREAM AWAY and had

breakfast. Kitty and I then went into New

Iberia as we both had appointments with the

podiatrist.

After the appointments we stopped by

the AT&T store to get the new SIM card for Kitty’s iPhone 5.

That was no problem, and we got the new card and had it installed

very quickly.

When we got back to DREAM AWAY, we

needed to do the backup of the iPhone 4S, and then restore to the

iphone 5. We started around 1830, and finally went to bed at 2330.

Still no successful restore of the data from the iPhone 4S to the

iPhone 5. Between AT&T and Apple, I am not a happy camper!

December 29, Sunday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the shop

and sanded the fiberglass

uprights for the hard dodger. I used 220 grit sandpaper to smooth out

the first coat of gelcoat.

It was going to get much warmer this afternoon, so I knew I would be

able to apply the second coat of gelcoat

later.

I spent some time cleaning up the shop

and moving items around. On the bad weather days, I will be in the

shop

getting some items ready to put on eBay.

That will be a fun process!

I loaded the the

“Box

O’ Resins” and the stainless steel upper base for

the hard dodger into the

Black

Beast, then went over to DREAM AWAY and had breakfast.

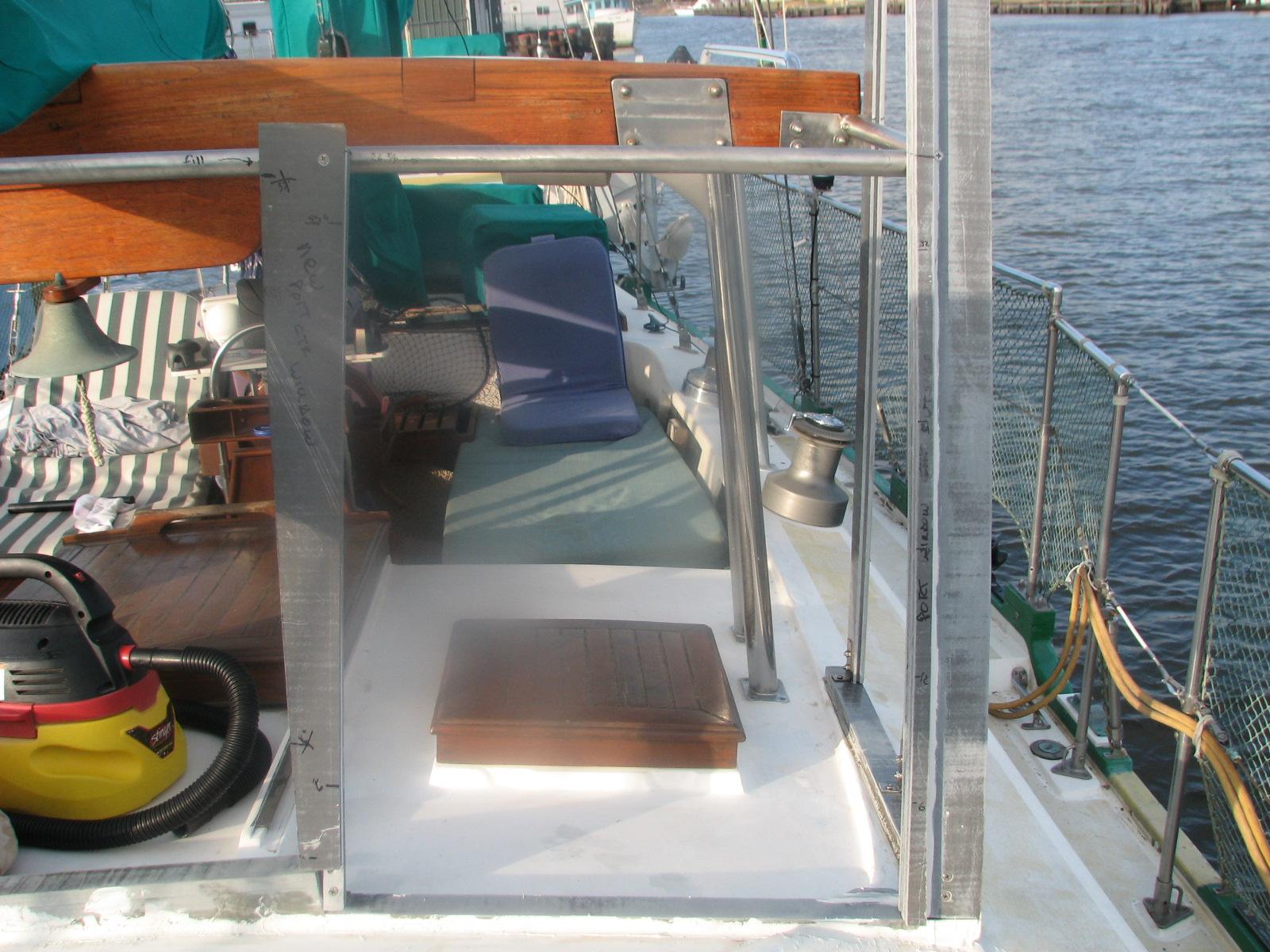

After breakfast Kitty and I attached the stainless steel upper base

for the hard dodger onto the boom gallows. We did not bolt down the

three new stainless steel supports to the boom gallows as yet.

When we finished that project, I

applied another application of the finishing

putty to the fiberglass

hard dodger base on DREAM AWAY.

I put three blobs of

finishing

putty on the mixing board. I added the

cream

hardener when it was needed. I then applied the

finishing

putty as needed. Fortunately I do not need warm

weather to sand dome the putty areas after it has hardened, just dry

weather!

I wiped the hard dodger uprights all

down with a tack

rag, to get all of the dust and debris off of them. I

got out all of the stuff I will need to apply the

gelcoat

to them.

I mixed up a pot of gelcoat

and applied it to all of the hard dodger uprights and the storm

anchor parts. It will have a couple of days to really set up, as I

have to wait for a warm day to apply the first coat of gelcoat

to the opposite side of the uprights.

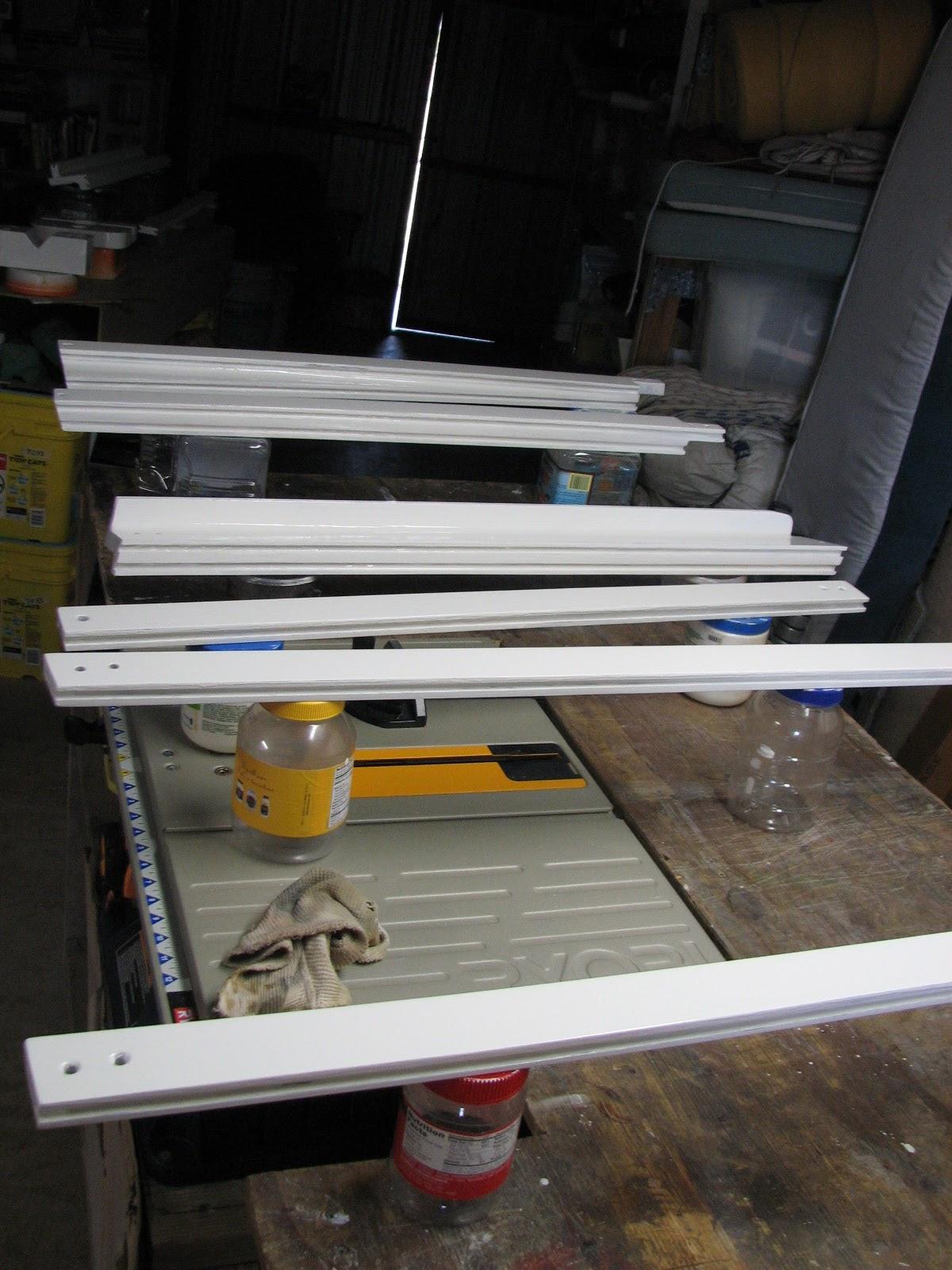

Second Coat Of

Gelcoat

Applied To The Hard Dodger Uprights

Second Coat Of

Gelcoat

Applied To The Hard Dodger Uprights

Second Coat Of

Gelcoat

Applied To The Hard Dodger Uprights

Second Coat Of

Gelcoat

Applied To Storm Anchor Parts

Before going over to the

shop to do the

gelcoating, Kitty and I discussed the plan for the handrails in the

main cabin for long passages. I believe we have come up with a plan

that is functional during a passage, and will be able to be removed

when in port and they are not needed. I will be working on this

project over the next few days.

December 28, Saturday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Did not go over to the shop

this morning because of the weather. It was cold and rainy from the

time I got up until well past noon!

I spent the morning on the computer

again catching up on stuff. At one rain brake, I went out to the

shower

trailer and turned on the heater, put some water in

the on board water tank and then drained the holding tank into the

sewer system.

Came back to DREAM AWAY from that

project with my box of metric tools in hand. I decided today is the

day I want to work on the generator.

Considering what happened when the

generator failed, and it’s inability to start, I decided I was

having a fuel problem. I had Kitty operate the start switch while I

bled the injectors. I had verified I was getting fuel to the injector

pump using the manual pump in the lift pump, but I was not getting

any fuel to the injectors.

No problem, I had a spare rebuilt

injector pump, which I swapped in. When I got the system all back

together, and again verified I had fuel to the injector pump, I tried

bleeding the injectors. Again no fuel!

I tried removing the stop switch from

the injector pump, and then was able to get fuel to the injectors! I

then had Kitty attempt to start the generator, and it started right

up and ran normally. I quickly inserted the stop switch into the

injector pump, and we were able to stop the generator. I installed

the stop switch properly, and we started the generator again. It ran

but not well, just like with the original problem. I surmised the

problem was with the stop switch partially actuating, not allowing

the injector pump to deliver the proper amount of fuel to the

injectors.

I have a spare stop switch, so I

installed it. By the way this stop switch is very difficult to

install because of it’s location. I could slide the generator out

on it’s slides, but that is very time consuming. It took about 20

minutes to get the stop switch installed into the injector pump. When

I got it installed, I had Kitty start the generator. It started right

up, but still was running bad.

So new injector pump, no change, new

stop switch, no change. The only remaining item the the circuit in

the stop relay. I have a spare, but by now it was 1730, and would

take another 45 minutes just to get the spares put away, the

generator buttoned up and the garage put back into shape.

I will continue with the generator on

the next bad weather day.

December 27, Friday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the shop,

and got back into sanding and polishing the stainless steel upper

support for the hard dodger. Sanding and polishing stainless steel is

a time consuming process, especially on a round piece of pipe.

I start out with a 120 grit flap disc

to get most of the major imperfections out of the metal. After that I

start sanding with 80 grit, then 100 grit, 120 grit, 220 grit and

finish off with 320 grit sandpaper. On stainless steel I really want

to look close to perfect, I continue with 400 grit, 600 grit, and

finish off with 800 grit sand paper. I am not going to that length

with this project!

Today while sanding, I took a picture

after using each grit of sandpaper, but the difference was hard to

discern. The pictures you will see here are of one when I started,

and one when I finished. I will also show a picture of a piece of

stainless steel I started with beside the finished piece of stainless

steel. With that you can really see the difference.

Stainless Steel After Sanding With 80

Grit Sandpaper

Stainless Steel After Sanding With 320

Grit Sandpaper

Original Piece On The Bottom, Polished

Piece On Top

I finished sanding the three pieces of

flat bar and some of the pipe, but I still had more to do on the

pipe.

After breakfast, I pressure washed the

underside of the

Black Beast.

Since

I had done the repair on the power steering hose I wanted to be able

to monitor the repair with a clean underside.

Kitty drove into New Iberia to drop off

the laundry, and I took the pressure washer out to Pier “C”, and

did some cleaning of pilings and started to work on getting all of

Pier “C” cleaned off before the spring!

When I finished the pressure washing, I

took the pressure washer and fuel can and walked back to the shop.

It was just a bit too cold to apply the finishing

putty to the lower base of the hard dodger on DREAM

AWAY. It was also too cold to attempt another coat of gelcoat

on the hard dodger uprights in the shop.

I got to work sanding and polishing the

upper stainless steel base for the hard dodger. I was able to finish

the polishing, so that piece is ready for installation.

December 26, Thursday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the shop,

and I am happy to report the gelcoat

I had applied on the hard dodger uprights, Tuesday had kicked off!

This application of gelcoat

will have to be sanded with 220 grit sandpaper, and a second coat

applied. The same thing will have to be done to the bottom half of

the uprights, as I can only do a half at a time.

Somewhat warm sunny day, so I started

in on sanding and polishing the upper stainless steel base for the

hard dodger. The three additional stainless steel supports I had

welded to the base needed to be sanded and polished.

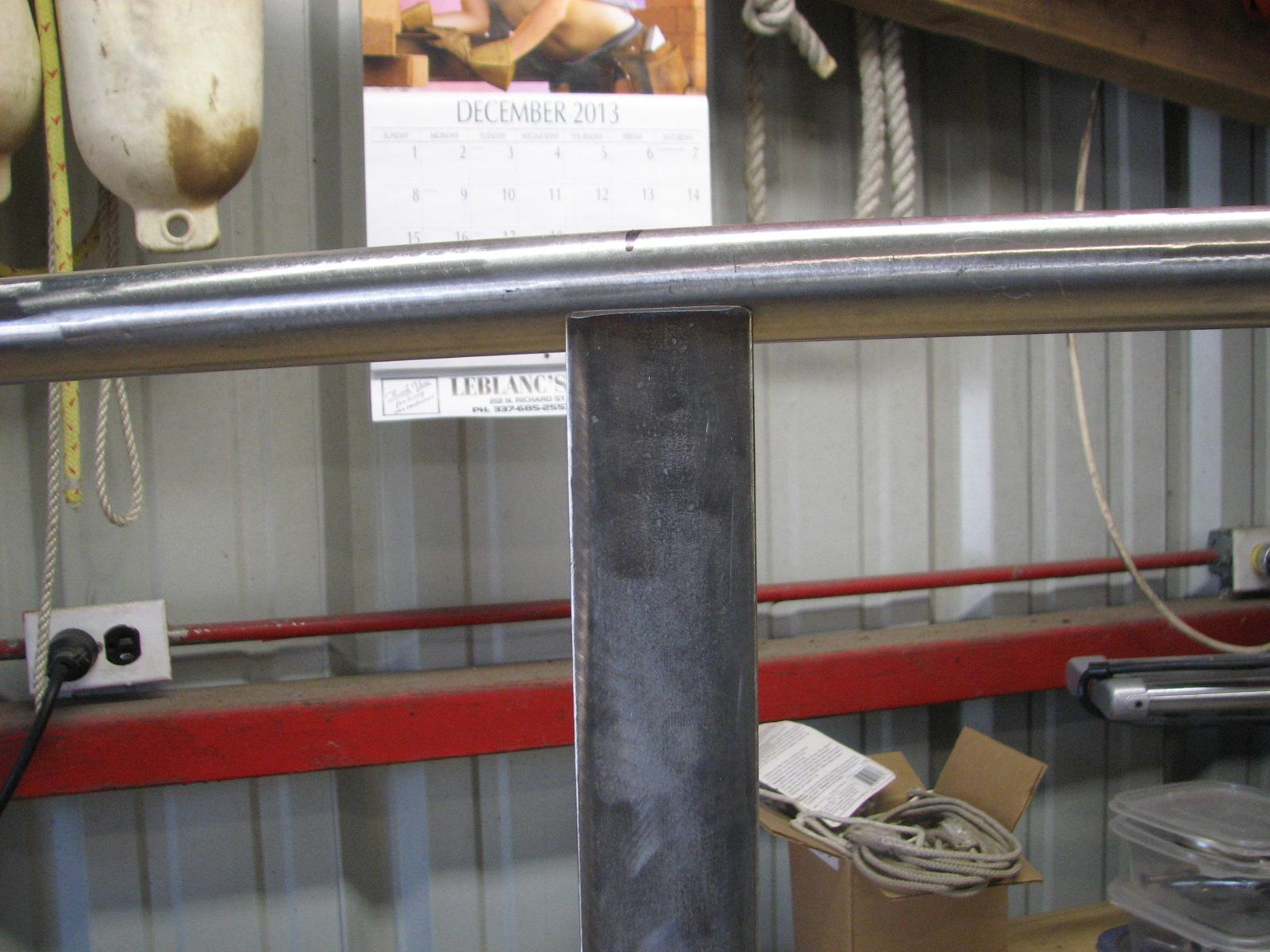

Base Outside On Table Preparing For

Sanding And Polishing

Welded Support On Pipe

Polished Support

Kitty called and was making breakfast,

so I left the shop

and went back to DREAM AWAY. After breakfast, Kitty went out to do

some errands. It is a warm sunny day ( relatively speaking) so I

walked over to the shop

and got all of my sanders and brought them all back to DREAM AWAY.

I got busy and sanded down all of the

finishing

putty I had applied to the hard dodger base. The wind

was out of the north, so most of the dust was blown to the bow and

not back into the cockpit.

After I did all of the sanding with the

power sander and hand sanding, I know I will need to make another

application of the finishing

putty. I hope the weather will permit the application

tomorrow.

I put all of the sanders and sandpaper

back into the milk crate on the cart, and then hosed down DREAM AWAY

to get all of the dust washed off. I took all of the sanders back to

the shop

and cleaned them all off with high pressure air. I blew all of the

dust off of me, and then headed back to DREAM AWAY for a welcome

shower.

December 25, Wednesday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Spent the day enjoying the holiday,

exchanging presents and relaxing. I caught up on some scanning, and

Kitty did some baking.

Went to a friends house for Christmas

dinner, which was wonderful. Stayed and watched the new Lone Ranger

film. After the film they loaded us up with left overs, and we came

back to DREAM AWAY.

December 24, Tuesday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

I went over to the

shop

and started in again on the stainless steel pieces I am attaching to

the stainless steel upper base for the hard dodger. Let me say today

is a beautiful day, but the temperature was 34 degrees when I first

came to the shop.

Yesterday I had finished the first

piece of stainless steel, and had cut the second piece. Now I

finished the final fit on the second piece.

Fitting Finished On First Piece

Fitting Finished On Second Piece

I then set up and measured the third

stainless steel piece. I made the cut with the chop

saw, and this time the cut was almost perfect. All I

had to do was some minor trimming, and the piece fit perfectly.

Measuring Third Piece Of Stainless

Steel

Now that all three pieces of stainless

steel were cut and fitted, I was ready to tack weld the pieces to the

stainless steel base pipe.

Three Stainless Steel Pieces Fitted To

Base Pipe

I set up the welder and made the tack

weld on all three pieces.

Tack Weld On One Piece Of Stainless

Steel

During the tack weld process, I

realized the position of the stainless steel base was very awkward to

do a very good job of welding. To actually complete the welding of

the pieces, I will have to reposition the base on the workbench.

Kitty called and said she was making a

nice hot breakfast, so I left the shop

and headed back to DREAM AWAY for hot coffee and breakfast.

After breakfast, I went back to the

shop,

and it was a lot warmer. First item was to make some repairs to the

Black

Beast. I had noticed a drip of oil at the front of the

engine, so it needed to be investigated. As it turned out, one of the

power steering hoses was leaking, so I tightened up the hose clamps

holding it together. That should fix the problem, but I will have to

pressure the underside of the truck.

Next item was to gelcoat

the fiberglass

hard dodger uprights and the storm anchor parts. The temperature was

in the mid 50’s, and it was bright and sunny, so I decided to give

it a go. I mixed up a batch of the gelcoat

and applied it to the uprights. Since I was at the lower end of the

temperature scale, I added a bit more MEKP

catalyst, but did not want to go overboard. We will see tomorrow if

the gelcoat

sets up overnight.

First Coat Of Gelcoat

Applied To The Hard Dodger Uprights

First Coat Of Gelcoat

Applied To The Hard Dodger Uprights

First Coat Of Gelcoat

Applied To The Hard Dodger Uprights

First Coat Of Gelcoat

Applied To Storm Anchor Parts

If the gelcoat

does not set up, I will have to mix up a good hot batch to apply and

complete the chemical process.

Now it was back to the stainless steel

pieces to be welded onto the hard dodger upper base. I moved the

stainless steel upper base on the workbench to make the welding

process much more convenient. This worked out very well, and I was

able to make some really good welds.

First Piece Welded On

Second Piece Welded On

Now all that remains, is to clean up

the welds, and then sand and polish the stainless steel so it can be

installed back on the boom gallows on DREAM AWAY.

I left the shop,

and went back to DREAM AWAY for a hot shower and dinner. We had

decide to have our Christmas dinner on Christmas eve. We are having a

Christmas Day dinner with some friends here locally.

Kitty And Dinner Ready To Go

December 23, Monday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

I then went over to the

shop

to see if it was possible to apply a coat of

gelcoat,

but it was too cold. No gelcoat

application until later in the day.

I then started working on the stainless

steel upper base for the hard dodger. I had screwed down the outer

frame of the base to the workbench so I would have a flat surface to

work from. Trying to emulate the boom gallows where the stainless

steel upper base would ultimately be attached to.

Stainless Steel Upper Base Screwed Down

To The Workbench

I needed to fit and cut the three

additional stainless steel pieces that would be welded onto the pipe

of the stainless steel upper base. I measured, and then set up the

chop

saw to make the cut.

Measuring Stainless Steel Piece To Be

Cut

After making the cut there was still

some adjustments that had to be made. I eventually got the stainless

steel piece adjusted so that it fit just right, and is ready to be

welded to the pipe.

Stainless Steel Piece Fitted To Pipe

I then set up and cut the second

stainless steel piece. I also had to do some additional adjusting to

get the piece to align properly. Thank goodness for power tools!

Second Piece During Alignment Process

By this time, Kitty was awake and had

called. Because it was so cold, I immediately closed up the shop

and headed back to DREAM AWAY for hot coffee and breakfast.

Right after breakfast, John stopped by

to have a tour of DREAM AWAY. He brought over his locked up computer

to have me take a look into and several sacks of oranges. He also

brought over some old paper charts that I can look over and see if I

might need any.

When John left Kitty and I went off to

run a bunch of errands. We had to deliver some Christmas gifts, go by

the post office, grocery shop, and get some sanding discs.

When we returned, I made a weeks worth

of food for our two cats, and squeezed all of the oranges John had

brought to us. Now we have fresh orange juice for Rum and OJ!

December 22, Sunday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Another day of catching up on the

computer email and scanning in documentation.

Around 1145 Kitty and I drove to John

and Sharons house for lunch. They had gumbo, turkey, ham and all of

the fixins! After lunch, Kitty and I went out to the “Bee House”,

and changed into our Santa suits.

John and Sharon had several

grandchildren at the house, and then Santa and Mrs Claus arrived with

a sack of presents, it was a lot of fun. We stayed for another 30

minutes giving out presents, and the quietly left.

We both came back to DREAM AWAY and

took a nap. I am mostly past the cold, but the nap was good.

December 21, Saturday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

I worked a little extra on the computer

trying to catch up on emails and financial issues.

Kitty and I then got into our Santa

Claus and Mrs Claus outfits, and drove over to the Creole

Market in West

End Park in New

Iberia. We parked near the swimming pool, until the

fire truck arrived. We boarded the fire truck, and the truck took us

around to the area of the park they had set up specially for Santa

Claus.

The kids were lined up for pictures and

conversation with Santa and Mrs Claus. It was a great time, and the

rainy weather held off, so the event was quite a success.

We left the park around 1300 and drove

back to DREAM AWAY. Kitty went off to Lafayette with our friend

Bonnie. I stayed on DREAM AWAY, to take a nap and try and get rid of

the cold I have! I also did catching up on emails.

December 20, Friday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

I then went over to the

shop

and got to work on the fiberglass

uprights for the hard dodger. I wiped them all down with a

tack

rag, to get all of the dust and debris off of them. I

got out all of the stuff I will need to apply the gelcoat

to them.

I also screwed down the stainless steel

upper base for the hard dodger to the workbench. This will make it

easier to cut and weld on the additional pieces of stainless steel.

The cold I am trying to shake, has me

feeling pretty rough, so I left the shop

and went back to DREAM AWAY to take a nap. Pretty much did nothing

the remainder of the day.

I did help our neighbor, Joel, change

the oil in his boat engine, and adjust the alternator on his boat

engine. Joel is young , and this is his first boat. He asked me for

my assistance on these two projects because he had never done either

before. Now he knows what to do, and has the confidence to do it

again on his own.

December 19, Thursday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

As soon as it was daylight, and with

first cup of coffee, I walked out to the end of Pier “C” to check

on CAJUN DREAM. It was still floating, and the water level in the

boat had not risen at all. This was good news. The port stuffing box

was the problem.

I went back to DREAM AWAY and finished

off the Maintenance Log update and checked email.

Around 0800, I went back out to CAJUN

DREAM to get the suction hose and the 2” pump. I returned these

items to the city warehouse. The mayor was actually at the warehouse

when I returned them, so I expressed our thanks to him and the city

for the loan of the pump.

I then went over to the shop

and started in on sanding the

last two fiberglass

uprights for the hard dodger. When the sanding was completed, I

arranged all of the hard dodger uprights, and the two pieces for the

storm anchor security system to be ready for the application of

gelcoat.

Hard Dodger Uprights Ready For Gelcoat

Application

Hard Dodger Uprights Ready For Gelcoat

Application

Storm Anchor Parts Ready For Gelcoat

Application

I loaded the the

“Box

O’ Resins” into the

Black Beast, and went to the

marina.

After breakfast, I applied finishing

putty to the areas of the hard dodger bottom base that

had not had any finishing

putty applied. I am hopeful the weather will be

favorable tomorrow or Saturday to be able to sand down the hard

dodger bottom base in preparation for the gelcoat

application.

I loaded the the

“Box

O’ Resins” back into the

Black Beast, and went to the

shop.

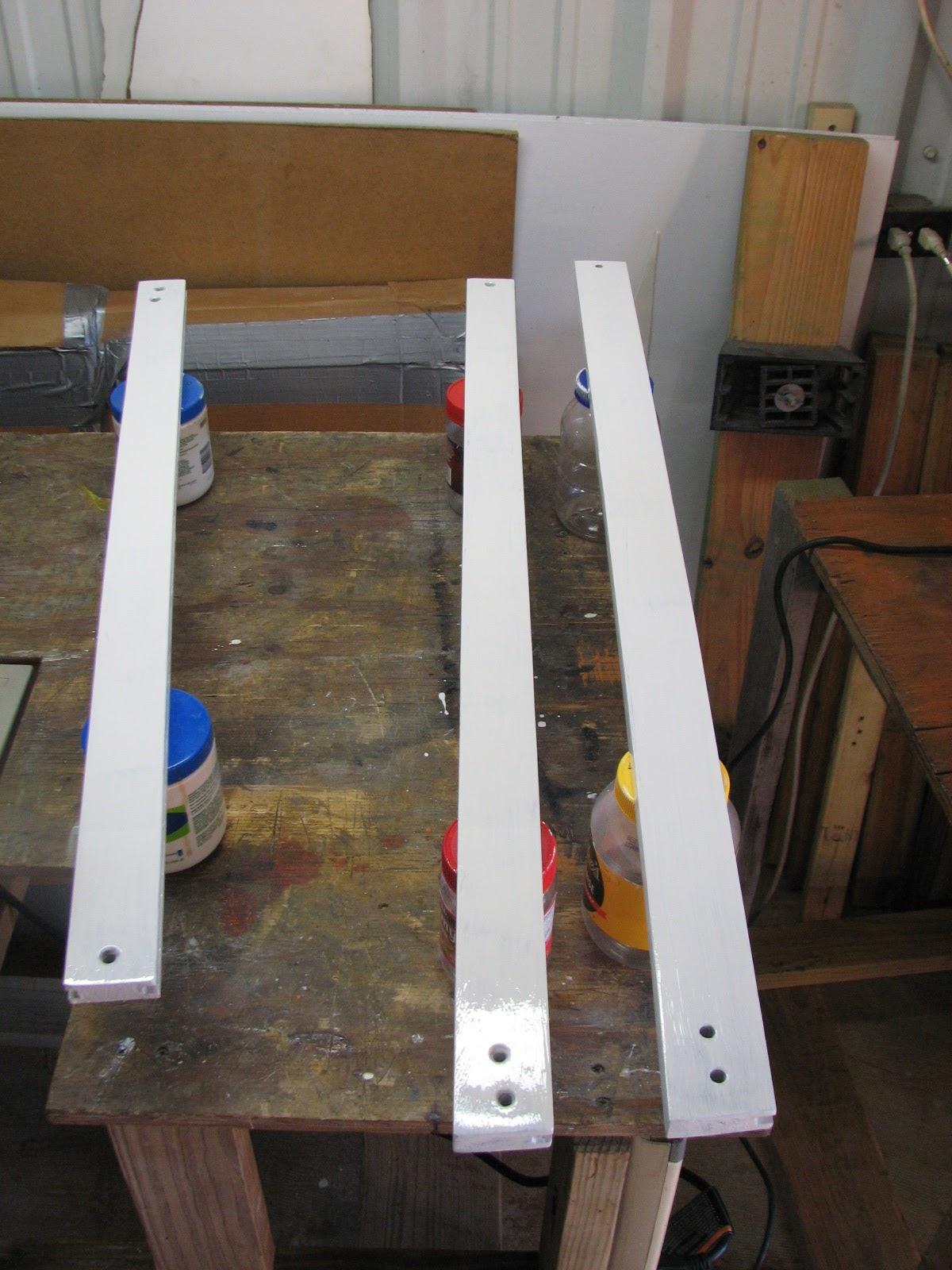

I wanted to get the three stainless steel pieces drilled out and

bent. I am hopeful to grill out steaks tomorrow night, and I need the

bottle of propane I had taken to the

shop back on DREAM AWAY. I just

did not want to move the bottle of propane back and forth too many

times.

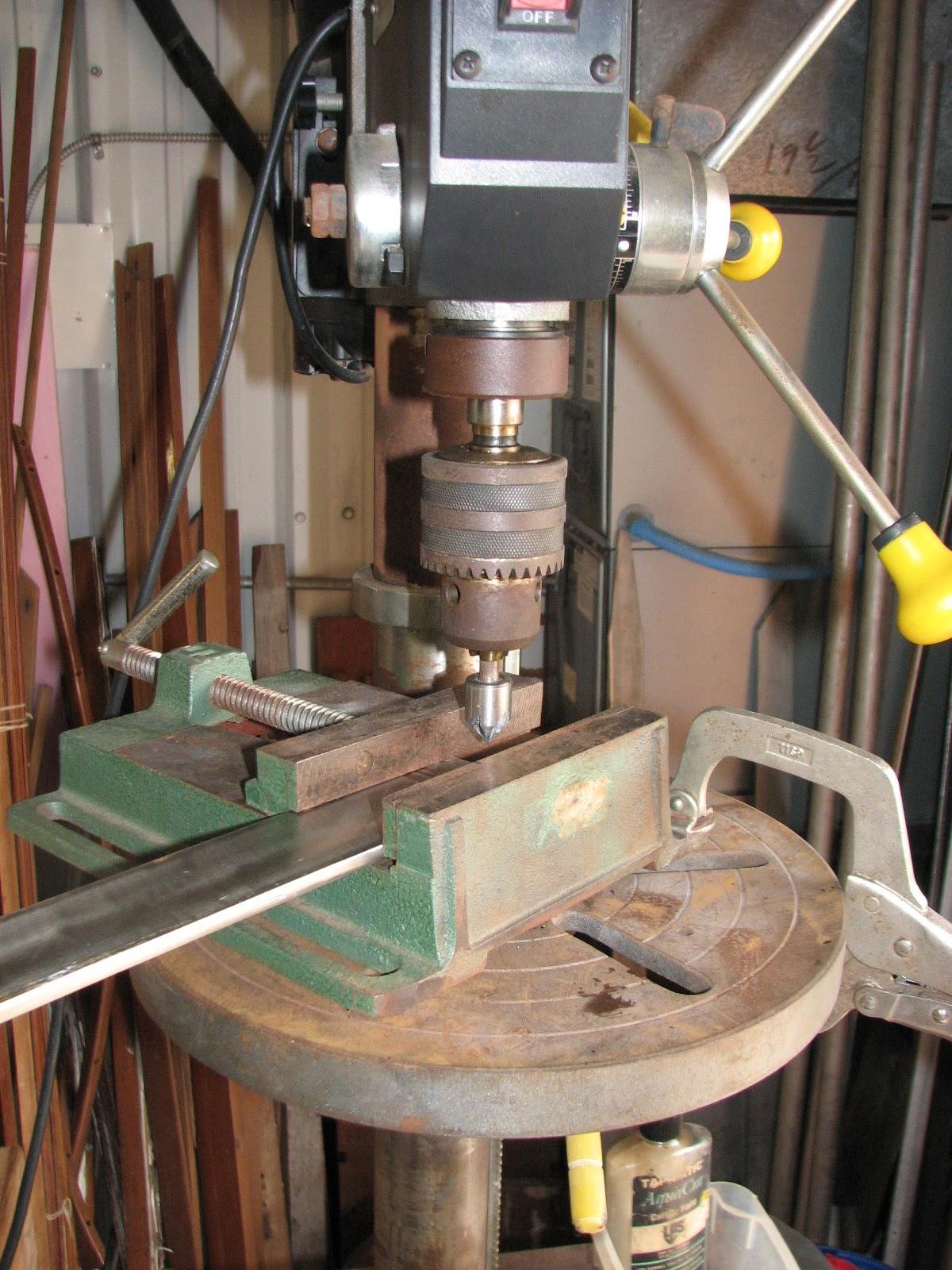

I set up the drill press, and measured

the pieces of stainless steel for the location of the holes. I center

punched each spot, and then drilled the holes, and cleaned up each

hole with the countersink.

When all of the holes were cleaned up,

I finished sanding the ends of the stainless steel pieces before

starting the bending operation. I got out my

Oxy-Propane torch

, and connected it to my oxygen tank and the propane tank.

I measured the stainless steel pieces

where the bend was to be, and inserted the stainless steel piece into

the vice. I then lit the torch, and heated up the stainless steel

piece, where the bend was to be, to a cherry red. When the piece was

a steady cherry red, I then bent the piece of stainless steel.

Flame Applied To The Stainless Steel Piece In The Vice

Stainless Steel Piece After Bend

Bent Piece And Next Piece Ready To Bend

When I had bent all three pieces, I got

out the high speed grinder with a 120 grit flap wheel, and cleaned up

the heated ends of the stainless steel pieces.

Cleaned And Polished Stainless Steel

Pieces

Cleaned And Polished Stainless Steel Pieces

Now all I have to do is weld the three

pieces of stainless steel onto the upper hard dodger stainless steel

base!

I was feeling pretty tired, as I am

trying to shake a cold, so I went back to DREAM AWAY, took a shower,

and then took a two hour nap!!

December 18, Wednesday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the

shop

and started in on sanding the fiberglass

uprights for the hard dodger. I am using power sanders with 180 and

220 grit sandpaper, and hand sanding with 220 grit sandpaper. Working

on getting the uprights as smooth as possible in preparation for the

application of gelcoat.

Had not finished all of the uprights by

the time Kitty called and said she was awake. When she called I went

back to DREAM AWAY and had breakfast.

We saw Johnal off when the train

arrived at the station. We ran a couple of errands on the way back to

Delcambre,

arriving around 1400. That is when the fun began!

We noticed the power boat, CAJUN DREAM,

at the end of Pier “C” was listing heavily to starboard. When

Kitty and I walked out to the boat, sure enough, it was sinking! Then

it all started, and Kitty was at her best making phone calls to

contact the owner, find out where the key to the companion way was

and to try and get a pump.

The owner, Bill, called back and told

us where the key to the companionway hatch was. I went down into the

boat, and it was not good. The water was almost up to the starboard

aft bunk. In the engine room the water had come up about half way on

the generator and the starboard engine.

Kitty was not having much luck getting

a pump, so T-Boy and jury rigged one of my air conditioner cooling

pumps. We got the electricity and hoses all connected to the pump at

my shop,

then brought it back to CAJUN DREAM. T-Boy had to leave, so Kitty

helped me try and get the pump working. Because the pump is a

centrifugal

pump, I could not get the pump low enough to get it

primed.

Finally, Kitty contacted the mayor of

Delcambre,

and she was told the city has a big 2” pump we could borrow. An

employee at the city wharehouse contacted me and told me to come and

get the pump. The warehouse is less than a block from the

marina.

Kitty was off to New Iberia on another errand, so I was walking to

the warehouse just as T-Boy was returning from his physical therapy.

We then drove to the warehouse and picked up the pump and brought it

back to the marina.

T-Boy and I put the pump into a dock

cart and took it out to CAJUN DREAM. We got the pump on deck, and the

suction hose down into the bilge. We started the pump, and after a

bit of priming, we were pumping out CAJUN DREAM. By this time more

help had arrived because of Kitty’s phone calls.

The Delcambre police chief and one of

the officers had arrived. One of the Iberia Parish Marine Patrol

Officers also arrived. After about an hour, we had the boat pumped

out, so we called it a day. Since we did not know what caused the

problem in the first place, I resolved to go back to CAJUN DREAM

later this evening.

I went back to CAJUN DREAM around 2100,

and it was filling up with water again! I pumped the boat as dry as I

could, then looked for a leak. I found the port stuffing box was

leaking in a steady stream. I went back to DREAM AWAY to get some

tools to tighten up the gland in the stuffing box. When I returned to

CAJUN DREAM, I was able to get the stuffing box to quit leaking. I

did a final pump down on the boat to get it as dry as possible. We

will see in the morning if the stuffing box was the source of the

problem.

December 17, Tuesday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

Went over to the

shop

and worked on the

Black Beast.

It was finally warm enough and sunny, I felt

like taking the driver’s door apart to replace the inside door

handle. It was a lot of fun, but I finally got the new door handle

installed and put back into service.

It was nice to be able to open the

driver’s door without having to roll down the window. I went back

to DREAM AWAY to have breakfast.

After breakfast it was back to the

shop,

and I started in on sanding the fiberglass

uprights for the hard dodger. When I got all of the uprights as

smooth as possible, it was time to add some more

finishing putty.

While the finishing

putty was sitting up, I cut out a piece of wood to

replace the piece of wood on the stern of DREAM AWAY that hold my

storage buckets.

Wood Cutout For Storage Buckets

I had a leftover piece of 2 x 6 that I

used to make a cat scratch pad for our friend Bonnie’s cat Ruby. We

know how a cat loves a scratch pad.

Next I started in sanding on the pieces

of stainless steel flat bar I am using for supports on the stainless

steel upper base of the hard dodger. It is better if I can get them

polished before I do the bending and welding that is necessary.

Stainless Steel Flat Bar Being Sanded

Tomorrow, I will get back to sanding

the uprights, and hopefully they will be ready for a

gelcoat

application.

December 16, Monday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

This was another day with no DREAM AWAY

projects. The morning was spent going to

Lafayette

and getting the holding tank discharge hose for the

shower

trailer repaired. While at the shop getting the hose

repaired, I got a 90 degree fitting added to the end to make the

emptying of the

shower

trailer holding tank much easier.

When we got back from

Lafayette,

I was able to drain the holding tank in the shower

trailer to ¼ full. Because we are empting the holding

tank via gravity flow, I can not completely empty the holding tank. I

then put the shower

trailer back into service.

We welcomed the owners of the transient

boat MIRAGE, that came in yesterday to the marina.

They fueled up MIRAGE, and are planning to leave tomorrow morning to

continue their journey to Port

Arthur, Texas.

Crew Of MIRAGE With Welcome Basket And

Dockmaster T-Boy

We then welcomed another cruising

yacht, RUTHIE, into the marina

later in the afternoon. They were scheduled to come in tomorrow, but

made good time and got in today. The dockmaster, T-Boy Renard, was in

Lafayette

when they arrived, so it was just Kitty and I to get them into the

dock, and present the North

Pier Marina welcome basket.

Johnal And Cindy With Welcome Basket

I spent the remainder of the day

cooking and preparing cat food for our two cats, Jillian

and Jordan. We are getting away from the canned food,

from the pet food companies for two reasons. First and foremost, the

food from the pet food companies is not very healthy, and when we are

cruising, the canned food is extremely difficult to get.

December 15, Sunday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

I spent a good portion of the morning

getting caught up on computer work and a bit of reading.

Our “uniforms” showed up in the mid

morning, so we were ready for the

Delcambre

Christmas parade. I dressed up as Santa Claus, and Kitty was dressed

up as Mrs Claus. The parade was supposed to be last weekend, but the

weather was so bad it was put off a week.

We were ready for the parade around

1330. The mayor of Delcambre

picked us up at the marina

in a police car, and we rode to the parade float on which we were to

ride, with lights flashing and sirens blaring.

We got on the float, and the parade

started around 1410 just before the high school. As we rode down main

street to the Delcambre

Shrimp Festival grounds we waved at all of the

children, and threw candy to them as we progressed.

Santa And Mrs Claus On Parade Float

When we got to the Delcambre

Shrimp Festival grounds, we got off of the float and I

sat on a very large chair, with Kitty beside me on a bench. We then

did photographs with Santa. We finally finished around 1615.

We went back to DREAM AWAY, and got out

of our Santa rig. Kitty took a nap to try and shake the cold she has

picked up, and I prepared food for the Kitties.

Around 1730 I welcomed a cruiser who

came into the marina

for a couple of days on their way from Florida to Texas. The boat was

supposed to come in tomorrow, so was a surprise when it arrived

today. They will get their Welcome Basket tomorrow.

December 14, Saturday,

2013

At 0715 I quit my traffic directing

job, and headed into the

Delcambre Shrimp Festival

building to get dressed into my Santa suit for the

Pancakes

With Santa

benefit. Kitty joined me and was dressed up as Mrs Claus. We worked the

Pancakes

With Santa benefit from 0800 until 1015. We had many

pictures taken with so many wonderful children, it was a lot of fun.

We then moved over to the Delcambre

Seafood And Farmers Market still dressed in our

outfits, and I sat in an old rocking chair and had my picture taken

with several children and adults.

Santa And Miss Glo At The Farmers Market

After the Delcambre

Seafood And Farmers Market, we changed back into our

civilian clothes, and went back to DREAM AWAY. We both had a short

nap, then kitty got into some baking to prepare for the night’s

activities.

We were preparing for the Christmas

Boat Parade. We attended several parties immediately

following the boat parade and the spectacular fireworks display. The

fireworks were great, it seemed like it was the grand finale during

the whole show! It was a wonderful and tiring day!

One Of The Decorated Boats

Some Of The Fireworks

December 13, Friday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

I went up to the parking lot to work on

the shower

trailer. A hose with quick release connector was

purchased to drain the on board holding tank into the new sewer

connection near the shower

trailer. I had previously tested the new water outlet.

It was not the best laid out but we had water next to the shower

trailer.

I used the hose attached to the fresh

water to fill the sewer discharge hose to verify operation. It works

pretty well, but I discovered that the waste discharge hose leaks at

the quick release connector. Not a good situation. I will have to

return the hose and connector to the place where it was purchased,

and get the leak repaired.

I then went over to the shop

and looked through my stash of stainless steel flatbar. I was able to

find the three pieces I will require for the supports on the

stainless steel base of the hard dodger.

I went back to DREAM AWAY, and we spent

the remainder of the day running errands and grocery shopping.

December 12, Thursday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. When the coffee is started, I

feed our two cats, Jillian

and Jordan, and spend time with them brushing their

beautiful coats.

I then went over to the shop

and got back into working on the stainless steel base for the hard

dodger. I finished up the welding, and then started in on the

grinding and sanding of the welds. I also sanded on the pipe to clean

up as many imperfections as possible.

I also drilled out all of the holes in

the pipe. I did some welding very near some of the holes, and I

wanted to make sure the bolts would still go through all of the

holes.

New Welds In Corner Of Pipe

New Welds In Corner Of Pipe

Sanded And Polished Corner Welds

Sanded And Polished Corner Welds

When I finished sanding and polishing

the pipe, I then cleaned up the shop.

Sanding and grinding on metal is very dirty work, so the shop

needed a good cleaning. I headed back to the marina,

but as I was locking up the shop,

I realized I had more to do on the stainless steel pipe base for the

hard dodger.

I had to fabricate three braces to weld

onto the pipe, to support the King

Starboard I will be using for the hard top on the hard

dodger.

At the marina

I talked with the plumber who is putting in the sewer and water pipes

for the shower

trailer. We are hoping the drain hose will work

properly. When the plumbers finish their work, I will have to run a

test of the new drain system.

Kitty and I then went off to New

Iberia to run errands, no more project were done on

DREAM AWAY.

December 11, Wednesday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

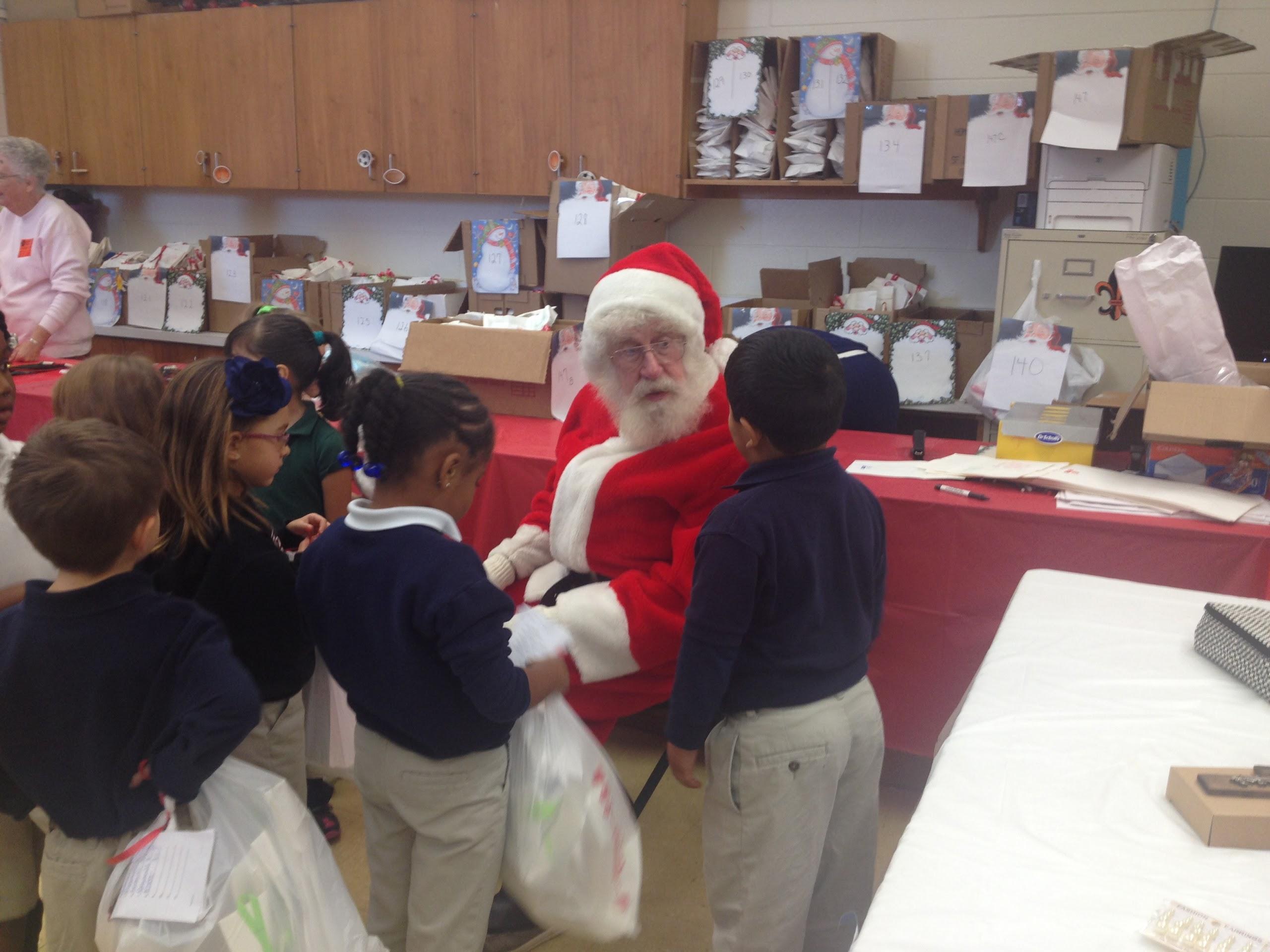

Kitty and I went off to the Delcambre

Elementary school again this morning, arriving around

0850. They have a Santa’s workshop at the school for all of the

kids, and I dressed up as Santa Claus. Kitty was a helper with the

other ladies to help the children do their Christmas shopping. We

worked Santa’s Workshop until 1300, and then had lunch.

Santa With One Of The Children

Santa Catching Up On The “List”

Kitty went to Pam’s Hair Hut to have

her hair done, and I walked back to DREAM AWAY. I changed into my

work clothes, and walked over to the shop

to get back into welding on the stainless steel base for the hard

dodger.

Unlike me, I had left the shop with the

welder all set up, so I got back into welding up the holes in the

base that needed filled, and then cleaning up some of the previous

welds.

Welded Up Hole In Hard Dodger Base

When I had finished the welding it was

time to get out the high speed angle grinder with a flap

disk attached. With the flap

disk I am able to smooth out the welds and to smooth

out minor imperfections in the pipe.

Welded Up Hole In Hard Dodger Base

After Using Grinder And Flap

Disk

Pipe Set Up In Shop

For Welding

Kitty called and said she was finished

at Pam’s Hair Hut, so I closed up the shop,

and walked back to DREAM AWAY. I will finish up the welding tomorrow

on the stainless steel pipe, and make some progress on the grinding

and sanding.

December 10, Tuesday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Kitty and I went off to the Delcambre

Elementary school again this morning, arriving around

0830. They have a Santa’s workshop at the school for all of the

kids, and I dressed up as Santa Claus. Kitty was a helper with the

other ladies to help the children do their Christmas shopping.

Jim (Santa) and Katherine (Kitty)

Santa With One Of The Children

We left the school when they had the

fourth graders come in, and then we went back after lunch to be there

for the pre-K and kindergarten. We will do the same thing tomorrow

for four classes of 1st graders.

No DREAM AWAY projects today.

We did go to the Port

of Delcambre meeting at 1800 to get out paychecks for

the last month. The good news is the port Director wants to keep us

both on in the coming year!

December 09, Monday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

The plumber was coming out today to

start work on the water connection and the sewer connection for the

shower

trailer. I wanted to make sure the shower

trailer was in the proper location for the plumber to

gauge size and location of the pipes.

I then went over to the shop,

and was going to start sanding on the uprights, but decided it was

too cold to be standing outside.

Since I had the stainless steel upper

base for the hard dodger inside the shop,

I decided to do some welding on it. I had some holes that needed

filling on the base, and some funky welds that needed to be cleaned

up a bit. I wanted the stainless steel base to look like someone with

a hint of welding ability fabricated the piece. Besides I need the

practice!

Filling Hole In Stainless Steel Base

Cleaning Up Funky Welds At The Corner

I then went back to DREAM AWAY, and had

breakfast. Kitty and I then went off to the Delcambre

Elementary school. They have a Santa’s workshop at

the school for all of the kids, and I dressed up as Santa Claus and

Kitty dressed up as Mrs Claus. It was great fun and all of the

younger kids really enjoyed it.

Santa And Kitty Getting Ready For The

Children

Santa And One Of The Elementary Classes

Kitty and I are going back again on

Tuesday and Wednesday to Santa’s workshop and dressing up again!

December 08, Sunday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

It was very cold and rainy all day, so

I spent the day working on the computer getting caught up on email,

computer work and scanning. It was a great day to be inside!

December 07, Saturday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

The bad news about working the table

was the table was right inside one of the main mall entrances, and the

weather outside was in the 30’s! We were cold during our time at

the table.

Group At Toys For Tot’s Booth

Including Jim And Kitty

When we got home we spent the remainder

of the day relaxing and watching college football.

December 06, Friday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop,

and finished cutting off the tops of the hard dodger uprights with

the Bosch

jig saw.

Cutting Off Tops Of Hard Dodger

Uprights

When I completed the cutting, I started

sanding the uprights. I want to get them smoothed out so I can apply

any necessary finishing

putty, but want to get them ready for the application

of gelcoat.

Setting Up To Sand The Uprights

Because the weather could not make up

it’s mind about raining, I decided to stop the sanding. I was

getting tired of moving the table and tools in and out of the shop

to miss the rain.

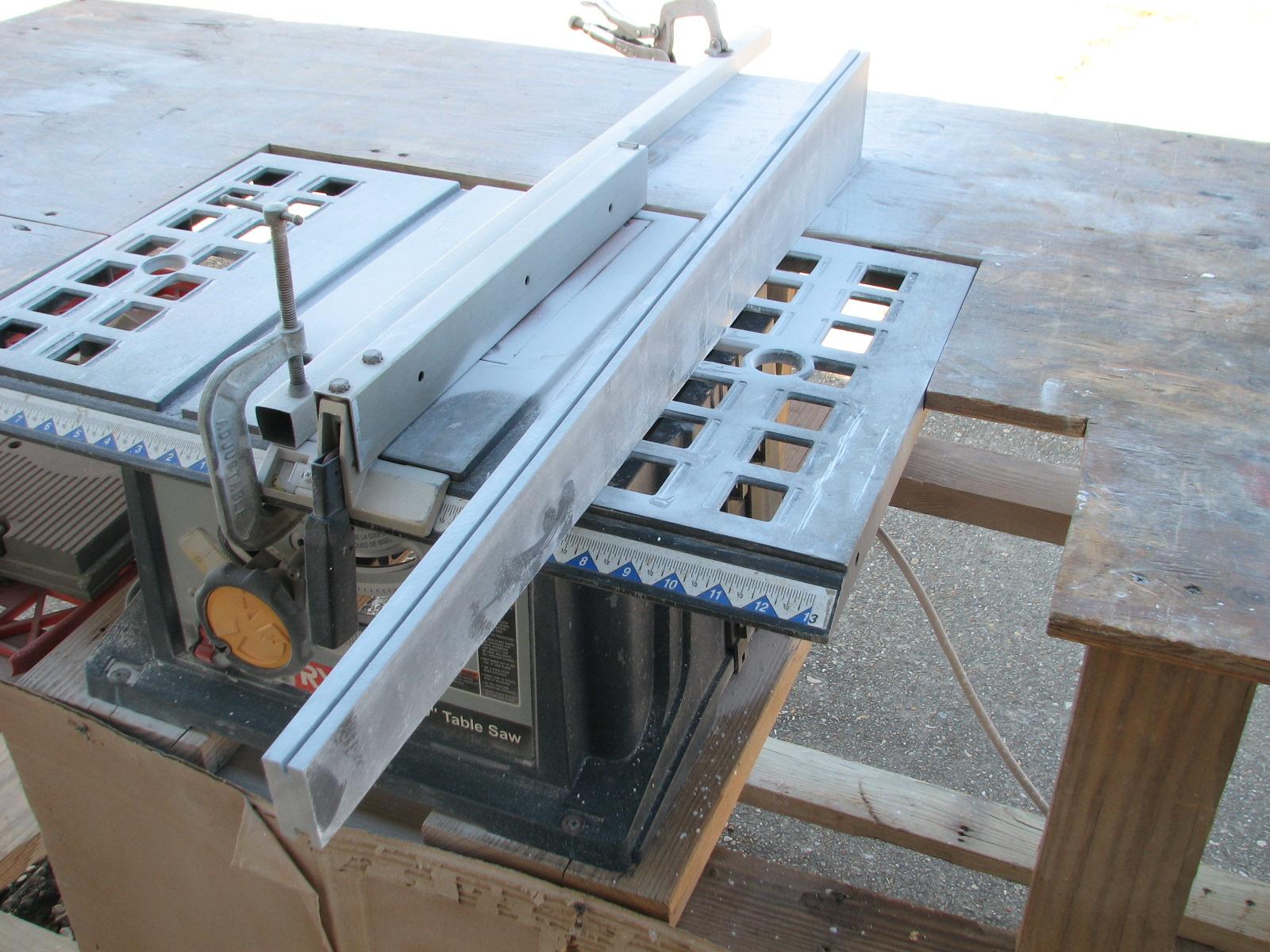

I decided to finish the integration of

the new Ryobi

table saw on my rolling saw table. I had to do some

moving of supports, and also cut out the space for the table on the

table saw. Overall pretty easy, and now I have an operations system

again.

Table On It’s Back To Remove A Couple

Of Supports

Table Back Together

I tried and tried, but the

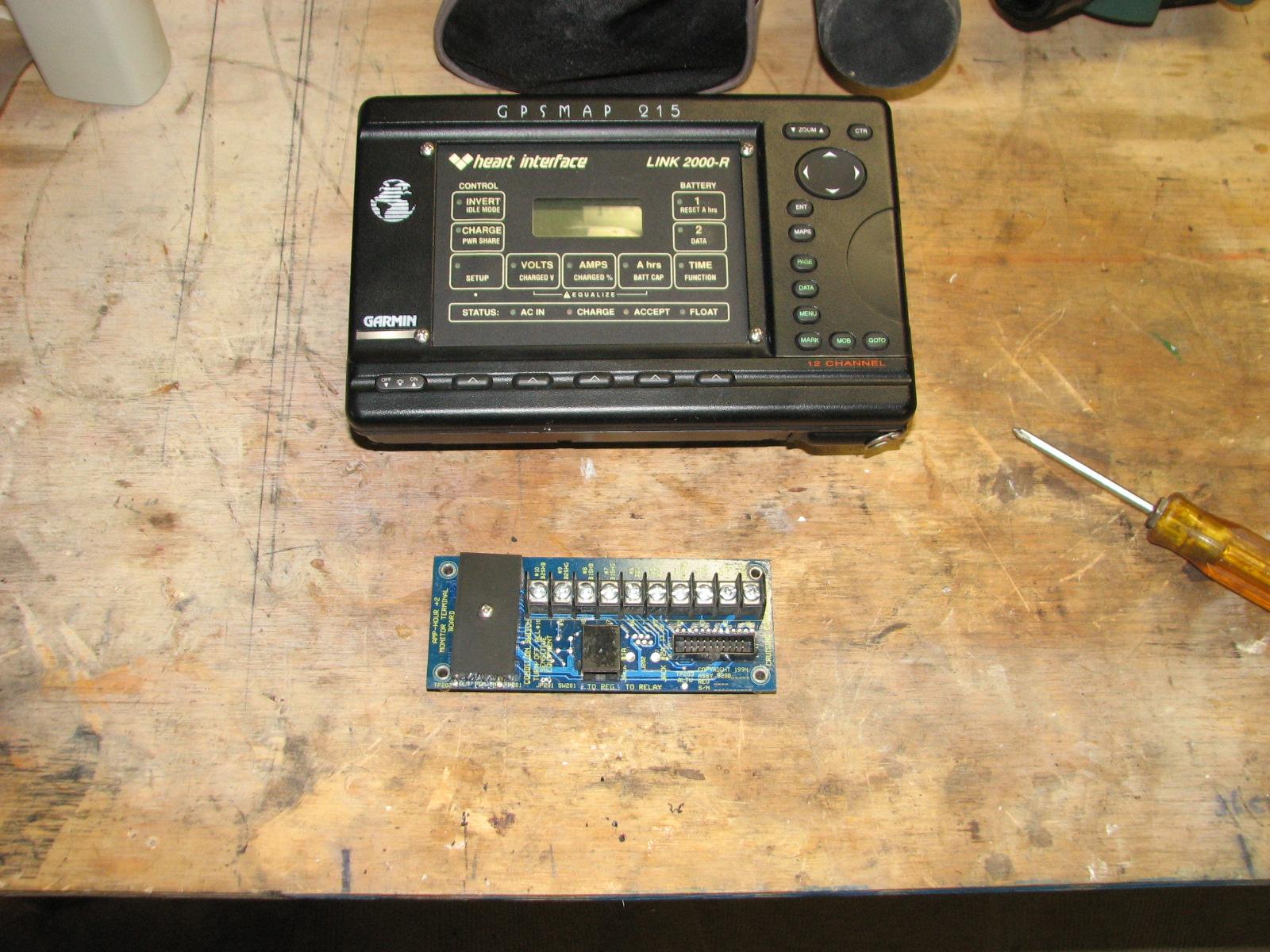

Garmin GPSMAP 215 housing with the

LINK 2000-R monitor

inside would just not fit in the space

available. I am disappointed as I had hoped it would work out. I am

sure I could move around the electronics in the

navigation station

and make it work. It would just take a lot of

time and resources that I do not have at this time.

I went with Kitty for her appointment

with the eye doctor in Youngsville.

When we returned it was late so no more DREAM AWAY projects.

December 05, Thursday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the shop,

and got to work on the housing for the

LINK

2000-R. I cut a slot out of the back of the Garmin

GPSMAP 215 housing so the cable from the LINK

2000-R monitor would reach to the terminal board. I

put the housing back together and checked out the installation.

Now it will be back to DREAM AWAY to

see if the housing will actually fit into the navigation

station.

Monitor And Terminal Board On Bench

Housing With Slot Cut In The Back

Housing With Cable Out The Back

Next on the list was to set up the new

Ryobi

10” table saw. I opened the box, and verified I had

all of the parts, which I did not. I was missing an allen wrench and

a handle for the crank to move the saw up and down.

A minor issue and I was still able to

set the saw up and see if it would fit on my table. Naturally I will

have to make a couple of modifications to the table, but nothing

major. I did verify the saw operated.

Box In Which The New Saw Arrived

Now I loaded the freshly painted

barrell, the two sanders, the

“Box O’ Resins”, the

Evolution Rage III

compound miter saw, and the

Bosch jig saw

into the Black Beast,

and went to the marina.

I wanted to get as much done today on the hard dodger, as there is a

bad cold front coming, and outside work will not be pleasant.

I got all of the tools and the two

modified uprights down to DREAM AWAY. Kitty and I got out all the

remaining tools we would need to fit the two modified uprights to the

hard dodger bases.

I called Ryobi

about the missing parts, and they said they would send them to me and

I could expect them within seven to 14 business days! I wonder where

the parts are coming from? I get parts from China via China Post in

seven total days!

We did a dry fit of the new starboard

upright, and made sure the measurements all worked out. It did! We

then clamped up the port modified upright. Then did the measurements

between the two modified uprights, and then between the modified

uprights, and the outboard uprights. No more that a 1/16” of an

inch difference.

Dry Fit Of Starboard Modified Upright

Now all the measurements were correct

so we would be able to have opening windows in the front of the hard

dodger. Next we needed to drill new holes in the stainless steel

upper base of the hard dodger for the two new modified uprights.

We drilled the holes for each upright,

then bolted the uprights to the lower and upper base. Then we did the

measuring all over again, and all of the measurements were within a

1/16” of an inch.

Port Modified Upright Bolted To Upper

Base

Kitty and I measured the tops of all of

the uprights on the hard dodger so they could be cut off even with

the top stainless steel base. When we finished the measuring and

marking the uprights for the cuts, we removed all of the uprights.

We also removed the stainless steel

base, as I had to weld up the holes that were no longer needed and to

clean up a couple of welds that did not look great. This will also

give me the opportunity to polish the stainless steel base.

The plan is to take all of the uprights

over to the shop

and cut them there. While I moved all of the tools and uprights to

the Black

Beast, Kitty put away the tools and vacuum cleaner

that stayed on DREAM AWAY.

Before leaving DREAM AWAY and heading

over to the shop,

I installed the second barrel on the aft deck.

Newly Painted Barrels On Aft Deck

Kitty had an errand to run, so she

dropped me off at the shop

with all of the tools and the uprights. I got all set up and did the

cutting off of the tops of the uprights. On four of the eight

uprights, I could not make the complete cut using the

Evolution Rage III

compound miter saw. I will have to use the

Bosch

jig saw to finish the cuts.

It was getting dark, so I decided to

finish the cuts in the morning. I put all of the uprights and tools

back into the shop.

Kitty arrived at that time, so we went back to DREAM AWAY for a late

dinner and showers.

Verifying Measurement On Upright

December 04, Wednesday,

2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

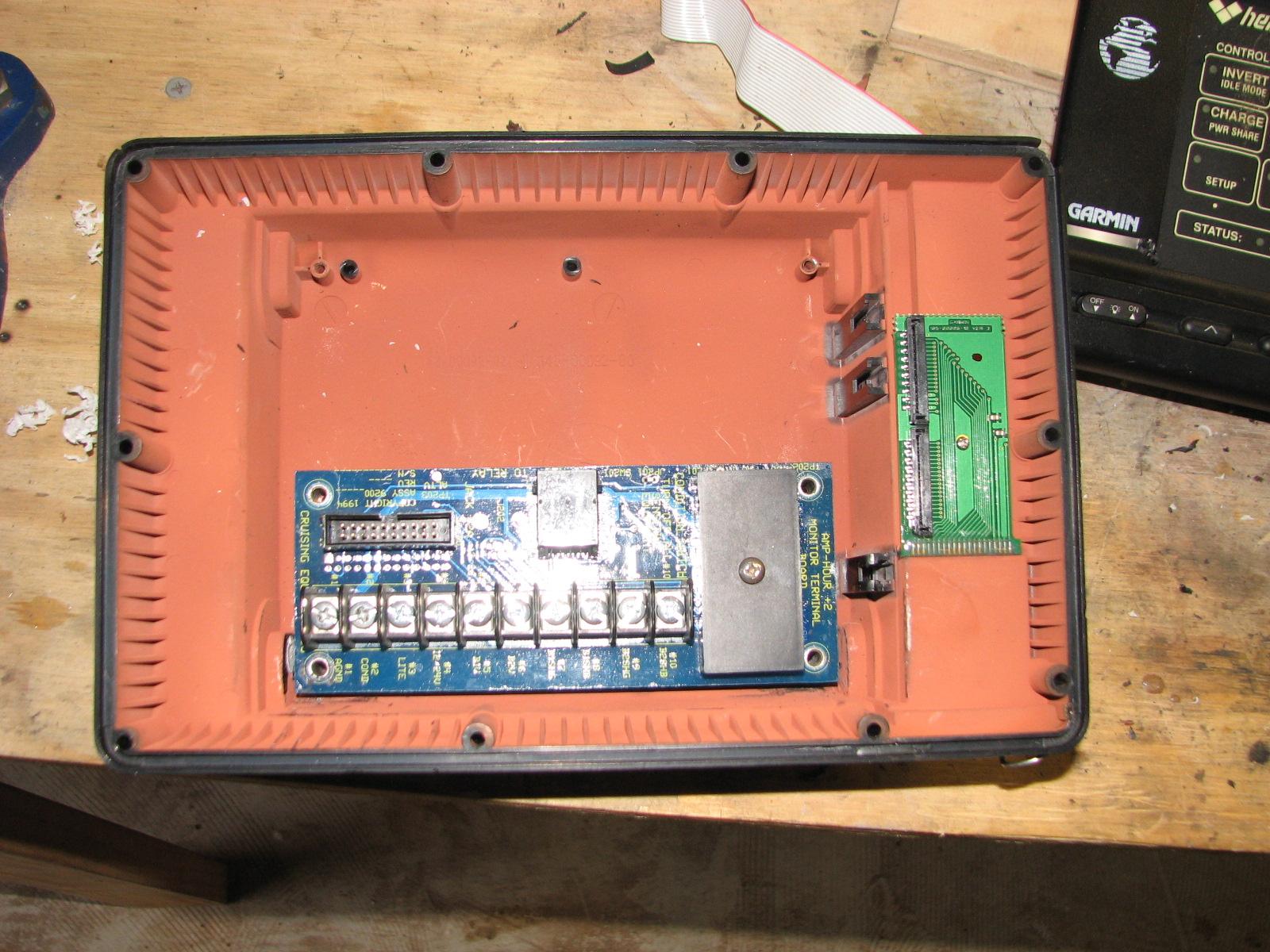

I went to the shop,

and got to work on the housing for the LINK

2000-R. I drilled the holes in the housing to bolt

the monitor to the front of the housing, and the terminal board to

the back of the housing.

I hope there is enough room inside the

housing for both of the LINK

2000-R parts and the connecting cable. I did not have

the fasteners with me at the shop.

When I go back to DREAM AWAY, I have the fasteners so I will be able

to verify.

I then got to work on the three Hella

Oval 100 spreader lights. I washed off all of the

green and cleaned them up. I will be putting them on eBay

for sale.

Went back to DREAM AWAY and got out all

of the fasteners to bolt the LINK

2000-R parts into the Garmin

GPSMAP 215 housing. Once the parts were bolted in the

Garmin

GPSMAP 215 housing the housing would not go together.

That was a bit disappointing, but not a big thing. I will just cut a

hole in the rear of the housing for the cable to pass through.

Went off to Lafayette

for Kitty’s doctor’s appointment. When finished with the

appointment, we stopped for groceries, and then it was off to Home

Depot to pick up the new Ryobi

table saw.

December 03, Tuesday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

I went to the shop,

and spent some time looking for stuff that I had left behind when we

made our trip to Atlanta.

It turned out the stuff was left in Kitty’s office at the Port

of Delcambre office!

While looking for the stuff, I came

across a Garmin

GPSMAP 215 that a friend had given to me. It was

defective, and I thought perhaps I could fix it. After looking at the

condition, screen was burned out, I decided it would probably cost

more to fix it than a new one would cost. Especially since I did not

really need one anyway.

When I went back to DREAM AWAY for

breakfast, I checked on the sizes. The Garmin

GPSMAP 215 case will just fit into the nav

station. I have a spare LINK

2000-R and the monitor terminal board, and they also

just fit into the housing.

Tomorrow I will take the spares and the

housing over to the shop and see if I can get them to fit together.

It would certainly look a lot better in the nav station.

The remainder of the day was spent

taking down the old Hella

Oval 100 55 watt spreader lights, and installing the

Lumateq

6 watt spreader lights.

I already had one of the Lumateq

6 watt spreader lights installed on the main port spreader. This was

the experiment that made me decide to replace all of the Hella

Oval 100 spreader lights. That experiment is discussed

in the Maintenance

Log For August.

Kitty assisted in getting me up the

main mast to the spreaders, and I removed the starboard spreader

light.

I disconnected the light from the

spreader and cut the wires leading to the mast. I went down the mast,

and Kitty and I got set up to go up the mizzen mast.

I went up the mizzen mast and

disconnected the starboard Hella

Oval 100 spreader light. I cut the wires from the

light leading to the mast.

Wires Hanging Down From Starboard

Mizzen Spreader Light

When it was disconnected from the mast

wiring, I went down the mast and into the”garage” to get the

Lumateq

spreader lights ready for installation. Kitty drove off to New Iberia

to run an errand.

I stayed on DREAM AWAY and prepared the

Lumateq

spreader lights for installation. The mounting bolts had to be moved

from the old spreader lights to the new ones, and I installed shrink

wrap butt connectors on each of the wires on the new spreader light.

By the time Kitty came back from her

errand, I had finished the set up of the spreader lights. It was back

up the mizzen mast to install the starboard and port lights on the

spreaders. The light had to be bolted onto the spreader then the

wires connected from the light to the mast wiring. Then I applied

heat from a heat gun to shrink the butt connectors to make a

watertight connection. Last I aligned the light for maximum deck

lighting.

Lumateq

Spreader Light Installed On Port Mizzen Spreader

When the mizzen mast was completed, it

was down the mizzen and up the main to install the port spreader

light. We checked the operation of the lights, and they all worked. I

came down the main mast, and then had to put everything away. When

that was all finished it was the end of the day.

After dinner and when it was very dark,

I checked the the mizzen and main spreader lights. I was very

impressed with the amount of light produced by the Lumateq

spreader lights. Now when I turn on all of the spreader lights, I am

consuming 24 watts, instead of the 220 watts with the Hella

Oval 100 spreader lights.

My only complaint with the new spreader

lights is they are advertised as marine lights, but they do not use

tinned wire. Typical for a large amount of electrical products

advertised as “Marine Grade”

December 02, Monday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Kitty went to the doctor’s in

Delcambre at 0800 to have some blood work done for her appointment on

Wednesday, and I accompanied her. On our way back to DREAM AWAY, we

stopped at LeBlanc Oil and picked up a couple of packages that were

waiting for us. When we got back on board DREAM AWAY we had

breakfast.

After breakfast, I went to the shop,

and Kitty worked on some home projects. I worked on several projects

during the course of the day. I did a time share of projects, worked

on one, then another, then back to the first. The discussion for

today will be handled like I worked on each project to completion. I

started out with the hard dodger uprights.

The uprights that I had glassed

together yesterday, had set up, so now it was time to sand them down,

and get them ready for an application of finishing

putty.

Hard Dodger Upright Ready For Sanding

When the finishing

putty had set up, I took the two uprights outside and

sanded them down smooth. The uprights are now readt to be fitted to

the lower and upper hard dodger base.

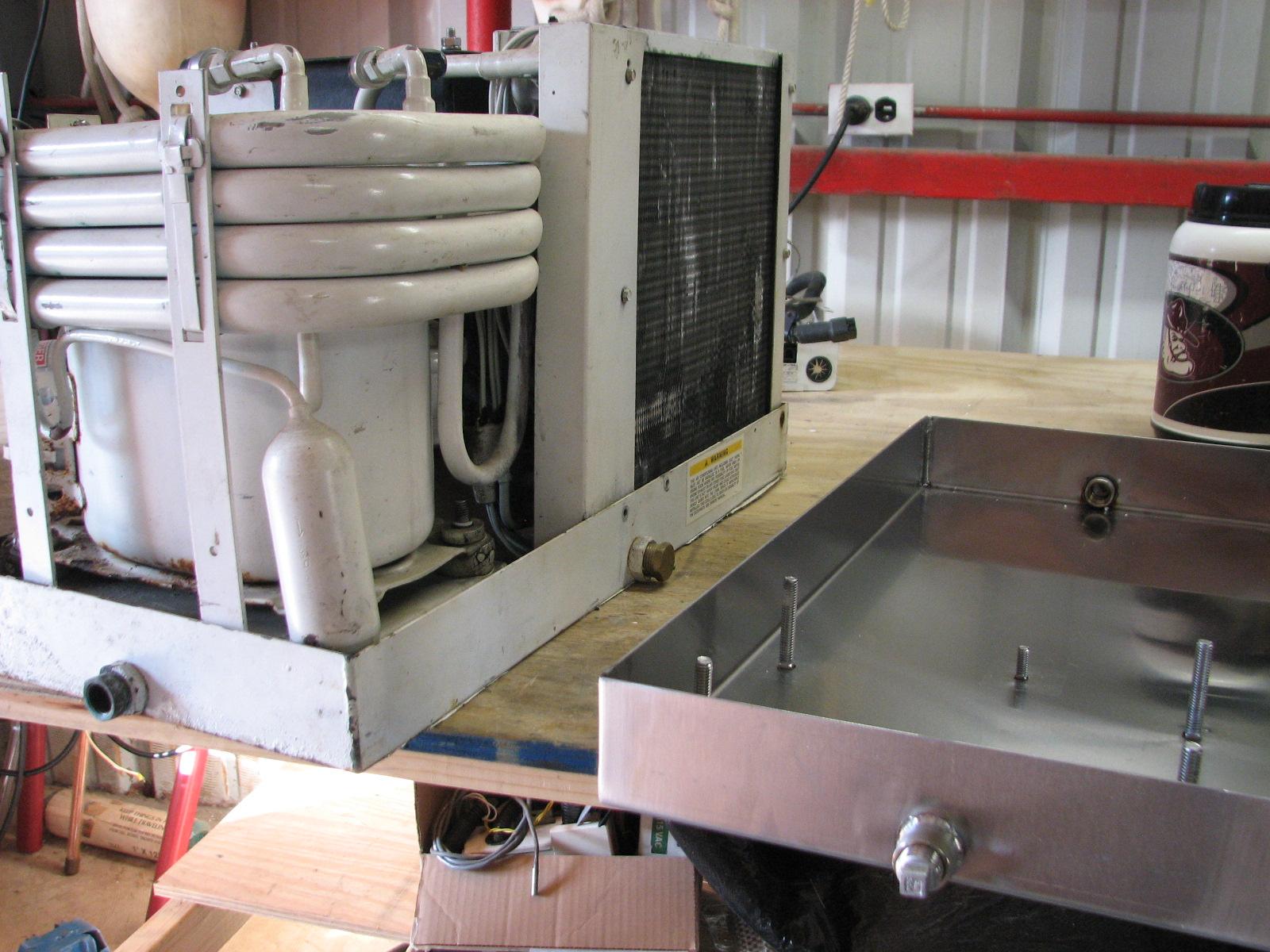

Next I worked on a new stainless steel

tray. Last june when we were in Atlanta,

my son, Stacy, told me he had a good friend who could manufacture a

couple of stainless steel trays. I needed one for the spare air

conditioning system and one for the generator.

Stacy was very aware of the problem

with the marine generator. The generator as it comes from the factory

has a very nice tray to catch any oil or water that should escape

from the engine. A great idea, except the tray is made from mild

steel. Just not a suitable in a salt water environment.

Stacy had seen the problem first hand

when he came to Georgetown,

South Carolina. That adventure is covered in the

Georgetown

to Delcambre passage. We had to remove the generator

to repair the transmission. Since the generator was out, we checked

with Northern

Lights to see about getting a stainless steel tray for

the generator. They had one, only $1400.00! We passed.

More or less the same issue with a tray

for the air conditioner. Any way, Stacy said if I could get him the

measurements his friend could make the two trays at a much cheaper

price. Since I had the air conditioner tray, I sent that tray and the

engineering drawings for the generator tray to Stacy.

The two fabricated trays arrived in

Delcambre

while we were in Atlanta on this last trip. I opened the package

today. What a surprise.

The two trays looked great.

Box From UPS

Packaged Trays Out Of Box

Air Conditioner Tray

Generator Tray

Getting the new generator tray will be

quite a lot of fun. I will have to pull the generator out of the

engine room and then swap out the trays.

I had the spare air conditioner in the

shop

sitting in the old mild steel tray, so I decided to swap the trays

out.

Air Conditioner In Old Tray Next To New

Tray

I took the old air conditioner out of

the original tray, by removing all of the bolts and screws holding it

to the tray. I then turned the complete unit upside down, and removed

the original tray.

Air Conditioner Upside Down, Old Tray

Removed

Once I had the original tray in hand, I

measured where several support screw holes were in the tray. These

holes had to be replicated in the new tray. I did the set up, and

then drilled the holes for the screws.

Drilling Holes In New Tray

WIth the holes drilled, all I had to do

was put the new tray on top of the air conditioner, make sure all of

the holes and supports were lined up, and turn the air conditioner

over. Once the unit was turned over, I tightened up all of the screws

and bolts, and the air conditioner is ready to go. I did not check it

out today, but will do a test run on the air conditioner tomorrow.

New Tray On Spare Air Conditioner

I finished off painting the second

trash bucket that I store on the stern of DREAM AWAY.

Finished Trash Bucket For DREAM AWAY

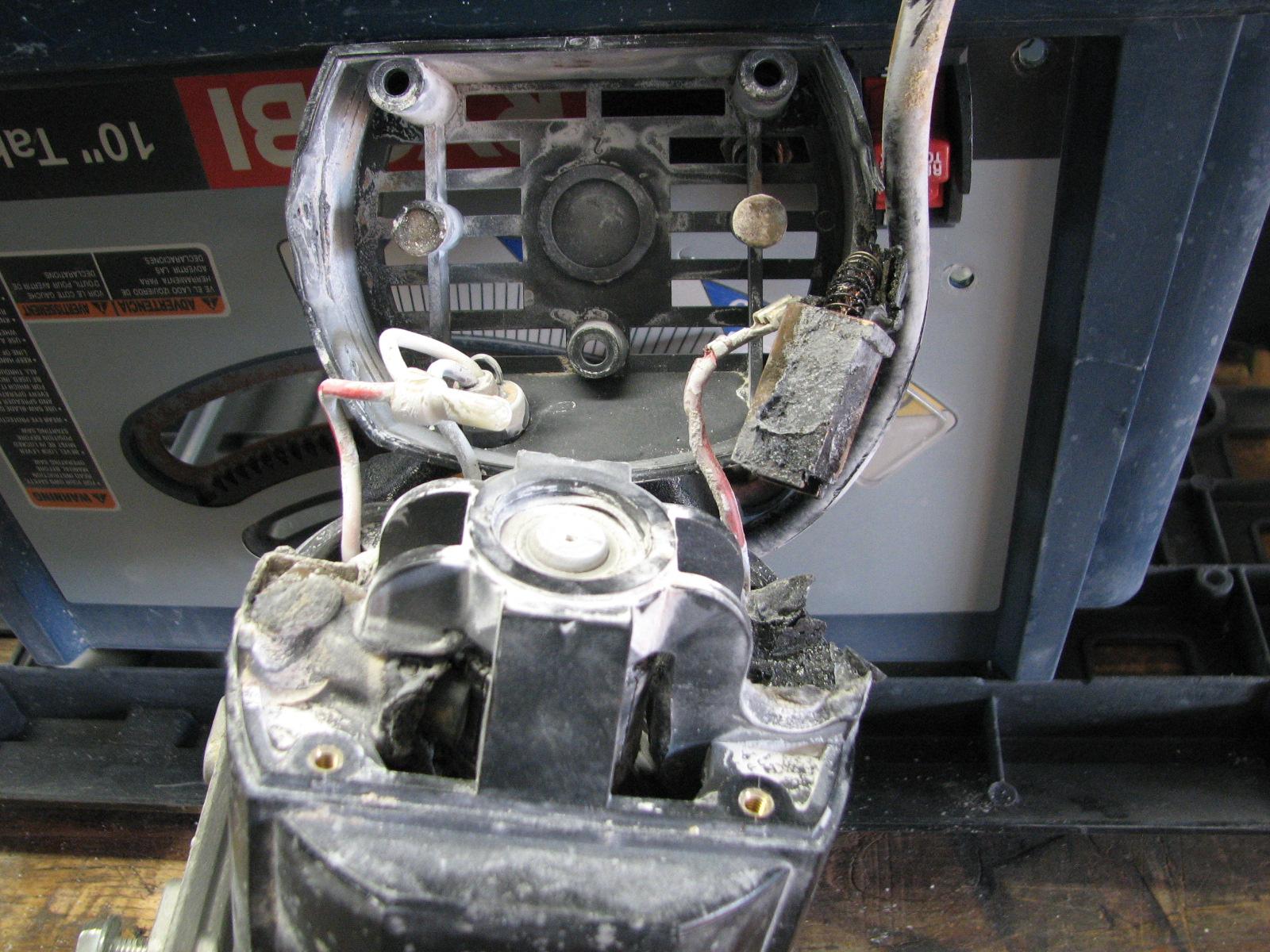

As I mentioned yesterday my table saw

had died, so today I looked into the problem. I was hoping it would

be something simple. I turned the saw upside down and checked that I

had power going to the motor through the switch. When that checked

out, I removed the motor.

Table Saw Ready For Motor Removal

When I removed the motor, I saw what

the problem was. The brush housings had melted the plastic case that

held them, and the brushes no longer made contact with the armature.

Melted Brush Housing In Plastic Case

Just to make sure of the problem, I

took the back cover off of the motor, and sure enough, both brush

housing had melted.

Brush Housing In Back Of Motor

That ended the projects for the day,

but when I got back to DREAM AWAY, I did some research on the Ryobi

10” table saw. I found a new motor at $168.00, and a

new table saw, the same model for $123.00 with a three year warranty!

I guess I will be purchasing a new

table saw!

December 01, Sunday, 2013

Started off the morning with my normal

ritual of getting on the Internet, answering email, and checking the

weather, while making a pot of coffee. I also spent time with our two

cats, Jillian

and Jordan.

Went over to the

shop

and worked on the

Black Beast.

The emergency light stays on when the brake is

off. The problem is obviously the switch, but it is a bear to get to.

Spent about 20 minutes trying to get to the switch, but no luck. Will

try the Internet and see if I can find a “How To”.

Next project was to get back to work on

the hard dodger uprights. I had already cut the new pieces of

Strongwell

Extren plate needed for the uprights. I now had to cut

the channels in each piece of the plate.

I rolled the table saw out of the shop,

and moved to the front door so the wind would blow the dust away from

inside the shop. I then set up the “fences” to get the channels

in the correct place on the ends of the plate.

“Fences” Set On Table Saw, First

Channel Cut Made

“Fences” Set On Table Saw, First

Plate Almost Finished

Now I had to cut off a piece of plate

that I had fiberglassed to the forward center uprights. One piece of

plate had to be cut off so I could glass the new cut pieces of plate

to the original uprights.

Left, Cut Upright, Right Upright To Be

Cut

Cut Upright With New Plate

Now that the uprights and new plates

were cut, I cut some fiberglass

strips, so I could glass the two pieces of plate together. These

would be the new center port and starboard uprights. Once the

fiberglass

was cut I did a dry fit that included the clamps I would use to hold

the two pieces of plate together.

Cut Fiberglass

To Glass The Two Pieces Of Plate Together

Dry Fit Of Two Pieces Of Plate With

Clamps

Dry Fit Of Two Pieces Of Plate With

Clamps

You know the drill! Now that the dry

fit was successful, it was time to mix up a batch of polyester

resin. I got all of the necessary items and mixed up a

small batch.

When the resin was mixed with the MEKP

hardener, I wetted out the fiberglass

mat on the one piece of plate, and then put the second piece of plate

on top of the wetted out fiberglass

mat. When I was satisfied with the set up, I clamped both pieces of

plate together. I did the same thing with the remaining two pieces of

plate.

Wetted Out Plate Clamped Together

Wetted Out Plate Clamped Together

Tomorrow, after the resin set up, we

will be able to install the uprights on the lower and upper base of

the hard dodger and see if they have fixed the problem.

During the cutting process with the

table saw, the motor on the saw quit working. I am sure it is because

of the fiberglass

dust that got into the motor. I will have to look into that problem

tomorrow.

I went back to DREAM AWAY, to have

lunch. After lunch I worked on some port projects around the marina.